Instruction Manual

Senior

Tele

m

aster

Plus AR

F

Wingspan:

Length:

Wing Area:

Weight (with battery):

94 in.

64 in.

1330 sq. in.

9 pounds

!

1

Before starting, use the

Contents list to take an

inventory and make sure it is

complete. If any parts are

missing or are not of

acceptable quality, contact

Hobby Express Support at

1-615-373-1444 .

This manual assumes the

builder possess intermediate

assembly skills. Seek help

from another pilot or an

experienced modeler if you

are unsure how to complete any steps in this manual.

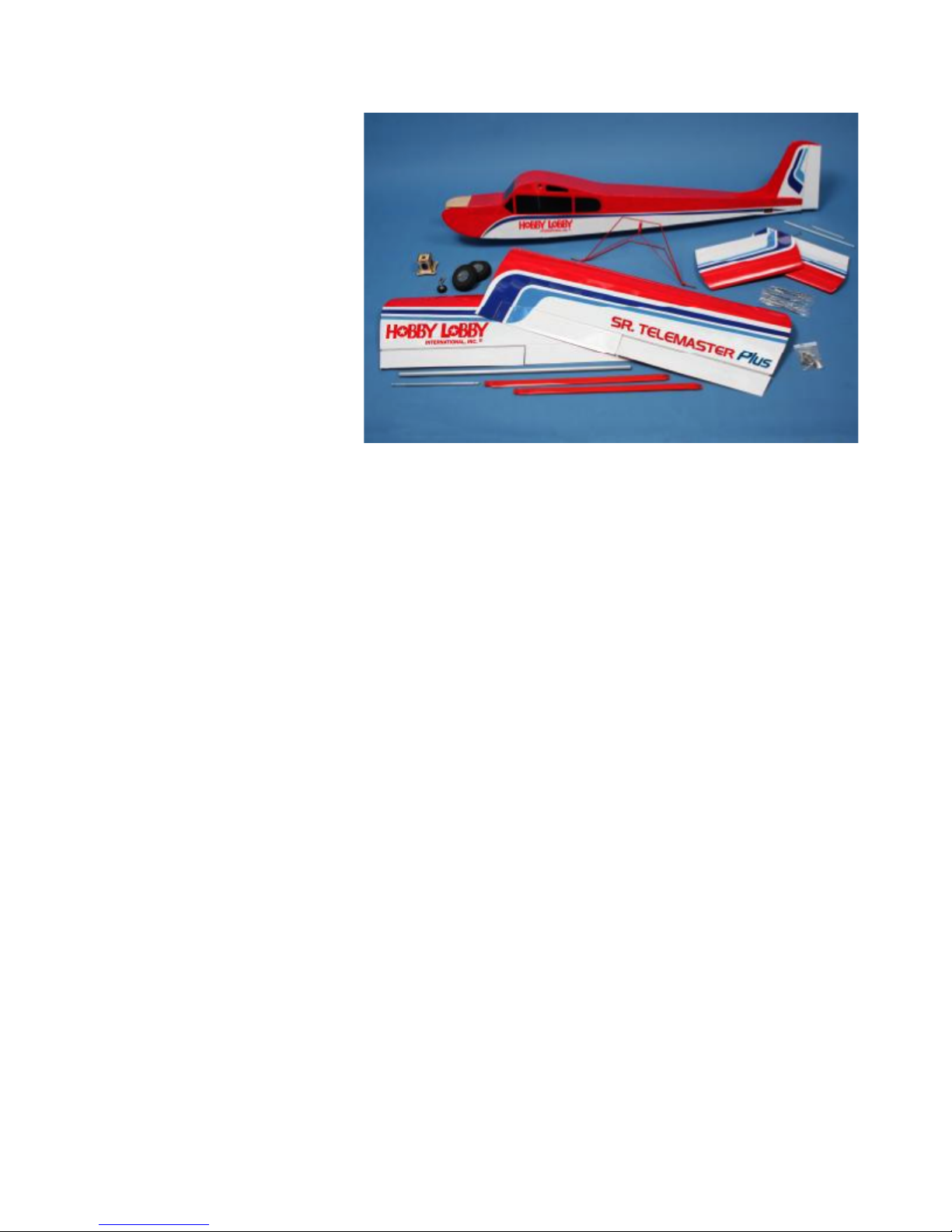

Contents List

! Fuselage

! 2 Wing Panels

! 2 Horizontal Stabilizers

! Vertical Stabilizer and Rudder

! Aluminum Wing Joiner Tubes

! Aluminum Stab Joiner Tubes

! 2 Aluminum Wing Struts

! Wire Landing Gear

! Main Wheels and Steerable Tail Wheel

! Wooden Motor Mount

! Pushrods, Control Horns, Pin Hinges and assorted fasteners

Additional Items Required

! 6-channel Aircraft Radio w/ Receiver (minimum)

