Page 1

INSTRUCTION MANUAL

WARNING! THIS IS NOT A TOY!

Assembly and operation of this aircraft must be done by or under

the direct supervision of a responsible adult. If not handled

correctly, this model is capable of inflicting serious bodily harm.

It is your responsibility and yours alone to assemble this model

correctly, properly install all R/C components and to test and

operate it in a safe and responsible manner.

Entire Contents © Copyright 1998 HCAA1010 V20

ARF1P01

Page 2

Stock # Description Qty

Al UM007P Aluminum Channel 1

ARF1F01 Plastic Fuselage Tube 1

ARF1P01 Instruction Book 1

ARF1R05 1/64 Plywood Fin

ARF1W02 Plastic Wing Protector 1

EM20481 Engine Mount Left 1

EM2048R Engine Mount Right 1

FWING02L Molded Foam Wing Left 1

FW1NG02R Molded Foam Wing Right 1

L-6U Landing Gear 1

NYLON87 CA Hinge Strip

PLTB009

PLTB011 24" Grey Outer Pushrod 2

PLTB012

PLTB013

WIRES 16 Threaded Link Rod 5

ARF1A01 Subpack

ARF1R04 1/4 x 1/2 x 13

ARF1S01 1/4 Balsa

ARF1S02 1/4 Balsa Stabili/er 1

ARF1S03 1/4 Balsa Elevator 1

ARF1W01 1/8 Plywood

ARF1A02 Subpack

ARF1R01 1/4 Balsa Fin Front 1

Loose in Box

Doubler 1

24"

White Inner

11-3/4"

11-3/4"

Inner Pushrod 1

Outer

Pushrod

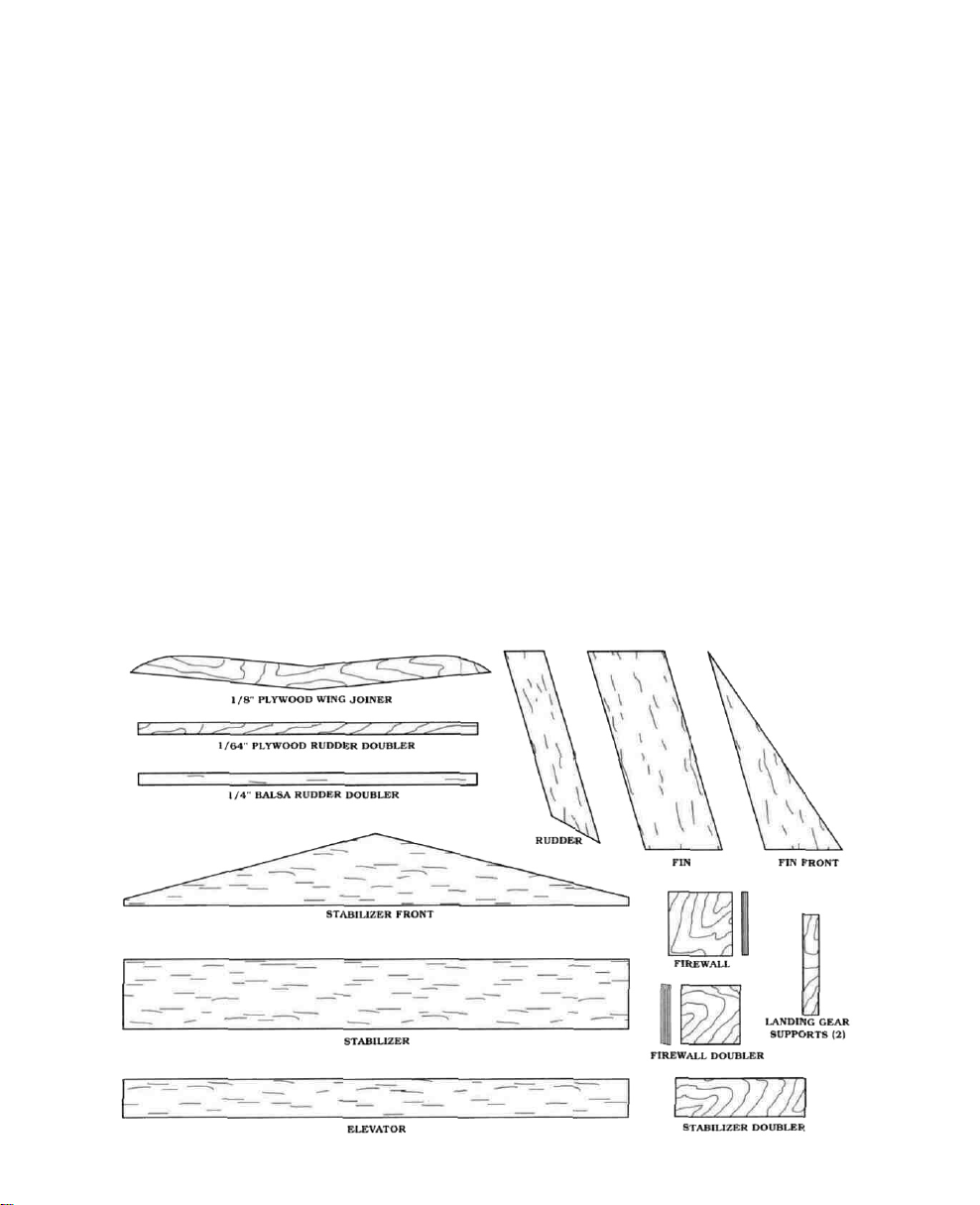

Stabilizer & Wing Parts

Balsa Fin Doubler 1

Stabili/er Front 1

Wing Joiner 1

Fin & Rudder Parts

1

Pushrod

1

PARTS LIST

Stock # Description Qty

ARF1R02 1/4 Balsa Fin 1

ARF1R03 1/4 Balsa Rudder 1

ARF1A03 Subpack

ARF1F03 9mm Plywood

ARF1F04 1/4 Plywood Firewall 1

ARF1F05 1/4 Ply

ARF1F06 Pushrod Holder

ARF1S04 1/16 Plywood

2

DOWEL030 1/4 x3 1/2 Dowel 4

ARF2A04 Subpack

ARF2W03 3/8 Tapered TE 2

ARF2W04 3/8 Tapered Aileron 2

ARF2A05 Subpack

ARF2W05 Grooved Center TE 2

ARF2W06 TE Support 2

ARF2W08 Servo Rails 2

NYLON20 Non threaded Swivel 2

NYLON21

WBNT110L Aileron Torque Rod Left 1

WBNT110R Aileron Torque Rod Right 1

Small Wood Parts

Firewall Doubler 1

Landing Gear Supports 2

(3/4 x 1

/2 x 1 ) 1

Stabili/er Doubler 1

Long Aileron Parts

Small Aileron Parts

Swivel

Clevis

Stock # Description Qty

ARF1MOI Subpack Hardware

(Contains the Following)

NUTS001 4 40 Blind Nut 6

NUTS002 4 40 Hex Nut 2

NUTS010 6 32 Hex Nut 4

NUTS014 8 32 Hex Nut 2

NYLON03 Nylon Control Horn 2

NYLON 17 Nylon Clevis 3

NYLON52 5 1/2 Nylon Tie 2

SCRW002 2 56 x 5/8 Bolt 4

SCRW010 #4x5/8

Sheet Metal Screw 4

SCRW024 #2 x 3/8

Sheet Metal Screw 8

SCRW052 4 40 x 5/8 Bolt 4

SCRW053 8 32 x I /2 Bolt 2

SCRW055 6 32 x 1 1/2

SH Cap Screw 2

SCRW104 4 40 x 1 1/4

Machine Screw 4

WBNT146 Prebent Tailskid 1

WIRES20 1 Threaded Link Rod 3

WSHR002 #4 Lock Washer 2

WSHR004 #6 Flat Washer 4

WSHR005 #4 Flat Washer 4

WSHR010 #8 Lock Washer 2

WSHR011 #8 Flat Washer 1

2

2

Page 3

TABLE OF CONTENTS

Parts List.................................................2

Introduction ............................................3

Additional Item Description .....................3

Additional Item Check List.......................4

Tools or Supplies Needed.........................5

Fin & Rudder Construction......................5

Installing CA Hinges ................................6

Stabilizer & Elevator Construction........... 8

Wing Assembly ......................................10

Covering................................................ 14

Installing the Hinges..............................14

Attaching the Control Horns.................. 15

Fuselage Construction........................... 15

Final Assembly ......................................22

Balancing..............................................23

Getting Ready for Flying ........................23

Flying....................................................23

Repairing .................................Back Cover

INTRODUCTION

Congratulations on your purchase of the

HOBBICO STURDY BIRDY II. THE FIRST

REAL SUPER TRAINER. You now own the

BEST FLYING durable trainer available. By

following these instructions as you assemble

the model, you will have a great flying plane.

