HobbyGrower Enthusiast6""x8, Enthusiast PC Greenhouse 6""x8 Assembly Instructions Manual

ASSEMBLY INSTRUCTIONS

ASSEMBLY INSTRUCTIONS

(Internal Dimensions)

Ent Spec Edition Ltr v2-0-4

Overall dimensions including base:

247.4 L x 193 W x 210 H cms

97.5" L

x 76" W x 82.7" H

Please read these instructions carefully before you start to assemble this greenhouse. To save time and

ensure proper assembly, follow the step-by-step instructions carefully in order. Assembly is easiest when

at least two people are present. Keep these instructions in a safe place for future reference.

An updated and/or improved version of this assembly guide may be available for download from the

HobbyGrower web site. Also, if you would like to view a brief general assembly video to gain a basic

understanding of how the structure is constructed, visit

http://www.hobbygrower.com, then click on the Assembly tab.

IMPORTANT!!!

SAFETY ADVICE

•Do not attempt to assemble the greenhouse in

windy or wet conditions.

•Take special care not to touch overhead power

cables with aluminum profiles.

•Ensure that there are no buried pipes or cable in

the ground before inserting the ground stakes.

•Always wear shoes and saftey goggles during

assembly.

•We strongly recommend the use of work glove

during assembly as aluminum profiles may have

sharp edges.

•Dispose of plastic bags and protective poly film

covers safely - keep them out of reach of small

children.

•The greenhouse must be positioned and anchored

on a flat, level surface.

GENERAL ADVICE

•Before beginning the assembly process, confirm

that all necessary parts have been included in the

package. It is advisable to lay the parts out in an

orderly fashion according to the part numbers so

that parts can be easily identified during the

assembly process. If parts are missing, contact

SPS International at (800) 994-5626.

•This is a multi-part assembly. Allow at least 4 hours

to assemble from start to finish. Do not begin

assembly if heavy winds or rains are expected

within 10 hours.

•Choose a sunny level location for your greenhouse,

away from overhanging trees.

•You can opt to use the base brackets supplied to

anchor your greenhouse to a concrete floor, or you

can use the base supplied base kit (see steps 36

through 38). If you intend to anchor your

•Do not lean on or push against the greenhouse

during construction.

•Keep children away from assembly area - the

aluminum profiles may have sharp edges.

•Do not position your greenhouse in an area

exposed to heavy wind.

•Do not attempt to assemble the greenhouse if

your are tired, have taken drugs or alcohol or if

you are prone to dizzy spells.

•If you use a step ladder, carefully follow the

manufacturer's instructions.

•Hot items such as recently used grills,

blowtorches, etc. must not be stored in the

greenhouse.

greenhouse directly to concrete, you must

purchase separately concrete anchor screws for

use with part number 24 anchor brackets. The area

required for the greenhouse including anchor

brackets is 104.5" (266cm) length x 83" (212cm)

width.

•It is advisable to use lubricant to ease the

connection between aluminum profiles and panel

(a mild soap and water solution is useful for this).

•Note that the door is permanently hinged on the right

hand side and therefore opens out and to the right.

•We strongly advise that you keep the special polyfilm protective covers on the side panels and the

first row of roof panels until that greenhouse is fully

assembled. You should however remove the polyfilm prior to installing the very top roof panels.

•Keep roof clear of snow and leaves.

CARE & MAINTENANCE

•Use mild soap and water and a soft cloth to wash

greenhouse glazing panels. Rinse with cold water.

•Do not use acetone, abrassive cleaners or

sponges, or other amonia-based cleaners to clean

the clear panels.

•Some chemicals and cleaners can be agressive to

TOOLS & EQUIPMENT REQUIRED

•100% "Silicone" Sealant

(compatible w/polycarbonate)

•Tape measure

•Work gloves

•Plastic or rubber mallet

the clear panels, which are made of polycarbonate.

