Page 1

HOBO® RX3000 Remote Monitoring Station Manual

Operating

Smart

Smart Sensor Network Cable

Length

Smart Sensor Data

Module Slots

Logging Rate

Time Accuracy

Battery Type

Rechargeable

Service

Memory

Alarm Notification Latency

Enclosure Access

LCD

Materials

Size

Weight

Mounting

Environmental Rating

HOBO RX3000 Remote

Monitoring Station

Models: RX3001-00-01 Ethernet

Included Items:

• Two plates for cable access

openings with eight

thumbscrews and one wrench

• Two rubber cable channels

• Rubber plugs

• Grease packet

• Two mounting plates with

four screws

• Grounding wire

• Two U-bolts

Required Items:

• HOBOlink

• HOBOware

with USB cable for RX3002

Wi-Fi models (optional for

RX3001, RX3003, and RX3004

models)

• AC adapter (AC-U30) or solar

panel (SOLAR-xW)

Optional Items:

• Smart sensors

• Analog sensor module

(RXMOD-A1)

• Relay module (RXMOD-R1)

• RXW Manager (RXMOD-RXW-

xxx) and RXW motes

• Water level sensor module

(RXMOD-W1) with water level

sensor (MX2001-0x-SS-S or

MX2001-0x-Ti-S) and cable

(CABLE-RWLMOD-xxx)

• External DC power cable

(CABLE-RX-PWR)

• Tripod kit (M-TPA or M-TPB)

• Guy wire kit (M-GWA)

• 1/2 inch stake kit (M-SKA)

• Grounding kit (M-GKA),

required if using wind speed

or wind direction smart sensor

Sensors, modules, and

accessories are available at

www.onsetcomp.com.

18255-R

RX3002-00-01 Wi-Fi

RX3003-00-01 Cellular

RX3004-00-01 Cellular 4G

® 3.7.2 or later

The HOBO RX3000 Remote Monitoring Station provides continuous logging for a broad range of

energy and weather monitoring applications with up to ten smart sensors, optional analog sensor,

water level sensor, and relay modules, and wireless sensor motes. Data from the RX3000 station is

transferred at regular connection intervals to HOBOlink® web-based software where you can

check the latest conditions, view graphs, configure sensors and alarms, set up a dashboard,

download your data, or schedule data delivery via email or FTP. Inside its weatherproof enclosure,

this durable station has a built-in LCD screen to check the current system configuration and status,

start and stop logging, add and remove smart sensors, and connect to HOBOlink on demand. Up

to three individual relays can be activated on the optional relay module while the optional analog

module has four analog inputs that support excitation power, scaling, and statistics

measurements. An optional RXW Manager module is also available for the station to set up the

HOBOnet Wireless Sensor Network, which can support up to 50 motes. All easy-to-install modules

can be configured with HOBOlink.

Specifications

Range -40° to 60°C (-40° to 140°F); no remote communications for battery

Sensor Connectors 10

Channels Maximum of 15 (some smart sensors use more than one data channel;

2

1 second (RX3001 and RX3002) or 1 minute (RX3003 and RX3004) to 18

±8 seconds per month in 0° to 40°C (32°F to 104°F) range;

/Power Source 4 Volt, 10 AHr, rechargeable sealed lead-acid; external power required

Battery

Life

32 MB, 2 million measurements, continuous logging

Hinged door secured by two latches with eyelets for use with user-

LCD is visible from 0° to 50°C (32° to 122°F); the LCD may react slowly

Outer enclosure: Polycarbonate/PBT blend with stainless steel hinge

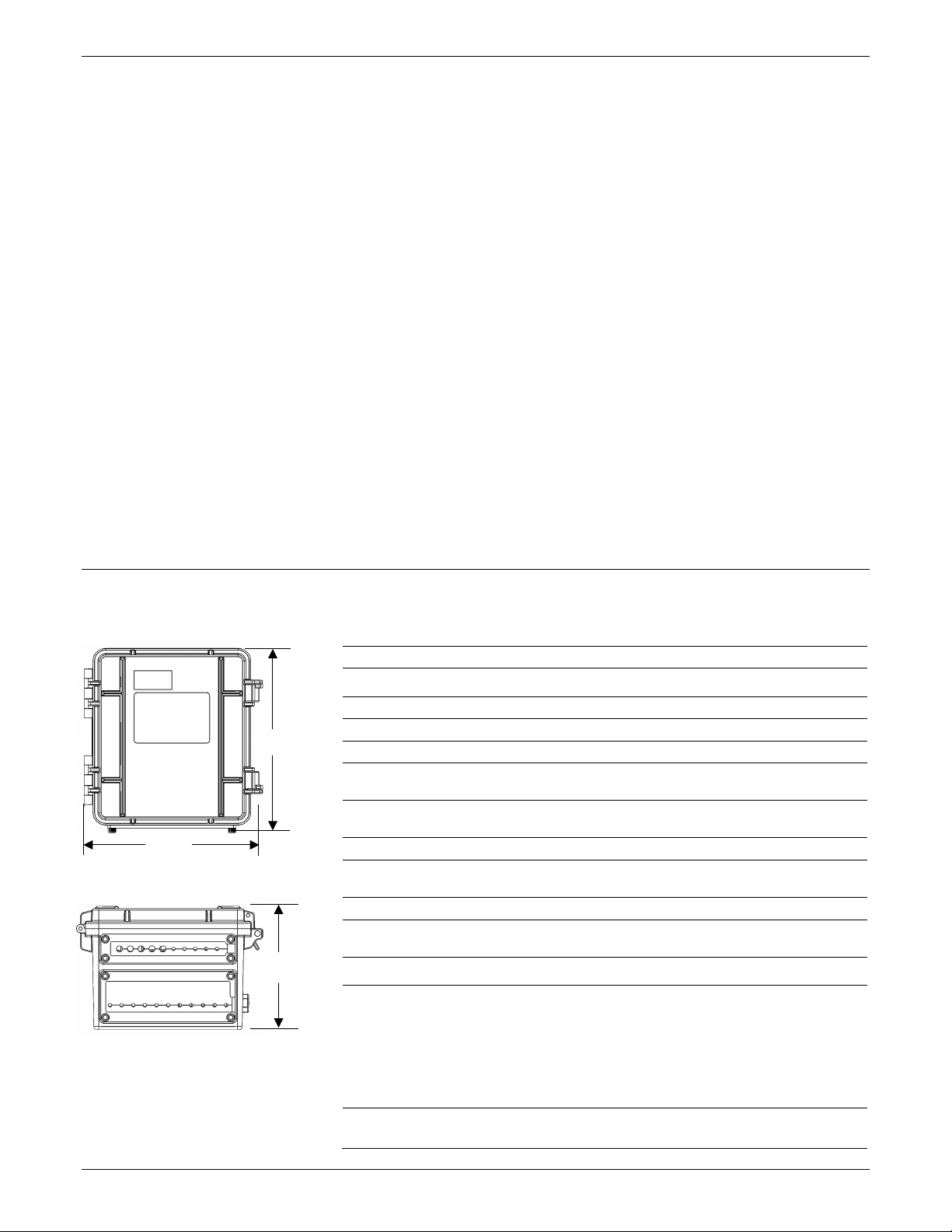

18.6 x 18.1 x 11.8 cm (7.3 x 7.1 x 4.7 in.); see diagrams on next page

2.2 kg (4.85 lb)

3.8 cm (1.5 inch) mast or wall mount

Weatherproof enclosure, NEMA 4X (requires proper installation of

voltage less than 3.9 V DC

100 m (328 ft) maximum

see sensor manual for details)

hours

±30 seconds per month in -40° to 60°C (-40° to 140°F) range

using one of these options: AC power adapter (AC-U30), solar panel

(SOLAR-xW), or external power source 5 V DC to 17 V DC with external

DC power cable (CABLE-RX-PWR)

Typical 3–5 years when operated in the temperature range -20° to 40°C

(-4°F to 104°F); operation outside this range will reduce the battery

service life

Logging interval plus 2–4 minutes, typical

supplied padlocks

or go blank in temperatures outside this range

pins and brass inserts; Inner enclosure: Polycarbonate; Gaskets:

Silicone rubber; Cable channel: EPDM rubber; Cable opening cover:

Aluminum with ABS plastic thumb screws; U-Bolts: Steel with zinc

dichromate finish

cable channel system)

The CE Marking identifies this product as complying with all relevant

directives in the European Union (EU)

See last page

RX3002: FCC ID R68XPICOW, IC ID 3867A-XPICOW

RX3003: FCC ID QIPEHS6, IC ID 7830A-EHS6; approved for use in

Taiwan and Japan

RX3004: FCC ID QIPPLS62-W, IC ID:7830A-PLS62W

Page 2

HOBO RX3000 Remote Monitoring Station Manual

Ethernet (RX3001)

Connector

Wi

Network Standards

Frequency Range

Antenna Connector

Data Rates

6, 9, 12, 18, 24, 36, 48, 54 Mbps (802.11g

Number of Selectable

Subchannels

Radio

Security

Maximum Receive Level

Receiver Sensitivity

Cellular (RX3003

Wireless Radio

Antenna

11.8 cm

4.7 in.

18.6 cm

(7.3 in.)

18.1 cm

Table of Contents

Specifications .......................................................................................... 1

Module Specifications ............................................................................. 3

Device Components and Operation ........................................................ 6

LCD Operation ......................................................................................... 7

Setting up the Station ............................................................................. 9

1. Log in to HOBOlink. ...................................................................... 9

2. Register the station. ..................................................................... 9

3. Install optional modules or user-supplied SIM. ............................ 9

4. Plug in the battery and charging device. ...................................... 9

5. Check and configure device communications. ........................... 10

6. Plug in and search for any smart sensors. .................................. 11

7. Add any wireless sensor motes. ................................................. 11

8. Connect analog sensors, relay devices, or water level sensors. . 12

9. Connect to HOBOlink. ................................................................ 13

10. Configure the station in HOBOlink. ............................................ 14

11. Start logging. .............................................................................. 17

12. If you installed a water level sensor module and sensor,

obtain a reference water level reading. ..................................... 17

13. If you installed a water level sensor module and sensor,

configure the water level and water flow channels in

HOBOlink. ................................................................................... 17

Viewing Data in HOBOlink ..................................................................... 18

Setting System and Sensor Alarms ........................................................ 19

System Alarms .................................................................................. 19

Sensor Alarms ................................................................................... 19

Setting up Water Level and Water Flow Channels in HOBOlink ............ 20

Setting up a Water Level Channel .................................................... 20

Setting up a Water Flow Channel for a V-Notch Weir ...................... 20

Setting up a Water Flow Channel for a Rectangular Weir ................ 21

Setting up a Water Flow Channel for a Trapezoidal Weir ................. 22

Setting up a Water Flow Channel for a General Flume .................... 23

Setting up a Water Flow Channel for a Stage-Discharge Table ......... 23

Starting and Stopping Logging .............................................................. 24

Adding or Removing Smart Sensors ...................................................... 25

Adding or Removing Modules ............................................................... 25

Adding or Removing Analog Sensors, Relay Devices, or Water Level

Sensors ................................................................................................. 26

Adding or Removing Motes .................................................................. 26

Managing Connections to HOBOlink ..................................................... 27

Checking Latest Conditions with HOBOware ........................................ 28

Deploying and Mounting the Station .................................................... 28

Guidelines for Deploying the Station................................................ 28

Guidelines for Deploying the HOBOnet RX Wireless Sensor

Network ..................................................................................... 28

Guidelines for Deploying a Water Level Sensor ............................... 29

Installing the Grounding Wire .......................................................... 30

Mounting the Station ....................................................................... 30

Installing the Weatherproof Rubber Cable Channel and Covers ..... 31

Care and Maintenance .......................................................................... 32

Troubleshooting.................................................................................... 32

Battery Information .............................................................................. 32

Specifications (continued)

(7.1 in.)