It will not only teach you how to fly, but will

stick by you while you learn, no matter how

long that may take!

The first thing you should do after reading

this paragraph is check the parts in this kit

against the parts list to make sure everything

is here.

We strongly recommend that you join the

Academy of Model Aeronautics. Being an AMA

member entitles you to liability insurance and

puts you in touch with your local flying

club. It also includes a subscription to MODEL

AVIATION magazine, which has a monthly

listing of the latest news in model aviation.

Insurance is the most important advantage of

the AMA membership. If your model hits

someone or something, you are liable for any

damage it causes.

You can contact the national Academy of

Model Aeronautics, which has more than

2,500 chartered clubs across the country.

Through any one of them, instructor training

programs and insured newcomer training are

available.

Contact the AMA at the address or toll-free

phone number below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Web Site:

HTTP:

//WWW.

We also recommend that you join your local

flying club. There you will find people who

can help you learn to fly and teach you the

safe ways of handling your aircraft.

MODELAIRCRAFT.

ORG

ADDITIONAL ITEMS

DESCRIPTION

Here is a description of some of the items you

will need to assemble your STURDY BIRDY II

GLUES

CA (Cyanoacrylate) glues will be used to glue

the wood parts together because they are

strong and very fast curing. Do not use CA

glues for the wing construction because most

CA glues will attack and dissolve the foam

wing. They come in different viscosities. Thin

CA glue can be used when gluing parts with

a good, tight joint. When using thin CA,

3

Page 4

assemble the parts first and then add the

glue. It will penetrate the joint and cure in a

couple of seconds. Thick and medium CAs

are applied to the parts before they are

assembled since the glue will not cure for

20-30 seconds. This longer curing time gives

you more time to get the parts assembled

accurately before the glue cures. The thicker

consistency also

CA accelerator spray can be very handy

for speeding up the curing process of the

thick CAs.

Epoxy is a two-part adhesive that has to be

mixed before it will cure. We will use epoxy

glue for the wing assembly since it takes a

little longer to cure and does not attack the

foam. Epoxies come in several different types

with many different curing times. You should

buy some epoxy with a 30-minute curing

time for use here.

ENGINE

The STURDY BIRDY II is designed to fly with

a standard .20 size 2-stroke engine. The OS

.20 FP is a great, inexpensive engine that

provides plenty of power. This combination is

ideal for the average beginner. A .25 - .30 size

engine can be used if you would like snappier

performance, especially at higher elevations

where the air is thinner. We recommend that

you do not use an engine larger than a .30

as the additional weight makes the plane

more difficult to fly at low speeds. The engine

mount provided with the STURDY BIRDY II

will fit most .20 - .30 engines.

helps

fill

poor fitting

joints.

FUEL TANK

The STURDY BIRDY III was designed to hold

a 6 oz. square tank. A 4 oz. tank will also

work but will give you shorter flight times.

COVERING

Although not absolutely necessary, the "tail

feathers" and the wing should both be

covered with a "low heat" type iron on

covering. EconoKote^ and Black Baron® Film

are both good coverings to use on your

STURDY BIRDY II. The covering will not

only make your plane look nicer, but it will

also add strength and make it last longer.

CHECK LIST OF ADDITIONAL

ITEMS YOU WILL NEED

D .20 -.30 2-Stroke Engine

D 4 Channel Radio

D 4 Standard Size Servos

D Several 9 X 4 or 9 X 6 Propellers

D 2-1/2" Wheels (2)

D 6 oz. Square Fuel Tank

D Box #64 Rubber Bands

D Thin CA (Cyanoacrylate) Glue loz.

D Thick CA (Cyanoacrylate) Glue loz.

D 30-Minute Epoxy 4oz.

D Roll of Low Heat Iron-On Covering

D Foam Rubber for Cushioning Receiver

D 12" Standard Size Fuel Tubing

D 3/4" Wide Nylon Reinforced Tape

RADIO

The STURDY BIRDY II requires 4 channels to

fly. The radio system you purchase should

have standard size servos so they will fit into

the fuselage channel. Mini or micro servos will

also work but they will require some

modifications to fit properly. Large servos will

not work in the STURDY BIRDY II.

Questions or Problems?

Contact us at:

4

Hobby Services

Attn: Service Department

1610 Interstate Drive

Champaign, IL 61821-1067

(217)

398-8970

Page 5

TOOLS & SUPPLIES NEEDED

D Sealing Iron D Razor Saw

D Hobby Knife D Pliers

D Screwdrivers D T-Pins

D Hammer D Wax paper

D Sanding Block or Bar Sander

D Nylon Reinforced Strapping Tape

D Hand or Electric Drill

D Drill Bits (3/32", 1/8". 3/16", 5/32", 7/32")

FIN & RUDDER

CONSTRUCTION

glue has cured, flip the pieces over and add a

little glue to the other side.