For a complete list of chemical compatibility, visit:

http://www.spscorp.com/compatibility

•To purchase replacement parts, contact customer

service at SPS International at (800) 994-5626, or

send an email to sales@spscorp.com.

•Crosshead Screwdriver

(a.ka. "Philips")

•Lubricant (mild soap & water

solution works well)

•Scissors

1

See next page for complete list of parts

•Step ladder

•Level

•Large Hammer (for anchor stakes)

•5/64" Drill bit

(or similar diameter nail)

2

1

2

3

4

5

6

8

9

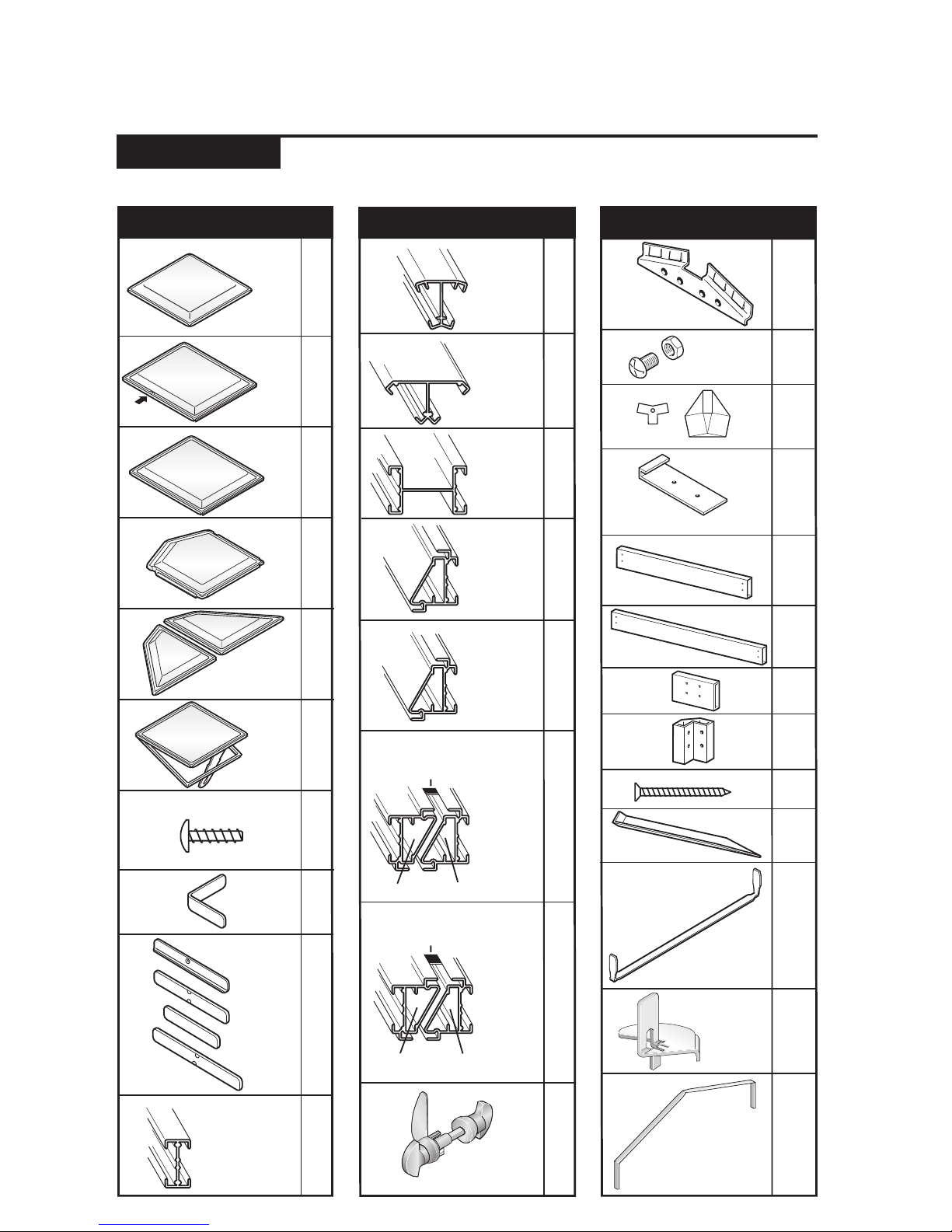

ITEM QTY.

