Hobbico Hobbistar 60 MK III Assembly Instructions Manual

WARRANTY

Hobbico guarantees this kit to be free from defects in both material and workmanship at the date of purchase. This warranty does not cover any

component parts damaged by use or modification. In no case shall Hobbico's liability exceed the original cost of the purchased kit. Further, Great

Planes reserves the right to change or modify this warranty without notice.

In that Hobbico has no control over the final assembly or material used for final assembly, no liability shall be assumed nor accepted for any damage

resulting from the use by the user of the final user-assembled product. By the act of using the user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is advised to return this kit immediately in new

and unused condition to the place of purchase.

ASSEMBLY INSTRUCTIONS

TM

© Copyright 2003 HCAZ3064 for HCAA2125 V1.1

Specifications:

Wingspan: 71 in [1805mm]

Wing Area: 888 sq in [57 dm

2

]

Weight: 7 - 8 lb [3180 - 3630g]

Wing Loading: 18 - 21 oz/sq ft [55 - 64 g/dm

2

]

Length: 55 in [1400mm]

Radio: 4-channel with 4 servos

Engine: .60 to .65 cu in [10.0 – 10.6cc] two-stroke

READ THROUGH THIS MANUAL BEFORE

STARTING CONSTRUCTION. IT CONTAINS

IMPORTANT INSTRUCTIONS AND WARNINGS

CONCERNING THE ASSEMBLY AND USE OF

THIS MODEL.

1610 Interstate Drive

Champaign, IL 61822

(217) 398-8970, Ext. 2

airsupport@hobbico.com

See more of our products at www.hobbico.com

2

INTRODUCTION.................................................2

SAFETY PRECAUTIONS........................................3

ADDITIONAL ITEMS REQUIRED.........................3

Radio system ........................................................3

Engine ..................................................................3

Tools, Building Supplies, Accessories....................4

Optional Supplies and Tools .................................4

Field Equipment....................................................4

KIT INSPECTION .................................................5

ORDERING REPLACEMENT PARTS......................6

TIGHTEN THE COVERING...................................7

PREPARATIONS ...................................................7

ASSEMBLE THE WING .........................................8

Join the ailerons....................................................8

Join the wing ........................................................9

ASSEMBLE THE FUSELAGE.................................10

Mount the stabilizer and fin................................10

Mount the landing gear .....................................13

Mount the engine ...............................................14

Install the fuel tank .............................................15

Mount the aileron servo......................................15

Hook up the controls..........................................16

Mount the muffler, prop and spinner ..................19

PREPARE THE MODEL FOR FLYING ..................20

Balance the model (C.G.) ...................................20

Center the servos ................................................21

Check the control directions...............................22

Center the control surfaces .................................22

Adjust the throttle ...............................................23

Set the control throws.........................................23

Identify your model ............................................24

Balance Propellers ..............................................24

Checklist.............................................................25

Charge the batteries............................................25

Gather your tools................................................25

FLIGHT PREPARATION......................................25

Check the controls..............................................25

Range check .......................................................26

Ground check.....................................................26

ENGINE SAFETY PRECAUTIONS .......................26

AMA SAFETY CODE...........................................27

FLYING...............................................................27

Taxiing ..................................................Back Cover

Takeoff ..................................................Back Cover

Flight.....................................................Back Cover

Landing.................................................Back Cover

MAINTENANCE TIPS............................Back Cover

Congratulations and thank you for purchasing the

Hobbico Hobbistar .60 MKIII. You've made the right

decision by purchasing a “real” model airplane that

uses a .60-size engine and a 4-channel radio. Once

assembled and set up, there will be no fiddling with a

temperamental engine or constant troubleshooting to

figure out how to get the model to fly. Under the

guidance of a flight instructor, all you'll have to do is

concentrate on learning to fly. And after you've

mastered the Hobbistar, the engine and radio may be

installed in your next model!

IMPORTANT:

The best thing you can do to insure success is to

find a flight instructor who will inspect your

model for airworthiness and provide flying

lessons. It cannot be stated strongly enough that,

if you do not already know how to fly an R/C

airplane, you will probably not be able to fly this

model by yourself. It may appear to be easy, but

over-controlling and disorientation quickly

overcome inexperienced fliers swiftly ending their

first flight. If you haven't yet done so, contact the

local hobby shop and ask them to introduce you

to an instructor or an R/C club representative. If

there is no club or experienced R/C pilot nearby,

it would be worth even a long drive to find one-if

only for just a few flight lessons (then you'll have

an idea of what to expect).

If there is no hobby shop in your area, contact the

AMA (Academy of Model Aeronautics), the

governing body of model aeronautics. The AMA

can direct you to the closest R/C club whose

membership should have qualified flight

instructors. With the added benefit of insurance

coverage provided by the AMA, most clubs

require AMA membership to fly at their field.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

IntroductionTable of Contents

3

1. Your Hobbistar .60 MKIII should not be

considered a toy, but rather a sophisticated, working

model that functions very much like a full-size

airplane. Because of its performance capabilities,

the Hobbistar .60 MKIII, if not assembled and

operated correctly, could possibly cause injury to

yourself or spectators and damage to property.