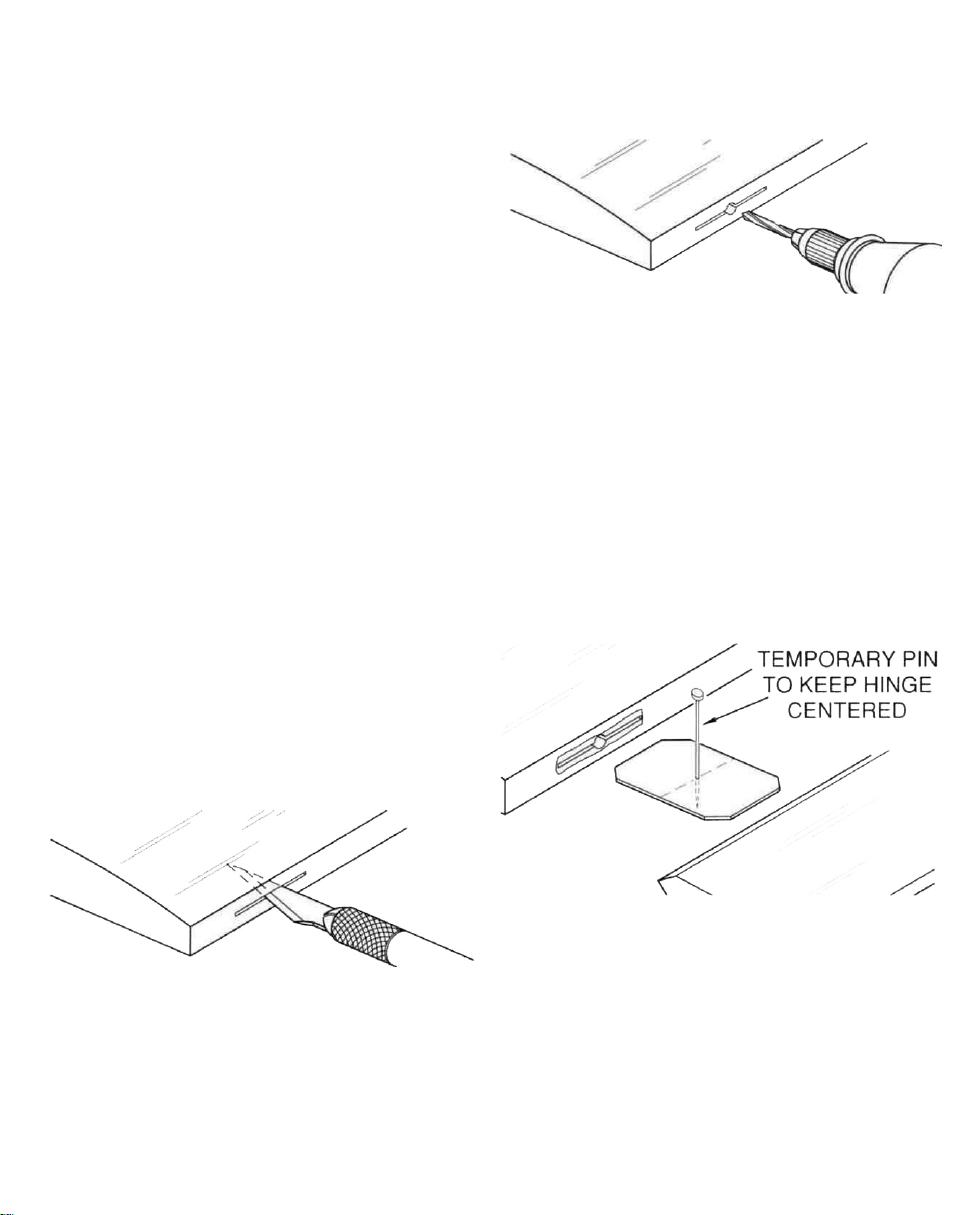

D 3. As shown in the above sketch, cut 18

hinges from the supplied 2" x 9" composite

hinge material. You will need five hinges for

the elevator and three for the rudder. Each

aileron gets three hinges.

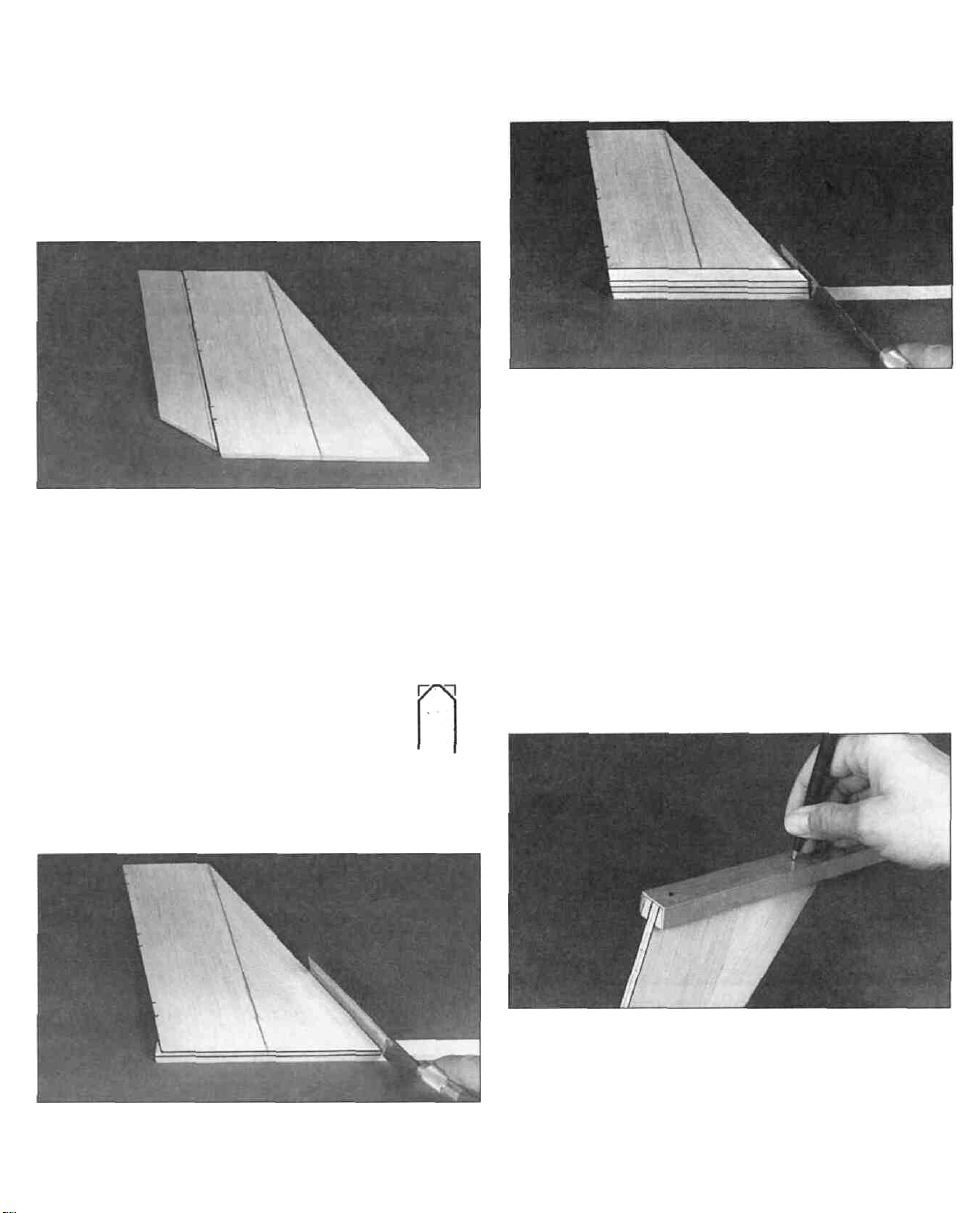

D 1. The fin is made up of the three pieces

shown above. Locate these three pieces and

lay them out.

D 2. Glue the front part of the fin to the main

part using thin CA. Assemble the two parts

and check to make sure they fit properly. Then

apply a line of CA along the joint. When the

D 4. Lay the rudder in place against the

trailing edge of the fin. Using a hinge as a

template, mark the hinge locations. They are

spaced out so that the outer hinges are

approximately 1" from the ends of the rudder

and the middle hinge is in the center.

D 5. Draw a line down the middle of the

trailing edge of the fin and also down the

middle of the leading edge of the rudder. A

sheet of wood (or anything) 1/8" thick laid

down next to the piece makes it easy to do

this. Transfer the hinge locating marks from

the side to the edges as shown above

5

Page 6

Note: Before proceeding to hinge the rudder.

read completely through the section on

Installing CA Hinges. Do not use any glue

until after the tail surfaces are covered.

INSTALLING CA HINGES

The hinge material supplied in this kit

consists of a 3-layer lamination of mylar and

polyester. It is specially made for the purpose

of hinging model airplane control surfaces.

Properly installed, this type of hinge provides

the best combination of strength, durability

and ease of installation. We trust even our best

show models to these hinges, but it is

essential to install them correctly. Please

read the following instructions and follow

them carefully to obtain the best results.

These instructions may be used to effectively

install any of the various brands of CA hinges.

The most common mistake made by modelers

when installing this type of hinge is not

applying a sufficient amount of glue to fully

secure the hinge over its entire surface area;

or, the hinge slots are very tight, restricting

the flow of CA to the back of the hinges. This

results in hinges that are only "tack glued"

approximately 1/8" to 1/4" into the hinge

slots. The following technique has been

developed to help ensure thorough and

secure gluing.

few times to provide more clearance (it is

really the back edge of the blade that does

the work here in widening the slot).

CAUTION: Do not drill this hole when

hinging a foam wing, as this hole would allow

too much CA to penetrate and cause damage

to the foam.

B. Drill a 3/32" hole, 1/2" deep. in the

center of the hinge slot. If you use a Dremel

MultiPro for this task, it will result in a

cleaner hole than if you use a slower speed

power or hand drill. Drilling the hole will twist

some of the wood fibers into the slot, making it

difficult to insert the hinge, so you should

reinsert the knife blade, working it back and

forth a few times to clean out the slot.

A. Cut the hinge slot using a # 11 blade in a

standard #1 knife handle. The slots should

be about 3/4" deep. The CA hinges provided

have a thickness that fits this type of slot

very well. Cut off the corners of the hinge at a

45 degree angle and trial fit the hinge into the

slot. If the hinge does not slide in easily, work

the knife blade back and forth in the slot a

C. Insert the hinges and install the control

surface. Verify the left-right positioning of the

control surface and close up the hinge gap to

1/32" or less. It is best to leave a very slight

hinge gap, rather than closing it up tight, to

help prevent the CA from wicking along the

hinge line. If you have cut your hinge slots too

deep, the hinges may slide in too far. leaving

only a small portion of the hinge in the control

surface. To avoid this, you may insert a small

6

Page 7

pin through the center of each hinge, before

installing. This pin will keep the hinge

centered while installing the control surface.