! 5000mah, 5-cell, 18.5v Lipo battery

! (6) Standard sized servos

! (4) 24” Servo extensions

! (2) 12” Servo extensions

! (3) 6” Servo extensions

! (1) Servo Y-harness

! 70-80 amp Brushless ESC

! AXI 4120/18 Brushless Motor and radial mount set

! APC 14x10 “E” Propeller

! Glues, solder, connectors

2

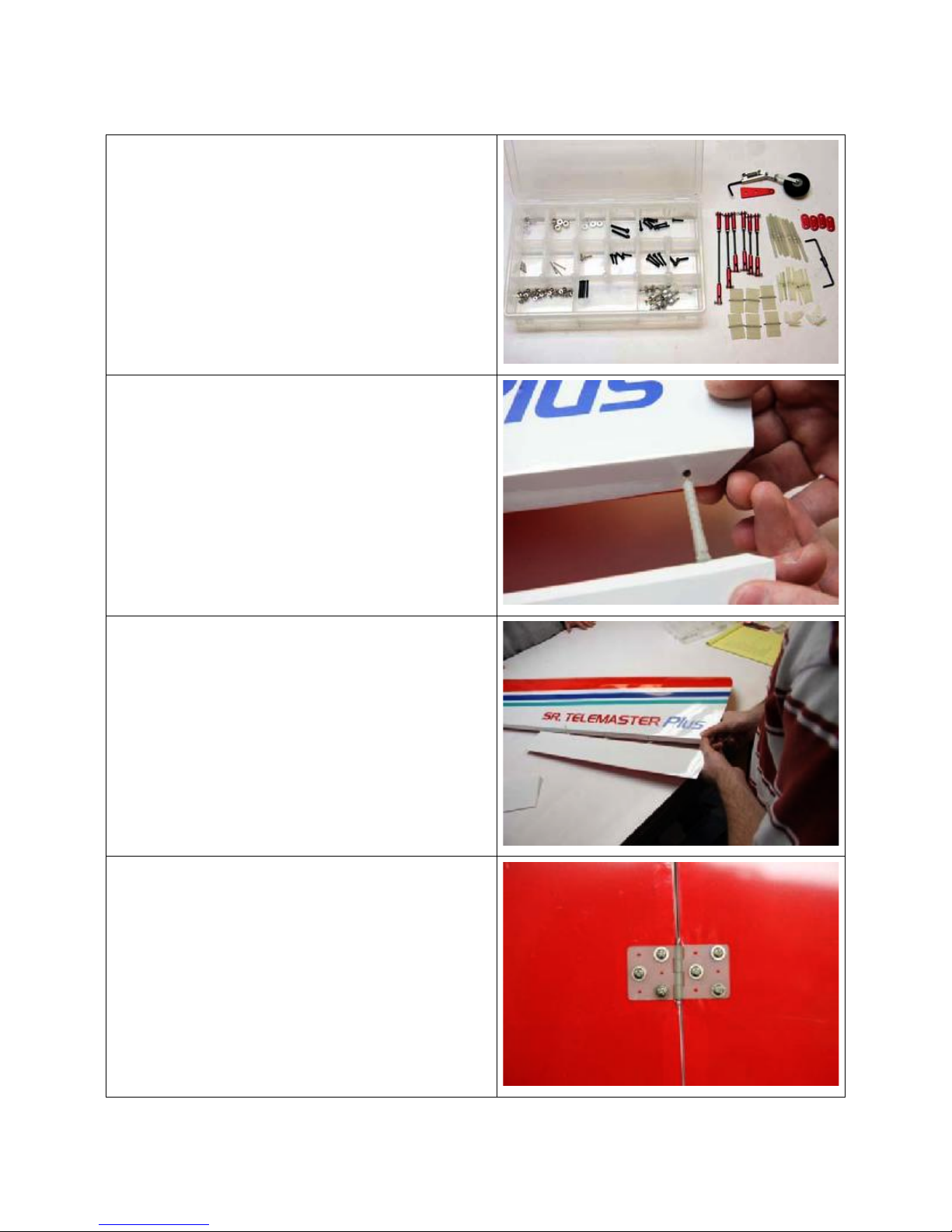

1. After unpacking all parts, sort the

hardware and place like parts into

separate holders. This will speed the

building process and give you a good

visual of all the hardware provided.

