Page 1

1

Instruction Manual

Telemaster Electro V2 ARF

Wingspan: 73-1/4 in.

Length: 53-1/2 in.

Wing Area: 848 sq. in.

Weight (with battery): 88 oz.

Page 2

2

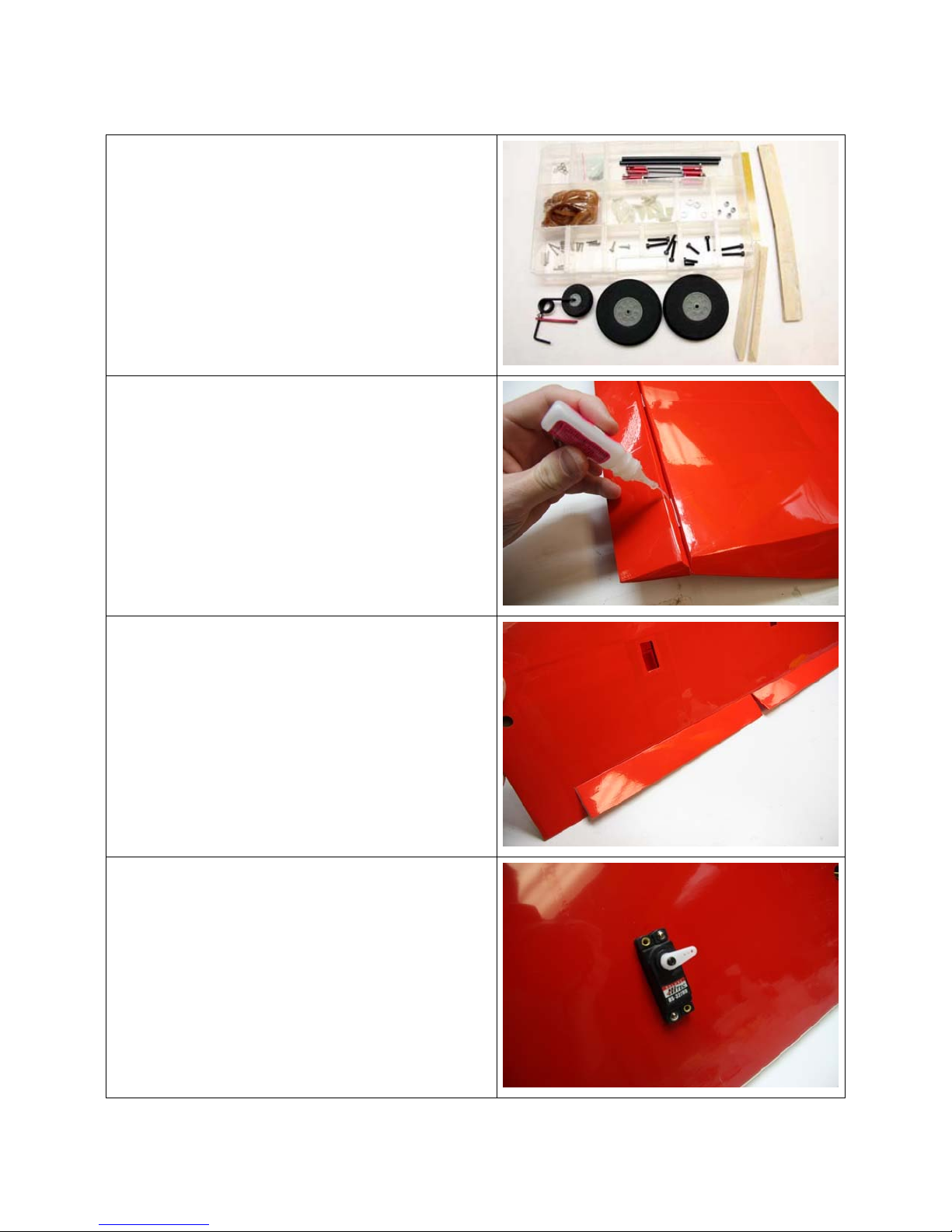

Before starting, use the

Contents List to take an

inventory and make sure it is

complete. If any parts are

missing or are not of

acceptable quality, contact

Hobby-Lobby.com Support

at 866-512-1444.