Note: When hinging the ailerons, which use

torque rods, use a toothpick to force epoxy

down the hole drilled for the torque rod. In

the case of the rudder, be sure not to let glue

get into the bearing tube.

D 6. Trial fit the fin and rudder together using

the hinges to check for proper alignment.

Do Not glue the hinges in place yet! Sand the

rudder and/or fin so they match each other at

the top.

D 7. Remove the hinges from the

rudder and bevel the leading edge

with your sanding block as shown in

the sketch. This is to allow the

rudder to swing either direction once

EDGE VIEW

the hinges are glued in place.

above. Use a razor saw to cut the excess off at

the leading and trailing edges.

D 9. Check the fit of the fin assembly into

the aluminum channel. It will most likely be

a little loose and we want a nice, tight fit. Add

a strip of the 1/64" plywood doubler to ONE

side of the fin. Glue it to the balsa doubler.

Check the fit again and if it is still a little

loose, add a plywood doubler to the other

side. If necessary, you can sand the plywood

slightly to help the assembly fit. Also, you

can have the covering material continue

down over the doublers if you need the

additional thickness.

D 8. Add the 1/4" x 1/2" balsa doubler to

each side of the fin as shown in the photo

D 10. Position the fin assembly in the channel

with the trailing edge of the fin even with the

end of the channel. Press it in place. Mark the

location of the stabilizer bolt holes on the

bottom of the fin and then remove the fin from

the channel.

7

Page 8

D 11. Wrap a piece of masking tape around a

7/32" drill bit about 1/2" from the end of

the

bit.

D 12. Drill two holes in the bottom of the fin

assembly to make a space for the stabilizer

bolts. Be careful not to drill any deeper than

the masking tape or you may drill through the

side of the fin.

STABILIZER

& ELEVATOR

CONSTRUCTION

D 14. The stabilizer and elevator are

assembled from these three main pieces.

Locate these and let's get started.

D 15. Glue the front of the stabilizer to the

back using thin CA just as you did for the fin

in step #2.

D 13. Use a sanding block to round the edges

of the fin/rudder assembly as shown above.

Give the sides a quick sanding with some fine

sandpaper to get them ready for the covering.

This completes the basic assembly of the fin

and rudder. The hinges and control horn will

be installed after everything is covered.

D 16. Mark the hinge locations using the

same technique you used in step #4. There are

five hinges used here. The outer hinges are

8

Page 9

approximately 1" from the edge. The middle

hinge is in the center and the other two hinges

are centered between the outer hinges and the

middle hinge. These hinge locations are not

critical, but proper placement makes it easier

to find the slots after the parts are covered.

Cut the slots for the hinges and test fit the

stabilizer and the elevator together to check for

proper alignment between the two parts.

D 17. Use some thick CA to glue the 1/16"

plywood doubler in place on the stabilizer. This

side is now the bottom of the stabilizer. Use

a ruler to get this piece centered as close as

possible. Use a drafting triangle or carpenter's

square to draw a line perpendicular to the

stabilizer trailing edge and through the center of

the stabilizer to the point where the leading

edges meet.

Sight down the bottom of the channel and line

the stabilizer up with the channel (using the

line you just drew). When you are satisfied with

the alignment, draw a line down both sides of

the channel on the top of the stabilizer.

D 19. Remove the pencil and rubber band.

With the stabilizer centered over the lines, drill

two 1/8" holes through the stabilizer using the

holes in the channel as a guide. The trailing

edge of the stabilizer should be slightly past

the end of the channel.

D 20. Use a sanding block with some fine

sandpaper to round off the leading edges,

trailing edge and the tips as you did for the

fin and rudder. Also sand the top and bottom

surfaces smooth. This completes the basic

assembly of the stabilizer and elevator. The

control horn and the hinges will be installed

after the tail is covered.

D 18. Use a pencil and a rubber band to hold

the stabilizer in place as shown in the photo.