2. You must assemble the model according to the

instructions. Do not alter or modify the model, as

doing so may result in an unsafe or unflyable model.

In a few cases the instructions may differ slightly

from the photos. In those instances the written

instructions should be considered as correct.

3. You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in firstclass condition, and a correctly sized engine and

components (fuel tank, wheels, etc.) throughout the

building process.

5. You must correctly install all R/C and other

components so that the model operates correctly on

the ground and in the air.

6. You must check the operation of the model before

every flight to insure that all equipment is operating

and that the model has remained structurally sound. Be

sure to check clevises or other connectors often and

replace them if they show any signs of wear or fatigue.

7. If you are not already an experienced R/C pilot,

you should fly the model only with the help of a

competent, experienced R/C pilot.

These are the items not supplied with the Hobbistar .60

MKIII that must be purchased separately. Where

appropriate, order numbers are provided in parentheses.

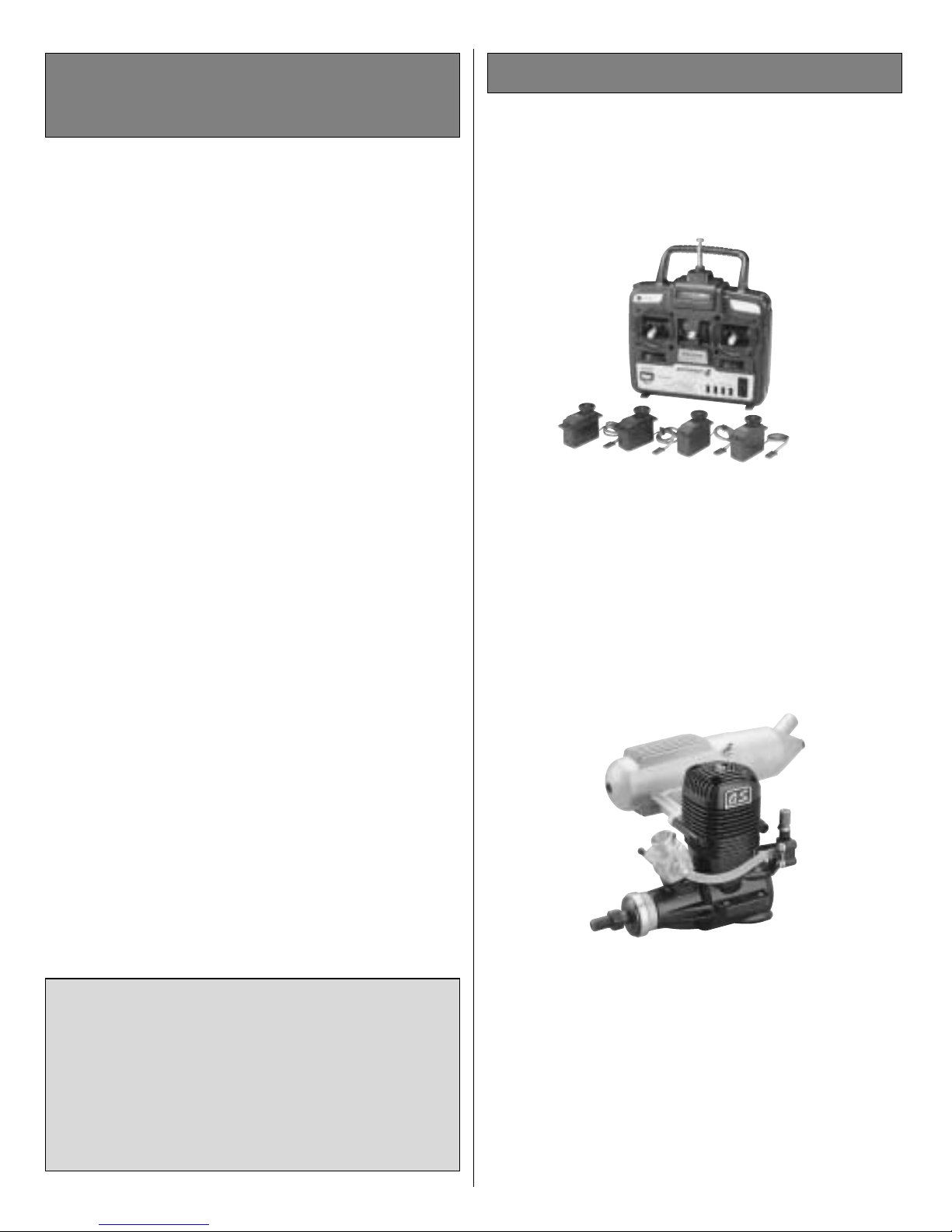

RADIO SYSTEM

A 4-channel radio control system with four servos is

required to fly the Hobbistar .60 MKIII. 4 “channels”

means that the radio is capable of operating four

controls. On a trainer model such as the Hobbistar

the controls are the ailerons, elevator, throttle and

rudder. Some 4-channel radio control systems

include only three servos, so a fourth servo may

have to be purchased separately.

