Page 1

Albatros DVa

Wingspan: 52 in. (1325mm)

Length: 41 in. (1045mm)

Wing Area: 723 in². (46.65dm²)

Flying Weight: 60 oz. (1.70kg)

Wing Loading 11.95 oz/sq. ft.

Center of Gravity 2.6 in. (66mm) back from LE top wing

1

Page 2

Additional Items Required

¨ 4-channel Aircraft Radio w/ Receiver (minimum)

¨ 3 cell Lipo battery 2100-2500mAh

¨ (1) Hitec HS-322 servo

¨ (2) eRC 8g servos

¨ (1) eRC 9g metal gear servo

¨ (2) 12” servo wire extensions

¨ eRC Brushless 45 amp ESC w/SBEC

¨ eRC Brushless BL25 Motor

¨ APC 12x6E Propeller

¨ 5-minute Epoxy Glue

¨ Thin CA Glue

¨ Phillips screwdriver

¨ Hex Drivers

¨ Needle Nose Pliers

¨ Hobby Knife

¨ Soldering iron and electrical solder

2

Page 3

1. Install the full size servo for the elevator in

the fuselage. Place the output shaft end of

the servo toward the tail of the airplane.

2. Install the 9g metal gear servo for the

rudder in the fuselage. Place the output

shaft end of the servo toward the tail as

well.

3. Before installing the servo arms, slip the

pushrods into the fuselage and attach “Zbend” end to servo arm.

4. Locate the horizontal stabilizer and the

CA hinges.

5. Insert CA hinges into pre-cut slots in

trailing edge of the horizontal stabilizer.

Insert the hinge 1/2 way into the surface

and put a pin through the hinge to keep it

centered.

6. Slip the elevator onto the CA hinges,

leave a small gap between elevator and

stabilizer.

7. Make sure that the elevator has the

mounting location for the elevator horn on

the right side of the center. The photo

shows the stabilizer from the top view.

8. Check that the elevator is centered on the

stabilizer and that the gaps are even

before you apply the CA to the hinges.

9.

3

Page 4

10. If there is too much wood showing on the

top of the stabilizer, iron on a scrap of the

matching covering from the spare covering

provided.

11. Slide the horizontal tail into the slot in the

fuselage and center. Do Not Glue yet.