9

Page 10

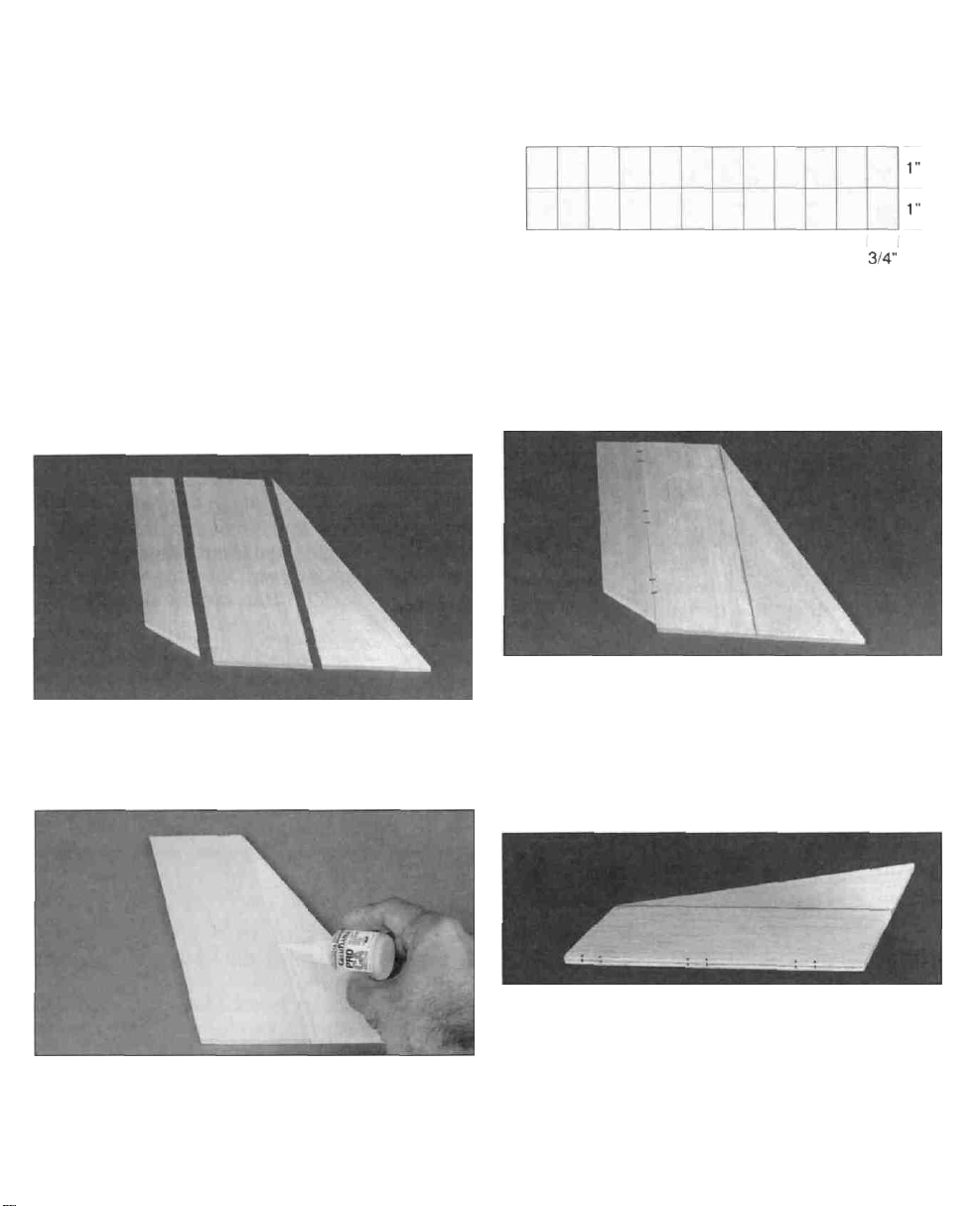

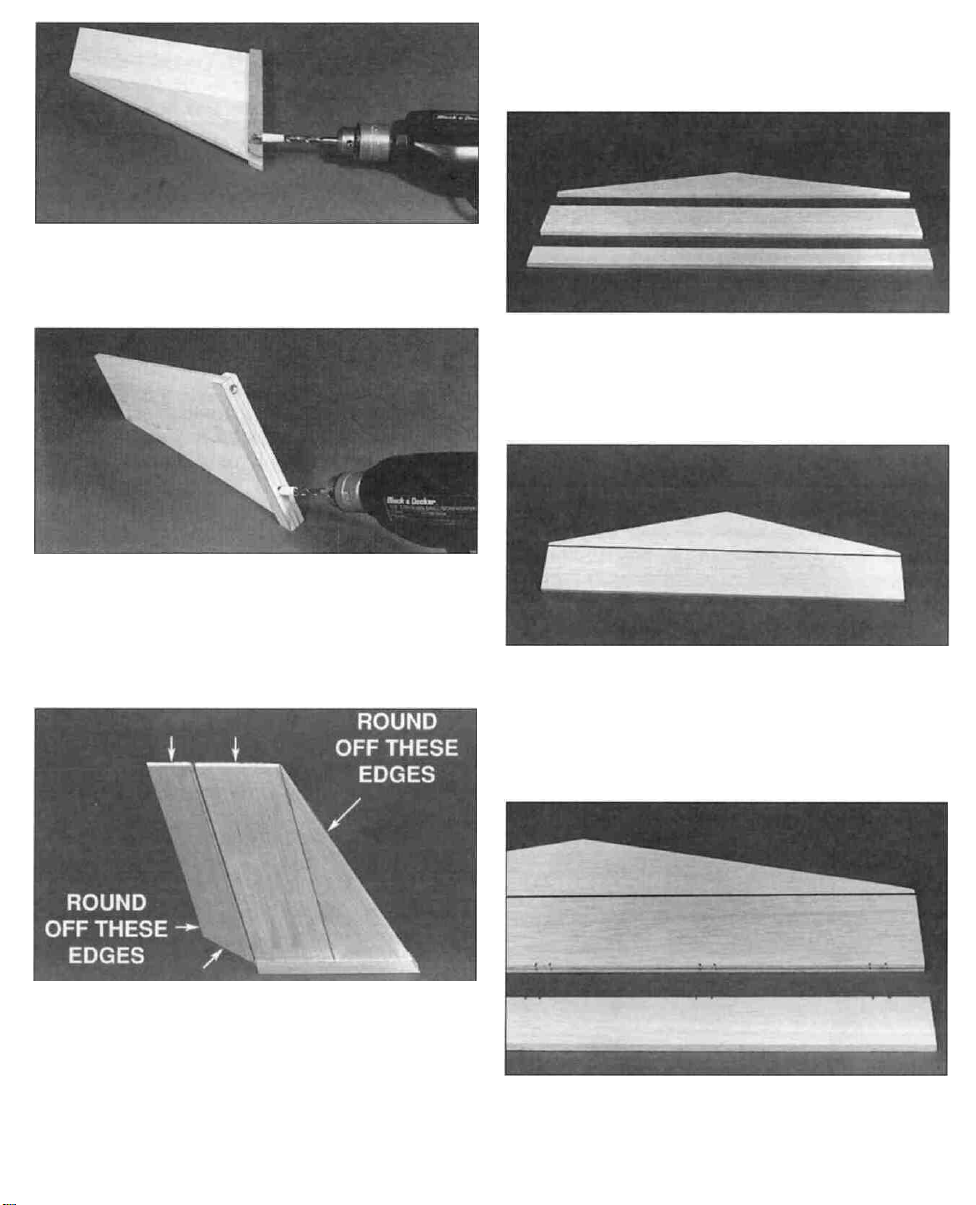

WING ASSEMBLY

INSTALL THE AILERONS

Balsa SUB TE 26-1/2" Long

D 1. Locate the two balsa 15/32" x 3/8 x

26-1/2" Sub Trailing Edge pieces (Sub TE).

Trial fit the Sub TE against the trailing edge of

each wing half. The Sub TE should be oriented

as shown in the sketch with the 90-degree

corners along the bottom of the wing. Epoxy

the Sub TE to the trailing edge of each wing

half. Pins or tape can be used to help hold the

Sub TE in place while the glue cures.

Use the sketch to help you determine which

side is the top and mark the top side of each

piece. Make another mark 7/16" from the

"inboard" end of each piece. Notch each piece

to make a slot for the torque rod.

Note: The threaded portion of each torque rod

should stick out the top of each wing. Also

there will be a "right" and a "left" center trailing

edge piece so don't make two exactly alike.

Balsa CENTER TE 3-7/8 " Long

D 2. Locate the two balsa 3/8" x 1-1/4" x

3-7/8" tapered center trailing edge pieces.

D 3. Use 150-220 grit sandpaper to roughen

the outer surface of the torque rod bearing.

Slide the bearing toward the threaded end of

the torque rod and put a small amount of

petroleum jelly around the ends of the

bearing tube to prevent epoxy from seeping

in. Spread some epoxy in the slot and on the

leading edge of the center trailing edge

pieces. Do not apply any epoxy within 1/4" of

the notch or you may glue the torque rod.

Insert the torque rods into the slots with the

threaded portions sticking out through the

notches. Position the center trailing edges

against the wing sub trailing edge. Align the

center trailing edges and pin or tape them in

place while the glue cures.

10

Page 11

D 4. Epoxy the two 11/32" x 2" x 1-5/8"

Tapered TE Supports to the inboard bottom of

each center trailing edge as shown in the photo.

D 5. Use a sanding block with 150-grit

sandpaper to sand the inner ends of the sub

trailing edge. center trailing edge and the

tapered trailing edge to match the angle of

the foam wing end. Be careful not to change

the angle of the foam wing.

AILERON

22-1/2" Long

ARF2W04

D 6. Hold the 3/8" x 1-1/4" x 22-1/4" Ailerons

in place against the sub trailing edge and under

the torque rods. Mark the location where the

torque rods will enter the ailerons. Drill a 3/32"

hole in each aileron to accept the torque rods.

D 7. Cut a groove in the leading edge of the

aileron to allow clearance for the torque rods.

Trial fit the ailerons in place and cut as

necessary until they fit.

D 8. Draw an accurate centerline along the

leading edge of the aileron and cut three

hinge slots in each aileron. The hinge slots

should be approximately 1-1/2", 10" and 18"

from the wing tip. Place the ailerons against

the sub trailing edge and mark the hinge

locations on the wing. Draw a center line

down the sub trailing edge and cut the hinge

slots to match the ailerons.

D 9. Using a sanding block, sand the leading

edge of each aileron to a "V" shape.

11

Page 12

D 10. Insert the hinges into the slots and

trial fit the ailerons in place on the wing. Do

not glue the hinges until after you have

covered the wing. Sand the outboard edge of

the sub trailing edges and the ailerons to

match the foam wing tips.

JOIN THE WING PANELS

D 1. Use a sanding block with some fine grit

sandpaper (240 - 320 grit) to remove the little

nubs and any mold lines left on the wing

from the molding process.

D 3. Lay some wax paper down on the work

surface and mix up one ounce of epoxy.

Spread the epoxy throughout the slot and on

the root (middle end) of the other wing panel.

Slide the two wing panels together and line

them up as close as possible. Use several

T-pins and masking tape to help hold them in

alignment. Flip the wing assembly over so that

the bottom of the wings are facing up and

make sure that the joiner is seated properly in

the slot. Wipe off any excess epoxy before it

starts to cure. It is important that the wings

are joined with both panels being accurately

aligned with each other.

D 4. Allow the epoxy from the last step to

fully cure.

D 2. Test fit the 1/8" plywood dihedral joiner

in the slots in the wing to make sure it fits

nicely. Mix up about 1/2 oz. of epoxy and

spread it throughout the slot in one wing

panel. With the wing panel upside down,

insert the joiner in place and squeeze out all

the excess epoxy so that the joiner is flush

with the bottom of the wing (which is facing

up). Try to use enough epoxy so that the slot

is completely full and level with the surface of

the wing.

