Page 1

Page 2

WELCOME TO THE

HOBIE WAY OF LIFE

Congratulations on the purchase of your new HOBIE 18’ and welcome to the HOBIE® sailing family. The HOBIE 18 cannot be

outgrown. A single adult can sail it at top performance - and a crew of four can cruise in comfort.

We offer this manual as a guide to increased safety and enjoyment of your new boat. The purpose of this publication is to

provide easy, simple and accurate instructions on how to get your Hobie 18’ ready for the water. Please read them carefully

and familiarize yourself with the boat and all of the parts spread before you.

Whether you are a new sailor or a veteran of many years, we recommend that you read this thoroughly before your first sail

and TRY IT OUR WAY FIRST! If you are new to sailing, this manual alone is not intended to teach you how to sail. There are

many excellent books, videos and courses on the safe handling of small sailboats. We suggest that you contact your local

sailboat dealer, college or Coast Guard Auxiliary for recommendations.

Watch for overhead wires whenever you are rigging, launching, sailing or trailering with the mast up. CONTACT OF THE

MAST WITH POWER LINES COULD BE FATAL! Be certain that the rigging area and the area that you will be sailing in are

free of overhead power lines. Report any such power lines to your local power authority and sail elsewhere.

We take pride in presenting the Hobie 18’ to you and hope that you'll take as much pride in owning her.

Fair winds and good sailing!

Page 3

1

This assembly manual takes you stepby-step through the setting-up and

sailing of your new HOBIE 18.

This manual will help you understand

each part in detail.

Note that this manual applies for

both Hobie 18 SE and SX models.

Setting up your HOBIE 18 PAGE

Packaging Layout.................................2

Framing the Hulls .................................3

Installing the Trampoline ...................4-6

Mast Assembly..................................7-8

Stepping the Mast ...........................9-11

Installing the Boom.............................11

Installing the Jib Blocks ......................11

Rudders and Tiller Cross Bar........12-13

Raising the Main Sail ....................14-15

Raising the Jib....................................16

Dagger Boards ...................................17

Illustrations....................................18-25

Sailing your HOBIE 18................PAGE

Balancing the boat ...................................26

Steering ....................................................26

Sail power.................................................26

Turning......................................................27

Launching.................................................27

Righting the boat ................................27-28

Docking and landing ................................28

Rudder tuning .....................................28-29

Trailering...................................................29

Maintenance.............................................29

Mooring.....................................................30

Hobie Class Associations........................30

Safety tips ..................................Back page

HOBIE 18 ASSEMBLY MANUAL

Page 4

2

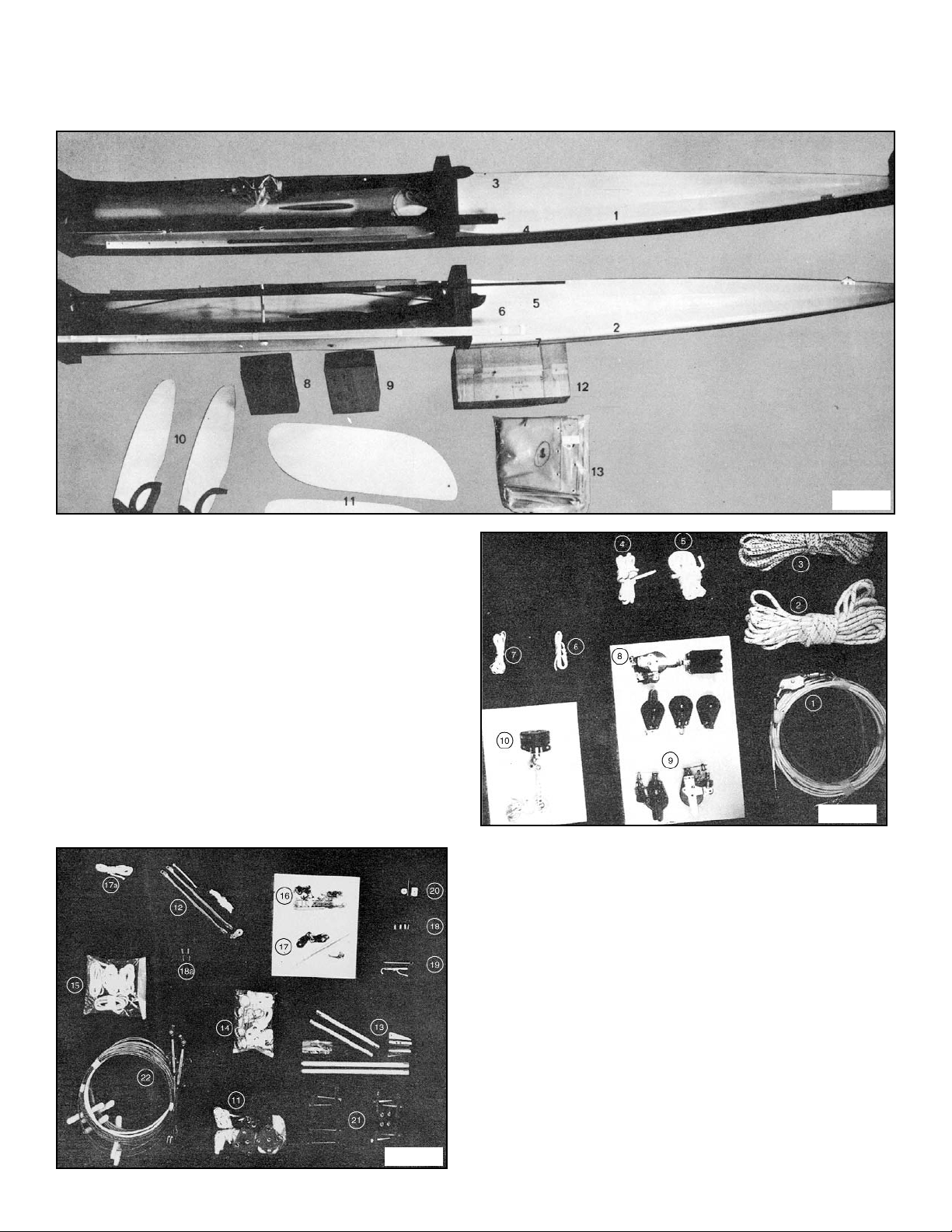

Packaging Layout

1. Port Hull

2. Starboard Hull

3. Back Bar

4. Boom

5. Tiller Cross Bar

6. Front Bar

7. Battens

8. Rigkit Box #1

9. Rigkit Box # 2

10. Rudders

11. Daggerboards

12. Sail Main and Jib

13. Trampoline

14. Mast (not shown)

Hobie Cat 18 SE Rig Kit Box #1 (fig 2)

Description Quantity

1. Shrouds, Forestay 2,1

2. 7/16” Mainsheet 48’ 1

3. 5/16” Jib Sheet 45’ 1

4. 1/4” Trampoline Lacing - Center 1

5. 1/4” Trampoline Lacing - Aft 2

6. Jib Luff Tensioner 2” 1

7. Jib Halyard Line 20” 1

8. Mainsheet Block Assembly 1

9. Jib Sheet Block 2

10. Jib Furling Assembly w/line 17” 1

Figure 1

Figure 3

Figure 2

See page 25 for descriptions

Page 5

3

Framing the Hulls

(Recommend two people)

Tools-HEX wrench (provided) and a screwdriver with a

1 /4" head.

Retaining Channel 8

Front Bar Inboard Bolt 3 3/4" 2

Front Bar Outboard Bolt 2" 2

Rear Cross Bar Inboard Bolt 2 1/ 2" 2

Rear Cross Bar Outboard Bolt 2" 2

Lock Nuts for 802-359 Outboard Bolts 4

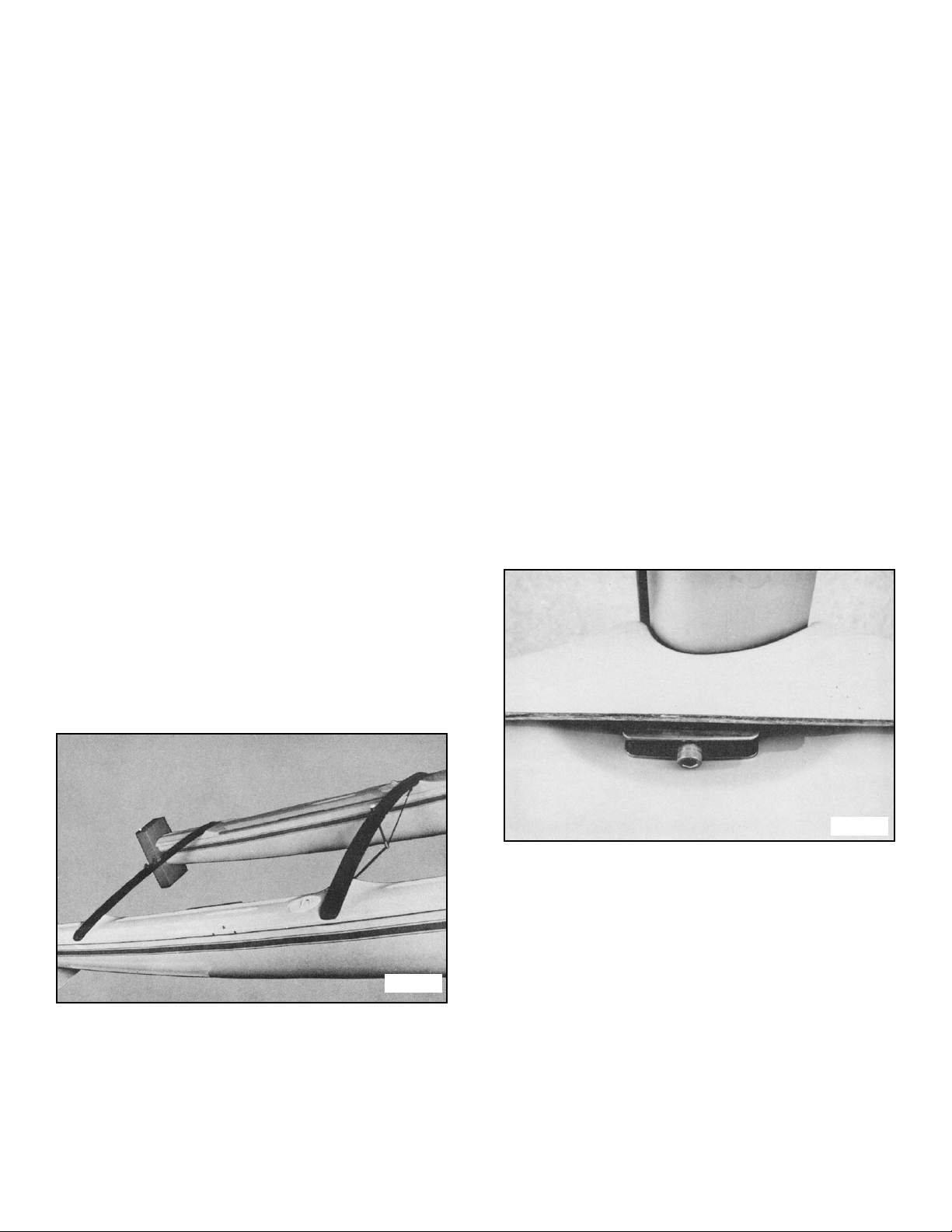

1. Place the boxes on level ground with the seams

facing up. Cut the bands and open the lid. Remove the

sail, trampoline, rig kits, (two boxes), dagger boards,

rudders, and metal work modular packages. See Figure

1.

