Page 1

TM

© Copyright 1993, Hobbico, Inc.

• Comes 70% prebuilt, requiring very little sanding.

• Control surfaces are preshaped and ready for covering.

• Wing features balsa sheeting over foam core.

• Meets all requirements for Quickie 500 racing.

• Can be customized with

three different tail

configurations

Stock tail design

V-tail design

(optional)

Mid-tail design

(optional)

Page 2

C ongratulations upon purchasing your

new Viper RTC kit. The Viper RTC is

assembled with only the finest materials

and workmanship so you can enjoy the

fun of flying more quickly and easily than

ever before. We have completed 70% of

the assembly. All that needs to be done is

final assembly and covering - you can

customize. This airplane is a joy to fly and

promises hours of pure enjoyment. If

Quickie 500 racing is your goal., you will

find the Viper to be a very competitive

performer in the racing circles. For more

information on Quickie 500 racing,

contact the Academy of Model

Aeronautics at the address shown below.

Two decisions must be made before construction of this

airplane can begin.

1. What size engine will be used?

2. What style of tail will be used?

1. Engine Size:

If a .25 size engine is to be used for powering your Viper, no

additional reinforcement is required to the nose. You may

skip the steps with the checkered flag ( ). If a .40 size

engine is going to be used, complete the steps marked with

a checkered flag ( ).

2. Tail Configuration:

Conventional Tail:

This is a normal tail and all of the wood

required to build this version is included with this kit. This is

the easiest of the three versions to build and is highly

recommended for flyers/builders with limited building

experience.

Mid-Tail:

The mid-tail offers a very unique appearance to

the Viper as well as offering better elevator response. This is

due to the fact the stabilizer and elevator are out of the wing

slip stream. Although the mid-tail is not difficult to build, it

will require careful attention to insure the stabilizer and fin

are square.This can be either an aerobatic or racing

configuration and requires some additional 3/16" balsa to

complete.

V-Tail:

The V-tail version is slightly more difficult to build

than the other two versions. Extra care must be taken to

make sure the tail assembly is square, level and at zero

incidence. V-tail airplanes theoretically reduce drag

because there is only two control surfaces. This is primarily

a racing configuration and 3/16" balsa is required for

completion. This configuration is not recommended for

beginners. This also requires a radio that mixes V-tails or an

electronic mixer for elevator/rudder.

90-Day Limited Warranty

If you, as the original owner of this model, discover defects in

parts or workmanship within 90 days of purchase, Hobbico will

repair or replace it—at the option of our authorized U.S. repair

facility, Hobby Services— without charge. Our liability does not

include cost of shipping to us. However, Hobby Services will pay

shipping expenses to return your model to you.

You must provide proof of purchase, such as your original

purchase invoice or receipt, for your model’s warranty to be

honored.

This warranty does not apply to damage or defects caused by

misuse or improper assembly, service or shipment. Modifications,

alterations or repair by anyone other than Hobby Services voids

this warranty. We are sorry, but we cannot be responsible for crash

damage and/or resulting loss of kits, engines, accessories, etc.

Repair Service

Your Viper must be returned directly to Hobby Services for

warranty work. The address is:

Hobby Services

Attn: Service Department

1610 Interstate Drive

Champaign, IL 61821-1067

Phone: (217) 398-0007

Hours: 9:00-5:00 CST Mon. thru Fri.

Please follow the instructions below when returning your model.

This will help our experienced technicians to repair and return it as

quickly as possible.

1. ALWAYS return your entire kit.

2. Include a list of all items returned and a THOROUGH, written

explanation of the problem and service needed. If you expect the

repair to be covered under warranty, also include your proof of

purchase.

3. Include your full return address and a phone number where you

can be reached during the day.

If your model is past the 90-day warranty period or is excluded

from warranty coverage, you can still receive repair service

through Hobby Services at a nominal cost. Repair charges and

postage may be prepaid or billed COD. Additional postage charges

will be applied for non-warranty returns. All repairs shipped

outside the United States must be prepaid in U.S. funds only.

All pictures, descriptions and specifications found in this

instruction manual and on the product package are subject to

change without notice. Hobbico maintains no responsibility for

inadvertent errors.

Academy of Model Aeronautics

5151 E. Memorial Drive

Muncie, IN. 47302

Tel. (317) 289-4236

JOIN THE AMA

About this manual:

- 2 -

Page 3

Other items you’ll need:

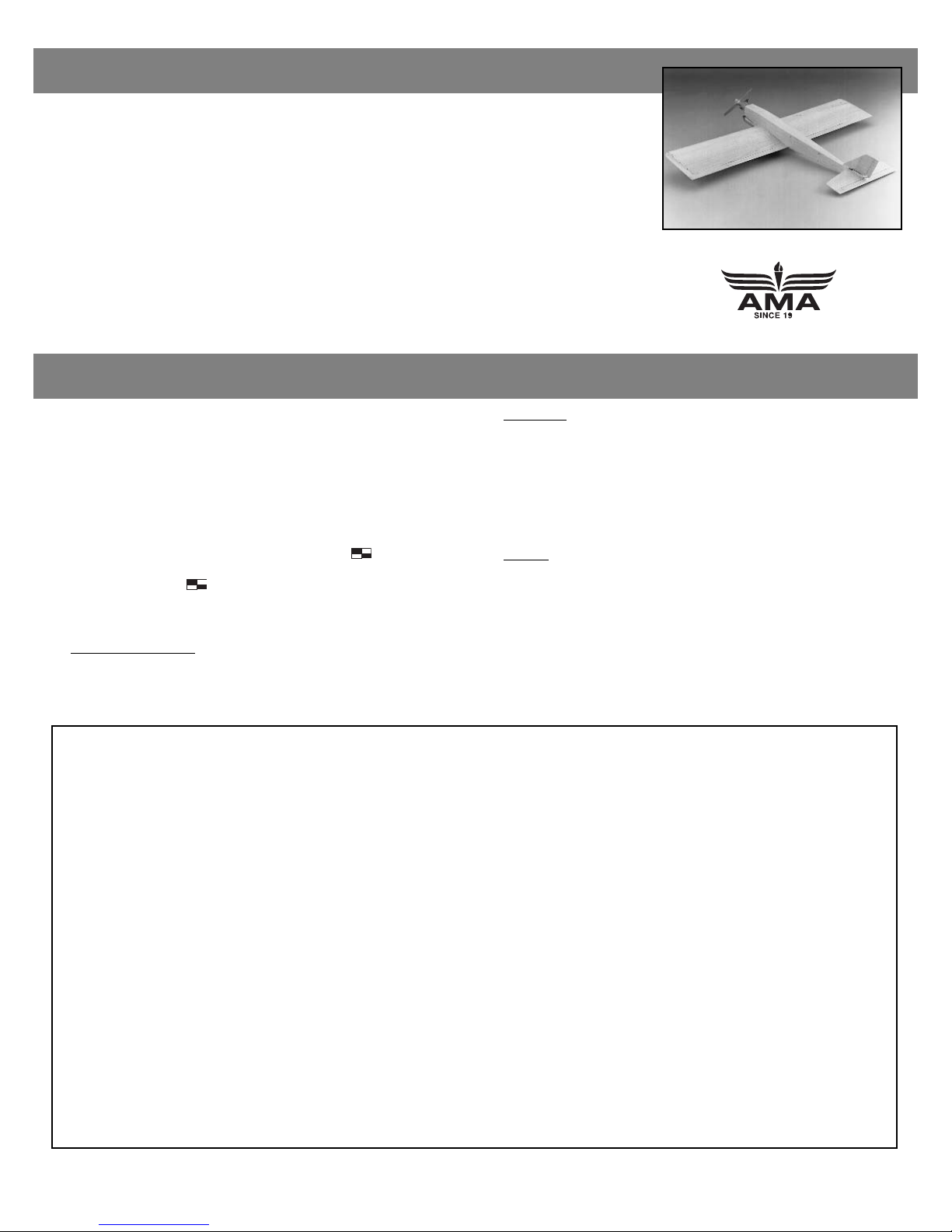

Glues

Choose any 5- or 6-minute epoxy, such as Hobbico Bullet, which has been formulated

especially for R/C model building. Epoxies offer a strong bond and a variety of curing

times suited for every step of assembly. You’ll also need an instant-setting CA

(cyanoacrylate), a thicker CA+, and a 30-minute epoxy, plus rubbing alcohol for easy

epoxy cleanup.

