Page 1

HOBO® Pro v2 User’s Manual

(Part # U23-00x)

Inside this package:

®

• HOBO

Pro v2 logger

• Clamp and mounting screws

Thank you for purchasing a HOBO data logger. With proper

care, it will give you years of accurate, reliable measurements.

The HOBO Pro v2 logger’s environmentally rugged case is

designed for years of reliable use in outdoor applications. It has

enough memory to record over 42,000 12-bit measurements.

The U23-001 and U23-002 models also feature user-replaceable

RH sensors.

The logger uses an optical USB communications interface (via a

compatible shuttle or base station) for launching and reading out

the logger. The optical interface allows the logger to be

offloaded without compromising the electronics. The USB

compatibility allows for easy setup and fast downloads.

®

software version 2.2.1 or higher is required for

Doc #10694-H, MAN-U23

Onset Computer Corporation

HOBOware

logger operation. Visit www.onsetcomp.com for compatible

software.

Specifications

Temperature Sensor

Operation range Internal sensors: -40° to 70°C (-40° to 158°F)

U23-002 external temperature sensor: -40° to 70°C (-40° to 158°F)

U23-003 and U23-004 external sensors: -40° to 100°C

(-40° to 212°F), with tip and cable immersion in fresh water

up to 50°C (122°F) for one year

Accuracy 0.2°C over 0° to 50°C (0.36°F over 32° to 122°F); see Plot A

Resolution 0.02°C at 25°C (0.04°F at 77°F); see Plot A

Response time

(typical to 90%)

Stability (drift) < 0.1°C (0.18°F) per year

Relative Humidity Sensor (U23-001, U23-002 only)

Operation range 0-100% RH, -40° to 70°C (-40° to 158°F)

Accuracy

Resolution 0.03%

Response time

(typical to 90%)

Stability (drift) < 1% per year typical; hysteresis 1%

Logger

Operation range -40° to 70°C (-40° to 158°F)

Real-time clock ± 1 minute per month 0° to 50°C (32° to 122°F)

Battery 1/2 AA, 3.6 Volt lithium, user-replaceable (part # HP-B)

Battery life (typical use) 3 years with 1 minute or greater logging interval

Memory (non-volatile) 64K bytes memory (approx. 21,000 temperature and RH measurements)

U23-001 Internal sensor: 40 minutes in air moving 1 m/sec

U23-002 external temperature sensor: 5 minutes in air moving

1 m/sec

U23-003 and U23-004 external sensors: 3 minutes in air moving

1 m/sec; 30 seconds in stirred water

Exposure to conditions below -20°C (-4°F) or above 95% RH may

temporarily increase the maximum RH sensor error by an

additional 1%

±2.5% from 10% to 90% RH (typical), to a maximum of ±3.5%.

See Plot B for full range.

U23-001: 40 minute in air moving 1 m/sec with protective cap

U23-002: 5 minutes in air moving 1 m/sec with protective cap

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

Accuracy/Resolution (˚C)

0

-40 -20 0 20 40 60 80 100

Accuracy

Resolution

Temperature (˚C)

Plot A

Plot B

© 2010 Onset Computer Corporation. All rights reserved. Patent #: 6,826,664.

Onset, HOBO, and HOBOware are registered trademarks of Onset Computer Corporation. Other products and brand names may be trademarks or registered trademarks of their

respective owners.

Page 2

HOBO Pro v2 User’s Manual

Materials All models: ASA styrene polymer housing and mounting clamp; polypropylene protective cap; Buna-N o-ring(s);

U23-001, U23-002 only: ASA styrene polymer RH sensor cap; modified hydrophobic polyethersulfone membrane

Cables U23-001: No cables

U23-002: One 184 cm (6 ft.) PVC cable; sensor diameter 1 cm (0.38 in.)

U23-003: Two 184 cm (6 ft.) PVC cables; sensor diameter 0.5 cm (0.20 in.)

U23-004: One 184 cm (6 ft.) PVC cable; sensor diameter 0.5 cm (0.20 in.)

Environmental rating

Launch modes Immediate start; delayed start

Logging interval

Offload modes Offload while logging; stop and offload

Battery indication Battery voltage can be viewed in status screen and optionally logged in datafile. Low battery indication in datafile.