CONTENTS

ITEM QTY.

ITEM QTY.

27

1

2

15mm (0.59") 10

2

3

2

2

Door

handle hole

23

10

10

24

8

1

31

1

32

33

1

5

3

2

4

(Assembly

required; see

steps 24A-C)

600 x 600mm

(23.6" x 23.6")

600 x700 mm

(23.6" x 27.5")

600 x700 mm

(23.6" x 27.5")

13

10

120mm (4.72")

100mm (3.93")

75mm (2.95")

120mm (4.72")

12

13

14

10

4

8

1

2

15

2

550mm (21.6")

17

1

6

6

21

22

10A

10B

10C

16

2

1290mm (50.7")

(Left door frame

and door jam)

(Bottom door jam

alignment bracket)

(Top door jam

alignment bracket)

(Door support)

1290mm (50.7")

550mm (21.6")

Door jam Door frame

(Door handle

assembly. Includes

3/32" allen wrench)

Plastic hinge plate

(Door frame

and door jam

assembly;

joined

together

with plastic

hinge plate)

(Door frame

and door jam

assembly

extension;

joined by

plastic

hinge plate)

(Left door frame

and door jam

extensions)

18

1

2

1190mm (46.8")

1290mm (50.7")

575mm (22.6")

530mm (20.8")

590mm (23.2")

1330mm (52.3")

Door jam Door frame

Plastic hinge plate

12mm (0.47")

11 18

8

590mm (23.2")

920mm (36.2")

1100mm (43.3")

1290mm (50.7")

4

2

19

1

25

26

27

28

29

16mm (.63")

4

4

40

6

4

6

30

797mm

(31.4")

920mm

(36.2")

Note: 1 inch = 25.4 millimeters (mm)

Important! Be sure to inventory and organize parts prior to beginning the assembly process.

1

Height:

200 cm (78.8")

1

6

1

1

6

1

1

1

1

5

4

1

3

1

3

2

1

1

5

3

3

3

1

3

1

1

Height:

10 cm (3.9")

Width:

193 cm (76")

25

Width:

190 cm (75")

26

25

1

26

25

1

Length:

247.4 cm (97.5")

26

26

25

25

25

Length:

245.5 cm (96.7")

