Page 1

INSTRUCTION MANUAL

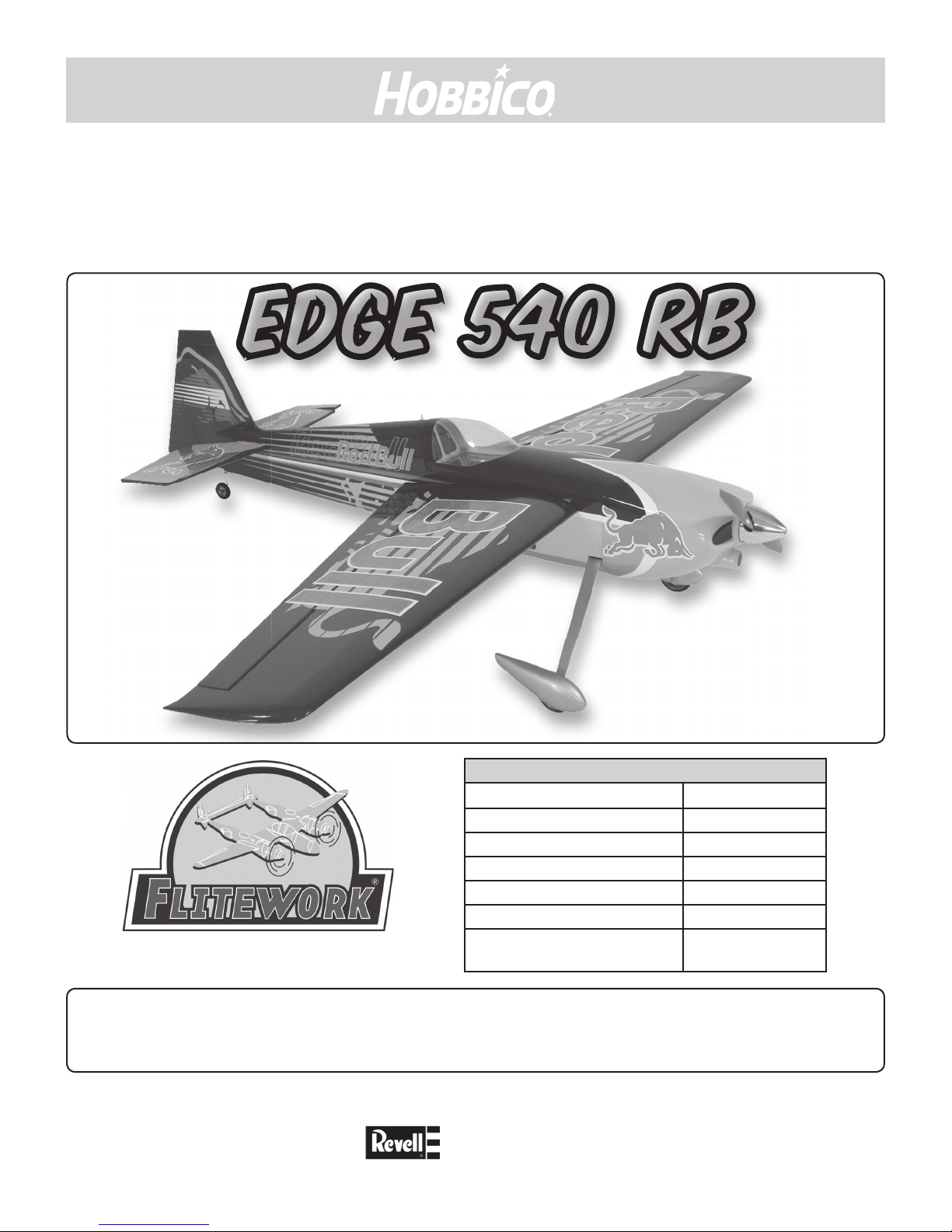

FLWA4140 - Edge 540 RB 1,2 m

EDGE 540 RB

Fully licensed through

Red Bull GmbH

Austria

78239

Version 1.00

Technical data : Edge 540 RB

Wingspan 1 290 mm

Lenght 1 150 mm

Take o weight 1 250 g

Wing Area 28 dm²

Wing loading 44,6 g/dm²

Battery LiPo 3S 2200 mAh

RC Functions Ailerons, elevator,

rudder, motor

Please read the instruction manual carefully and take notice of the safety guidelines.

If the model is given to a third party, always include this instruction manual to the model.