This manual assumes the

builder possess intermediate

assembly skills. Seek help

from another pilot or an

experienced modeler if you

are unsure how to complete any step in this manual.

Contents List

! Fuselage

! 2 Wing Panels

! Horizontal Stabilizer and Elevator

! Vertical Stabilizer and Rudder

! Wooden Wing Joiner

! Aluminum Landing Gear

! Main Wheels and Steerable Tail Wheel

! Pushrods, Control Horns, Pin Hinges and assorted fasteners

Additional Items Required

! 6-channel Aircraft Radio w/ Receiver (minimum)

! 4000mah, 4-cell, 14.8v Lipo battery

! (6) Standard sized servos

! (2) 12” Servo extensions

! (4) 6” Servo extensions

! 50-60 amp Brushless ESC

! AXI 2826/12 Brushless Motor and radial mount set

! APC 12x6 “E” Propeller

! Glues, solder, connectors

Page 3

3

1. After unpacking all parts, sort the

hardware and place like parts into

separate holders. This will speed the

building process and give you a good

visual of all the hardware provided.

2. Begin by hinging the ailerons to the main

wing panels using the CA hinges. Insert

the hinges fully then flex and apply thin

CA glue to the hinges from the top and

bottom allowing the glue to wick into the

wood. There should only be a small gap

between the ailerons and the wing.

3. Once the hinges are set, flex the ailerons

a few times to break-in the hinge.

4. Now install the flaps in the same manner

as you did the ailerons.

5. After all wing control surfaces are hinged,

check for free movement and prepare to

install the servos.

6. Add 12” servo extensions to the aileron

servos and insert the servos in the wing

with the output arm facing the trailing

edge of the wing and screw in place.