Dimensions

One RJ45/100BaseT

-Fi (RX3002)

IEEE 802.11b/g/n

2.412–2.484 GHz

1, no diversity supported

1, 2, 5.5, 11 Mbps (802.11b);

Radio

Modulations OFDM, DSSS, DBPSK, DQPSK, CCK, 16QAM, 64QAM

WEP 64/128, WPA-PSK, AES end-to-end encryption, WPA2,

-72 dBM for 54 Mbps, -87 dBm for 11 Mbps, -89 dBm for 5.5 Mbps,

and RX3004)

RX3003:

RX3003: Penta band

802.11n, HT20 MCS0 (6.5 Mbps) to HT20 MC87 (65 Mbps)

Up to 14 channels; profiles available will include USA, France, Japan,

Spain, Canada, and “Other” (multiple countries)

protocols not listed are not supported

-10 dBm (with PER <8%)

-90 dBm for 2.0 Mbps, -92 dBm for 1.0 Mbps

GSM/GPRS/EDGE: Quad band 850/900/1800/1900 MHz,

UMTS/HSPA+: Five band 800/850/900/1900/2100 MHz

RX3004:

GSM/GPRS/EDGE: Quad band 850/900/1800/1900 MHz

UMTS/HSPA+: Seven band 800/850/900/1800/1900/2100 MHz

LTE: Twelve Band 700/800/850/900/1800/1900/2100/2600 MHz

RX3004: 4G LTE

1-508-759-9500 (U.S. and International) 2 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

Page 3

HOBO RX3000 Remote Monitoring Station Manual

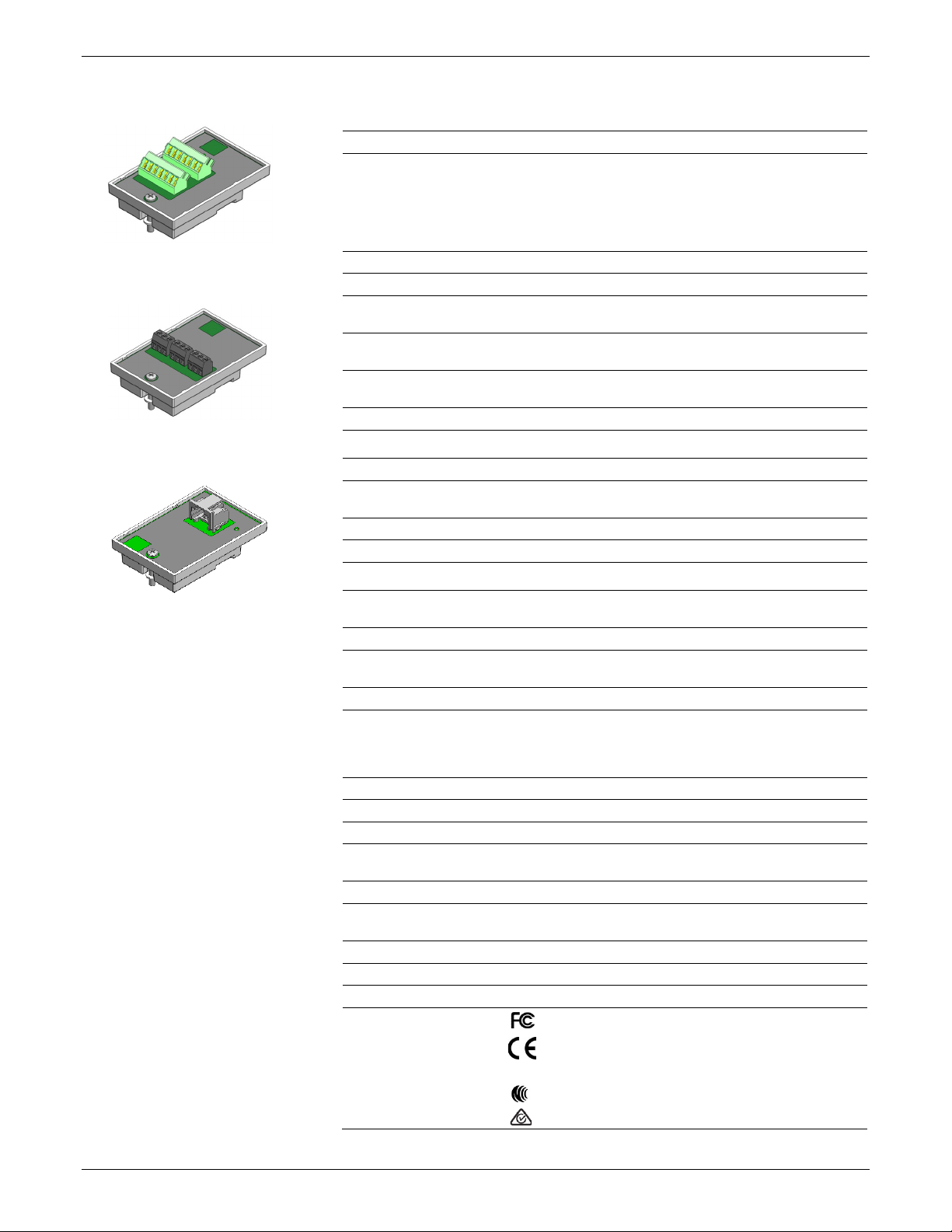

Optional Analog Sensor Module (RXMOD

Input Channels

Measurement Range

Accuracy

Resolution

Field Wiring

Minimum/Maximum Input

Voltage

Minimum/Maximum Input

Current

Minimum Source Impedance

for Current Measurement

Excitation Voltage

Optional Relay Module (RXMOD

Relays

Alarm Output Relays

Voltage

Current

Optional RXW Manager Module (RXMOD

Operating Temperature

Range

Radio Power

Transmission Range

At least 304.8 m (1,000 ft) line of sight at 1.8 m (6 ft) from the ground,

Wireless Data Standard

Radio Operating Frequencies

Modulation Employed

Data Rate

Duty Cycle

Maximum Number of Motes

Power Source

Dimensions

Weight

Materials

Environmental Rating

Compliance Marks

Module Specifications

-A1)

Four, single-ended, in addition to smart sensor data channels

Analog Sensor Module (RXMOD-A1)

Relay Module (RXMOD-R1)

and

15 bits

Two- or three-wire via screw terminals, 16–24 AWG

12 V DC ±5% at 200 mA maximum per module

Three independent relays

Each relay contact closure can be configured as normally open,

30 V max

1 Amp max

0–25.6 mA DC, ±5 µA ± 0.15% of reading

0–2.5 V DC, ±0.25 mV ±0.2% of reading

0–5 V DC, ±0.25 mV ±0.2% of reading

0–10 V DC, ±0.3 mV ±0.2% of reading

0–20 V DC, ±0.6 mV ±0.2% of reading

0–33 V DC, ±1.20 mV ±0.2% of reading

0/33 V DC

0/25.6 mA

20 KΩ

-R1)

normally closed, or pulsed for one second

RXW Manager Module

(RXMOD-RXW-xxx)

1-508-759-9500 (U.S. and International) 3 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

-RXW-xxx)

12.6 mW (+11 dBm) non-adjustable

IEEE 802.15.4

OQPSK (Offset Quadrature Phase Shift Keying)

Up to 250 kbps, non-adjustable

<1%

Powered by the RX3000 station

Mote: 16.2 x 8.59 x 4.14 cm (6.38 x 3.38 x 1.63 inches)

Mote: 159 g (5.62 oz)

Mote: PCPBT, silicone rubber seal

Mote: IP67

-25° to 60°C (-13° to 140°F)

457.2 m (1,500 ft) typical

RXMOD-RXW-900: 904–924 MHz

RXMOD-RXW-868: 866.5 MHz

RXMOD-RXW-921: 921 MHz

RXMOD-RXW-922: 916–924 MHz

Up to 50 wireless sensors or 336 data channels per one HOBO RX

station

Cable length: 2 m (6.56 ft)

RXMOD-RXW-900: See last page

RXMOD-RXW-868: The CE Marking identifies this product as

complying with all relevant directives in the European Union

(EU).

RXMOD-RXW-921: See last page

RXMOD-RXW-922: See last page

Page 4

HOBO RX3000 Remote Monitoring Station Manual

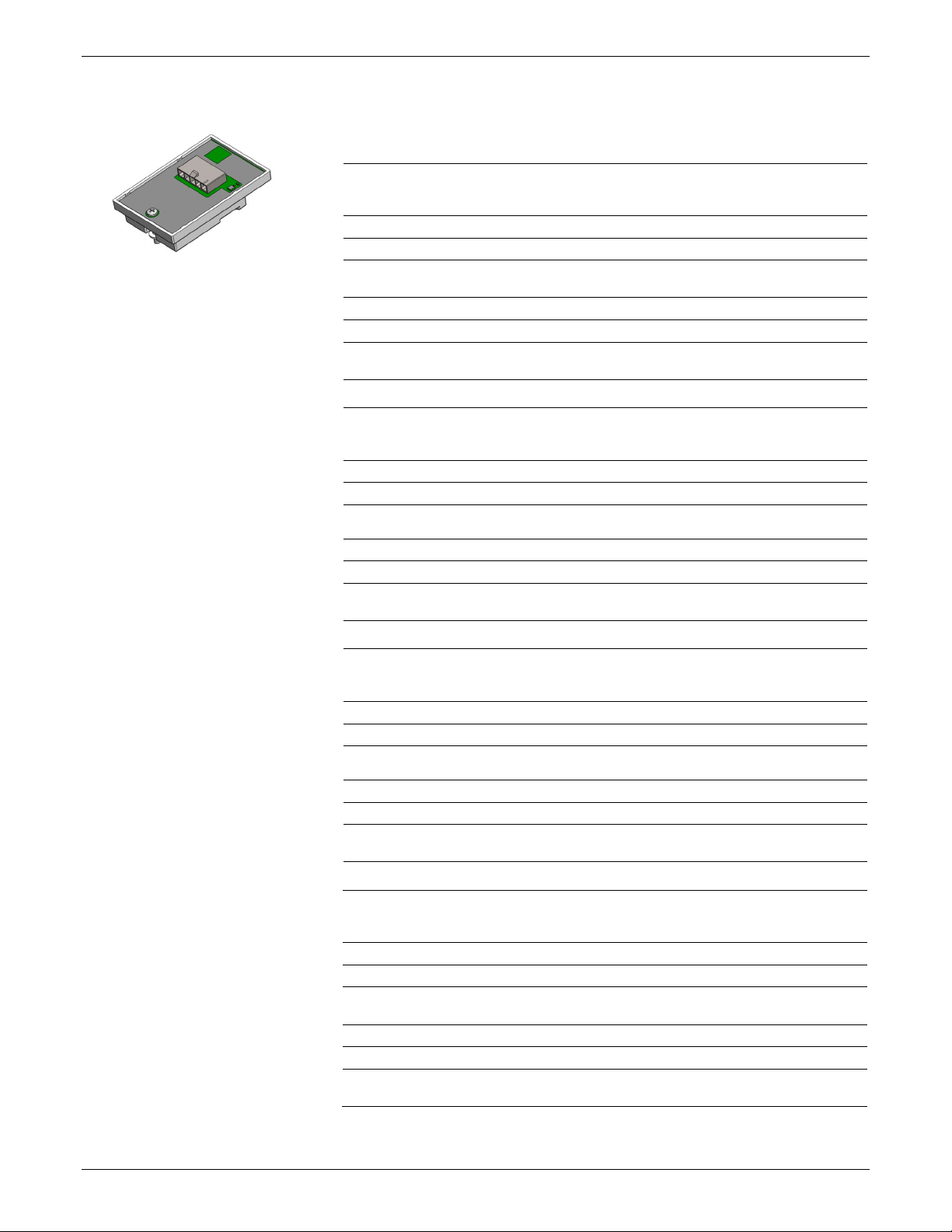

Optional Water Level Sensor Module (RXMOD

Pressure (Absolute) and Water Level Measurements

Operation Range

Factory Calibrated Range

Burst Pressure

Water Level Accuracy*

Raw Pressure Accuracy**

Resolution

Pressure Response Time

(90%)***

Pressure (Absolute) and Water Level Measurements

Operation Range

Factory Calibrated Range

Burst Pressure

Water Level Accuracy*

Raw Pressure Accuracy**

Resolution

Pressure Response Time

(90%)***

Pressure (Absolute) and Water Level Measurements

Operation Range

Factory Calibrated Range

Burst Pressure

Water Level Accuracy*

Typical error: ±0.05% FS, 3.8 cm (0.125 ft) water

Raw Pressure Accuracy**

Resolution

Pressure Response Time

(90%)***

Pressure (Absolute) and Water Level Measurements

Operation Range

Factory Calibrated Range

Burst Pressure

Water Level Accuracy*

Raw Pressure Accuracy**

Resolution

Pressure Response Time

(90%)***

Module Specifications (continued)

-W1)

MX2001-01-SS-S and MX2001-01-Ti-S

Water Level Sensor Module

(RXMOD-W1)