1. The dagger board and rudder are in cardboard

sleeves on each side of the hull.

2. Leave the hulls in the end pieces so that they will be

supported in the upright position while being framed.

3. Place the hulls 8 feet apart with the metal trampoline

track facing the inside.

4. Place the backbar across the aft saddles with the

traveler at the back.

5. Locate the bar firmly in the saddles and insert the aft

inboard bolt assembly under the port rail. *See Figure 4.

Start the bolt by hand to insure proper engagement. Do

not start the bolt with the hex wrench as you might cross

thread the internal assembly. If the bolt has trouble

advancing into the bar do the following;

a. Rock the hull with quick movements as you turn the

bolt.

b. Double check the bars alignment with the saddle.

c. Have another person lift and lower the bow as you

turn the bolt.

If you are still having trouble advancing the bolt remove

the back bar from the boat and try the bolt in it. Look for

metal chips or dirt particles inside the bar which could

be hindering the bolt's progress.

*Port refers to left, starboard refers to right.

IMPORTANT

Read this before framing the hulls.

Prior to inserting each crossbar bolt, (Framing the

hull, step 5), apply approximately 1/8th (about one

teaspoon full) of the tube of silicon sealant around

the unthreaded portion of each bolt. This will seal

the area around each bolt and prevent unwanted

water from entering the hull.

6. Install the aft inboard bolt assembly on the starboard

side as described in step 5. It is important that the hulls

be parallel and level at this time. The frame will be very

difficult to attach to the hulls if they are misaligned.

Once the aft inboard bolts are installed, STOP. Do not

install the outboard bolts. This will be done later.

7. Place the front bar across the forward saddles. The

lengthwise track opening should be facing toward the

bows. See Figure 5.

8. With the bar seated firmly in the saddle insert the

forward inboard bolt assembly under the port rail. The

bolt is fitted into the bar by the same procedure as the

aft bolt assemblies.

9. Install the inboard bolt assembly on the starboard

side of the cross bar. If there are any problems

advancing the bolt refer to instructions in step 5A, B, C.

Once the bolts are engaged, STOP. Do not tighten them

down.

Figure 5

Figure 4

Page 6

11. Install all four outboard bolts in the manner

described in step 10. To insert the bolts in the front

corner castings it will be necessary to remove the cover

plates. Be careful when extracting the cover plate

retaining screw. It is made of aluminum and can be

galled. See Figure 6.

12. Use the hex drive to tighten the bolts. Follow this

order to secure the bolts.

inboard front

inboard aft

outboard aft

outboard front

It may be necessary to repeat this sequence more than

once to seat the front and back bars firmly into the

saddles. Once the bolts are tight check the dolphin

striker rod for looseness. If it is loose, tighten the nuts at

either end of the rod where it exits the outboard section

of the corner casting.

13. Replace the cover plates on the front corner

castings. Be careful not to damage the retaining screw

as you are installing it.

14. Re-check the cross bar after five hours of sailing. It

will probably be necessary to tighten some of the bolts.

TRAMPOLINE ASSEMBLY

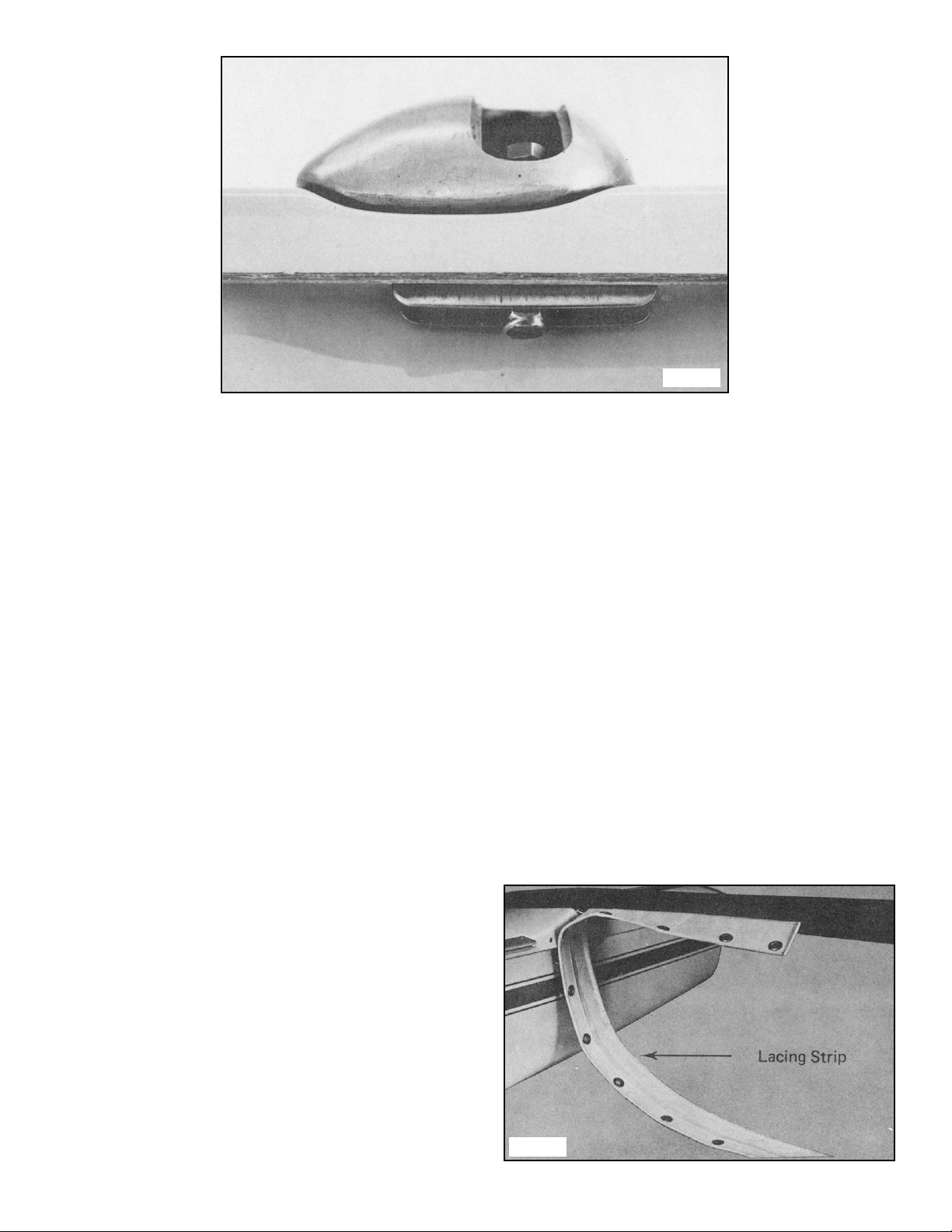

1. Install the aft lacing strip. Feed the lacing strip into

the rear cross bar at the right just inside the hull where

the track has been cut away. See Figure 7. Center it

on the rear cross bar.

2. Lay the trampoline halves face down forward of the

front cross bar and between the hulls. The long row of

grommets should be on the inside and the short row of

grommets will be up at the bow. See Figure 8

3. With the port trampoline half still face down, lead the

short side (without grommets) into the front cross bar at

the opening in the center of the bar and slide it over to

the hull. See Figure 9

4. Pass the trampoline between the front cross bar and

the dolphin striker so that it is covering the bottom of the

cross bar.

10. The four outboard bolt assemblies are identical. To

install, first slip the bolt through the outer end of the

corner casting and down through the rail of the boat.

Place the stainless steel channel over the bolt's

exposed section which is under the rail. Spin the nylock

nut on the bolt but do not tighten the bolt down at this

time.

Figure 7

Figure 6

4

Port and Starboard

Port and Starboard

Port and Starboard

Port and Starboard

Page 7

Figure 9

Figure 8

5

Page 8

6

5. Insert the aft outboard corner of the trampoline into

the extrusion on the inside of the hull and pull the

trampoline as far aft as it will go.

6. Repeat steps 2-5 for installing the starboard

trampoline.

7. In front of the rear cross bar there is a hole in either

inboard rail. Insert the port aft lacing line into this hole

on the port hull and exit it straight down. Tie a knot in

the tail of the line and then pull the knot up under the

rail.

8. Thread the lacing line from the inboard rail to the

corner grommet on the AFT lacing strip and then to the

corner grommet on the port trampoline. Temporarily tie

the line off to the rear cross bar.

9. Repeat this procedure for the starboard side of the

trampoline.