Hardware

Tools and accessories required for assembly include

a hobby knife; flat tip screwdriver; file; needle nose

pliers; drill bits; ruler; and 3 feet of medium fuel

tubing.

Model Engine

Power your Viper with any high-quality, .25-size

model engine. The O.S. ..25 FP, SuperTigre G-34 and

Irvine .25 RC are just a few examples. Look for

features such as easy break-in, easy starting, efficient

carburetion and low maintenance. Check the

manufacturer’s recommendations for propellers to

use with your engine. For Quickie 500 racing you will

want to choose a high performance, .40 size engine.

Radio Equipment

To let you send the commands that control your Viper’s

“flight path,” you’ll need a 4-channel aircraft radio system

with four standard servos. Many 4-channel radios include

just three servos. You may need to purchase the fourth

separately. The servos and radio receiver will be mounted

on-board your model and need to be cushioned from jolts

and vibration. One-quarter inch thick foam rubber sheets

are available for this purpose.

Getting Ready for Flight

Your Hobbico Viper is ready for takeoff in as little as 15-20 hours. Your

hobby dealer can help you decide what accessories you’ll need for flight.

You will need glow fuel with a 10-15% nitro blend to keep your engine

performing at its peak...and your Viper will have the power to perform the

impressive aerobatic maneuvers.

Other General Items Required

Masking Tape

Fine Line Felt Tip Pen

A Wooden Match

Balsa Filler

Covering Material

Sealing Iron

1/4"-20 Tap

Engine Mount

Hex Wrench for #6-32 Bolt

3M "77" Spray Adhesive

90Þ Triangle

Sand Paper (220 grit)

Drill and Drill Bits:

1/16", 1/8", 9/64", 5/32", #7

or 3/16", 1/4"

Additional Items Required for Optional Quickie Racer, V-Tail or Mid Tail

1 sq. Yard 2oz. Fiberglass

3/16 Hard Balsa (V-Tail and Mid Tail)

Wire and Tube Pushrod

Cable Pushrod (for throttle)