0 to 207 kPa (0 to 30 psia); approximately 0 to 9 m (0 to 30 ft) of

310 kPa (45 psia) or 18 m (60 ft) depth

Typical error: ±0.05% FS, 0.5 cm (0.015 ft) water

<0.02 kPa (0.003 psi), 0.21 cm (0.007 ft) water

0 to 400 kPa (0 to 58 psia); approximately 0 to 30.6 m (0 to 100 ft) of

500 kPa (72.5 psia) or 40.8 m (134 ft) depth

<0.04 kPa (0.006 psi), 0.41 cm (0.013 ft) water

water depth at sea level, or 0 to 12 m (0 to 40 ft) of water at 3,000 m

(10,000 ft) of altitude

69 to 207 kPa (10 to 30 psia), 0° to 40°C (32° to 104°F)

Maximum error: ±0.1% FS, 1.0 cm (0.03 ft) water

±0.3% FS, 0.62 kPa (0.09 psi) maximum error

<1 second at a stable temperature

MX2001-02-SS-S

water depth at sea level, or 0 to 33.6 m (0 to 111 ft) of water at

3,000 m (10,000 ft) of altitude

69 to 400 kPa (10 to 58 psia), 0° to 40°C (32° to 104°F)

Typical error: ±0.05% FS, 1.5 cm (0.05 ft) water

Maximum error: ±0.1% FS, 3.0 cm (0.1 ft) water

±0.3% FS, 1.20 kPa (0.17 psi) maximum error

<1 second at a stable temperature

MX2001-03-SS-S

0 to 850 kPa (0 to 123.3 psia); approximately 0 to 76.5 m (0 to 251 ft)

of water depth at sea level, or 0 to 79.5 m (0 to 262 ft) of water at

3,000 m (10,000 ft) of altitude

69 to 850 kPa (10 to 123.3 psia), 0° to 40°C (32° to 104°F)

1,200 kPa (174 psia) or 112 m (368 ft) depth

Maximum error: ±0.1% FS, 7.6 cm (0.25 ft) water

±0.3% FS, 2.55 kPa (0.37 psi) maximum error

<0.085 kPa (0.012 psi), 0.87 cm (0.028 ft) water

<1 second at a stable temperature

MX2001-04-SS-S and MX2001-04-Ti-S

0 to 145 kPa (0 to 21 psia); approximately 0 to 4 m (0 to 13 ft) of

water depth at sea level, or 0 to 7 m (0 to 23 ft) of water at 3,000 m

(10,000 ft) of altitude

69 to 145 kPa (10 to 21 psia), 0° to 40°C (32° to 104°F)

310 kPa (45 psia) or 18 m (60 ft) depth

Typical error: ±0.075% FS, 0.3 cm (0.01 ft) water

Maximum error: ±0.15% FS, 0.6 cm (0.02 ft) water

±0.3% FS, 0.43 kPa (0.063 psi) maximum error

<0.014 kPa (0.002 psi), 0.14 cm (0.005 ft) water

<1 second at a stable temperature

1-508-759-9500 (U.S. and International) 4 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

Page 5

HOBO RX3000 Remote Monitoring Station Manual

Water Level Sensor and Cable

Dimensions

Weight

Materials

Environmental Rating

Barometric Pressure (RXMOD

Operation Range

Temperature Calibrated

Range

Accuracy

Water Level Accuracy*

Resolution

Response Time

Stability (Drift)

Temperature (Water Level Sensors MX2001

Operation Range

Accuracy

Resolution

Response Time (90%)

Stability (Drift)

Module Specifications (continued)

Sensor (MX2001-0x-SS-S and MX2001-0x-Ti-S): 2.54 cm (1.0 inches)

Stainless sensor (MX2001-0x-SS-S): Stainless steel housing, Viton

IP68; cable is waterproof for continuous immersion up to 112 m

66 to 107 kPa (9.57 to 15.52 psia)

±0.2 kPa (±0.029 psi) over full temperature range at fixed pressure;

Typical error: ±0.075% FS, 0.3 cm (0.01 ft) water

<0.01 kPa (0.0015 psi)

<1 second at stable temperature

<0.01 kPa (0.0015 psi) per year

diameter, 9.91 cm (3.9 inches) length

Cable (CABLE-RWLMOD-xxx): 0.47 cm

diameter, 0.2 to 400 m (0.65 to 1,312 ft) length

Note: The length of the water level logger cable can vary -0% to +3%

+10 cm (3.9 inches) from the length ordered.

Stainless sensor (MX2001-0x-SS-S): Approximately 141.4 g (4.99 oz)

in air; approximately 93.4 g (3.3 oz) in fresh water

Titanium sensor (MX2001-0x-Ti-S): Approximately 80 g (2.83 oz) in

air; approximately 37 g (1.3 oz) in fresh water

Cable (CABLE-RWLMOD-XXX): 39 g (1.38 oz) per 1 meter (3.28 ft)

and Buna-N O-rings, ceramic sensor in stainless steel end cap

Titanium sensor (MX2001-0x-Ti-S): Acetal housing, Viton and BunaN O-rings, ceramic sensor in Titanium end cap

Cable (CABLE-RWLMOD-XXX): Polycarbonate end cap, PVC end cap,

nylon collar nut, Viton O-rings, polyurethane jacket

(368 ft), refer to sensor model specifications for sensor depth rating

-W1)

-20° to 50°C (-4° to 122°C)

maximum error ±0.5% FS

Maximum error: ±0.15% FS, 0.6 cm (0.02 ft) water

±0.03 (0.185 inches ±0.01)

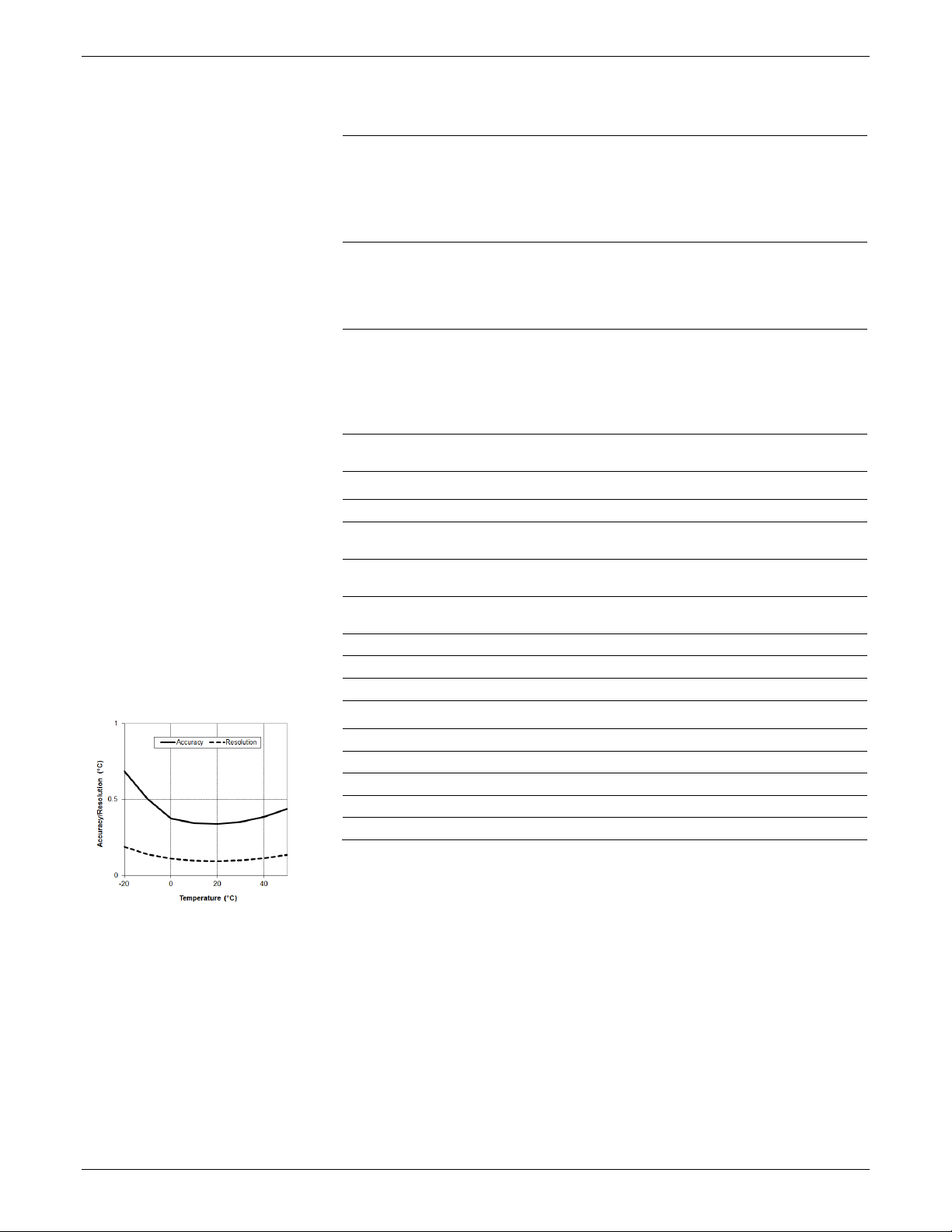

Plot A

1-508-759-9500 (U.S. and International) 5 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

-0x-SS-S and MX2001-0x-Ti-S)

-20° to 50°C (-4° to 122°F)

±0.44°C from 0° to 50°C (±0.79°F from 32° to 122°F), see Plot A

0.1°C at 25°C (0.18°F at 77°F), see Plot A

5 minutes in water (typical)

0.1°C (0.18°F) per year

* Water Level Accuracy: With accurate reference water level measurement, known water density,

and a stable temperature environment. System Water Level Accuracy equals the sum of the

Barometric Water Level Accuracy plus the selected sensor Water Level Accuracy.

** Raw Pressure Accuracy: Absolute pressure sensor accuracy includes all sensor drift, temperature,

and hysteresis-induced errors.

*** Changes in Temperature: Allow 20 minutes in water to achieve full temperature compensation of

the pressure sensor. There can be up to 0.5% of additional error due to rapid temperature changes.

Measurement accuracy also depends on temperature response time.

Page 6

HOBO RX3000 Remote Monitoring Station Manual

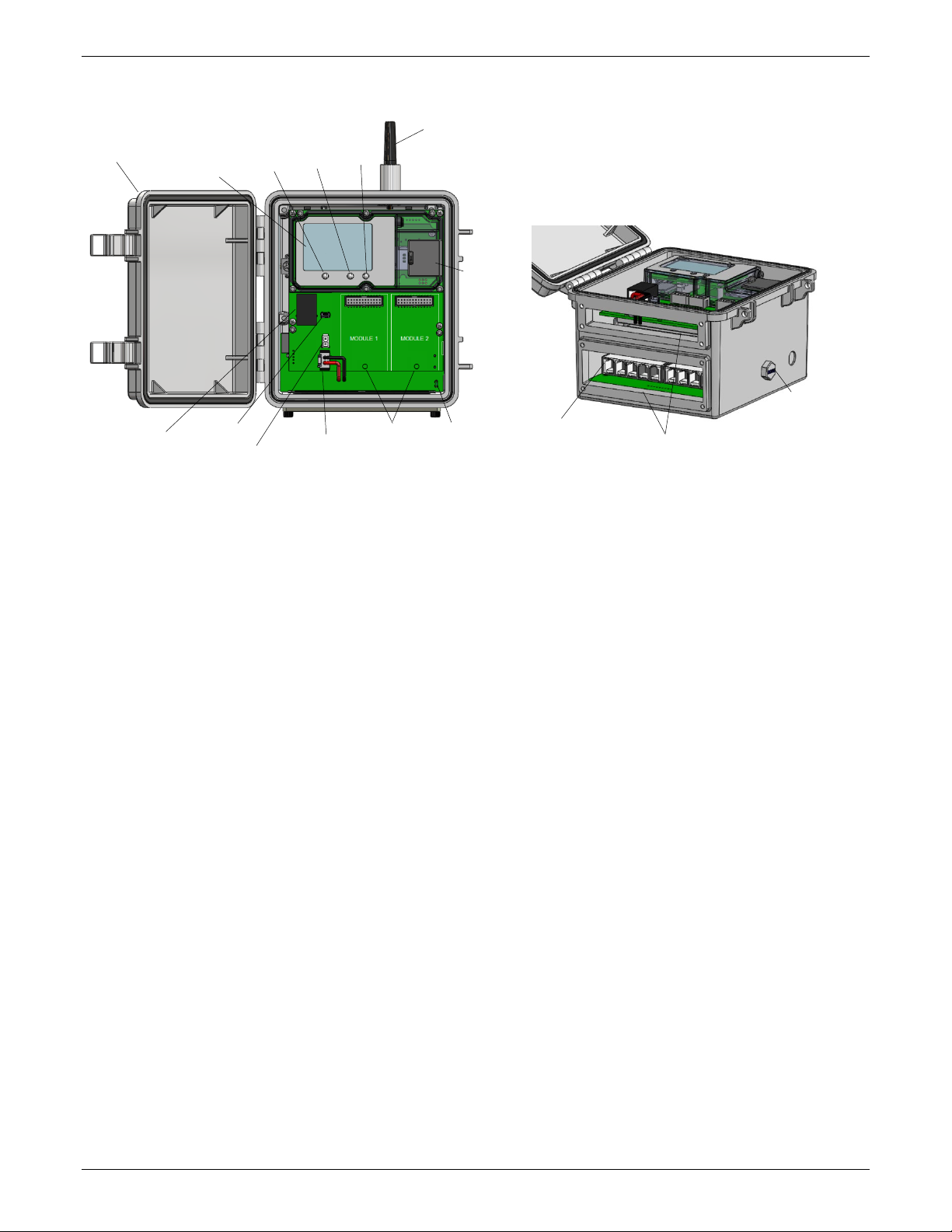

Battery Port

Smart Sensor

Cable Access Openings

Vent

SIM Card

LCD Screen

Ethernet

(RX3001)

