Page 1

esp FIREbeam

INSTALLATION MANUAL

Page 2

This manual details the installation of:

ESP FIREbeam Reflective Optical Beam Smoke Detector

If you have any queries regarding these products or their functionality please contact:

Hochiki Europe (UK) Limited

Grosvenor Road

Gillingham Business Park

Gillingham

Kent ME8 0SA

Tel: +44 (0) 1634 260133

Fax: +44 (0) 1634 260132

Web: http://www.hochikieurope.com

Email: psupport@hochikieurope.com

2011 Hochiki Europe (UK) Ltd. All rights reserved. No part of this document may be reproduced, stored in a

retrieval system, or transmitted, in any form or by any means, without the prior permission in writing of Hochiki

Europe (UK) Ltd.

Hochiki Europe (UK) Limited reserves the right to alter the specifications of its products from time to time without

notice. Although every effort has been made to ensure the accuracy of the information contained in this document

it is not warranted or represented by Hochiki Europe (UK) Limited to be a complete and up-to-date description.

Document Details:

Title: ESP FIREbeam Reflective Optical Beam Smoke Detector - Installation Manual

Issue 2.0

Issue Date December 2011

Part No. 2-3-0-1340

Page 3

ESP FIREbeam – Installation Manual Page 3 of 19

Table of Contents

1 Distance and Position Guidelines ..................................................................................................................... 4

1.1 Distance ...................................................................................................................................................... 4

1.1.1 5 to 40 metres - The Standard ESP FIREbeam ..................................................................................... 4

1.1.2 40 to 80 metres - The Standard ESP FIREbeam + Mid Range 40 to 80m Kit ....................................... 4

1.1.3 80 to 100 metres - The Standard ESP FIREbeam + Long Range 80 to 100m Kit ................................. 4

1.2 Position ....................................................................................................................................................... 5

2 Installing, Commissioning and Testing ............................................................................................................ 6

2.1 Step 1 - Mounting the Head ........................................................................................................................ 6

2.2 Step 2 – Programming the Analogue Address ........................................................................................... 6

2.3 Step 3 - Mounting the Controller ................................................................................................................. 7

2.4 Wiring Configuration ................................................................................................................................... 7

2.5 Step 4 - Commissioning .............................................................................................................................. 8

2.5.1 Stage One - Language and Commissioning Speed ............................................................................... 8

2.5.2 Stage Two - Pre-alignment ..................................................................................................................... 8

2.5.3 Stage Three – Manual Alignment ........................................................................................................... 9

2.5.4 Stage Four - Auto-Alignment ................................................................................................................ 11

2.6 Step 5 - Testing ......................................................................................................................................... 11

2.6.1 Fault Test .............................................................................................................................................. 11

2.6.2 Fire Test ................................................................................................................................................ 11

3 Screen and Menu Systems ............................................................................................................................... 12

3.1 Home Screen ............................................................................................................................................ 12

3.2 How To Use the Menu System ................................................................................................................. 13

3.3 Individual Menu Items ............................................................................................................................... 14

3.3.1 Language .............................................................................................................................................. 14

3.3.2 Commissioning ..................................................................................................................................... 14

3.3.3 Mode Change ....................................................................................................................................... 15

3.3.4 Beam Maintenance ............................................................................................................................... 17

3.3.5 Diagnostics ........................................................................................................................................... 18

4 Technical Specifications .................................................................................................................................. 19

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 4

Page 4 of 19 ESP FIREbeam – Installation Manual

1 Distance and Position Guidelines

These guidelines are recommendations only and it is important that you refer to your appropriate governing

standards at all times.

