Page 1

2007 Adventure Island Rudder “T” Handle Kit

As you start sailing your Hobie Mirage Adventure Island in more challenging conditions, you may

require more force to keep the rudder locked in the down position. This rudder lock upgrade kit will

allow you to apply more holding power for the rudder. To install this new system you will be removing

the up/down handle that you are currently using. Follow the instructions below for the kit installation.

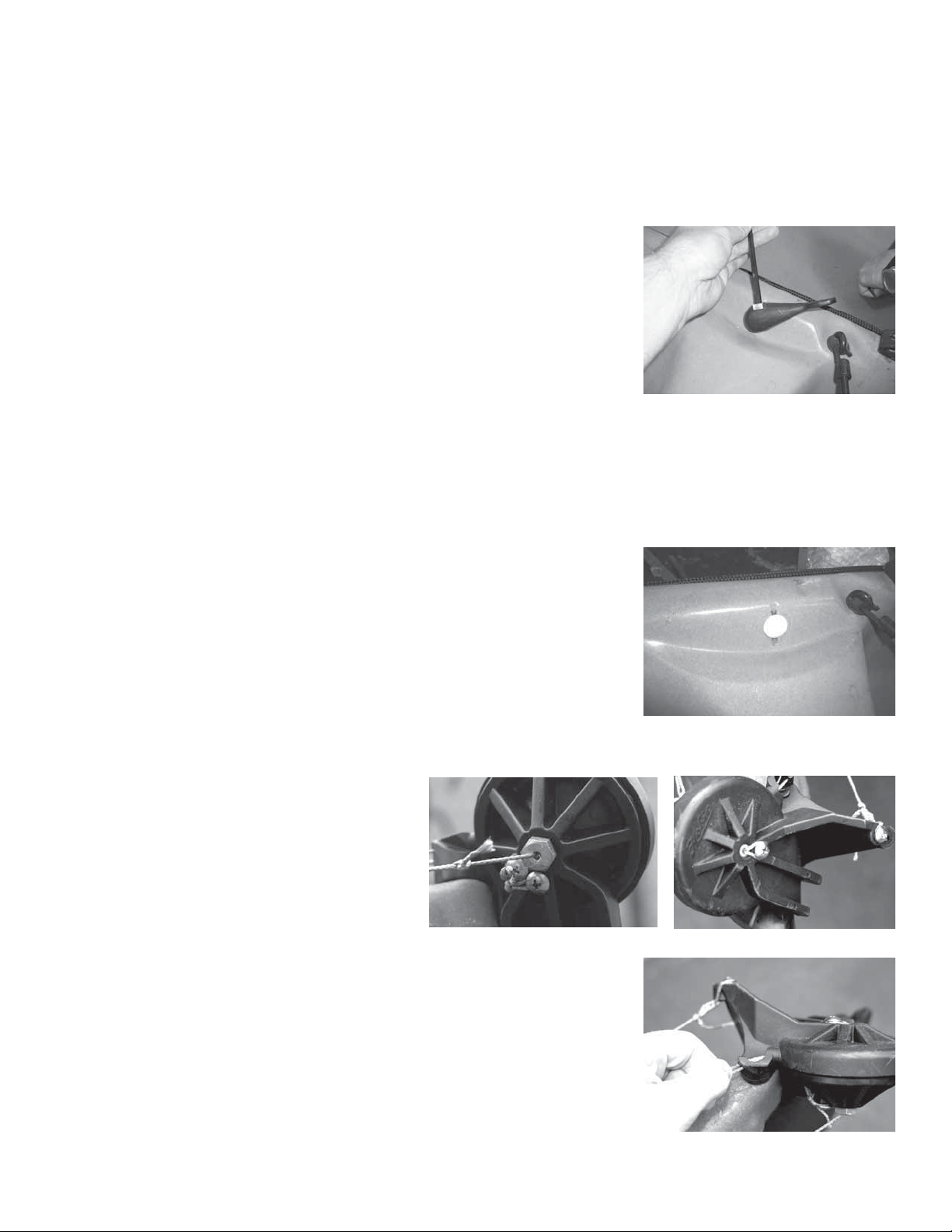

1. Using an Allen key wrench, unscrew the bolt that is passing

through that handle and pull the handle off of the control arm shaft.

