Page 1

READ THROUGH THIS INSTRUCTION MANUAL

FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

HCAZ3005 for HCAA2025 V1.0Entire Contents © Copyright 2004

Champaign, Illinois

(217) 398-8970

E-mail: airsupport@hobbico.com

INSTRUCTION MANUAL

ALMOST-READY-TO-FLY RADIO CONTROLLED MODEL AIRPLANE

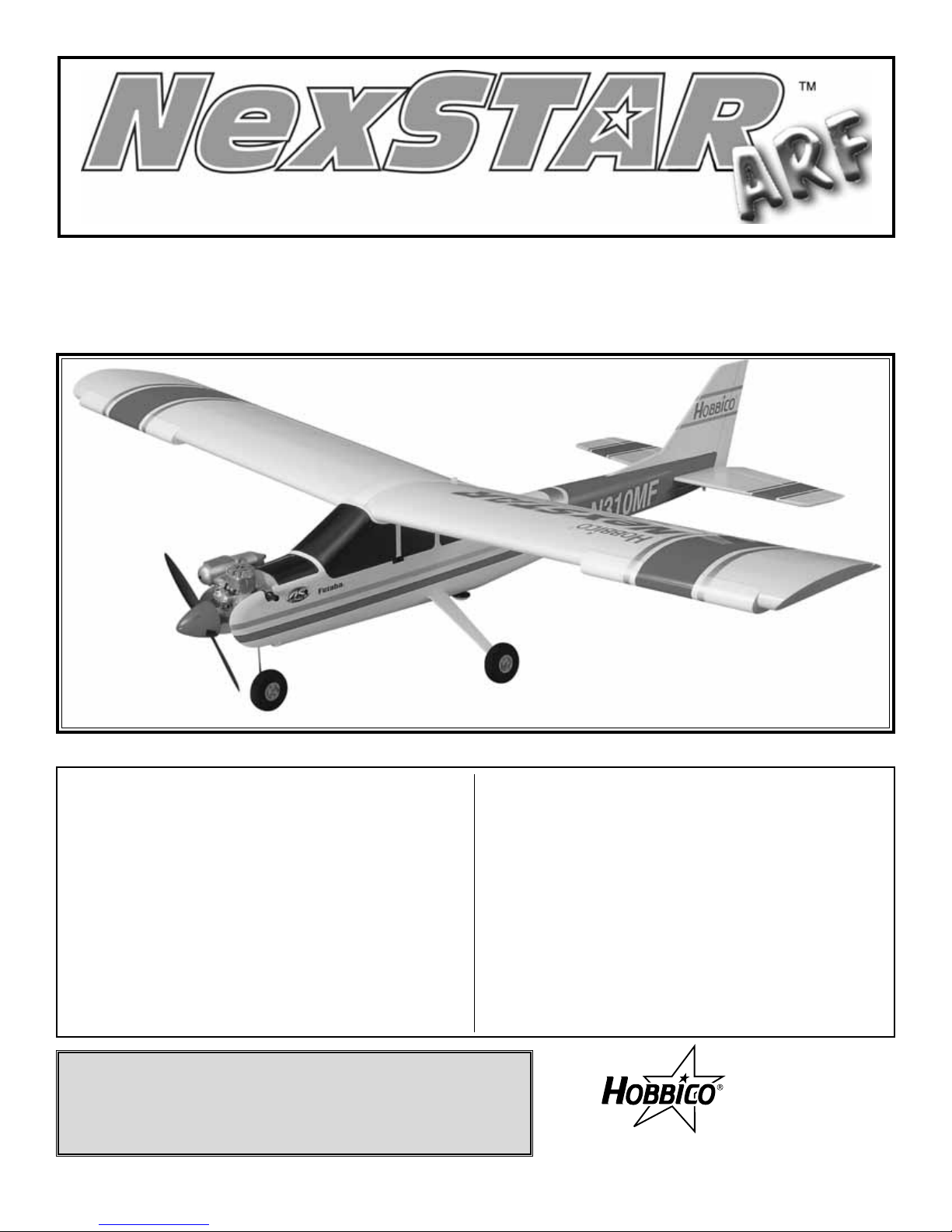

Wingspan:68-3/4 in [1745mm] Length:56 in [1420mm]

Wing Area: 722 sq in [46.6 dm2]

Weight: 6.25–6.75 lb [2835–3060 g]

Wing Loading: 21 oz/ft2[63 g/dm2] Radio: 4-5 channel

Engine: .46–.50 cu in [7.5–8.2cc] two-stroke

.52–.56 cu in [8.5–9.2cc] four-stroke

Hobbico®guarantees this kit to be free from defects in both

material and workmanship at the date of purchase.This warranty

does not cover any component parts damaged by use or

modification. In no case shall Hobbico’s liability exceed the

original cost of the purchased kit. Further, Hobbico reserves

the right to change or modify this warranty without notice.

In that Hobbico has no control over the final assembly or material

used for final assembly, no liability shall be assumed nor accepted

for any damage resulting from the use by the user of the final

user-assembled product. By the act of using the user-assembled

product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

this kit immediately in new and unused condition to the place

of purchase.

To make a warranty claim, send

the defective part or item to

Hobby Services at this address.

Include a letter stating your name, return shipping address, as

much contact information as possible (daytime telephone number,

fax number , e-mail address), a detailed description of the problem

and a photocopy of the purchase receipt. Upon receipt of the

package the problem will be evaluated as quickly as possible.

WARRANTY

Hobby Services

3002 N. Apollo Dr. Suite 1

Champaign IL 61822

USA

Page 2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

AMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . 3

DECISIONS YOU MUST MAKE. . . . . . . . . . . . . . . . . . . 3

Radio Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Engine Recommendations . . . . . . . . . . . . . . . . . . . . . . . 3

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . . . . . . 4

Hardware and Accessories. . . . . . . . . . . . . . . . . . . . . 4

Building Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Optional Supplies and Tools . . . . . . . . . . . . . . . . . . . . 4

IMPORTANT BUILDING NOTES . . . . . . . . . . . . . . . . . . 4

KIT INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ORDERING REPLACEMENT PARTS . . . . . . . . . . . . . . 6

ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Assemble the Wing. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Install the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Alternate Engine Installation . . . . . . . . . . . . . . . . . . . 13

Landing Gear Installation . . . . . . . . . . . . . . . . . . . . . 14

Install the Tail Surfaces. . . . . . . . . . . . . . . . . . . . . . . 16

Radio Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

GET THE MODEL READY TO FLY . . . . . . . . . . . . . . . 20

Charge the Batteries. . . . . . . . . . . . . . . . . . . . . . . . . 20

Check the Control Directions . . . . . . . . . . . . . . . . . . 20

Check the Control Throws . . . . . . . . . . . . . . . . . . . . . 21

Adjust the Throttle . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Balance the Model . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Identify Your Model . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AMA SAFETY CODE . . . . . . . . . . . . . . . . . . . . . . . . . 23

ENGINE SAFETY PRECAUTIONS . . . . . . . . . . . . . . . 23

CHECK LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

FINAL PREPARATIONS . . . . . . . . . . . . . . . . . . . . . . . 24

Gather Your Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

At the Shop Checklist . . . . . . . . . . . . . . . . . . . . . . . . 24

Flight Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Check the Frequency . . . . . . . . . . . . . . . . . . . . . . . . 25

Check the Controls. . . . . . . . . . . . . . . . . . . . . . . . . . 25

Range Check the Radio . . . . . . . . . . . . . . . . . . . . . . 25

Fueling the Nexstar ARF. . . . . . . . . . . . . . . . . . . . . . 25

FLYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Taxiing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

MAINTENANCE TIPS . . . . . . . . . . . . . . . . . . . . . . . . . 27

AFTER YOU MASTER THE NEXSTAR ARF . . . . . . . . 27

Removing the SpeedBrakes Training Flaps . . . . . . . . 27

Removing the SpinControl Airfoil Extensions. . . . . . . 27

Installing Dual Aileron Servos . . . . . . . . . . . . . . . . . . 27

NEXSTAR SELECT ARF FAQs. . . . . . . . . . . . . . . . . . 30

FIN SKETCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Congratulations and thank you for purchasing a Hobbico

NexSTAR ARF, the next generation in Radio Control

Trainers.You have made the right decision by purchasing a

“real” model airplane with the latest in aerodynamic and

assembly technologies. Once assembled and set up, the

NexSTAR will give you many hours of relaxing easy flying.

Under the guidance of an experienced flight instructor, all

you have to do is to concentrate on learning to fly.And after

you have mastered the NexSTAR, your engine and radio

may be transferred to your next model.

For the latest technical updates or manual corrections to the

Hobbico NexSTAR ARF, visit the Hobbico web site at

www.hobbico.com.

Open the “Airplanes” link, and then

select the Hobbico NexSTAR ARF. If there is new technical

information or changes to this model a “tech notice” box will

appear in the upper left corner of the page.

We urge you to join the AMA (Academy of Model

Aeronautics) and a local R/C club. The AMA is the

governing body of model aviation and membership is

required to fly at AMA clubs. Though joining the AMA

provides many benefits, one of the primary reasons to join

is liability protection. Coverage is not limited to flying at

contests or on the club field.It e ven applies to flying at pub lic

demonstrations and air shows. Failure to comply with the

Safety Code (excerpts printed in the back of the manual)

may endanger insurance coverage. Additionally, training

programs and instructors are available at AMA club sites to

help you get started the right way. There are over 2,500

AMA chartered clubs across the countr y. Contact the AMA

at the address or toll-free phone number below:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

IMPORTANT!!!

Two of the most important things you can do to preserve the

radio controlled aircraft hobby are to avoid flying near fullscale aircraft and avoid flying near or o v er g roups of people .

AMA

INTRODUCTION

TABLE OF CONTENTS

2

Page 3

1. Your Hobbico NexSTAR ARF should not be considered a

toy, but rather a sophisticated, working model that functions

very much like a full-size airplane. Because of its

performance capabilities, the Hobbico NexSTAR ARF, if not

assembled and operated correctly, could possibly cause

injury to yourself or spectators and damage to property.

2. You must assemble the model according to the

instructions. Do not alter or modify the model, as doing so

may result in an unsafe or unflyable model. In a few cases

the instructions may differ slightly from the photos.In those

instances the written instructions should be considered as

correct.

3. You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in first-class

condition, and a correctly sized engine and components

(fuel tank, wheels, etc.) throughout the building process.

5. You must correctly install all R/C and other components

so that the model operates correctly on the ground and in

the air.

6. You must check the operation of the model before every

flight to insure that all equipment is operating and that the

model has remained structurally sound. Be sure to check

clevises or other connectors often and replace them if they

show any signs of wear or fatigue.