The Flitework Gmbh assumes no liability in case of misprints. Technical amendments reserved.

Distributed by :

Designed in Austria - Made in China

www.hobbico.de

Page 2

TABLE OF CONTENTS

Introduction ........................................................................................ 2

General informations ...................................................................... 2

Environment protection infos ....................................................2

Safety Precautions ...........................................................................3

Additional items required ............................................................3

RecomMended accessories ..........................................................3

Kit check ................................................................................................ 4

Spare parts ........................................................................................... 4

Contenu du kit .................................................................................... 5

Installing the elevator ....................................................................6

Elevator linkage ................................................................................. 7

Mounting the rudder ......................................................................8

Rudder linkage ...................................................................................9

Installing the landing gear ........................................................ 10

Installing the motor ...................................................................... 11

Mounting the main wings .......................................................... 12

ENGLISH

Introduction

Installing the RC components .................................................. 12

Installing the battery ................................................................... 13

Final ight preparation ............................................................... 13

Center of gravity (C.G.) .............................................................13

Balance the Model Laterally .................................................. 13

Check the Control Directions ................................................ 13

Set the Control Throws ............................................................ 14

Check-List .......................................................................................... 14

Hobbico Service Line Europe ................................................... 14

Hobbico Service Line USA .......................................................... 14

Flitework Service Line..................................................................14

The Flitework Edge 540 1.2m is a handy sized model, which is constructed for a big range of aerobatic- or 3D ight.

In case of the light weight construction the ight characteristics are very good-natured. This Edge is a nice designed

trainer for every day.

The original plane is located in Hangar 7 of Red Bull - Salzburg/Austria. Red Bull uses it for air shows, own by the

multiple champion of the Red Bull Airrace - Hannes Arch.

Attention please!

Remote controlled model planes are not a toy! For assembling, ying and servicing such models, you need a high

grade of technical comprehension and liability. Careless assembling and operation may cause personal and material

damage.

Because the Flitework GmbH has no inuence on assembly, RC installation, operation and servicing of the ight

device, any liability is rejected under explicit advice to these dangers.

GENERAL INFORMATIONS

• Read this manual and its safety precautions carefully! Keep this manual

and if you give the model to a third party, put this manual to the model.

• Take care, that you are familiar with your transmitter and all electronic

• The symbols on the package show you, that the model and its accessories

should not be put to waste. All electric and electronic parts should be deposed

to places of waste management.

ENVIRONMENT PROTECTION INFOS

components, used in your plane.

• Take care of all safety instructions of tools, which are you using to

assemble this model.

• Only take glues, which are recommended for the specic materials and

which are approved for model business.

• Batteries and accumulators must be removed from

the devices and should be deposed to the correct

waste management organisation. Take information

from your home town government.

• Before assembling please check all parts of this kit. If some parts are

missing or have a mistake, please call.

2

Page 3

SAFETY PRECAUTIONS

❍ 1. Your Edge 540 1.2m should not be considered a toy, but

rather a sophisticated, working model that functions very

much like a full-size airplane. Because of its performance

capabilities, the Edge 540, if not assembled and operated

correctly, could possibly cause injury to yourself or

spectators and damage to property.

❍ 2. You must assemble the model according to the

instructions. Do not alter or modify the model, as doing

so may result in a unsafe or unyable model. In a few

cases the instructions may dier slightly from the photos.

In those instances the written instructions should be

considered as correct.

❍ 3. You must take time to build straight, true and strong.

❍ 4. You must use an R/C radio system that is in rst-class

condition.

❍ 5. You must correctly install all R/C and other components

so that the model operates correctly on the ground and

in the air.

❍ 6. You must check the operation of the model before

every ight to insure that all equipment is operating and

that the model has remained structurally sound. Be sure

to check clevises or other connectors often and replace

them if they show any signs of wear or fatigue.

❍ 7. If you are not already an experienced R/C pilot, you

should y the model only with the help of a competent,

experienced R/C pilot.

❍ 8. While this kit has been ight tested to exceed normal

use, if the plane will be used for extremly high stress

ying, such as racing, or if an engine larger than one

in the recommended range is used, the modeler is

responsible for taking steps to reinforce the high stress

points and/or substituting hardware more suitable for the

increased stress.