2. Begin by hinging the ailerons to the main

wing panels using the larger pin hinges.

Apply a drop of 3-in-1 oil to the pivot of

each hinge point; this is to keep the glue

from fouling the hinge operation. Use 30minute epoxy and insert into each hole

of the control surface, then insert the

hinge and set aside to cure.

3. Once the hinges are set in each control

surface, dry fit them to the wing panels

and check that the movement is smooth

and the alignment is suitable. When

satisfied, apply glue to the hinge

pinholes in the wing and insert the

control surface into position. Maintain

small gaps between the main wing and

the control surface. Check for free

movement.

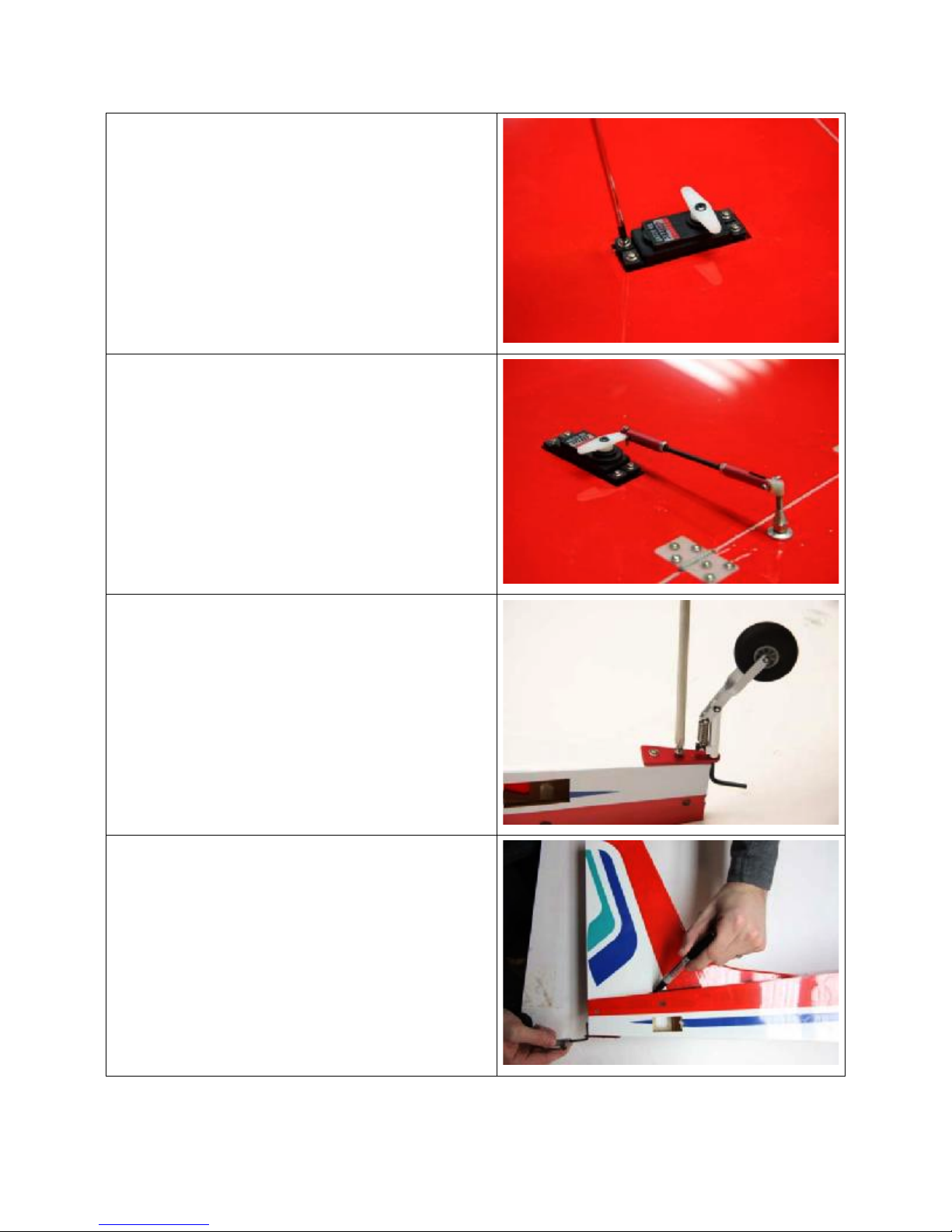

4. Now find the 6 flat hinges and 18 of the

smallest screws. Locate the mount

points on the wing and flaps (there are

hardware blocks under the covering) and

use a screwdriver to install the flap

hinges.