7. If you are not an experienced pilot or have not flown this

type of model before, we recommend that you get the

assistance of an experienced pilot in your R/C club for your

first flights.If y ou’ re not a member of a club, your local hobby

shop has information about clubs in your area whose

membership includes experienced pilots.

Remember: Take your time and follow the instructions to

end up with a well-built model that is straight and true.

This is a partial list of items required to finish the Hobbico

NexSTAR ARF that may require planning or decision

making before starting to build.Order numbers are provided

in parentheses.

There are four different w a ys y ou can set up your Ne xSTAR.

The “standard,” most economical setup would be to use four

servos - three servos in the fuselage (for the throttle, rudder

and elevator) and one servo in the wing f or the ailerons.This

requires only a standard, 4-channel radio. The second

option would be to use two servos in the wing (one for each

aileron). Using two aileron servos will increase the roll rate

(for when you are ready to graduate to slightly more

advanced aerobatics).This option will require a Y-harness to

connect the servos, but a standard 4-channel radio ma y still

be used. The third option would be to “mix” the two aileron

servos electronically so the ailerons can be operated as

both ailerons and flaps (flaperons).Doubling the ailerons as

flaps adds another dimension to your flying regimen as you

will be able to execute super-slow landings and flight. The

use of flaperons will require a minimum 5-channel computer

radio for mixing the servos electronically. The fifth option is

for those who have a 5-channel, non-computer radio, but

still desire functional flaps.This will require a sixth servo to

operate the flaps separately. Instructions are provided on

how to cut the ailerons so the inboard portion can be

operated as flaps. All of these options may be done with

standard servos and the regular 500mAh-600mAh battery

pack that came with your radio (special servos or a larger

battery pack are not required).

The recommended engine size range for the Hobbico

NexSTAR ARF is .46 to .50 two-stroke or .52 to .56 four-stroke .

If an engine in the upper end of the size range is used,

remember that this is a model that is intended to fly at scalelike speeds, so throttle management should be practiced.Any

engine in the lower range will be able to fly this model with

authority. Therefore, the engines in the high range are only

recommended for modelers who fly at high altitude.

Engine Recommendations

Radio Equipment

DECISIONS YOU MUST MAKE

NOTE:We, as the kit manuf acturer , provide y ou with a top quality

kit and great instructions, but ultimately the quality of your

finished model depends on how you build it;therefore, we cannot

in any way guarantee the performance of your completed model,

and no representations are expressed or implied as to the

performance or safety of your completed model.

PRO TECT YOUR MODEL,Y OURSELF

& OTHERS...FOLLOW THESE

IMPORTANT SAFETY PRECAUTIONS

3

Page 4

4

In addition to the items listed in the “Decisions Y ou Must

Make” section, the following is a list of hardware and

accessories required to finish the Hobbico NexSTAR ARF.

Order numbers are provided in parentheses.

❏ 6" [150mm] Servo extension (HCAM2701 for Futaba®)

❏ R/C foam rubber (1/4" HCAQ1000, or 1/2" HCAQ1050)

❏ 3/4" to 1" [19 to 25mm] Heavy duty transparent tape

❏ Hook & loop material (1" x 6" [25 x 150mm] GPMQ4480)

❏ Stick-on segmented lead weights (GPMQ4485)

If you decide to install two aileron servos in your wing connected

to the same channel, you will also need the following:

❏ 1 additional standard servo (for a total of 5)

❏ Y-harness (HCAM2751 for Futaba)

❏ 12" [300mm] servo extension (HCAM2711 for Futaba)

❏ 2 Control horns

❏ 4 2-56 x 3/4" screws

❏ 2 Nylon clevises

❏ 2 Nylon faslinks

❏ 2 Silicone retainers

❏ 2 2-56 x 6" pushrods

If you decide to install two aileron servos in your wing

connected to different channels for flaperons, you will need:

❏ 1 additional standard servo for a total of 5

❏ 5-channel computer radio

❏ (2) 12" [300mm] servo extension (HCAM2711 for Futaba)

❏ 6" [150mm] servo extension (HCAM2701 for Futaba)

❏ 2 Control horns

❏ 4 2-56 x 3/4" screws

❏ 2 Nylon clevises

❏ 2 Nylon faslinks

❏ 2 Silicone retainers ❏ 2 2-56 x 6" pushrods

If you decide to install two aileron servos and one flap servo

in your wing, you will need:

❏ All materials listed in one of the options above

❏ 1 additional standard servo for a total of 6

❏ 6" [150mm] servo extension (HCAM2701 for Futaba)

❏ 2 Nylon clevises ❏ 2 Nylon faslinks

❏ 2 Silicone retainers ❏ 2 2-56 x 6" pushrods

In addition to common household tools and hobby tools, this

is the “short list” of the most important items required to

build the Hobbico NexSTAR ARF.

❏ #1 Hobby knife (HCAR0105)

❏ #11 blades (5-pack, HCAR0211)

❏ 3/4" to 1" [19mm to 25mm] Heavy duty transparent tape.

❏ Threadlocker thread locking cement (GPMR6060)

❏ Small metal file (TAMR4046)

Here is a list of optional tools mentioned in the manual that

will help you build the Hobbico NexSTAR ARF.

❏ Top Flite®MonoKote®sealing iron (TOPR2100)

❏ Pliers with wire cutter (HCAR0630)

❏ Switch & Charge Jack Mounting Set (GPMM1000)

❏ Servo horn drill (HCAR0698)

❏ AccuThrow™Deflection Gauge (GPMR2405)

❏ CG Machine™(GPMR2400)

❏ Precision Magnetic Prop Balancer™(TOPQ5700)

There are two types of screws used in this kit:

Socket Head Cap screws are designated by a number and

a length.

For example #6 x 3/4"

This is a number six screw that is 3/4" long.

Machine screws are designated by a number , threads per

inch, and a length.

For example 4-40 x 3/4"

This is a number four screw that is 3/4" long with forty

threads per inch

.

·

Photos and sketches are placed before the step they

refer to. Frequently you can study photos in following

steps to get another view of the same parts.

·

SHCS is the abbreviation for Socket Head Cap Screw

which is a machine screw with a socket head.

·

The stabilizer and wing incidences and engine thrust

angles have been factory-built into this model. However,

some technically-minded modelers may wish to check

these measurements anyway. To view this information

visit the web site at www.hobbico.com and click on

“Technical Data.” Due to manufacturing tolerances which

will have little or no effect on the way your model will fly,

please expect slight deviations between your model and

the published values.

·

To convert inches to millimeters, multiply inches by

25.4 (25.4mm = 1")

IMPORTANT BUILDING NOTES

Optional Supplies & Tools

Building Supplies

Hardware & Accessories

ADDITIONAL ITEMS REQUIRED

Page 5

Before starting to build, take an inventory of this kit to make sure it is complete, and inspect the parts to make sure they

are of acceptable quality. If any par ts are missing or are not of acceptable quality, or if you need assistance with assembly,

contact Product Support.When reporting defective or missing parts, use the part names exactly as they are written in the

Kit Contents list.

Great Planes Product Support Telephone: (217) 398-8970, ext. 5

3002 N Apollo Drive, Suite 1 Fax: (217) 398-7721

Champaign, IL 61822 E-mail: airsupport@greatplanes.com

KIT INSPECTION

5

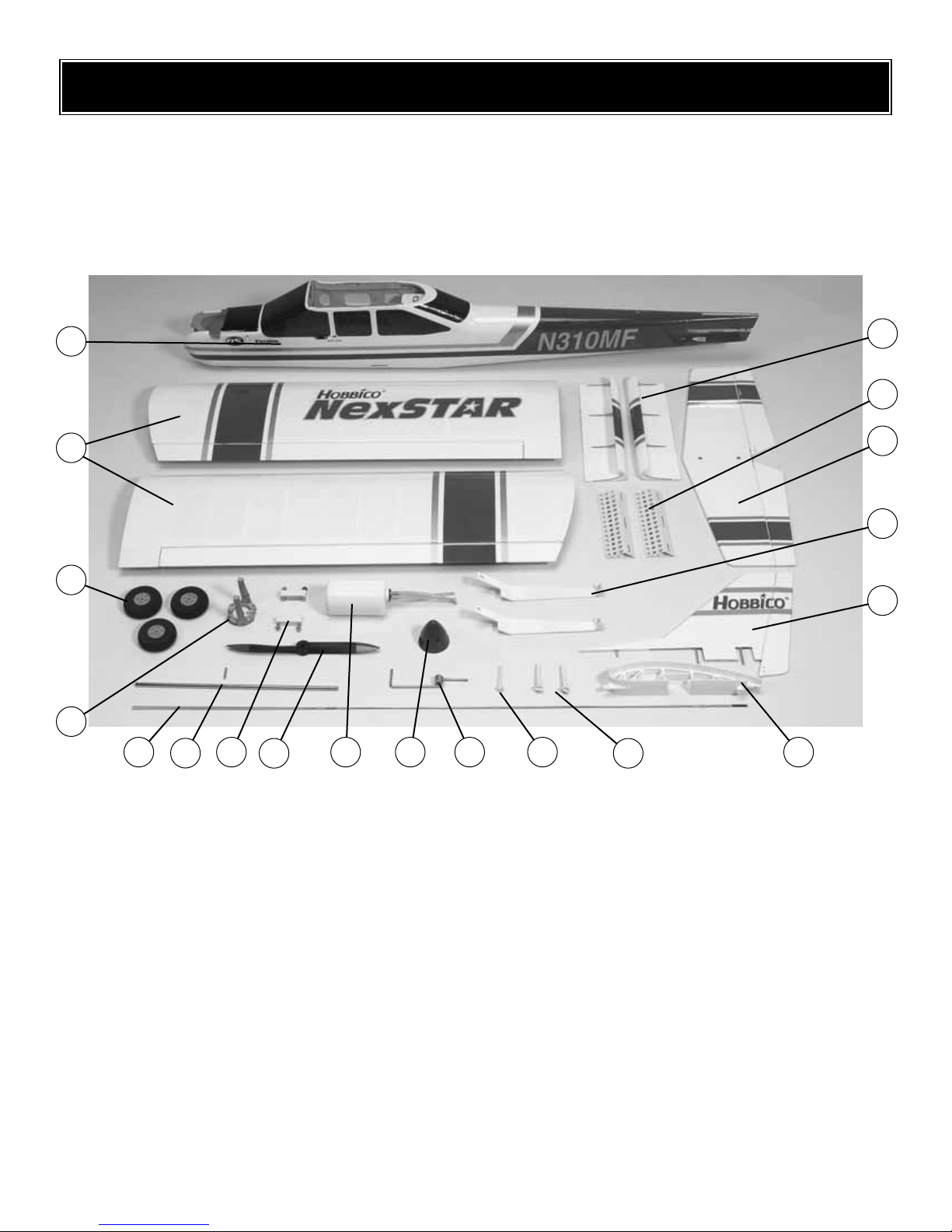

Parts photographed

1. Fuselage

2.Wings

3.Wheels

4. Engine mount

5. 2mm Control rods

6.Wing joiner rods

7. IsoSmooth engine mount

8. 11" x 5" [280 x 127mm] NexSTAR nylon propeller

9. Assembled fuel tank

10. 2-1/2" [64mm] Spinner

11. Nose landing gear

12. 1/4-20 x 2" [51mm] Nylon wing bolt

13. EasyAlign tail bolts

14. CenterCore wing Joiner

15. Fin/Rudder

16. Aluminum main landing gear

17. Stab/elevator

18. SpeedBrakes training flaps

19. Leading Edge Airfoil Extensions

Parts not photographed

4 Nylon clevis

4 Nylon Faslinks

4 Silicone retainers

2 Nylon Aileron Control Horns

4 #4 x 3/4" [19mm] Wood screws

6 #4 x 5/16" [8mm] Machine screws

4 4mm x 3/4" [19mm] Machine screws

4 4mm x 1-1/8" [30mm] Machine screws

4 4mm Nuts

4 4mm Washers

4 4mm Lock washers

2 Nylon control horns

4 #2 x 1/2" [12mm] Wood screws

2 Screw-lock pushrod connector

1

2

3

4

6

5 7

8

9 10 11 12

16

13

14

15

19

18

17

Page 6

Replacement parts for the Hobbico NexSTAR ARF are

available using the order n umbers in the Replacement Parts

List that follows.The fastest, most economical service can be

provided by your hobby dealer or mail-order company.