ADDITIONAL ITEMS REQUIRED

❍ 1 x Motorset FW 3545/100 (Référence : FLWA8003)

❍ 3 x Servos TSX10 (Réf. : TACM0210) (Elevator/Ailerons)

❍ 1 x Servo TSX20 (Réf. : TACM0220) (Rudder)

❍ 1 x LiPo 3S 2200 - 2 500 mAh 25C (Order No: GPMP0861

or FPWP2253)

❍ 1 x Receiver min 4 channels (Tactic TR624 Order No.

TACL0624 or Tactic TR625Order No : TACL0625)

❍ 2 x 300 mm servo extensions (HCAQ7332)

❍ 2 x 100 mm servo extensions (HCAQ7330)

RECOMMENDED ACCESSORIES

❍ Hobby knife

❍ Flat screw driver

❍ Philips screw driver

❍ 5 min. Epoxy glue

❍ CA glue thin

❍ Set of driller

❍ Thread lock - blue

❍ Long nose pliers

❍ Mini grinder

ENGLISH

Flitework quality

We, as the kit manufacturer, provide you with a top quality kit

and instructions, but ultimately the quality and yability of

your nished model depends on how you build it; therefore,

we cannot in any way guarantee the performance of your

completed model and no representations are expressed or

implied as to the performance or safety of your completed

model.

3

3

Page 4

KIT CHECK

Before starting to build, use the Kit Contents list to take an

inventory of this kit to make sure it is complete and inspect

the parts to make sure they are of acceptable quality. If any

parts are missing or are not of acceptable quality, or if you

need assistance with assembly, contact Hobbico Product

Support.

Service center Revell GmbH

Henschelstr. 20-30, 32257 Bünde,

Germany

Tel: +49 52239 65144

Email: service@hobbico.de

Hobbico Product Support

3002 N. Apollo Drive Suite 1

Champaign IL 61822 USA

Telephone: (217) 398-8970 ext. 6

Fax: (217) 398-7721

ENGLISH

E-mail: airsupport@hobbico.com

SPARE PARTS

Spare parts can be purchased from hobby shops or mail order/

Internet order rms. Hardware items (screws, nuts, bolts)

are also available from these outlets. If you need assistance

locating a dealer to purchase parts, contact Product Support.

NOTES

Service-Abteilung Revell GmbH

Henschelstr. 20-30, 32257 Bünde, Germany

Tel: 01805 110111 (nur für Deutschland)

(Anrufkosten: 14 Cent/Min. a. d. dt. Festnetz;

Mobilfunk max. 42 Cent/Min.)

