Page 1

Telemaster 40 Deluxe

Assembly Manual

Hobby Lobby International

5614 Franklin Pike Circle

Brentwood TN 37027 USA

Phone 866-512-1444

MADE IN THE USA

Page 2

Page 3

Terminology used in this manual.

With the precision of laser cut parts and notch and tab construction, the assembly and gluing sequence

becomes very important. If components are glued in place to soon, they will not allow enough movement to install other components. When instructed to install a part, do only that. You will be instructed

to glue it when it is no longer required to be moveable.

Test Fit:

Test t and install but do not glue.

Install and glue:

Permanently install the part.

Locate and prepare:

Find the parts requested, you can locate them faster using the parts locator pages at the back of this

manual. The parts locator will direct you to the correct sheet number as well as describe the part for

easier identication. Most of the parts are supplied still in the sheet. These sheets are called the carrier

sheet and the parts are held in the carrier sheet by small breaks in the cutting line. These are called

retainer breaks and in most cases the parts can be extricated by simply exing the carrier sheet and the

retainer breaks will release the parts. In harder materials it may be necessary to use your hobby knife to

sever the retainer breaks to remove the parts. After removing the parts, a small nub may remain where

the retainer break was, this must be removed with a light swipe of sandpaper so it will not interfere with

the parts t.

Adhesives:

There are four primary types of adhesives recommended for constructing your model. They are CyanoAcrilate (referred to as CA) in all viscosities, Aliphatic Resin Glue (carpenters glue), Polyurethane glue

referred to as PU and Epoxy. CA is the primary adhesive to use however there are times when it is not

the best choice.

They are:

1. When you need more time to carefully position a part than a fast setting adhesive will allow.

2. When attaching plastic such as a windshield (Use Pacer formula 560 here).

3. When gluing laser cut aircraft grade plywood’s. The microwave set adhesives used in aircraft grade

plywood does not ablate well under a laser beam. As a result it burns the wood bers near by leaving

a charred edge. Fast setting CA adhesives do not allow time for the adhesive to penetrate this layer of

char and bond to the wood ber underneath. Use a slower setting adhesive such as Aliphatic Resin for

maximum strength use Epoxy on aircraft grade ply parts. Lite Ply’s do not use this type of adhesive and

do not suffer from this problem.

To apply thin CA we recommend the Dave Brown pipets available from Hobby Lobby. Be sure to stretch

the end (pull it with a pair of pliers) to a thin applicator tip, as they are not supplied in this conguration.

1

Page 4

Your Telemaster kit can be constructed with several options. You can build it as a standard gear (tail

dragger), the classic Telemaster stance or a more modern tricycle gear model. You can also build

either of these to accommodate the Telemaster Float kit for operation off of water. As you progress

through the assembly procedures we will point out the various deviations from the basic standard

gear conguration.

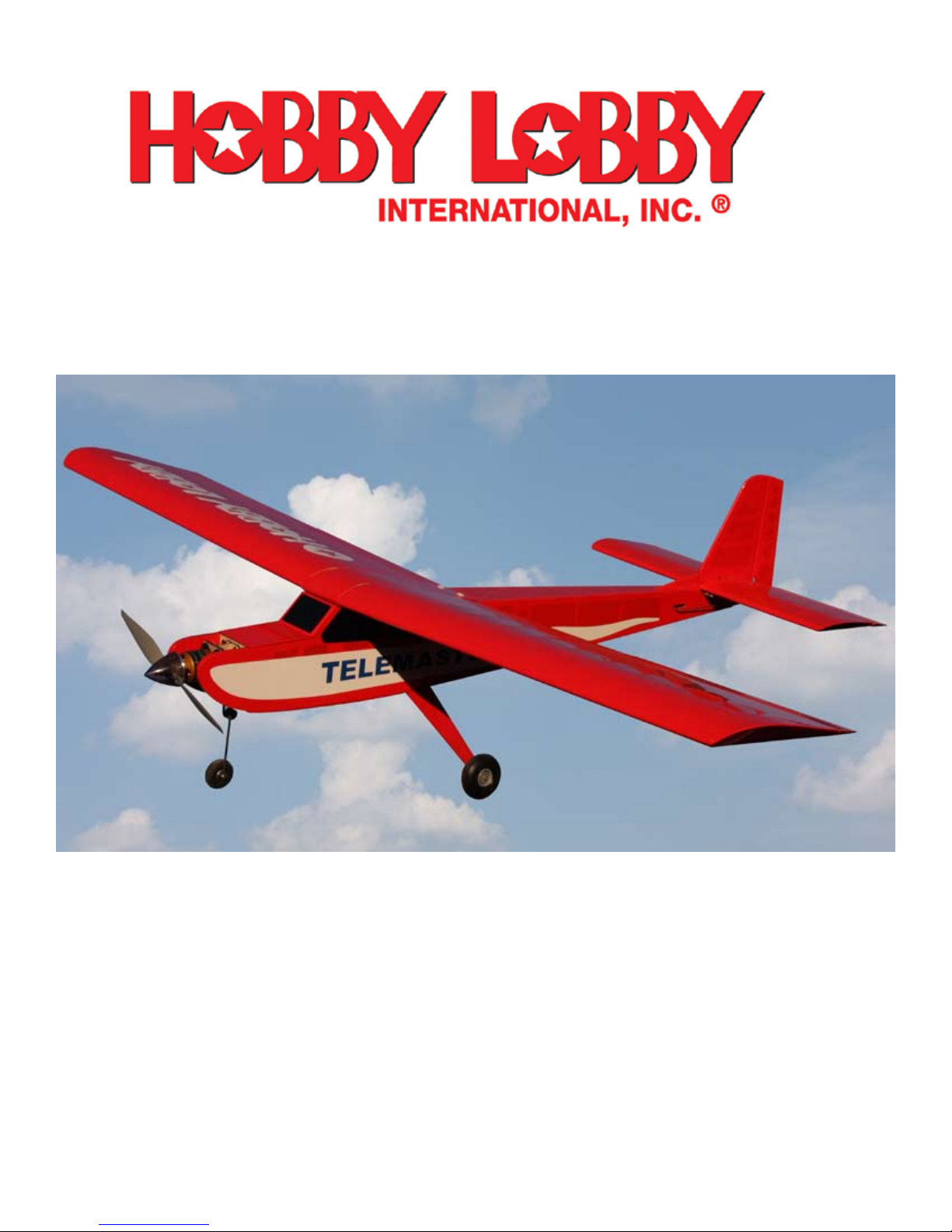

Assembling the registration pins.

We will be using two types of pins; registration pins and push pins. Registration

pins are assembled from two ber blocks

and two specially prepared 2-1/2” nails.

Push pins will be used to temporarily secure parts to the building board.

Locate the two pinning blocks supplied.

Note that they have a counter sink on one

side. This is the side that the nail must be

inserted from. Place the block on a piece

of scrap wood to prevent the ber block

from tearing out when the nail is driven

through. Now hammer the nail through

just far enough to exit the block. Next

place the block up against the side of the

bench or other heavy object and nish installing the nail. When done, the nail head

should be in the recess so the block can

sit at on the bench. Repeat this process

with the second pinning block assembly.

FUSELAGE ASSEMBLY

c 1

c 2

Locate the rewall sections, FW-A and

FW-B. Place FW-B on the registration

pins. Test t FW-A; make sure you have

the correct orientation so the holes line

up. Apply thick CA to FW-B and then install FW-A with the labeled side up.

Install four #6-32 blind nuts in the holes

provided from the FW-B side.

NOTE: The bolt pattern on the rewall will

t the Hobby Lobby 40 size glow motor

mount Cat #MT11022 as well as the elec-

tric motor mount supplied.