To locate a hobby dealer, visit the Hobbico web site at

www.hobbico.com. Choose “Where to Buy” at the bottom

of the menu on the left side of the page. Follow the

instructions provided on the page to locate a U.S., Canadian

or International dealer. If a hobby shop is not available,

replacement parts may also be ordered from Tower

Hobbies®at www.towerhobbies.com, or by calling toll free

(800) 637-6050.

Parts may also be ordered directly from Hobby Services by

calling (217) 398-0007, or via facsimile at (217) 398-7721,

but full retail prices and shipping and handling charges will

apply. Illinois and Nevada residents will also be charged

sales tax. If ordering via fax, include a Visa®or MasterCard

®

number and expiration date for payment.

Mail parts orders and payments by personal check to:

Hobby Services

3002 N Apollo Drive, Suite 1

Champaign IL 61822

Be certain to specify the order number exactly as listed in

the Replacement Parts List. Payment by credit card or

personal check only; no C.O.D.

If additional assistance is required for any reason contact

Product Support by e-mail at:

productsupport@greatplanes.com

or by telephone at (217) 398-8970.

REPLACEMENT PARTS LIST

Order

Number Description How to purchase

HCAA3736 . . Wing kit . . . . . . . . . . . .Local hobby dealer

HCAA3737 . . Spin-Control Airfoil

Extensions/Speed

Brakes . . . . . . . . . . . . .Local hobby dealer

HCAA3738 . . Fuselage kit

w/o engine mount . . . .Local hobby dealer

HCAA3739 . . Engine mount . . . . . . .Local hobby dealer

HCAA3740 . . IsoSmooth

engine mount . . . . . . . .Local hobby dealer

HCAA3741 . . Tail set . . . . . . . . . . . . .Local hobby dealer

HCAA3742 . . Landing gear . . . . . . . .Local hobby dealer

HCAA3743 . . Decal set . . . . . . . . . . .Local hobby dealer

HCAA3744 . . NexSTAR nylon

11 x 5 prop . . . . . . . . .Local hobby dealer

Missing pieces . .Contact Product Suppor t

Instruction manualContact Product Suppor t

Full-size plans . . . . . . . . . . . .Not available

This new mount may look like other aluminum engine

mounts, but make no mistake, it is unique. The engine

mounting lugs are installed in rubber boots that absorb

engine vibration to protect your airframe and radio

components, increasing their life span. The IsoSmooth

engine mount works so well that you should check your

propeller for nicks or cracks, because with this mount, you

won't feel a thing.

The NexSTAR ARF is equipped with a high speed needle

valve extender/limiter to make engine adjustments safer

and easier.The extender/limiter has been set at the factory

to limit the movement of the high speed needle so that it

cannot be adjusted out of the optimum range.This way the

engine will always work at its peak performance without the

worry of engine damage. The extender/limiter will allow the

needle to be set from the leanest desired setting for safe

operation (fully clockwise) to the richest desired setting for

break in (fully counterclockwise).

Extender/Limiter

IsoSmooth™Engine Mount

ORDERING REPLACEMENT PARTS

6

Page 7

The wings of most trainers are mounted with rubber bands.

This allows for some flexibility in case of a hard landing.

Rubber bands work well, but they are just plain ugly and a

mess. The PivotFlex Wing Mounting System combines the

looks of a bolt-on system with the flexibility of rubber bands.

The new system allows the wing to move under sudden

loads (such as a wing tip hitting the ground) and will release

the wing from the airplane under extreme loads such as a

crash—all that while looking great.

The EasyAlign Tail Mounting System aligns the stabilizer

with the fuselage and fin while tightening the tail bolts.The

tail bolts slide into blocks in the fuselage under the

stabilizer. As the tail bolts are tightened, both the fin and

stab are aligned and secured while strengthening the aft

area of the fuselage.No tools are necessary for installation.

To speed and simplify assembly, the Hobbico NexSTAR

ARF comes equipped with the SnapGear Landing Gear.

This new gear offers effortless and tool less main landing

gear installation. It takes only a few seconds to install the

landing gear and it can also be removed from the fuselage

in seconds.

The Hobbico NexSTAR ARF uses a three-line fuel line

system to simplify fueling and de-fueling.

Three-Line Fuel System

SnapGear™Landing Gear

EasyAlign™Tail Mounting System

PivotFlex™Wing Mounting System

7

Page 8

The CenterCore wing rib is a nylon part that comes

preinstalled onto one of the wing halves.It performs several

functions: it aligns the two wing halves; it is a mount for the

aileron servo;the incorporated wing dowel holds the wing in

place; and it holds and aligns the wing bolt to the PivotFle x

™

Wing Mounting System. Joining the wing halves and wing

installation on the fuselage has never been easier.

These are the extensions that are installed at the leading

edge near the tips of the wings. These extensions were

developed by NASA (National Aeronautics and Space

Administration) to help light airplanes prevent stalls and

spins during landing approaches. That is exactly what they

do for your NexSTAR ARF. They slow down the airplane,

increase its stall resistance and prevent it from spinning, all

desired characteristics of a trainer airplane. The wing

extensions can be remov ed after you become proficient with

the NexSTAR ARF, for faster, more aerobatic performance.

The SpeedBrakes Training Flaps were designed to allow your

NexSTAR ARF to fly slower, reduce top speed and shorten

the landing approach. Thanks to these flaps, your NexSTAR

ARF will bleed off speed quickly when the throttle is reduced

so that long landing approaches are not necessary.

Additionally, the top speed is considerably reduced to make

the airplane easier to handle. These SpeedBrakes can also

be removed after acquiring some experience with the

airplane for faster, more aerobatic performance.

SpeedBrakes™Training Flaps

SpinControl™Airfoil Extensions

CenterCore™Wing Rib

8

Page 9

For this section you will need:

Note: The following steps show the assembly of the wing

using one aileron servo. For a 2-servo installation, please

refer to the section “After You Master the NexSTAR in its

Original Form” on page 27.

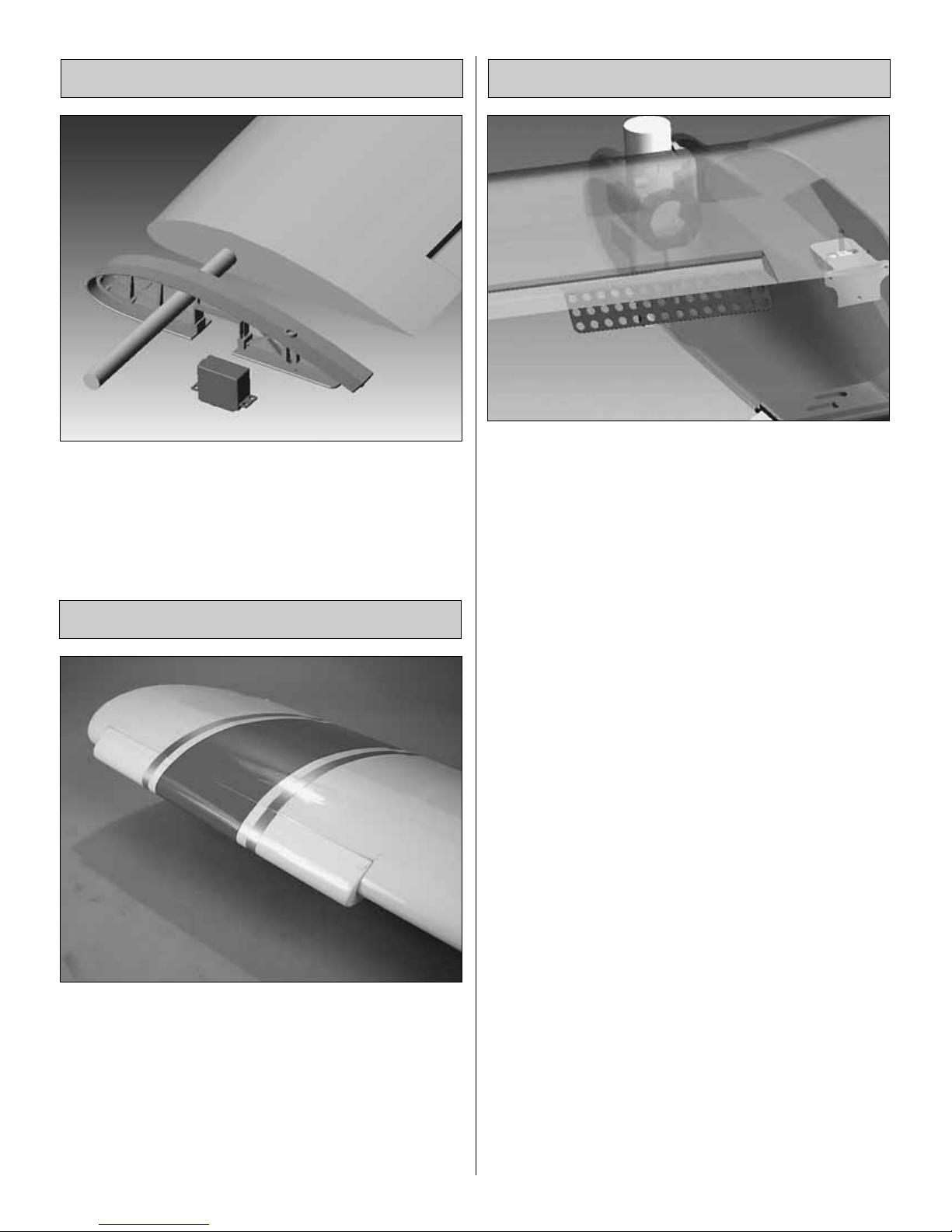

❏ 1.Mark a line on the bottom of the wings 1/4" [6mm] from

the end of the tips.