Weight U23-001: 57 g (1.5 oz); U23-002: 118 g (3.1 oz); U23-003: 138 g (3.7 oz); U23-004: 102 g (2.7 oz)

Dimensions Housing measures 10.2 × 3.8 cm (4.0 × 1.5 in.)

NIST certificate Temperature certificate available for additional charge

Electronics housing is NEMA 6P equivalent (tolerant of brief submergence);

Units with RH sensors are NEMA 4 equivalent (splash-resistant)

Fixed-rate or multiple logging intervals, with up to 8 user-defined logging intervals and durations; logging intervals from

1 second to 18 hours (refer to HOBOware software manual)

The CE Marking identifies this product as complying with the relevant directives in the European Union (EU).

Accessories available

• RH sensor replacement kit for U23-001

(Part # HUM-RHPCB-1)

• RH sensor replacement kit for U23-002

(Part # HUM-RHPCB-2)

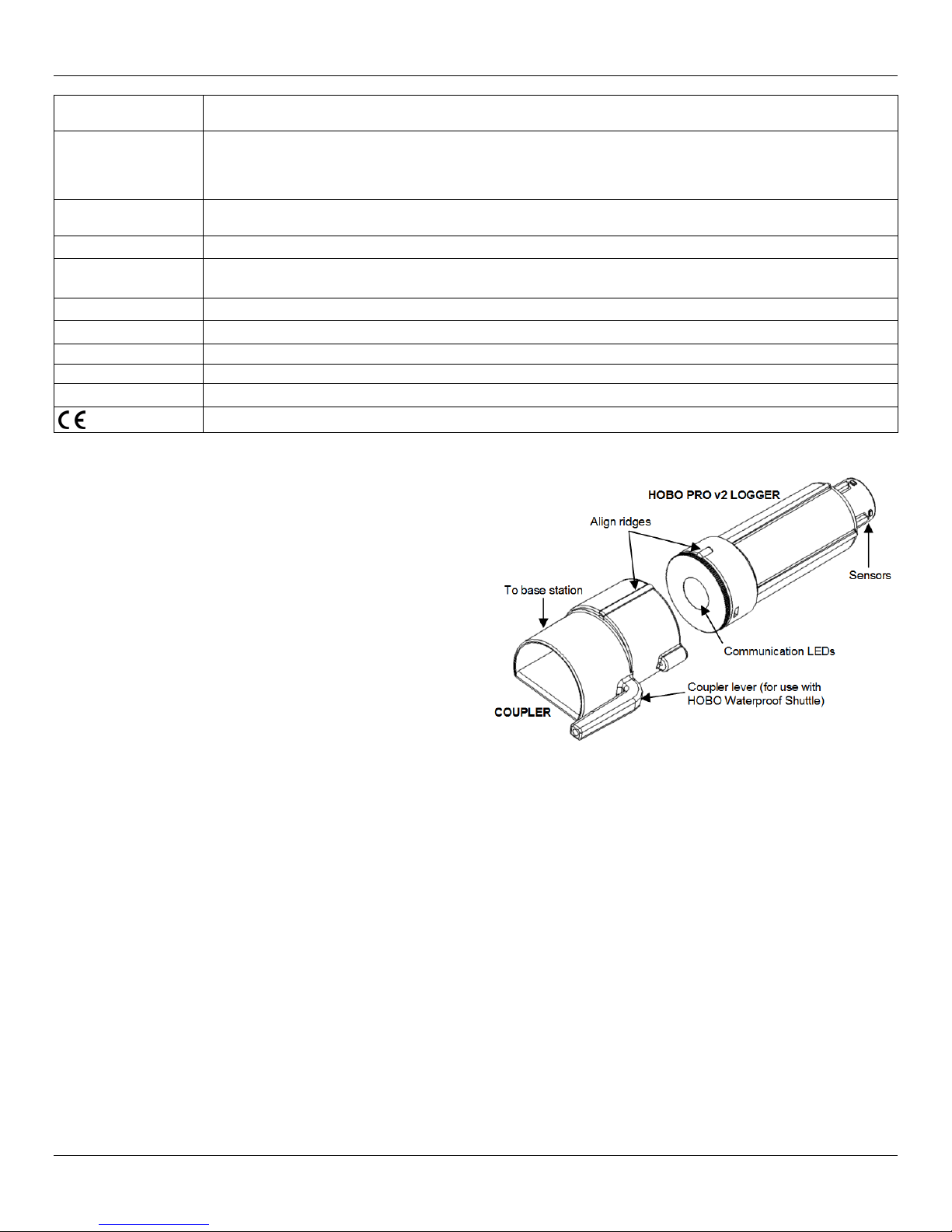

Connecting the logger

The HOBO Pro v2 requires a coupler (Part # COUPLER2-E)

and USB-Optic Base Station (Part # BASE-U-4) or HOBO

Waterproof Shuttle (Part # U-DTW-1) to connect to the

computer.