3

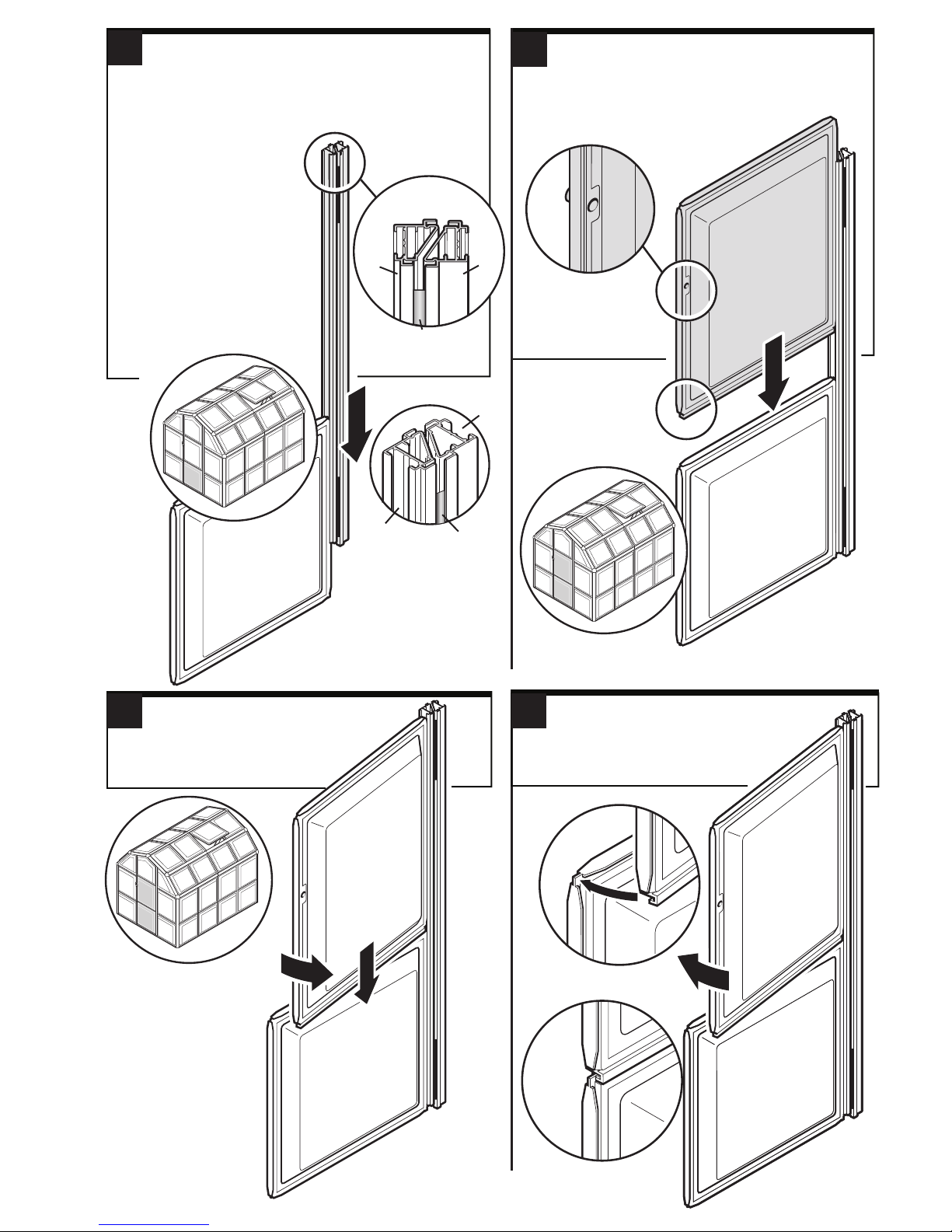

Door Assembly

1

Select profile 17-1290mm.

IMPORTANT: You must ensure that the profile is

oriented right-side up and with the plastic hinge

plates facing out (Fig A).

Slide profile onto a

square panel 1 (door

frame side

of profile).

Fig. A

(viewed from top)

Important: Note

orientation of angle

2

Slide the rectangular panel 2 (must be

the panel with the door handle hole) onto

the profile ensuring it has the interlocking

slot at its bottom.*

When necessary use a

lubricant to ease

connection between

aluminium profiles and

panels (mild soap and

water works well for this).

1

Door

frame

Plastic hinge

17/1290

Door

frame

Door

hinge

Door

jam

Door

jam

Door

handle

hole

Interlocking slot at

bottom of panel 2

MUST USE

PANEL

2

*

1

To interlock the two panels, first

3

pull the top panel back slightly

as shown (A), then push

down fully.

A

4

Push the top panel back so it

interlocks and is flush with

the bottom panel.