6 oz. Hayes Fuel Tank

Candle Wax

45 Minute Epoxy

- 3 -

Page 4

FUSELAGE PREPARATION

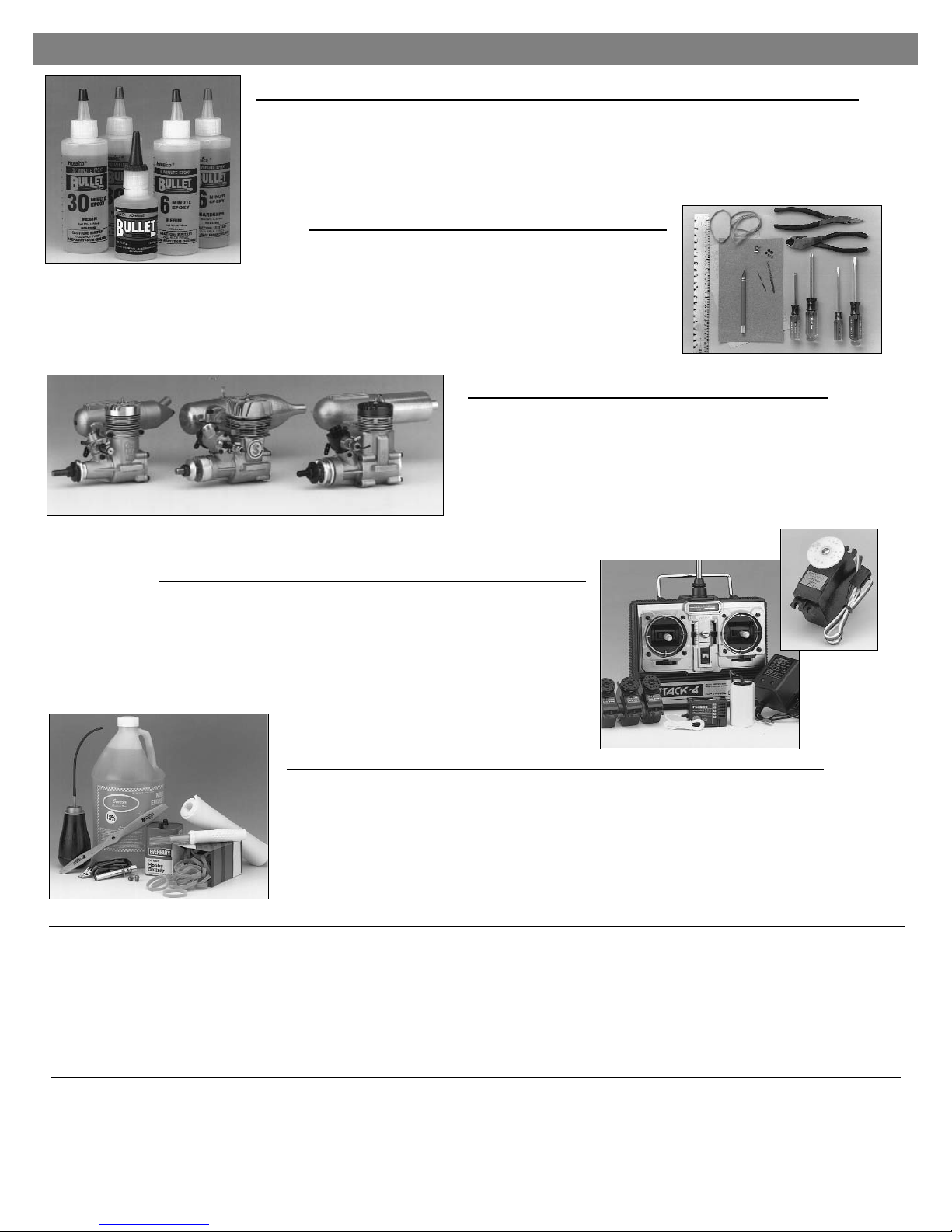

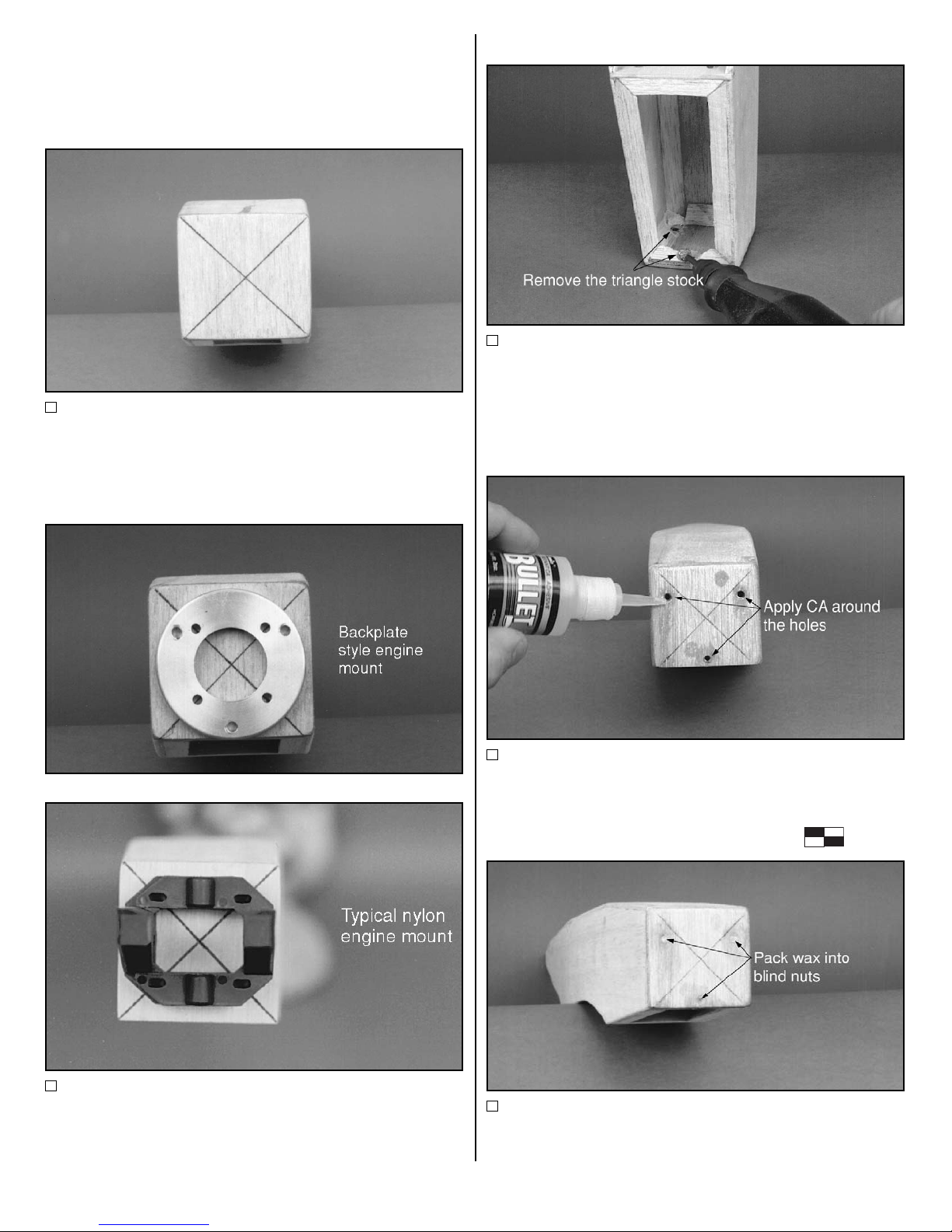

Marking firewall for engine mount

1. With a straight edge, draw lines from corner to corner

on the firewall. This will help you position the engine mount.

Drilling holes for engine mount

2. Center the engine mount on the firewall using the lines

as a reference. Mark and drill 5/32" (4mm) holes according to

the motor mount you plan to use.

Installation of blind nuts

3. Using a file or a Moto-Tool™, remove the triangle stock

around the holes drilled through the firewall. This creates a flat

surface to mount the blind nuts against. Install #6-32 blind

nuts into the holes and apply thick CA to secure them in place.

Hardening blind nut holes

4. Apply thin CA to the outside of the holes to harden the

firewall around the blind nuts.

Protecting blind nut threads

5. Pack wax into each of the blind nuts to protect the

threads from being clogged by epoxy.

- 4 -

Page 5

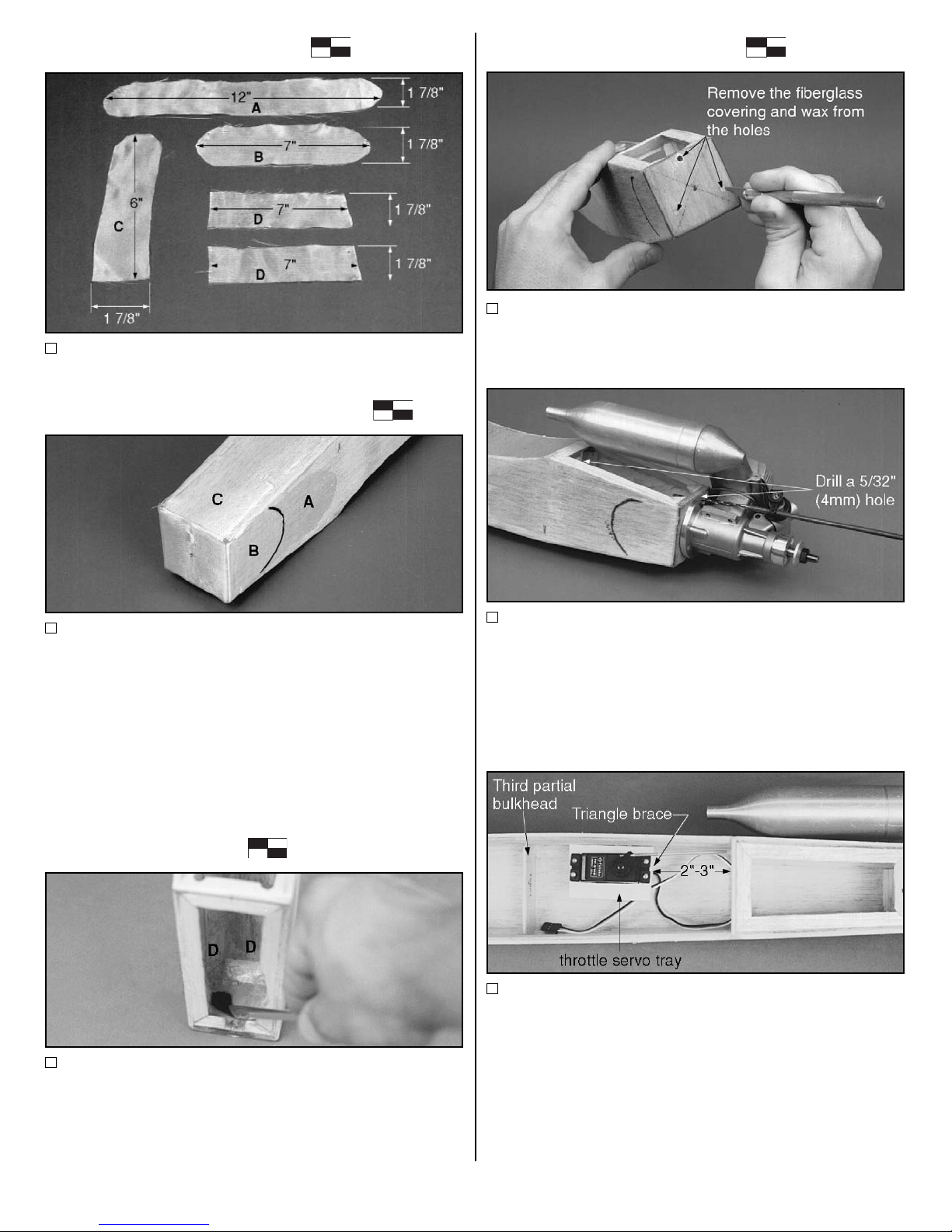

Cutting fiberglass cloth

6. Cut (5) pieces of 2 oz. fiberglass cloth as shown. Mark

the center of pieces A, B, and D.

Installing the fiberglass cloth

7. Apply a very light coat of 3M "77" spray adhesive to the

nose of the fuselage. Place the center of piece "A", cut in the

previous step, at the center of the firewall and wrap the

remainder around the left and right sides of the fuselage. Wrap

piece "C" starting at the bottom of the firewall up over the top of

the fuselage. Wrap piece "B" starting at the center of the

firewall over pieces A and C and around the sides of the

fuselage. Coat the fiberglass cloth with 45 minute epoxy and

remove all excess epoxy with a squeegee.

Fuel proofing the

fuel compartment

8. Install piece "D" of the fiberglass cloth on the inside,

wrapping from one side over the firewall to the other. Install

the other piece "D" from the bottom of the firewall to the top

of the fuselage. Completely coat the entire fuel tank

compartment, making sure all of the fiberglass is saturated

and the fuel compartment is fuel proof.