Note: The tape used in this step is 3/4" wide

nylon filament reinforcing tape. This is

self-adhesive tape with nylon filaments

running the length of the tape. It is also

referred to as "nylon filament strapping tape,"

or "nylon reinforced packaging tape." You can

obtain it at any store that sells stationery and

packaging materials or at most hardware

stores. Be sure to use 3/4" wide tape.

Narrower tape will not provide the wing with

12

Page 13

proper reinforcement. Make sure the tape is

applied with no wrinkles and that the strips

are straight and parallel from wingtip to

wingtip. If this tape is not applied, if it is

applied incorrectly or if a different type of

tape is applied, we cannot be responsible

for any wing failure that may occur.

D 5. Place the wing upside down on the edge

of a table so that only 1/2 of the wing (from

one wing tip to the center joint) is resting on

the table. Starting at the wing tip that is

resting on the table, lay a strip of nylon-

reinforced strapping tape down so that it

crosses over the center joint directly over the

wing joiner.

INSTALL THE WING PROTECTOR

D 1. Use a sharp hobby knife or a Dremel®

Tool with a tapered cutting bit to trim out the

servo and torque rod cut-outs in the Plastic

Wing Protector. There are scribe lines on the

bottom surface of the protector to help guide

you. Trial fit the aileron servo in place and

trim as necessary to make it fit properly. Use

scissors or your hobby knife to trim the

outside edges of the wing protector along the

remaining scribe lines.

D 2. Place the wing protector on the center of

the wing so the torque rods fit through their

holes. Draw a line on the wing around the

servo cutout. Remove the protector and carve

out a hole in the foam wing to fit your servo.

Carve out an extra 1/4" square groove in front

and behind the servo cut-out for the servo

rails. Drill a 1/2" diameter hole for the servo

wires down through the front edge of the servo

cutout. Be careful not to cut the plywood wing

joiner when performing these operations.

Press the tape firmly onto the wing and down

into the fillet (where the bottom of the wing

meets the mounting platform) and then flip

the wing around and continue the strip of

tape out to the other wing tip. Apply two

more strips of tape between this strip and the

trailing edge of the wing. The fourth strip

should be added between the first strip and

the leading edge of the wing. The previous

photo shows where the strips should be

located. Try to get this tape stuck down

as tightly as possible because it adds a

tremendous amount of strength to the wing

when properly applied. Make sure you do not

change the washout (twist) or dihedral

(V-shape) of the wing when applying the tape

strips. If you are planning on doing some

aerobatics or combat with your STURDY

BIRDY

tape on the top surface of the wing.

II,

you should

also

put

three

strips

of

D 3. Glue the 3/16"x l/4"x 1-1/4" Basswood

Servo Rails in place along the front and back

edges of the servo cut-out. Put the aileron

servo in place and mark on the plastic

protector where the servo mounting screws

should be. Drill 1/1 6" diameter holes on the

marks you just made and mount the servo

using the screws provided with your radio.

D 4. Trial fit the wing protector assembly on

the wing and enlarge the cutouts in the foam

13

Page 14

wing if necessary to make the protector lie

flat against the wing. When satisfied with

the fit, remove the servo. Use coarse

sandpaper to roughen the bottom of the wing

protector so the glue will hold better. Use

epoxy to glue the protector in place.

D 5. Trial fit the ailerons for this step. Mount

the aileron servo with the screws provided in

the radio system and assemble the pushrods

as shown in the sketch above. Attach the

pushrods to the torque rods by screwing the

Aileron Clevis Connector onto the threaded

portion of the torque rod. Use a pair of needle

nose pliers to make the Z-bends and attach

them to the servo horn. Turn on your radio.

plug in your aileron servo and adjust the

centering of the servo horn until it is

centered and the right aileron moves up

when you move the transmitter stick to the

right. Adjust the nylon clevis until each

aileron is in a neutral position when the

transmitter sticks and trims are centered.

Also adjust the position of the nylon clevis

connector on the torque rod to achieve 7/16"

of up and down movement.

are also going to cover the wing, which will

help it look nicer longer (and add a

small amount of strength), you can save a

little money by buying only one roll of low

temperature covering (EconoKote, Black

Baron Film, etc.) and using it for both the

wing and the tail surfaces. Otherwise you can

use any type of covering for the tail surfaces,

but remember to use a low heat covering for

the wing. A few stripes or your AMA number

can really add to the looks of your STURDY

BIRDY II.

D 2. Follow the instructions that come with

the covering and cover the tail surfaces at

this time. It is a good idea to cover the bottom

surfaces first to get familiar with the covering

since these surfaces will normally not be

seen. When covering the wing, cover right

over the tape and plastic wing protector. Try

to use as little heat as possible.

ATTACHING THE CONTROL HORNS

COVERING

D 1. The tail surfaces (fin, rudder, stabilizer

and elevator) should be covered with one of

the iron-on coverings to help protect them

from becoming fuel soaked and ruined. If you

D 1. Position the nylon control horn on the

left side of the rudder about 1" up from the

bottom with the four holes lined up with the

leading edge. Use a drop of Thin CA to tack

glue the horn in place.

14

Page 15

D 2. Drill two 3/32" holes through the

rudder using the control horn as a guide.

D 3. Secure the horn to the rudder with two

2-56 x 5/8" machine screws. The screws

should thread into the nylon "nut plate" on

the opposite side of the rudder. Although not

necessary, you may use some wire cutters or

an abrasive cutoff wheel to cut the screws off

even with the plate.

D 4. The other control horn should be

installed on the top surface of the elevator

about 1" to the right of the centerline. Follow

the same procedure for installing this

control horn.

INSTALLING THE HINGES

D 1. After covering the tail surfaces and the

wing, the hinges can be installed. Use your

hobby knife to find the slots you cut earlier

and make slits in the covering so you can

push the hinges into place and trial fit the

pieces together again. (Refer to the CA hinge

section on page 6.)

D 2. The control surfaces will take some

abuse in the learning-to-fly process, so you

must securely glue the hinges in place. Use

four to six drops of CA on each side of the

hinge to secure them. Try to get the surfaces

as close together as possible, but work the

control surfaces back and forth while the

glue is curing to make sure they work freely

without binding. Also, be careful not to glue

the two surfaces together.

FUSELAGE CONSTRUCTION

D 1. Locate the 3/8" plywood

firewall doubler and round

off the corners with a

sanding block. Test fit the

doubler into the front of the

plastic fuselage tube as

shown above. The firewall

doubler should fit into the

fuselage with a snug but not

tight fit. The front of the

fuselage is cut at a slight

angle so the firewall and thus

the engine will point down slightly. Because

of this angle the top and bottom edges of the

firewall doubler are also cut at a slight angle.

Make sure you install the firewall doubler so

all of its sides match up nicely with the sides

of the fuselage as shown in the sketch.

15

FIREWALL

DOUBLER

Page 16

D 2. The 3/8" plywood firewall doubler is

now glued to the 1/4" plywood firewall front.

Use either Thick CA or epoxy and make sure

that the front of the firewall doubler is

centered on the back of the firewall. Wipe

away all excess glue that squeezes out.

Tick marks for alignment

Determine where the mount should be

installed on the firewall. Use the template in

the left column to make it easy to locate the

mounting holes. Photocopy or cut out the

template and tape it in place on the firewall.

Poke a T-pin though the template to

accurately mark the bolt locations on the

firewall. Drill a 1/8" diameter hole at the four

pin holes and install the mount using 4-40

bolts, #4 flat washers and 4-40 blind nuts.

The length of the bolts will be determined by

the thickness of the firewall. A 1/4" firewall

will usually require 7/8" long bolts. Do not

tighten the bolts all the way yet.

D 3. Cut or break the "spreader bar" off each

mount half. Carefully trim any extra plastic off

each mount half left by the spreader bar. The

surfaces where the spreader bars were attached

need to be very smooth to allow the mount

halves to fit together. Also trim the flashing off

any other rough edges. Snap the two mount

halves together as shown in the sketch.