Charging Port

USB Port

Module Slots

Station Door

Antenna

Grounding

Wire Port

Connect/

Start/

Button

Select

Button

Device Components and Operation

(RX3003)

Connector

Stop

Search

Button

Station Door: This is the protective, hinged door covering the

LCD and electronics. The station serial number and device key

needed for HOBOlink registration are located on the inside of

the door.

LCD Screen: This shows details about system, module, and

sensor operation (see LCD Operation).

Select Button: Use this button to cycle through information

about the smart sensors and optional modules (see LCD

Operation).

Start/Stop Button: Use this button to start and stop logging or

clear a fault code (see LCD Operation).

Connect/Search Button: Use this button to connect to

HOBOlink or search for new smart sensors (see LCD Operation).

Antenna: This is the external radio antenna for cellular

communication in the RX3003 model. The RX3002 and RX3004

models use an internal antenna.

SIM Card/Micro SIM Card: A SIM card is installed in the RX3003

model or a micro SIM card is installed in the RX3004 model to

enable cellular communications.

Grounding Wire Port: Use this port to connect a grounding wire

(see Deploying and Mounting the Station).

Module Slots: These are two slots for installing optional analog

sensor, relay, water level sensor, or RXW Manager modules

(see Setting up the Station).

(RX3003) or

Micro SIM Card

(RX3004)

Connectors

Battery Port: Use this port to plug in the internal battery cable

(see Setting up the Station and Battery Information).

Charging Port: Use this port to plug in an AC adapter, solar

panel, or external power source to keep the battery charged

(see Setting up the Station and Battery Information).

USB Port: Use this port to connect the station to the computer

via USB cable as needed for HOBOware.

Ethernet Connector: Use this port to connect an Ethernet RJ45

cable for the RX3001 model (see Setting up the Station).

Smart Sensor Connectors: Use these input jacks to connect up

to 10 smart sensors (see Setting up the Station). The station can

support up to 15 smart sensor data channels; some smart

sensors have more than one data channel.

Cable Access Openings: These are the two openings for

connecting cables and wires to the station (see Setting up the

Station). Install the cover plates and rubber cable channels in

these openings to create a weatherproof seal (see Deploying

and Mounting the Station).

Vent. This vent allows pressure to equalize inside the station

while keeping water out. Note that the pressure inside the

station does not match the outside air pressure exactly.

Therefore, a barometric pressure sensor deployed within the

case cannot measure the true atmospheric pressure unless it

has its own unrestricted vent to the outside.

1-508-759-9500 (U.S. and International) 6 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

Page 7

HOBO RX3000 Remote Monitoring Station Manual

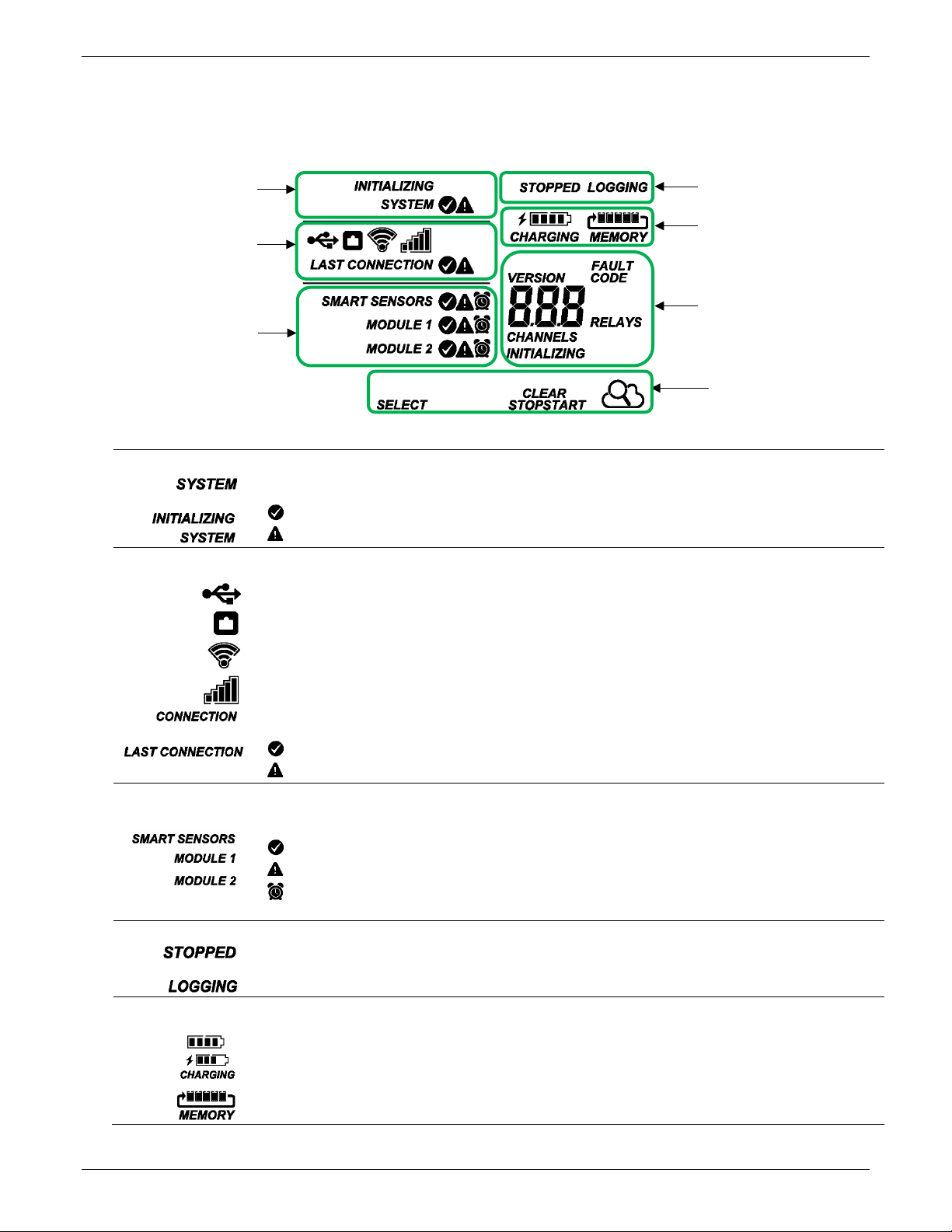

System Status

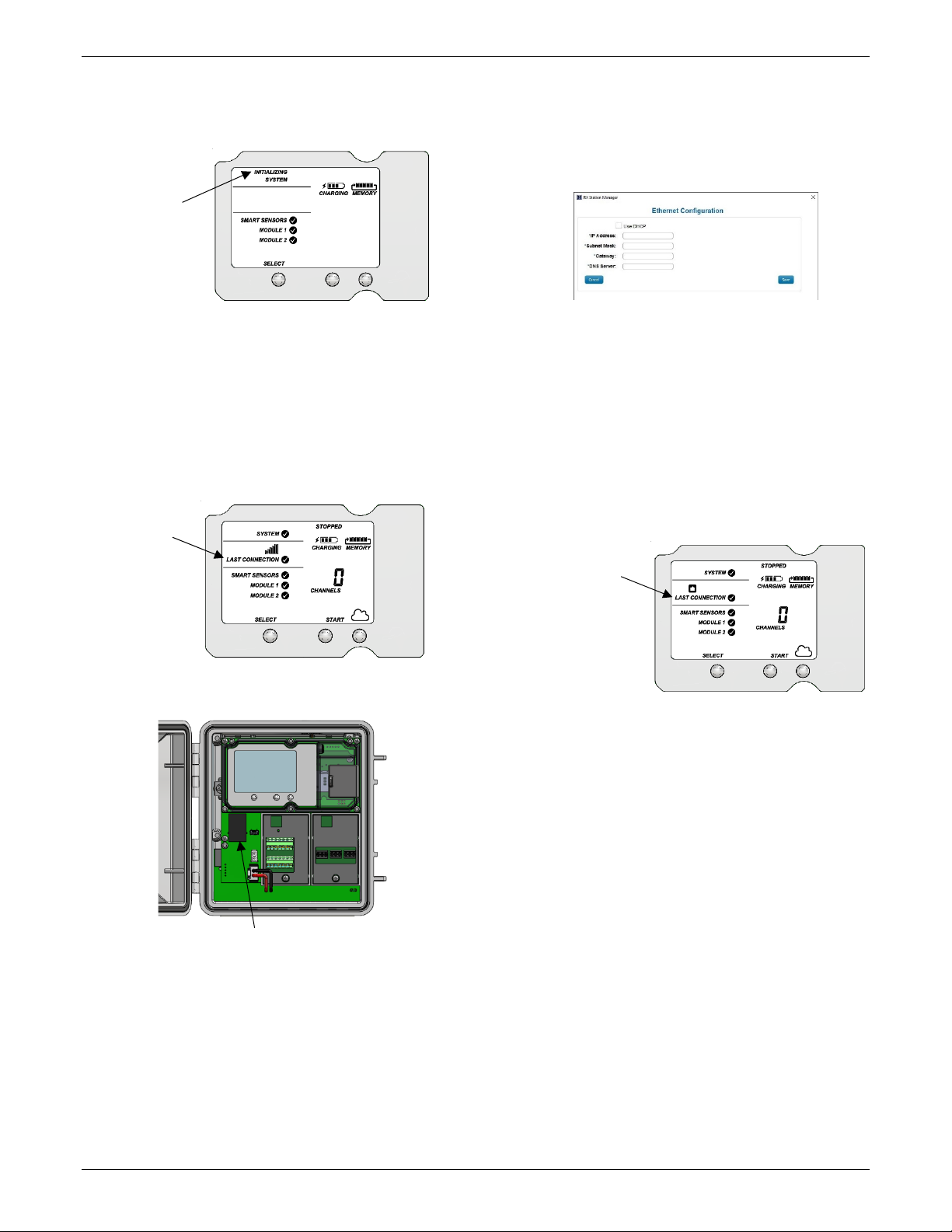

When the station is powered up, “Initializing System” flashes in the upper left part of the LCD. After initialization is

Connection Status

This part of the LCD shows the communication method used for connecting to HOBOlink and the system connection

status.

This indicates the station is using Wi-Fi to connect to HOBOlink. This also shows the strength of the wireless signal; the

more bars there are, the stronger the signal. This will blink while connecting to HOBOlink.

indicates there was a problem with the last connection; check the Connections log in HOBOlink.

Smart Sensor and

This part of the LCD shows the status of the smart sensors and any optional modules installed. Module 1 is installed in the

One of the following symbols will also appear next to smart sensors or a module (if applicable):

Logging Status

Battery and

Memory Status

This part of the LCD shows the current battery level and memory.