Email: Hobbico-Service@Revell.de

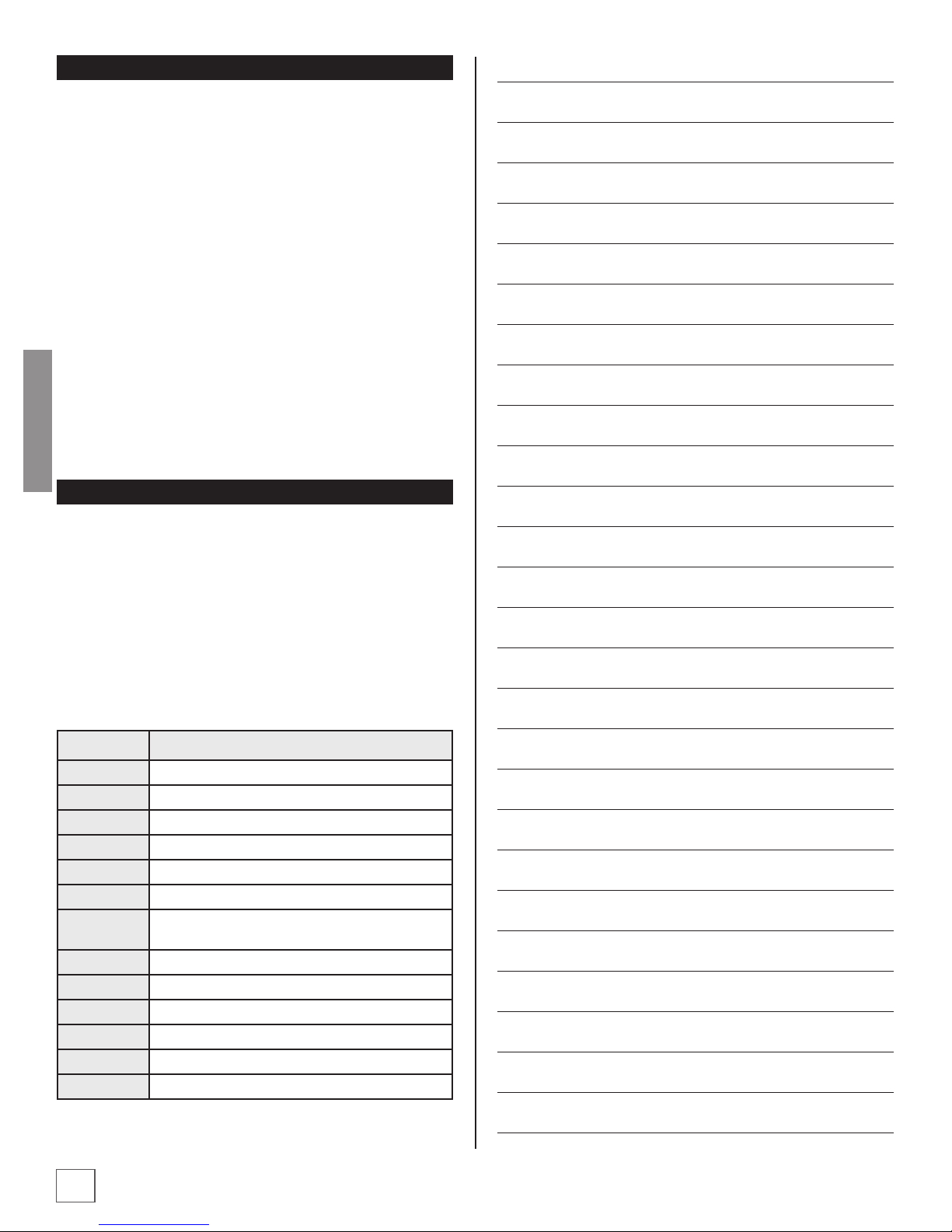

Order N° Part name

FLWA4141 Edge 540 RB 1.2m Fuselage

FLWA4142 Edge 540 RB 1.2m Elevator complete

FLWA4143 Edge 540 RB 1.2m Main wing set

FLWA4144 Edge 540 RB 1.2m Carbon wing joiner

FLWA4145 Edge 540 RB 1.2m Motor cowl

FLWA4146 Edge 540 RB 1.2m Canopy

FLWA4147

FLWA4148 Edge 540 RB 1.2m Wheel pants

FLWA4149 Edge 540 RB 1.2m Rudder

FLWA4996 Edge 540 RB 1.2m Tail gear complete

FLWA4997 Edge 540 RB 1.2m Main wheels

FLWA4998 Edge 540 RB 1.2m Linkage set

FLWA4999 Edge 540 RB 1.2m Screw set

Edge 540 RB 1.2m Landing gear bow

including axles and screws.