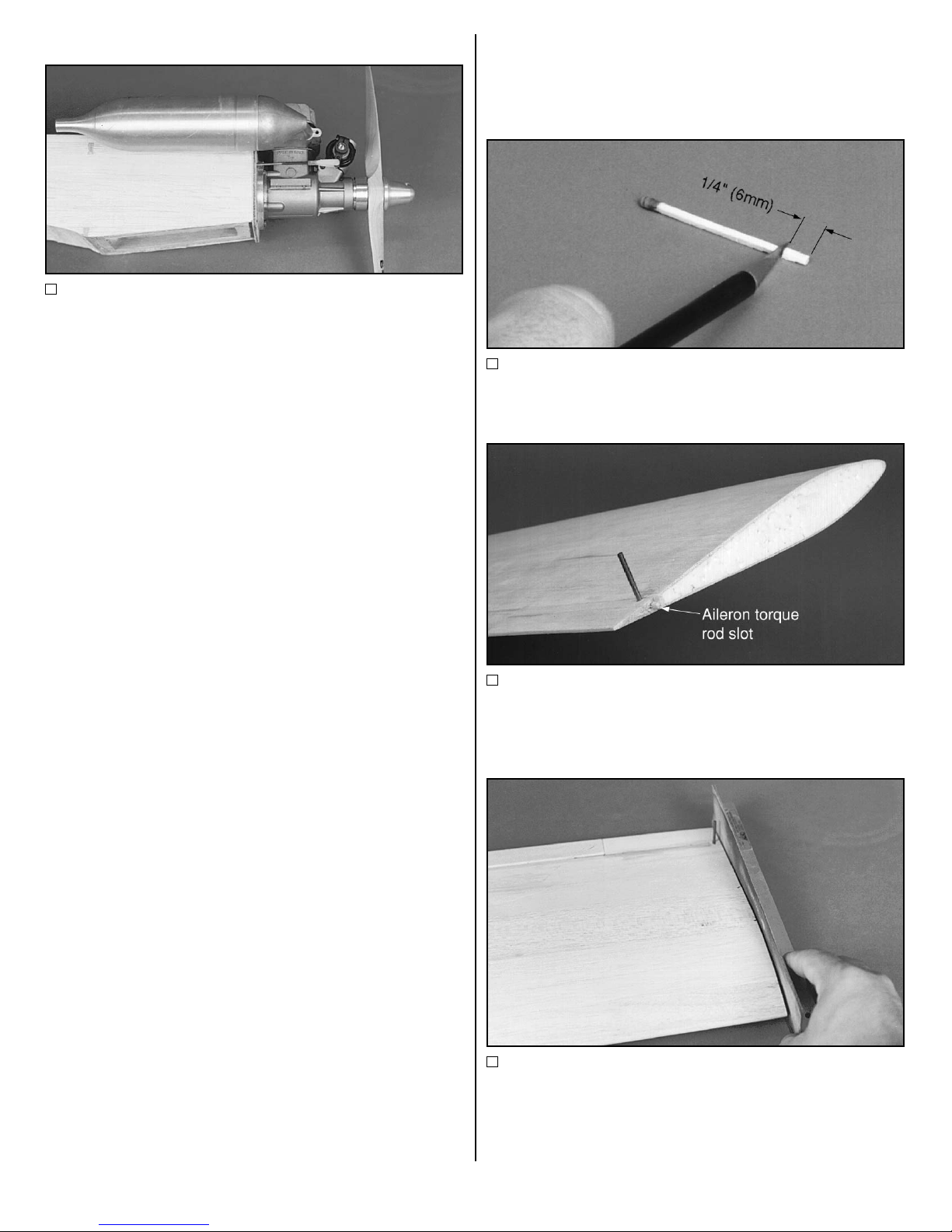

Opening the blind nuts

9. Using a hobby knife, remove the fiberglass covering the

bolt holes. Pick the wax out of each of the blind nuts.

Drilling hole for throttle rod tube

10. Using a 5/32" (4mm) drill bit, drill a hole through the

firewall directly behind the throttle arm. This will be the hole

for the throttle rod tube. Drill another hole through the second

bulkhead and in the most direct path to the throttle servo.

Make sure it does not interfere with the wing saddle. Note: A

long drill bit is shown but not nexessary.

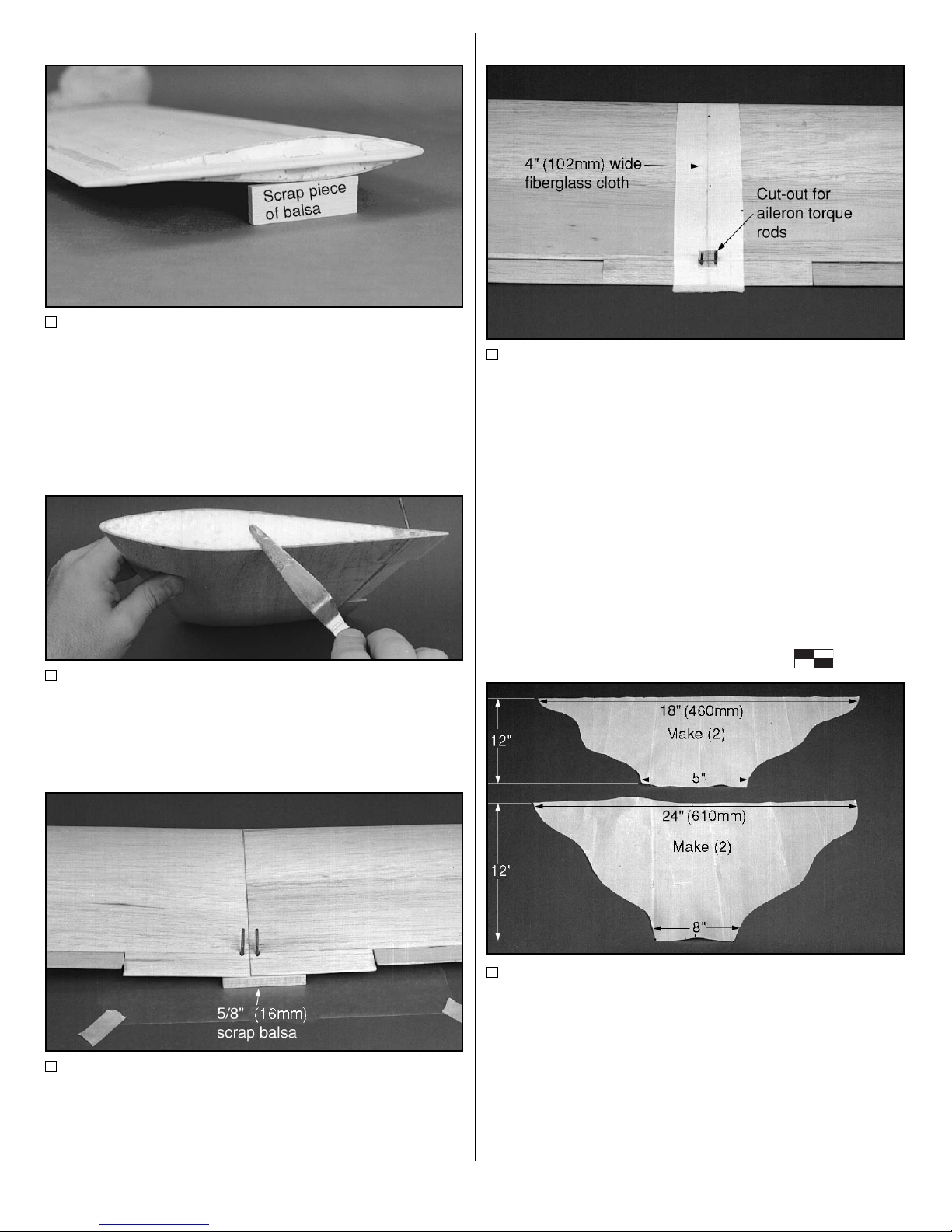

Installation of throttle servo tray

11. Using a file, enlarge the throttle servo tray hole to

accommodate the servo being used. Then, with thick CA,

install the throttle servo tray as shown. Make sure that

enough room is left under the servo tray to accommodate the

throttle servo you'll use. Also make sure the throttle servo will

not interfere with the aileron servo. Install the servo tray 2" to

3" from the second bulkhead. Locate the triangle brace and

install it under the front portion of the servo tray using thin

CA. Mount the throttle servo according to the manufacturer's

recommendations.

- 5 -

Page 6

Installation of throttle rod

12. Roughen the entire throttle rod tube using sandpaper.

Slide the tube through the hole in the firewall and the first

bulkhead. Slide the rod into the tube and direct the rod

straight to the servo arm with as little bending as possible.

Apply epoxy to the tube where it goes through the firewall

and the first bulkhead. Also attach the tube securely to the

side of the fuselage. Thread a clevis onto the throttle

pushrod. Slide the pushrod into the tube and out past the

servo. Mark the pushrod where the pushrod crosses the

outside hole of the throttle servo arm. Place a "Z" bend at this

mark. Connect the "Z" bend to the throttle servo arm. Adjust

the pushrod using the clevis. Note: It may be necessary to

replace the pushrod with a cable in some engine positioning

situations.