2. Push the control arm shaft in so that it falls in the hull. Reach inside the hull and grab the control

arm to take both of the lines off of it. This part is to be removed from the hull as it won’t be needed

anymore. Also, untie the bungee cord and loop of line from the small spectra lines.

3. Plug the hole that is created with the push in cap that is

included with this kit.

4. To install the new tubes and lines, you

will need to partially disassembly the rudder housing. Start by loosening the screws

and unwrapping the lines completely from

the two screws on the underside of the rudder and the one screw on top of the rudder

near the main bolt.

5. Pull on the lines that exit the hull so that they completely pull

out of the rudder housing.

Page 2

6. With the up and down control lines loose, pull on them and remove them from the hull with the tubes. If they get hung up inside

the hull, you can cut whatever is preventing you from taking out

the lines. You will no longer need these lines and tubes with this

kit.

7. With the old tubes and lines removed, install the new tubes with

lines that are in this kit into the holes that you just removed the old

tubes from. Getting the end fittings into the holes will be a tight

squeeze, so you may need a small hammer to tap them into the

holes so that they are fully installed. IMPORTANT: When these

lines are installed, the right line will be for the DOWN control

and the left line will be for the UP control.

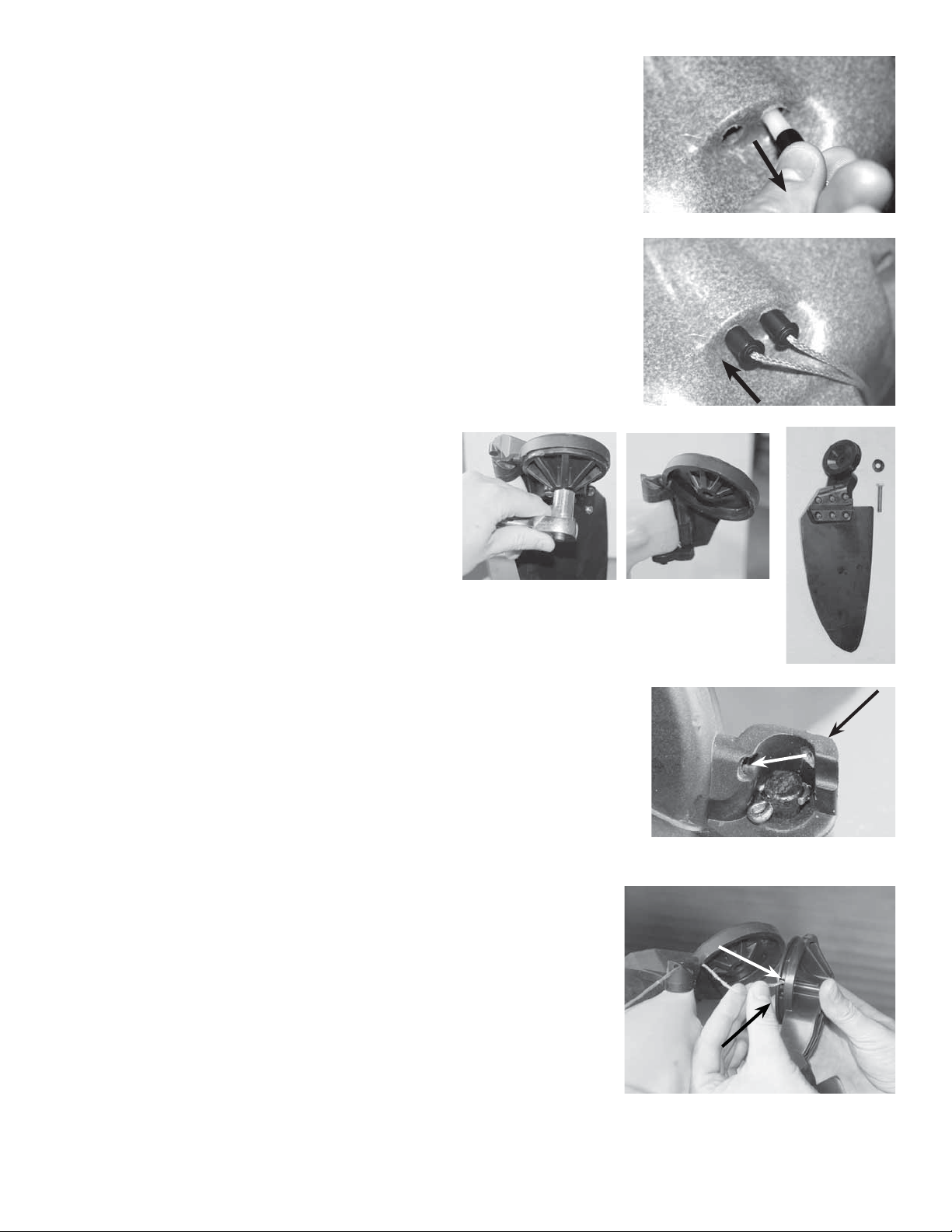