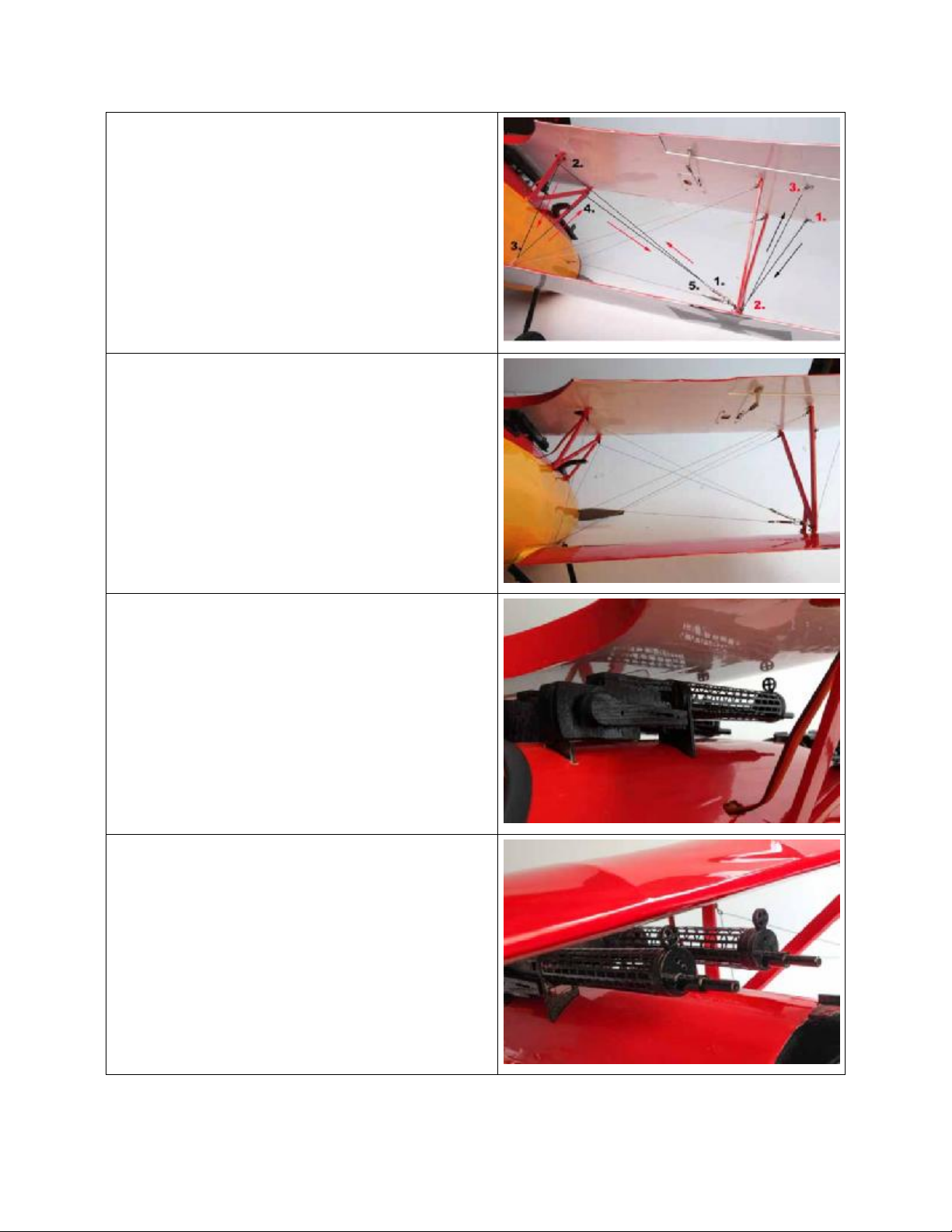

12. Locate the vertical fin and rudder and

hinge together in the same manner as the

horizontal stabilizer and elevator.

13. Insert the vertical fin and rudder into the

slot on the top of the fuselage. There are

tabs on the bottom of the vertical fin that

must engage in slots on the horizontal

stabilizer.

14. When satisfied with the fit CA the joints

using thin CA and a small tip to keep

things neat.

15. Screw the nylon control horns to the

elevator and rudder. The elevator horn is

on the bottom right of the elevator and the

rudder is on the left side of the rudder.

Use the 6 shorter screws that look like the

photo to the right.

4

Page 5

16. Single 35” piece of stranded wire is for the

tail brace. The other pairs of wires will be

used later for the main rigging of the

wings.

17. Locate the tail brace parts shown in photo.

You will also need the 35” wire and 2

crimp tubes.

18. Install the U shaped metal over the tail

skid and bolt in place with a swivel on

each side.

19. Slide the wire through one of the crimp

tubes then through the swivel and back

through the crimp. Lock in place by

crimping the tube with a pair of pliers.

20. Thread the wire through the pre-drilled

holes in stabilizer and fin and finish by

repeating the process on the other crimp

21. Attach the pushrods to the rudder and

elevator and adjust to neutral position.

22. Remove the servo hatches from the

bottom of the upper wing.

23. Test fit the micro servo making sure that

the servo arm does not bind on the

opening of the servo hatch.

24. If the servo arm is not centered in the

opening, adjust by cutting the wood

mounting ears for proper fit.

5

Page 6

25. With servo mounted on hatch, extend the

length of the servo wire with a 12”

extension. Tape the connection so that it

cannot be pulled loose.

26. Tie the male plug end of the extension to

the pull string located in the wing.

27. Cut open the hole on the bottom of upper

wing near the cabane strut attachment.

28. Fish the servo extension through the wing

and out the exit hole.

29. Repeat this process for the other aileron.

30. Screw each hatch in place using 4 small

washer head screws.

31. Install the CA hinges in the leading edge

of the ailerons. Insert them 1/2 way in the

control surface and pin the center to

prevent the hinge being further inserted.

6

Page 7

32. Check the hinge gap and keep it small.

Using the shaft of the pin as a guide is a

good idea.

33. When satisfied with the fit of the aileron,

CA it in place with a quick shot of thin CA

glue. Flex the control surface down and

add 3 drops to each hinge then flex

aileron up and repeat the process.

34. Nip the excess screw length off with a pair

of side cutters or a Dremel cut-off wheel.

35. Locate the remaining 2 nylon control

horns and the longer screws and install in

the pre-drilled locations on each aileron.

7

Page 8

36. The photo at the right shows the parts

needed to assemble the landing gear. Not

shown in the photo are the 3 wheel

collars, you will need them as well.

37. Slide one wheel onto axel and then one of

the wheel collars.

38. Next slip on one of the landing gear leg

attachment parts onto the axel with the

bends leaning away from the wheel as

shown.

39. Install the landing gear legs onto the

attachment part.

40. Slide the landing gear spreader bar with

its airfoil facing in the direction of flight.

The longer leg is the rear leg.

41. Slide on the other landing gear attachment

part followed by another wheel collar and

tighten.

42. Install the remaining landing gear legs.

8

Page 9

43. Slip on the second wheel and the final

wheel collar and tighten, make sure that

the wheels rotate freely.

44. The assembly should look like the photo to

the right and is ready to install into the

slots in the fuselage.

45. Carefully install the wire ends into the slots

on the fuselage and slip them fully into the

pockets.

46. Locate the 4 ply inserts as shown.

47. Insert one ply spacer into each of the

slots. Do not apply glue, we will add a few

drops of CA when we have them all

complete.

9

Page 10

48. You may need to use the end of a piece of

ply to aid in inserting the spacers, they are

a tight fit.

49. Once fully inserted apply a few drops of

thin CA to retain the spacers.(See photo)

50. If you are using the recommended eRC

BL25 motor, you will need to install the

laser cut ply mounting disc to the rear of

the motor instead of the X-mount that

came with the motor.