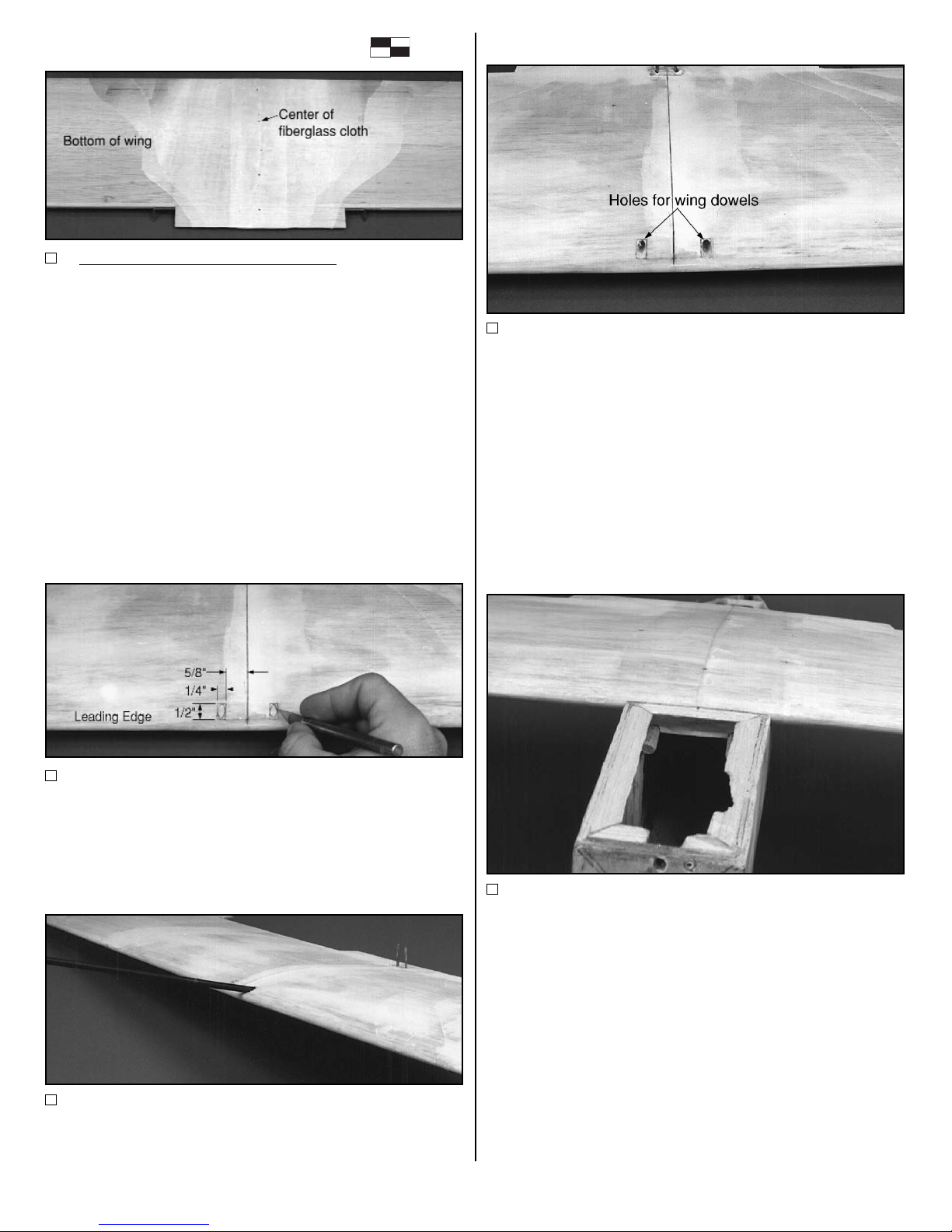

ASSEMBLY OF WING

Making an alignment peg

1. Cut about 1/4" (6mm) off the end of a wooden match or

similar piece of wood.

Installation of alignment peg

2. Using thick CA, glue the piece of match into the hole in

the aileron torque rod slot in the trailing edge of one of the

wing panels. This will serve as an alignment peg.

Trial fitting wing halves

3. Position the two wing halves together and check their fit.

Adjust the angle of root center section using a sanding block.

This should be done with the wing on a flat surface and one

of the wing panels blocked up to the proper dihedral angle. It

is 5/8" (16mm) for Quickie 500 racing or aerobatics and 1"

(25mm) for beginners.

- 6 -

Page 7

Setting wing dihedral

4. Use a piece of 5/8" (16mm) or 1" (25mm) scrap balsa to

block up one wing panel. This will account for the dihedral

required for the wing. If this is your first low wing airplane,

increase the dihedral from 5/8" (16mm) to 1" (25mm). Place

a piece of wax paper on your building surface to prevent the

wing from sticking to the surface.

Applying epoxy to wing panel

5. Using 30- or 45-minute epoxy, apply a liberal amount of

epoxy to each wing panel as shown, making sure that epoxy

is applied to the balsa sheeting as well as the foam core.

Wing panel assembly

6. Assemble the wing panels together and remove any

epoxy that may have squeezed out. Block up the trailing

edge using a piece of 5/8" (16mm) balsa. Masking tape

should be used to hold the panels tightly together until the

epoxy has fully cured. Note: Wax paper was used to prevent

the wing from sticking to the building surface.

Fiberglassing the wing joint

7. Apply 30- or 45-minute epoxy and thoroughly saturate

the fiberglass cloth. Once saturated, squeegee off as much

epoxy as possible. Remember, this is excess weight. Once

the epoxy has cured, repeat this procedure for the top of the

wing. Hobbylite filler should be used to smooth the transition

from the fiberglass to the wood skin. Make sure a cut out is

made to fit around the aileron torque rods and that no epoxy

is allowed into the torque rod openings.

Cutting the fiberglass cloth

8. Cut 2 oz. fiberglass cloth into the panel dimensions

shown above. Cut two of each panel.

- 7 -

Page 8

Applying the fiberglass cloth

9. Start with the bottom of the wing first. Mark the center of

the fiberglass panels cut in the previous step. Apply the 24"

(610mm) wide piece first and then the 18" (460mm) wide

piece over the top of it, making sure that the center marks

line up on the center section of the wing. Apply 30- or 45minute epoxy and thoroughly saturate the fiberglass cloth.

Once saturated, squeegee off as much epoxy as possible.

Remember, this is excess weight. Once the epoxy has cured,

repeat this procedure for the top of the wing. Hobbylite filler

should be used to smooth the transition from the fiberglass to

the wood skin. Note: The fiberglass goes right over the

landing gear blocks. Once the epoxy cures, use a hobby

knife to remove the fiberglass from the wire slots.

Cutting holes for hold down dowels

10. Using the photo as a reference, draw 2 boxes as

shown and then 2 ovals inside the boxes. Using a hobby

knife, cut through the fiberglass and balsa and remove only

the oval portions drawn.

Drill holes for hold down dowels

11. With a 1/4" (6mm) drill bit, drill holes into the foam core

at approximately the angle shown, 3" deep. Note: A long drill

bit is shown, but is not required.

Trimming the hold down dowels

12. Cut (2) wing hold down dowels to 3-1/2" (89mm).

Round one end of each of the dowels. Insert the round end of

each of the dowels into the holes in the wing. Trial fit the wing

onto the fuselage, checking the fit with the first bulkhead. If

necessary, adjust the bulkhead grooves or oblong the holes

in the wing to achieve a good, snug fit between the bulkhead

and the dowels. If necessary, adjust the wing saddle until the

wing fits perfectly to the fuselage.

Installation of hold down dowels

13. Apply a generous amount of 30-minute epoxy both to

the wing hold down dowels and to the holes in the wing for

the dowels. Insert the dowels, with the flat end out, into the

wing. Leave 5/8" (16mm) of the dowels protruding past the

leading edge of the wing. Install the wing onto the fuselage

and hold the dowels snug against the bulkhead until the

epoxy cures. Make sure the 30-minute epoxy does not

contact the fuselage.

- 8 -

Page 9

Marking the aileron servo hole

14. Using the aileron servo as a reference, mark and cut a

hole in the center section of the wing, starting the hole 3-3/4"

(95mm) to 4" (102mm) from the leading edge of the wing.

Make sure that the position chosen does not allow the aileron

servo to interfere with the throttle servo.

Installing the aileron servo tray

15. Locate the aileron servo tray and adjust the size of the

hole to correspond with the hole already cut in the wing.

Using 6-minute epoxy, glue the aileron servo tray to the wing.

Installation of aileron servo and rods

16. Install the servo and connect the torque rods using the

(2) 8" (203mm) pushrods, (2) clevises and (2) aileron torque

rod connectors. "Z" bends should be used on the pushrod

ends that connect to the servo. Note: The small hole in front

of the servo tray is for the aileron servo wire.

Drilling for the wing hold down bolts

17. Install the wing onto the fuselage as shown. Check to

make sure that the distance between the wing tip trailing

edge and the tail of the fuselage are the same for each side.

Mark the outside of the fuselage and the inside of the wing

hold down block on each side. Place a mark halfway

between these marks and 1/2" (13mm) ahead of the trailing

edge. Drill holes through the wing and hold down blocks

perpendicular to the wing at these marks using a #7 or 3/16"

(5mm) drill bit. Remove the wing and enlarge the holes in the

wing with a 1/4" (6mm) drill.