The battery indicator shows the approximate battery power remaining. In this example, the battery is fully charged. The

When the station is logging, it will record data indefinitely, with newest data overwriting the oldest data until the station is

System Status

Connection Status

Smart Sensor and

Logging Status

Battery and Memory Status

Channel and Device

Button Symbols

LCD Operation

This example shows all symbols illuminated on the LCD screen with an overview of what each section of the LCD represents. Refer to the

table below for details about each section and associated symbols.

Information

Module Status

This part of the LCD shows the overall system status.

complete, “System” remains illuminated and one of these symbols will appear:

or

indicates the system is ok.

indicates there is a problem with the system; check the Device Information panel on your station page in HOBOlink.

Module Status

This indicates the station is connected via a USB cable.

This indicates the station is using Ethernet to connect to HOBOlink. This will blink while connecting to HOBOlink.

This indicates the station is using a cellular network to connect to HOBOlink. This also shows the strength of the cellular

signal; the more bars there are, the stronger the signal. This will blink while connecting to HOBOlink.

When the station is attempting to connect or is currently connected to HOBOlink, “Connection” flashes on the LCD. After

the connection is complete, “Last Connection” remains illuminated and one of these symbols will appear:

or

indicates the last connection to HOBOlink was ok.

left slot and Module 2 in the right slot.

indicates the smart sensor or module is ok.

indicates there is a problem with the smart sensor or module; check your device page in HOBOlink.

indicates a sensor alarm has tripped and will flash on the LCD until the alarm is cleared; check the Alarms log in

HOBOlink.

This part of the LCD indicates whether the station is currently logging.

“Stopped” indicates the station is not currently logging while “Logging” indicates it is currently logging. Press the

Start/Stop button to start or stop logging as desired. Note that “Logging” will blink until the first data point is logged after

or

the Start button is pressed.

or

lightning bolt will appear when an AC adapter, solar panel, or external power source is plugged into the station. “Charging”

will flash while the battery is being charged.

stopped. This continuous logging is represented by the arrow in this symbol.

1-508-759-9500 (U.S. and International) 7 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

Page 8

HOBO RX3000 Remote Monitoring Station Manual

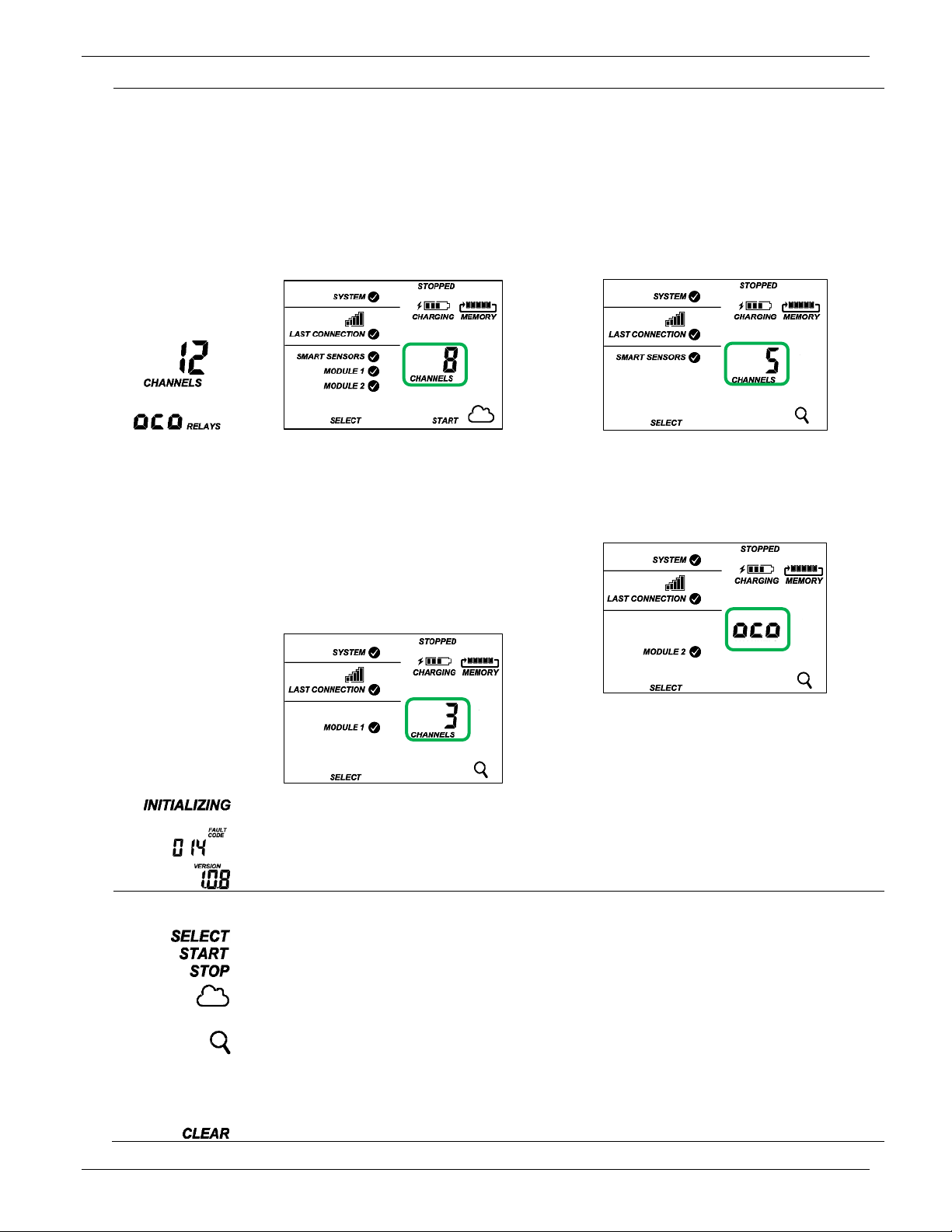

Channel and

This part of the LCD shows the number of channels and other information about each module. It also shows general device

This is a numerical code that appears when a system fault has occurred. You may need to provide this code to Onset

This is the version number of the station firmware. It only appears when powering up the device.

Button Symbols

Press this button to cycle through status information about the smart sensors and two optional modules.

Press this button to start logging. This option is not available while the station is actively connected to HOBOlink.

Press this button to connect to HOBOlink. This option is only available on the main LCD screen. It is not available when

a connection is underway or active.

Use this button to clear a fault code.

Device

Information

or

information. Press the Select button to scroll through four screens: the main screen, smart sensors screen, Module 1, and

Module 2 screens.

Main Screen

When viewing the main LCD screen, the total number of

channels in use by the system is displayed. This is a

combination of smart sensor channels and enabled

sensor channels. For example, if there are 5 smart sensor

channels and 3 analog sensor channels, then 8 channels

are shown on the main screen, as in the following

example.

Smart Sensors Screen

When viewing the smart sensors screen, the number of smart

sensor channels is displayed. Note that some smart sensors

have more than one channel associated with them so the

number of channels may not match the number of physical

smart sensors. In this example, there are 5 smart sensor

channels.

Module 1 and 2

When viewing the Module 1 or Module 2 screen,

information about that particular module is displayed. If

an analog sensor module is installed, the number of

enabled analog sensors is displayed in the channels count

(three sensors in this example). If an RXW Manager

module is installed, the channel count represents all

measurement channels plus a battery channel for each

mote in the HOBOnet RX Wireless Sensor Network. For

example, one temp/RH wireless sensor has a channel

count of three as shown below: two for temperature and

RH and one for the mote battery.

When a relay module is installed, the state of each relay is

shown on the module screen. In this example, a relay module

is installed in the Module 2 slot so this shows whether each

relay is open “o” or closed “c”. In this example, the first and

third relays are open, and the second one is closed.

If a water level sensor module is installed, the channel count is

listed as 4. This represents barometric pressure, water

pressure, differential pressure, and water temperature. Water

level and water flow channels are derived in HOBOlink and not

included in the channel count shown on the station LCD.

This will blink in the lower right part of the LCD when a firmware update is underway. It will display which module or

element is being updated.

Technical Support. See Troubleshooting for details.

Use the three buttons below the following symbols to operate the station. Press any of the three buttons to turn on the

LCD.

Press this button to stop logging. This option is not available while the station is actively connected to HOBOlink.

scrolling through smart sensor and module information with the Select button. In addition, this option is not available while

Press this Search button for the station to detect all currently installed smart sensors or to add motes to your HOBOnet RX

Wireless Sensor Network. As you add or remove smart sensors while the station is stopped, press the Select button and

then the Search button for the system to recognize your changes. This option is not available for smart sensors while the

station is logging. To add motes to the HOBOnet RX Wireless Sensor Network, press the Select button to switch to the

module for the RXW Manager and then press the Search button for the station to find the motes. The station can search for

motes whether it is logging or stopped.

1-508-759-9500 (U.S. and International) 8 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

Page 9

HOBO RX3000 Remote Monitoring Station Manual

Connect the battery cable here

Plug in an AC adapter

or solar panel here

Insert the connectors

Tighten the screw on installed modules

Notes on LCD Operation:

• The LCD will turn off after 5 minutes of inactivity. Press

any button to turn the LCD back on.

• There can be a delay before the LCD updates. For

example, if you plug in an AC adapter, it may take a few

seconds before the lightning bolt icon appears on the

LCD. This delay is by design to preserve battery life.

Setting up the Station

Follow these steps to set up the station.

1. Log in to HOBOlink.

Go to www.hobolink.com and log in to an existing account

or create a new one. You’ll receive an email to activate the

new account.

2. Register the station.

In HOBOlink, click Devices, RX Devices, and then the

Register a Device link. Give the station a name and enter

the serial number and device key from the label inside the

station door.

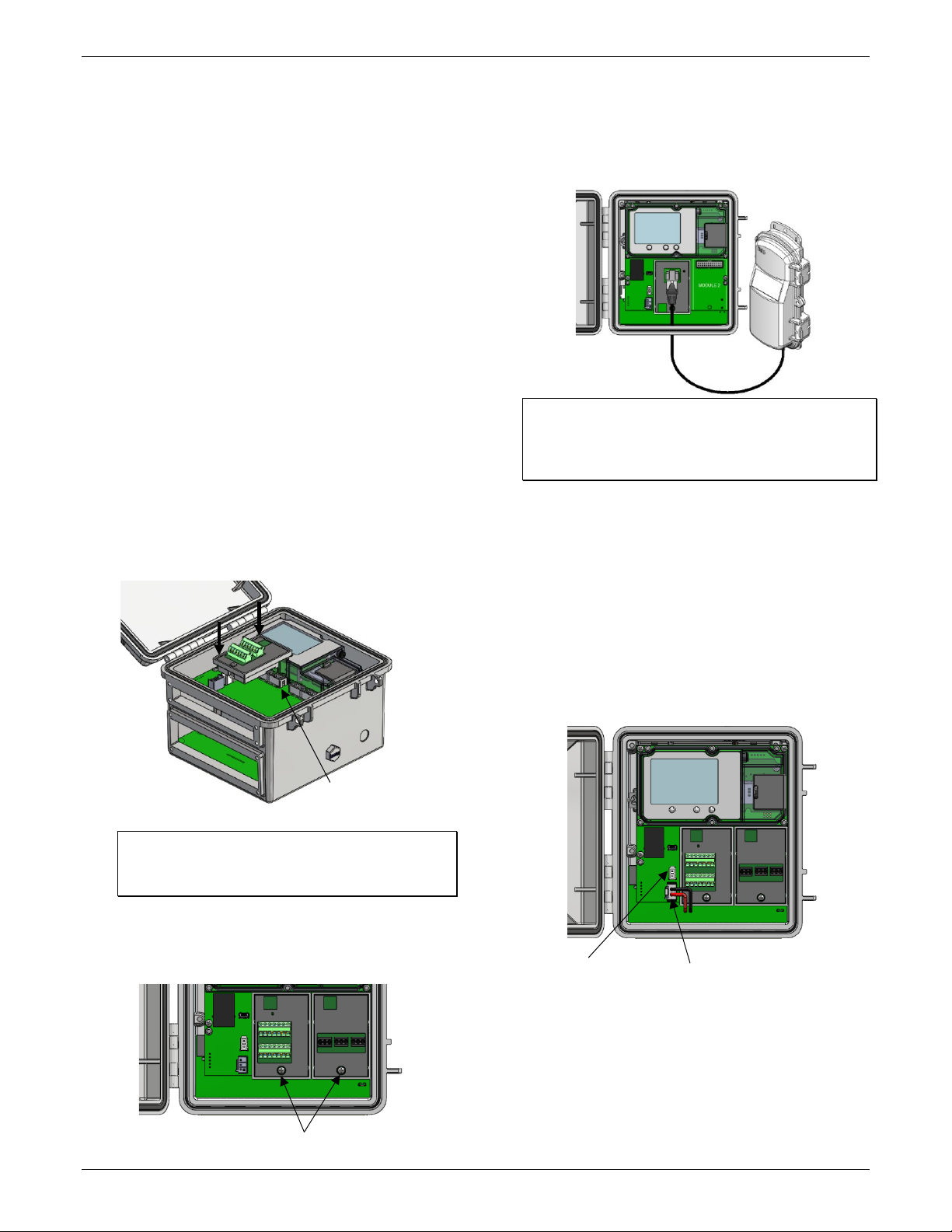

3. Install optional modules or user-supplied SIM.

a. Make sure the station is powered down (unplug any

charging device and then disconnect the battery).

b. Insert the connector on the back of the module into the

receptacle in the left or right module slot. Add a second

module to the other slot if desired.