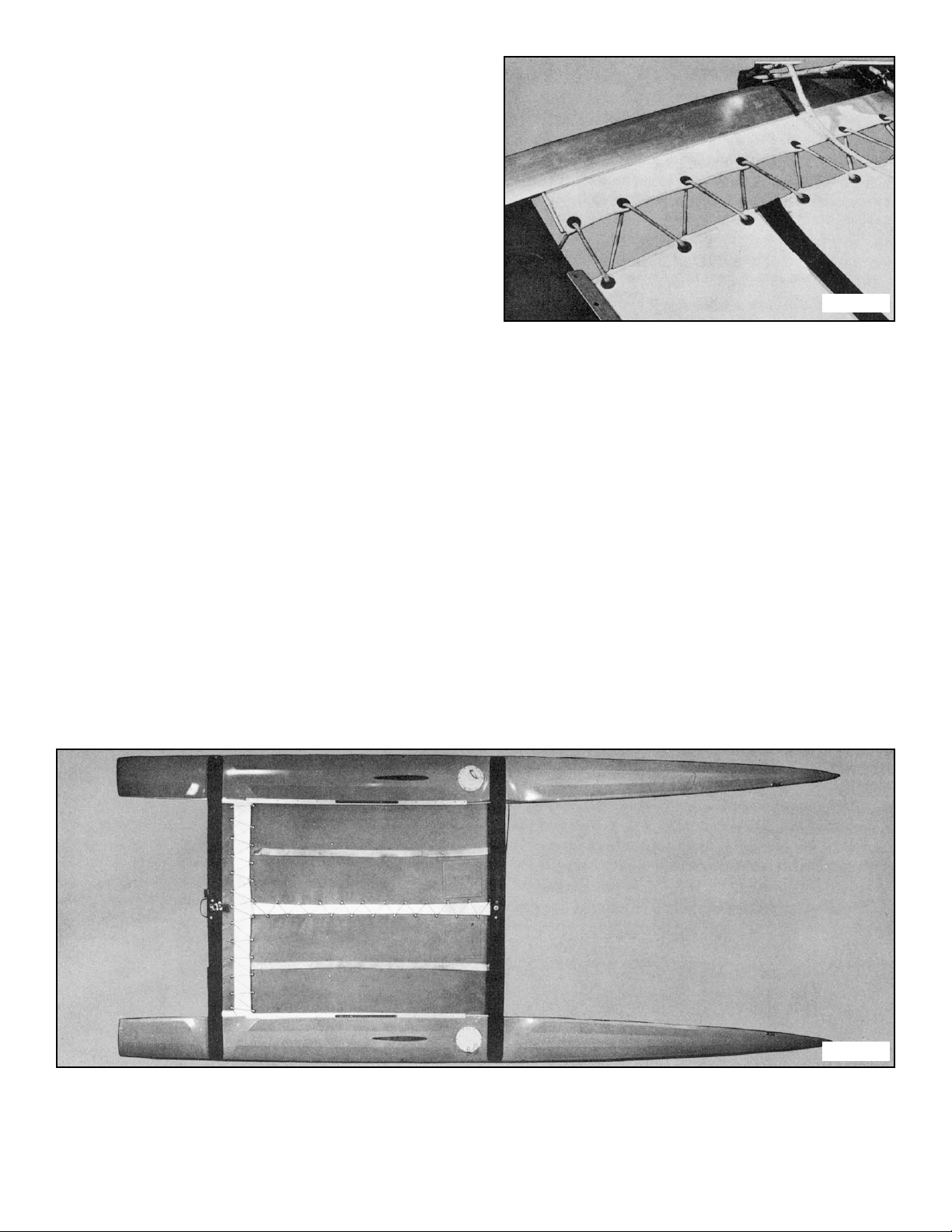

10. Attach the center trampoline lacing line to the

forward-most grommet on the starboard trampoline.

Lace it down to the rear taking out the slack as you go.

11. Untie the aft lacing lines and complete the lacing

starting at the outboard side and working toward the

center. See Figure 10. With use the trampoline will

stretch and require periodic re-tightening.

Figure 10

Figure 11

Page 9

7

MAST ASSEMBLY

1. Support mast at both ends on saw horses or other

such devices. Ref: Illus. #1, Pg. 20.

2. Spreaders. In the rig kit you will find all the parts of

the spreader assembly.

3. The larger of the two pairs of aluminum rods (1-1), is

the spreader arm. Attach it to the aft tab of the spreader

root (1-2). Use a 3/16" x 11/16" clevis pin (1-3).

turnbuckle on the bolt, pass the bolt through the mast at

the compression sleeve which is located 1 foot above

the mast base(1-14). The shackled end of the MRCY

should be behind the mast.

4. Locate the slide (1-4) on the spreader arm so that the

large wing of the slide is closest to the mast, and facing

forward.

5. Line up the inboard hole on the slide with the

outboard hole on the spreader arm and insert the slide

adjustment pin 3/16" x 13/16" (1-5). The slide is now

positioned in the raked forward attitude.

6. Connect the smaller brace rod (1-6) between the

forward tab on the spreader root and the wing on the

slide, with the brace pin 3/16" x 9/16" (1-7).

7. Secure all the clevis pins with the cotter keys

provided.

8. Repeat steps 3-7 for the opposite side of the mast.

9.There will be two large cotter pins (1-8) left over, place

them to one side, they will be used later to retain the

diamond wires in the spreader arm tips.

10. Mast rotation control yoke (MRCY). In the rig kit you

will find the parts of the MRCY. You will also need the

diamond wires which can be identified by the

turnbuckles on one end.

11. IMPORTANT follow this sequence to assemble the

MRCY and diamond wires.

12. Hold the two arms of the

yoke (1-9) together at the

ends with the small holes.

Attach the small block (1-10)

and shackle (1-11) to this

end, see Figure 12. (There is

a short line packed with the

MRCY, set it to one side for

now.)

13. Pass the long bolt (1-12)

through the large hole in one arm of the MRCY (1-9).

Slide the toggle of diamond wire turnbuckle (1-13) over

the bolt and move it next to the MRCY arm.

14. With one arm of the MRCY and one diamond wire

turnbuckle on the bolt, pass the bolt through the mast at

the compression sleeve which is located 1 foot above

the mast base( 1-14). The shackled end of the MRCY

should be behind the mast.

15. Slide the turnbuckle toggle of the opposite diamond

wire over the exposed portion of the bolt. Install the

remaining arm of the MRCY on top of the turnbuckle

toggle.

16. Put the retaining nut (1-15) on the exposed threads

of the bolt and finger tighten only. It will be tightened

later. See figure 13.

17. Loosen the lock nuts at each end of the turnbuckle

body and expand the turnbuckle 2-1/2". Note that both

lock nuts spin in the same direction to unlock.

18. Attach the opposite end of the diamond wire to the

diamond wire tang (1-16) which is located 2 feet below

the mast tang (1-17). Install clevis pins (1-19) and cotter

pins (1-20).

Figure 13

Figure 12

NOTE: The style of rotator yoke shown in

Figure 12 is the older mast rotator style.

Current models do not have a pulley. See page

20 for details on the new style.

Page 10

8

19. Slip the port diamond wire into the tip of the port

spreader arm. Make sure that the anti-chafing roller on

the diamond wire is above the spreader tip. Secure the

diamond wire by installing one of the long cotter pins (1-

8) through the tip of the spreader.

20. Repeat this procedure for the starboard diamond

wire.

21. Tighten the nut (1-15) of the through mast bolt which

is at the lower end of the diamond wires.

22. Tighten the diamond wires by rotating the turnbuckle

bodies. The turnbuckles must be adjusted equally since

over-tightening one side will induce a bend into the

mast. See Figure 14.

WARNING

The diamond wire adjustment not only affects boat

performance but also affects the mast structural

integrity. If the diamond wires are loose or broken

the mast will be permanently distorted or could fail

completely. The diamond wires cannot be tightened

sufficiently by hand. It will require the assistance of

a wrench to make the last two or three revolutions

of the turnbuckle body. Additionally, the diamond

wire will stretch with use and require periodic

inspection and re-tightening.

23. Once the diamond wires are adjusted, spin the

locknuts up against the turnbuckle body tight. You can

do this by hand.

24. Tie a piece of string through one turnbuckle body

and over through the other turnbuckle body. This will

keep the turnbuckle from unscrewing.

25. Locate the shrouds and forestay in the rig kit. They

are packed together and are the only rigging which is

vinyl coated. The three wires are already attached to a

large shackle. Remove the pin from the shackle and

attach it to the mast tang (1-17) at the lowest of the.

holes in the tang. See Figure 15. Secure the safety wire,

which is attached to the thumbscrew, to the shackle

body. This will keep the pin from unscrewing.

26. The double trapeze wire has a single thimble at its

upper end. Engage this thimble to the shackle on the

opposite set of trapeze wires after you have inserted the

shackle through the upper set of holes in the mast tang.

See Figure 15.

Figure 15

Figure 14

Page 11

STEPPING THE MAST.

DANGER - Do not attempt to step the mast in an

area of low overhead wires. A mast contacting an

electrical wire could be fatal.