Assembly of the rewall is underway. FW-B has been installed

on the pins and now glue will be applied to the top of FW-B and

then FW-A will be installed on the pins and pressed into contact

with FW-B.

2

Page 5

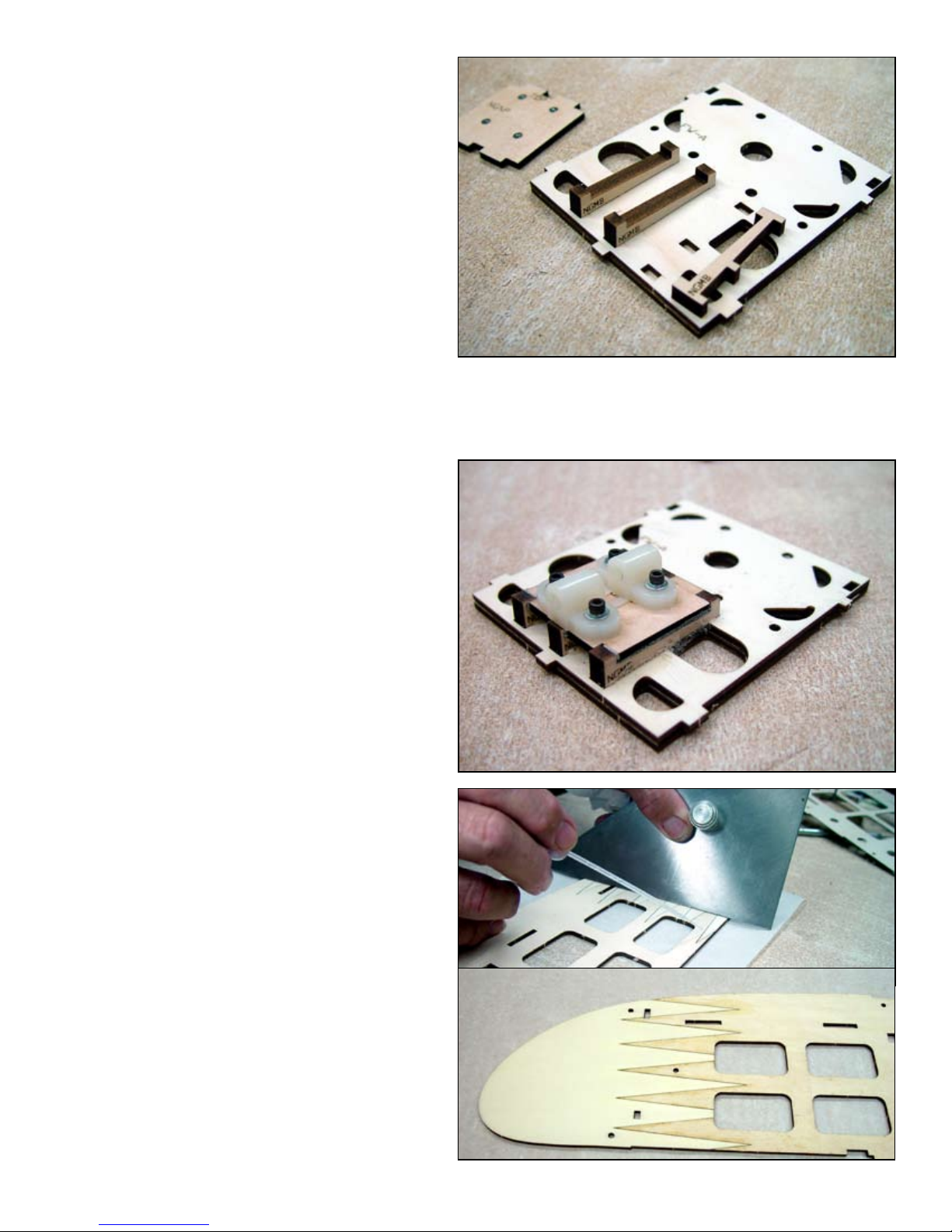

c 3

TRIKE VERSION ONLY

A. Locate NGNP and install four #4-40

blind nuts.

B. Install and glue three NGMB into FW-A

in the slots provided. Use Epoxy or PU

glue for this.

C. Install and glue NGNP to the three

NGMB parts, the blind nuts should be on

the side facing FW-A.

ABOVE: Three nose gear mounting brackets (NGMB) are being installed into the rewall assembly. BELOW: The nose gear

nut plate NGNP has been installed onto the three nose gear

mounting brackets and the nylon nose gear bearing has been

installed.

c 4

The fuselage sides are supplied in two

sections, FS-A and FS-B, they are joined

by a nger joint at the front. Place the

parts over a piece of parchment paper

and apply thin CA. Wipe off any excess

glue and sand out any bumps.

ABOVE: A straight edge is being used to force

the two fuselage sections at against the building

board while thin CA is being applied.

BELOW: The nished nger joint.