4

Page 5

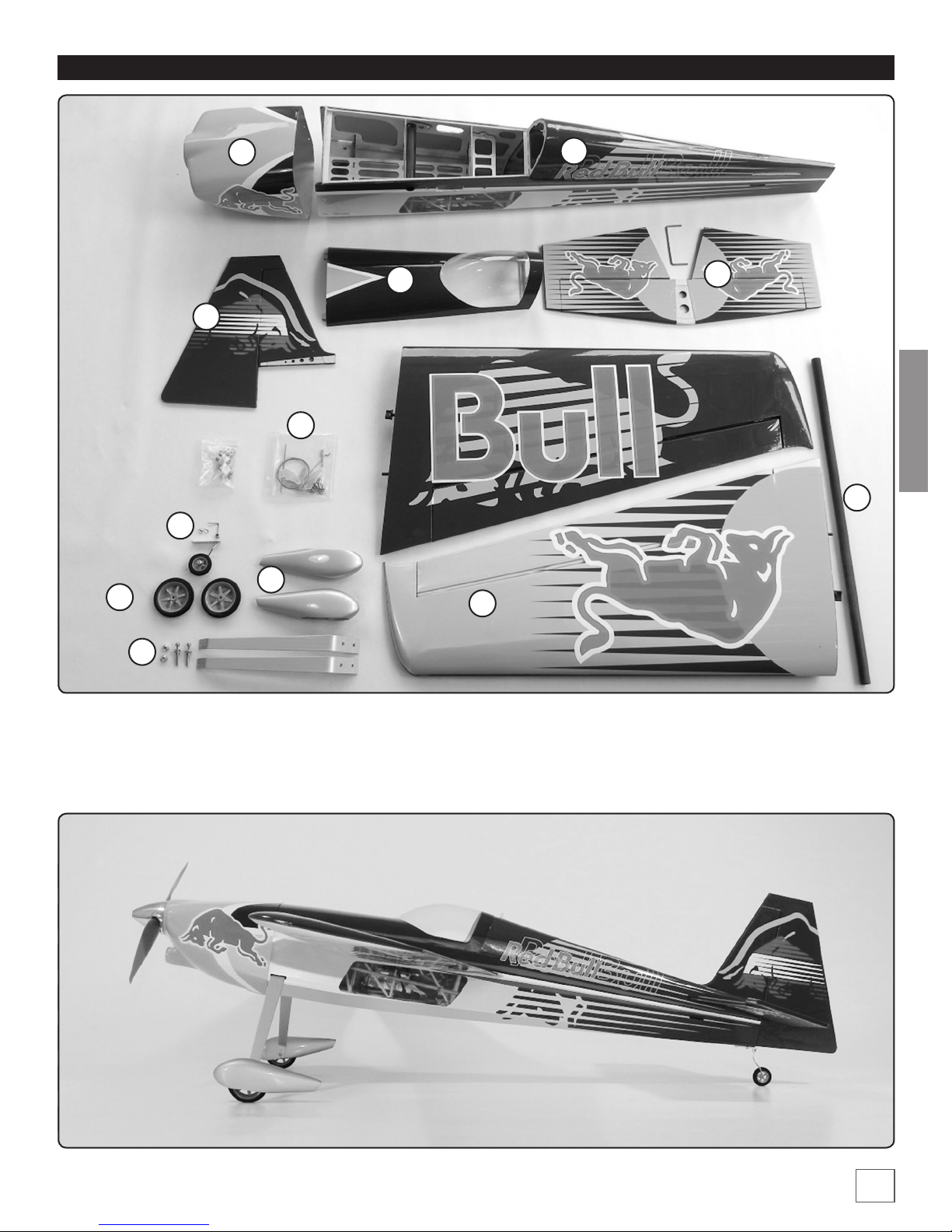

CONTENU DU KIT

12

11

1

3

5

10

9

6

2

4

ENGLISH

7

8

1 Painted motor cowl

2 Fuselage

3 Canopy

4 Elevator complete with connection

bracket

5 Rudder

6 Wing set

7 Carbon ber wing joiner 460x13mm

8 Landing gear bows with axles

9 Wheel pants

10 Linkage- and screw set

11 Tail landing gear

12 Main wheels

5

Page 6

INSTALLING THE ELEVATOR

❏ 1. Put the eece hinges into the slots of the elevator aps.

Mark the middle of the hinges with a permanent marker. Drill

1.5mm holes into the marked spots of the aps. These holes

are adhesion channels for the thin liquid CA glue. With this

system, you get a bigger bonding area than without the hole.

ENGLISH

It is very important, that the hinges are well glued..

❏ 2. Repeat the same procedure for the elevator.

❏ 4. Check the correct placement, measuring the distance

from elevator to a center point of the fuselage on both sides.

Now mark the fuselages shape on the elevator on both sides.

❏ 5. Take out the elevator and remove the covering lm

between the lines. Use a sharp hobby knife to cut the lm. Be

careful, that you do not cut into the wood of the elevator.

❏ 6. Put the elevator again into the fuselage and check the

correct alignment.

❏ 3. Put the elevator into the fuselage and look for a correct

alignment according to the center line of the fuselage.

6

❏ 7. Use thin CA glue with a needle applicator, to glue the

elevator into the fuselage. Be careful, that no CA glue is

dropping on the lm. You never can remove CA spots from

the covering lm.

Page 7

❏ 10. Remove oozing epoxy glue with cotton buds and look,

that the ap gaps are free of glue.

❏ 11. Is the epoxy glue hardened and are the aps are

movable smoothly, you can glue the eece hinges with thin

CAglue. Take the needle of a syringe for application. Start the

application from the middle of the hinges, where the 1,5mm

hole has been drilled. After the CA-glue is dry, move the aps

sometimes back and forth to get them smoothly movable.

ELEVATOR LINKAGE

ENGLISH

❏ 8. Draw the outer side of the elevator plus 1mm gap on

both sides to a paper sheet. Take the elevator aps and the

steel bracket, put it together and compare the distances with

your drawing. If necessary, rework the drill holes so, that the

aps are matching to the drawing. Both aps should be at

on the table .

Do not glue the brackets to the aps at this moment.