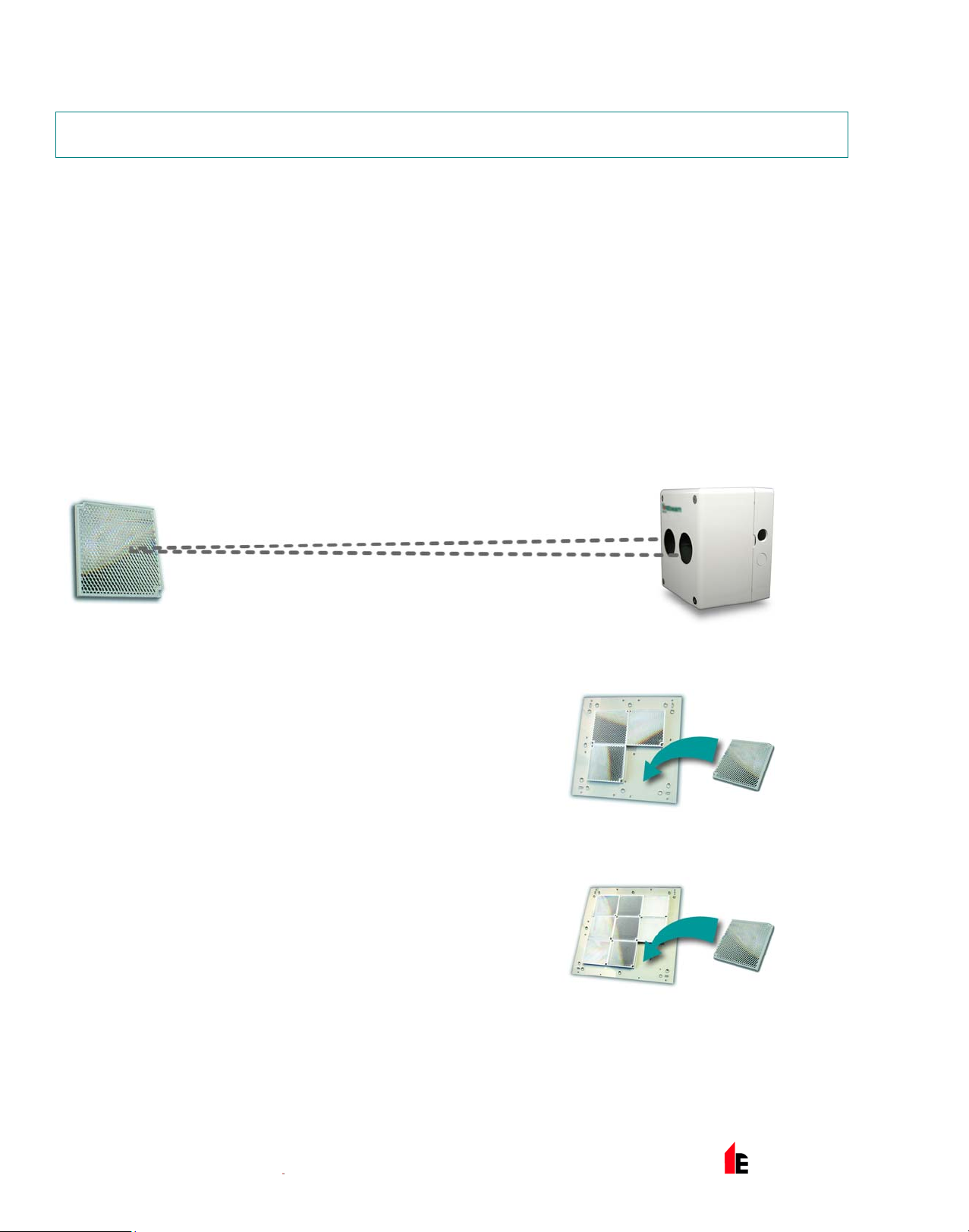

When positioning your ESP FIREbeam there are important factors that you should consider, mainly what distance

you are covering and the optimal position in the building.

1.1 Distance

The standard ESP FIREbeam is suitable for distances of 5m to 40m to the reflector. If you require 40m to 80m you

will need to use the mid range reflector extension kit. For ranges of 80m to 100m you will require the long range

reflector extension kit.

1.1.1 5 to 40 metres - The Standard ESP FIREbeam

The standard ESP FIREbeam comes boxed with the head unit, low level controller, one reflector, 3mm

allen key and quick start installation guide, this should be used for distances over 5m and up to 40m.

1.1.2 40 to 80 metres - The Standard ESP FIREbeam + Mid Range 40 to 80m Kit

For distances of 40 to 80 metres you will need to use the standard ESP

FIREbeam and a mid range extension kit (the mid range kit comes with

a backing plate and 3 extra reflectors, you will need to add the reflector

from the standard kit to the mid range kit with the screws provided).

1.1.3 80 to 100 metres - The Standard ESP FIREbeam + Long Range 80 to 100m Kit

For distances of 80 to 100 metres you will need to use the standard

ESP FIREbeam and a long range extension kit (the long range kit

comes with a backing plate and 8 extra reflectors, you will need to add

the reflector from the standard kit to the long range kit with the screws

provided).