3

Page 6

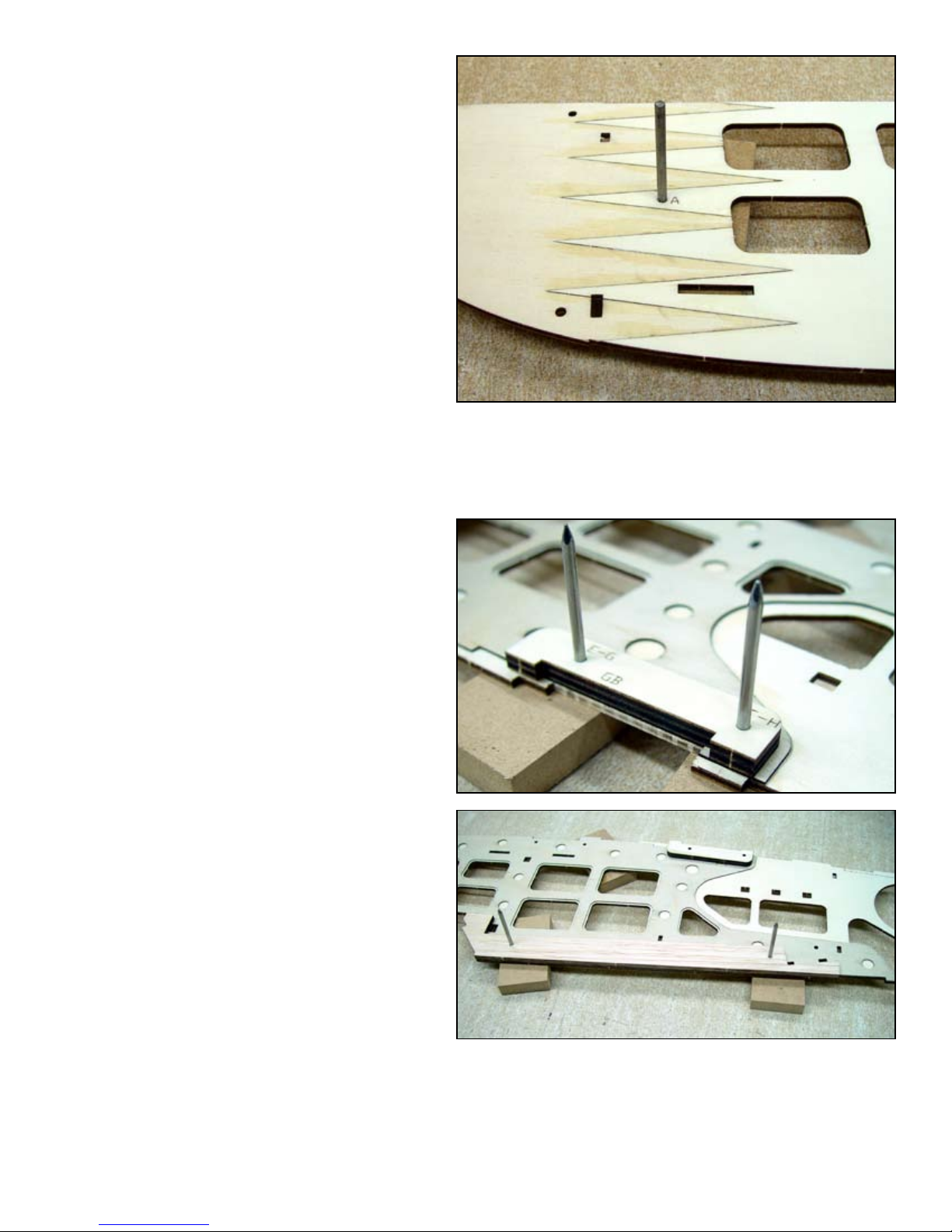

c 5

We will now start the fuselage side subassemblies; make sure you make a left

and a right side. Place one of the fuselage sides on the registration pins using

holes A and D. Slide FD down the pins to

test t. When satised with the t, remove

FD and apply thick CA to the back (the

side facing the FS assembly) and then

reinstall it onto the pins and slide it into

contact with the FS assembly. Apply even

pressure until the CA has cured. Repeat

this process for the remaining side and

remember to make it a mirror image of the

side you just created.

c 6

c 7

c 8

If you are building the trike version, remove the dash cut material by register pin

holes G and H.

Next we will install the mains landing gear

brace (GB). If your are building the standard gear version (tail dragger) install the

register pins in holes E and F and install

GB. If you building the trike version, install the register pins in holes G and H

and install GB

Place the register pins in holes B and C

and install and glue the fuselage wing

saddle (FWS).

ABOVE: The right fuselage side with a registration pin inserted

in holes A and D ready to install the doubler FD.

BELOW: With the registration pins inserted in holes G and H,

the gear brace for the trike version is being installed.

4

Page 7

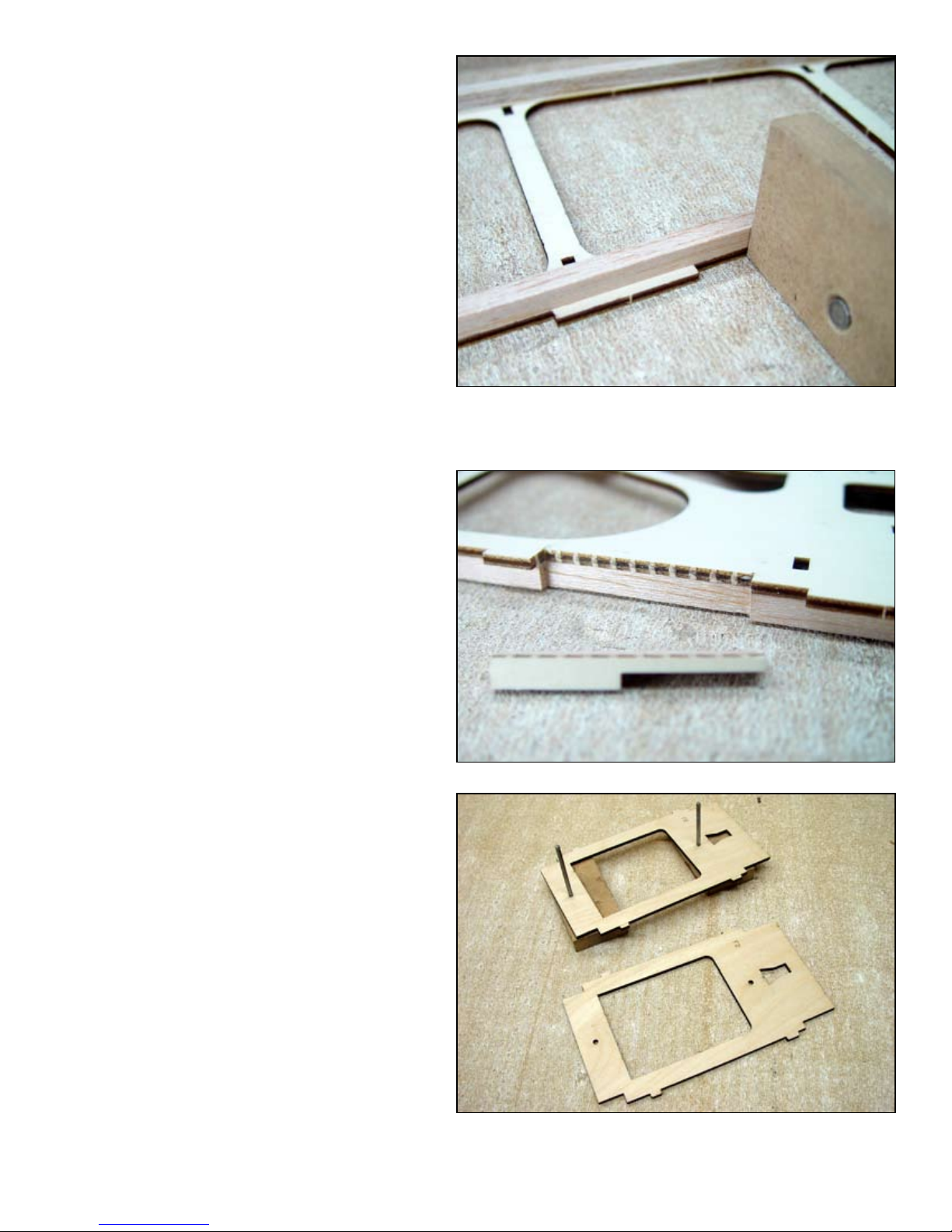

c 9

Locate four ¼” x ¼” x 36” sticks, they will

be glued into each corner of the fuselage

aft section. Start with one stick butted up

against FD. Note that the stick must be

glued in line with the inner notches. This

stick will terminate at and to include F9.

c 10

c 11

Install the top corner stringer starting at

the back of FWS and terminating at and

to include F9.

ABOVE: The 1/4” square corner stringers are being installed.

One of the pinning blocks is being used to align the stringer

with the edge of the fuselage side.

If you plan to use oats you will need to

install the oat hard point. Remove the

dash cut material just behind F4, includ-

ing a notch in the ¼” square stringer.

c 12

Assemble F2 from two 1/8” ply sections

using the register pins.

ABOVE: F2 is being assembled on the registration pins, thick

CA is used to laminate the two parts.

5

Page 8

c 13

Install two 1/4” x 20 blind nuts into

FWBP.

c 14

c 15

The rst glue up of the fuselage will consist of the rewall assembly FW-A&B, the

fuselage oor FF, the F2 assembly, F3,

F4, the wing bolt plate FWBP, the hatch

mounting plate FHMP and the servo tray

FST. Use a slow curing adhesive such

as aliphatic resin to allow time to work.

Glue each part and install it into the right

side. Next apply glue to the left side of all

these components and install the left side.

Place a at board or other object on this

assembly until it has cured. Make sure all

tabs are bottomed in the notches and all

components t ush to both sides.

ABOVE: Joining the fuselage side assemblies begins by installing formers, the fuselage oor, wing bolt plate and the forward

hatch mounting plate in one side and then applying glue to the

top side of these components and installing the remaining fuselage side. In the photo, the wing bolt plate and the forward hatch

mounting plate remain to be installed.