ENGINE

A .60 to .65 cu in two-stroke model airplane engine

is required to fly the Hobbistar .60 MKIII. Basically,

there are two types of two-stroke engines; “ball

bearing” and “non ball bearing” engines. In addition

to having a crankshaft supported by two ball

bearings, most ball bearing engines have other

performance features that boost power and RPM

(and price). For the Hobbistar .60 MKIII, an

economical, non ball bearing engine is more than

suitable. Should you decide to go “all-out” and

Items Required

We, as the kit manufacturer, provide you with a

top quality kit and instructions, but ultimately the

quality and flyability of your finished model

depends on how you build it; therefore, we

cannot in any way guarantee the performance of

your completed model, and no representations

are expressed or implied as to the performance or

safety of your completed model.

Protect Your Model, Yourself & Others

Follow these Important

Safety Precautions

purchase a more powerful ball bearing engine

anyway, you’ll have to remember to throttle back to

slow the model while learning to fly. A suitable

propeller and spare propellers will also be required

(most two-stroke .60 engines run well with a 12 x 6

or 11 x 7 propeller, but refer to the recommendations

in the instructions that came with the engine).

TOOLS, BUILDING SUPPLIES AND ACCESSORIES

These are the rest of the items required to assemble

the Hobbistar .60 MKIII.

❏6" [150mm] servo extension (HCAM2701 for Futaba

®

)

❏ R/C foam rubber (1/4" [6mm] - HCAQ1000, or

1/2" [13mm] - HCAQ1050)

❏ Medium silicone fuel tubing (GPMQ4131)

❏ #64 rubber bands (1/4 lb [113g] box, HCAQ2020)

❏ Stick-on segmented lead weights (GPMQ4485)

❏Threadlocker thread locking cement (GPMR6060)

❏ 1/2 oz. [15g] Thin Pro

™

CA Glue (GPMR6001)

❏ 1/2 oz. [15g] Medium Pro CA+ Glue (GPMR6007)

❏ Pro 30-minute epoxy (GPMR6047)

❏ Denatured alcohol (for epoxy clean up)

❏ #1 Hobby knife (HCAR0105)

❏ #11 blades (5-pack, HCAR0211)

❏ #1 Phillips screwdriver (HCAR1022)

❏ #2 Phillips screwdriver (HCAR1024)

❏ Pliers

❏ Small metal file

❏ Masking tape

❏ 12mm (or appropriate size) prop wrench or

crescent wrench

❏ Drill and drill bits: 1/16" [1.6mm], 5/64" [2mm],

3/32" [2.4mm], #19 (or 11/64") [4.4mm]

OPTIONAL SUPPLIES AND TOOLS

These items are not absolutely required, but are

mentioned in the instructions and will help you

assemble the Hobbistar .60 MKIII

❏ Top Flite

®

MonoKote®sealing iron (TOPR2100)

❏ Top Flite Hot Sock iron cover (TOPR2175)

❏ 4 oz. [113g] aerosol CA activator (GPMR634)

❏ CA applicator tips (HCAR3780)

❏ CA debonder (GPMR6039)

❏ Epoxy brushes (6, GPMR8060)

❏ Mixing sticks (50, GPMR8055)

❏ Mixing cups (GPMR8056)

❏ Builder's Triangle Set (HCAR0480)

❏ Pliers with wire cutter (HCAR0630)

❏ Masking tape (TOPR8018)

❏ K & S #801 Kevlar thread (for stab alignment,

K+SR4575)

❏ Panel Line Pen (TOPQ2510)

❏ CG Machine

™

(GPMR2400)

❏ Precision Magnetic Prop Balancer™ (TOPQ5700)

❏ Prop Reamer (GPMQ5005)

FIELD EQUIPMENT

When ready to fly, you'll need the equipment to fuel

the plane and start the engine. Perhaps you've already

made arrangements with the R/C club or your flight

instructor to borrow theirs, but eventually you'll want

to get your own. Refer to your hobby dealer for

specific recommendations on what to purchase.

Following is a list of the most important items…

❏ Model engine glow fuel (5%, 10% or 15%

nitromethane content is suitable)

❏ Hand-crank or electric fuel pump system with

fuel lines and fittings for transferring fuel from the

container into the fuel tank in the model.