Tapping the holes

18. Using a 1/4"-20 tap, carefully tap the holes in the hold

down blocks. Once tapped, reinforce the hold down blocks

using thin CA along the joint and the triangle stock.

- 9 -

Page 10

INSTALLATION OF

CONVENTIONAL TAIL

SURFACES

Important: Make sure this is the tail configuration you have

chosen to use. If it is not, turn to page 11 for mid-tail or

page 13 for V-tail.

Marking the horizontal stabilizer

1. Mark the exact center of the stabilizer and draw a center

line perpendicular to the trailing edge on the top and bottom of

the stabilizer.

Installation of the horizontal stabilizer

2. Check the fit if the stabilizer in the stabilizer saddle. Sand

the saddle to make a perfect fit. Apply 30-minute epoxy to the

stabilizer saddle and to the bottom of the stabilizer itself.

Install the stabilizer onto the fuselage and check to insure that

the distance between the trailing edge of the wing tip and the

trailing edge of the stabilizer are the same. Then, sighting

from the rear, check to make sure the stabilizer is parallel with

the wing. Set the stabilizer assembly aside to cure.

Installation of vertical stabilizer

3. Using a 90Þ triangle, install the vertical stabilizer using

30 minute epoxy. Make sure the fin lines up perfectly with the

center line of the fuselage.

Bracing the vertical stabilizer

4. Locate the (4) pieces of 1/4" (6mm) triangle stock. Sand

the front and back to achieve a pointed appearance on each

end. Using thick CA glue, install the (2) longer triangle stock

pieces on top of the stabilizer and up against the vertical

stabilizer. Do not use the 6" (150mm) piece of 1/4" (6mm)

triangle stock for this step.

Bracing the horizontal stabilizer

5. Install the (2) shorter triangle stock pieces underneath

the stabilizer and against the fuselage. Skip to page 15 if you

are assembling the conventional tail.

- 10 -

Page 11

Relocating the antenna tube

6. Drill a 1/8" (3mm) hole and install the antenna tube and

secure using thick CA. Trim the antenna tube flush to the

fuselage.

MID TAIL DESIGN

(Follow this section for mid-tail only)

Trim the horizontal stabilizer

1. Carefully remove 1/2" (13mm) of balsa from the trailing

edge of the existing stabilizer. Using the elevator template on

page 22 as a reference, slot the trailing edge of the stabilizer for

the hinges with a #11 knife blade. This will allow using CA style

hinges. CA hinges are recommended for the mid-tail design.

Cutting a new vertical stabilizer and

rudder

2. Cut out the new vertical stabilizer (3/16" (5mm) balsa is

not provided) using the template provided on page 21. Cut a

slot from the center of the leading edge of the stabilizer 3/16"

(5mm) wide and 1-3/4" (45mm) deep, to form the interlock for

the vertical stabilizer. Round the leading edge of the vertical

stabilizer. Slot the stabilizers for hinges, using a #11 knife

blade, according to the template.

Joining the horizontal and vertical

stabilizer

3. Install the horizontal stabilizer into the vertical stabilizer.

Using a 90Þ triangle to square the fins, apply thin CA glue to

- 11 -

Page 12

the joint. Once the fins are tacked into place, go over the joint

again with thick CA glue. Cut the 1/4" (6mm) triangle stock

provided into (4) pieces 2-3/4" (70mm) long. Install the

triangle stock along each joint to reinforce the joints. Bevel

the front and rear of the triangle stock to eliminate drag.

Remove the plywood reinforcement

4. Using a razor saw, remove 3/16" (5mm) of the plywood

reinforcement from the aft end of the fuselage to make room

for the vertical stabilizer.

Installation of the fin assembly

5. Apply 30-minute epoxy to the vertical stabilizer and to

the slot in the fuselage, also making sure to apply glue to the

tail skid mounting plate. Install the fin assembly into the

fuselage and make sure the stabilizer is square with the

wing. Note: You may find it easier to cover the entire fin

assembly with MonoKote®, except the bottom portion, before

installing it onto the fuselage. Use scrap balsa about 3/16"

(5mm) thick to fill the old stabilizer saddle of the fuselage.

Drill a hole in the top left scrap piece for installation of the

elevator pushrod.

Installing the rudder pushrod

6. Drill a hole and install the rudder pushrod according to

the recommendation of the manufacturer. Great Planes™

Rod-in-Tube pushrods are recommended.

Relocating the antenna tube

7. Drill a 1/8" (3mm) hole and install the antenna tube and

secure using thick CA. Trim the antenna tube flush to the

fuselage.

Making the elevators

8. Cut out (2) mid-tail elevators using the template

provided on page 22. Use a #11 knife blade to slot the

elevator for CA type hinges in the location shown. Drill a

3/32" (2.4mm) hole according to the template for the

elevator for the interlink. Recess the elevator to receive the

interlink and bevel the leading edge of the elevator. Use 30minute epoxy to glue the interlink into the elevator halves.

Make sure the elevators are perfectly level and straight

across. Drill holes and attach the control horn according to

the portions indicated on the template for the rudder and the

elevator.

- 12 -

Page 13

Attachment of pushrods

9. Attach the pushrods to the controls according to the

manufacturer's recommendations. Use the rudder horn with (2)

holes and a full length horn for the elevator shown above.

Connecting the servos to the

pushrods

10. Refer to page 15 steps 1, 2, and 3 to install the servo

tray. With the elevator and rudder perfectly level and straight,

mark the point where the pushrod passes over the servo arm

about 1/2" (13mm) from the center. Make Z-bends at the

marks and install the servo arms onto the Z-bends.

11. Do not permanently install the control surfaces until

after the Viper is covered.

V-TAIL DESIGN

(Follow this section for V-tail only)

Cutting new stabilizers

1. From hard balsa, cut (2) stabilizers, (4) triangle braces, and

(2) elevators using the templates provided on page 22 and 23.

Slot the stabilizers and elevators using a #11 knife blade, for

CA style hinges. Use the template for hinge position.

Attach the triangle braces to the

stabilizers

2. Using thick CA glue, tack glue one of the triangle braces to

the bottom of one of the stabilizers at the trailing edge, and

another brace close to the leading edge. Set the assembly on

a flat surface and sand the root of the stabilizer perpendicular

to the surface. Repeat this procedure for the other stabilizer.

This will make a perfect joint between the two halves.

Glue the stabilizers together

3. Trial fit the two stabilizers together and make sure the

trailing edge is straight. Once the trailing edge is straight, glue

the two stabilizers together.

- 13 -

Page 14

Reinforce the stabilizer joint

4. Break the four triangle braces from the stabilizers and

remove any excess CA with 220 sand paper. Sand the

pointed joint at the bottom of the two stabilizers. Reinforce the

joint on both sides using 1" (25mm) wide 6 oz. fiberglass or

carbon fiber (not included).

Trim the tail of the fuselage

5. Lay the template provided over the tail of the fuselage

and trim the fuselage accordingly.

Checking incidence of the tail

6. Check the incidence of the stabilizer on the newly cut

cradle. This should be done with the top of the fuselage as a

reference and perfectly level. The top of the fuselage is the

thrust line. Use of a simple line level is recommended.

Attach the stabilizer

7. Once the incidence of the stabilizer is correct, check to

make sure the distance from the trailing edge of the wing tip to

the trailing edge of the stabilizer is exactly the same on each

side. Check to make sure it is square to the wing and tack glue

the stabilizer into place using thin CA glue. Re-check the

measurements and if it hasn't moved, permanently glue the

stabilizer in place with 30 minute epoxy. Let stand until the

epoxy cures.

Install the pushrod braces

8. Install a piece of scrap balsa over the top of the V-tail as

shown. Drill (2) holes and mount the pushrods according to

the recommendations of the manufacturer of the pushrod.

Great Planes™ Rod-in-Tube pushrods are recommended. Cut

out and drill holes in the ruddervators according to the

template on page 23 and mount the control horns.

Connecting the ruddervator servos

9. With the ruddervators level, mark the point where the

pushrods pass over the servo arms about 1/2" (13mm) from

the center. Make Z-bends at the marks and install the control

arms onto the Z-bends. Attach the pushrods to the servos.

Install the antenna tube

10. The antenna tube should be routed out under the V-tail

as shown.