Before pulling the tail section together we

need to pre-assemble F9 with FTGM and

F8 with SMP. Use your square to assure

that these components are at 90º to each

other.

c 16

Install the F8 and F9 assemblies at the

same time. Apply glue to both sides of

these assemblies and install. Pulling the

tail section together. It is very important

that these parts be completely inserted

into their respective notches to assure the

stabilizer mount will be level. Use clamps,

tape or rubber bands to assure these

parts t tightly.

ABOVE: The fuselage tail gear mount (FTGM) has been joined

with F9 and the stabilizer mounting plate (SMP) has been

joined with F8

6

Page 9

c 17

Install and glue F5, F6 and F7. Install

each former into the notches on one side

and then tip into the other side.

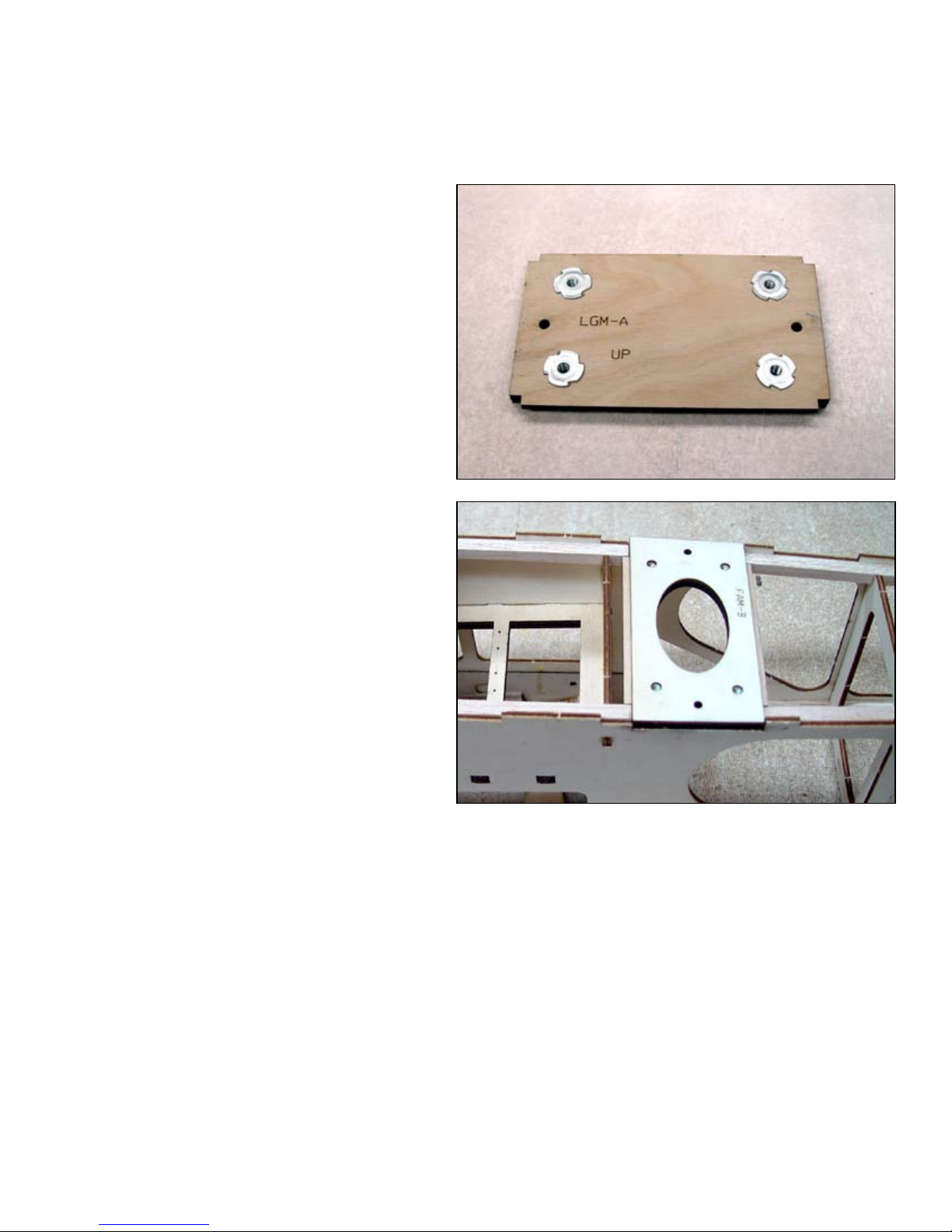

BELOW: The landing gear assembly is ready to be installed

into the fuselage. The word UP refers to its position in the fuselage, the nuts must be facing the inside of the fuselage.

c 18

c 19

Using the registration pins, assemble

the landing gear mount from LGM-A and

LGM-B. Install four #6-32 blind nuts from

the LGM-A side and install and glue it into

the fuselage side at GB. Remember this

can be positioned at one of two locations,

forward for standard gear and aft for trike

gear.

If you have opted to install the oat hard

point, now is the time to install it. Assem-

ble FAM-A and FAM-B using the register

pins. Install four #6-32 blind nuts from the

FAM-A side. Install and glue it at the location indicated just aft of F4.

c 20

Install one ¼”magnet into the hole in

FHMP, this will be part of the hatch hold

down system. Make the magnet ush

with the top of FHMP so the hatch can

t tightly.

7

Page 10

c 21

Place the remaining magnet near the one

installed in FHMP and let them join. Mark

the top of the top magnet with a magic

marker. Locate the hatch components

FHA and two FHA-H. Place the FHA on

the bench with the labeled side down and

install the remaining magnet in the hole

provided with the side you just marked

facing down. With the labeled side still

facing down, install the two FHA-H rail

hooks.

c 22

c 23

Install and glue the 4” length of 3/8” triangle stock in the notch provided at the

base of the windshield. The wide side of

the triangle stock will be perpendicular to

FHMP.

ABOVE: 3/8” Triangle stock installed.

Below: Windshield (WS) has been added.

Install and glue WS, note that a small

chamfer must be planed into it at the top

where it contacts F2.

8

Page 11

c 24

c 25

Place the hatch cover assembly onto the

fuselage and install and glue the ¾” x 4”

triangle stock onto the hatch cover. This

should butt snugly up against the 3/8” triangle stock installed in step 21.

Install and glue the top turtle deck FTD.

Use clamps or masking tape to pull the

sides snugly against FTD. Start at the tail

section and work forward.

BELOW: Clamps and tape secure the sides tightly to the top as

the adhesive cures, use this same method when installing the

fuselage bottom.

c 26

c 27

c 28

If you are building the trike version, install

LG-PLUG assembly in the notch where

the main gear would have gone. This assembly consists of LG-PLUG-A and LGPLUG-B and assembles just like the LG

assembly did.

Next we will install the fuselage bottom

FB. Note the two dash cut sections in

FB, if your building the standard version

both of these will remain intact. If you

are building the trike version, the forward

most dash cut area must be removed to

accommodate the gear mounting assem-

bly LGM-B. If you are using the oat hard

point you will need to remove the aft most

dash cut area.

Install and glue one FA to the forward bottom fuselage section just behind the rewall on each side.

ABOVE: Mount for the trike mains on the left and on the right

for the optional oat kit.

BELOW: The forward bottom sheeting BS-A and BS-B has

been installed.

c 29

Assemble the forward bottom sheeting

BS-A and BS-B and glue it into position

between the rewall and LGM.

9

Page 12

c 30

Install and glue the nose ller pieces NF.

c 31

c 32

If you are building the trike version, now is

a good time to install and adjust the nose

gear steering cable. Note that a ball link is

used on the steering tiller arm.