3

5. After all wing control surfaces are hinged

and the epoxy has cured, check for free

movement and prepare to install the

servos.

6. Add a 12” servo ext. to the Flap servos

and insert the servos in the wing. Screw

in place with the output shaft facing the

trailing edge of the wing.

7. Locate the control horns and pushrods

and install them for both flaps.

8. Repeat the process to install the servos,

control horns and pushrods for the

ailerons. Use 24” extensions for the

aileron servos. The aileron servos are

oriented in the same direction as the

flaps with the output shaft facing the

trailing edge of the wing.

9. Locate the tail wheel, mounting plate,

and two screws. Install the tail wheel as

shown.

10.Dry fit the vertical stabilizer in the

fuselage. Use a marker and mark the

vertical stab where it meets the fuselage.

Use a hobby knife and remove the

covering below the marked line. Cut the

covering about 1/8” below the marked

line. Use only enough force to cut the

covering. Do not cut into the wood.

4

11.Tape off the area on the fuselage with

masking tape, mix up some 30-minute

epoxy and glue the vertical stab in place.

The stabilizer should be flush with the

back of the fuselage. Make sure it is

straight while the glue cures. Clean up

any epoxy that squeezes out with a paper

towel and rubbing alcohol.

12.Trail fit the rudder using 3 pin hinges.

Trim the covering away where the tail

wheel steering wire inserts in the rudder.

13.Epoxy the tail wheel wire and the 3 pin

hinges to the rudder and vertical fin in the

same way you did with the ailerons and

flaps. There should only be a small gap

between the fin and the rudder.

14.Once the epoxy has set, install the rudder

nylon control horn.

15.Connect a 24” servo extension to the

rudder servo and install the servo with

the output shaft facing forward as shown.

You can tape the servo lead to the

extension so they will not be accidentally

disconnected.

5

16.Locate the Horizontal Stabilizer, eight

smaller pin hinges, a nylon control horn,

pushrod, aluminum tubes, and the

elevator U-Connector.

17.The U-connector can be separated with a

setscrew. This allows you to remove the

horizontal stabs later for transport. The

larger connector piece needs to be glued

into the right elevator and the matching

wire glued into the left elevator as shown.

18.Now hinge the elevator control surfaces

to the stabilizers with 30-minute epoxy

making sure not to foul the hinge pivots

with glue. Check for free movement.

19.Insert the aluminum tubes in the fuselage

and slide on the horizontal stabilizers.

20.Make sure the U-connector pieces line up

and that the wire piece inserts into the

connector. Move the rudder over to

access the setscrew and tighten it with an

Allen wrench. Make sure the elevators

are aligned before tightening the

setscrew.

6

21.With the plane upside down, secure the

horizontal stabilizers to the larger spar

tube with the provided Allen head screws.

Note: Do not over tighten the screw.

22.Connect a 24” servo extension to the

elevator servo and install the servo with

the output shaft facing rearward as

shown. You can tape the servo lead to

the extension so they will not be

accidentally disconnected.

23.Locate the main landing gear, wheels,

bolts, aluminum straps, and wheel

collars. Note: 4 bolts will be longer and

are used for the rear mounts.

24.Install the wheels using a wheel collar on

both sides of each wheel.

7

25.Place the landing gear in the slots on the

bottom of the fuselage. The end with the

spring will face the rear as shown. Use

the bolts and aluminum straps to secure

the landing gear. The 4 longer bolts are

used in the rear mounts.

26.Slide both aluminum tube joiners all the

way into one wing panel.

27.Locate the tube retainer holes in the

bottom of the wing.

28.Drill a hole through both sides of the

larger tube with a 3mm drill bit. Be careful

not to drill through the wing.

29.Drill a hole through both sides of the

smaller tube with a 2mm drill bit. Be

careful not to drill through the wing.