❏ 9. Sand the connection bracket on the gluing areas for

better adhesion of the epoxy glue. Put the bracket into the

fuselage. Fix the eece hinges with pins in the aps. Put eposxy

glue into the 2mm holes of the aps and into the groove of the

ap. Also put a little bit epoxy glue on both sides of the steel

bracket. Put aps and elevator together and x with tape. Take

care, that both aps are in plane and not distorted. Distorted

elevator aps are like ailerons.

❏ 1. Sand the elevator lever on both sides on the adhesive

area. Remove the lm over the slot for the lever. Put tapes

around the slot to avoid ugly glue spots on the lm and glue

the lever into the slot.

7

Page 8

❏ 2. Put a servo extension cable (300-350mm) to the

elevatorservo and x the connectors with shrinking tube or

adhesive tape.

ENGLISH

MOUNTING THE RUDDER

❏ 1. 18mm from the bottom of the rudder, drill a 2mm hole

for the tail gear. Make a small groove from the hole to the

bottom of the rudder.

❏ 3. Remove the lm on the left side of the fuselage from the

servoframe. Place the servo and drill 1,5mm holes for screws.

Screw the servo on the fuselage.

❏ 4. Mount the pushrod carrier into the ap lever. Use blue

locking agent for all screws and look for good movement of

the carrier. Hook the rod into the servolever and put it through

the hole of the carrier. Bring servolever and ap into neutral

position and x the clamp screw of the carrier. Always take

care of smoothly mobility of the ap!

❏ 2. Remove the lm from the border of the groove to have

area for gluing.

❏ 3. Now assemble the tailgear like in the picture below.

8

Page 9

❏ 4. Roughen the steel wire on the adhesive surface and glue

it with epoxy glue into the rudder. The wheel axis should be

rectangular to the rudder ap. The pivot point of the rudder

should match with the pivot point of the tail gear.

RUDDER LINKAGE

❏ 1. Thread the steering wires into the fuselage, using a

plastic bowden cable. The wires should be crossed inside the

fuselage.

ENGLISH

❏ 2. Thread the wire rst trough the clamp sleeve and then

trough the rudder lever, than back to the sleeve. Crimp the

sleeve with plieres and bend the outstanding end backwards.

❏ 5. Now you can glue the ber glass lever symmetric into

the slot of the rudder.

❏ 6. Insert the eece hinges into the rudder and x them

with pins. Now put the rudder into the fuselage and glue the

eece hinges like you did with the elevator.

❏ 7. Drill 1,5mm holes through the holes of the aluminium

tail gear holder. Screw the tailgear with 2.3x11mm wood

screws onto the fuselage.

❏ 8. Put the tail wheel on the axis and x it with the aluminium

adjusting collar. Use locking agent for the set screw.

❏ 3. Fit the rudder servo with rubber bushings and metal

sleeves. Put the rudder servo to its place and drill 1.5mm holes

for the screws. Fix the servos with the provided screws.

❏ 4. Screw the linkage

carriers to the servo lever.

Use blue thread lock and

take care, that the carriers

keep mobile. Adjust the

rudder servo to neutral

position and mount the

servo lever.

9

Page 10

❏ 5. Thread the steering wire into the eye bolts and the clamp

sleeves. Adjust the wire so, that the eye bolt can easy reach

the linkage carrier of the servo lever. Then crimp the sleeves,

shorten the wires and bend the end. Put the eye bolts through

ENGLISH

the linkage carriers until the wires have a light tension and x

them with the set screw.

INSTALLING THE LANDING GEAR

❏ 2. Screw the wheel together with the pants onto the

aluminium landing gear bow.

❏ 3. Put the gear bows into the slots of the fuselage and x

them, using 2pcs of M3x8mm screws on both sides. Don’t

forget locking agent.

❏ 1. Install the axle and use distance shims, to center the

wheels in the wheel pants. Fix the wheel on the axle, using the

aluminium adjusting collar. (Thread lock!!)

10

❏ 4. Adjust the wheel pants according to the fuselage, drill

a 1,5mm hole through the hole in the gear bow and x the

pants with the provided wood screws.

Page 11

INSTALLING THE MOTOR

❏ 1. Screw the prop adapter and the aluminium cross to the

motor. Use blue thread lock.

❏ 4. Bring the motor cowl in the correct position. Check the

position with the spinner base plate. There should be a gap of

2mm between the cowling and the spinner. Fix the cowl with

tapes in this position.