Locate and prepare the ve electric motor mount parts, MMA, MMB, MMH, MMV

and MMBP. Use Epoxy to or PU to as-

semble these components. Note that the

bolt pattern on the motor mount bolt plate

(MMBP) is the same as that used on the

Hobby Lobby 40 sized glow motor mount

catalog # MT11022. Use the pinning

system to assemble the laminated parts

MMA and MMB. Install MMH and MMV in

the bolt plate MMBP. Next glue the MMA/

MMB assembly to MMH and MMV.

c 33

Install the motor mount with four #6-32 X

3/8” socket head bolts and at washers.

This concludes the basic fuselage assembly. You will want to install all radio gear and control

linkages before covering the model. Once covered you will not have access to some parts of the

model.

10

Page 13

STABILIZER ASSEMBLY

c 1

c 2

c 3

Cover the stabilizer plans with parchment

or waxed paper. Prepare the stabilizer

plate (SP). Install four #4-40 blind nuts

into the holes provided. They should be

installed from the top. Pin this part in place

over the plans. Place the pins through the

blind nuts to keep them out of the way.

Iinstall the stabilizer false leading edge

(SFLE). Position the tab on SP into the

notch in SFLE and glue.

Install the stabilizer 1/8” X 1/2” basswood

bottom spar. Place into the notches provided on either side of SP and glue it in

place. Align the outer ends of tn

he spar with the plans and pin in place

with push pins.

c 4

c 5

c 6

c 7

c 8

c 9

Install and glue the false trailing edge

(SFTE) to the aft edge of SP. The center

notch will position it correctly.

install and glue two S1 ribs in the notches

provided.

install but do not glue two stabilizer sheer

webs (SSW). These will remain loose until all the ribs have been installed.

install but do not glue all remaining stabi-

lizer ribs, S2 through S6.

Before gluing the assembly this far, make

sure the bottom spars are aligned with

the plans. Begin by gluing each rib and

sheer web to the bottom spar. Make sure

each rib is bottomed in the sheer web

slot. Then glue the false leading and false

trailing edges to each rib.

install the stabilizer tips (SWT). They

should butt against S6 and against FLE,

FTE and SW. Glue these into position.

11

Page 14

c 10

Install the top spar from 1/8” X 1/2”

basswood stock. Taper the ends to butt

t to the stabilizer tips SWT. When your

satised with the t of this bevel, glue the

top spar into position.

c 11

c 12

Note that at the center of the false trailing edge and false leading edge there is

a low spot. This is to accommodate the

center section sheeting. Before installing

it you will need to sand the top of the false

trailing edge and the false leading ush to

and at the same angle as the ribs.

Install and glue the center section top

sheeting sections SCS-A and SCS-F. After the glue has cured, remove the dash

cut material in the center to allow for in-

stallation of the vertical n.

12

Page 15

c 13

Install and glue the trailing edge STE. The center notch will determine position.

c 14

c 15

c 16

c 1

Install and glue the leading edge SLE. The center notch will determine position.

Use a plane and sanding bar to shape the leading and trailing edges of the stabilizer. Sand all

surfaces as required in preparation for covering.

Use a hobby knife to continue the hinge slots TE into the false trailing edge SGTE.

This completes the assembly of the stabilizer.

Elevator assembly.

Locate the shaped elevator. Note that the

two elevators are connected by a web at

the center. Keep this web in place until after installing the elevator joiner parts EJ-A

and EJ-B. Place the trailing edge against

a straight edge and pin to the workbench.

Then install and glue EJ-A and EJ-B. Note

that the elevator horn will attach to EJ-A

on the elevator half.

c 2

c 1

c 2

Sand the joiner to contour with the leading edge and then sand the taper at each

end to match that of the stabilizer.

This concludes the elevator assembly.

Rudder assembly

Prepare all rudder components, R1, R2,

R3-A and two R3-B. Glue R2 to R1; note

the correct orientation. The end of R2

marked TOP should be toward the tip of

the rudder. After installing it, trim the bot-

tom to match the angle of the stabilizer

opening in R1.

R3-A is laminated between too R3-B parts

to form both the rudder horn mount and

also provide a slot for the tail wheel arm.

This will allow the empennage assembly

to be removed easily. Glue R3-B to R3-

A, then ip the assembly over and glue

the remaining R3-B to R3-A. Glue this assembly into the notch provided in R1.

13

Page 16

c 22

Sand the rudder assembly at and then

round off the trailing edge. Extend the

hinge slots into R1 and slightly bevel both

sides of the assembly to allow for movement when installed.

This concludes the rudder assembly

Vertical Fin assembly

c 1

c 2

c 3

c 4

c 5

c 6

c 7

Laminate the two V1 using the register pins.

Glue V1 to V2 and then glue V3 to V2. Note that the vertical n assembly is self aligning and

need not be built over the plans.

Glue V4 to the V1, V2 and V3 assembly.

Install and glue the cross members, V6 and V7.

Install and glue the trailing edge piece V5, Note the correct orientation of V5. The end marked

TOP should be at the tip of the vertical n.

Trim the bottom of V5 to align with the opening in V1.

Sand this assembly at, Note that the leading edge will be rounded later after you can mark the

location where the dorsal n VF intersects with it. Extend the hing slots into V4.

This completes the vertical n assembly.

Wing joiner platform assembly

c 1

c 2

c 3

c 4

Locate and prepare the wing platform

WP. Note that the wing platform is not

built over the plans.

Use the registration pin system to install

WP-F at the aft end of WP.

The wing joiner WJ, must be laminated

from two 3/32” ply parts. Use the register pins to glue these two together to form

WJ. Place the parts back to back (label

out on both pieces) to neutralize any potential warp.

Glue the joiner assembly into WP, use

your square to assure that WJ is perfectly perpendicular to WP. As shown in the

photo on the next page

14

Page 17

c 5

Install and glue WP-FLE to the leading

edge of WP.

c 6

c 7

c 8

c 9

c 10

c 11

c 12

Use Epoxy or thick CA to install and glue

WP-1A to WJ, WP and WP-FLE.

Install and glue WP-1B to WJ and WP.

Install WP-B1 and WP-B2.

Install and glue rib WP-2 on both sides

of SP.

Use one of your register pins to install and

glue one WP-DS to the inside of each W1

rib. These will support the 1/8” alignment

dowels we will install next.

Locate the 1/8” hardwood dowel. Use

sandpaper to round off both ends and then

cut the ends off to make two 3/8”lengths

with rounded ends. Glue the cut ends into

the holes at the aft end of the WP-2 ribs.

These will insure correct wing alignment

when assembling the wing panels.

Use a plane to remove the bulk of material

on WP-F to contour with the ribs in preparation for installing the top sheeting.

c 13

c 14

Plane or sand the false leading edge WPFLE to contour with the ribs.

Locate and assemble the platform top

sheeting sections CS-A, CS-B, CS-C and

CS-D. Place CS-A on a piece of parchment

paper with the labeled side up. Butt CS-B

up against CS-A but with the labeled side

down on CS-B. Apply thin CA along the

joint and then immediately wipe up any

excess with a QUICK wipe with a paper

towel. Flip the piece over and wipe off any

excess CA on the parchment paper or the

back of the assembly. Continue with this

process until all sections are joined. By

ipping every other section over you are

improving the t between parts, there is a

very slight expansion of the kerf from top

to bottom and this technique eliminates

any gap. Determines the best side of this

assembly and sand it while still at on the

bench.

15

Page 18

c 15

Use the register pins to position the top sheeting and glue it into position. Use tape or weights to

hold it in position until the adhesive has set.

c 16

c 17

c 18

c 19

Install and glue WP-LE into position on the leading edge.

Plane and sand LE to contour with the ribs.

Locate the wing hook parts, two WH-A and one WH-B. Use the register pins to laminate these

parts with one WH-A on either side of WH-B.