8. Use a socket or a wrench and unthread the

bolt that passes through the center of the rudder housing. This will allow the rudder to come

apart.

9. Feed the DOWN control line through the two holes that are just

above the rudder pin. When installed, the line will come on the

inside of the rudder housing.

10. Feed the DOWN control line into the upper hole on the rudder

part of the assembly and tie a knot in the end of the line to keep it

from pulling through.

Upper Hole

Lower Hole

Page 3

11. Now feed the UP control line through the same two holes above

the rudder pin to the inside of the rudder housing. Wrap the line so

that it goes over top and around the drum. Insert the end of the line

into the lower hole indicated in step 10 and tie a knot at the end of

the line.

12. Slide the bolt through the rudder portion of the assembly and place the plastic

washer over the threaded end. Insert

then end of the bolt into the housing and

bolt the rudder assembly back together.

As you insert the rudder half into the

housing, you have to be careful to not

allow the rudder lines fall off the track

around the circular rudder drum. To prevent this, pull up on the up/down control

lines that are exposed on the deck to

remove the slack and keep the lines tight

around the drum.

Thread in the bolt to hold the two halves

together. IMPORTANT NOTE: DO NOT

SCREW DOWN THE BOLT SO THAT

IT IS TIGHT. YOU ACTUALLY WANT IT

TO BE A FAIRLY LOOSE CONNECTION

ALLOWING AN 1/8”-1/4” OF

MOVEMENT. IF IT IS TOO TIGHT, THE

RUDDER WILL NOT GO UP PROPERLY.