If you installed an RXW Manager module:

Plug the cable from the RXW Manager mote into the jack on

the module, making sure the cable is inserted through the

bottom of the station case. Do not reconnect the power on

the station until the mote is plugged in as shown.

WARNING: If you inadvertently install modules while the

power is on, you must disconnect and then reconnect the

battery and charging device to guarantee proper

operation.

If you are installing your own SIM:

Before continuing, follow the instructions at

https://www.onsetcomp.com/support/ manuals/installingsim-rx3000-station.

4. Plug in the battery and charging device.

a. Plug in the battery cable.

b. Feed the AC adapter or solar panel cable through the

smaller of the two cable openings and plug it in. You can

also use an optional external DC power cable (CABLERX-PWR) with your own powering device in place of the

AC adapter or solar panel.

Tip: Install the analog module, water level sensor, or

RXW Manager module on the left and the relay module

on the right for easier cable routing.

3. Using a Phillips-head screwdriver, tighten the screw at

the bottom of each module. In this example, an analog

module is installed in the Module 1 slot and a relay

module is installed in the Module 2 slot.

1-508-759-9500 (U.S. and International) 9 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

on the module here

Page 10

HOBO RX3000 Remote Monitoring Station Manual

“Initializing

A checkmark

Plug in an Ethernet cable here

A checkmark

c. Once the battery cable is plugged in, “Initializing

System” will flash on the LCD. A checkmark appears next

to “System” after the station initialization is complete.

System”

flashes when

the battery

cable is first

plugged in

5. Check and configure device communications.

For RX3003 and RX3004 cellular models:

After the station powers up in the previous step, it will

connect to HOBOlink automatically within two minutes. The

cellular icon and “Connection” will flash while the

connection is underway. Once the connection is complete, a

checkmark appears next to Last Connection. Note that the

entire initialization process may take several minutes; wait

until Last Connection and the checkmark appears before

continuing to step 6.

appears next to

Last Connection

after connecting

to HOBOlink

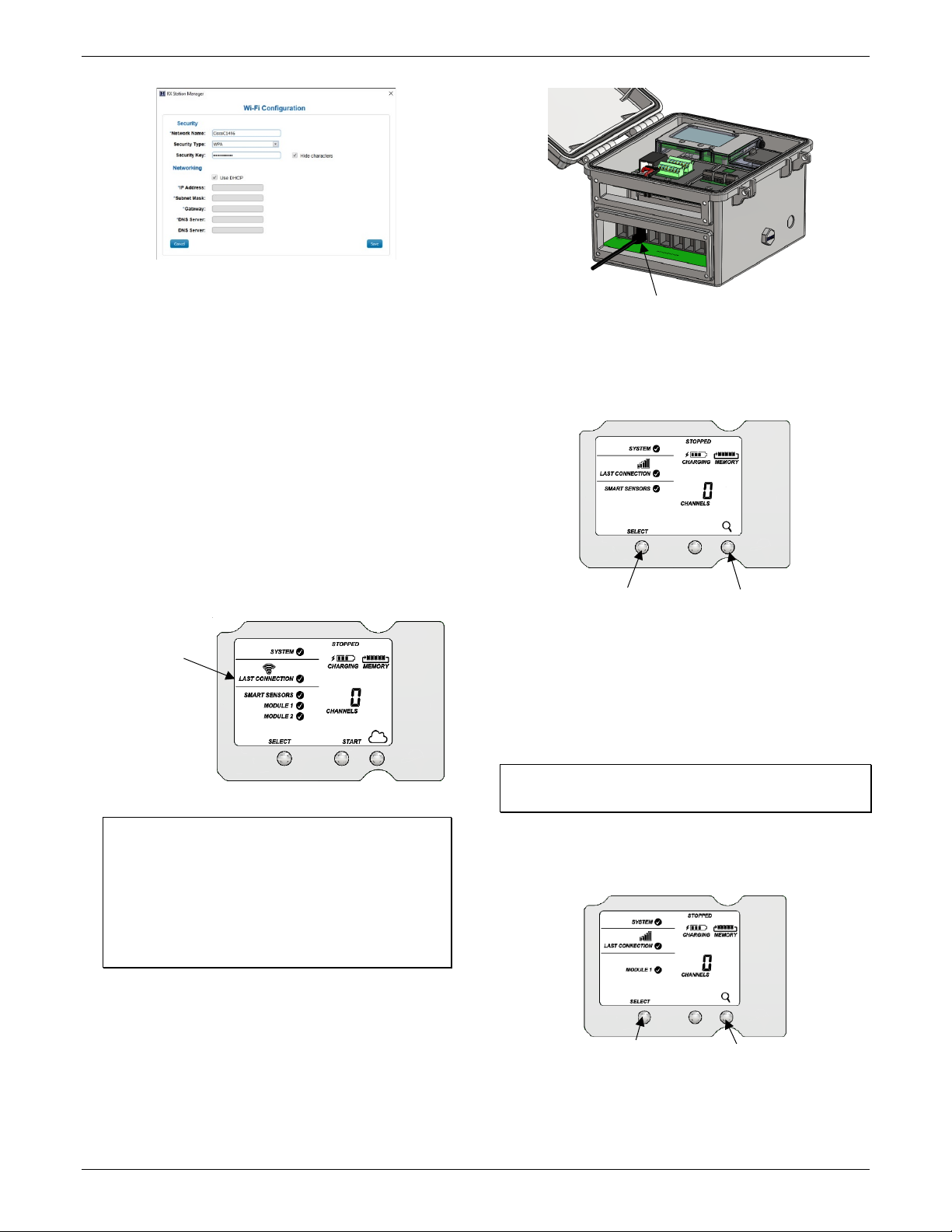

For RX3001 Ethernet models:

a. Plug in an Ethernet cable.

b. The station uses DHCP by default. If your network uses

DHCP, skip to step i.

If your network uses static IP addresses, connect the

station to the computer with the USB cable. (Consult

your Network Administrator if you are unsure whether

your network uses static IP addresses or for help with

the following steps).

c. In HOBOware, select Manage RX Station from the

Device menu. (On a computer with Microsoft®

Windows®, you may see a warning that Windows

Firewall has blocked some features. Select Domain

networks and click Allow Access.)

d. In the RX Station Manager, click the Actions button and

select Network Access.

e. Deselect the Use DHCP checkbox.

f. Enter the IP Address, Subnet Mask, Gateway, and DNS

Server. Consult your Network Administrator for the

appropriate addresses to complete these fields.

g. Click Save in the RX Station Manager. Click Done and

then close the RX Station Manager.

h. Disconnect the USB cable.

i. Press the Connect button on the station (the cloud

should be visible on the LCD screen) to connect to

HOBOlink. The Ethernet icon and “Connection” will flash

while the connection is underway. Once the connection is

complete, a checkmark appears next to Last Connection.

Wait for the checkmark and then continue to step 6.

appears next to

Last Connection

after connecting

to HOBOlink

For RX3002 Wi-Fi models:

a. Connect the station to the computer with the USB

cable.

b. In HOBOware, select Manage RX Station from the

Device menu. (On a computer with Microsoft®

Windows®, you may see a warning that Windows

Firewall has blocked some features. Select Domain

networks and click Allow Access.)

c. In the RX Station Manager, click the Actions button and

select Network Access.

d. Enter the Security information for your Wi-Fi network.

Type the Network Name, select the Security Type, and

type the Security Key. Select the Hide characters

checkbox to hide any characters typed into the Security

Key field. Consult your Network Administrator or

wireless router documentation for help with

determining your network security type.

1-508-759-9500 (U.S. and International) 10 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

Page 11

HOBO RX3000 Remote Monitoring Station Manual

Press the Select button to view

Press the Search button for the station

Plug in smart sensors here

A checkmark

Press the Search button for the

Press the Select button to switch to the

e. The station uses DHCP by default. If your network uses

DHCP, skip this step.

If your network uses static IP addresses, deselect the

Use DHCP checkbox. Enter the IP Address, Subnet Mask,

Gateway, and DNS Server. Consult your Network

Administrator if you are unsure whether your network

uses static IP addresses or for the appropriate addresses

to enter in this fields.

b. Press the Select button to view the smart sensors on the

LCD and then press the Search button (the magnifying

glass icon should be visible as in the following example).

The station will search for all connected smart sensors

and show the number of channels after a few seconds.

f. Click Save in the RX Station Manager. Click Done and

then close the RX Station Manager.

g. Disconnect the USB cable.

h. Press the Connect button on the station (the cloud

should be visible on the LCD screen) to connect to

HOBOlink. The Wi-Fi icon and “Connection” will flash

while the connection is underway. Once the connection

is complete, a checkmark appears next to Last

Connection. Wait for the checkmark and then continue

to step 6.

the smart sensor screen

to find all connected smart sensors

appears next to

Last Connection

after connecting

to HOBOlink

6. Plug in and search for any smart sensors.

Important: If this RX3000 station is a replacement for an

existing U30 station, it is imperative that you power down

the U30 station being replaced (disconnect the battery

and AC adapter or solar panel) before you remove the

smart sensors and connect them to the RX3000. Do not

repower the U30 station or allow it to connect to

HOBOlink again unless at least one different smart sensor

is connected to the U30 station first.

a. Feed the smart sensor cable for one smart sensor

through the larger of the two cable openings and plug it

into one of the 10 smart sensor connectors. Repeat for

any additional smart sensors.

Note that some smart sensors have more than one

channel associated with them so the number of

channels may not match the physical number of smart

sensors connected (for example the temperature/RH

smart sensor has two channels: one for temperature

and one for RH).

7. Add any wireless sensor motes.

Important: Keep the mote(s) near the RX3000 station while

completing these steps.

a. Press select to switch to the module where the RXW

Manager is installed (Module 1 or Module 2) and then

press the Search button to wait for motes to join the

network.

module with RXW Manager installed

station to search for motes to join

1-508-759-9500 (U.S. and International) 11 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

Page 12

HOBO RX3000 Remote Monitoring Station Manual

J1

J2

This signal strength icon

a network.

Once a network is found,

left to right.

c.

d.

This network connection “x”

to five minutes.

Once the mote has finished

a.

b.

Press this button for 3 seconds

Feed analog sensor,

b. Install the rechargeable batteries in the mote and press

the button on the mote for 3 seconds.

c. Watch the mote LCD during the process of joining the

network.

blinks while searching for

icon blinks while the mote

completes the registration

process, which may take up

the icon will stop flashing

and the bars will cycle from

joining the network, the “x”

icon is removed and the

channel count on the station

LCD increases by the number

of measurement channels

for the mote plus the

Note: If the mote cannot find the network or has

trouble remaining connected during this process, make

sure the mote is in a vertical, upright position and

within range of the station.

Repeat these steps to add other motes. Press the

Search button on the station when finished adding

motes.

Important: If you will be installing the weatherproof rubber

cable channel in the cable access opening as described in

Deploying and Mounting the Station, the cable diameter for

analog sensors or relay devices must be 4.0 mm (0.156 in.) to

fit through one of the smaller holes or 6.4 mm (0.25 in.) to fit

through one of the larger holes. If the cable diameter is too

small, build up the diameter using heat shrink. If the cable is

too big, splice on another cable with a smaller diameter to fit

through the hole. If you are using the rubber cable channel

designed for the water level sensor, reserve the medium

holes for the water level sensor cable.