Test t but DO NOT Glue this assembly into the opening provided in WP. When installed correctly

it should t at on WP. Epoxy this permanently in position After covering the model.

This completes the assembly of the wing platform.

Wing assembly

Lay one of the wing plans on the bench and cover it with a piece of waxed paper. You will be

building the wing over the plans. If the plans are slightly out of size, do not be concerned. The

paper they are printed on will shrink and stretch with changes in humidity and temperature. The

parts will always determine the correct location of components so only use the plans to insure

alignment and location of parts. Place the plans with the leading edge of the wing away from the

edge of the bench you will be working from. We will begin by building the LEFT wing. Some of

the procedures will be reversed for the right wing.

c 1

c 2

c 3

c 4

Locate and prepare one false leading

edge (FLE).

Align a straight edge with the aft edge of

FLE on the plans and secure it in this position with push pins.

Place FLE in front of the straight edge,

note alignment lines at the front of W2 on

the plans. Align the notch in FLE with the

lines in front of W2 and use a pinning tab

to press FLE up against the straight edge.

Tack glue the pinning tab to FLE and then

secure the tab to the building board with

push pins.

Moving down the wing, install a pinning

tab in the same manner at every other rib.

This will secure the false leading securely

to the building board and insure a straight

wing. Make sure it is at on the building

board.

16

Page 19

c 5

Prepare TE, TES and TESB. Note that the notches in TESB are 1/4” deep on one side and 3/16”

deep on the other. Place it on the bench with the 1/4” side facing you. Install and glue TES in the

front (3/16”) notches. It is best to place this up against a straight edge to insure that the assembly

will be straight.

c 6

c 7

c 8

Install TE into the 1/4” notches facing you, this is the trailing edge sub-assembly.

Prepare the top and bottom sheer webs

SW-T and SW-B. When preparing the

sheer webs, remove the small half ellipse shaped pieces at the root ends but

DO NOT remove the dash cut material

Prepare two spar box caps SBC. We will

be gluing these to each sheer web in the

following steps. Lay the sheer webs on the

bench with the labeled side up. (NOTE:

When assembling the right wing you will

want these on the bench with the labeled

side down.) Place one SBC on the register pins as shown in the same orientation

as SW-T. (Photo A) Slide SW-T down into

contact with SBC. Very lightly, tack glue

SW-T to SBC through the small half ellipse openings (Photo B). Tack glue to the

outside edge, NOT the inside edge. When

cured, carefully remove from the pins and

ip the assembly over. Glue SBC to SW-T

at the inboard end (Photo C) then ip the

assembly over with the labeled side up.

Carefully cut along the dash cut lines and

remove the internal section of balsa from

SW-T (Photo D). This will become the

socket for the wing joiner and is intentionally a snug t. If there is any material inside the pocket it must be removed now.

Glue SW-T and SBC along the entire inside line of the joiner opening.

A

Tack Glue Here

B

C

c 9

c 10

Locate and prepare all wing ribs W1

through W12. Note that W1, W2 and W3

are two piece ribs.

Starting with W4 in the rst slot next to

SBC, slide each rib into the appropriate

notch in SW-B.

17

Page 20

D

c 11

c 12

c 13

Slide SW-T down into the slots just be-

hind SW-B. Use nesse not force, when

everything is lined correctly they will fall

in place. IMPORTANT next we will tack

glue SW-T and SW-B together capturing

all ribs from W4 through W12 however it

is very important that SW-T and SW-B be

exactly aligned before applying glue. Use

nger pressure on top and bottom of the

sheer web assembly to assure they are

aligned and then glue them. Do not glue

the ribs. Use the glue ports (ellipses) cut

into each sheer web.

Place each rib into its respective slot in the

trailing edge subassembly, do not glue.

Slide the leading edge tab of each rib into

the appropriate notch in FLE. Carefully

check the alignment of the assembly and

then pin the trailing edge subassembly to

the building board.

c 14

c 15

This much of the wing assembly is now

ready fore some glue. Start with the leading edge making sure all parts are bottomed in there notches in FLE.

Install and glue the two-piece ribs, W1,

W2 and W3.

18

Page 21

c 16

Install the top spar ange SPF-T. Apply

glue to the top of the sheer webs from

W12 to the root and to each rib in the

ange notch at the top of each rib. Place

SPF-T onto the wing and use a straight

edge to weigh it down until it cures. Check

that the ange is in good contact with the

sheer webs along the entire length.

c 17

c 18

c 19

Locate and prepare the wing tip WT. Install and glue WT to W12, FLE, the sheer

web assembly, FTE and TE.

Locate and prepare the trailing edge top

sheeting TES-T. Plane a small amount of

material off of the trailing edge to bring it

into contour with the trailing edge of the

ribs. Install and glue TES-T in place. Assure that it is bottomed in the notches.

Note the indentation at the root end. Re-

move any glue that squeezes out into this

area, as it will interfere with the center

sheeting when it is installed later.

Locate the cardboard cable tunnel tube

and cut one piece 6-3/8” long and another

9-3/8”long. Install the 9-3/8” section rst

into the holes in the wing ribs. Push this

tube through until it just protrudes through

W7. Install the 6-3/8” tube until it just protrudes through W3. Glue both tubes in

place.

c 20

Locate and prepare one top center section sheeting TCS. Install and glue this

part. TCS should butt snugly up against

TES-T.

c 21

Locate and prepare the top leading edge

sheeting LES-T. Before we can install

LES-T we will need to sand the top of WT

to contour with W-12. Test t LES-T and

sand WT until you gat a good t. LES-T

will lay on top of the top wing spar ange

SPF-T and butt up against the ribs at the

aft edge of the spar ange. It should also

butt up against the center section sheeting TCS.

19

Page 22

c 22

Use slow CA, apply a liberal bead to the

top of the spar ange the full length including the tip section of the sheer webs.

We will glue it to the ribs and the leading

edge from the bottom later. Install LES-T

and hold in place with a straight edge until

cured.

c 23

c 24

c 25

c 26

Locate and prepare the top wing tip sheeting WTS-T. Install and glue this between

the leading and trailing edge sheeting on

top of W12 and WT.

Remove the push pins and then remove

the wing assembly from the building

board. Snap off all the pinning tabs from

FLE. Do not be concerned about minor

damage to FLE; it will be covered by LE

later.

Turn the wing assembly over and install

and glue the bottom spar ange SPF-B in

the same manner as you did the top spar

ange.

From the bottom of the wing assembly,

glue the leading edge sheeting to each rib

and the leading edge. This is easily done

by applying nger pressure to the sheeting at each rib and applying thin CA. Start

at the center of the wing and work out in

one direction to the end. Then return to

the center and complete the process in

the other direction.

c 27

Locate and prepare two wing servo

mounts WSM and four wing servo mount

screw rails, part B. Use the pin register

system to install two WSMB screw rails to

the back of each servo mount WSM.

c 29

Install and glue one servo mount assem-

bly into position between W3 and W4.

The screw rails should be facing in.

c 30

Install and glue the remaining servo

mount assembly into position between

W7 and W8.

c 31

Locate and install the bottom center section sheeting BCS.

20

Page 23

c 32

Install and glue two wing sheeting gussets WGS. These will install at the wing

tip at the corners of W12 and TES and

W12 and the bottom spar ange SPF-B.

These will support the wing tip sheeting

and should be glued in ush with the bottom of W12.

c 34

c 35

c 36

Install and glue the bottom wing tip sheeting, WTS-B.

Install and glue the bottom leading edge

sheeting BLE.