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 5

ESP FIREbeam – Installation Manual Page 5 of 19

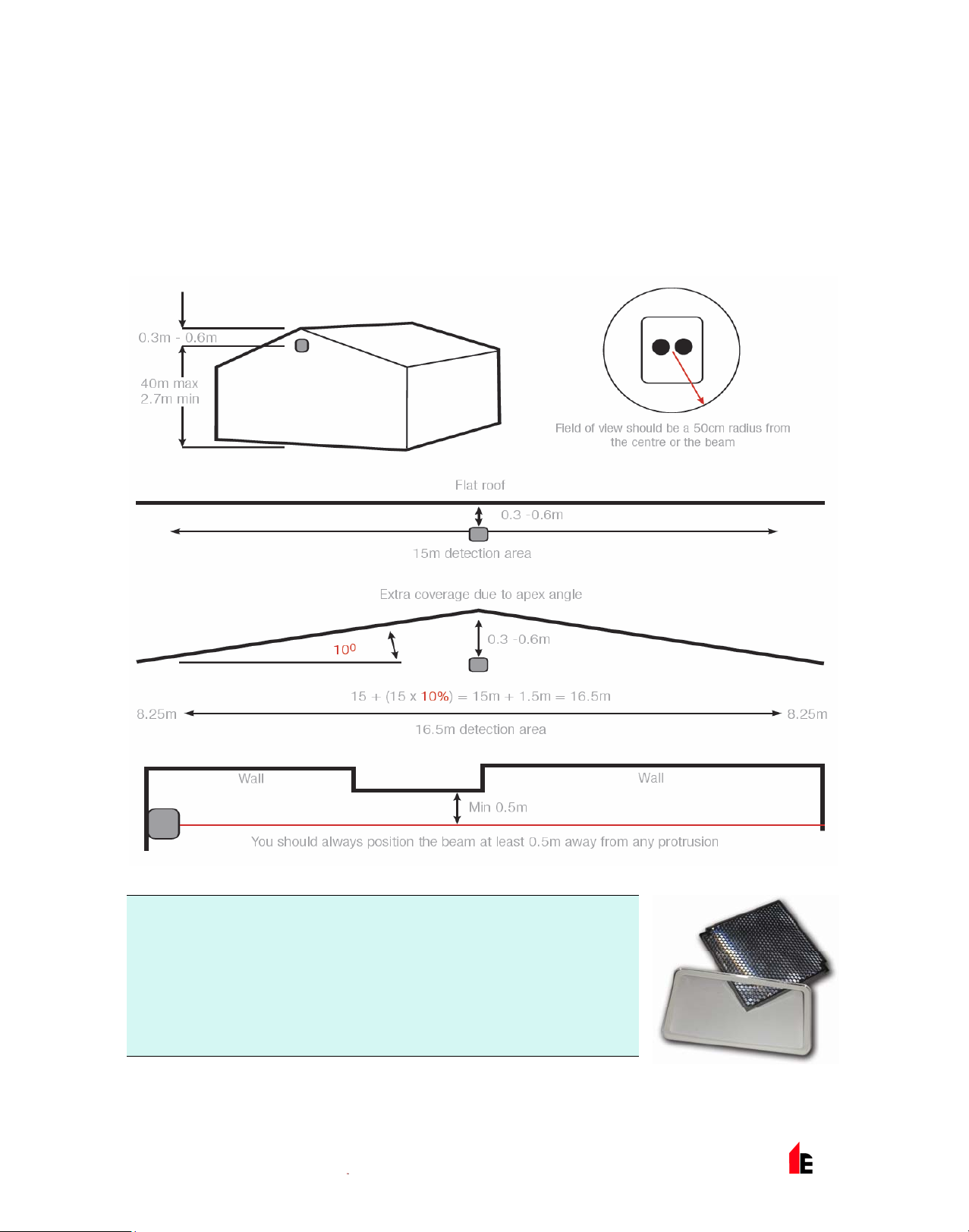

1.2 Position

A roof is considered flat unless the height of the apex is greater then 0.6m. If the roof is flat the ESP FIREbeam

system can be placed anywhere under the roof between 0.3m and 0.6m below the roof, up to a maximum height of

40m from the floor. The ESP FIREbeam has a detection area of 7.5m either side of the beam. If the roof is

considered to have an apex, place the ESP FIREbeam system 0.3m to 0.6m down from the top of the apex, up to a

maximum height of 40m from the floor. The maximum protected area either side of the beam can be extended by

1% for every degree of roof pitch, see the example below:

NOTE: Careful design consideration should be made when positioning

beams and reflectors in environments that can be susceptible to

condensation i.e. warehouses near to water that have areas open

to the outside environment or that are exposed to quick extreme

changes in temperature. To assist with this problem that can affect

all beam detectors we produce an anti-fog kit comprising of a

specially coated reflector and lens cover. Individual reflectors are

also available. The standard ESP FIREbeam and range kits can be

supplied as anti-fog sets as a special order.