51. The motor shaft must be shortened by

about 1/4" so that the rear of the collet

adapter touches the anodized motor case.

52. If this is not done the spinner will have too

large a gap behind it.

53. Slide the ESC into the fuselage and screw

the motor mount to the firewall with the

supplied allen head screws.

10

Page 11

54. The installation should look like the photo

to the right.

55. With the dummy motor installed, the

battery hatch installs and is held in place

with magnets.

56. Install cabane struts on fuselage. Use

small machine screw, washer and nut.

57. Cabane should be mounted to the bottom

side of the supports as shown.

58. Install the outboard struts to the bottom of

the upper wing. Mount them to the outside

of the supports.

59. The installation should consist of. A screw

through the strut and then the support.

Slip a swivel onto the screw then a washer

followed by the nut, snug in place.

60. Photo shows the two additional swivels

that are installed with small wood screws

to the outboard underside of the upper

wing. The location is pre-drilled.

11

Page 12

61. In addition to the cable you will need this

hardware.

62. Machine screws, washers and nuts to

attach struts to wings and fuselage

63. Turnbuckles, cable connectors and cable

crimps to attach cable and adjust cables.

64. Locate the cables and separate into

groups shown.

65. Two 21” pieces at outboard wing tips

66. Bottom wing strut attachment front hole.

67. From the outside of the strut insert screw

with swivel through strut an strut

attachment. Slide another swivel to the

screw then a washer and nut.

68. With a screw and nut attach the base of 2

cable connectors to the top of the swivel.

69. Take one of the 74” cables and attach a

turnbuckle as shown.

70. Insert wire end through crimp, then

through eye on turnbuckle, back through

crimp in opposite direction, make a loop

and insert cable through crimp in the same

direction again.

71. Snug up cable and crimp the tube with a

pair of pliers.

72. Photo shows assembly uncrimped.

12

Page 13

73. Install swivel on side of fuselage nose with

washer head wood screw.

74. Unscrew the turnbuckle so that you will

have adjustment room later.

75. Start at the location shown in photo.

76. Slip one crimp on cable and thread cable

through swivel on nose and back through

crimp.

77. Next the cable goes through the upper

rear swivel then down to loop at root of

lower wing, finishing at upper front strut.

78. Slip a crimp on cable before inserting in

swivel, then back through the crimp. The

same process as at the turnbuckle.

79. DO NOT TIGHTEN AND CRIMP AT THIS

TIME

80. Repeat process on opposite wing.

81. Install one turnbuckle to cable connector

at outboard lower strut as shown.

82. Take one of the 51” cables and connect it

to the turnbuckle with crimp as before.

13

Page 14

83. Thread cable through rear upper cabane

swivel, then through a cable crimp, then

the lower wing root connector and back

through the crimp before going to the

upper cabane swivel and back to the

turnbuckle at the base of the outboard

strut.

84. Make sure that you have adjustment room

on the turnbuckle. Snug up the cables

before crimping.

85. Using the 21” cables create the outboard

rigging starting at the upper front swivel.

86. Three crimps will be used. One at the

beginning, middle and end. No

turnbuckles are used here.

NOTE: When complete you will have 2

extra turnbuckles for spare parts in case of

loss.

87. When adjusting the rigging it is very

important to adjust it evenly and make

sure not to warp the wing structure. It is

possible to warp the wings to the extent

where control with the flight surfaces may

be impossible.

VERY IMPORTANT: Once wires are adjusted

it is a very good idea to put a dab of glue

(UHU Por or similar) on each of the nuts and

the turnbuckle adjustments.

88. Slip pre-made machine guns into position

on mounting tabs. A touch of glue like Uhu

Por will help hold it in place.

14

Page 15

89. The spinner is vacuformed and the

Low Rate= 7/8” Each Direction

backplate is aluminum. Both must be

balanced as well as the 12x6 APC E-prop.

90. For best results use a prop balancer.

Aileron Control Throws

High Rate= 5/8” Up and 1/2" Down

Low Rate= 3/8” Up and 1/4" Down

Rudder Control Throws

High Rate= 1-1/8” Each Direction

Elevator Control Throws

High Rate= 1” Up and Down

Low Rate= 3/4" Up and Down

CG

2.6” back from the leading

edge of the upper wing

Battery

3-cell 2100mAh Lipo

WARNING – THIS IS NOT A TOY!

Radio controlled model aircraft are capable of inflicting serious injury and/or property damage if not assembled, operated, and

maintained in a competent and safe manner. If you are not already experienced with radio controlled models, we strongly suggest

Hobby-Lobby guarantees this kit to be free from defects in both material and workmanship at the date of purchase. This warranty

does not cover any component parts damaged by use or modification. In no event shall Hobby-Lobby’s liability exceed the original

that you find an experienced modeler to assist you.

Warranty

cost of the purchased kit.

15

Page 16

Hobby Lobby International, Inc.

5614 Franklin Pike Circle

Brentwood, TN 37027

1-866-WE-FLY-RC

(1-866-933-5972)

www.hobby-lobby.com

16

Loading...

Loading...