Page 4

4

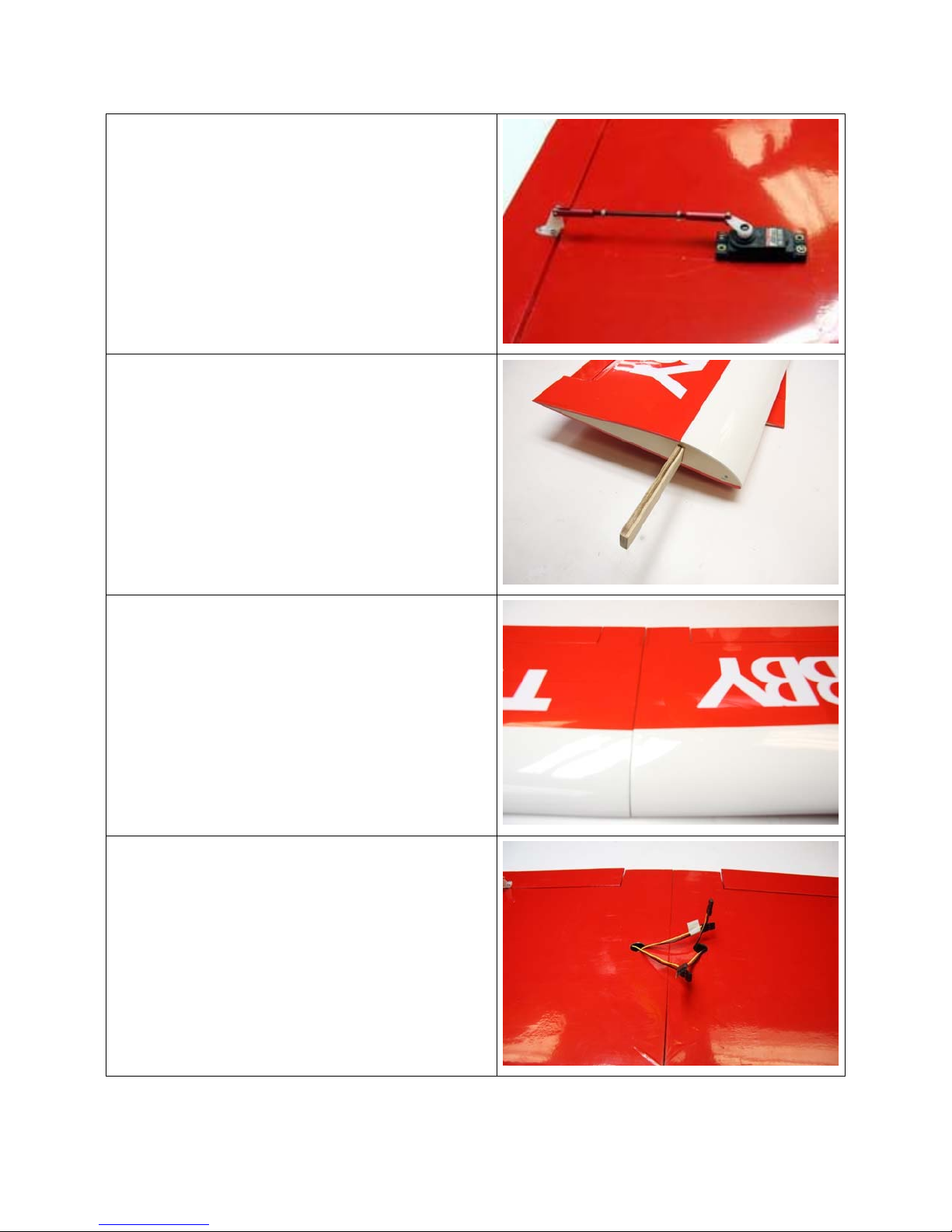

7. Install the flap servos in the same manor.

The output arms on the two flap servos

should face the same direction. The

servo control horns for both flap servos

should also face the same way. That will

allow them to operate together when tied

into the flap channel on the receiver.

Install the control horns and linkages to

the flaps and the ailerons.

8. Mix up some 30-minute epoxy and apply

to the ends of the wings and in the slots

for the wooden wing joiner.

9. Slide the wings together and make sure

they are aligned. Use rubbing alcohol

and a paper towel to wipe off any excess

glue that squeezes out.

10. The servo wires should exit the holes on

the bottom of the wing as shown.

Page 5

5

11. Locate the fiberglass plate and place on

top of the wing at the trailing edge. Trace

the outline and remove the covering

below the traced line. Glue the fiberglass

plate to the wing with medium or thick CA

glue.

12. Locate the horizontal stabilizer with

elevator. Install the elevator to the

stabilizer with the CA hinges using thin

CA glue. There should be a very small

gap between the stabilizer and the

elevator.

13. Trail fit the stabilizer to the fuselage. Use

a marker and trace the area around the

fuselage.

14. Use a hobby knife and carefully cut the

covering away just inside the traced lines.

Note: Use a sharp blade and only use

enough force to cut the covering. Do not

cut down into the wood.

Page 6

6

15. Mix up some epoxy and glue the

horizontal stabilizer to the fuselage.

Make sure it is centered and parallel to

the horizon.

16. Locate the two balsa wood triangle stock

pieces. These will be used to strengthen

the stabilizer. Hold them in place as

shown and trace around the edges.

Remove the covering and glue them in

place on both sides of the fuselage using

CA glue or epoxy.

17. With the fuselage right side up, trail fit the

vertical stabilizer. Trace the area on the

vertical stabilizer, remove the covering,

and use epoxy or CA glue to install it.

Make sure to wipe off any excess glue.

18. Locate the tail wheel and prepare to

install it into the rudder.

Page 7

7

19. Use 5-minute epoxy to glue the tail wheel

wire into the slot in the rudder.

20. Install the rudder onto the vertical

stabilizer using the CA hinges and thin

CA glue.

21. Use the two larger wood screws to install

the tail wheel plate to the bottom of the

fuselage.

22. Install the rudder and elevator control

horns as shown.

Page 8

8

23. Locate the main landing gear, wheels, 4

locknuts, 4 washers, 4 mounting bolts,

and the 2 long bolts that will be used as

axles.

24. Start by installing a washer on the axle

bolt, then the wheel, then another

washer, and finally a locknut. Tighten the

nut, but not too much. The wheel should

spin freely.

25. Slide the remaining axle through the

outside of the landing gear hole and

secure with the remaining locknut.

