Page 1

PLEASE READ THESE OPERATING INSTRUCTIONS CAREFULLY.

Misuse and/or abuse of this instrument may cause injury and/or damage to

the meter or the equipment under measurement. Please read and follow all

instructions carefully. Please inspect the meter and test probes for wear or

abnormalities prior to every use. If a flaw exists, do not attempt to take any

measurements. Replace the damaged equipment. Never touch exposed

wiring, connection, or line circuit conductors when attempting to take

measurements. Damage resulting from a failure to follow instructions will

void the warranty.

HCAZ3064 for HCAP0360© Copyright 1999 Printed in China

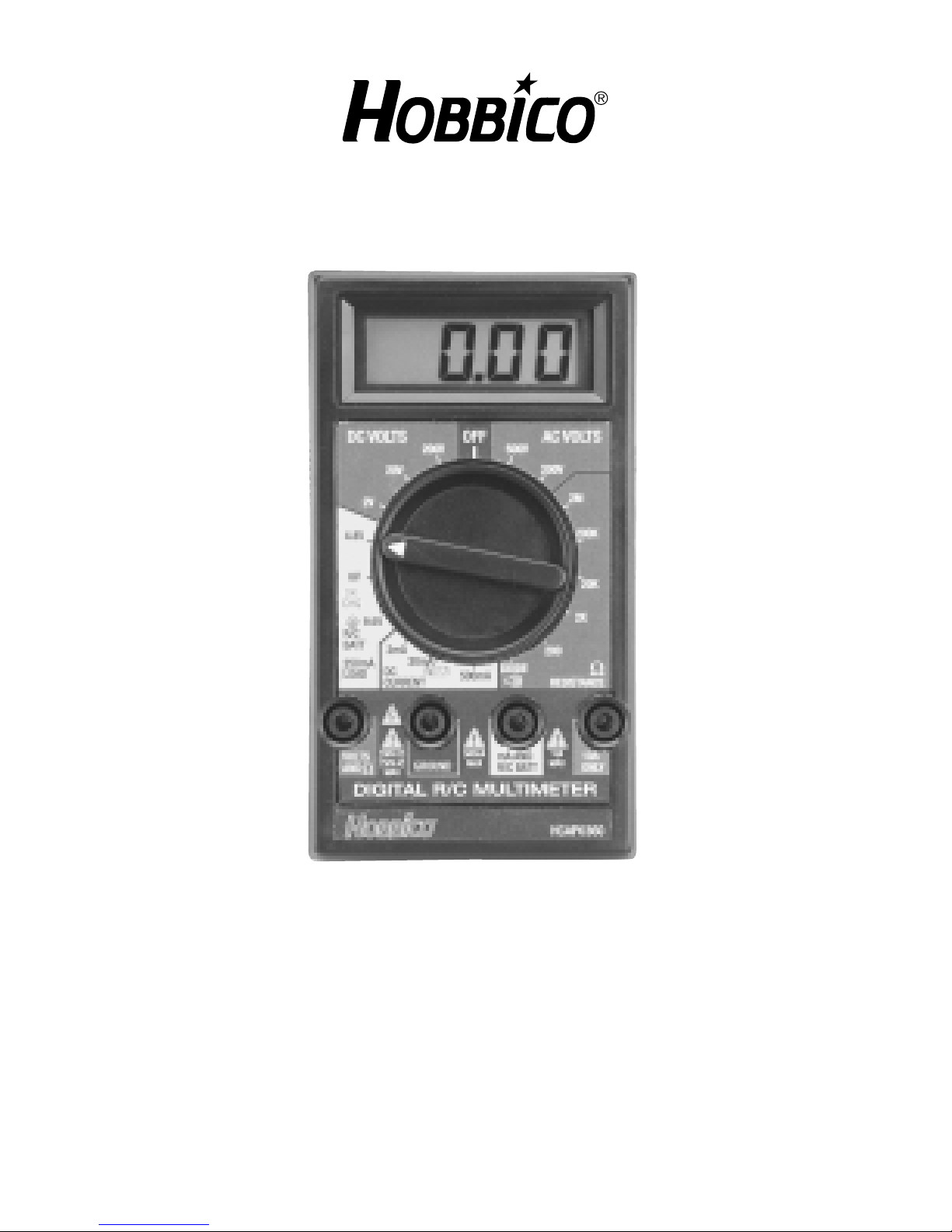

DIGITAL R/C MULTI-METER

OPERATION MANUAL

Page 2

· Pocket-size

· Simple operation

· 300 hour battery life

· Maximum 10A DC current range

· Recessed safety designed input terminals

· Built-in table stand

· Overload protection on all ranges

· Diode test function

· Audible continuity buzzer

· R/C battery test function with 250mA simulated load and

go/no-go LED

· 15 minute auto-off function

Display: 3-½ digit LCD, 0.5" numerals,

maximum reading “1999” with

automatic polarity sign and

weak LCD battery indicators

Overrange Indication: A “1” will blink in the most

significant digit

Sampling Rate: 2.5 times per second

Operating Environment: 32° to 122°F (0° to 50°C) at less

than 70% relative humidity

Storage Environment: -4° to 140°F (-20° to 60°C) at

less than 80% relative humidity

Power Source: One 9V carbon zinc battery

Power Consumption: 30mW typical

Battery Life: 300 hours typical

Sleep Mode: 15 minute auto-off timer

Low Battery Indicator: Battery symbol in LCD window

SPECIFICATIONS

FEATURES

2

Page 3

Max. Common Mode Volts: 500V DC or AC peak voltage

Accuracy Temp. Coefficient: (10°C-18°C and 28°C-50°C)

less than 0.1x applicable

accuracy specification per

degree C

Fuse: 0.8A, 250V, 5 x 20mm fast

acting cylindrical glass

Dimensions: 5.0" x 2.8" x 1.4"

Weight: Approximately 7.0oz. (200g)

including battery

Accuracies are +/- (% of reading + number of digits) at 23°C

(+/-5°C), less than 75% relative humidity.

R/C Battery Check

Range Resolution Red LED Green LED

4.8V 0.01V 2.0 - 4.7V 4.9V or higher

6.0V 0.01V 2.0 - 5.9V 6.1V or higher

9.6V 0.01V 2.0 - 9.5V 9.7V or higher

Overload protection: 0.8A / 250V fuse on mA inputs.