11. Do not permanently install the control surfaces until the

model is covered.

- 14 -

Page 15

PUSHROD INSTALLATION

Trimming the servo tray

1. Enlarge the holes in the elevator and rudder servo tray to

fit the servo being used. Mount the servos in the servo tray

and set the servo tray into place, with the servos resting on the

top of the fuselage as shown. With a pen, place a mark on

each side of the fuselage using the tray as a guide. Note: In

most .25-.40 size engine applications, it is best to mount the

servos aft of the fourth bulkhead. To do so, use the template

on page 24 to trim the servo tray to fit. If you intend to use a

.19 size engine, or a very light engine, simply mount the servo

tray ahead of the bulkhead. It will be necessary to lengthen the

pushrods by about 2-1/2" (64mm) over the dimensions shown

on page 16.

Installation of the servo tray

2. Cut the 6" piece of 1/4" (6mm) triangle into

(2) 3" (76mm) pieces. Using the marks as a guide, glue (2)

pieces of 1/4" (6mm) triangle stock 3" (76mm) long into place

on the inside of the fuselage. This will insure an 1/8" (3mm)

gap between the servos and the top of the fuselage. Using

thick CA glue, install the servo tray onto the triangle stock.

Trimming the control horns

3. Cut both of the control horns as shown. The smaller

version will be the elevator control horn and the one with 2

holes will be the rudder control horn. Note: This is for the

conventional tail configuration. For the mid tail, cut the rudder

horn as shown, but do not cut the elevator control horn. Do not

cut the control horns for the V-tail configuration. Note: For high

performance .40 size applications we recommend the use of

Great Planes™ Rod-in-Tube type pushrods for elevator

and rudder.

Drilling the dowel rod

4. Drill 1/16" (1.6mm) holes 3/4" (19mm) from each end of

both the wooden pushrods.

Making the V-groove

5. Make a small groove on each end of the pushrods from

the 1/16" hole to the end.

- 15 -

Page 16

Installation of rods

6.Using thick CA, secure one of the unthreaded rods onto

one end of the pushrod and the threaded rod on the other side.

Installation of heat shrink tubing

7. Cut the black heat shrink tubing into 4 equal pieces and

install on over each of the pushrod joints. Shrink the tubing with

either a match or a heat gun.

Assemble the pushrods for aft

mounted tray

8. Bend the pushrods as shown. Note: Trial fit before

making "Z" bends and cutting off extra wire.

Installation of elevator control horn

9. Set the elevator control horn in place, centered on the

hole in back of the fuselage, and mark the hole locations with a

pen. Drill 5/64" (2mm) holes at the marks. Install the control

horn using (2) 2mm screws and the control horn backing plate.

Attach the clevis to the control horn. It may be necessary to

enlarge the opening at the rear of the fuselage to allow free

movement of the pushrod. If necessary, enlarge the hole using

a round file.

Connecting the elevator pushrod

10. With the elevator in the neutral position and the servo

arm 90Þ to the servo, place a mark on the pushrod at the point

it intersects the outside hole on the servo arm. This should be

about 1/2" (13mm) from the center of the servo arm. Make a

"Z" bend at the mark and install it onto the servo arm.

Installation of rudder control horn

11. Hold the control horn (with 2 holes on it) in place as low

on the rudder as possible. With the 2 holes aligned over the

hinge line, mark the screw holes on the rudder. Drill (2) 5/64"

(2mm) holes at these marks and install the control horn using

(2) 2mm screws and the control horn backing plate.

- 16 -

Page 17

Slot for rudder pushrod

8. Make a slot 1" (25mm) long starting 1/4" (6mm) behind

the leading edge of the stabilizer. This slot should go through

the triangle stock and the stabilizer.

Installation of rudder pushrod

9. From the inside of the fuselage, insert the threaded end

of the rudder pushrod through the slot in the rear stabilizer.

Thread a clevis onto the pushrod and attach it to the rudder

control horn.

Adjustment of rudder control horn

10. With the rudder in the neutral position and the rudder

servo arm 90Þ to the servo, place a mark on the pushrod at

the point it intersects the outside hole of the servo arm. This

should be about 1/2" (13mm) from the center of the servo arm.

Make a "Z" bend at this mark and install onto the servo arm.

Make sure the elevator and rudder pushrods do not contact

each other. If so, bend the rudder pushrod slightly to

avoid contact.

FINISHING THE FUSELAGE

Straightening the fuselage

1. In some cases the sides of the fuselage bow in slightly. If

this happens, simply install a couple of scrap pieces of balsa

to return the fuselage sides to their original shape.

Relocating the antenna exit hole

2. On the conventional and mid-tail configurations, it is

necessary to relocate the exit for the antenna tube. To do this

drill a 9/64" (3mm) hole under the stabilizer about 3" (76mm)

from the end of the fuselage. Glue the tube in place using thick

CA. A pushrod may be used to hold the exit straight while

gluing.

Installation of lower sheeting

3. Install the lower sheeting using thick CA glue and sand

the sheeting flush with the fuselage sides. Then round the

corners to a 1/4" (6mm) radius.

- 17 -

Page 18

Inspection hole

4. Use a round file or Moto-Tool™ to cut an inspection hole

in the bottom sheeting of the fuselage. Make sure that the

corners are rounded with at least a 1/4" (6mm) radius. This

hole should be large enough to remove a servo if necessary.

Cover the hole with clear tape or clear MonoKote® covering

after the entire model is covered.

Installation of tail skid

5. Drill an 3/32" (2mm) hole for the tail skid 2-1/2" (64mm)

from the end of the fuselage. Using the skid as a guide, locate

the position for the front hole. After covering is complete, glue

the skid in place using thick CA or epoxy.

Removing fiberglass over the gear

blocks

6. Using a #11 knife blade, trim the fiberglass that is

covering the landing gear slot. Use a piece of 220 grit

sandpaper to trim the edges.

Installation of landing gear

7. Install the landing gear into the landing gear block. If the

fit is too snug, run a 5/32" (4.0mm) drill bit into the hole. Make

sure you do not drill through the top of the wing. Place the

landing gear straps over the wire and mark the holes with a

pen. Drill 1/16" (1.6mm) holes at the marks and secure the

straps in place. Install a wheel and then a wheel collar to

secure. Repeat this procedure for the other side.

Assemble the fuel tank

8. Assemble the fuel tank as shown. The fuel tank supplied

is about 4 oz., which is perfect for .19 to .25 engines. If you

plan to race the Viper, you will want to replace this with a

Hayes 6 oz. fuel tank.

- 18 -

Page 19

Drill the fuel line exit hole

9. Cut a 1/2" (13mm) round hole 1/2" (13mm) back from the

front of the fuselage. This will serve as the exit for the fuel

lines. This may seem slightly unconventional, but the

advantage is, it does not weaken the firewall at all.

Trim the fuselage for the fuel tank

10. With a hobby knife, trim the triangle stock flush with the

number two bulkhead. This will make installation of the fuel

tank easier. Thoroughly coat the inside of the fuel tank

compartment with 30-minute epoxy to fuelproof the wood.

Install the fuel tank

11. Route the fuel lines through the hole and install the fuel

tank as shown. Make sure fuel lines are not pinched against

the firewall. Pack 1/4" (6mm) foam around the fuel tank to

isolate the fuel tank from vibration.

Installation of fuel tank

compartment hatch

12 Using thick CA, install the fuel tank compartment hatch.

Sand the edges flush with the fuselage sides and then radius

to a 1/4" (6mm).

Finishing the model

Applying the covering

Remove all of the fittings, pushrods and control horns. This

will make covering much easier and neater. It will take about 2

rolls of MonoKote® to cover the Viper. Use your imagination

and you can create a very attractive airplane. Once the Viper

is covered, re-install all of the fittings. Cover the servo access

hole and the fuel tank compartment hole with clear tape or

clear MonoKote®. Note: Check to insure there is adquate

clearance, about 1/32" (1mm) on each end of the aileron to

prevent binding.

Wing bolt reinforcement plate

Place the wing bolt reinforcement plate over the bolt holes

on the bottom of the wing. Center it on the center line of the

wing. Mark the location and remove the covering from

underneath. Using thick CA, glue the plate in place. Re-drill

the holes from the top of the wing using a 1/4" (6mm) drill.

Apply covering to the plate.