To connect analog sensors:

You can connect a two- or three-wire sensor or transducer

to one of the four terminals in the analog module.

a. Loosen the screw for each pin on the screw terminal.

b. Feed the wire through the smaller of the two cable

access openings.

c. Insert the appropriate wire into the screw terminal (see

the pinout table below). The wire should be trimmed to

expose 0.25 inches ±0.04 inches of bare wire.

d. Tighten the screw.

e. Plug in the battery and then the charging device to

power up the station.

Analog Module Pinout Table

Pin # Pin Description

1 CH1 SIGNAL 1 CH3 SIGNAL

2 CH1 GND 2 CH3 GND

3 +12V Excitation 3 +12V Excitation

4 GND (EX. RTN) 4 GND (EX. RTN)

5 CH2 SIGNAL 5 CH4 SIGNAL

6 CH2 GND 6 CH4 GND

7 SHIELD 7 SHIELD

Pin # Pin Description

8. Connect analog sensors, relay devices, or water level sensors.

Note: You may wait to connect these until you are at the

deployment site.

Power down the station (unplug any charging device and

then disconnect the battery). Connect any sensors or

devices to the optional modules as described in the

following sections. Be sure to feed any cables or wires

through the smaller cable access opening shown below.

1-508-759-9500 (U.S. and International) 12 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

relay, and water level

sensor cables through

this opening to

connect them to the

optional modules

Note: All four input channels share the same common ground.

Analog Module Functional Diagram

To connect relay devices:

You can connect up to three devices to the relay module.

The relays are only for low power switching. To switch to

higher power, use an appropriately rated relay and use the

station relay to switch the external relay on or off.

a. Loosen the screw for each pin on the screw terminal.

Page 13

HOBO RX3000 Remote Monitoring Station Manual

Pin Desc.

Pin Desc.

Pin Desc.

Press the Connect button

Press the Select button to

Insert this

Use one of these two medium holes

for the water level sensor cable

b. Feed the wire through the smaller of the two cable

access openings.

c. Insert the appropriate wire into the screw terminal (pins

1 and 2 are interchangeable, pin 3 is optional; see the

pinout table).

d. Tighten the screw.

e. Plug in the battery and then the charging device to

power up the station.

Relay Module Pinout Table

RELAY-1

1 Relay 1 Relay 1 Relay

2 Relay 2 Relay 2 Relay

3 Shield 3 Shield 3 Shield

RELAY-2

RELAY-3

To install a water level sensor:

a. Feed the water level sensor cable through the smaller of

the two cable access openings.

b. Insert the connector at the end of the cable into the

receptacle on the module as shown below. The

connector will snap into place once installed. Be careful

not to push, pull, or twist the cable while installing the

connector.

iv. Close the cable channel and press it into the opening.

v. Install the cover plate with loosely installed

thumbscrews.

vi. Lightly coat rubber plugs with a small amount of

grease and use them to fill the empty holes. Use one

of the rubber plugs included with the water level

sensor module to fill the empty medium hole. Use the

rubber plugs from the channel kit included with the

station to fill any remaining large and small holes.

Insert the thin part of the plug into the hole and push

it in until the thick part fills the hole.

vii. Tighten the thumbscrews on the cover plate.

viii. Repeat these steps with the large cable channel. See

Installing the Weatherproof Rubber Cable Channel

and Covers for additional details.

e. Insert the water level sensor cable jack into the water

level sensor. Screw on the locking nut (hand tight).

connector onto

the receptacle

on the module

c. Install any other sensors and cables that will be using the

top cable access opening.

d. Install the top rubber cable channel into the cable access

opening.

i. Use silicone grease to lightly coat all four outer edges

and the inside of the rubber cable channel shipped

with the water level sensor module (do not use the

small rubber cable channel shipped with the RX3000

station).

ii. Use the grease to lightly coat the portion of the water

level sensor cable that will be in the cable channel.

Repeat for all other cables.

iii. Position the cable channel around the cables, routing

the cables through the proper grooves. Use one of

the medium-sized holes shown below for the water

level sensor cable.

Important: Make sure the O-rings on the cable jack end

and the sensor mating housing surfaces are clear of any

debris. Any contamination of these surfaces can cause

leaks that may lead to sensor failure.

f. Plug in the battery and then the charging device to power

up the station.

9. Connect to HOBOlink.

Use the Select button to return to the main LCD screen that

shows all sensors and modules and then press the Connect

button (the cloud icon should be visible as shown in the

following example). This is necessary for HOBOlink to

identify the newly added sensors (it does not start logging;

this will be done later in this procedure). Note that analog

sensors will not be listed in the channels count on the LCD

until they are configured in HOBOlink in the next step.

1-508-759-9500 (U.S. and International) 13 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

return to the main LCD screen

Page 14

HOBO RX3000 Remote Monitoring Station Manual

Or, you can choose a specific item

Use the Next button to save changes and

10. Configure the station in HOBOlink.

Select Devices, RX Devices, and then click the icon next

to your station. Use the configuration screens in HOBOlink

to finish setting up the station, starting with General

Configuration (the nickname, time zone, and image for the

station). Use the Next button to move from one

configuration screen to the next or use the left menu to

select a specific item to configure. Follow the steps in the

next subsections to configure the readout settings, smart

sensors, wireless sensors, and optional modules. Any

changes you make will take effect the next time the station

connects to HOBOlink. Note: Click Save or Next in any

screen to save your changes. You will lose any changes

made if you click Back without clicking Next or Save first.

move through each configuration screen

Smart Sensors Logging and Configuration

You can configure both the global settings that affect all smart

sensors (logging interval and sampling interval) and the settings

for each smart sensor (labels, graphs, and scaling).

a. Click Smart Sensors Logging from the menu on the left.

b. Select the logging interval. This will be used by all

configured smart sensors.

c. Enable the sampling interval and enter the rate to use in

minutes and seconds.

Tip: When a sampling interval is configured, the station

will take multiple measurements within a given logging

interval and then average them together to create a

single logged data point. This is only an option for the

following smart sensors that support measurement

averaging: temperature (S-TMB-M0xx), PAR (S-LIAM003), solar radiation (S-LIB-M003), barometric

pressure (S-BPA-CM10 and S-BPB-CM50), 4-20mA input

(S-CIA-CM14), 12-bit voltage input (S-VIA-CM14), and

FlexSmart TRMS module (S-FS-TRMSA-D). Disable the

sampling interval if none of your smart sensors support

measurement averaging to avoid unnecessary drain on

the battery power.

d. Click Save or click Next.

to configure from this menu

Readout Configuration

a. Set the connection interval, which is how often the

station will connect to HOBOlink. For the RX3003 and

R3004 cellular models, the minimum connection

interval depends on your communication plan.

b. If you wish to set up a second connection interval, select

the “Night mode” checkbox. Select when night mode

should begin and end and then enter the connection

interval you want to use during that part of the day.

(The night mode schedule can take effect any time

during the day; it does not have to be at night.) Use this

option to save data in your communications plan (if

applicable) or to conserve battery power at night when

solar charging is unavailable. You can view current plan

usage in the Device Information section on your

station’s page in HOBOlink.

c. Click Save or click Next.

e. Click a smart sensor from the menu.

f. Type a label for the smart sensor (optional) and click to

enable or disable the graph (enabled by default).

g. To set up scaling for the smart sensor, click the Enable

Scaling checkbox and fill in the Scaled Units, Multiplier,

Offset, and Scaled Measurement Type fields.

h. Click Save. You can also click Next to move from one

smart sensor to the next.

1-508-759-9500 (U.S. and International) 14 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

i. Repeat steps e–h for any additional smart sensors you

need to configure.

Water Level Sensor Module Configuration

You can configure both the global settings that affect all

water level sensor channels (logging interval and sampling

Page 15

HOBO RX3000 Remote Monitoring Station Manual

interval) and the settings for each individual channel. The

water level sensor includes the following four channels that

automatically record data at each logging interval:

barometric pressure, water pressure, differential pressure,

and water temperature. You can also configure water level

and water flow channels that calculate data based on the

logged data from the four sensor channels and the values

you enter in HOBOlink.

a. Click Water Level Sensors Logging from the

Configuration menu.

b. Select the logging interval. This will be used by all

channels associated with this sensor.

c. Enable the sampling interval (if desired) and enter the

rate to use in minutes and seconds.

d. Click Save or Next.

To add labels or scaling:

a. Click Barometric Pressure from the Configuration menu.

b. Type a label for the channel (optional) and click to enable

or disable the graph (enabled by default).

c. To set up scaling for the channel, click the Enable Scaling

checkbox and fill in the Scaled Units, Multiplier, Offset,

and Scaled Measurement Type fields.

d. Click Save. Repeat steps a–d for Water Pressure, Diff

Pressure, and Water Temperature.

Wireless Sensor Configuration

You can configure both the global settings for the RXW

Manager module that affect all sensor motes (logging

interval) and the settings for each individual mote (labels,

enabled graphs, and scaling).

a. Click Module <#>: Wireless Sensors Logging from the

menu on the left.

b. Select the logging interval to be used for all wireless

sensors, which can be different than the one used for

smart sensors and analog sensors (if applicable).

c. Click Save or Next.

d. Click one of the motes from the menu under Module <#>:

Wireless Sensors Logging as shown in the following

example. Click the serial number or name for the mote,

not the measurement type.

e. Type a label for the mote (optional) and click to enable

the battery graph for the mote if desired. The label will

also automatically be applied to any mote sensors

without a default label.

f. Click Save or click to Next to move to either the next

mote (if it was a repeater) or the sensor measurement

type for that mote.

Important: Do not configure the water level and water flow

channels yet. Configure any other sensors or relays as

necessary, continue to step 11 to start logging, and then

obtain a water reference level reading in step 12.

1-508-759-9500 (U.S. and International) 15 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

Page 16

HOBO RX3000 Remote Monitoring Station Manual

g. Click one of the mote measurement types from menu

under Module <#>: Wireless Sensors Logging as shown

in the following example

h. Type a label for the measurement type (optional) and

click to enable or disable the graph (enabled by default).

i. To set up scaling for the wireless sensor, click the Enable

Scaling checkbox and fill in the Scaled Units, Multiplier,

Offset, and Scaled Measurement Type.

j. Click Save or click Next.

k. Repeat steps d–j for any additional motes you need to

configure for the module.

Analog Module and Sensor Configuration

You can configure both the global settings for the analog

module that affect all connected analog sensors (logging

interval, statistics, and excitation) and the settings for each

individual analog sensor (enabled logging and graphs,

labels, sensor type, and scaling).

a. Click Module <#>: Analog Sensors Logging from the

menu on the left.

b. Select the logging interval to be used for all analog

sensors, which can be different than the one used for

smart sensors and wireless sensors (if applicable).

d. Enable “Use excitation power” if you want sensors to

use the 12 V DC excitation voltage provided by the

station. Select warmup and enter the seconds or

milliseconds (5 milliseconds to 120 seconds), or select

continuous. Note that the excitation power selected will

be used for all of the module’s configured sensors.

• With warmup, the station supplies excitation power,

12 V DC, for a brief period prior to each

measurement. This allows you to select the minimum

warm-up time needed to allow for sensor

stabilization while conserving battery power. For

example, if you specify a warm-up of one second and

set the logging interval for the module to one minute,

the station will power the external sensor for one

second, log a measurement, and then turn off the

excitation power for the next 59 seconds. Note that

the excitation mode is automatically set to

Continuous if the warmup time selected is within one

second of or greater than the logging or sampling

intervals.

• With continuous, the station supplies constant

excitation power to the sensor for the entire duration

of the deployment. Continuous mode is required if the

sensor needs more than two minutes of warm-up time.

Important: Continuous mode operation will greatly affect

battery operating life and is not recommended.

Note that excitation power will not be enabled until

logging begins (if “Logging” is blinking on the LCD, then

excitation is not being used).

e. Click Save. You can also click Next to move from one

analog channel to the next.

f. Click one of the four analog sensor channels from the

menu, such as Channel 1 shown in this example.

g. Select “Enable Graph” if you want the sensor data to be

graphed in HOBOlink.

h. Select “Enable this channel” if you want the station to

c. Click the Enable checkbox under Sampling Interval if you

want to log statistics. Enter the sampling interval to be

used for calculating the statistics (must be a factor of

the logging interval). Select the statistics to be logged:

minimum, maximum, average, and standard deviation.

The selected statistics will be calculated between each

logging interval at the sampling interval rate you select.

Each statistical value will then be logged at each logging

interval.