Load current each selection: 250mA

DC Voltage

Range: 2V, 20V, 200V +/- (0.8% of

reading + 1 digit)

Overload protection: 1000V DC or 750Vrms AC for

15 seconds

Impedance: 10M

AC Voltage (50-400Hz)

200V selection: +/- (1.5% of reading + 4 digits)

RANGES

3

Page 4

500V selection: +/- (2.0% of reading + 4 digits)

Overload protection: 1000V DC or 750Vrms AC for

15 seconds

Impedance: 10M

DC Current

Range: 2mA, 20mA, 500mA +/- (1.2%

of reading + 1 digit)

10A selection: +/- (2.0% reading + 3 digits)

Overload protection: 0.8A / 250V fuse, no protection

for 10A selection

Resistance

200 selection: +/- (1.5% reading + 3 digits)

2k , 20k , 200k , 2M : +/- (1.0% of reading + 1 digit)

Overload protection: 400V DC / AC rms

Diode Test

Test current: 1.0mA +/- 0.6mA

Test voltage: 3.2V maximum

Continuity Test

Audible indication: less than 50 approx.

1. Read these operating instructions thoroughly and completely

before operation. Pay close attention to the WARNINGS and

CAUTIONS which will inform of potentially dangerous

procedures.

2. Always inspect your meter, test probes and accessories for

any sign of damage or abnormality before every use. If any

abnormal conditions exist (broken test probes, cracked plugs,

SAFETY RULES

4

Page 5

faulty display, etc.), do not attempt to take any

measurements.

Refer to the Troubleshooting Guide at the rear of this manual

for further information.

3. Never ground yourself when taking electrical measurements.

Do not touch exposed metal pipes, outlets, fixtures, etc.,

which might not be at ground potential. Keep your body

isolated from ground by using dry clothing, rubber shoes,

rubber mats, or any approved insulating material.

4. Never touch exposed wiring, connections or any live circuit

conductors when attempting to take measurements.

5. Never replace the protective fuse inside the meter with a fuse

of a different rating.

6. When testing for voltage, make sure the voltage function is

operating properly by reading a known voltage in that range

before assuming that a zero reading indicates a no-voltage

condition.

7. Calibration and repair on the meter itself should be performed

only by a qualified technician.

8. To avoid electric shock use CAUTION when working with

voltages above 40V DC or 20V AC. Such voltages pose a

shock hazard, and should always be considered dangerous.