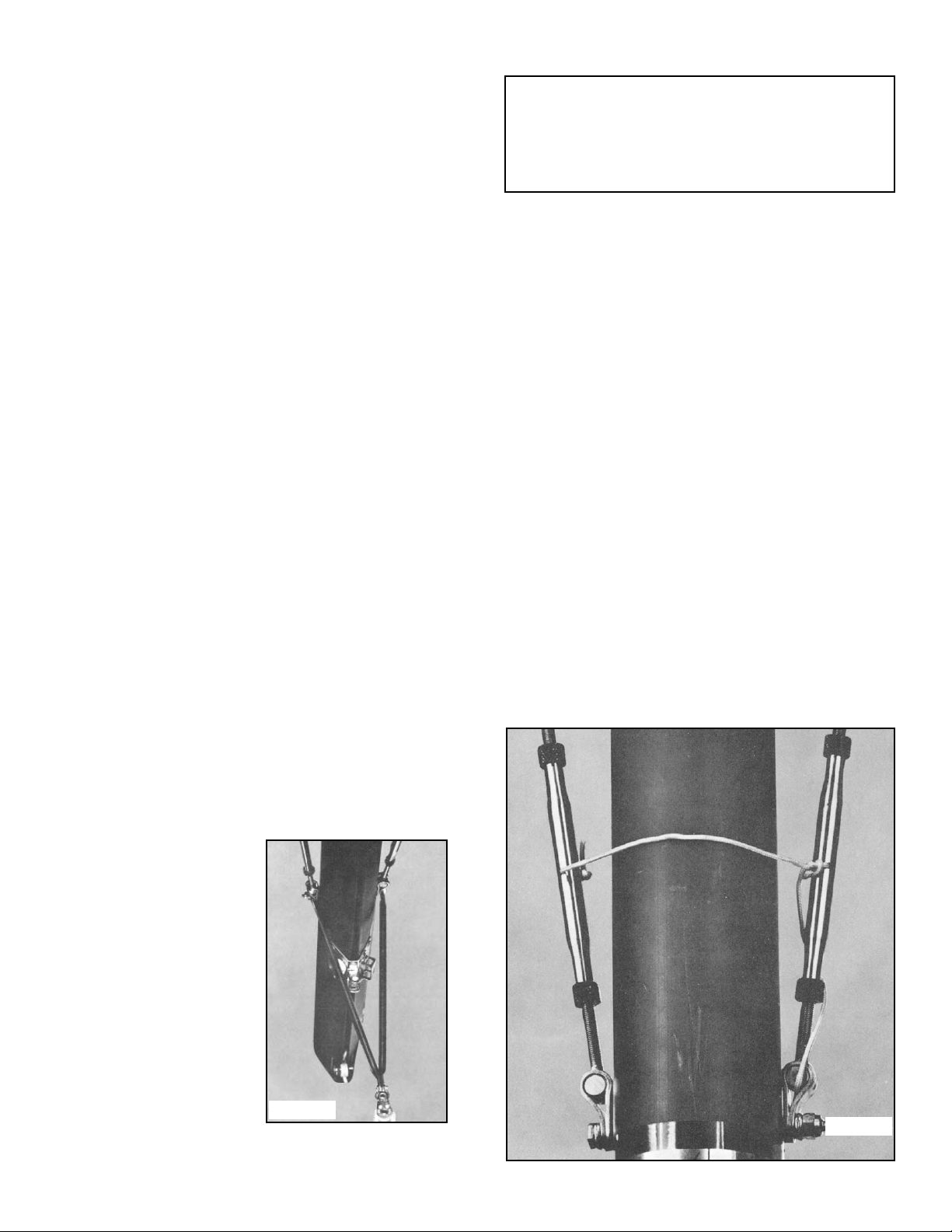

1. Secure the four trapeze wires near the bottom of the

mast so that they will be out of the way while the mast is

being raised.

2. Attach the jib halyard line to each end of the jib

halyard wire to form a very large loop. Tie the line

around the fork at the bottom of the forestay. The

halyard line must be connected to the wire before the

mast is raised or you will be unable to hoist the jib later.

See Illustration.

3. Carry the mast over to the boat and place the hinge

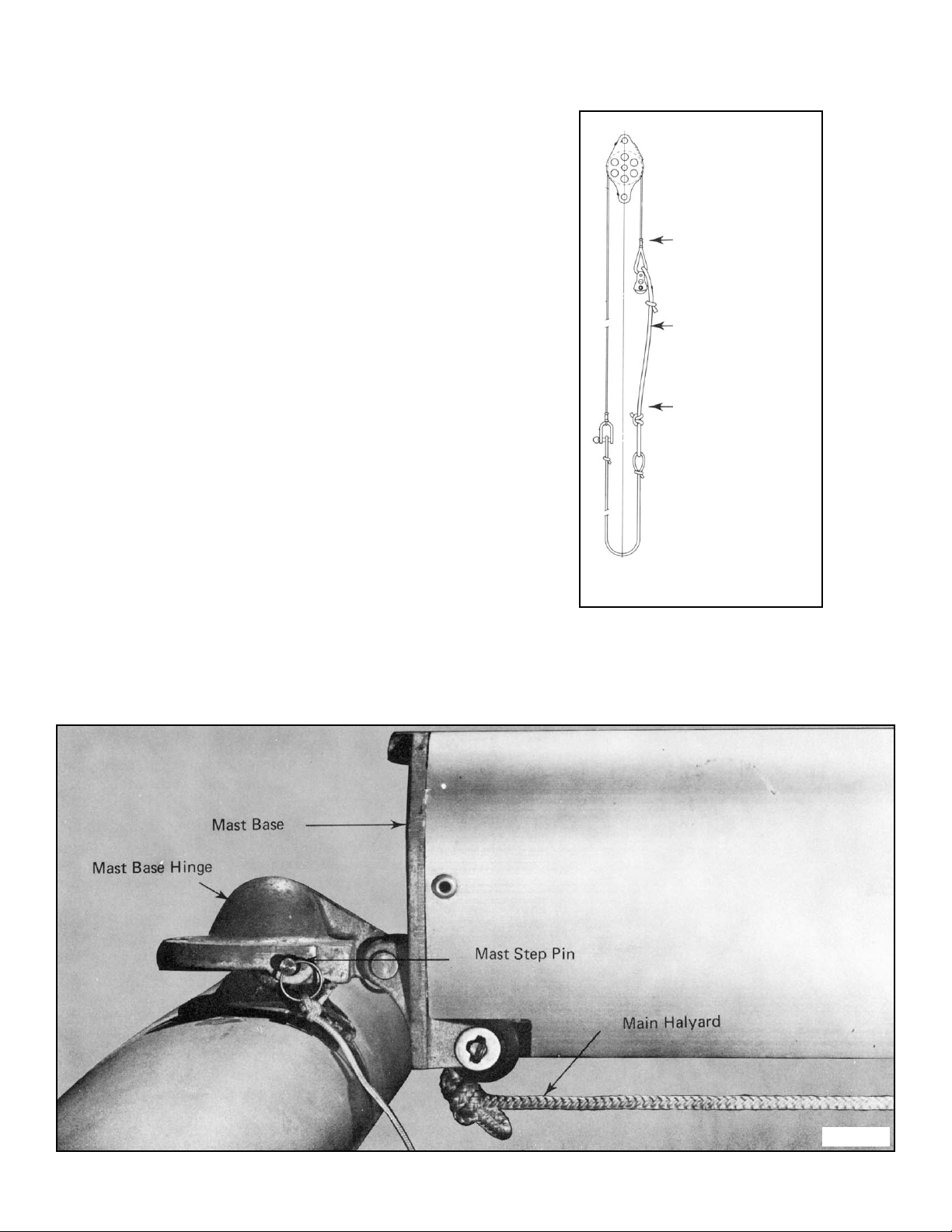

of the mast base over the mast step which is located on

the front bar, see Figure 17. The sail track should be

facing down. Note: when lowering the mast over the

trampoline be sure to guide the mast rotation control

yoke between the trampoline halves.

Figure 17

Figure 16

9

Jib Halyard Wire

Luff Tensioner

Jib Halyard Line

Page 12

4. With the hinge in place over the step insert the mast

step pin through the entire assembly so that it is visible

on the opposite side on the hinge.

5. Attach the bridle wires to the bow tangs. Attach the

roller furler mechanism between the bridle wires. Make

sure the oblong hole

in the roller furler is

aft. See Figure 18.

6. Attach the port

shroud to the port

stay adjuster and the

starboard shroud to

the starboard stay

adjuster. Secure the

shrouds to the top

hole in the stay

adjuster at this time.

See Figure 19.

7. Secure the base

of the stay adjuster

to the anchor pin on

the respective hull.

CAUTION:

We recommend two people for stepping the mast. It

is heavy for one person and could slip causing

injury or damage.

8. Stand on the trampoline next to the back bar and

raise the mast to your shoulders. Make sure the shrouds

are not fouled and the stay adjusters are free before

advancing further. Do not raise the mast in an area with

any overhead wires. If everything is clear walk straight

ahead raising the mast as you go. See Figures 20, 21,

and 22.

9. Once the mast is in the vertical position lean your

weight against the

mast to hold it in

place. The second

person can now let

go of the mast and

attach the forestay

to the top of the

stay adjuster which

extends from the

roller furler

assembly. See

Figure 18.

10. Remove the

mast step pin only

after the forestay

has been secured.

Store the pin in the

pouch on the

trampoline.

11. Once the mast

has been raised

untie the trapeze

wires. In the rig kit

you will find a bag

which contains 4

trapeze dogbones,

4 rope locks and 4

trapeze adjusting

lines.

12. Tie the

adjusting line onto

one of the

shockcord loops

which is located at

the outside rail

adjacent to the stay

adjuster.

Figure 22

Figure 21

Figure 20

Figure 19

Figure 18

10

Page 13

13. Lace it through the rope lock and then through the

thimble at the end of the trapeze wire. Now tie the line

onto either end of the dogbone. See Figure 23.

14. Repeat this process for the other three trapeze wires

at the respective locations.

BOOM INSTALLATION

1. Attach the gooseneck pin which extends from the

front of the boom to the gooseneck yoke on the mast.

See Figure 24.

2. Tie the line which was packed with the mast

rotation

control yoke to the forward-most jam cleat on the boom.

See step 11 of mast assembly. Run the line through the

JIB BLOCK INSTALLATION

1. The large jib blocks are packed in the rig kits.

Remove the jib track end stop on the jib track and slide

the car on the bottom of the block into the track. See

Figure 25. Note that the slide adjustment knob is aft of

the block assembly.

Figure 25

Figure 24

Figure 23

11

block on the end of the mast rotation control yoke and

then feed it through the jam cleat. Tie a knot

in the end of the line so that it will not slip back through

the jam cleat.

See Figure 35.

Once again, be sure to note that this is the older

style of mast rotator. With the newer style, the line

does not run through a pulley, but through a ring at

the end of the control yoke. Run the line through

the ring and into the jam cleat.

Page 14

Hobie 18 and SX18 UPDATES

INSTALLING THE RUDDER ASSEMBLY

The rudders were updated after 1987. The newer

rudders use a black plastic cam to lock the rudder in the

down position. Locate the left and right rudder

assemblies. The left one has a red dot and the right one

a green dot. The tiller arms should have a slight bow

towards the centerline of the boat.