❏ Glow plug igniter for starting the engine

❏ Battery for glow plug igniter (if not already

attached to igniter)

❏ Electric starter and 12v battery

❏ Field box for carrying starting equipment and tools

4

5

1

2

2

6

5

10

9

7

15

14

8

11

12

13

3

4

Kit Inspection

1. Fuselage

2. R&L wing halves w/ailerons

3. Stab w/elevator

4. Fin w/rudder

5. Main landing gear wires (2)

6. Nose gear wire

7. Fuel tank w/hardware

8. 1/4" x 1/2" x 10" [6 x 12 x 255mm]

balsa stick (fuel tank, receiver,

battery mounting) (2)

9. Cast aluminum engine mount

10. 2-3/4" [70mm] foam wheels (3)

11. 2-3/4" [70mm] white plastic

spinner w/4 spinner screws

12. 1/8" [3.2mm] plywood fuselage

servo tray

13. 1/8" [3.2mm] plywood wing

servo tray

14. 1/8" [3.2mm] plywood wing

joiners (3)

15. Hardwood wing dowels (2)

Before starting to build, take an inventory of all the parts to make sure the kit is complete and inspect the

parts to make sure they are of acceptable quality. If any parts are missing or are not of acceptable quality,

or if you need assistance with assembly, contact Product Support. When reporting defective or missing

parts, use the part names exactly as they are written in the Kit Contents list on this page.

Product Support:

Telephone: (217) 398-8970

Fax: (217) 398-7721

E-mail: airsupport@hobbico.com

Parts Photographed

(1) nylon nose steering arm

(1) nylon nose gear mount

(2) 2mm x 9-7/8" [250mm] threaded one-end

wire aileron pushrods

(1) 2mm x 27" [685mm] threaded one-end wire

throttle pushrod

(1) 2mm x 19-3/4" [500mm] wire nose wheel

steering pushrod

(2) nylon aileron torque rod horns

(2) nylon straps (main landing gear)

(5) nylon clevises

(5) nylon pushrod keepers

(2) nylon control horns w/mnt plates

(5) silicone retainers for clevises

(15) precut CA hinges

(4) 4 x 25mm Phillips-head screws (engine

mounting)

(6) 4 x 20mm Phillips-head screws (engine

mount, nose gear bearing)

(10) 4mm lock washer

(10) 4mm flat washer

(4) 4mm nut

(2) 2 x 16mm Phillips-head machine screws

(rudder control horn mnt)

(2) 2 x 20mm Phillips-head machine screws

(elevator control horn mnt)

(4) 3 x 12mm Phillips-head self-tapping screws

(main LG straps)

(4) 5mm wheel collars (main wheels)

(5) 4mm wheel collars (nose wheel)

(10) 3 x 5mm screw (for screw-lock connector,

wheel collars)

(1) 3 x 8mm screw (nose steering collar)

(2) 2mm washer (for pushrod connector)

(2) pushrod connector (screw-lock type)

(2) thumb nuts (for pushrod connectors)

(2) metal engine mount straps

(2) aileron torque rods (factory installed in wing)

(6) 4mm blind nuts (factory installed in firewall)

(1) 13-1/2" [340mm] plastic pushrod tube (throttle)

(1) 11-1/4" [285mm] plastic pushrod tube (for

nose wheel)

(2) 36" [915mm] threaded one-end pushrods

(elevator, rudder)

Parts Not Photographed

0" 1" 2" 3" 4" 5"

0 10 20 30 40 50 60 70 80 90 100 110 120 130

Inch Scale

Metric Scale

6

Ordering Replacement Parts

To order replacement parts for the Hobbico Hobbistar .60 MKIII ARF, use the order numbers in the

Replacement Parts List that follows. Replacement parts are available only as listed. Not all parts are

available separately (an aileron cannot be purchased separately, but is only available with the wing kit).

Replacement parts are not available from Product Support, but can be purchased from hobby shops or mail

order/Internet order firms. Hardware items (screws, nuts, bolts) are also available from these outlets. If you

need assistance locating a dealer to purchase parts, visit www.hobbico.com and click on “Where to Buy.”

If this kit is missing parts, contact Product Support.

Item

Description How to Purchase

Missing pieces Contact Product Support

Instruction manual Contact Product Support

Plans Construction Plans Not available

Hardware Individual hardware items Contact your hobby supplier

Parts listed below Contact your hobby supplier

HCAA3120 Fuselage Set (Fuselage, servo tray,wing dowels(2))

HCAA3121 Wing Set (Right & left wing panels w/ailerons, hinges (8), plywood wing

joiners (3), aileron servo tray)

HCAA3122 Tail Set (Fin & rudder, stab & elevator, hinges (7))

HCAA3123 Landing Gear Set (5mm main gear wires (2), 4mm nose gear wire, 5mm wheel

collars & screws (4), 4mm wheel collars & screws (2))

The Hobbistar .60 MKIII ARF is factory-covered with iron-on heat shrinkable model airplane covering.

Should repairs ever be required, the covering can be patched with Top Flite MonoKote or other similar

model airplane covering that has an iron-on adhesive on the back and shrinks with heat. Most coverings

are packaged in six-foot rolls, but some hobby shops sell covering by the foot. If only a small piece is

needed for a minor patch, perhaps a fellow modeler would give you some.