5

Page 6

6

Digital

Display

Rotary

Selector

Switch

R/C Battery

Load Test

Range With

2-color

Go/No-Go

LED

Input

Terminals

Figure 1

Page 7

1. Digital Display: A 3-½ digit liquid crystal display (LCD), with

0.5" numerals, maximum reading of “1999” with automatic

polarity sign and low battery indicator (see figure 1).

2. Rotary Selector Switch: Select desired measurement by

rotating dial to the appropriate position.

3. Input Terminals: Color coding of the measurement selections

helps determine which banana jacks (recessed for safety) the

probes should be connected to for measurement.

This meter has a self-contained 9V battery which can be easily

replaced if necessary. When the low battery indicator

appears

on the LCD, or if the LCD will not illuminate in any way, the internal

9V battery is likely in need of replacement (see figure 2).

BATTERY REPLACEMENT

FRONT PANEL CONTROLS

7

Page 8

WARNING: Before attempting to replace the battery, first

disconnect the test probes from any energized circuit and then

disconnect the test probes from the instrument.

1. Disconnect the test probes from any energized circuit, and

from the meter.

2. Turn the dial to the “OFF” position.

3. Remove the single screw from the rear of the case with a

Phillips screwdriver.

4. Remove the battery from the case, and disconnect the

connector.

5. Replace the battery with another 9V type battery. These

batteries can be found at any local convenience or

department store.

6. Reverse the above procedure to close the meter’s case.

A 0.2A, 250V, 5 x 20mm fast acting glass fuse is installed inside

the meter and is used to protect the ampere ranges (but NOT

including the 10A range). If the DC Current ranges (except the

“10A ONLY” range) do not operate, the internal fuse may need to

be replaced. Refer to figure 2.

WARNING: Before attempting to replace the fuse, disconnect the

test probes from any energized circuit and then disconnect the test

probes from the instrument. Replace the fuse only with a fuse with

equivalent ratings. Always use fast acting type fuses.

1. Disconnect the test probes from any energized circuit and

then from the meter.

2. Turn the dial to the “OFF” position.

3. Remove the single screw from the rear of the case with a

Phillips screwdriver.

FUSE REPLACEMENT

8

Page 9

4. Remove the battery from the battery clip.

5. Remove the fuse from the clips located in the center of the

p.c. board.

6. Install the replacement fuse (making certain it is of the same

specifications as the original fuse). Prior to inserting the fuse,

make sure each clip is crimped so that the fuse will be held

tightly inside the clips when inserted. A loose fuse inside the

clips will cause intermittent operation of the meter.

7. Replace the battery and rear cover by reversing the above

procedure.

The Digital R/C Multi-Meter’s selection ranges and input jacks are

color coded for convenience and safety. The red test probe

should always be inserted in the input jack whose color

matches the color of the range in which the dial is positioned.

If the dial is set anywhere in the yellow range, for example, the red

test probe must be in the jack marked yellow, and so on. Before

making any measurements always examine the meter and

accessories for damage, contamination (like dirt, oil, or water, etc.)

and defects. Examine the test probes for cracked or frayed

insulation and make sure the probes plug snugly into the meter ’s

jacks. If any abnormal conditions exist do not attempt to make any

measurements and refer to the Troubleshooting Guide in the rear

of this manual for further instructions.

AC or DC Voltage Measurements

1. Insert the black probe into the black “GROUND” jack, and the

red probe into the red “VOLTS AND ” jack.

2. Move the dial to the 200V DC position if DC volts are to be

measured, or into the 500V AC position if AC volts are to be

measured. Always start in the highest range of the function

OPERATION

9

Page 10

being measured and work down from there. Note these areas

of the selection range are red in color, to match the color of

the proper jack in which the red test probe should be inserted

for this type of measurement. CAUTION: To avoid possible

electric shock, instrument and/or equipment damage, do not

attempt to take any voltage measurements if the voltage is

above 200V DC or if the voltage is unknown. The “GROUND”

jack potential should not exceed 500V measured to ground.

3. Apply the test probes to the two points at which the voltage

reading is to be taken. Be careful not to touch any energized

conductors with any parts of your body.

4. Turn the dial to the next lower range for a more accurate

reading only if the reading is within that next lower range.

5. When measurements are completed, disconnect the test

probes from the circuit under test.

DC Current Measurements

WARNING: This meter is NOT designed to measure AC current.

Attempts to measure AC current could cause permanent damage

to the meter and/or the equipment under test and void the

warranty.