❏ 2. Install the Airfoil Extensions on both wings as shown

using 3/4" to 1" [19 to 25mm] heavy duty clear plastic tape.

❏ 3.Locate the Spin-Control Airfoil Extension decals on the

decal sheet and apply them to both wings following the

scheme on the top of both wings. Also apply the NexSTAR

decal on the top of the left or right wing.

❏ 4. Install the CenterCore wing rib on the right wing using

two #4 x 3/4" [19mm] screws.

❏ 5. Install the aileron ser vo as shown using the hardware

supplied by the manufacturer.

1 Left wing

1 Right wing

2 Airfoil extensions

2 SpeedBrakes training

flaps

1 CenterCore wing rib

1 Steel wing rod

1 Anti-Rotation steel pin

2 Nylon clevises

2 Nylon faslinks

2 Silicone retainers

2 2-56 X 6" [150mm]

pushrods

2 Nylon horns

4 #4 x 3/4" [19mm]

Wood screws

6 #4 x 5/16" [8mm]

Wood screws

1 Standard servo

1 Phillips screwdriver

3/4" to 1" [19 to

25mm] Heavy duty

clear plastic tape

Assemble the Wing

ASSEMBLY

9

Page 10

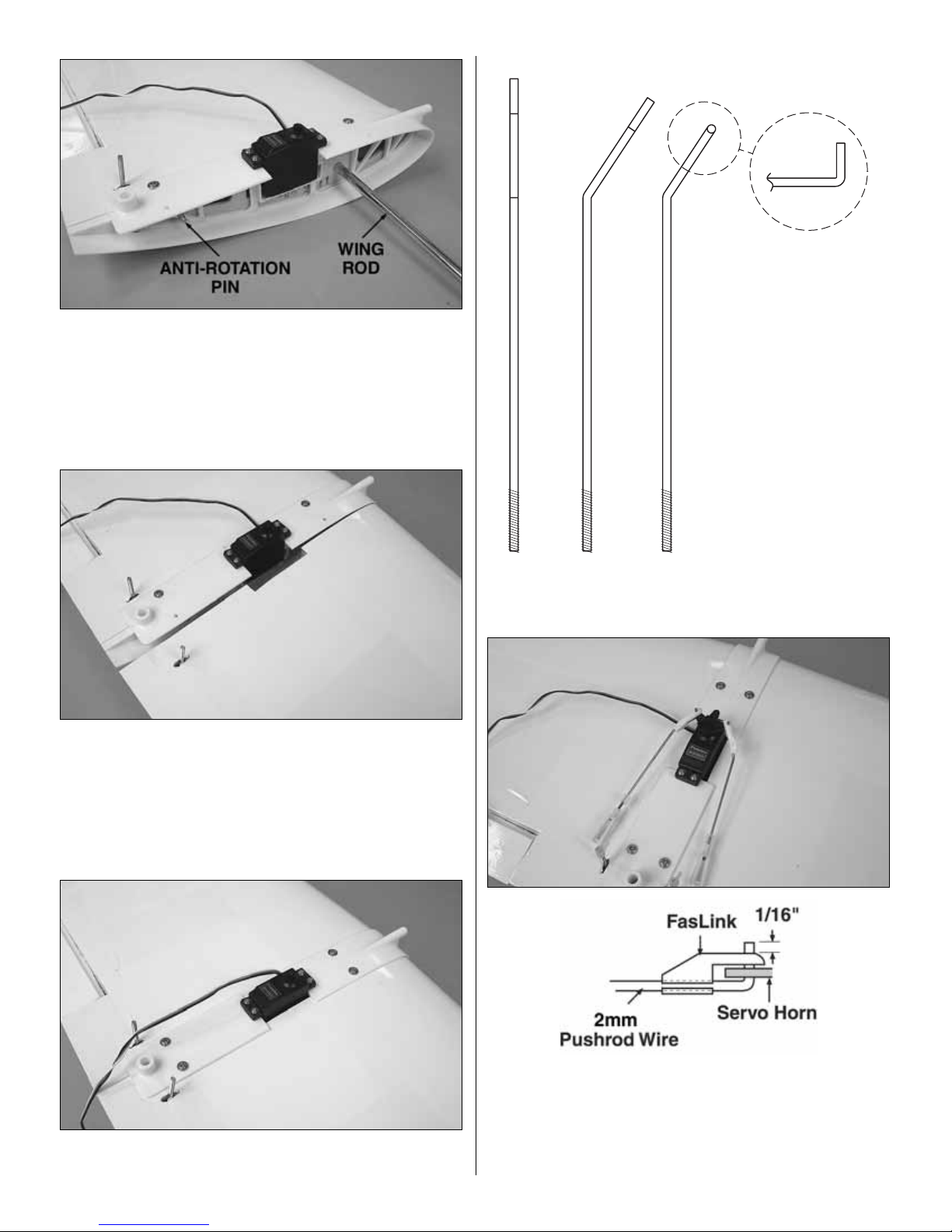

❏ 6. Install the wing rod and the anti-rotation pin into the

right wing.

❏ 7.Carefully slide the left wing all the way onto the rod and

into the CenterCore wing rib until it stops.

❏ 8.Use tw o more #4 x 3/4" [19mm] screws to hold the two

wing halves together.

❏ 9. Cut and bend a 2mm x 6"[150mm] pushrod to match

the sketch above. Make a left and a right pushrod.

❏ 10. Cut a servo arm as shown above and use a Hobbico

Servo Horn Drill (or a #48 or 5/64" [2mm] drill bit) to enlarge

the servo arm holes. Install the arm on the servo. Install a

clevis and a clevis retainer on the threaded end of the

pushrods.Slide the unthreaded end of the pushrod into y our

servo arms and install Faslinks to secure them.

10

Page 11

❏ 11. Install the nylon horns on the aileron torque rods.

Thread them in until the bottom of the horn is about 1/2"

[12mm] from the wing surface. Connect the clevises to the

horns. Slip the clevis retainers over the clevises.

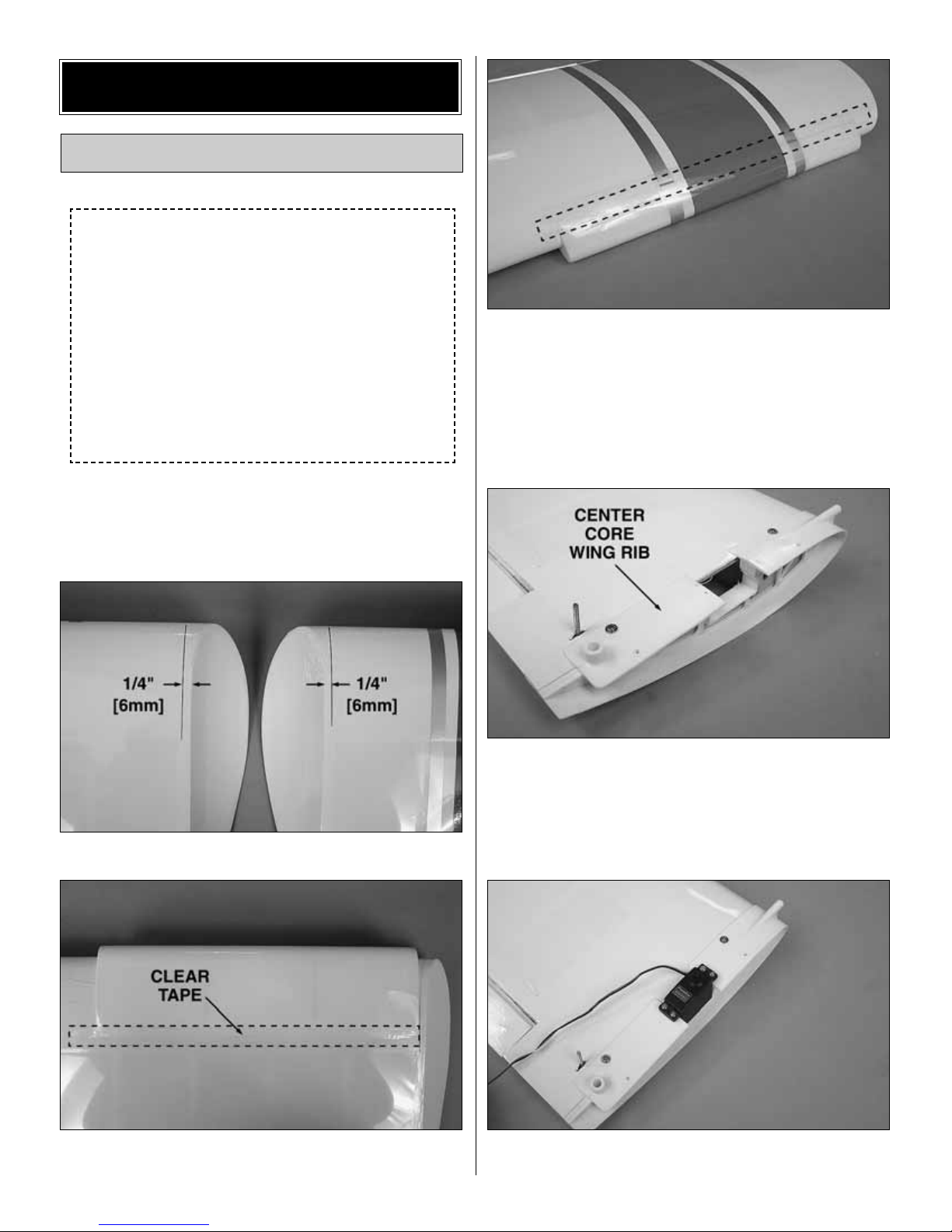

❏ 12. Locate one of the SpeedBrakes Training flaps. There

are three small holes drilled into the trailing edge of the wing

near the center.Install the flap to the wing using three #4 x

1/4" [6mm] screws. The inner end of the flap should align

with the end of the aileron.

❏ 13. Install the other flap onto the other wing using three

more #4 x 1/4" [6mm] screws.The wing is now complete.

Note: Install the leading edge extensions and the flaps

for your initial flights. The airplane has been designed

around them and it performs better as a trainer with them

installed. Never attempt to fly the airplane for the first time

without them or with just one of the devices as the model will

be difficult to trim.Do not let anyone’s opinion get in the way .

Install both these devices for your initial flights. If after

a few flights you decide to remove the extensions or flaps,

then read the section “After You Master the NexSTAR in its

Original Form” on page 27.