Plane or sand the leading edge perfectly at in preparation for installing the leading edge. Locate

and install LE, use push pins and tape to secure it until the adhesive has set. Plane and sand the

leading edge to contour with the ribs. It is important to use the lite ply Wing Leading Edge Template supplied to shape the leading edge. A leading edge that is misshaped can have undesirable

ying characteristics.

This concludes the assembly of the left wing panel. Return to step one of the wing assembly

instructions and repeat steps 1 through 35 for the right wing panel. Remember to reverse the procedure to install SBC onto the sheer webs. Sand all surfaces in preparation for covering. Cover

the wings with your preferred covering system.

Use Epoxy or PU glue to assemble the wing platform and the wing halves.

c 1

c 2

c 3

Flap assembly

When assembling the aps, you will be

making a left and a right ap. It is best

to assemble both aps at the same time

to avoid making two of the same hand.

Place the ap base (FLB) on the bench

and glue the ap hard point (FLHPB) in

the notch provided. The correct orientation is with the labeled edge toward the

leading edge.

Glue the ap leading edge (FLE) to the

ap base assembly.

Glue all ap ribs (FL-2 & FL-1) to the ap

base assembly.

ABOVE: FHP has been glued into FB, note the correct orientation. The notch should be closest to the leading edge.

21

Page 24

Aircraft Weight Oz. Per Sq. Ft.

Lbs. Oz. Wing Loading

5 0 13.7

5 4 14.3

5 8 15.0

5 12 15.7

6 0 16.4

6 4 17.1

6 8 17.8

6 12 18.4

7 0 19.1

7 4 19.8

c 4

Carefully align the slot in the ap hard

point block (FLHPB) with the slot in FLHP

and glue in place.

c 5

c 6

c 7

Before installing the top sheet, the leading and trailing edges as well as FLHPB

must be sanded to contour with the ap

ribs. Take care not to sand into the ribs or

the position tabs on the leading edge, just

sand down to them and then glue on the

top sheeting (FLT).

The ap control horn can be installed after the ap has been covered.

When installing the ap onto the wing, it is

a good idea to pin the hinges after gluing.

This can easily be accomplished bu drilling a 1/16th inch hole through the bottom

sheeting, the hinge and the ap leading

edge and wing trailing edge and the gluing in a round tooth pick. Trim the tooth

pick

ABOVE: The ap assembly has been sanded to contour

with the ribs and the top sheet is ready to be installed.

Note that the position tabs on the leading edge have not

been sanded.

Wing loading chart

The following pages contain the parts locator list. Use this to quickly locate required parts.

ABOVE: The assembled aps, on the right with the control horn and the hinges temporarily installed. These will

be removed and the nal installation will be after the aps

are covered.