As shown in the original instructions, position the

rudders at the transom. There are two bushings and two

washers provided with the each new assembly. Slide

the bushings in from the bottom and place the longer

one in the lower casting hole. Install a cotter key in each

rudder pin. Assemble as shown below. Then insert the

remaining cotter keys in the top of the rudder pins to

hold the rudders in place.

INSTALLING THE TILLER CONNECTOR

The tiller arms have swivels on the ends. Point the

connector rods upwards and slide the tiller connector

end fitting over the rods. Place the adjustable end of

the connector rod to the port (left) side of the boat. Pull

the small tabs forward and over the rod and lock them in

the slots. Rudder toe-in adjustments can be made with

the threaded end fitting on the tiller cross bar. Typical

adjustment has rudders in parallel.

INSTALLING THE SAIL BATTENS

Unfold the sail and lay it out on the trampoline. There

will be a small bundle of thin lines tied to the top of the

sail. These are the batten tension lines. Tie the batten

tension lines to one of the small grommets at the end of

each batten pocket as diagramed in figure 28 (one to

each batten pocket). Tie the lines using a bowline knot

as found in the "knots" diagramed on page 4. It is best

to tie the lines all to one side of the sail. Insert each

batten (shortest batten at the top to longest batten at the

bottom of the sail).

Note that the batten ends have a "V" jam cleat

molded into them. These "V" jam cleats will keep

the tension line from slipping in only one direction.

Note the hollowed-out side of the cleats. Pull the

line from the flush side toward the hollowed side.

The upper batten is narrower and has a different cleat

shape. To be sure this cleat works correctly, position it

so that the hollowed out side of the cap faces the

bowline that you have tied to the sail grommet. Position

the larger caps so that the hollowed sides face away

from each knot.

Following the diagram in figure 28, lace the tension lines

through each batten end cap. Pass the line through the

hole in the cap, then through the grommet on the

opposite side. For the smaller caps, pass the line over

the "V' cleat, pull tension forcing the batten into the

pocket, then pull the line into the cleat to hold it. For the

larger caps, pass the line through the second hole in the

cap, then pass the line through the first grommet and

back to the "V" cleat. Pull tension on the line forcing the

batten into the pocket and cleat it. Tie a small figure 8

knot in the end 1 of each line to prevent the battens

from falling from the sail if the line releases from the

cleat. Tension each batten so that the batten is well

seated and the wrinkles in the batten pockets are

removed. Excessive batten tension will cause the sail to

be more difficult to handle.

12

Figure 27

Figure 28

Figure 26

Page 15

13

RUDDER AND TILLER CROSS BAR

INSTALLATION (Pre 1987 boats)

1. Disengage the tiller arm from the lower casting and

lock the tiller arm and rudder in the kicked up position.

This will pull the rudder blade up and out of the way so

the rudder pin can be installed.

2. Hold the lower casting up to the transom of the boat

and fit the casting over the gudgeons. Slide the rudder

pin up through the casting and gudgeons with the hole

in the rudder pin closest the bottom. Once the hole in

the pin is above the casting at the lower gudgeon, stop

and insert the cotter key which is packed with the rudder

pins. Bend over the legs of the key to secure it in place.

The rudder can be lowered now. See Figure 29 and 30.

3. To distinguish the port rudder from the starboard

rudder, the port rudder arm will bend toward the center

of the boat when on the port hull.

4. Attach the tiller cross bar to the tiller arm as shown in

figure 31.

Figure 32

Figure 31

Figure 30

Figure 29

Page 16

14

RAISING THE SAILS

1. Point the boat into the wind before you begin this

operation.

2. Lay the main sail out on the trampoline. Insert the

battens into the batten pockets starting at the top of the

sail and working your way down. The batten has a tip on

each end. The end without any holes goes into the sail

first. Slip the batten in until it seats into the batten

pocket protector at the leading edge of the sail.

3. Thread the batten tie through the aft batten tip and

the sail as shown in Figure 33. Secure the end of the

batten ties with a figure eight knot.

4. Attach the twist shackle on the end of the main

halyard to the grommet in the headboard and feed the

sail into the sailtrack in the mast. See Figure 34. Note

the metal ring connected to the twist shackle. It will

engage the latching mechanism at the top of the mast.

(see Figure 34a). Continue to raise the sail by pulling

the main halyard out from the base of the mast.

5. It is recommended that you lubricate the leading edge

of the sail with paraffin from time to time to reduce wear

from the sail track. It will also make it easier to raise the

sail.

6. Raise the sail until the metal ring above the halyard

shackle engages the halyard hook at the top of the

mast. Store the excess halyard line in the pouch on the

trampoline.

7. Tie the downhaul line to the tack of the sail and lace

the downhaul as shown in Figure 35.

8. Attach the outhaul car on the boom to the clew of the

main. See Figure 36.

9. To lower the main, untie the downhaul and slide the

leading edge of the sail up the sailtrack a few inches.

Next pull hard on the main halyard and the metal ring

and the top of the sail will overrun the halyard hook,

rotate the mast to the starboard then release the

halyard.

Figure 34

Figure 33

Figure 34a

Page 17

10. Attach the three boom blocks to the hangers on the

boom. Secure the ratchet block to the top of the traveler

car. Thread the mainsheet through the blocks as shown

in Figure 37. Slip the other end of the mainsheet

through the traveler jam cleat, then guide the line

through the center of the traveler, and secure at the

dead eye on the back bar.

11. With only the main sail up tighten the shrouds. First

move the traveler car all the way over to the port side of

the back bar. Next pull the mainsheet in very hard. The

port shroud should be slack now and can be moved

down in the stay adjuster. Repeat this procedure for the

starboard shroud. Note: Tension on the shrouds must

be relieved before lowering the main sail. If you intend

to unstep the mast.

H18SX Downhaul Instructions

1. Using the twist shackle, attach the double block to the

sail luff grommet.

2. Tie off the downhaul line (10' of 3 /16" yt braid) to the

sail luff grommet.

3. Run the line through the cheek block on the left hand

side of the gooseneck yoke.

4. Continue to the double block, then to the cheek block

on the right hand side of the gooseneck yoke, then back

through the second sheave on the double block.

5. Tie off on mast downhaul cleat located below the

boom.

15

Note: Old style mast rotator shown here.

Figure 37

Figure 36

Figure 35

Page 18

16

Raising the Jib

1. Attach the shackle on the end of the jib halyard wire

to the head of the jib.

2. Wrap the luff pocket of the jib around the forestay and

engage the zipper an inch or so. Next thread the jib

halyard line inside the luff pocket. See Figure 38.

3. Raise the sail by pulling on the jib halyard line and at

the same time advance the zipper down the luff until the

jib tack is even with the roller furling housing.

4. Attach the jib tack to the shackle on the neck of the

roller furling housing. .

5. Untie the jib halyard line and connect the luff

tensioner to the block on the end of the jib halyard.

Thread the tensioner down through the tack shackle,

then back up through the block on the jib halyard.

Secure the line in the jam cleat on the sail. See Figure

39.

6. IMPORTANT. Only apply the jib luff tension after the

shrouds and forestay have been tightened. To do so

beforehand could result in the jib halyard being broken

when the slack in the shrouds is taken up.

7. Attach the jib clew blocks to the jib clew, see Figure

40.

8. Thread the jib sheet through the port jib block, then

around the jib clew block. Take the line back and tie it

off at the becket on the jib block. See Figure 41.

9. Thread the remaining portion of the jib sheet through

the starboard jib block in this same fashion.

10. The roller furler line can be temporarily secured in

the jam cleat on the back side of the front cross bar.

Roller furler line adjustment on

take up spool.

a. Disconnect jib clew blocks

from jib clew.

b. Pullout the roller furler line

from the housing until the take

up spool is empty and secure the

line to the cleat on the front bar.

c. Wrap the sail clockwise

around the forestay until it is

completely furled.

d. Reattach the jib clew blocks to

the jib clew. The jib is now in the

furled position.

To unfurl the jib, release the

roller furler line which is cleated

on the front bar, and pull on the

jib sheet.

To furl the jib, release the jib sheet (both port and

starboard) pull the furler line until the jib is completely

furled. Do not partially furl the sail, this will cause

uneven stretching of the exposed sail.

Figure 41

Figure 40

Figure 39

Figure 38

Page 19

DAGGER BOARDS

1. Slip the shock cord through the hole in the upper

portion of the dagger board, take both ends to the hole

on the out board deck flange. Pass both ends through

the hold and tie a knot under the rail.

2. Pass the rope handle through the same hole in the

dagger board as before. Tie the two ends together to

form a large loop which will serve as the handle. See

Figure 42.

3. When raising or lowering the board do not rock it fore

and aft. This will cause damage to the trailing edge. Pull

the leading edge of the dagger board aft about 1/4 of an

inch so that it is not contacting the lip of the deck and it

can be easily moved up and down.

4. IMPORTANT. If you expect contact with an object or

the shore, pull the dagger boards up out of the way.

Severe damage can resuIt if the boards contact any

solid object regardless of the speed.