For this section you will need:

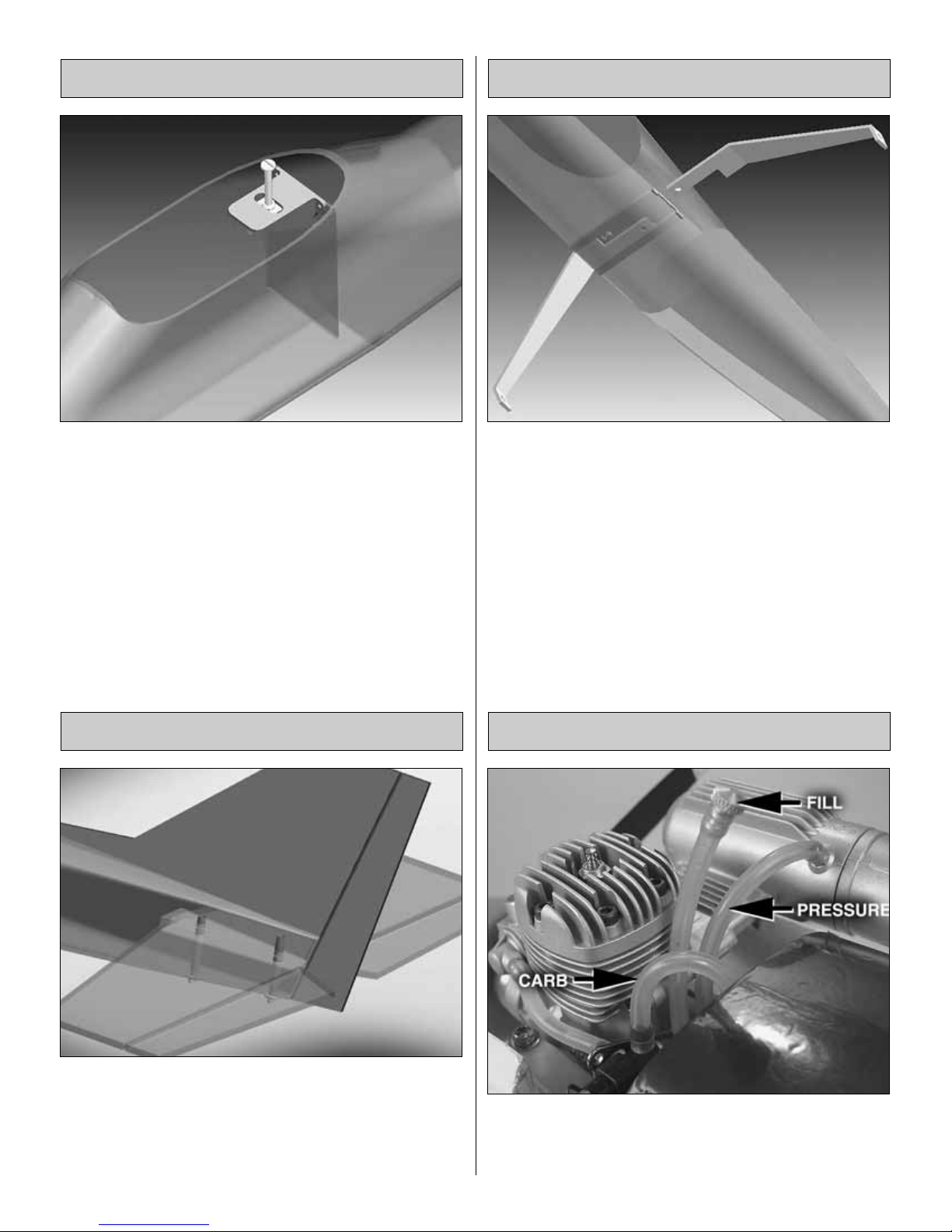

❏ 1. Slide the fuel tank into the fuel tank compartment.

Make sure the fuel tubing comes out through the hole in the

firewall. Slide the fuel tank in until the neck of the fuel tank

comes out the firewall as shown above. Use a Phillips

screwdriver to tighten the fuel tank screw and secure the

tank in place.

❏ 2.Use four 4mm x 20mm machine screws and four 4mm

washers to install the engine mount as shown above. Use

Great Planes Thread Locking Compound on the machine

screws before you tighten them.

Engine

Fuel tank

Metal engine mount

4 4mm x 20mm Engine

mount machine

screws

IsoSmooth complete

engine mount

4 4mm x 30mm

IsoSmooth engine

mount screws

4 4mm Nuts

8 4mm Washers

4 4mm Lock washers

2-56 x 17-1/2"

[445mm] pushrod.

Phillips screwdriver

Install the Engine

11

Page 12

❏ 3. Install the IsoSmooth rubber boots on the engine

mounting lugs. The IsoSmooth rubber boots have been

designed to fit most .46 size engines. If the boots do not fit

your engine, then you will have to use an alternate method

to install your engine (see below).

❏ 4. Use four 4mm x 30mm machine screws, four 4mm

washers, four 4mm loc k w ashers and f our 4mm n uts to secure

the engine with the IsoSmooth nylon bracket on the engine

mount. Use Great Planes Thread Locking Compound on the

screws to prevent them from coming loose with vibration.

❏ 5. Install a clevis and a clevis retainer on the threaded

end of the 17-1/2" [445mm] pushrod. Bend the pushrod

slightly as shown above to clear the engine mounting bolts.

❏ 6.Slide the pushrod into the guide tube and then connect

the clevis to the carburetor arm as shown above. Slip the

clevis retainer onto the clevis.

❏ 7. Mount the muffler on the engine following your engine

manufacturer’ s recommendations .Also, install the glow plug

and connect the fuel lines to the engine.The red line goes

to the pressure tap on the muffler, the g reen line goes to the

needle valve, and the blue line is the fill line. Cap the fill line

with the aluminum plug supplied.

12

Page 13

❏ 8. Install the spinner backplate, propeller, propeller

washer and propeller nut to the engine. Align the propeller

with the marks on the spinner backplate and then tighten

the propeller nut securely.

❏ 9. Fit the spinner cone to the back plate. Then, use a

Phillips screwdriver to tighten the spinner screws snugly, but

not over-tight.

Selecting the correct propeller for an

airplane is very important. Your

NexSTAR ARF comes equipped with

a specially-designed nylon 11x5

propeller (HCAA3744) with painted

tips. The painted tips are a safety

feature that will help you see the

propeller arc as the engine is running.

Propeller (HCAA3744)

Keep away from the propeller while the engine is running.

The engine size used on the NexSTAR ARF is powerful

enough to cause damage if anything (including you) gets in

the propeller arc.The propeller is made out of flexible nylon

so that it won’t break on light contact with the runway or

weeds. If the propeller ever gets in contact with anything

while the engine is running, inspect it before running it

again. Check for cracks, scuffled tips or unbalanced blades.

If necessary, replace the propeller. The Hobbico NexSTAR

ARF was designed around an 11x5 propeller for best

performance. The 11x5 propeller helps keep the airplane

speed down at full throttle; it increases takeoff performance

on any surface, including tall grass; and it acts as a brake

when the nose is pointed down. Should you ever need to

replace the propeller, replace it with the same or similar

11x5 propeller.There is no benefit to using a larger propeller

or one with more pitch.

Carefully balance your propeller and spare propellers

before you fly. An unbalanced prop can be the single most

significant cause of vibration that can damage your model.

We use a Top Flite Precision Magnetic Prop Balancer

™

(TOPQ5700) in the workshop and keep a Great Planes

Fingertip Prop Balancer (GPMQ5000) in our flight box.

Your engine is now installed.

❏ 1. If the engine rubber boots do not fit the engine of your

choice, you will have to install the engine as shown above

using two metal straps (included), four 4mm x 30mm, four

4mm nuts, four 4mm washers and four 4mm lock washers.

Alternate Engine Installation

13

Page 14

For this section you will need:

❏ 1.File two flat spots on the nose gear wire as shown above.

❏ 2.Install the nylon nose gear bracket to the firewall using

two 4 x 20mm machine screws and two 4mm flat washers.

Use Great Planes Thread Locking Compound on the

machine screws before tightening them.

❏ 3. Place a wheel collar in the nylon steering arm as

shown.Use the 4 x 6mm [1/4"] machine scre w on the wheel

collar. Slide the steering pushrod’s “Z” bend through the

hole in the steering arm.

❏ 4. Slide the steering arm’s pushrod into its guide tube.

Install the nose landing gear leg through the nylon bracket,

the steering arm and then the engine mount. Tighten the

screw on the steering arm.

❏ 5. Install the nose wheel on the nose gear wire. Use two

wheel collars, one on each side of the wheel, to align it and

secure it in place.Apply some Great Planes Thread Locking

Compound to the screws.

❏ 6. Install a wheel axle on each aluminum landing gear

leg. File a flat spot near the end of the axle.

❏ 7. Install a wheel on each of the axles and then secure

them with a wheel collar. Use some Great Planes Thread

Locking Compound on the screws.

Nose gear wire

Aluminum main gear

(2 parts)

3 Wheels

2 Landing gear axles

1 Nylon nose gear

bracket

2 4mm x 19mm

Machine screws

2 4mm Washers

1 Steering arm

5 4mm Wheel collars

1 Steering pushrod

Phillips screwdriver

Metal file

Landing Gear Installation

14

Page 15

❏ 8.Slide one of the main landing gear legs into the landing

gear slot as shown above. Push it in until you hear a “click”

or until it does not slide in any more.Note:The two landing

gear legs are identical, so it does not matter which one you

install on the left side or right side of the airplane.

❏ 9. Install the other landing gear leg on the other side of

the fuselage the same way. Once they are both installed,

apply a light force to pull them out.You should not be able

to pull them out. If they do pull out, then push them back in

again until they are secured properly. Note:The legs may fit

a little loose inside the pocket.This is normal as long as you

are not able to pull the landing gear legs out.

Landing gear installation is complete.

Note: Should you ever need to remove the landing gear

from the fuselage, insert a screwdriver into the hole under

the fuselage farther from the leg you want to remove. Apply

light pressure to the tab inside the hole and pull the landing

gear leg out. Once the tab is moved, the screwdriver must

be removed to allow the leg to come all the way out. Do the

same with the other landing gear leg.

Note: If your landing gear does not insert easily in the

fuselage or it does not lock in, clean up any glue or paint

blobs that may be on the gear or in the mounting

mechanism. Inser t the gear again and make sure it does

lock in.

Note: If your landing gear legs spread after a hard landing,

remove the legs from the airplane and bend them back to

the correct position with a vise. Do not try to straighten the

legs while installed in the airplane as that may damage the

Snap Gear Landing Gear mechanism.

15

Page 16

For this section you will need:

Note: It is recommended that you apply the fuselage, stab

and fin decals at this point. It is easier to do when the parts

are all apart.