ENGLISH

❏ 2. Screw the motor with 4 pcs of M4x20 screws and the

12mm distance rolls against the rewall frame. Also use thread

lock for this connection. The motor cables should be place on

left side.

❏ 3. The ESC can be xed inside on the left side of the

fuselage, using a doublesided adhesive tape or a cable tie..

❏ 5. The cowling should overhang the rewall frame for

about 10mm. Then the position is OK.

❏ 6. Drill on both sides 1,5mm holes through the cowling

and through the wood of the fuselage. You can sti out the

hole in the wood, using thin CA-glue. Then you can mount

the cowling with 4 pcs of 2.3x8 wood screws. Do not install

the propeller and the spinner, until all radio adjustments are

nished. So the propeller cannot make any damage or hurts, if

somethging goes wrong during RC adjustment.

11

Page 12

❏ 7. On the bottom side of the fuselage you can cut out the

opening for cooling air stream.

MOUNTING THE MAIN WINGS

❏ 1. Glue the ailerons into the wings, like you did with

elevator or rudder aps.

ENGLISH

❏ 2. Remove the covering lm from the servo- and ap slots.

Glue the aileron ap levers with epoxy glue into the slots.

Sand the adhesive areas of the levers before.

❏ 4. Hook the Z-cranked end of the linkage into the servo

horn. Insert the other end into the hole of the linkage carrier.

Set the servo and the aileron ap into neutral position. Fix the

clamp screw of the carrier. Don’t forget locking agent.

❏ 5. Repeat the procedure for the second main wing.

INSTALLING THE RC COMPONENTS

For operation you need at least a four channel receiver. We

recommend the Tactic TR624 (TACL0624). Additional you

need 2 pcs of 100mm Servo extension cables for connecting

the aileron servos (HCAQ7330).

If you dismount the wings for transport, you can disconnect

the aileron servos easily.

If you reinstall the wings for ight, take care, that the aileron

servos are connected to the correct channels!!

❏ 3. Put the servos into the servo slots. The servo lever should

point to the exterior end of the wing. Drill 1,5mm holes and

screw the servos into the wing. Use the screws, provided with

the servos. Install the linkage carrier like you can see in the

picture above. The clamp screw shall point to the fuselage.

Use blue locking agent for the nut of the carrier. Take care of

a good mobility of axis of the carrier. Otherwise the linkage

becomes sti.

12

In the picture you can see a possible arrangement of the

RC-components.

The receiver is xed with a double sided adhesive tape to the

left side of the fuselage. The cables were folded, if to long and

bundled with cable ties. The plugs for left and right aileron

servo are marked with a paint stick.

Very important is, that the antenna of the Rx is free and not

surrounded with cable jam. Also avoid the silver colored parts

of the lm. This lm includes aluminium particles, which are

shielding the 2.4GHz signal a little.

Page 13

FULL

THROTTLE

RUDDER

GOES

RIGHT

ELEVATOR

GOES DOWN

LEFT AILERON

GOES DOWN

RIGHT AILERON

GOES UP

4 CHANNELS SETUP

(STANDARD MODE 1)

FULL

THROTTLE

RUDDER

GOES

RIGHT

ELEVATOR

GOES DOWN

LEFT AILERON

GOES DOWN

RIGHT AILERON

GOES UP

4 CHANNELS SETUP

(STANDARD MODE 2)

INSTALLING THE BATTERY

As underlay of the battery, a anti-slip mat of the DIY-store is

very useful. You can x this mat with a double-sided adhesive

tape to the battery-place.

For xing the battery, we recommend the Flitework battery

belt with 200mm.

The 2200mAh battery in correct position.

CHECK THE CONTROL DIRECTIONS

❍ 1. Turn on the transmitter and receiver and center the

trims. If necessary, remove the servo arms from the servos

and reposition them so they are centered. Reinstall the

screws that hold on the servo arms.

❍ 2. With the transmitter and receiver still on, check all the

control surfaces to see if they are centered. If necessary,

adjust the clevises on the pushrods to center the control

surfaces.

ENGLISH

FINAL FLIGHT PREPARATION

CENTER OF GRAVITY C.G.

More than any other factor, the C.G. (center of gravity/

balance point) can have the greatest e ect on how a model

ies and could determine whether or not your rst ight will

be successful. If you value your model and wish to enjoy it

for many ights, DO NOT OVERLOOK THIS IMPORTANT

PROCEDURE. A model that is not properly balanced may be

unstable and possibly un yable.