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 6

Page 6 of 19 ESP FIREbeam – Installation Manual

2 Installing, Commissioning and Testing

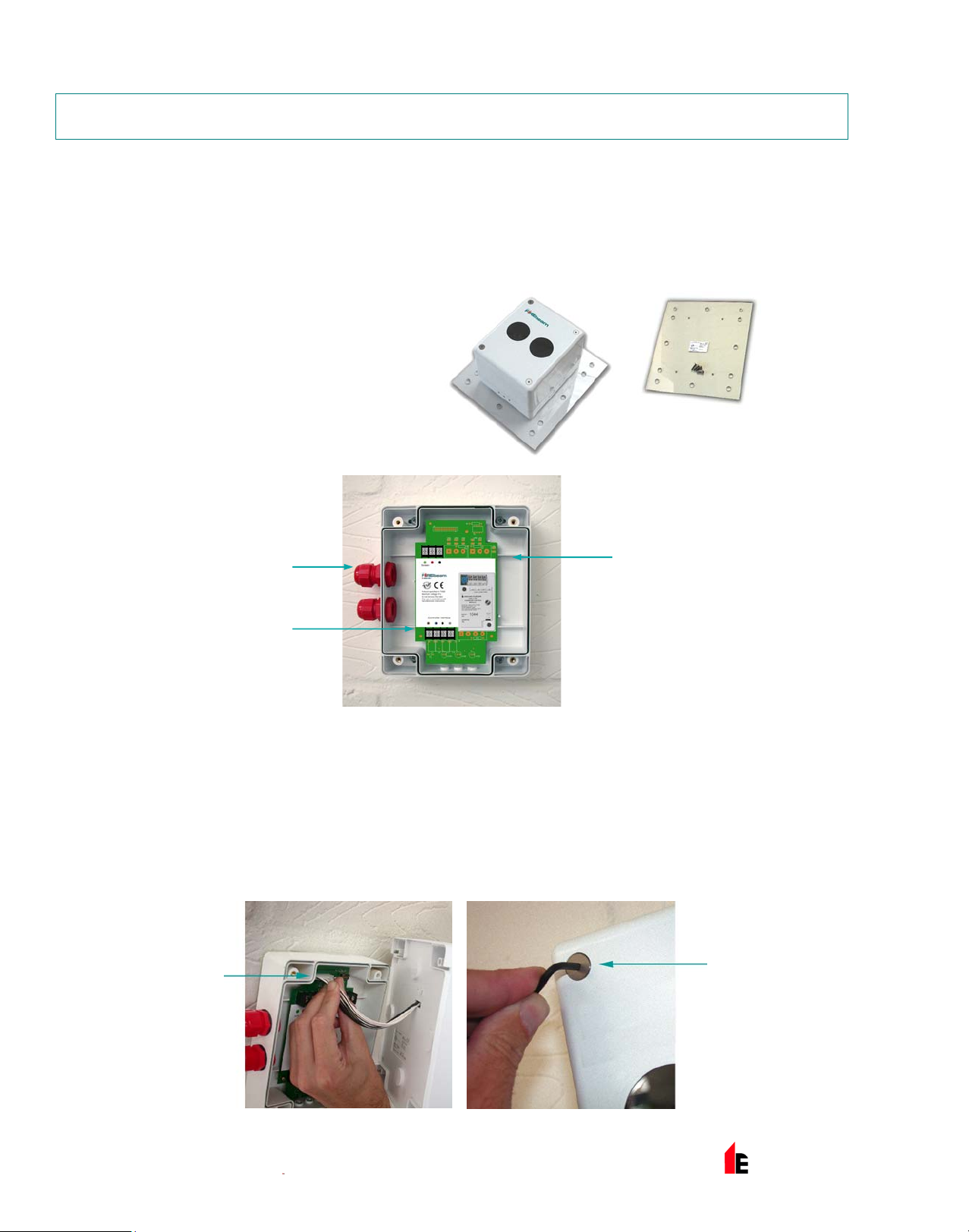

2.1 Step 1 - Mounting the Head

Screw the head backing plate to the wall - always try to use as sturdy a location as possible, such as bric k or major

structural steels (avoid mounting to outer metal cladding etc). Avoid mounting the head where direct sunlight can

shine directly into the ‘eyes’ of the beam (care should be taken when mounting in glass atriums). Ambient sunlight

will not affect the beam.

Also available - unistrut adapter plate

Use this accessory for easy mounting to unistrut

fabrication. Holes are pre-drilled to the correct pitch

of the head and conveniently positioned for use with

unistrut.

2 knock-outs are provided on

both sides. Take care when

using drills not to damage the

circuit board.

Wire to low level controller using

bottom colour coded terminals.

Wire into system as required

(see “Wiring Configuration” on

page 7). Ensure that all wiring

is below the level of the front

edge of the box.

Screw in through holes provided

outside of the rubber seal.

2.2 Step 2 – Programming the Analogue Address

The FIREbeam is programmed via the integral FIREbeam Control Module situated on the main PCB within the

head unit. To program an address you will require a TCH-B100 Hand Held Programmer and a PL-3 Programming

Lead (both provided separately). Connect the PL-3 Programming Lead to the TCH-B100 Hand Held Programmer

and then to the blue programming socket on the FIREbeam Control Module. Refer to the TCH-B100 Instructions

for further details on programming addresses. The programmed address can be written on the module label in the

space provided.

Once the unit is

programmed connect

the head to the base

plate by first plugging

in the connector.

Do not force in, white

wires should be

uppermost. Should

you forget to connect

this the controller

screen will read

ERROR.

Screw the head

screws down with

the 3mm allen

key provided.

Your wiring

should be flush

and not flattened

by tightening

down screws.

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 7

ESP FIREbeam – Installation Manual Page 7 of 19

2.3 Step 3 - Mounting the Controller

Important mount the controller at eye level and ensure easy access.

Screw in through holes

provided outside of the rubber

seal. Wire to head using colour

coded terminals.

If this connection is not made

ERROR will appear on the

controller, this connection can

be checked by reading the

resistance across the black and

grey terminals, they will read

110 ohm if OK or 220 ohm if

not connected properly.

2.4 Wiring Configuration

The output current will need to be set at 22mA. The output will also need to be programmed so that it is powered in

its normal state. On a control panel reset the output will need to change state for a minimum period of 5 seconds.

NOTE: You should consult the relevant control panel documentation on how to program this functionality.

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 8

Page 8 of 19 ESP FIREbeam – Installation Manual

2.5 Step 4 - Commissioning

Commissioning the ESP FIREbeam is a simple procedure outlined in the following step by step explanation.

2.5.1 Stage One - Language and Commissioning Speed

IMPORTANT. Do NOT put the reflector up or COVER it if already in place.