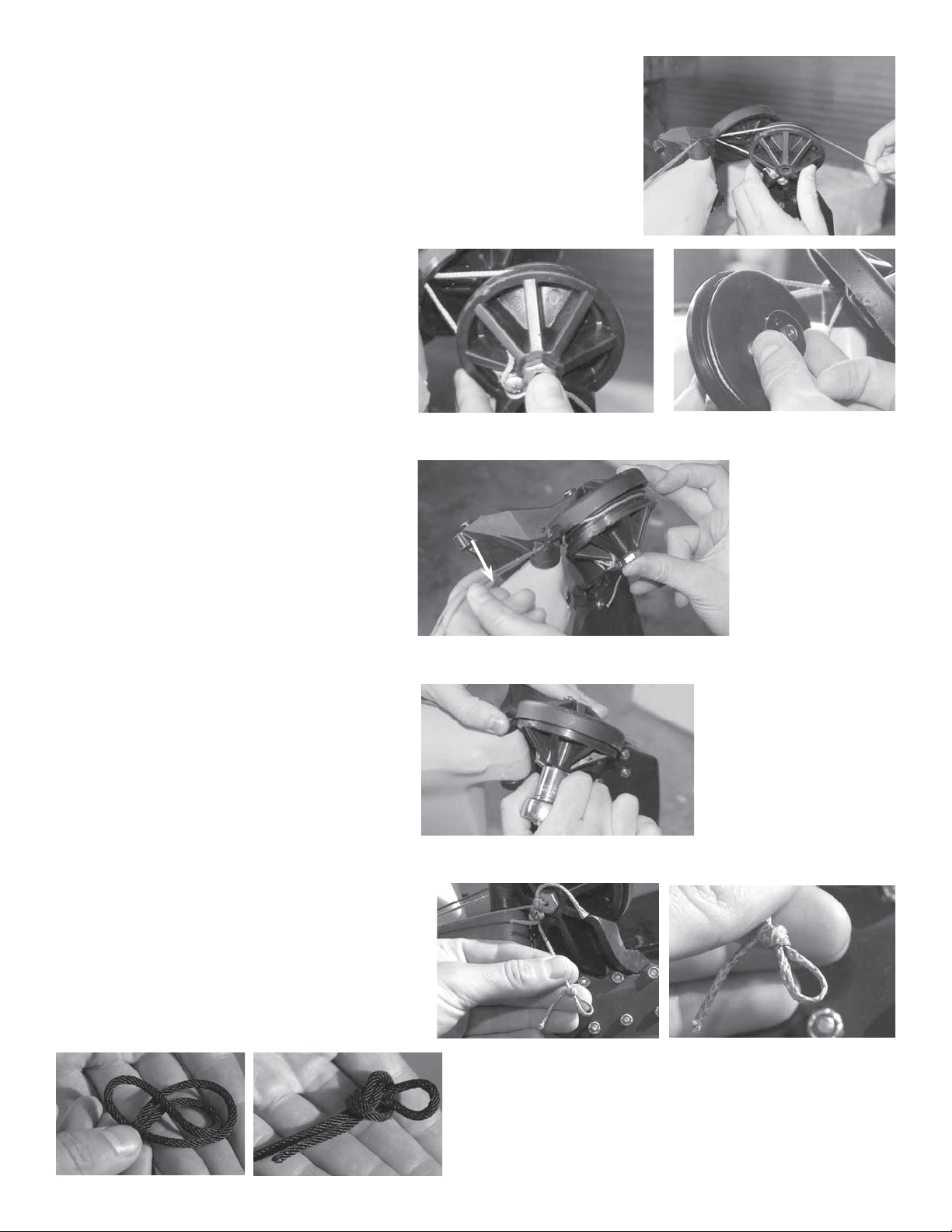

13. Take the ends of the lines that you fed

through the rudder and make the loop so

that it is small enough to pass a screw head

through. The size of the loop isn’t that critical, but do not make it any more that 3/4”

big. See the pictures below on how to tie

the knot needed for this loop

Page 4

14a. Place the loop around the screw and thread the screw back into

the rudder.

14b. Follow the sample procedure with other screw and control line.

14c. Once the loops are held down with the screw, leave these lines alone for a bit and finish up the

instructions below.

15. Locate the cleat in the kit and place it on the right side of the

kayak along the forward edge of the map pocket. Center the middle

of the cleat to the point of the corner of the rails. Draw a small dot

on the kayak to locate a drilling location. The hole location should be

slightly below the top of the cleat jaws.

16. Drill a hole in the dotted location with a 5/16” drill bit

17. Insert one of the two the small

length of rigid tube into the hole and

press the black fitting at the end of the

tube into the hole. It will be a tight fit,

so you may need to give it a couple

taps with a hammer to get it into the

hole.

Drill

Location

Page 5

18. Locate the cleat on the right side map pocket just like in step

7 and use the holes in the cleat as a guide to drill two 11/64” holes

through the map pocket frame and kayak hull material underneath

it. Make sure to center the cleat along the width of the map pocket

frame so that it rests on a nice flat surface.