The CG-point is 70-80mm back from the leading edge of

the main wing, measured close to the fuselage. The middle

of the wing joiner are at 80mm. Mark the CG with a permanent

marker or with small adhesive dots.

The nose of the plane should point downward a little, if you

hold the model at the CG points. Move the battery until the

CG is correct.

❍ 1. With the wing level, have an assistant help you lift the

BALANCE THE MODEL LATERALLY

model by the engine propeller shaft and the bottom of

the fuse under the TE of the n. Do this several times.

❍ 2. If one wing always drops when you lift the model, it

means that side is heavy. Balance the airplane by adding

weight to the other wing tip. An airplane that has been

laterally balanced will track better in loops and other

maneuvers.

❍ 3.The right drive direction of the motor should be tested

without mounted propeller.

Do not test the power drive with mounted propeller in

your workshop!!

13

Page 14

ENGLISH

Elevator

Rudder

Ailerons

SET THE CONTROL THROWS

These are the recommended

control surface throws :

3D rate Normal aerobatics

Up

Maximum

Right

Maximum

MaximumUpMaximum

Down

Maximum

Left

Maximum

Down

20 mmUp20 mm

Right

40 mm

30 mmUp30 mm

Down

Left

40 mm

Down

❍ 6. Make sure all hinges are securely glued in place.

❍ 7. Reinforce holes for wood screws with thin CA where

appropriate (servo mounting screws, cowl mounting

screws, etc.).

❍ 8. Conrm that all controls operate in the correct direction

and the throws are set up according to the manual.

❍ 9. Make sure there are silicone retainers on all the clevises

and that all servo arms are secured to the servos with the

screws included with your radio.

❍ 10. Secure connections between servo wires and Y

connectors or servo extensions and the connection

between your battery pack and the on/o switch with

vinyl tape, heat shrink tubing or special clips suitable for

that purpose.

❍ 11. Make sure any servo extension cords you may have

used do not interfere with other systems (servo arms,

push rods, etc.).

❍ 12. Balance your propeller (and spare propellers).

❍ 13. Tighten the propeller nut and spinner.

❍ 14. Place your name, address, AMA number and

telephone number on or inside your model.

❍ 15. Inspect all cables from ight to ight!

❍ 16. If you wish to photograph your model, do so before

your rst ight.

❍ 17. Range check your radio when you get to the ying

eld.

CHECKLIST

During the last few moments of preparation your mind

may be elsewhere anticipating the excitement of the

rst ight. Because of this, you may be more likely to

overlook certain checks and procedures that should be

performed before the model is own. To help avoid this,

a checklist is provided to make sure these important

areas are no overlooked. Many are covered in the

instruction manual, so where appropriate, refer to the

manual for complete instructions. Be sure to check the

items o as they are completed (that's why it's called a

check list!).

❍ 1. Check the C.G. according to the measurements

provided in the manual.

❍ 2. Be certain the battery and receiver are securely

mounted in the fuse. Simply stung them into place with

foam rubber is not sucient.

❍ 3. Look for a correct position of your receiver antenna or

antennas. The antenna should not be close to other wires

inside the fuselage.

❍ 4. Balance your model also laterally.

❍ 5. Use threadlocking compound to secure critical

fasteners such as the set screws that hold the wheel

axles to the struts, screws that hold the carburetor arm (if

applicable), screw-lock push rod connectors, etc.

Have a ball! But always stay in control and y

in a safe manner.

GOOD LUCK AND GREAT FLYING!

HOBBICO SERVICE LINE EUROPE

Service department Revell GmbH

Henschelstr. 20-30, 32257 Bünde, Germany

Tel: +49 52239 65144

Email: service@hobbico.de

HOBBICO SERVICE LINE USA

Hobbico Product Support

3002 N. Apollo Drive Suite 1

Champaign IL 61822 USA

Telephone: (217) 398-8970 ext. 6

Fax: (217) 398-7721

E-mail: airsupport@hobbico.com

FLITEWORK SERVICE LINE

Service department Flitework GmbH

Geymannstr. 27, 4713 Gallspach, Austria

Tel: +43 664 3231 059

Email: technik@itework.at

14

Page 15

NOTES

ENGLISH

15

Page 16

ENGLISH

Flitework GmbH

Geymannstraße 27

4713 Gallspach

Austria / Europe

16

Tel: +43 664 3231059

Skype: itework

Mail.: oce@itework.at

www.itework.at

Loading...

Loading...