22

Page 25

Part # Qty. Sheet # SIZE Material Description

ACP 1 1 1/16” X 2-2/2” X 4” AC PLY Anti crush plate

AH 2 24 3/32” X 4” X 48 AC PLY Aileron horn

BCS 2 2 1/16” X 6” X 36” BALSA Bottom center sheeting, wing

BLE 1 8 1/16” X 4” X 36” BALSA Bottom leading edge sheeting, wing

BLE 1 9 1/16” X 4” X 36” BALSA Bottom leading edge sheeting, wing

BS-A 1 17 1/8” X 4” X 36” BALSA Bottom sheeting part A, fuselage

BS-B 1 17 1/8” X 4” X 36” BALSA Bottom sheeting part B, fuselage

CS-A 1 3 1/16” X 4” X 36” BALSA Center section sheeting part A, wing platform

CS-B 1 3 1/16” X 4” X 36” BALSA Center section sheeting part B, wing platform

CS-C 1 3 1/16” X 4” X 36” BALSA Center section sheeting part C, wing platform

CS-D 1 3 1/16” X 4” X 36” BALSA Center section sheeting part D, wing platform

EH 1 24 3/32” X 4” X 48 AC PLY Elevator horn

EJ-A 1 33 1/4” X 4” X 7” BASSWOOD Elevatot joiner part A

EJ-B 1 17 1/8” X 4” X 36” BALSA Elevatot joiner part B

F2 2 16 1/8” X 12” X 12” AC PLY Fuselafe former #2

F3 1 19 1/8” X 12” X 48” LPLY Fuselafe former #3

F4 1 21 1/8” X 6” X 17” LPLY Fuselafe former #4

F5 1 19 1/8” X 12” X 48” LPLY Fuselafe former #5

F6 1 19 1/8” X 12” X 48” LPLY Fuselafe former #6

F7 1 20 1/8” X 12” X 48” LPLY Fuselafe former #7

F8 1 19 1/8” X 12” X 48” LPLY Fuselafe former #8

F9 1 20 1/8” X 12” X 48” LPLY Fuselafe former #9

FA 2 11 1/4” X 4” X 36” BALSA Fuselage side part A

FAM-B 1 20 1/8” X 12” X 48” LPLY Float aft mount part A

FB 1 19 1/8” X 12” X 48” LPLY Float aft mount part B

FD 2 10 1/32” X 12” X 30” AC PLY Fuselage doubler

FF 1 19 1/8” X 12” X 48” LPLY Fuselage oor

FH 2 24 3/32” X 4” X 48 AC PLY Flap horn

FHA 1 21 1/8” X 6” X 17” LPLY Fuselage hatch part A

FHA-H 2 16 1/8” X 12” X 12” AC PLY Fuselage hatch part H

FJ-A 1 33 1/4” X 4” X 7” BASSWOOD Hatch magnet retainer

FLE 2 18 1/8” X 3” X 36” BALSA False leading edge, wing

FLHP-A 1 19 1/8” X 12” X 48” LPLY Float hard point part A

FLHP-B 1 19 1/8” X 12” X 48” LPLY Float hard point part B

FS-A 2 20 1/8” X 12” X 48” LPLY Fuselage side part A

FSB 2 19 1/8” X 12” X 48” LPLY Fuselage side part B

FST 1 14 1/4” X 5” X 12” LPLY Fuselage servo tray

FTD 1 19 1/8” X 12” X 48” LPLY Fuselage turtle deck

FTGM 1 14 1/4” X 5” X 12” LPLY Fuselage tail gear mount

FW-A 1 19 1/8” X 12” X 48” LPLY Firewall part A

FW-B 1 19 1/8” X 12” X 48” LPLY Firewall part B

FWBP 1 14 1/4” X 5” X 12” LPLY Fuselage wing bolt plate

FWS 23 23 3/16” X 4” X 36” BALSA Fuselage wing saddle

23

Page 26

Part# Qty. Sheet# Size Material Description

GB 2 14 1/4” X 5” X 12” LPLY Gear brace

HB 4 33 1/4” X 4” X 7” BASSWOOD Horn block

HB 2 18 1/8” X 3” X 36” BALSA Horn block ller

LE 2 13 1/4” X 3” X 36” BALSA Leading edge, wing

LES-T 1 4 1/16” X 4” X 36” BALSA Leading edge sheeting, wing top

LES-T 1 5 1/16” X 4” X 36” BALSA Leading edge sheeting, wing top

LGM-A 2 16 1/8” X 12” X 12” AC PLY Landing gear mount part A

LGM-B 1 20 1/8” X 12” X 48” LPLY Landing gear mount part B

LG-PLUG 4 22 1/8” X 4” X 36” BALSA Landing gear plug

MMA 1 16 1/8” X 12” X 12” AC PLY Motor mount part A

MMB 1 16 1/8” X 12” X 12” AC PLY Motor mount part B

MMH 1 16 1/8” X 12” X 12” AC PLY Motor mount horizontal

MMV 1 16 1/8” X 12” X 12” AC PLY Motor mount vertical

MMBP 1 16 1/8” X 12” X 12” AC PLY Motor mount bolt plate

NF 2 11 1/4” X 4” X 36” BALSA Nose ller

NGMB 3 33 1/4” X 4” X 7” BASSWOOD Nose gear mounting bracket

NGNP 1 16 1/8” X 12” X 12” AC PLY Nose gear nut plate

PINNING TABS 14 17 1/8” X 4” X 36” BALSA Pinning tab

R1 1 12 1/4” X 4” X 36” BALSA Rudder part #1

R2 1 12 1/4” X 4” X 36” BALSA Rudder part #2

R2-B 2 1 1/16” X 2-2/2” X 4” AC PLY Rudder hard point part B

R3-A 1 20 1/8” X 12” X 48” LPLY Rudder hard point part A

RU 1 24 3/32” X 4” X 48 AC PLY Rudder

S1 2 12 1/4” X 4” X 36” BALSA Stabilizer rib #1

S2 2 26 3/32” X 3” X 36” BALSA Stabilizer rib #2

S3 2 26 3/32” X 3” X 36” BALSA Stabilizer rib #3

S4 2 26 3/32” X 3” X 36” BALSA Stabilizer rib #4

S5 2 26 3/32” X 3” X 36” BALSA Stabilizer rib #5

SBC 4 15 1/64” X 5” X 10” AC PLY Spar box cap, wing

SBS 2 18 1/8” X 3” X 36” BALSA Stabilizer bottom spar

SCS-A 1 3 1/16” X 4” X 36” BALSA Stabilizer center sheeting, aft

SCS-F 1 3 1/16” X 4” X 36” BALSA Stabilizer center sheeting, for

SFLE 1 17 1/8” X 4” X 36” BALSA Stabilizer false leading edge

SFTE 1 17 1/8” X 4” X 36” BALSA Stabilizer false trailing edge

SLE 1 12 1/4” X 4” X 36” BALSA Stabilizer leading edge

SMP 1 24 3/32” X 4” X 48 AC PLY Stabilizer mounting plate

SP 1 21 1/8” X 6” X 17” LPLY Stabilizer plate

SPF-B 2 24 3/32” X 4” X 48 AC PLY Spar ange bottom, wing

SPF-T 2 24 3/32” X 4” X 48 AC PLY Spar ange top, wing

SQUARE 1 14 1/4” X 5” X 12” LPLY Square

SSW 2 18 1/8” X 3” X 36” BALSA Stabilizer sheer web

ST 2 26 3/32” X 3” X 36” BALSA Stabilizer tip

24

Page 27

Part# Qty. Sheet# Size Material Description

STE 1 12 1/4” X 4” X 36” BALSA Stabilizer trailing edge

STS 1 17 1/8” X 4” X 36” BALSA Stabilizer top spar

TCS 2 2 1/16” X 6” X 36” BALSA Wing top center sheeting

TE 2 13 1/4” X 3” X 36” BALSA Wing trailing edge

TES 2 23 3/16” X 4” X 36” BALSA Wing trailingf edge spar

TES-B 2 6 1/16” X 4” X 36” BALSA Trailing edge sheeting bottom, wing

TES-T 2 7 1/16” X 4” X 36” BALSA Trailing edge sheeting top, wing

V1 2 22 1/8” X 4” X 36” BALSA Vertical n part #1

V2 1 12 1/4” X 4” X 36” BALSA Vertical n part #2

V3 1 12 1/4” X 4” X 36” BALSA Vertical n part #3

V4 1 12 1/4” X 4” X 36” BALSA Vertical n part #4

V5 1 12 1/4” X 4” X 36” BALSA Vertical n part #5

V6 1 12 1/4” X 4” X 36” BALSA Vertical n part #6

V7 1 12 1/4” X 4” X 36” BALSA Vertical n part #7

VF 1 11 1/4” X 4” X 36” BALSA Vertical n

W1 2 27 3/32” X 3” X 36” BALSA Rib #1, wing

W1 2 28 3/32” X 3” X 36” BALSA Rib #1, wing

W10 1 29 3/32” X 3” X 36” BALSA Rib #10, wing

W10 1 30 3/32” X 3” X 36” BALSA Rib #10, wing

W11 1 29 3/32” X 3” X 36” BALSA Rib #11, wing

W11 1 30 3/32” X 3” X 36” BALSA Rib #11, wing

W12 1 29 3/32” X 3” X 36” BALSA Rib #12, wing

W12 1 30 3/32” X 3” X 36” BALSA Rib #12, wing

W2 2 27 3/32” X 3” X 36” BALSA Rib #2, wing

W2 2 28 3/32” X 3” X 36” BALSA Rib #2, wing

W3 2 27 3/32” X 3” X 36” BALSA Rib #3, wing

W3 2 28 3/32” X 3” X 36” BALSA Rib #3, wing

W4 1 27 3/32” X 3” X 36” BALSA Rib #4, wing

W4 1 28 3/32” X 3” X 36” BALSA Rib #4, wing

W5 1 27 3/32” X 3” X 36” BALSA Rib #5, wing

W5 1 28 3/32” X 3” X 36” BALSA Rib #5, wing

W6 1 27 3/32” X 3” X 36” BALSA Rib #6, wing

W6 1 28 3/32” X 3” X 36” BALSA Rib #6, wing

W7 1 29 3/32” X 3” X 36” BALSA Rib #7, wing

W7 1 30 3/32” X 3” X 36” BALSA Rib #7, wing

W8 1 29 3/32” X 3” X 36” BALSA Rib #8, wing

W8 1 30 3/32” X 3” X 36” BALSA Rib #8, wing

W9 1 29 3/32” X 3” X 36” BALSA Rib #9, wing

W9 1 30 3/32” X 3” X 36” BALSA Rib #9, wing

WH-A 2 TBD 3/32” X 3” X 7” AC PLY Wing hook part A

WH-B 1 16 1/8” X 12” X 12” AC PLY Wing hook part B

WJ 2 24 3/32” X 4” X 48 AC PLY Wing joiner

25

Page 28

Part# Qty. Sheet# Size Material Description

WP 1 19 1/8” X 12” X 48” LPLY Wing platform

WP-1A 1 16 1/8” X 12” X 12” AC PLY Wing platform part A

WP-1B 1 17 1/8” X 4” X 36” BALSA Wing platform part B

WP-2 2 26 3/32” X 3” X 36” BALSA Wing platform part 2

WP-B1 1 17 1/8” X 4” X 36” BALSA Wing platform brace #1

WP-B2 1 18 1/8” X 3” X 36” BALSA Wing plarform brace #2

WP-DS 2 26 3/32” X 3” X 36” BALSA Wing platform dowl support

WP-F 1 11 1/4” X 4” X 36” BALSA Wing platform ller

WP-FLE 1 18 1/8” X 3” X 36” BALSA Wing platform false leading edge

WP-LE 1 11 1/4” X 4” X 36” BALSA Wing platform leading edge

WS 1 23 3/16” X 4” X 36” BALSA Windshield, fuselage

WSG 4 22 1/8” X 4” X 36” BALSA Wing sheeting gusset

WSM 4 19 1/8” X 12” X 48” LPLY Wing servo mount

WSMB 8 16 1/8” X 12” X 12” AC PLY Wing servo mount brace

WT 2 25 3/32” X 4” X 36” BALSA Wing tip

WTS-B 2 3 1/16” X 4” X 36” BALSA Wing tip sheeting, bottom

WTS-T 2 2 1/16” X 6” X 36” BALSA Wing tip sheeting, top

26

Page 29

27

Page 30

Brentwood TN 37027 USA

Hobby Lobby International

5614 Franklin Pike Circle

Phone 866-512-1444

Loading...

Loading...