Slide the mount halves apart until the engine

mounting lugs will sit flat on the beams.

Adjust the mount until the firewall centerline

(or offset line) is centered between the "tick"

marks on the mount. Tighten the 4-40 bolts

to hold the mount halves in position.

Determine how far forward the engine should

be positioned on the beams and mark where

to drill the mounting holes. Remove the

engine and drill a 3/32" hole at each mark.

Put a drop of oil in each hole and install the

engine using the #4 x 5/8" screws provided.

If you prefer to use 4-40 machine screws (not

included) to install your engine, just tap the

holes you drilled with a 4-40 tap.

With the engine installed on the mount, mark

the location for the throttle pushrod and fuel

lines. Remove the engine and mount. Drill a

3/16" hole in the firewall for the throttle and

two 7/32" holes for the fuel and vent lines.

16

Page 17

D 4. Use a small piece of coarse sandpaper

to scuff up the inner floor of the aluminum

channel in the area around the front 11/64"

bolt hole.

end of the channel. Square battery packs fit

nicely but most flat

packs

will

also

fit.

Just

tape them flat onto the channel. The battery

should protrude approximately 1/8" past the

end of the channel to keep the fuel tank from

rubbing against the end of the channel.

D 5. Insert one of the 8-32 x 1/2" machine

screws into the hole so that it sticks out the

bottom of the channel and glue it in place

with plenty of thick C A or epoxy. This screw

will be covered by the battery pack,

prohibiting a screwdriver from being used to

keep it from turning. Glue it securely, but be

careful not to get any glue on the threads.

D 6. Use some nylon reinforced strapping tape

to securely hold the battery pack on the front

D 7. The servos are "press fit" into the

aluminum channel and then held in place with

nylon strapping tape. Standard size servos

should fit very nicely and smaller servos can be

held in place by using a piece of wood to fill the

space between the servo sides and the channel.

Large servos will not work in the STURDY

BIRDY II. The servos should be placed as far

forward in the channel as possible and right

next to each other, but do not overlap the servo

mounting lugs. The front two servos should be

mounted with their servo output shafts

towards the back of the plane and the back

servo should have its output shaft towards the

front of the plane. The servo wires should be

routed out to the side of the servo without

going under any servos. Wrap two layers of

nylon strapping tape all the way around each

servo and the aluminum channel to hold it in

place. Hook up the entire radio system and

turn it on (see the instructions included with

your radio). Adjust the transmitter trims so

they are in the middle of their slots.

17

Page 18

Remove the screws that hold the servo horns

in place and adjust the horns so that they are

perpendicular to the servo. This will be their

neutral position. It is a good idea to use single

arm servo horns rather than the round horns

most servos come with. The sketch shows how

to cut a horn for use here. Reinstall the screws

that hold the horns in place.

D 8. Attach the stabilizer/elevator to the

back of the channel using two 4-40 x 5/8"

machine screws, two #4 flat washers, two

4-40 lock washers and two 4-40 nuts.

D 9. Press the fin/rudder into the channel

with the back edge of the fin even with the

back edge of the channel as shown in

the photo.

D 10. Assemble the two pushrods by

screwing a 1" threaded rod into one end of

each inner pushrod and then screwing a

nylon clevis onto each threaded rod. The rod

should thread into both the pushrod and the

clevis at least 13 turns.

The sketch shows how the pieces are

installed. The prebent tail skid is held in

place by the rear screw.

D 11. Attach the two long pushrods to the

two rear servos as shown in the photo. Slide

18

Page 19

the outer pushrod tubes over the inner

pushrod until they are about 1/2" from the

servo end of the inner pushrod.

D 12. Press the balsa pushrod holder into

the channel about 6" in front of the fin and

secure the pushrods to it with the nylon tie

wrap. It is a good idea to seal the balsa

pushrod holder with a light coat of epoxy that

will also help hold it in place.

Note: The rudder pushrod goes to the left side

of the fin. The elevator pushrod goes to the

right side (as viewed from the back).

D 14. Install the link rods in the 2nd hole

from the outer end of each control horn. With

the control surfaces and the servo horns in

their neutral positions, cut the inner pushrod

so the link rod will thread into the inner

pushrod approximately 2/3 of the way.

Install the link rods into the inner pushrods

and adjust so that the control surfaces are at

neutral positions.

D 15. Wrap the receiver in at least 1/4" thick

foam rubber to protect it from vibration, hard

landings, etc. and use two rubber bands to

hold the foam rubber in place. Disconnect

the rudder and elevator pushrods from the

servos and slide the pushrods under the

rubber bands on the top of the receiver.

Position the receiver behind the servos and

reattach the clevises to the servo horns. The

switch can be servo taped to the fuselage

behind the receiver so it can be reached from

the back of the fuselage.

D D 13. Cut 2" off the threaded end of two of

the 12" long link rods. Use a pair of long nose

pliers to bend the "Z" in the unthreaded end

of the 2" pieces.

The receiver antenna should exit out the

back of the fuselage without encountering

any other wires if possible. Use a small

rubber band to hold the antenna on a T-pin

inserted in the top of the fin.

19

Page 20

D 16. Assemble the throttle (short) pushrod

by screwing the remaining nylon clevis and

1" long threaded rod into one end of the short

inner pushrod and snapping this assembly

onto the throttle servo horn.

D 17. Attach the plastic fuselage tube to the

channel by sliding it over the channel

assembly and pushing the front 8-32 screw

through the middle hole in the bottom of the

tube. Put the aluminum landing gear in place

on the 8-32 screw and secure the whole

assembly with a #8 lock washer and an 8-32

hex nut. Insert the remaining 8-32 screw in

the rear hole from the bottom and secure it

with a # 8 lock washer and an 8-32 hex nut

in the channel. It is a good idea to use some

medium strength thread locking cement on

these bolts.

D 18. Slide the two 1/4" plywood landing

gear supports into the fuselage, one on each

side of the aluminum channel. The front of

the supports should be even with the front of

the aluminum channel.

D 19. Tack glue or hold these in place for the

next step.

D 20. Drill a 1/8" diameter hole in each

support using the attached landing gear as a

guide. Remove the supports from the fuselage

20

Page 21

and enlarge the holes to 5/32". Insert a 4-40

blind nut in each hole and use a hammer to

seat the blind nut in place. Replace the

supports into the fuselage with the blind nut

facing up and use the 4-40 x 5/8" machine

screws to hold everything together.

D 21. Assemble your fuel tank according to

the manufacturer's instructions. Connect the

fuel tank to the engine by routing the fuel

tubing through the two holes in the middle of

the engine mount and attaching the pickup

line to the carburetor and the vent line to the

pressure tap on the muffler. Make the fuel

lines long enough so that there is a 1" gap

between the fuel tank and the back of the

firewall. Also make sure that the fuel lines

are not kinked.

extends about 1/4" past the front of the

firewall. Remove the engine assembly from the

fuselage and glue the outer pushrod in place.

D 23. Reinstall the engine assembly into the

fuselage. Push two 1/4" x 3-1/2" dowels into

place in the four holes at the front of the

fuselage. The dowels should be a nice, tight

fit. If they are too tight you can enlarge the

holes slightly with your hobby knife. If they

are too loose you can use a drop of glue to

hold them in place. Do not use very much

glue on the front dowels since you will need

to remove the dowels to get the fuel tank out

of the fuselage. Secure the engine assembly

to the fuselage with four #62 or #64 rubber

bands as shown in the next photo.

Note: There are eight #2 x 3/8" sheet metal

screws provided if you would rather screw

the firewall in place instead of using the

rubber bands to hold it on. Tests have shown

that the rubber bands work extremely well

and help eliminate damage to the front end

during crashes.

D 22. Slide the whole engine assembly into

place in the front of the fuselage with the

throttle pushrod extending through the hole in

the firewall. Cut the outer pushrod so it starts

about 1/2" from the 1" threaded rod and

D 24. Cut the inner pushrod to length and cut

and install the remaining 1" threaded link rod

to hook up the throttle control. Make sure you

can achieve both full throttle and idle without

binding of any kind. It is also nice if you can

shut the engine off at low throttle and full

down throttle trim. Bend the link rod if

necessary to make this possible. The entire

engine / fuel tank assembly can be removed at

any time by simply removing the rubber

21

Page 22

bands, the throttle clevis from the servo horn

and the two front dowels. This makes

adjustments and checking of the fuel system

quick and easy.