17

Figure 42

Page 20

HOBIE CA

HOBIE CA

T 18

T 18

’

’

18

Page 21

19

INDEX

NO. DESCRIPTION

1 Arm

2 Brace

3 Slide

4 Diamond Wire (one side)

5 Gooseneck Yoke

6 Check Block

7 Mast Rotation Line

8 Modified Swivel Block

9 Shackle

10 Mast Rotation Assembly

11 Pin-Pawl Bearing, 5.5.

12 Ring-Halyard Line

13 Hook for Halyard Lock Assembly

14 Jib Furling Assembly

15 Bridle Wire Assembly

16 Screw - 5.5. (1/4 x 20)

17 Back Up Plate - Bow Tang

18 Nylock Nut (1/4 x 20)

19 Mast Tang

20 Trapeze Wire (one side)

21 Shackle

22 Shroud

23 Pigtail with Swivel

24 Jib Halyard Block Assembly

25 Clevis Pin

26 Mast Hinge Casting

27 Mast Base Casting

28 Screw RD. HD. 1/4 x 20

29 Star Lock Washer

30 Sheave

31 Clevis Pin

32 Washer

33 Bushing

34 Pad. Mast step

35 Mast Step

36 Rivet

37 Left Front Corner Casting

38 Boom Outhaul Slide Assy.

39 Cotter Key

40 Outhaul Car

41 Clevis Pin

42 Sheave

43 Rollers

44 Pin

45 Outhaul Line

46 Boom

47 Boom Block

48 Single Block with Becket

49 Boom Block

50 Main Sheet Line

51 Triple Block

52 Left Rear Corner Casting

53 H-18 Ratchet Block

54 Traveler Assembly

55 Channel

56 Bushing

57 Bolt 3/8 x 16 - 3 (rear only)

58 Swivel Main Sheet Fairlead

59 Rear Crossbar

60 Tiller Crossbar with Rudder Adjuster

61 Tiller Arm Bent

62 Upper Rudder Arm Right/Starboard

63 Right Rear Corner Casting

64 Channel

65 Nylock Nut - versus drawing

66 Upper Rudder Casting

67 Lower Rudder Casting - bare

68 Rudder Pin

69 Lower Gudgeon

70 Jib Sheet Line

71 Jib Sheet Block

72 Front Crossbar Assembly

73 Right Front Corner Casting

74 Bolt - Cover Plate

75 Flange

76 Storage Cover w/Handle

Page 22

20

Illustration No. 1

Mast Assembly

1-1 Spreader Arm

1-2 Spreader Root

1-3 Clevis Pin 3/16" x 11/16"

1-4 Slide

1-5 Clevis Pin 3/16" x 13/16"

1-6 Brace

1-7 Clevis Pin 3/16" x 9/16"

1-8 Cotter Pin

1-9 Mast Rotation Control Yoke

1-10 Block

1-11 Shackle

1-12 Bolt 4-1/8" Lg.

1-13 Diamond Wire

1-14 Mast Base Assembly

1-15 Nut Nylock

1-16 Diamond Wire Tang

1-17 Mast Tang

1-18 Mast Extrusion

1-19 Clevis Pin 3/16" x 1/2"

1-20 Cotter Pin

Old Style Yoke

New Style Yoke

Page 23

21

Illustration No. 2

Jib Halyard Assembly

2-1 Jib Block Housing

2-2 Jib Halyard Wire

2-3 Luff Tensioner

2-4 Jib Halyard Line

2-5 Jib Block Sheave

2-7 Clevis Pin

2-8 A Cotter Pin

2-9 Swedge

2-10 Thimble

2-11 Block

2-12 Shackle

Illustration No. 3

Tiller Connector Kit

3-1 Bolt

3-2 Half Ball

3-3 Tiller Crossbar

3-4 Plastic Washer

3-5 Tiller Arm

3-6 Washer

3-7 Spring

3-8 Nut

Page 24

22

*Rudder system Pre-1987 shown

Illustration No. 6

Rudder Assembly

6-1 Rudder Blade-Drilled

6-2 Lower Rudder Casting Assembly

6-3 Port Upper Rudder Housing Assembly

6-4 Nut Nylock

6-5 Bolt 2" Lg

6-6 Spring

6-7 Delrin Screw

6-8 1 / 4" I.D. Nyliner

6-9 Rudder Cam

6-10 Upper Rudder Housing Casting

6-11 Rivet

6-12 Locking Sleeve

6-13 Pin Upper Rudder Housing

6-14 Pin Lower Rudder Housing

6-15 Tiller End Cap

Illustration No. 7

Outhaul Car Assembly

7-1 Adjuster Pin Retaining Ring

7-2 Outhaul Slide Car

7-3 Clevis Pin 1 /4" x 7 /8"

7-4 Ball Roller Bearing

7-5 Clevis Pin 1 /4" x 5 /8"

7-6 Pin-Bearing

7-7 Sheave

7-8 Cotter Key

Page 25

Illustration No. 8

Traveler Assembly

8-1 1- 1/4" Lg H.H. Bolt

8-2 Deck Plate

8-3 Sheave

8-4 Spacer

8-5 Car Assembly

8-6 Cotter Pin

8-7 H.H. Nuts-Nylock

8-8 Bearing Cylinder

8-9 Pin-Clevis

8-10 Bearing Ball

Illustration No. 9

Roller Furler Assembly

9-1 Upper Retaining Ring

9-2 Top Nyliner

9-3 Bottom Nyliner

9-4 Yoke

9-5 Housing

9-6 Interior Retaining Ring

9-7 Bearing Sleeve

9-8 Bearing Race

9-9 Bearing Cage

9-10 Bearings

9-11 Tube

9-12 Spool

9-13 Screw Truss Head

23

Page 26

Illustration No. 10

(old style)

Dolphin Post Assembly

10-1 Screw RHMS

10-2 Internal Lock Washer

10-3 Washer

10-4 Mast Step Pad

10-5 Bushing

10-6 Mast Step Casting

10-7 Dolphin Striker Post

10-8 Dolphin Striker Sleeve

Illustration No. 11

(new style)

Dolphin Post Assembly

11-1 Screw RHMS

11-2 Washer

11-3 Bearing

11-4 Mast Step Casting

11-5 Dolphin Striker Post

11-6 Dolphin Striker Sleeve

24

Page 27

Illustration No. 12

(new style)

Tiller Connector

12-1 Tiller Connection Rod

12-2 Tiller Arm Swivel End Cap

12-3 Tiller Arm Insert

12-4 Bolt

12-5 Washer

12-6 Insert Bearing

12-7 Retainer Clip

12-8 Screw

Parts Relating to Diagram on Page 2

11 Trapeze Seat Assy.

2 Trapeze Seat

2 Trapeze Hook

2 Trapeze Lacing Line 6'

12 Mast Rotation Control Yoke Assy.

2 Mast Rotation Control Yoke

1 Shackle 1 Block

1 Mast Rotation Control Line 3'

1 Mast Rotation Control Yoke Retaining Bolt

1 Retaining Bolt Nut

13 Spreader Assy.

2 Spreader Arm

2 Brace

2 Slide

2 Spreader Arm Root Pin 3/16" x 11/16"

2 Spreader Arm Slide Pin 3/16" x 13/16"

4 Brace Pin 3/16" x 9/16" 8 Cotter Pins 1/2"

2 Spreader Arm Tip Cotter Pins 3/4"

14 Adjustable Trapeze Equipment

4 Dogbone

4 Rope Lock

4 Adjustable Trapeze Line 30"

15 Dagger Board Kit

2 1/4" Shock, Card 46"

2 1 /4" Rope Handle 29"

16

2 7 Hole Stay Adjuster Assy.

2 Drain Plug

2 Drain Plug Gasket

1 Tiller Connection Kit

17

2 Rudder Pin

2 Cotter Pin for Rudder Pin

2 Jib Clew Block

1 Shackle

1 Gooseneck Vertex

1 Clevis Pin "

1 Split Ring

1 Gooseneck Bolt

1 Nut

17 A 1 Down Haul Line

18 Bridle Wire Clevis Pins

4 Bridle Wire Clevis Pins

4 Split Rings

18A Diamond Wire Clevis Pins 1

2 Upper Diamond Wire Clevis Pins

2 Cotter Pin

19 Mast Step Pin

1 Mast Step Pin

1 Split Ring

1 Mast Step Pin Retaining Line

20 Traveler Bearing Kit

1 Traveler Bearing - Ball

1 Traveler Bearing Slug

1 Long Cotter Pin

21

8 Retaining Channel

2 Front Bar Inboard Bolt 3 3/ 4"

2 Front Bar Outboard Bolt 2"

2 Rear Cross Bar Inboard Bolt 2 1/2"

2 Rear Cross Bar Outboard Bolt 2"

4 Lock Nuts for 802-359 Outboard Bolts

2 Bridle Wire

2 Diamond Wire

2 Trapeze Wire

25

Page 28

26

SAILING YOUR HOBIE 18’

Safe and sane guideline for the beginner; and an easy

review for the experienced.

Always wear a life jacket when boating.

BALANCING THE BOAT

When sailing, sit on the upwind side of the boat (wind on

your back) just in front of the tiller, facing the sail.

Balance your weight further outboard as the boat begins

to tip or heal over with the wind in the sails. Tuck one

foot under the hiking strap for balance. Use your hand

that is forward to hold and control the mainsheet. Use

your hand that is aft to steer.

STEERING

Steer the boat by pushing the tiller away from you to

turn towards the wind. Pull the tiller towards you to turn

away from the wind. Keep the movement of the tiller to a

minimum to prevent over-steering. This will help you

keep the boat moving in a straight line as you pay

attention to other watercraft and sail adjustments.

SAIL POWER

Face the sail in order to pay close attention to the trim or

adjustment of the sail. When the front of the sail, just

behind the mast, luffs or flutters in the breeze, you lose

power. To start moving, pull the sail in just enough to

stop the sail from luffing. There are also short ribbons

hanging on either side of the sail. Follow the diagram of

sail and course adjustments above using the "tell tails"

to get the most performance out of the sail for all angles

of sailing. The tell tails react to air flowing over the sail

and will help you see that the sail is pulled in too tight or

too loosely. If you pull the sail too tight you will stall the

sail power. Ease the sail out until it luffs, then pull it in

just a little until it stops luffing. You will adjust the trim

whenever the wind changes direction or you change

course.

Refer to the sail trim diagram below for approximate sail

settings for the different points of sail or directions you

will be sailing. Note the "can't sail zone". You cannot sail

in this direction due to the fact that the sail will luff

constantly when pointed into the wind. If you get stuck in

irons (or stop pointed into the wind) you will need to

reverse the rudder and push the sail forward to backwind it. The jib should be back winded by the crew to

assist. This will back the boat up. Reverse the rudders

and let the sail out until the boat is positioned more

across the wind (close reach). Then you can correctly

trim the sail and start moving forward.

WIND

COMING

ABOUT

FALLING

OFF

HEADING UP

WIND

CAN'T SAIL IN

THIS AREA

Close Hauled

Close Hauled

Close Reach

Close Reach

Medium Reach

Broad Reach

Medium Reach

Broad Reach

Downwind Run

Page 29

27

TURNING

To tack or turn the boat into and across the wind to the

opposite direction (also known as "coming about"),

follow the points of sail guide illustration and take the

boat to the close hauled point of sail. This is when you

are nearly 35 degrees from sailing straight into the wind.