To convert inches to millimeters, multiply inches by 25.4

1/64" = .4mm

1/32" = .8mm

1/16" = 1.6mm

3/32" = 2.4mm

1/8" = 3.2mm

5/32" = 4mm

3/16" = 4.8mm

1/4" = 6.4mm

3/8" = 9.5mm

1/2" = 12.7mm

5/8" = 15.9mm

3/4" = 19mm

1" = 25.4mm

2" = 50.8mm

3" = 76.2mm

6" = 152.4mm

12" = 304.8mm

15" = 381mm

18" = 457.2mm

21" = 533.4mm

24" = 609.6mm

30" = 762mm

36" = 914.4mm

Metric Conversions

Examine the covering on the model. Occasionally,

the covering requires tightening to remove wrinkles

that develop. If necessary, use a model airplane

covering iron with a covering sock to tighten the

covering and remove wrinkles. Hint: Poke three or

four pin holes in the covering between the “ribs” in

the tail surfaces, allowing air to escape to fully

tighten the covering. Note: If you haven't yet

purchased a covering iron (or borrowed one from a

friend), this step may be done later.

There are a few steps that require 30-minute epoxy

that can be done first to speed assembly.

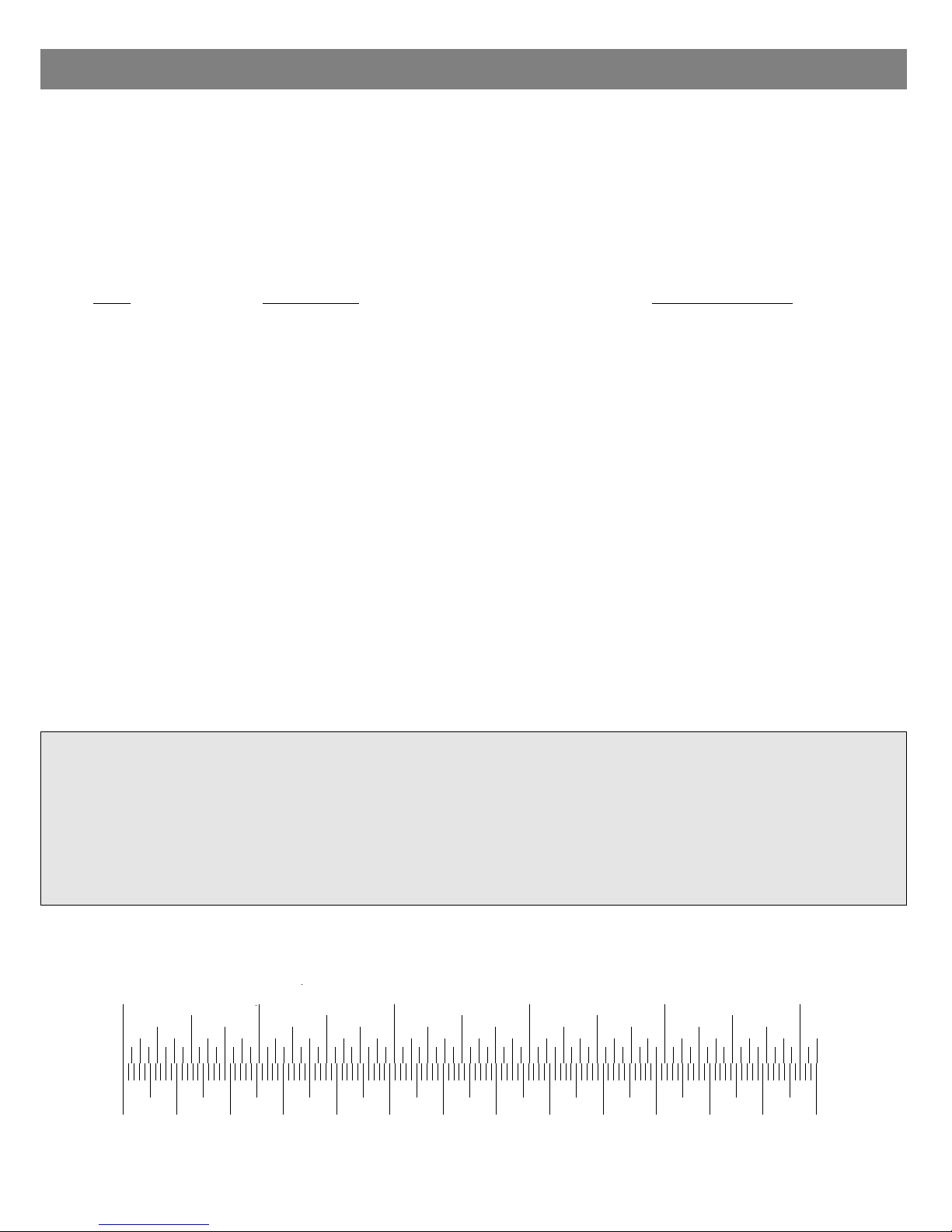

❏ 1. Use 30-minute epoxy to glue together the three

1/8" [3.2mm] plywood wing joiners. Be certain to

apply epoxy to all mating surfaces. (In other words,

apply epoxy to both sides of the joiner in the middle

and to the inside of both the joiner on the top and the

joiner on the bottom.) Hold the joiners together with

clamps. Wipe away excess epoxy before it hardens.