1-508-759-9500 (U.S. and International) 16 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

record data for this channel. If the channel is not

enabled, then it will not be part of the channel count

shown on the LCD.

i. Type a label for the sensor (optional).

j. Select the sensor/input type, which is needed to set the

voltage or current range for the analog input.

k. Click the Enable Scaling checkbox and then enter the raw

and scaled unit values as defined in the sensor manual.

Type the scaled measurement type.

Page 17

HOBO RX3000 Remote Monitoring Station Manual

Press this button to start logging

“Logging”

begins

Channel count

l. Click Save. You can also click Next to move from one

channel to the next.

m. Repeat steps f–l for any additional analog sensors you

need to configure for the module.

Relay Module Configuration

a. Click one of the three relays from the menu on the left,

such as Relay 1 in the following example.

b. Type a label and select Open or Closed for the Normal

Relay State. The label can be used to show what Open

or Closed corresponds to in your system (for example,

“closed relay turns pump on”).

c. Select what should happen on the next connection with

the station: open relay, close relay, or leave it at its

current state.

d. Click Save or click Next.

e. Repeat steps a–d for any additional relays you wish to

configure.

Tip: Refer to Setting System and Sensor Alarms for details on

using sensor alarms to activate the relays.

11. Start logging.

After you have finished configuring all the settings in

HOBOlink, you can start logging when ready. Press the Start

button on the station to start logging. The station will

connect to HOBOlink (“Connection” will blink on the LCD)

and then logging will begin at the logging interval specified

for smart sensors and analog sensors (if applicable).

Once logging begins, “Logging” appears in the upper right

corner of the LCD as shown in the following example.

“Logging” will blink until the first logging sample is

recorded. At that point, it will stop blinking and remain

illuminated until logging is stopped. Also note that the

channels count on the LCD screen will be updated to

include any analog sensors that were enabled in HOBOlink.

appears

when logging

updated for any

enabled analog

sensors

Important: See Deploying and Mounting the Station for

installation steps and other deployment guidelines. If using

the station outdoors or in harsh indoor conditions, you

must install the sensor cable channels and the plates for

weatherproofing. This must be completed before

continuing to step 12 if you are using a water level sensor.

12. If you installed a water level sensor module and sensor, obtain a reference water level reading.

Make sure the water level sensor is deployed in its final

location and the station is logging. Take a reference level

reading, measuring the water level from your reference

point.

Important: Note the reference level reading as well as the

date and time it was taken.

13. If you installed a water level sensor module and

sensor, configure the water level and water flow

channels in HOBOlink.

Perform the following steps in the field in HOBOlink with a

mobile device to verify that the system is logging the

water level correctly while you are still at the station site.

Water Level Configuration

a. In HOBOlink, select Devices and then RX Devices and

click the icon next to your station.

b. Under the water level sensors module in the

Configuration menu, select Water Level.

You can also start logging from HOBOlink. Select Start/Stop

from the Configure menu in HOBOlink and click Start.

Logging will not begin until the next time the station

connects to HOBOlink. Press the Connect button on the

station to connect to HOBOlink at any time.

1-508-759-9500 (U.S. and International) 17 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

Page 18

HOBO RX3000 Remote Monitoring Station Manual

next scheduled connection, press the Cloud button on the

station LCD to connect to HOBOlink immediately. Note that the

reference water level information entered in this step will not

affect data already stored in HOBOlink.

Viewing Data in HOBOlink

Data is uploaded to HOBOlink each time the device connects.

For a snapshot of the latest conditions, click Devices, then RX

Devices, and click the device name to view the readings from

the last connection for smart sensors and logged analog

sensors. You can also view any enabled graphs as shown in the

following example.

c. Click the checkbox to Enable Channel.

d. Click the checkbox to Enable Graph and type a label

(optional).

e. Enter the reference water level and date and time

noted in step 12.

• If the water level surface is below the reference

point, enter the reference water level as a negative

number.

• If the water level surface is above the reference

point, enter the reference water level as a positive

number.

See Setting Up Water Level and Water Flow Channels

in HOBOlink for example diagrams showing reference

points.

f. Select the appropriate water density.

g. Click Save.

Water Flow Configuration

a. Select Water Flow from the Configuration menu.

b. Click the checkbox to Enable Channel.

c. Click the checkbox to Enable Graph and type a label

(optional).

d. Choose the measurement method for water flow.

e. Enter the appropriate information for the method

selected. See Setting Up Water Level and Water Flow

Channels in HOBOlink for more details on water flow

measurement methods.

f. Click Save.

Water level and flow data will be calculated starting with the

next connection to HOBOlink. If you don’t want to wait for the

Logged data is saved in a database. You can export this data on

demand as needed or set up automatic exports that are

delivered to email and/or FTP addresses on a schedule you

specify.

To download and export data:

1. In HOBOlink, click Data and Exports.

2. Click Create New Export.

3. Follow the instructions on the screen to select the name,

format, time zone, and time frame, and then the devices

and sensors to include in the export. Reorder the sensors as

needed.

4. Click Save to keep these settings for future use or click

Export Data to export immediately.

To set up a scheduled data delivery:

1. Click Data and then click Data Delivery).

2. Click Create New Delivery.

3. Under General Settings, type the name of the delivery

schedule and the frequency of delivery. Enable the Active

checkbox. Select other settings if desired.

4. Under Select Data to Export, choose the name of the

custom data export you want to be delivered (or follow the

previous set of steps to set up a custom data export).

5. Under Data Destination, select FTP/SFTP or Email for the

delivery method and fill in the appropriate fields.

6. Click Save. Data will then be delivered on the schedule you

selected.

For more information on Data Delivery, see the HOBOlink Help.

See also HOBOlink Help for other ways to monitor your station,

including setting up a map or using dashboards.

1-508-759-9500 (U.S. and International) 18 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

Page 19

HOBO RX3000 Remote Monitoring Station Manual

Tripped smart

Setting System and Sensor Alarms

You can set up both system and sensor alarms in HOBOlink.

System alarms can trip when there is a missed connection, the

battery is low, or if there is a smart sensor failure. With a

sensor alarm, you can configure an alarm to trip at one level

and clear at another.

System Alarms

To add a system alarm:

1. In HOBOlink, click Devices, then RX Devices, and find the

station you want to configure. Click the arrow next to

and select Alarm Configuration.

2. Click Edit System Alarms.

3. For Missed Connection alarms:

a. Under Communication, select the Missed Connection

checkbox.

b. Set the length of time for HOBOlink to wait after the

station has missed a connection before an alarm trips.

c. Select the action to be taken when this alarm trips: send

an email or text. Enter the details and then select “Send

on Clear Also” if you want an email or text when the

alarm clears as well.

Important: Standard data fees and text messaging rates

may apply when using text notifications. Onset does not

charge a fee or guarantee delivery of text alerts, which is

subject to your carrier’s service and location. See the

HOBOlink Help for additional details on alarm

notifications.

d. Click Add Action if you want multiple actions to be taken

when the alarm trips (for example send an email and a

text).

4. For Battery Low and Sensor Failure alarms:

a. Under Device, select the Battery Low and/or Sensor

Failure checkboxes.

b. Select how you want to be notified when these alarms

trip: by email or text. Enter the appropriate addresses

and then select “Send on Clear Also” if you want an

email or text when these alarms clear as well.

5. Click Add Action if you want multiple actions to be taken

when the alarm trips (for example send an email and a

text).

6. Click Save. Changes will take effect the next time the station

connects to HOBOlink.

Red alarm symbols will appear in HOBOlink when these alarms

trip (if enabled).

Note for wireless sensors: If a wireless sensor mote goes

offline from the network for 30 minutes, the station will

automatically connect to HOBOlink to report the missing mote

regardless of any alarm settings in place. Unless the mote has

no battery power, it will continue logging data even if it is

offline from the network. Once the mote is back online, any

logged data will be uploaded during regular connections to

HOBOlink. Note: Once a mote is back online, it enters recovery

mode as HOBOlink receives the data logged while it was offline.

During this period of recovery, data for that mote will

temporarily be unavailable for data delivery, dashboards, and

data feeds. See the HOBOlink help for additional details.

Sensor Alarms

To add a sensor alarm:

1. In HOBOlink, click Devices, then RX Devices, and find the

station you want to configure. Click the arrow next to

and select Alarm Configuration.

2. Click Add a Sensor Alarm.

3. Select the sensor.

4. Select whether the alarm should trip above or below a

value or within a range.

5. Enter the sensor reading(s) for the alarm threshold.

6. Enter the number of logged data points you want the

station to record before the alarm trips.

7. If you selected the alarm to trip above or below a specific

reading, then select when the alarm should clear: above or

below the same value or a different value. Enter the value if

necessary.

8. Select the action to be taken when the alarm trips: send an

email or text or close, open, or pulse one of the three relays

if a relay module is installed. For email or text, enter the

details and then select “Send on Clear Also” if you want an

email or text when the alarm clears as well.

Important: Standard data fees and text messaging rates

may apply when using text notifications. Onset does not

charge a fee or guarantee delivery of text alerts, which is

subject to your carrier’s service and location. See the

HOBOlink Help for additional details on alarm

notifications.

9. Click Add Action if you want multiple actions to be taken

when the alarm trips (for example, close the relay and send

an email).

10. Add any optional notes for this alarm.

11. Click Save. Changes will take effect the next time the station

connects to HOBOlink.

12. Repeat steps 2 through 11 for each additional sensor alarm

you want to add.

A red alarm symbol appears next to that sensor in HOBOlink

when it trips. An alarm symbol will also appear on the LCD.

sensor alarm

and analog

sensor alarm

1-508-759-9500 (U.S. and International) 19 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

Page 20

HOBO RX3000 Remote Monitoring Station Manual

Setting up Water Level and Water Flow Channels in HOBOlink

If both a water level sensor module (RXMOD-W1) and water

level sensor are installed, the station will automatically log four

measurement channels:

• Barometric pressure

• Water pressure

• Differential pressure

• Water temperature

In addition, you can set up two additional channels in

HOBOlink:

• Water level

• Water flow

These derived channels are only available once enabled in

HOBOlink. The data for these two channels are calculated at

each logging interval based on the measurements from the

pressure and temperature channels and the settings and values

you enter in HOBOlink.

If a water level sensor is not physically connected to the

module, barometric pressure will be the only channel logged

related to the water level sensor. You will not be able to set up

water level and water flow unless you install the water level

sensor as described in Setting up the Station. Similarly, if you

unplug a water level sensor while a station is logging, only

barometric pressure will be logged and the rest of the water

level sensor channels will report errors.

Setting up a Water Level Channel

Important: Make sure the station has started logging and you

have taken a reference water level reading from the location

where the sensor is deployed with the date and time of the

reading before performing these steps.

To set up a water level channel:

1. In HOBOlink, select Devices and then RX Devices and click

the icon next to your station.

2. Under the water level module in the Configuration menu,

select Water Level.

3. Click the checkbox to Enable Channel.

4. Click the checkbox to Enable Graph and type a label

(optional).

5. Enter the reference water level and date and time the

reading was taken.

• If the water level surface is below the reference point as

shown below, enter the reference water level as a

negative number.

• If the water level surface is above the reference point as

shown below, enter the reference water level as a

positive number.

6. Select the appropriate water density for your deployment

location.

7. Click Save.

Water level will be calculated starting with the next connection

to HOBOlink. Note that the reference water level information

entered in this step will not affect any previously logged data. It

will only be use for data logged from the point of the next

connection to HOBOlink forward. If this is the first time that

water level has been configured for this station, then the data

stored will go back to the date and time of the reference water

level. If you make other updates to the reference water level,

then the data will only be updated from the time of the next

connection to HOBOlink.

Setting up a Water Flow Channel for a V-Notch Weir

If you are using a v-notch weir similar to the upper diagram

below along with the water level sensor, then HOBOlink can

calculate the flow rate for each water level reading using the

following two values that you enter:

• The notch (vertex) angle in degrees or radians, which is

represented as θ in the second diagram.

• The distance from the reference point to the v-notch

vertex, which is represented as WLv in the second

diagram. This value must be entered in the same units as

the reference water level you entered for the water level

channel (meters or feet).

1-508-759-9500 (U.S. and International) 20 www.onsetcomp.com

1-800-LOGGERS (U.S. only)

Page 21

HOBO RX3000 Remote Monitoring Station Manual

The HOBOlink water flow calculations for a v-notch weir

assume the following:

• The stilling well with the water level sensor should be

placed at a distance of at least 4 x hmax upstream of the

weir.

• In general, if the notch area is small relative to the area of

the approach channel, the weir is “fully contracted” and