2

B

1

1

2

2

1

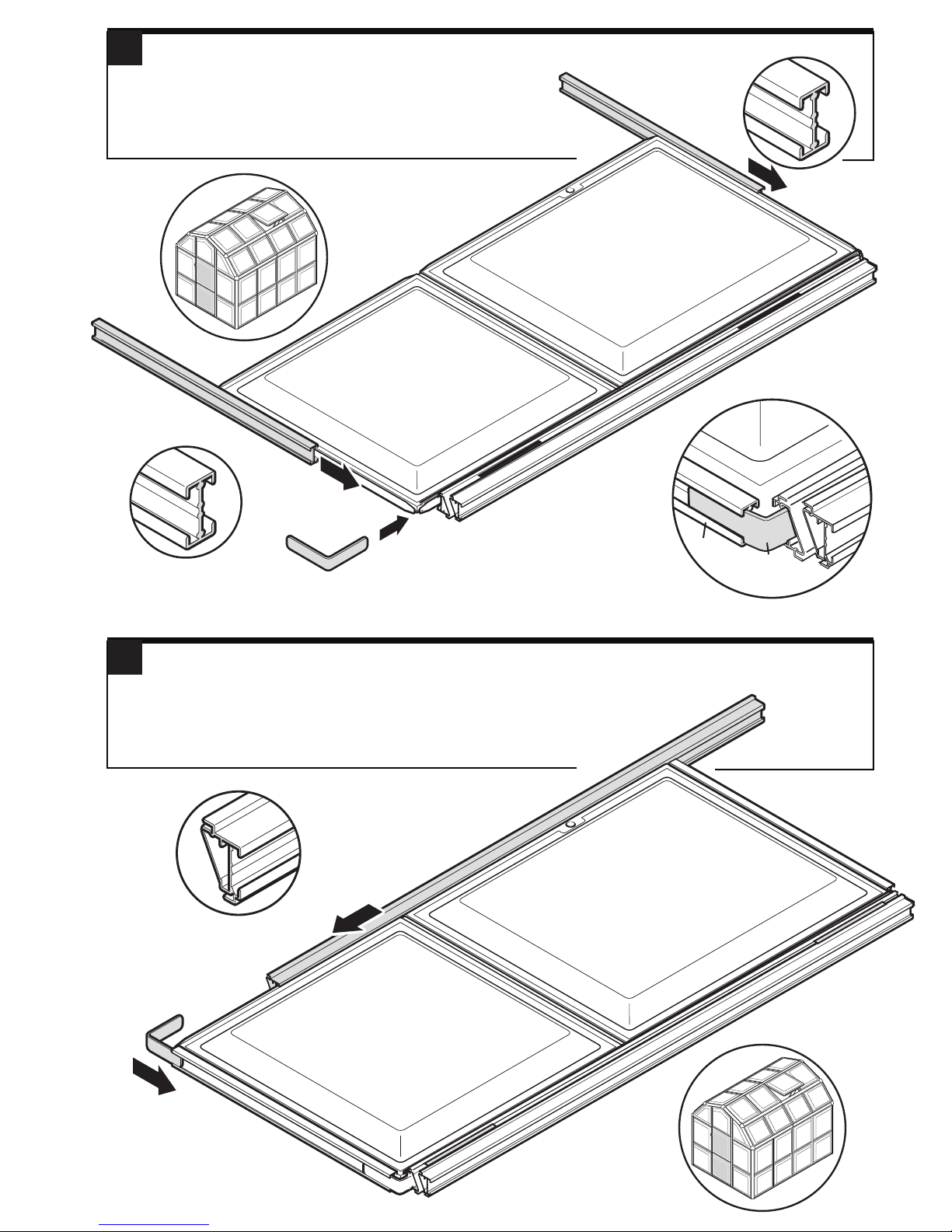

4

Lay the assembly on the floor and insert an angled bracket 9 only

5

into the bottom of profile 17-1290mm (A).

Slide a 11-590mm profile onto the top and bottom of

the door assembly (B), ensuring the angled bracket 9

slots into the bottom profile (see close up diagram).

1

11/590

11/590

B

2

B

9

11/590

Slide another angled bracket 9 into the other end of the bottom profile 11-590 (A). .

6

A

17/1290

Slide the 16-1290mm profile (B) on to the long side of the door

ensuring the angled bracket slots into the end of it .

IMPORTANT! Do nothing more to the door at this stage.

6

16/1290

B

11/590

2

9

9

A

11/590

1

5

Loading...

Loading...