❏ 1. Install a nylon clevis and a clevis retainer on the two

steel pushrods.Slide both pushrods into their guide tubes in

the tail of the airplane.

❏ 2.Position a nylon control horn on the bottom of the right

elevator all the w ay against its inner edge.Mark the location

of the control horn mounting holes. Drill through the mar ks

with a 1/16" [1.6mm] drill bit. Secure the control horn to the

elevator using two #2 x 1/2" [12mm] screws.

❏ 3. Position a nylon control horn on the rudder as shown

about 1/8" [3mm] from the bottom edge.Note that one of the

edges of the control horn is aligned with the hinge line of the

rudder. Mark the location of the control horn mounting

holes. Drill through the marks with a 1/16" [1.6mm] drill bit.

Secure the control horn to the rudder using two #2 x 1/2"

[12mm] screws.

❏ 4. Insert the horizontal stabilizer into the stab slot as

shown above. Insert the two nylon fin tail bolts half-way into

the bottom fuselage and into the stab to hold it in place.

❏ 5. Place the fin over the sketch found on the last page of

the manual and make sure the fin rods are bent at the same

angle as the ones shown on the sketch.This step is cr itical

to make the fin installation easier.

Stabilizer

Fin

2 Control horns

4 #2 x 1/2 [12mm]

Screws

2 Nylon tail bolts

2 Nylon clevises

2 Silicone clevis

retainers

2 2mm Steel pushrods

Phillips screwdriver

Install the Tail Surfaces

16

Page 17

❏ 6. Insert the ver tical stabilizer into the fin slot as shown

above. During installation, make sure the rudder control

horn is below the elevator so that it does not interf ere.It may

take a little maneuvering to slide the aft fin rod in front of the

wood block in the fuselage slot.

❏ 7.Tighten the bolts until they fit snugly against the bottom

of the fuselage. Note: Over tightening these bolts will

damage the nylon threads and may cause in flight failure.

Do not over tighten these bolts.

❏ 5.Connect both the ele v ator and rudder pushrod cle vises

to their control horns.Use the second hole from the outer tip

of the control horn for both of them. This will allow you to

obtain the recommended throws. Slide the silicone clevis

keeper over the clevis.

Tail assembly is complete.

For this section you will need:

❏ 1. Install the elevator, rudder and throttle servos in the

fuselage servo tray as shown above using the hardware

supplied by the radio manufacturer.

3 Standard size servos

1 6" [150mm] Extension

servo mounting

Hardware

2 Faslinks

2 Complete screw-lock

pushrod connectors

Foam sheet

Pliers

Phillips screwdriver

Radio Installation

17

Page 18

❏ 2. Wrap the receiver and the battery with foam and then

install them on the radio tray. Use the hook and loop

material supplied to secure them in place.

❏ 3. Install a 6" [150mm] extension on the receiver’s aileron

channel. Connect the radio switch to the receiver and the

battery .Use heat shrink tubing to secure the battery connection.

Install the radio tray in the fuselage with two #4 x 3/8" [9mm]

wood screws.Connect all the servos to the receiver.

❏ 4.Install the radio switch to the fuselage on the opposite side

of the muffler.If you desire, you can also install a charge jack.

This will allow you to charge the batteries or check their voltage

at the field without taking off the wing.In the instruction manual

airplane we installed an Ernst charge jack.

❏ 5.Route the receiver antenna under the servo tr a y. Install

a retainer on it and then slip it through the plastic guide tube

in the middle until it exits at the aft end of the airplane.

Secure the antenna with tape. Tur n on the transmitter and

then the receiver and center all the trims on the transmitter .

❏ 6. Cut the elevator, throttle and the rudder servo arms as

shown. Install a Screw-Lock Pushrod Connector on the throttle

and the rudder arm as shown above.Note the holes where the

Screw-Lock Pushrod Connectors are connected.

18

Page 19

❏ 7. Slide the steering pushrod and the throttle pushrod

through the Screw-Lock Pushrod Connectors. Install the

servo arms centered on the servos and center the rudder

and elevators.

❏ 8. Mark the elevator and rudder pushrods where they

meet with the servo arm holes. Bend the pushrods 90

degrees up at the mark.Enlarge the servo arm holes where

the pushrods will be connected with a Hobbico Servo Horn

Drill (or a #48 or 5/64" [2mm] drill bit.) Slide pushrods into

the servo arms. Note the ser vo arm holes used to connect

the elevator and rudder pushrod.

❏ 9. Install a Faslink on the elevator and rudder pushrods

to secure them to the servo arms. Cut off the excess wire.

❏ 10. Center the nose wheel and tighten the steering’s

Screw-Lock Pushrod Connector. Move the throttle stick to

full power and then fully open the carburetor by pushing on

the throttle pushrod. Make sure the throttle servo is working

in the correct direction and reverse it if necessary. Install the

throttle’s servo arm as shown and tighten the Screw-Lock

Pushrod Connector. Cut any excess wire and replace the

servo arm screws.

❏ 11. Remove the aileron servo arm and connect the

aileron servo to the receiver aileron servo extension.Center

the transmitter trims and reinstall the aileron servo arm

making sure it is centered. Replace the ser vo arm screw.

Use thread locking compound on the screws.

Note: The control surfaces should be centered when the

trims in your transmitter are centered. Minor adjustments

can be made by screwing or unscrewing the nylon clevises

on the control surfaces.

19

Page 20

Now the plane is assembled, but there are a few things that

must be done before it will be ready to fly.You must carefully

perform all of the following Setup procedures. If possible,

have your flight instructor assist you.

If you have not yet charged the batteries, you may still

proceed. However, as the batteries have not yet been fully

charged, they may not provide enough power to make it all

the way through the setup procedures. If the batteries quit

working, set your tools aside and charge the batteries as

described in the instruction manual for the radio control

system that you are using.

Follow the battery charging instructions that came with your

radio control system to charge the batteries. You should

always charge your transmitter and receiver batteries the

night before you go flying, and at other times as

recommended by the radio manufacturer.

❏ 1. Move the right control stick on the transmitter to the

right as shown in the photo. Observe the direction the

ailerons move.

The right aileron should move up and the left aileron should

move down.Moving the control stick to the left should make

the ailerons move the opposite way. If the ailerons do not

respond as described, reverse the direction using the

reversing switch for the aileron on the face of the

transmitter. If necessary, refer to the instructions in your

radio instruction manual to identify and operate the

reversing switch.

❏ 2. Move the right stick down and observe the direction the

elevator moves.

Moving the right stick down should make the elevator move

up. Note that moving the elevator stick down moves the

elevator up (which, in flight, pushes the tail down, thus

increasing the angle of the wing and making the model

climb).The best way to keep this in mind is to think in terms

of a pilot in an airplane. He pulls the control stick back to

“pull up” the nose of the plane.

Check Control Direction

CAUTION: Unless the instructions that came with your

radio system state differently, the initial charge on new

transmitter and receiver batteries should be done for 15

hours using the slow-charger that came with the radio

system.This will “condition” the batteries so that the next

charge may be done using the fast-charger of y our choice.

If the initial charge is done with a fast-charger, the

batteries may not reach their full capacity and you may be

flying with batteries that are only partially charged.

Charge the Batteries

GET THE MODEL READY TO FLY

20

Page 21

❏ 3. Move the left stick to the right and obser ve the rudder.

Moving the stick to the right should make the rudder (and

the nose wheel) move to the right. If necessary, use the

reversing switches on the transmitter to make the rudder

respond in the correct direction.

The next procedure is to make sure the controls move the

correct amount.The control throws are a measure of how far

the flight controls (ailerons, elev ator and rudder) move .If the

controls move too much, the plane will respond too quickly

and be difficult to control. If the controls do not move

enough, it may not be possible to recover from adverse

situations or to level out for landing. Due to the great effect

the control throws have on the w ay a model flies, the control

throws must be checked.

Control Throws Chart

The throttle is to be set up so that when the throttle stick is

all the way down, and the throttle trim le ver is all the way up ,

the carburetor will be nearly, but not fully closed and the

engine will idle at a low RPM. This will keep the engine

running when the throttle stick is pulled all the way down

(toward you) for landing. When it is time to shut the engine

off after landing, move the trim lever down to close the

carburetor the rest of the way.

Here’s how to set up the carburetor…

❏ 1.With the transmitter and receiver on, move the throttle

trim lever and the throttle stick all the way down.

❏ 2.Observe the opening in the carb uretor.If the carburetor is

fully closed, proceed to step 3. If the carburetor is nearly, but

not fully closed, loosen the screw on the screw-lock connector

on the throttle servo arm and move the pushrod back until the

carburetor is closed.Securely tighten the screw.

❏ 3.Move the throttle trim lever all the wa y up, but leave the

throttle stick all the way do wn.Now the carburetor should be

partially open (about 1/32" to 1/16" [1 to 1.5mm]).

Adjust the Throttle

UP DOWN

Ailerons 1/2" [13mm] 3/8" [9mm]

Elevator 1/2" [13mm] 1/2" [13mm]

RIGHT LEFT

Rudder 3/4" [19mm] 3/4" [19mm]

Check the Control Throws

21

Page 22

❏ 4.Move the throttle stick on the transmitter all the wa y up .

The carburetor should be fully open.

❏ 5. If you are not able to achieve these settings, more or

less movement may be required from the throttle pushrod.

The same as the control surface throws, this is done by

relocating the clevis on the carburetor arm to the other hole,

or by relocating the pushrod connector on the servo arm to

another hole.

DO NOT DISREGARD THIS STEP!

This important step is also referred to as “checking the

C.G.” (center of gravity).Simply stated, the center of gravity

is the point at which the model balances when lifted under

the wing. If the C.G. is too far forward, the model will be

“nose-heavy” and could be difficult to takeoff and land and

lose some of its self-correcting tendencies.If the C.G.is too

far aft, the model will be “tail-hea vy”and the controls may be

too sensitive, making the model too difficult to control—

especially for an inexperienced pilot! Follow the instructions

to balance the model correctly, thus giving you the greatest

chances for success!

❏ 1. There is a decal with two black lines on the underside

of the wing.Those mark the forward and aft CG limit for the

NexSTAR ARF.The forw ard CG limit is 3-3/16" [81mm].The

aft CG limit is 3-9/16" [90mm] from the LE.

❏ 2. Make certain the model is in “ready-to-fly” condition

with all components mounted and installed (propeller,

spinner, landing gear, etc.). The fuel tank must be empty.

❏ 3. Mount the wing to the fuselage with the nylon wing

bolt. Lift the model on both sides of the fuselage with your

fingertips between the two lines on the bottom of the wing.

❏ 4. If the fuselage is level when lifting the model with your

fingers anywhere between the lines, the C.G. is correct.