Power up the unit and you will see

the screen will then default to

Access the menu by pressing the

enter button

The first screen you see is

through languages, when you have found your language press enter or if you are happy with English pres s the

English. If you need to change this use the right and left hand keys to scroll

or

down key to continue. If you have changed the language the system will continue in your chosen language.

enter and you will now see the commissioning speed screen. In most cases it is recommended to

Press

use fast mode (in normal mode the system uses 3.5mA, in fast mode it uses 17mA) - if you are commissioning

more than one beam at a time and the system cannot support the extra draw it may be necessary to use normal

mode to prevent excessive current draw. Fast mode allows x 4 times faster motor response and it may be quicker

to commission each beam in turn. Once commissioning is complete the ESP FIREbeam will automatically revert to

normal low power mode - (3.5mA).

Use the

the

left and right keys to toggle between fast and normal, the * indicates which mode is selected. Press

enter key to continue.

2.5.2 Stage Two - Pre-alignment

The next screen is pre-alignment - this is probably the most important part of setting up your beam. Pre-alignment

sets up the amount of power you need for the distance you are covering and can indicate if you are receiving

unwanted reflections from anything else in the beam path.

enter to begin pre-alignment. Remember no reflector. You will see the screen below, take a moment to

Press

understand what the figures on the screen mean.

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 9

ESP FIREbeam – Installation Manual Page 9 of 19

Receiver sensitivity starts off at 5% and output power starts at 10%. The beam will start by raising its sensitivity

first and can rise all the way up to 100%, after this the output power will rise. The objective of pre-alignment is to

adjust the output power to the correct levels for the distance to be covered. As there is no reflector we are looking

for a reflection off the far wall. Power levels will rise until they reach a maximum of anything up to 6 to 7% of

received signal strength (figures may fluctuate between these values), once this is achieved the power level will

automatically stop rising any further.

By looking at the table below you need to judge if you are receiving enough power to cover the required distance.

5m.........5% 30m......20% 60m......40% 90m......65%

10m.......10% 40m......25% 70m......50% 100m....75%

20m.......15% 50m......30% 80m.......60%

NOTE: Anything more than these levels is good and continue down to 9. If you are receiving noticeably less read

on below.

These figures are approximate but if you are receiving noticeably less than these figures you may be receiving a

reflection from an object nearby and not the far wall. By moving the beam (looking at the far wall) left (x-) right (x+)

up (y+) and down (y-) you can move the beam path away from the obstacle. By doing this you will be able to

achieve a suitable output power. In extreme cases it may be necessary to physically move the beam head to obtain

a clear line of sight.

Once you are happy with your power readings press

pressing the right key.

NOTE It may be that no reflection is received and power and sensitivity levels rise to their maximum, if this is the

case pre-alignment will automatically register Pre-Align - Complete. Confirm these settings by pressing the

right key.

OR if no reflection is seen

you will see this screen

enter to accept pre-alignment and confirm these settings by

2.5.3 Stage Three – Manual Alignment

You will now see the manual alignment screen showing anything between 0 and 6%. This is the amount of

received signal with no reflector that the beam is picking up from the environment.

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 10

Page 10 of 19 ESP FIREbeam – Installation Manual

NOW place or uncover the reflector on the blank wall directly opposite the beam head ensuring there is a clear path

through any obstructions such as structural steels etc.

NOTE: It is important that there is a clear line of sight between the reflector and beam head. The beam must see

at least 200mm of clear space around the reflector to enable the beam to see the edges of the reflecto r to

allow successful auto alignment in the following stage.

Once the reflector is in place and visible there should be a big jump in the received signal (AQ). This means that

the head is seeing and receiving a signal back from the reflector. In most cases this will result in a received signal

of over 100%.

As long as there is a received signal of over 40% you can move onto the next stage, see “Stage Four - AutoAlignment” on page 11.

If the AQ reading is below 40% it means the head is not seeing the reflector and will abort Auto Alignment. The

next stage is to manually move the beam to achieve an AQ reading of over 40%, ideally over 100%. The higher

the AQ the quicker it will auto align. This is done by manually moving the x and y motors to obtain a received

signal from the reflector.

In the example below we can see that the reflector is below the eye line of the beam head, so in this case you

would need to lower the angle of the beam (-Y) until you receive an AQ of over 40%.

The beam can be moved on both X and Y axis to a maximum 5 degrees using the

left (x-), right (x+), up (y+) and down (y-) keys. Looking at the reflector this

will move the beam across the reflector as shown:

Holding the keys down will quickly scroll through to your desired position, on release of the button the screen will

revert to the actual beam position and can be seen stepping toward the requested position.

To confirm the beam is seeing the reflector, cover the reflector as this should drop the AQ and therefore prove the

beam is on the reflector.

In the example above moving the y axis down (y-)

results in a greater AQ

You will now see the manual alignment screen showing anything between 0 and 6%. This is the amount of received

signal with no reflector that the beam is picking up from the environment.

Try and achieve as high an AQ as possible, it must be

over 40% to auto align. The higher the AQ the quicker

the auto align, above 100% is good

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 11

ESP FIREbeam – Installation Manual Page 11 of 19

2.5.4 Stage Four - Auto-Alignment

Having received an AQ reading of over 40% in manual mode press enter to exit manual and enter again to go into

auto alignment mode.