❏ 2. Round the ends of both 1/4" [6.5mm] wing

dowels. Cut the covering from the holes in the

fuselage for the dowels and glue them into position

with 30-minute epoxy. Lightly coat the dowels with

epoxy. (Only the front dowel is shown in the photo,

but there is a dowel at the aft end of the cutout in the

fuselage for the wing.)

❏ 3. Use a hobby knife to bevel the inside edges of

the holes in the main landing gear rail where

indicated by the arrows to accommodate the bend

in the landing gear wire. Seal the exposed wood in

the landing gear rail with a light coat of epoxy.

Preparations

Tighten the Covering

7

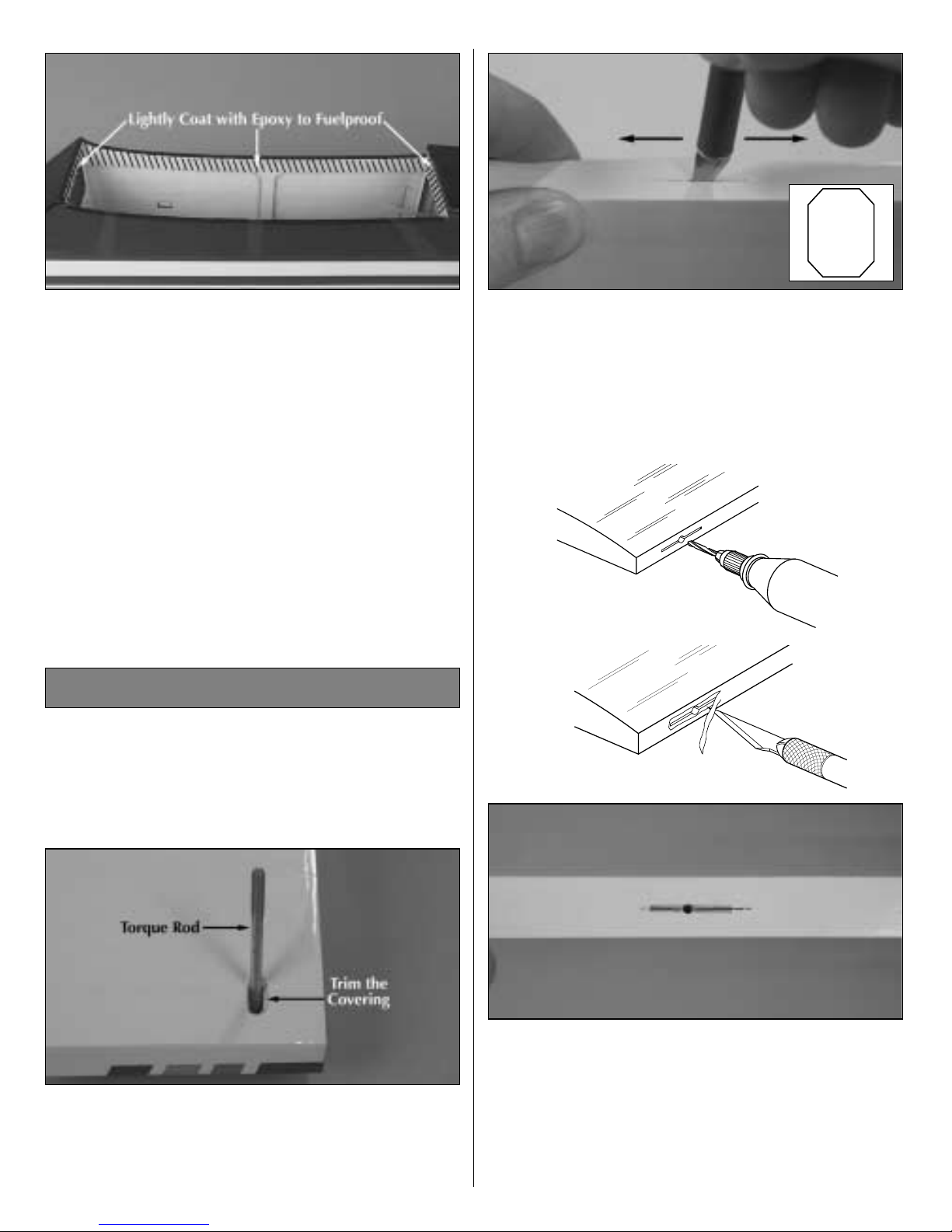

❏ 4. Seal the edges of the covering around the

engine compartment with a thin coat of 30-minute

epoxy. Also use 30-minute epoxy to lightly coat the

inside of the fuselage all the way around the

opening for the wing (as indicated by the shaded

area). This will fuelproof the bare wood in case

engine exhaust residue seeps in.