Proceed to the checklist in the following section.If you cannot

find a spot between the two lines where the airplane balances,

then either one of the following will happen: If the tail drops

when lifting the model, the plane is tail heavy and will require

nose weight to balance. If the nose drops, the plane is nose

heavy and will require tail weight. Do not be concerned if your

model requires a few ounces of nose or tail weight. Almost all

models require additional weight to balance and fly correctly!

If additional weight is required to balance the plane, purchase Great

Planes®Self Adhesive Lead Weights (GPMQ4485).The weight is

segmented in 1/4 oz.increments and is easy to work with.If adding

weight to the tail, attach it to the left side of the fuselage (opposite

the muffler) under the stab.If adding weight to the nose, attach it to

the inside of the fuselage side next to the engine.

❏ 5. If you found it necessary to add weight, recheck the

C.G. after doing so.

Whether you fly at an R/C club or somewhere on your o wn, you

should have your name , telephone n umber, address and AMA

number on or in your model so it can be identified and returned

in case it lands somewhere awa y from the flying site.Fill out the

I.D .tag found in the back of the manual and use spray adhesiv e

or tape to stick it in the model.

Identify your Model

Balance the Model

22

Page 23

Read and abide by the following e xcerpts from the Academy

of Model Aeronautics Safety Code.For the complete Safety

Code refer to

Model Aviation

magazine, the AMA web site

or the Code that came with your AMA license.

GENERAL

1. I will not fly my model aircraft in sanctioned events, air

shows, or model flying demonstrations until it has been

proven to be airworthy by having been previously,

successfully flight tested.

2. I will not fly my model aircraft higher than approximately

400 feet within 3 miles of an airport without notifying the

airpor t operator. I will give right-of-way and avoid flying in

the proximity of full-scale aircraft. Where necessary, an

observer shall be utilized to supervise flying to avoid having

models fly in the proximity of full-scale aircraft.

3.Where established, I will abide by the safety rules for the

flying site I use, and I will not willfully and deliberately fly my

models in a careless, reckless and/or dangerous manner.

5. I will not fly my model unless it is identified with my name

and address or AMA number, on or in the model.Note:This

does not apply to models while being flown indoors.

7. I will not operate models with pyrotechnics (any device

that explodes, burns, or propels a projectile of any kind).

RADIO CONTROL

1. I will have completed a successful radio equipment ground

check before the first flight of a new or repaired model.

2. I will not fly my model aircraft in the presence of

spectators until I become a qualified flier, unless assisted b y

an experienced helper.

3. At all flying sites a straight or curved line(s) must be

established in front of which all flying takes place with the

other side for spectators.Only personnel involved with flying

the aircraft are allowed at or in the front of the flight line.

Intentional flying behind the flight line is prohibited.

4. I will operate my model using only radio control

frequencies currently allowed by the Federal

Communications Commission.

5. I will not knowingly operate my model within three

miles of any pre-existing flying site except in

accordance with the frequency sharing agreement

listed [in the complete AMA Safety Code].

9.Under no circumstances ma y a pilot or other person touch

a powered model in flight; nor should any part of the

model other than the landing gear, intentionally touch

the ground, except while landing.

Keep all engine fuel in a safe place, away from high heat,

sparks or flames, as fuel is very flammable. Do not smoke

near the engine or fuel and remember that engine exhaust

gives off a great deal of deadly carbon monoxide.Therefore

do not run the engine in a closed room or garage.

Get help from an experienced pilot when learning to

operate engines.

Use safety glasses when starting or running engines.

Do not run the engine in an area of loose gravel or sand;the

propeller may throw such material in your face or eyes.

Keep your f ace and body as well as all spectators aw ay from the

plane of rotation of the propeller as you start and run the engine.

Keep these items away from the prop: loose clothing, shir t

sleeves, ties, scarfs, long hair or loose objects such as

pencils or screwdrivers that may fall out of shirt or jacket

pockets into the prop.

Use a “chicken stick” or electric star ter to start the engine.

Do not use your fingers to flip the propeller .Make certain the

glow plug clip or connector is secure so that it will not pop

off or otherwise get into the running propeller.

Make all engine adjustments from behind the rotating propeller .

The engine gets hot! Do not touch it during or right after

operation.Make sure fuel lines are in good condition so fuel

will not leak onto a hot engine, causing a fire.

To stop a glow engine, cut off the fuel supply by closing off

the fuel line or following the engine manufacturer’s

recommendations. Do not use hands, fingers or any other

body part to try to stop the engine. To stop a gasoline

powered engine, an on/off switch should be connected to

the engine coil. Do not throw anything into the propeller of a

running engine.

Failure to follow these safety precautions may result

in severe injury to yourself and others.

ENGINE SAFETY PRECAUTIONSAMA SAFETY CODE (excerpts)

23

Page 24

❏ 1. Fuel proof all areas exposed to fuel or exhaust

residue such as the wing saddle area, etc.

❏ 2. Check the C.G. according to the measurements

provided in the manual.

❏ 3. Be certain the battery and receiver are securely

mounted in the fuse. Simply stuffing them into place

with foam rubber is not sufficient.

❏ 4. Extend your receiver antenna and make sure it has

a strain relief inside the fuselage to keep tension off

the solder joint inside the receiver.

❏ 5. Use threadlocking compound to secure critical

fasteners such as the set screws that hold the wheel

axles to the struts, screws that hold the carburetor arm

(if applicable), screw-lock pushrod connectors, etc.

❏ 6. Add a drop of oil to the axles so the wheels will

turn freely.

❏ 7. Make sure all hinges are securely glued in place.

❏ 8. Reinforce holes for wood screws with thin CA

where appropriate (servo mounting screws, cowl

mounting screws, etc.).

❏ 9. Confirm that all controls operate in the correct direction

and the throws are set up according to the manual.

❏ 10. Make sure there are silicone retainers on all the

clevises and that all servo arms are secured to the

servos with the screws included with your radio.

❏ 11. Secure connections between servo wires and

Y-connectors or servo extensions, and the

connection between your battery pack and the

on/off switch with vinyl tape, heat shrink tubing or

special clips suitable for that purpose.

❏ 12. Make sure any servo extension cords you may

have used do not interfere with other systems

(servo arms, pushrods, etc.).

❏ 13. Make sure the fuel lines are connected and are

not kinked.

❏ 14. Balance your propeller (and spare propellers).

❏ 15. Tighten the propeller nut and spinner.

❏ 16. Place your name, address, AMA number and

telephone number on or inside your model.

❏ 17. Cycle your receiver battery pack (if necessar y) and

make sure it is fully charged.

❏ 18. If you wish to photograph your model, do so before

your first flight.

❏ 19. Range check your radio when you get to the

flying field.

If you haven't already done so, refer to the Futaba

instruction manual for the radio control system and charge

the batteries in the plane and in the transmitter overnight

the night before you go flying.

In addition to the equipment required to fuel and start the

engine mentioned near the beginning of the manual, you

should start a collection of tools that may be required for

adjustments and maintenance at the flying field. The

following is a list of the most important items.

Now it's time to do a final check before taking the model to

the field. These checks are best done in the peace and

comfort of your own shop, so take the time now to make

certain your model is ready.

❏ 1. Check to see that the screws on the wheel collars that

hold on the wheels are fully tightened.

❏ 2. Be certain the silicone retainers on all the nylon

clevises are in position.

❏ 3. Make certain the elevator, rudder and ailerons

respond in the correct directions.

❏ 4. Make certain the wing is securely joined.

❏ 5. Check to see that the fin bolts that hold the fin and

stab in position are present and secure. These may

become slightly loose after the first 10-15 flights.

❏ 6. Make certain the propeller and spinner are secure.

❏ 7. Make certain you have balanced the model according

to the instructions.

❏ 8. Check to see that the screws that hold the servo arms

to the servos are present and secure.

❏ 9. Make certain you have filled out the I.D. card and

placed it inside the model.

At-the-Shop Checklist

1 Medium (#1) Phillips

screwdriver

1 Medium (#1) flat

screwdriver

1 5/16" (or 8mm) Socket

wrench (for glow plug)

1 7/16" (or 11mm) Wrench

or crescent wrench (for

propeller nut)

Gather your Tools

FINAL PREPARATIONS

Check List

24

Page 25

Flight preparation is to be done at the flying field.

Be certain your flight instructor performs these following

checks with you.

1. Get the frequency clip from the frequency control board

at your flying site.

2. Connect the aileron extension and mount the wing to the

fuselage with the nylon wing bolt supplied with this kit.

3.Turn on the transmitter and receiver. One at a time, operate

each control on the airplane using the sticks on the transmitter.

Make certain each control is responding correctly.This m ust be

done before ev ery flight.There are several types of malfunctions

that can be discovered by perf orming this elementary task, thus

saving your model!

A range check must be performed before the first flight of a

new model. It is not necessary to do a range check before

every flight (but it is a good idea to perform a range check

before the first flight of each day).A range check is the final

opportunity to reveal any radio malfunctions, and to be

certain the system has adequate operational range.

1. Tur n on the transmitter and receiver. Leave the transmitter

antenna all the way down. Walk away from the model while

simultaneously operating the controls.Have an assistant stand

by the model and tell you what the controls are doing to confirm

that they operate correctly. You should be able to walk

approximately 100 feet from the model and still have control

without any “glitching“ or inadvertent servo operation.

2. If everything operates correctly, return to the model and

start the engine. Perform the range check with your

assistant holding the plane with the engine running at

various speeds. If the servos chatter or move inadvertently,

there may be a problem. Do not fly the plane! With the

assistance of your instructor, look for loose servo

connections or binding pushrods. Also be cer tain you are

the only one on your frequency, and that the battery has

been fully charged.

The NexSTAR ARF comes with a three-line fuel line system.To

fuel the airplane, remove the fuel line plug from the filling line

(green) and connect the fuel pump to it.Disconnect the pink line

from the exhaust.Fill the tank until fuel comes out the pink line.

Re-connect the pink line to the exhaust nipple.Replace the plug

to the fill line.The airplane is now fueled.It is not required but

it is highly recommended that the fuel tank be filled all the

way up before each flight. A full fuel tank will give you 12 to

15 minutes of flight time.

To remove fuel from the fuel tank, remove the fuel line plug

from the filling line (green) and connect the pump to it.

Pump out any fuel that may be in the fuel tank.Replace the

fuel line plug to the green line.NOTE:You may hav e to low er

the nose of the airplane to completely de-fuel the tank.

Fueling the NexSTAR ARF

Range Check the Radio

Check the Controls

IMPORTANT: Your radio control system transmits a

signal on a certain frequency.Be certain you know what

the frequency is.This is expressed as a two-digit number

(42, 56, etc.), and can be found on the container the

transmitter came in and is also located on the transmitter .

There are several different frequencies, but there is still a

chance that someone else at the flying field may be on

the same frequency as you. If you turn on your

transmitter while that person is flying, a crash will result.