- 19 -

Page 20

Wing saddle seal

Use of bathtub silicone sealer is recommended for sealing

the wing to fuselage joint. This is an excellent method, used by

many experts because it results in a permanent and nearly

perfect wing saddle joint. Briefly, the technique is as follows:

1. Cover the top of the wing center section with waxed paper

or plastic kitchen wrap. Pull out all wrinkles and tape it to the

wing. 2. Squeeze out a bead of silicone sealer onto the wing

saddle area of the fuselage. 3. Lay the wing in the saddle and

push down gently. The excess silicone sealer will squeeze out.

4. Allow to dry without disturbing for at least 24 hours. 5.

Remove the tape; then remove the wing from the saddle

(leaving the waxed paper or plastic wrap in place)

6. Gently pull the waxed paper or plastic wrap away from the

sealer. 7. Using a new single-edge razor blade, trim the

sealer flush with the wing fillets, and along the inside of the

fuselage.

Control surface installation

Apply petroleum jelly to the moving portion of each of the

hinges from one of the ailerons. Apply a small amount of

epoxy to one side of the hinge and in the hinge slot on the

aileron. Repeat this procedure for the other two hinges. Set

aside to cure. Once cured, repeat this procedure on the wing,

using a small stich to pack the aileron torque rod hole with

epoxy. Then install the aileron onto the wing. Make sure no

epoxy remains on the moving portion of the hinge. If it does,

remove the epoxy quickly with alcohol. Repeat this procedure

for the other aileron, rudder and elevator.

Radio installation

Install the receiver, battery and switch according to the

manufacturer's recommendations. Protect the equipment with

1/4" (6mm) foam rubber. Move the battery and receiver back

and forth until the proper center of gravity is achieved. Route

the antenna through the antenna tube. Use scrap balsa and

foam to secure the receiver and battery pack.

Balancing the model laterally

With the wing attached to the fuselage and level, lift the

model by the engine propeller shaft and at the centerline of the

fin. Do this several times. Notice if one wing drops when you

lift. The wing that drops is the heavy side. Balance the model

by gluing weight to the inside of the light wing tip. Note: An

airplane that has been laterally balanced will track better in

loops and in other maneuvers.

Balancing the model fore and aft

Mark the center of gravity on each wing panel with a felt tip

pen. This mark should be placed 2-1/4" to 2-3/4 (57mm to

70mm) back from the leading edge of the wing. This is a good,

safe balance range. You may choose to try different balance

points to change the performance of your Viper, but do not

move the balance point more than 1/4" (6mm) at a time.

Balancing should be done with the fuel tank empty.

- 20 -

Page 21

Adjusting the control surface throws

Use the surface throw gauges on page 24 to adjust the

surface throws.

Sport flying

Aileron: 1/4" up and down

Elevator: 1/4" up and down

Rudder: 3/4" left and right

Quickie 500 racing

Aileron: 3/16" - 1/4" up and down

Elevator: 3/16" up

1/8" down

Rudder: 3/4" left and right

Pre-Flight

Charging the batteries

Follow the battery charging procedures in your radio instruction

manual. You should

always

charge your transmitter and receiver

batteries the night before you go flying, and at other times as

recommended by the radio manufacturer.

Ground check the model

If you are not thoroughly familiar with the operation of R/C models,

ask an experienced modeler to check to see that you have the

radio installed correctly and that all the control surfaces do what

they are supposed to. The engine operation must also be checked

and the engine "broken in" on the ground by running the engine for

at least two tanks of fuel. Follow the engine manufacturer's

recommendations for break-in. Check to make sure all screws

remain tight, the hinges are secure and the prop is on tight.

Range check the radio

Check the operation of the radio before every time you fly. This

means with the transmitter antenna collapsed and the receiver and

transmitter on, you should be able to walk at least 100 feet away

from the model and still have control. Have someone help you.

Have them stand by your model and, while you work the controls,

tell you what the various control surfaces are doing.

Repeat this test with the engine running at various speeds while

an assistant holds the model. If the control surfaces are not

operating correctly at all times,

do not fly!

Find and correct the

problem first.

Before you fly

1.Make sure that no other fliers are using your radio

frequency.

2.Your radio transmitter must be the FIRST thing you turn ON,

and the LAST thing you turn OFF.

Fuel storage and care:

1. Do not smoke near your engine or fuel.

2. Store all engine fuel in a safe, cool, dry place, away from

children and pets.

3. Always wear safety glasses.

4. Make certain that your glow plug clip is securely attached to

the glow plug—and cannot pop off, possibly falling into the

spinning propeller.

5. Use a “chicken stick” or electric starter to start the engine—

NOT your fingers.

6. Make sure that the wires from your starter and glow plug

clip cannot become tangled with the spinning propeller.

7. Do not stand to the side of the propeller when you start or

run the engine..

8. If any engine adjustments are necessary, approach the

engine only from behind the spinning propeller.

Take-off and flying

Flying the Viper is very much like flying any other airplane.

Remember to check the C.G. before your first flight. Set the

control surfaces to the recommended deflection and make

sure the fuel tank is full. Because there is no tail whee,l you

will find it difficult to taxi the Viper. You should start the engine

and carry it to the runway for take-off. While an assistant holds

the tail of the Viper, advance the throttle to at least half power.

With a slight bit of up elevator to hold the tail down, release

the Viper. It will quickly accelerate and leave the ground.

Slowly release the elevator once a gradual climb is

established. Fly the Viper around and get used to the way it

handles. Note the responsiveness and the feel of the controls

so that changes can be made, if necessary, once you land.

Landing

Landing is much simpler than you would expect an airplane of

this type. The Viper carries speed well and glides extremely

well. It actually glides so well that you may find it easier to land

dead stick than with power on. Get the power off early. Start

your approach about 200 feet out and about 50-75 feet of

altitude. Reduce the speed using the elevator and control the

lateral positioning with the rudder. You will find that the Viper

is very responsive to control inputs all the way to the ground.

Once the Viper is over the landing point, continue to increase

the elevator pressure to flare the airplane and allow it to settle

onto the runway.

Racing

If you should decide to race your Viper, obtain a copy of the

AMA rule book and become familiar with the Quickie 500

rules. The best advice anyone could ever give to someone just

starting in racing is "learn to fly the airplane first".

If you can do

this you can race. Consistency is the name of the game in

racing. You must start and finish every race to acquire points.

Learn to fly the course very well before you start trying to go

fast. Keep the Viper light, around 3-1/2 to 3-3/4 pounds

(1.6kg to 1.7kg) and it will be a very good racer. Better

performance and more accurate controls can be achieved if

the control surfaces are sealed using clear tape or clear

MonoKote®. This will also help reduce high speed flutter.

- 21 -

Page 22

VIPER TEMPLATES

Bevel the Leading Edge

Mid-Tail Elevator

Make (2) from 3/16" (5mm) Hard Balsa

Drill 5/64" (2mm) Holes

Taper to 1/16" (1.6mm)

Mid-Tail Vertical Fin

3/16" (5mm) Hard Balsa

Mid-Tail Rudder

3/16" (5mm) Hard Balsa

Bevel the Leading Edge

Taper to 1/16 (1.6mm)

Drill 5/64" (2mm) Holes

- 22 -

Recess here

Drill 5/64" (2mm) hole

for interlock

Hinge locationHinge location

Grain direction

Page 23

V-Tail Fuselage Template

V-Tail Stabilizer

Make (2) from 3/16" (5mm) Hard Balsa

V-Tail Elevator

Make (2) from 3/16" (5mm) Hard Balsa

Bevel the

Leading Edge

Taper to

1/16"

(1.6mm)

Drill 1/16" (1.6mm) Holes

- 23 -

Hinge location

Page 24

V-Tail Crutch

Make (4)

Bottom

Servo Tray

Trim the existing servo tray to size

for mounting behind bulkhead #4.

Surface Throw Gauges

Cut out the gauge and Tape or glue the throw gauge to a

piece of cardboard to keep it from flexing.

- 24 -

IMPORTANT

The threaded coupler will need to be soldered onto the end

of the throttle rod. Sand 1/2" of the paint off of one end of

the throttle rod. Put solder flux on the end of the throttle rod

and place the coupler on the rod. Apply heat from a

soldering iron on the coupler and apply solder to the rod

and xoupler joint. The solder will wick into the coupler. Let

the coupler cool before installing the clevis.

Throttle Rod

Sand the shaded area.

Threaded Coupler

Loading...

Loading...