With the boat moving forward and not stalling, push the

tiller away from you slowly. When the boat is pointing

straight into the wind the boat will become level. Ease

the mainsheet trim out just a little. At this time move

your body to the other side of the boat, switch hands

with tiller and mainsheet and begin to bring the rudder

back to straight. The crew should move across the

trampoline at the same time. The crew is responsible to

ease the jib sheet just after the main sail is released and

sheet the jib onto the new course before the mainsheet

is trimmed. This action by the crew will prevent the boat

stalling head to wind. As the boat comes across the

wind and falls off onto the opposite, close hauled point

of sail, bring the tiller all the way back to the straight

position and pull the mainsail back in for the proper sail

trim. If you stall pointing into the wind and you cannot

steer the boat, refer back to the sail power description

concerning getting stuck in irons.

When sailing downwind, the turn from one point of sail

across to the other is called a jibe. The jibe is completed

by turning away from the wind (falling off) to the

opposite point of sail rather than into the wind as when

tacking. Care must be taken when attempting a jibe as

the boat will be at full power and you cannot easily depower it without turning back into the wind. Also, be

aware that the boat will be less stable in this maneuver

as the sail will now have to swing clear across from fully

out one side of the boat to fully out the other.

To start a jibe, turn the boat away from the wind and let

the sail out slowly. Keep the turn going at a steady rate

and begin pulling the sail back in as the boat nears the

straight downwind direction. This will help prevent the

sail from slamming all the way across when the sail fills

from the opposite side. Duck below the sail to avoid

getting hit as the wind fills the sail from the opposite side

and swings across the boat. Attempt to control the

speed of the sail while it crosses the deck by

maintaining some tension on the mainsheet. Then ease

the mainsheet out quickly as the boat turns past the

downwind direction onto the new point of sail. Trim the

sail correctly for the desired point of sail.

LAUNCHING THE BOAT

Launching the boat is easiest when the boat can be

pointed into the wind to keep it de-powered and floated

into deep enough water to lower the rudders. It is

possible to launch in shallow water with the rudders

partly up. Try not to steer with too much force on the

rudders until you lock them in the down position. Keep

the sail loose and trimmed out completely until you can

power up and steer away from any obstacle. Trim the

sail in quickly to get the boat moving forward and steer

away from the wind slightly to prevent stalling into the

wind.

When launching from a beach where the wind is blowing

from the beach towards the water you simply keep the

boat pointed into the wind. Drift backwards with the

rudders in the up position and your weight towards the

front of the boat. Stay forward as the boat drifts into

deeper water.You can hold the sail out to catch wind

backwards to increase reverse speed. Then move to the

rear and lower the rudders. It will be easiest to lower

only one rudder while moving backwards. Then lower

the other when the boat begins to move forward again.

Be aware of the intended direction you wish to sail when

lowering the rudder and steer the boat as the rudder

drops into the water. There will be a lot of force on the

rudder to turn one way or the other when going

backwards. Plan ahead and steer the rudders so that

they will be pointing in that direction before dropping it

into the water. Steer the boat while going backwards so

the bow turns away from the wind and toward the

direction you wish to sail. As the sail begins to fill with

wind, the boat will slow then begin to move forward.

Trim in the sail and off you go.

RIGHTING THE BOAT

If you tip the boat over, stay with the boat. The boat will

not sink and is easy to right. It is not necessary, but it is

easier, to right the

boat when the bow

and the mast are

pointed into the

wind as in the

following diagram.

There will be less

wind resistance

and better control

in this position. Be

sure the mainsheet

is released, then

swim around to the

bottom of the boat.

Skipper and crew should climb up on the hull and stand

up. Using the righting line, skipper and crew pull the

righting line that is against the upper hull and hold the

Page 30

28

line while slowly leaning back away from the trampoline.

Lean to approximately 45 degrees for best leverage. As

the mast and sail lift out of the water and the upper hull

begins to drop back into the water, drop down to your

knees then into the water. Hold onto the righting line

near the crossbar or the crossbar itself near the hull that

you were standing on. This will prevent the hull from

being lifted into the air by momentum which could cause

the boat to capsize once again. Be well aware of the hull

and crossbar coming down over your head. Holding the

crossbar or righting line will also insure that you remain

with the boat when it is righted. Climb aboard and

continue sailing. Be well aware of the hull and crossbar

coming down over your head. Holding the crossbar or

righting line will also insure that you remain with the

boat when it is righted.

DOCKING

Docking the Getaway properly will prevent damage.

Always dock and rig on the leeward side of a dock (the

side the wind reaches last). Come in slowly and always

be aware of the wind direction so you can properly depower the boat when needed. The stronger the wind the

more difficult the docking will be. Until you feel

confident, you may want to practice with a friend who

will remain on the dock and help slow you down if

necessary.

BEACH LANDINGS

Landing on a beach is simple. The idea is to reach the

beach in the point of sail nearest straight into the wind

as possible. This will assure that you can properly depower the sail once beached.

Approaching a beach when the wind is blowing from the

beach out towards the water will require some planning

so that you maintain power. Turn into shore just before

the hulls or rudders touch bottom. Plan so the final tack

towards the location you choose to land is the tack that

is nearest straight into the wind. Get a little closer to the

beach than you need on the pervious tack to account for

wind shifts in direction and speed. This will give you a

little room for error. This will allow you to point a little

further away from the wind after the tack to gain speed

before heading up into the beach to de-power at the last

moment.

When approaching a beach when the wind is blowing

onshore, sail in towards the beach from either side of

the landing spot. Sail in just short of touching the bottom

with the rudders. Allow some distance to turn the boat

out towards the water and into the wind just out from the

landing spot. Turn sharply to head into the wind and

stall the boat. Raise the rudders and drift back onto the

beach. Always keep the boat pointed into the wind

while beached and keep the sail trimmed out and uncleated.

RUDDER TUNING

You may adjust the rake of your rudder blades on your

Hobie Getaway. The amount of rake in a rudder blade

affects the "feel" at the tiller. Basically, more forward

blade rake neutralizes the pull on the tiller and less

forward rake increases the pull on the tiller. Tuning

blades for a comfortable feel is a matter of individual

preference but a close to neutral "feel" generally

provides the best steering. The following sketches are of

a Hobie 16 rudder assembly

but the adjustments are the

same.

1) The first step in making

any rudder rake adjustment

is to determine the existing

rake. This is done with the

rudder assembly hanging on

the boat's transom, blade

down and locked. Using a

straight edge or snap line,

extend the centerline of the

rudder pivot pins down,

across the leading edge of

the blade and draw a pencil

line along that length. Measure the distance from the

pencil line to the most forward spot 12" down the blade

from the bottom of the casting.

Rudder blade rake is pre-set at the factory to 1-1/8".

This amount will be best for the average sailor and is a

good starting point from which to begin any

adjustments.

2) To make any adjustment to the rake, unlock the tiller

arm from the rudder housing and leave it unlocked.

3) If you wish to increase the amount of forward rake in

the rudder blade, turn

the rake adjusting screw

counterclockwise using

a 3/16" Allen wrench.

Determine the increase

in the rake by extending

a new line from the

centerline of the pivot

pins. Re-measure the

distance from the pencil

line to the leading edge.

1-1/8"

Aft for more pull on

the tiller

Forward for less

pull on the tiller

12"

Screw

Sketch B

Page 31

29

6) Hobie Cat rudder

blades are preset to

break away from the

locked down position at

17-26 pounds by testing

with a line around the

rudder blade seven

inches above the lowest

tip of the blade. Once

the rake is changed, the

breakaway tension

should be rechecked.

The tension may be

adjusted by turning

the 3/4" internal

screw in the

housing. The screw

tensions an internal

spring. Turn it

clockwise to

increase and

counter clockwise to

decrease the tension.

TRAILERING

CAUTION: Boat and mast should be securely attached

to trailer with adequate tie-down straps. Failure to do so

could cause extensive damage or serious injury!

LOADING YOUR TRAILER

The weight of the boat, equipment and additional gear

should never exceed the manufacturer's rated weight

capacity. Proper distribution of the load is of vital

importance. Too much weight on the hitch will cause

Continue to adjust and measure until you have the desired

amount of forward rake.

4) If you wish to decrease the amount of forward rake turn

the adjusting screw clockwise using a 3/16" Allen wrench.

Check the decrease in the rake by the procedure in step 3

above .

5) Next, while holding the rudder forward against the lower

casting, carefully latch the tiller arm down onto rudder

housing. Loosen the adjusting screw on top of the tiller arm

about 3/4 turn. Slide the adjusting screw forward (toward

bow of boat) until it stops, then retighten. See sketch C.

Sketch C

Screw

"tail dragging" of the towing vehicle, impairing steering

and raising headlights into the eyes of oncoming traffic.

Too little or negative weight on the hitch, and the trailer

will sway or "fishtail". The solution to proper distribution

is often adjusting movable gear. A more permanent

solution is to shift the axle position before taking your

boat to water the very first time.

TOWING

Extra caution is necessary when towing any trailer. The

heavier the rig, the more time required to accelerate,

pass, and stop. For this reason, the maximum speed for

vehicles with trailers is less than without a trailer in most

states. A long rig requires a larger turning radius. Curbs

and obstructions should be given wide clearance. Most

boats on trailers obstruct the rear view of the driver.

When this happens, an additional rear view mirror on

the right side of the towing vehicle is required by law.

The trailer boatman should be familiar with traffic and

highway laws relating to the towing of trailers. Towing a

Hobie has particular hazards that should be mentioned.

A Hobie is very wide. Obstacles should be given plenty

of room when you are passing them. Tie down straps or

lashings should be of sufficient size and diameter and

placed on all four corners.

The mast support on a trailer is subject to a lot of

side-to-side motion and consequently may fatigue

where it is welded to the trailer. All this can be reduced

by tying a line from each bow to the mast support. This

will stiffen the rig up and prolong the life of the trailer.