D 25. Each wheel axle is made up using a

6-32 x 1-1/2" machine screw, two 6-32 hex

nuts and two #6 washers. The sketch above

shows how these parts are assembled. It is a

very good idea to use some medium strength

thread locking cement between the screw and

the hex nuts. Also make sure that the wheel

can turn freely.

B. The rudder moves to the right when the

left transmitter stick is moved to the

right (looking at the plane from the rear).

C. The throttle is closed almost all the way

when the left transmitter stick is down

(back) and is open completely when the

stick is up (forward).

4-CHANNEL RADIO SETUP

(STANDARD MODE 2)

ELEVATOR MOVES UP

RIGHT AILERON MOVES UP

LEFT AILERON MOVES DOWN

RUDDER MOVES RIGHT

D 26. Slide the two 1/4" x 3-1/2" wing

dowels into their holes in the fuselage.

Secure with a few drops of CA.

FINAL ASSEMBLY

D 1. With the fin positioned correctly, apply

a few drops of thin CA around the base to

hold it in place. This type of gluing method

will keep the fin/ rudder in place unless the

plane is crashed pretty hard, in which case

the fin will come out of the channel, usually

without breaking.

D 2. Turn the radio system on and adjust all

of the trims on the transmitter so that they

are in the middle of their slots.

D 3. Check the following:

A. The elevator moves up when the right

transmitter stick is moved down (back).

CARBURETOR WIDE OPEN

D 4. Check to make sure that the tail control

surfaces are in a neutral (straight) position

and the servo arms are perpendicular to the

aluminum channel when the transmitter stick

is at neutral. Also check the control throws on

the tail surface. You should be able to move

the rudder 3/4" both directions and the

elevator should move 1/2" both directions.

This should give you a plane that is fairly

responsive but not too radical.

D 5. Install the second nylon tie wrap

around the aluminum channel and the

pushrods right in front of the tail surfaces.

This will help keep the control surfaces

from fluttering.

22

Page 23

BALANCING

With the wing rubber banded to the fuselage,

the fuel tank empty and everything else in its

place, lift the model by placing one finger-tip

on the bottom of each wing at the

approximate location of each end of the wing

joiner which is 3" back from the leading edge.

The

STURDY

slightly nose down or level. If the plane hangs

with the nose pointing up, then you will need

to add some weight to the nose of the plane.

There are several ways you can add this

weight, including stuffing lead weight around

the fuel tank or using one of the heavy prop

nuts available. Under no circumstances

should you try to fly the plane if it does not

balance correctly!

BIRDY

II

should

hang

just

GETTING READY TO FLY

D Use at least four rubber bands to hold the

engine/firewall in place and use eight #64

rubber bands to hold the wing in place.

D We recommend that you use a nylon

propeller for your first flights since it will not

break as easily as wood. Sand the edges of the

prop before you use it. The edges of nylon props

are very sharp and should be dulled before use.

If a prop is damaged in any way it should be

discarded and a new prop used in its place.

D Be sure to conduct a range test on your

radio system before every flying session. The

instruction manual that came with your

radio should explain how to properly do this.

D If you are using a new engine in your

plane, break it in on the ground according to

the manufacturer's instructions before

attempting to fly the plane.

D

Never

over with your finger. Always use either an

electric starter or a "Chicken Stick."

try to

start

the

engine by flipping

it

D Always adjust the needle valve on the

engine from the back of the plane. Never reach

over a rotating prop! Treat these engines with

the utmost respect, they are not toys!

D After each flight, check the propeller,

engine bolts, control surfaces, control

linkages, hinges and rubber bands for

damage or looseness and correct if

necessary. An once of prevention here will

keep you happily flying longer.

FLYING

The STURDY BIRDY II is a very stable Hying

airplane with a unique self-recovery system

designed into it. This makes it one of the

easiest flying planes available. However, it is

highly recommended that you consult an

experienced pilot to help trim out the plane

and help you with your first flights. The most

important thing to remember when learning

to fly is that you need to be able to relate to

the control inputs as if you were sitting in

the plane. If you don't, it will seem like the

rudder is working backwards when the plane

is flying towards you. It may also seem a

little strange that you pull the stick down

(back) in order to make the plane go up, but

this is how it works in real planes. It is a

good idea to keep facing the same direction

that the model is flying.

The STURDY BIRDY II should be hand

launched into the wind for your first flights.

Have a helper hold the plane firmly behind

the landing gear with the wings level while

you check the controls. Advance the throttle

to full throttle. Your helper should then take

a few running steps and let the plane fly out

of his hand with a slight push (being careful

to keep the wings level). A strong throw is not

necessary. Be prepared to make any initial

adjustments to keep the plane climbing

slightly and flying straight. Your control

inputs should be very gentle until the plane

has climbed high enough to be out of danger

23

Page 24

of hitting any ground based objects

(especially the ground). Once you have

reached a safe altitude, trim the plane for

straight and level flight with the engine

running about half throttle. If you get

disoriented or the plane does not seem to be

doing what you think it should, just release

the control sticks and the plane will right

itself. If you see that the plane is heading for

danger which you can not prevent, reduce

the throttle to idle and pull the elevator stick

back (up elevator) to reduce the impact

speed. When the plane banks into a turn, it

is normal for the nose to drop down so be

prepared to put in a little up elevator to keep

it flying level.

Once you are familiar with how the STURDY

BIRDY II handles under power, pull the

throttle back to near idle and slow the plane

down. Be sure to do this at a safe altitude! Feed

in up elevator to try to keep the plane flying at

the same altitude. If the plane stalls (falls off to

one side abruptly) just release the control

sticks, advance the throttle to at least 1/2 and

gently pull in some up elevator. Try to

determine the slowest speed the plane will fly at

and remember that you need to stay above that

speed when landing and taking off to avoid a

stall. If you find the plane getting too high and

it is hard to determine what it is doing, reduce

the throttle to idle and be patient. The STURDY

BIRDY II will lose altitude fairly quickly and

you can resume control.

When preparing to land it is a good idea to

make several practice passes from a safe

altitude and gradually get lower until you feel

comfortable with your approach. Then on one

of your next passes, just decrease the

throttle and the plane will land by itself.

Landing is really not very tricky if you just

concentrate on guiding the plane with the

rudder where you want it to go and let it

settle to the ground. Of course it helps to fly

at a field that is big enough so you don't have

to worry about where you need to land.

The STURDY BIRDY II also handles very

nicely on the ground despite the fact that it

is a tail dragger without a steerable tall

wheel. When taxiing in grass, hold in up

elevator until the plane is moving pretty well

to help keep it from nosing over. To steer the

model when it is moving slow, throw in full

rudder and use bursts of throttle to move the

plane around.

REPAIRING

The STURDY BIRDY II is very tough, but

there may be crashes hard enough to break

parts of the plane. The fuselage should not

be repaired. It is inexpensive and very easy

and quick to replace. Due to the nature of

plastic, it is very hard to properly mend if

cracked or broken. It should be replaced for

safety reasons.

The foam wing will really take a beating and

survive. Small dents and dings can be

removed by patching or reheating the

covering material. A broken wing can be

quickly repaired with epoxy, but check the

nylon tape and replace it if needed. If the

wings get bent you can straighten them by

bending them the opposite direction and

adding a couple more strips of strapping

tape. It is important that the wings are kept

in their original configuration with the

molded-in washout (wing twist). This gives

the STURDY BIRDY II its exceptional

recovery characteristics.

The tail surfaces can be repaired with CA

glues, or new surfaces can be cut from 1/4"

balsa available from your local hobby shop.

If dirt gets into the carburetor or onto the engine

it should be cleaned off before it has a chance to

get inside the engine and cause damage.

Good Luck and Happy Flying!

Loading...

Loading...