1. Install the logger software on your computer before

proceeding.

2. Follow the instructions that came with your base station or

shuttle to attach the base station or shuttle to a USB port on

the computer.

3. Make sure the logger’s communications window is clean and

dry. (Use a clean, nonabrasive cloth, if necessary.) If the

logger is damp, wipe off excess moisture.

4. Attach the coupler to the base station or shuttle, then insert

the logger into the coupler with the ridge on the logger

aligned with the ridge on the coupler.

5. If you are using the HOBO Waterproof Shuttle, briefly press

the coupler lever to put the shuttle into base station mode.

6. If the logger has never been connected to the computer

before, it may take a few seconds for the new hardware to be

detected by the computer.

Use the logger software to launch the logger, check the

7.

logger’s status, read it out, stop it manually with the software,

or let it continue to record data until the memory is full. Or,

use the HOBO Waterproof Shuttle to read out and relaunch

the logger in the field.

Refer to the software user’s guide for complete details on

launching, reading out, and viewing data from the logger.

Important: USB communications may not function properly

at temperatures below 0°C (32°F) or above 50°C (122°F).

Note: The first time you launch the logger, the deployment

number will be greater than zero. Onset launches the loggers to

test them prior to shipping.

2

Page 3

HOBO Pro v2 User’s Manual

Operation

A light (LED) in the communications window of the logger

confirms logger operation. (In brightly lit areas, it may be

necessary to shade the logger to see the LED blink.) The

following table explains when the light blinks during logger

operation:

When: The “OK” light:

The logger is logging

The logger is awaiting a

start because it was

launched in Start At

Interval or Delayed Start

mode

Blinks once every one to four

seconds (the shorter the logging

interval, the faster the light blinks);

blinks when logging a sample

Blinks once every eight seconds

until logging begins

Sample and event logging

The logger can record two types of data: samples and events.

Samples are the sensor measurements recorded at each logging

interval (for example, temperature every minute). Events are

independent occurrences triggered by a logger activity, such as

Bad Battery or Host Connected. Events help you determine what

was happening while the logger was logging.

The logger stores 64K of data, and can record over 42,000 12-bit

measurements.

Replacing the RH sensor

The RH sensor (on models U23-001 and U23-002) is protected

by an ASA styrene polymer cap and a modified hydrophobic

polyethersulfone fluid barrier membrane that allows vapor to

penetrate while protecting the sensor from condensation.

RH sensor performance may degrade over time. To replace the

RH sensor in your logger, refer to the diagram and instructions

for your logger:

U23-001

1. Turn the RH sensor cap counter-clockwise slightly and pull

to remove it. Discard the sensor cap, membrane, and o-ring.

Clean the sensor end of the logger.

Face-on view wit h spacer installed

Logger

Spacer

Protective Membrane

RH Sensor Board

RH Sensor

O-ring

Deploying and protecting the logger

• To clean the logger’s case, use a sponge with warm, soapy

water.

• Use the included clamp to mount the

logger to a surface. The clamp has two

holes for the screws, 44 mm (1.7 inches)

apart.

The clamp is slightly tapered to

accommodate the logger. Install the

clamp so the logger fits better with its

communication window facing up. This

will prevent condensation from pooling

around the sensor and/or grommet.

• A solar shield is recommended if the

logger will be exposed to sunshine.

• Periodically inspect the three desiccant packs located in the

logger cap. If they are not bright blue, dry them following the

instructions below.

To dry a desiccant pack, remove it from the logger cap and

leave in a warm (≤70

blue color is restored. (Refer to the “Battery” section for

instructions on removing and replacing the logger cap.).

If a desiccant pack remains pink and will not turn blue, replace

it with a new desiccant pack (Onset Part #: DESICCANT1)

o

C (158oF), dry location until the bright

WARNING: Do not touch

the actual sensor (black

chip). Doing so may

compromise accuracy.