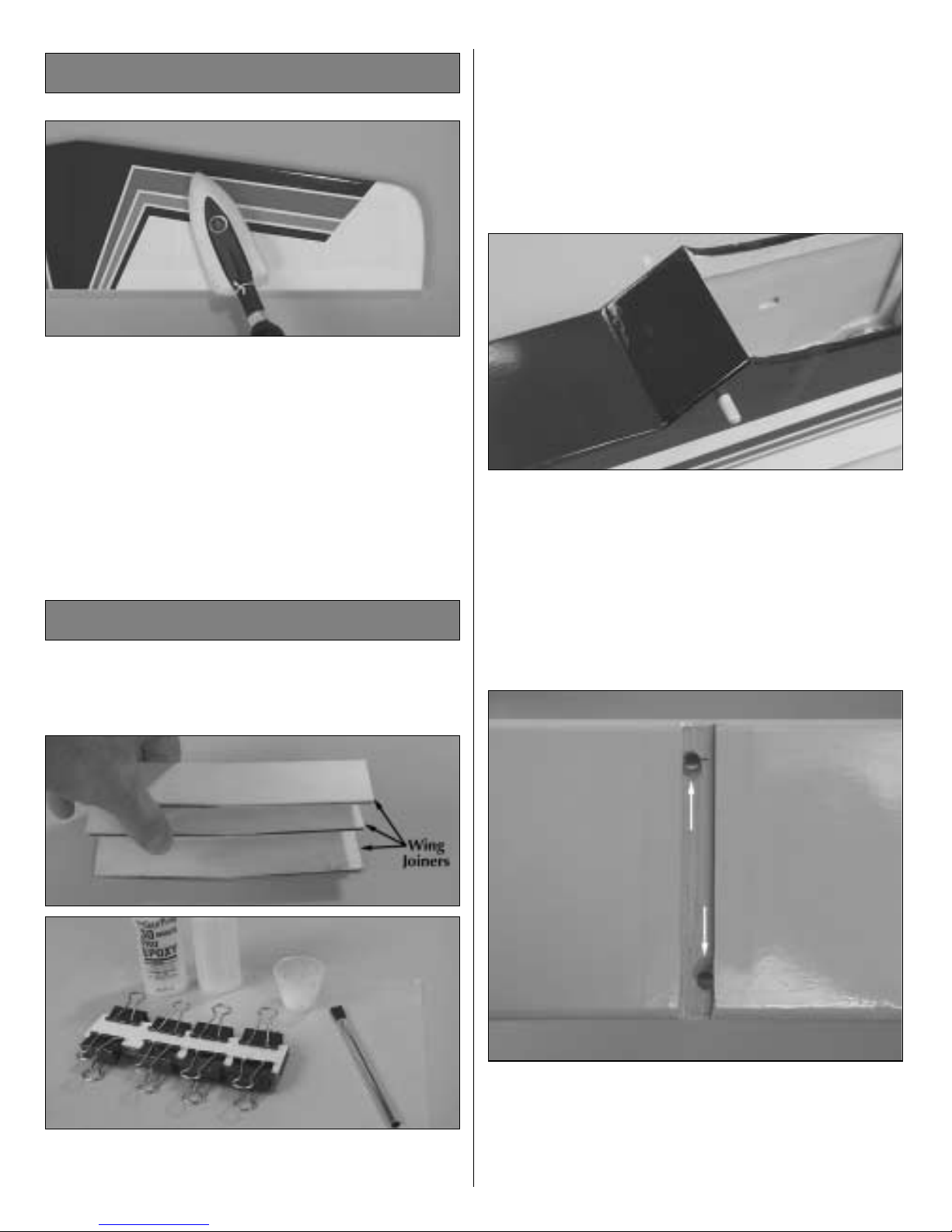

JOIN THE AILERONS

Start with the right wing so yours matches the

photos the first time through.

❏❏1. Use a hobby knife with a #11 blade to neatly

trim the covering from the bottom of the right wing

around the aileron torque rod to allow full, unrestricted

movement of the rod.

❏❏2. Test fit the aileron to the wing with four CA

hinges but do not glue them in yet. If it is difficult to

join the aileron to the wing because the hinge slots

are too tight, remove the hinges. Widen the hinge

slots by inserting a #11 blade and moving it back

and forth a few times.

❏❏3. Remove the aileron from the wing. Drill a

3/32" [2.4mm] hole 1/2" [13mm] deep in the center

of the hinge slots to allow the thin CA used for gluing

in the hinges to fully “wick” all the way in. Cut a small

strip of covering from all the hinge slots in the wing

and aileron. For the best result, use a high-speed tool

such as a Dremel to drill the holes.