NEVER turn on your transmitter until you have

permission from your instructor, and until you have

possession of the frequency clip used for frequency

control at the flying site.

Check the Frequency

FLIGHT PREPARATION

25

Page 26

Do not attempt to fly by yourself. The Hobbico NexSTAR

ARF has many features that make learning to fly R/C an

easier experience, but the help from an instructor is

invaluable. An instr uctor is going to be able to inspect your

airplane to make sure everything is working correctly and

he will also be able to give you a few tips and comments on

how to improve your flying. Also, make sure you fly at an

AMA sanctioned flying field.

Remember, it is assumed that your instructor is operating

the model for you.

Before the model is ready for tak eoff, it must first be set up to roll

straight down the runway.With the engine running at a low idle,

place the plane on the runway and, if your flying field permits,

stand behind the model. Advance the throttle just enough to

allow the model to roll. If the model does not roll straight down

the runway, shut the engine off and adjust the nose gear

pushrod as necessary .Do not use the rudder trim to correct the

nose wheel because this will also affect the rudder. Note:

Crosswinds may affect the direction the model rolls, so this test

should be done in calm conditions, or with the model facing

directly into the wind.

If possible, takeoff directly into the wind.If you are experienced,

taking off in a crosswind is permissible (and sometimes

necessary—depending upon the prevailing wind conditions and

runway heading).Taking off into the wind will help the model roll

straight and also reduces ground speed for takeoff. Taxi the

model onto the runway or hav e an assistant carry it out and set

it down, pointing down the runway into the wind.When ready,

gradually advance the throttle while simultaneously using the

left stick (rudder/nose wheel) to steer the model.Gain as much

speed as the runway and flying site will practically allow before

gently applying up elevator lifting the model into the air .Be ready

to make immediate corrections with the ailerons to keep the

wings level, and be smooth on the elevator stick, allowing the

model to establish a gentle climb to a safe altitude before

making the first turn (away from yourself). Do not “yank” back

the elevator stick forcing the plane into too steep of a climb

which could cause the model to quit flying and stall.

Once airborne, maintain a steady climb and make the initial turn

away from the runway. When at a comfortable, safe altitude,

throttle back to slow the model, thus giving you time to think and

react. The Hobbico NexSTAR ARF should fly well at half or

slightly less than half throttle. Adjust the trims so the plane flies

straight and level.After flying around for a while, and while still at

a safe altitude with plenty of fuel, practice slow flight and e x ecute

practice landing approaches by reducing the throttle further to

see how the model handles when coming in to land.Add power

to see how the model climbs as well.Continue to fly around while

learning how the model responds. Mind your fuel level, but use

this first flight to become familiar with the model before landing.

When ready to land, pull the throttle stick fully back while flying

downwind just before making the 180-degree turn toward the

runway. Allow the nose of the model to pitch downward to

gradually bleed off altitude.Continue to lose altitude, but maintain

airspeed by keeping the nose down while turning. Apply up

elevator to le v el the plane when it reaches the end of the runway

and is about five to ten feet off the ground.If the model is too far

away, carefully add a small amount of power to fly the model

closer.If going too fast, smoothly advance the throttle and allow

the model to gain airspeed, then apply elevator to climbout and

go around to make another attempt.When finally ready to touch

down, continue to apply up elevator, but not so much that the

airplane will climb.Continue to apply up ele vator while the plane

descends until it gently touches down.

The NexSTAR ARF has been designed to make steep landing

approaches so that the landing approach is short and easy.The

Speed Brake Training Flaps excel at maintaining flying speed

even in steep dives, and when the airplane is leveled-out, they

also help to increase lift. You can also make a long landing

approach and use throttle to keep the airplane flying at a very

low speed until you reach the runway threshold where you

should cut the throttle for the airplane to land.

After you have landed and shut the engine off, adjust the

pushrods on the ailerons, elev ator and rudder as necessary

so the trim levers on the transmitter may be returned to

center.This will not be required on any of the controls that

did not need trim adjustments.

Landing

Flight

Takeoff

Taxiing

IMPORTANT: Be aware of your proximity to R/C club

sites. If there is an R/C site within six miles of where you

are flying, and if you are operating your model on the

same frequency at the same time as somebody else,

there is a strong possibility that one or both models will

crash due to radio interference. There is great potential

for an out-of-control model to cause property damage

and/or severe personal injury. We strongly urge you to fly

at an R/C club site where frequency control is in effect so

you can be assured you will be the only one flying on

your channel.

FLYING

26

Page 27

✔ After flying for the day, use your fuel pump to drain

excess fuel from the tank.

✔ After each day's flying, use spray cleaner and paper

towels to thoroughly clean the model. After a complete

flight there will be a fair amount of exhaust oil residue

sprayed on y our fuselage .Do not be concerned with this.

It is normal. The oil used in model engines does not

completely burn with combustion.

✔ The Hobbico NexSTAR ARF is factory-covered with iron-

on model covering film. Should repairs ever be required,

the covering can be patched with new pieces of iron-on

covering.Among se veral types of covering that will work,

Top Flite MonoKote film may be used to make repair

patches to this model. MonoKote is packaged in six-foot

rolls, but some hobby shops also sell it b y the foot.If only

a small piece of covering is needed for a minor patch,

perhaps a fellow modeler would give you some. The

covering is applied with a model airplane covering iron,

but in an emergency a regular iron set to a lower

temperature could be used.

✔ Check all screws that hold the wings together, tail bolts,

engine bolts, wheel collars, etc.

✔ Check all the high-stress areas for crac ks or f atigue such

as the landing gear area, the wing mounting area, stab

and fin mounting area. Before storing the model until the

next fly day, wrap some paper towels around the engine.

Some oil may accumulate and drip off of the engine and

muffler while the airplane is stored.

After you feel comf ortable flying the Hobbico Ne xSTAR ARF

and you want to improve its high speed performance, the

first thing you can do is to remove the SpeedBr akes Tr aining

Flaps. Remove the six screws that hold them in place.The

NexSTAR ARF was optimized to fly with the flaps on, so if

you remove them, you will have to retrim the elevator.

Without flaps, the NexSTAR ARF will try to pitch down (nose

down) until you re-trim it.Without the SpeedBrakes Training

Flaps, the airplane will fly much faster at any throttle setting

and longer landing approaches will be needed. Also, the

NexSTAR ARF will not slow down as quickly when the nose

is pointed down and stall speed will increase slightly.

The second thing you can do to improve the high speed and

aerobatic performance of the Hobbico NexSTAR ARF is to

remove the SpinControl Airf oil Extensions.These extensions at

the leading edge of the wings are held in place with tape that

can be carefully removed.Once you remove these extensions,

you will need to re-trim your elevator to align it with the

stabilizer. The SpinControl Airfoil Extensions produce the

opposite effect of the SpeedBrakes Training Flaps in pitch,

so if you remove both,the net pitch effect would be almost

non existent. After you remove these extensions, the

NexSTAR ARF will be faster and able to spin and snap.Also,

the stall speed will increase slightly.

Dual Aileron Servos.

The Hobbico NexSTAR ARF comes equipped with dual aileron

servo trays for dual aileron servos. If you wish to use flaperons

you will need to upgrade your radio system to 6 channels. To

install the dual aileron servos, use the following instructions.

For this section you will need:

1 Additional aileron

servo (same type as

that already installed

in your NexStar)

1 “Y” harness

2 2 mm Pushrods

2 Nylon clevises

2 Clevis retainers

2 Faslinks

1 Servo mounting

hardware set

1 Screwdriver

1 Wire cutter

1 Pliers

1 Thin CA

Dual Aileron Servos

SpinControl Airfoil Extensions

SpeedBrakes T raining Flaps

AFTER YOU MASTER THE NEXSTAR

ARF IN ITS ORIGINAL FORM

Clean Up

MAINTENANCE TIPS

27

Page 28

❏ 1.Disconnect the aileron servo pushrods from the aileron

horns and remove the original aileron servo.

❏ 2. Locate the dual aileron ser vo trays in the wing. They

are located on the underside of the wing at the 6th bay in

from the wing tip. Trim the covering over the opening and

use a sealing iron to seal the covering to the tray.

❏ 3.Connect both servos to the “Y”harness.Make sure the

“Y” harness exits through the hole in the center of the wing.

Use the strings pre-installed inside the wings to pull the

servo leads. Install the aileron servos into the trays.

❏ 4. Install the aileron control horn (not included) on the

aileron as shown above. Make sure you use thin CA to

reinforce the holes in the aileron.

❏ 5. Cut the servo arm as shown above.Use a 6"[152mm]

pushrod, a clevis, clevis retainer and Faslink to make the

necessary aileron pushrod.

❏ 6. Set up your new dual servos on your radio to have the

same aileron throw as the original airplane. Center the

servo arms and install the servo arm screws on them.

Your dual aileron servo installation is now finished.

Note:To install flaperons, you will need to upgrade to a radio

capable of flaperon mixing.In this case, the tw o aileron servo

leads will connect to two different channels in your receiver.

Follow your radio manufacturer's instructions to setup the

flaperon mixing in your Hobbico NexSTAR ARF.

28

Page 29

The Hobbico NexSTAR Select can also be equipped with

dual aileron servos and flaps. To set up the airplane this

way, you need to follow the above instructions for the dual

servo installation and then install the flaps as indicated

below. The necessary hinges on the wing were located

where needed when the wing was built.

For this section you will need :

❏ 1. Draw a line on the aileron 10" [254mm] away from the

aileron end at the root and use a hobby saw to cut the

aileron at that line.

❏ 2. Install the flap servo in the center of the wing, where

the original aileron servo was.

❏ 3. Using one of the 6" [152mm] pushrods, a nylon clevis,

clevis retainer and a Faslink, make a pushrod and connect

it to the flap servo and flap horn as shown above.

❏ 4. Bend the second pushrod as shown above and

connect it to the first with two 5/32"[4mm] wheel collars.

Tighten the two 6-32x1/4" [6.4mm] socket head cap screws

to secure the two flap pushrods together as shown above.

❏ 5.The flaps should only be able to move down 1/2" [13mm].

There is no up movement for the flaps.

Flap installation is finished.

Note: To install dual servo and flaps, you will need to

upgrade to a 6 Channel radio. In this case, the two aileron

servo leads will connect to two different channels in your

receiver and then the flap servo to another channel. Follow

your radio manufacturer's instructions to set up the aileron

mixing and flaps in your Hobbico NexSTAR Select.

1 Additional servo to be

used for flaps.

1 6"[152mm] Servo

extension

2 2 mm Pushrods

2 Nylon clevises

1 Faslink

2 5/32"[4mm] Wheel

collars

2 6-32x1/4" [6.4mm]

Socket head cap

screws.

1 Screwdriver

Dual Aileron Servos & Flaps

29

Page 30