RH Sensor Cap

2. There may be a spacer installed on the RH Sensor Board.

Remove and discard the spacer.

3. Note the orientation of the small circuit board containing the

RH sensor. With a pair of needle-nose pliers, grip the sensor

board pins. Pull out and discard the board.

4. Use needle-nose pliers to hold the pins on the new sensor

board, push the board gently but firmly and install it in the

same orientation as the old board. Make sure it engages with

the pins inside the logger housing. Do not touch the sensor

itself; only touch the sides of the board.

5. Install the new spacer on the sensor board by placing the

spacer onto the third pin from the left (use the topmost hole

on the spacer instead of the center hole).

6. Make sure the o-ring is clean and seated properly, and set the

protective membrane on top (either side can face up).

7. Put the sensor cap back on. Push down and turn it slightly

clockwise to close it securely. Do not force it. If the cap does

not go on easily, the sensor may be installed incorrectly.

Check the sensor orientation and try again.

8. Check logger status in HOBOware to verify the RH reading.

3

Page 4

HOBO Pro v2 User’s Manual

U23-002

1. Grasp the cap and membrane and pull firmly. Discard them.

2. Note the orientation of the small circuit board containing the

RH sensor. Pull it out and discard it.

Cable from logger

& protective membrane

Receptacle

RH sensor

RH sensor cap

3. Holding the sides of the board only, push gently but firmly to

install the new sensor (Onset part # HUM-RHPCB-2) in the

same orientation. WARNING: Do not touch the actual

sensor (black chip) itself; doing so may compromise

accuracy.

4. Put the new sensor cap and membrane on. Do not force the

cap. If it does not go on easily, the sensor may be installed

backwards. Reverse the sensor and try again.

Battery

Typical battery life is about three years. Actual battery life is a

function of the number of deployments, logging interval, and

operation/storage temperature of the logger. To obtain a threeyear battery life, use a logging interval of one minute or greater,

and operate and store the logger at temperatures between 0° and

40°C (32° and 104°F).

Frequent deployments with logging intervals of less than one

minute, and continuous storage/operation at temperatures above

40°C, will result in significantly lower battery life. For example,

continuous logging at a one-second logging interval will result in

a battery life of approximately one month.

The logger can report and log its own battery voltage. If the

battery falls below 3.1 V, the logger will record a “bad battery”

event in the datafile. If the datafile contains “bad battery” events,

or if logged battery voltage repeatedly falls below 3.3 V, the

battery is failing and should be replaced before the next

deployment. To change the battery:

2. Carefully pull out the circuit board containing the battery. (If

the logger has an external sensor, you will probably find it

easier to push the cable(s) into the case to push the circuit

board out.)

3. Examine the desiccant packs that were packed into the case.

If the desiccant is not bright blue, put the desiccant packs in a

warm, dry place until the blue color is restored.

Protective cap

Circuit board

Battery

Cable from sensor

(if applicable)

Desiccant packs

Grommet for cable

(if applicable)

4. Install a new 1/2 AA, 3.6 Volt lithium battery (part # HP-B).

The positive end of the battery should face towards the

communication LEDs.

5. Use a clean, dry cloth to wipe away any moisture inside the

case.

6. Push the board and the desiccant packs back into the case,

taking care not to bend the communication LEDs. Align the

board with the grooves inside the case. (If you try to put the

board in upside-down, the battery will get in the way.)

7. Make sure o-ring on the protective cap is still in place. It

should not be pinched, twisted, or trapping dirt or lint, which

could interfere with the protective cap.

8. Line up the bumps on the protective cap with the notches in

the logger’s case. Push and turn the cap slightly clockwise.

Pull the slack in the sensor cable(s) and tighten the grommet,

if applicable.

WARNING: Do not cut open, incinerate, heat above

100°C (212°F), or recharge the lithium battery. The battery

may explode if the logger is exposed to extreme heat or

conditions that could damage or destroy the battery case. Do

not dispose of the logger or battery in fire. Do not expose the

contents of the battery to water. Dispose of the battery

according to local regulations for lithium batteries.

1. Turn slightly counter-clockwise and pull to remove the

protective cap. Loosen the cable grommet on the opposite

end, if the logger has an external sensor.

4

Loading...

Loading...