LAUNCHING AND RETRIEVING

Prepare boat for launching at the top of the ramp or

parking facility. Remove all tie-down straps, check boat

plugs and fasten boat painter. Do not release winch line

until the boat is in the water. Back trailer to the left if

possible; backing left gives better launching visibility.

Avoid dunking wheel bearings wherever possible. Never

leave the towing vehicle unattended on the ramp with

only the parking brake set. If vehicle must be left while

on the ramp, set transmission in "park" or first gear, in

addition to setting the parking brake. In retrieving your

boat, make sure that the boat is properly placed on the

trailer. Pull trailer up steadily to prevent spinning the

wheels.

MAINTENANCE

Lights: Most state laws require two red taillights on the

rear that may be combined with the stop and turn

signals. Vehicles over 80 inches in width require

clearance lights. If lights are dunked, waterproof light

fixtures should be used. If water is allowed to enter, the

lamp may crack and short out the entire system. Water

also promotes contact corrosion. Always carry spare

Page 32

A good anti-fouling paint can be applied for some

protection from marine growth before mooring. Before

painting, it is suggested that the area be masked off to

ensure a clean line. No friction reducing paints or agents

may be employed on a Hobie Cat during competition.

HOBIE CLASS ASSOCIATION

The Hobie Class Association was started by a group of Hobie

owners who got together back in 1968 to organize some

racing and other activities. Hobie was the mainstay of the

group promoting the activities himself. At that time, it wasn't

really a class association but simply a group of owners

wanting to have fun with their new toys. Hobie would write

brief newsletters from the factory announcing regattas as they

developed across the country. He published a set of class

rules rigidly restricting changes and modifications which can

be made to the boat. As the class started to grow, people were

hired to help administer the program. At that point, the

association became a little more formal: the groundwork for

the establishment of fleets was developed and the Hobie Cat

Hotline was initiated as a class newsletter.

The Class Association was originally organized around one

basic consideration: to extend each Hobie owner's enjoyment

through organized, family oriented activities. Innovations were

made in racing procedures and the regatta structures. A

policy of including the whole family in the activities developed

to assure everyone would have fun at Hobie regatta. The

Association continually strives to develop better programs so

owners may further enjoy their Hobies

KNOW YOUR KNOTS

FIGURE 8 KNOT

BOWLINE KNOT

HALYARD KNOT

CLEATING OFF A LINE

30

lamps. The wire coupling to the towing vehicle should

be high enough to stay dry. Never rely on the trailer

hitch for ground connection. Four-pole connectors

should be used.

The mast should not extend over three feet behind the

rear light assembly.

Wheels: Tires should ALWAYS be inflated to

manufacturer's recommended pressure. Always carry a

spare wheel and a jack that fit the boat trailer. If wheel

bearings are always dunked, waterproof bearings and

caps should be considered. If water is allowed into the

hub, lubricating grease will float away and bearings will

burn out or seize, causing damage and a safety hazard.

Waterproofed bearings should be inspected prior to

each boating season, others more often. Special care

should be given when traveling on unimproved

roadways with small diameter wheels.

If a spare wheel is not available, a spare wheel bearing

set should be taken on long trips in case the grease seal

has been broken.

FRAME AND ROLLERS

Rust should not be allowed to accumulate. Remove rust

and repaint with anti-rust paint. Some trailers offer

galvanized coating to prevent rust. Rollers should roll

freely and should not have checks, breaks or flat spots.

TOWING VEHICLE

Most vehicles are limited in towing capacity. Towing

heavy loads places extra demands on the engine,

transmission, brakes and other systems vital to the

vehicle. Towing "packages" are available through most

auto dealers and should be considered for heavy boats.

MOORING:

Mooring a Hobie is not recommended as it will cause

deterioration and discoloration of the hull. If, however, it

has to be moored for a short time the main thing to

remember is make sure everything is snug and secure.

Obviously the first thing to do is tie the boat securely to

the mooring. Then furl the sail and secure all gear so it

can't chafe when swells and boat wakes rock and thrash

to boat. Last, but very important, be sure all shrouds are

tight so the mast can't flop and fatigue the wires in the

shrouds. Many an unsuspecting boat owner has moored

his boat for a few days only to return to find his mast

laying in the water. The easiest way to tighten the

shrouds is to run a line around a shroud, under the

boom and around the other shroud. Tightening this line

will tighten the shrouds and minimize fatigue and wear.

Another method is to install a shroud tension adjuster (a

single line tied to the bridle intersection and run through

a cleat near the mast on the front cross bar). Tightening

the shroud adjuster will tighten the shrouds.

FIGURE 8 KNOT

AT END OF LINE

Page 33

About your Hobie 18’

There are ways of going faster on a catamaran,

while still staying within the eight foot beam, trailerable

size range. Basically, you put a taller mast on, use

daggerboards, and go to a half round hull shape.

The Hobie 18 is the end result of our efforts - mine, Phil

Edwards' (my longtime friend and co-designer of the

18), and those of all the guys on our research and

development team.

First thing, on the 18 you've got daggerboards .

. . the price you pay having symmetrical hulls. And while

they do keep you a little busier - having to raise them up

or down at times - I have found that our boards, with

their raked back leading edge, and the fact that they fit

their trunks well, are really quite easy to use. One quick

tug and they spring up or down, or lock part way, almost

automatically. Under heavy kelp conditions the boards

can be pulled up part way, leaving a very raked back

leading edge which will help dispense of kelp and

sometimes even knock it down and keep it from hanging

up on the rudders.

I find the 18 rudder assembly and locking

mechanism to be much easier to use than the 16's,

which is darn good. Locking the rudders down on the 18

is a more "natural" movement, which in itself is an

improvement over the 16.

The Hobie 18 has a built in mainsheet traveler

car which can be used either as a roller bearing type

traveler or a slider, as we furnish both rollers and slugs.

I have found the best combination is one roller and one

slug. This allows the traveler to move reasonably free

but still provides enough friction so that when you're

pumping or sheeting your main, the traveler car does

not want to keep coming at you all the time. Also, the

fact that it is built internally into the rear crossbar makes

for a clean and neat installation.

One of the really neat features on the 18 is the

roller furling jib. When you're sitting out there luffing,

waiting to start a race or just taking it easy, or even if

you just want to single-hand sail, all it takes is one

simple pull of the string and in about two seconds your

jib is neatly put away. And, of course, it is the ultimate

detuner for heavy air when you want to get some sail

area off the boat fast. Whereas most roller furling jibs

are attached permanently to the forestay, on the Hobie

18 we put a zipper luff with an internal halyard inside the

zipper so you may take the jib off the boat at any time.

That same halyard also serves as your luff tension,

which is another reasonably critical tuning device.

The Hobie 18 is an extremely "tuneable" boat.

You've got all the adjustments - fore and aft, in and out luff tension on your jib, and, with the diamond

spreaders on the mast, you are also able to control your

mast bend both ways. Also, the 18 has a controllable

mast rotation device and an internal roller outhaul.

Being as this boat does have a few more strings and

lines on it than a 16, we designed and specially tooled a

boom that carries internally your outhaul and mast

rotation control, to try to keep the lines tucked inside as

neatly as possible.

All of the fittings on the boom are moveable;

with the loosening of a screw you may slide any of the

leads fore or aft as you find convenient. This really

made it simple on us designwise because we didn't

have to figure out exactly where everything should go,

and you, in turn, aren't stuck with our decision and can

move them around until they are comfortable to you.

Being able to control the mast rotation, tension

the diamond wires, and even rake the spreader on the

diamond wires (this may be moved fore and aft to pump

the mast either forward or back slightly) leaves a

tremendous amount of room for tuning the sails on the

18 and getting the maximum performance out of them.

To keep the mast clean and allow for an efficient air

flow, we ran an internal main halyard (the jib halyard is

already internal inside of the jib luff).

Another set of features on the 18 which I like

are the inspection plates in each hull. You can look in

there and see what's happening, and the holes are big

enough so you can stuff things away in the hull. . .

lunch, beer, jackets, whatever. Also, there is a goodsized pocket on the trampoline that halyard ropes and

assorted odds 'n ends may be stuffed into so you don't

have a lot of loose line laying around on your boat.

It is important to remember that the "fastest"

boat isn't necessarily the "best" boat for everyone. What

is the best boat - whether it be an 18, a 16, a 14, or

some other type of boat altogether, is the one that best

suits an individual's particular wants and needs. A boat

that is the most useful to you personally, one that you

will get the most enjoyment out of, is the best boat in the

world!

Hobie Alter

31

Page 34

CAUTION / SAFETY TIPS

•

Watch for overhead power lines. Never rig,

trailer or sail the boat near overhead power lines.

Contact with a power line could be fatal.

•

Install Drain Plugs. Even the most experienced of

boaters forget to install the drain plugs sometimes.

When installing the plugs, be sure that the threads

and gaskets are free of sand/ grit. Any debris on

the plug could cause a water leakage.

•

Sail to your experience. Do not try to do more

than you can. Do not take the Hobie 18 out in the

surf and do not head out for the ocean unless you

are a real professional.

•

Wear a life jacket. Wearing life vests while sailing

is something that is very important and should be

done at all times. Also, a sailboat could sail away

by itself if a person were to fall overboard. The best

advice to a sailor is to stay with the boat. If they

happen to fall overboard, or when righting the boat,

they should hold onto the boat and not let it get

away.

•

Learn the right-of-way rules and when in

doubt, give way to others.

•

When trailering the Hobie 18 be sure to tie the

boat and all the loose parts to the trailer in a

secure manner. Stop and check the tie downs

often.

•

Hobie Cat does not recommend leaving the

Hobie 18 in the water on a mooring. Accelerated

wear to the boat and rigging will be experienced.

Damage to the hull material is possible. Limitation

of the mast rotation and tensioning of the rigging

are required to lessen this wear. Inspect rigging

often and tape rigging rings and shackles to prevent

loosening.

For your nearest HOBIE dealer

or

for help and information call:

1 (800) HOBIE - 49

HOBIE CAT

4925 Oceanside Blvd.

Oceanside, CA. 92056

Phone (760) 758-9100 Fax (760) 758-1841

Hobie 18’ in Flight

WWW.HOBIECAT.COM

32

Part # 63450001

Loading...

Loading...