First you will see the sensitivity and power readings drop if the received signal is over 100%. Once at 100% or if

the reading is under 100% the ESP FIREbeam will automatically move its y and x axis until it centres itself onto the

middle of the reflector. It does this by seeing highs and lows as it falls on and off the reflector (seeing the edges of

the reflector) once it has found all the edges it will then calculate and move to the centre of the reflector.

Auto alignment in ‘fast’ mode will take, on average, 3 minutes and in normal mode up to 30 minutes; the better the

beam is aligned before auto alignment (high AQ readings) the shorter the align time. Once finishe d

Complete

You will now see this screen, AQ may fluctuate a couple of % above and below 100%

Now proceed to Step 4 – Testing, the final stage of commissioning.

will appear on the screen, simply press left to get back to OK and exit.

Align

2.6 Step 5 - Testing

2.6.1 Fault Test

This is done to confirm that the returned signal is from the reflector. Cover the entire reflector within one second. If

the beam is correctly targeted onto the reflector the AQ will drop to 0% (max 10%) and will fall into a ‘fault’ condition

(after 10 seconds). Amber LEDs will flash on the controller and the beam head, the word

the display. If the AQ is still above 10% reflections are also being returned from something else other than the

reflector. This should be rectified and a fault test performed again until AQ drops below 10%.

2.6.2 Fire Test

FAULT will appear on

Having completed the fault test the fire test confirms the functionality of the beam. Having just covered the reflector

completely for the fault test now let the beam recover to its normal state and then cover half the reflector, in effect

restricting the returned signal to 50%, the beam should then fall into a ‘fire’ condition (after 10 seconds).

Once you have successfully completed both tests your ESP FIREbeam is commissioned. You can now fine tune

your beam to suit the environment if needed. Look through the following menus to see adjustments that can be

made.

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 12

Page 12 of 19 ESP FIREbeam – Installation Manual

3 Screen and Menu Systems

3.1 Home Screen

NORMAL

FIRE

FAULT

ERROR

This is the screen you would normally see when the beam is

commissioned.

The air quality level has fallen below the fire threshold setting.

If alarm is set to latching and you need to reset from fire press

see this screen and press enter again to reset and return to the normal

screen.

This can also be reset by dropping the power to the beam for 5 seconds.

If set to auto reset it will reset to normal automatically.

The beam path has been fully blocked within 1 second (used when fault

testing in commissioning.

No communication with the controller. This could be that the flying lead is

not connected, or that the head is not connected to the controller. This

can be checked by reading the resistance across the black and grey

terminals, if connected it should read 110ohms, if not connected at one

end this will read 220ohms.

enter to

ALIGN

DIRT

COMP

This screen will appear when the beam is performing a self alignment,

normally because of building movement.

This is due to the compensation for dirt build up reaching its maximum FAULT or FIRE LED may be flashing.

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 13

ESP FIREbeam – Installation Manual Page 13 of 19

3.2 How To Use the Menu System

Press enter to go into the menu system, then press down to go through the main menu options:

Select this option to change system language

Select this option to commission the ESP FIREbeam

Select this option to make all changes and adjustments to the beam

Select this option to carry out routine maintenance

Select this option to access power and temperature headings

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 14

Page 14 of 19 ESP FIREbeam – Installation Manual

3.3 Individual Menu Items

3.3.1 Language

The language is factory set to English as default. If this is okay press

enter to continue to commissioning or up to return to the home screen.

To change the language use the right and left keys to change to

your preferred language and press

will then continue in the language of your choice. Languages currently

available are: English, Dutch, Italian, French, Spanish, Czechoslovakian

and German.

enter to confirm your choice – you

3.3.2 Commissioning

Press enter to go into the ‘Commissioning’ menu and access the sub

menus.

In Commission Speed, pressing

normal and fast. It is recommended in most cases to use fast mode (in

normal mode the system uses 3.5mA, in fast mode it uses 17mA). If you

are commissioning more than one beam at a time and the system cannot

support the extra draw it may be necessary to use normal mode to prevent

excessive current draw. Fast mode allows four times faster motor

response and it may be quicker to commission each beam in turn. Once

commissioning is complete the ESP FIREbeam will automatically revert to

normal low power mode - (3.5mA).