30.Remove the tubes and enlarge the hole

of the larger tube to 4.5mm and chamfer

the edges. Enlarge the hole of the

smaller tube to 3.5mm and chamfer the

edges.

31.With a marker, indicate the left or right

side depending on which side you drilled

and indicate top or bottom.

32.Put the tubes back in and secure them

with a 3mm x15mm allen head screw for

the small tube and a 4mmx30mm screw

for the large tube. Slide the tubes though

the fuselage and put the other wing on.

Drill the 3mm and 2mm holes in the tubes

as you did for the other wing. Remove

the wing and enlarge the holes to 4.5mm

and 3.5mm. Install the wing and secure it

with two allen head screws as before.

8

33.With the plane upside down, back out the

rear landing gear mount screws. Locate

the two wing struts. They are airfoil

shaped for a left and right strut. Slide the

strut end with two holes into the slot just

below the landing gear and tighten the

screws back down.

34.Use a bolt to secure the other ends of

each strut to the wing. Your wings are

now fully assembled. You may remove

them now to more easily finish the

remaining assembly steps.

35.Locate the motor mount, bolts and

washers. These items are used to secure

the motor mount block to the fuselage.

This kit does not include bolts to secure

your motor to the motor mount. You will

need to provide your own screws for that

purpose.

36.Install the motor to the motor mount first

as shown.

9

37.Now insert the motor mount to the

fuselage.

Note the keyed slots for orientation.

38.Secure the motor mount with the supplied

bolts and washers.

39.Connect the ESC to the motor and secure

with Velcro or double-sided tape.

40.The receiver can be accessed through

the hatch in the bottom of the plane. This

area is also where the optional drop box

will be located. Install the receiver with

Velcro or double-sided tape. Install the Yharness into the flap channel and the

three 6” extensions into the appropriate

channels for the ailerons and throttle.

Locate the ends of these leads near the

opening for the wings.

41.Install the hatch cover using 3 small

screws.

10

42.Install the battery using the supplied

Velcro straps. Position the battery to

achieve the proper center of gravity,

which is listed below.

43.Install the magnetic hatch by putting the

back end in first and then laying the front

down. Remove the hatch by first lifting

the front and pulling up and away.

44.Congratulations, you’ve finished the

assembly. Follow the information listed

below for recommended control throws

and center of gravity.

CG Location

Forward position for CG is 5-1/2” back from the L eading Edge of wing.

Aft position for CG is 6-1/2” back from the Leading Edge of wing.

NOTE: The CG on a Telemaster is much farther aft than a normal trainer aircraft

this is due in part to the lifting stabilizer. This CG should be achievable using the

recommended components without the need for additional weight added to t he

nose of the aircraft.

Control Throws

Ailerons = 25mm Up and 20mm Down

Flaps = As much as you want!

Elevator = 20mm Up and Down

Rudder = 35mm Left and Right

11

Preflight

If you are new to flying R/C aircraft we recommend you have a fellow R/C modeler help

you with the first flight. Some items you will need to complete on your first preflight are:

1. Aircraft assembled correctly and ready for flight.

2. All control throws set per this manual.

3. Transmitter fully charged and on the correct model.

4. Aircraft balances at the recommended location.

5. Flight batteries are fully charged and secure.

6. All electronics are operating correctly, in the proper direction, and secure.

7. Complete a radio range check per your radio’s manual.

8. Balance propeller and make sure it is secure.

9. Wait for a calm or light wind day for first flights.

Flying

You will soon find out the Senior Telemaster Plus is a real pleasure to fly. Takeoffs,

landings, and flaps down slow flight are all easy to accomplish. Even if you have never

flown a tail wheel airplane before, the Senior Telemaster Plus is an easy transition.

We hope you enjoy your Telemaster as much as we do!

Happy Landings!

WARNING – THIS IS NOT A TOY!

Radio controlled model aircraft are capable of inflicting serious injury and/or property damage if not assembled, operated, and

maintained in a competent and safe manner. If you are not already experienced with radio-controlled models, we strongly suggest

that you find an experienced modeler to assist you.

Warranty

Hobby Express guarantees this kit to be free from defects in both material and workmanship at the date of purchase. This

warranty does not cover any component parts damaged by use or modification. In no event shall Hobby Express liability exceed

the original cost of the purchased kit.

Completely read through this manual before starting construction.

12

!

(1-615-373-1444)

www.hobbyexpress.com

13

Loading...

Loading...