26. Install the main landing gear to the

fuselage with the 4 mounting bolts. Note:

the landing gear has a straight edge and

a tapered edge. The tapered edge faces

the rear.

Page 9

9

27. Slide the two pushrods through the

fuselage from the front. You will need to

remove the clevis from the threaded wire

and insert that end first.

28. Make sure the pushrods go through the

proper holes. You can twist and flex the

rods as required. Once they get through

the first two holes it slides easier through

the rest. Note: The pushrods will cross

paths and exit on opposite sides at the

rear of the fuselage.

29. Reinstall the clevis on both pushrods and

connect to the rudder and elevator

control horns. Note: The clevis can be

used for mechanical adjustment to center

the control surface.

30. Install the elevator and rudder servos as

shown. The out put arm should face the

rear. Connect the servo arms onto the

pushrod z-bends before installing on the

servos.

Page 10

10

31. Insert the two carbon fiber rods into the

slots on the fuselage and secure with thin

CA glue.

32. The receiver can be mounted using

Velcro, double-sided tape, or a zip tie.

Use 6” servo extension leads for the flap

and aileron servo channels to make

connecting them easier when installing

the wing. Use the included rubber bands

to install the wing on the fuselage.

33. Install the radial mount plate to your

motor and use 4 bolts to mount the motor

to the firewall. Install your prop and

secure with a washer and nut.

34. The ESC can be installed in the

fuselage next to the battery area or

along side the motor mount. Use Velcro

or double-sided tape to secure it.

Page 11

11

35. The battery is inserted through the front

hatch and is secured using the supplied

Velcro straps. Slide the battery forward or

aft to achieve the proper CG, which is

listed below.

36. Install the magnetic hatch by putting the

back end in first and then laying the front

down. Remove the hatch by first lifting

the front and pulling up and away.

37. Congratulations, you’ve finished the

assembly. Follow the information listed

below for recommended control throws

and center of gravity.

CG Location

Forward position for CG is 3-3/4” back from the Leading Edge of wing.

Aft position for CG is 4-1/2” back from the Leading Edge of wing.

Control Throws

Ailerons = 10mm Up and Down for Low Rates

20mm Up and Down High Rates

Flaps = As much as you want!

Elevator = 10mm Up and Down for Low Rates

15mm Up and Down for High Rates

Rudder = 10mm Left and Right for Low Rates

20mm Left and Right for High Rates

Page 12

12

Preflight

If you are new to flying R/C aircraft we recommend you have a fellow R/C modeler help

you with the first flight. Some items you will need to complete on your first preflight are:

1. Aircraft assembled correctly and ready for flight.

2. All control throws set per this manual.

3. Transmitter fully charged and on the correct model.

4. Aircraft balances at the recommended location.

5. Flight batteries are fully charged and secure.

6. All electronics are operating correctly, in the proper direction, and secure.

7. Complete a radio range check per your radio’s manual.

8. Balance propeller and make sure it is secure.

9. Wait for a calm or light wind day for first flights.

Flying

You will soon find out the Telemaster Electro is a real pleasure to fly. Takeoffs,

landings, and flaps down slow flight are all easy to accomplish. Even if you have never

flown a tail wheel airplane before, the Telemaster Electro is an easy transition.

We hope you enjoy your Telemaster as much as we do!

Happy Landings!

WARNING – THIS IS NOT A TOY!

Radio controlled model aircraft are capable of inflicting serious injury and/or property damage if not assembled, operated, and

maintained in a competent and safe manner. If you are not already experienced with radio-controlled models, we strongly suggest

that you find an experienced modeler to assist you.

Warranty

Hobby-Lobby guarantees this kit to be free from defects in both material and workmanship at the date of purchase. This warranty

does not cover any component parts damaged by use or modification. In no event shall Hobby-Lobby’s liability exceed the original

cost of the purchased kit.

Completely read through this manual before starting construction.

Page 13

13

Hobby Lobby International, Inc.

5614 Franklin Pike Circle

Brentwood, TN 37027

(1-866-512-1444)

www.hobby-lobby.com

Loading...

Loading...