Press

enter here to start pre-alignment. In pre-alignment you should

ALWAYS COVER THE REFLECTOR. Starting at 10% power and 10%

receiver sensitivity, the receiver sensitivity will automatically increase to a

maximum of 100% then the output power will increase. These settings will

automatically stop when a received signal strength reaches 6% - this

received signal is the returned strength of the output signal without a

reflector (if no return signal is received the beam will reach full power and

the screen will say Pre-Align - complete). If you don’t receive high enough

output power and receiver sensitivity readings this will usually be because

you are receiving a reflection from an object nearby - use the left, right, up

and down keys to avoid the obstruction. When happy with your readings

press enter and confirm by pressing the right button, this will take you to

manual alignment - if you wish to abort Pre-Align press the left button.

right or left changes between

2011 Hochiki Europe (UK) Ltd

Press

enter to go into manual alignment - NOW THE REFLECTOR

CAN BE PLACED OR THE COVER CAN BE REMOVED. You should see

a large jump in signal strength. If no jump is seen use the X and Y keys to

locate the reflector (the better the single strength the better the beam is

aligned) try to achieve a figure of around 100% or over for optimum auto

alignment times - you must achieve signal strength over 40% to start auto

alignment. Press

enter to start auto-alignment. The beam will calibrate its power

Press

and search for the edges of the reflector – adjusting its power as it aligns

itself onto the reflector. Once it has found all four edges twice it will then

centre itself on the middle of the reflector and the screen will say

complete

aborted

received signal and the signal has dropped out. Press

return to auto alignment.

2-3-0-1340/ISS2/DEC11

this means something has crossed the beam path of the

enter to okay this and go to auto alignment.

. Press enter to return to the home screen. If you see align

back / left to

align

Page 15

ESP FIREbeam – Installation Manual Page 15 of 19

3.3.3 Mode Change

Here we can make changes to how the beam behaves. Press enter to

go into the ‘Mode Change’ menu and access the sub menus.

Threshold - use the right and left keys to increase or decrease

the beams sensitivity. It is factory set at 35% (meaning the received

signal has to drop by 35% to trigger the fire relay. This sensitivity can be

adjusted between 25% (sensitive) and 50% (less sensitive). Press

enter to return to ‘Mode Change’ or down to go to ‘Time to Fire’.

Time to Fire - you can adjust how long the beam has to be in fire

before the fire relay is triggered. This is factory set at 10s, you may want

to increase this if there is something that may momentarily obscure the

beam path (birds/forklift truck etc). This can be adjusted between 2 and

30 seconds by using the

return to ‘Mode Change’ or down to go to ‘Time to Fault’.

Time to Fault - you can adjust the time to fault between 2 and 60

seconds (factory set at 10 seconds). For a beam to go into fault the

beam path must be totally blocked within ONE second. By using the

right and left keys. Press enter to return to ‘Mode Change’ or

down to go to ‘Auto Reset’).

right and left keys. Press enter to

Auto Reset - the beam is factory set to auto reset when the received

signal raises above the fire threshold hysteresis. This can be set to

latching if your system requires this. Change by using the

right and

left keys. Press enter to return to ‘Mode Change’ or down to go to

‘Align On/Off’.

Align On/Off - you may want to turn the auto alignment function off, for

example, in an environment that often gets filled with welding smoke, the

auto align function kicks in when the received signal drops below 90%,

the point that the beam automatically checks for building movement. The

beam will try to align through the smoke which could be a problem if it is

unable to see the edges of the reflector. Use the

to turn off and on. When turning this function off extra care should be

taken to ensure that the beam head is on a sturdy fixing, in other words,

a brick wall or major structural steel. Auto alignment will still function in

commissioning. Press

to ‘Align Time’.

enter to return to ‘Mode Change’ or down to go

right and left keys

Align Time - this is factory set to 4hrs, you can adjust this, by using the

right and left keys, between 0 to 12 hours depending on your

environment. Press enter to return to ‘Mode Change’ or down to go to

‘Green Flashing Light On/Off’.

Green Flashing Light On/Off - you can turn the green flashing LED,

located on the head and controller, on or off using the

keys. This is a useful way of identifying the beam head you are working

with. Press

enter to return to ‘Mode Change’ or down to go to ‘Phase’.

right and left

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 16

Page 16 of 19 ESP FIREbeam – Installation Manual

Phase - When using multiple beams that face each other the beam output signals

could phase together and can cause unreliable readings, by setting each beam to

phase differently alleviates this problem. Use the

each beam a different phase pattern (length between output beam sample times)

you can choose between 0 (default setting) and 6. Press

‘Mode Change’ or

down to go to ‘Hysteresis’.

right and left keys to give

enter to return to

Hysteresis - Changing the hysteresis will change the delay in returning from a

fire state back to a normal state. For example, the beam is factory set at 15% so if

the beam falls into fire at 65% (35% threshold) it has to recover 15% to 80%

before it returns to normal. This action prevents small fluctuations in returned

signal causing the beam to fall in and out of a fire state. This can be adjusted

between 1% and 40% by using the

return to ‘Mode Change’ or

Press

enter to return to ‘Mode Change’.

down to go to ‘Comp Fire – Fault’.

right and left keys. Press enter to

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 17

ESP FIREbeam – Installation Manual Page 17 of 19

3.3.4 Beam Maintenance

Press enter to go into the ‘Beam Maintenance’ menu and access the

sub menus.

Dirt Comp - This screen shows how much the beam has compensated

for dust build-up on the beam head and reflectors, ALWAYS take a note of

this value as part of your routine maintenance to see any build-up pattern.

If you see figures above +50% you should clean both the lens face and

the reflectors (once cleaned you should instigate an auto alignment to recalibrate the beams settings). It is possible that you may see a negative

number here, this can happen when the ESP FIREbeam has been

commissioned in a ‘dirty’ atmosphere such as builders dust which, once

cleared, the beam then compensates for. To reset, perform an auto

alignment to re-calibrate the beam. Press

Maintenance’ or

down to go to ‘Alarm & Fault Event Counts’.