AWAY FROM THE SLOT

CUT THE COVERING

DRILL A 3/32" HOLE

1/2" DEEP, IN CENTER

OF HINGE SLOT

Assemble the Wing

8

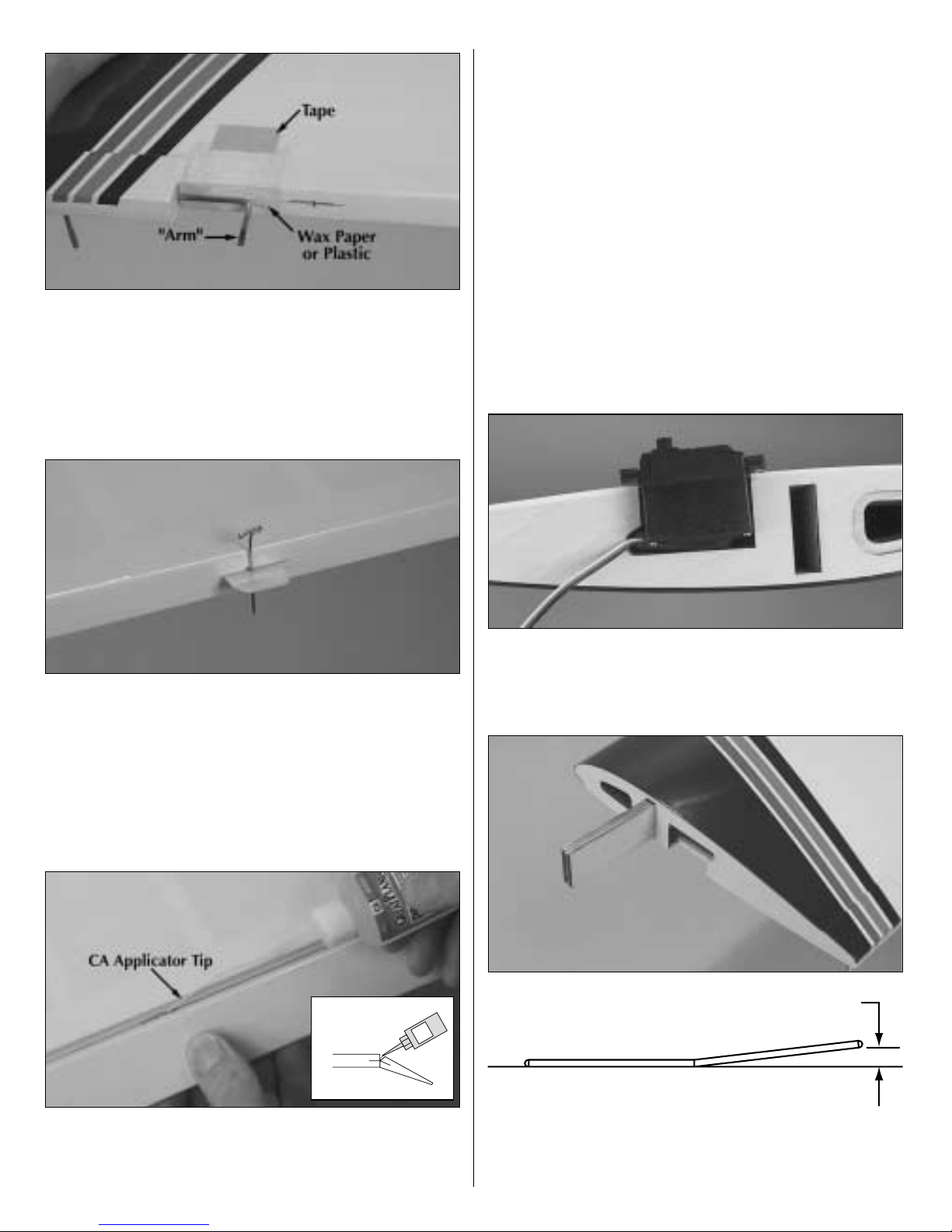

❏❏4. Tape a small piece of wax paper or a piece of

plastic from a sandwich bag to the wing under the

aileron torque rod. Coat the “arm” portion of the

torque rod and the hole and the slot in the aileron for

the torque rod with 30-minute epoxy. Immediately

proceed to the next step.

❏❏5. Join the aileron to the torque rod and wing

with the hinges. If the hinges don't remain centered,

stick a pin through the hinge to hold it in position.

Be certain there is a small gap between the aileron

and the wing—just enough to slip a piece of paper

through or to see light through. Remove any pins

that were used to center the hinges.

❏❏6. Apply six drops of thin CA to both sides of all

the hinges. Allow a few seconds between drops so

the CA fully soaks into the hinge rather than being

drawn into the hinge gap thus gluing the aileron to

the wing. Note the CA applicator tip (HCAR3780)

on the CA bottle to control and pinpoint the CA that

comes out.

❏❏7. Stack a few paper towels over each other and

cut them into approximately 2" [50mm] squares.

Moisten one of the squares with denatured alcohol

and use it to wipe away excess epoxy that came out

of the aileron.

❏ 8. Return to step 1 and join the left aileron to the

left wing panel the same way.

JOIN THE WING

❏ 1. Test fit the aileron servo in both wing halves to

make sure the servo fits. If necessary, enlarge the cut

outs in the wing to accommodate the servo.

❏ 2. Test fit the wing joiner you glued together earlier

into both wing halves, then test fit the wing halves

with the joiner. There should be no gap in the wing.

2-3/8" (± 3/8")

9

T

H

IN

C

A

Loading...

Loading...