19. Place the padeye fitting over the cleat. Using the provided hardware, through bolt the cleat to the kayak. You will need to reach inside of the middle hatch to put on the washers and nuts on the inside

of the kayak.

20. Drill a hole and insert the other tube in the opposite side of

the kayak as well. A cleat will not be installed on the left side of

the boat, but using the same location on the map pocket corner as

you drilled on the right side is a good reference.

21. Remove the nuts that bolts on the block that routes the

mainsheet back to the forward deck mounted bar. The screws

themselves don’t need to be removed, so just take off the nuts.

22. On the opposite side of the kayak where the mainsheet

routing pulley is, you will need to drill two holes. Using a block

in the kit as a drilling guide, drill two holes so that the rearmost hole is 5” in front of and 3” down from the brackets on the

forward deck mounted bar so that the holes are symmetric with

the holes on the other side of the kayak.

Page 6

23. Through bolt the two pulleys on the inside of the kayak.

On the RIGHT side of the kayak, use the existing screws that

are being used to attach the mainsheet routing pulley line and

place nuts on the outside of the new block to hold it in place.

On the LEFT side of the kayak, use the new screws and nuts

in the kit and bolt it through the holes that you drilled. When

mounting the blocks make sure to take note that there is a

larger gap on one side of the pulley which should be located toward the bow of the boat as shown in the pictures (see arrow).

24. Locate the two line assemblies which have the webbing

scrunched along the length of the line. Take note of the section of the line that has a longer length of line after the webbing

attached to the line.

25. Take the end of the line that has a longer length after the

webbing and feed it up through the bottom and around the

pulley. Continue to feed that line back to the tubes that you

pressed in on step 9 and 12 and feed it through the tube so

that it exits the hull. Do this on both sides of the kayak so

that both of the pulleys that you bolted to the kayak have lines

wrapping around them and coming out through the tubes.

Kayak Bow

26. Take the ends of the line and feed them through the “T” handles. Tie a simple knot as close to

the ends of the lines as possible and pull the knots into the handles.

27. With the one end of the lines tied to the “T” handle, pass the other ends of the line along the side

of the kayak so that it runs all the way to the stern. You will need to reach inside of the middle hatch

to help pass them down the length of the kayak. It is important that the line is passing on the outside

of any of the inside features like the mirage well, daggerboard well and cart scuppers.

Page 7

28. Pull the lines all the way back to the rear hatch and tie a simple

knot approximately 4” from the end of the lines.

29. Now you are going to lock the small lines with loops at the end coming from the rudder to the

knots that you just tied. To do this, follow the diagram below to form a cinch around the line up to the

knot. Make sure that you know what line is the up and which is the down line coming from the

rudder. To do this pull on the rudder lines to see what one start to pull the rudder up. The line

that makes the rudder go UP should be attached to the line running along the left side of the

kayak.

The system should look like the diagrams below.

Pulley

Small Tubing

Webbing

T Handle

Rudder Line and

Larger Line Connection

Page 8

DOWN CONTROL LINE

T Handles

Pulleys

UP CONTROL LINE

29. Your up/ down rudder system is now ready to go

a. Pull on the right “T” handle to lower the rudder. Pull

the line tight and cleat off to hold it in the down position.

b. To raise the rudder, uncleat the lock down line and pull

the “T” handle on the left side of the boat. IMPORTANT!

When the rudder is in the locked down position, it will

have some flexibility in the system due to stretch in

the rope, but it should be uncleated and raised prior

to beaching.

Webbing

Rudder Line and

Larger Line Connections

30. Place the stickers on the “T” handles to label which one does what. The “UP” sticker should go

on the left handle and the “DOWN” sticker should go on the right handle. To ensure a good adhesion,

make sure that the handles are clean of any water or debris.

Loading...

Loading...