Alarm & Fault Event Counts - Here we can see how many times the

beam has gone into fire or fault since the beam was commissioned or

since the event log was last cleared.

enter to return to ‘Beam

Press

enter to clear events.

left / back to return to ‘Beam Maintenance’ or down to go to

Press

‘Self Test’.

Self Test

enter to perform a fire test, this works by running a test algorithm

Press

to lower the output power, the receiver sees this as obscuration. When

the received signal drops below the threshold point the beam will trip the

fire relay – this relay will not trip until the time to fire has passed which

could be anything between 2 and 30 seconds.

Press

left / back to end test, the fire test should show on the panel.

Press left / back to return to beam maintenance or down to go to

‘On/Off’.

On/Off

If something needs to be maintained in the beam path use the right and

left keys to turn the system on and off. This will show as a fault on the

panel. Press

enter to return to ‘Beam Maintenance’.

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 18

Page 18 of 19 ESP FIREbeam – Installation Manual

3.3.5 Diagnostics

Press enter the ‘Diagnostics’ menu and access the sub menus.

IR Power

This screen shows the amount of output power that is being transmitted. It

can be increased or decreased by using the right and left keys.

enter to return to ‘Diagnostics’ or down to go to ‘RX Sensitivity’.

Press

RX Sensitivity

This screen shows the receiver sensitivity and can be changed by using the

right and left keys. Press enter to return to diagnostics or down to

go to ‘Temperature’.

Temperature

Here you can see the temperature at the beam head and the amount of

compensation being made for temperature (no adjustments can be made

here).

Press

enter to return to diagnostics.

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Page 19

ESP FIREbeam – Installation Manual Page 19 of 19

4 Technical Specifications

Electrical Specifications

Supply Voltage 17 to 41 Vd.c.

Supply Current 3.5mA (constant current) in all operational states

Constant Current 17mA (constant current) in fast commissioning

Environmental Specifications

Temperature -10°C to +55°C

Humidity 10 to 95% RH Non-condensing

Ingress Protection Index IP65 when suitably mounted and terminated

Mechanical Specifications

Beam Head 180mmH x 155mmW x137mmD, Weight 1.1Kg

Controller 185mmH x 120mmW x 62mmD, Weight 0.55g

40KIT80 Mid-Range Reflector 293mmH x293mmW x 5mmD, Weight 0.8Kg

80KIT100 Long Range Reflector 394mmH x 394mmW x 5mmD, Weight 1.8Kg

Adapter (mounts the Beam Head onto unistrut) 270mmH x 250mm W x 5mmD, Wei ght 0.6g

Optical Specifications

Optical Wavelength 870nm

Maximum Angular Alignment ±5°

Maximum Angular Misalignment Beam Head ±0.3°, Reflector ±2° (static not auto-aligning)

Operational Specifications

Protection

Range

Alarm Sensitivity Levels 25%(1.25dB) to 50%(3dB) in 1%(0.05dB) increments (default 35% (1.87dB))

Alarm Condition

Alarm Indication

Test/Reset Features

Fault Sensitivity Level 90%

Fault Condition

Fault Indication

Normal Condition

Auto-align/Beam

Contamination Compensation

ESP FIREBEAM Standard Product 5 to 40 metres

40KIT80 Mid-Range Reflector Kit 40 to 80 metres

80KIT100 Long Range Reflector Kit 80 to 100 metres

Obscuration drops to below pre-defined sensitivity level. Time to Alarm Condition

adjustable 2 to 30 seconds in 1 second increments (default 10 seconds)

Controller Status – FIRE, Controller Red Flashing LED, Head Red Flashing LED,

Alarm Relay Change Over (CO) Contact Rating 2A @ 30 VDC

Beam test function by controller. Alarm latching/auto-reset selectable (default

auto-reset). Alarm reset in latching mode by controller reset function, removing

power for >5 seconds, apply 12 to 24 VDC to reset connections in Beam Head.

Obscuration drops to below the fault sensitivity level within 1 second Power Down

or Supply Voltage < 9 VDC. Commissioning modes, Pre-Alignment and Auto

Alignment. Beam turned off during Beam Maintenance. Time to Fault Condition

adjustable, 2 to 60 seconds in 1 second increments (default 10 secon ds)

Controller Status – FAULT, Controller Yellow Flashing LED 1 Second, Head

Yellow Flashing LED 1 Second, Fault Relay Change Over (CO) Contact Rating

2A @ 30 VDC

Obscuration level is above the Alarm sensitivity level, Controller Status –

NORMAL, Controller Green Flashing LED, Programmable on/off, Head Green

Flashing LED Programmable on/off

Auto-align during normal operation if obscuration drops below 90% for the

duration of the align time set (doesn’t effect normal operating mode)

Beam Contamination Compensation 4 hour monitoring. Compensation data

available at the controller

2011 Hochiki Europe (UK) Ltd

2-3-0-1340/ISS2/DEC11

Loading...

Loading...