1. Always start at the highest range of the function to be

measured and move down from there.

2. Insert the black probe into the black “GROUND” jack, and the

red probe into the blue “10A ONLY” jack.

3. Adjust the dial to the blue “10A” position. Note this area of the

selection range is blue in color to match the color of the

proper jack in which the red test probe should be inserted for

this type of measurement only. CAUTION: The 10A range is

NOT protected in any way and has a very low internal

resistance. Do not attempt to take a current measurement if

the current is unknown or above 10A DC. The “GROUND”

terminal potential should not exceed 500V measured to

ground.

10

Page 11

4. Completely de-energize the circuit in which the current is to

be measured. Place the meter in series with the conductor

carrying the current which is to be measured. Energize the

circuit.

5. If the reading is less than 0.20 amps, you can move the dial

to a lower selection for greater accuracy. CAUTION: Before

changing ranges, always de-energize the circuit completely.

Failure to do so could damage the meter or equipment under

test and void the warranty.

6. Before moving the dial to a lower current range, you must first

move the red probe to the yellow “mA AND R/C BATT” jack

(noting the DC current selection range is yellow in color to

match the proper jack color). Then, move the dial to the

500mA DC Current selection. CAUTION: The mA ranges are

fuse protected. To avoid possible electrical shock, meter

damage and/or equipment damage do not:

A. Attempt to take mA current readings on circuits having

more than 500mA (0.5A) of current flow.

B. Apply a voltage between the “GROUND” and “mA” jacks

exceeding 250V AC or DC, as permanent equipment damage

and/or injury could result. Partial circuit damage may result for

voltages below 250V AC or DC.

C. Raise the “GROUND” terminal potential above 500V to

ground.

D. Energize the circuit. If the reading is within the next lower

range, switch to that range after completely de-energizing the

circuit under test. Re-energize the circuit and try again.

Continue changing to lower ranges if the reading is within the

next lowest range to obtain the best accuracy.

Resistance and Diode Measurements, and Continuity Check

1. Insert the black probe to the black “GROUND” jack, and the

red probe into the red “VOLTS AND ” jack. CAUTION: All

11

Page 12

resistance and diode measurements should be taken on

de-energized circuits only. To avoid possible electrical shock,

instrument and/or equipment damage, do not connect the

“GROUND” and “VOLTS AND ” jacks to circuits having a

potential difference exceeding 250V AC or DC. Do not

connect the “GROUND” terminal to potentials exceeding

500V to ground.

2. Set the dial to the proper “ -Resistance” range desired for

measurement (again noting this selection area is red to match

the color of the proper jack in which to insert the red test

probe).

3. For resistance measurements:

A. Completely de-energize the circuit or device which is to be

measured.

B. Connect the test probes to the device. A reading of “1.---”

indicates an overrange condition, meaning the actual

measured

resistance value of the device under test is too large for the

current position of the dial. Move the dial to the next highest

resistance range and try again. If overrange occurs again,

move to the next highest setting until a reading is displayed.

4. For diode measurements:

A. The “DIODE” test range measures resistance from 000

up to 1999 and is used to test the forward resistance value

of diodes.

B. Connect the red probe to the diode’s anode, and the black

probe to the cathode. Note: On most diodes, the negative or

cathode side is marked with a line around the diode.

C. A reading of “1.---” indicates a resistance greater than is

normal (>2k ), which means the diode has an open circuit

and is defective. This reading could be displayed if the meter

is connected to the diode in reverse, in which event the

probes need to be reversed to properly measure the diode. A

reading of approximately “.700” is normal and typically

indicates the diode is good.

12

Page 13

5. For continuity measurements:

A. Move the dial to the selection marked “DIODE” with the

buzzer icon underneath.

B. Touch the red and black probes together to confirm the

audible buzzer sounds and that the LCD reads “.000”.

C. Completely de-energize the circuit or device which is to be

measured. Place the probes across the conductor or circuit to

be measured.

D. If the buzzer sounds and LCD reads “.000”, perfect

continuity is occurring.

E. If the buzzer sounds and the LCD reads under “.050”, only

partial continuity exists (a small resistance exists somewhere

in the circuit).

F. If the buzzer does not sound and the LCD reads a value

greater than “.050”, continuity does not exist.

R/C Battery Test Measurements

1. Insert the black probe into the black “GROUND” jack, and the

red probe into the yellow “mAAND R/C BATT” jack.

2. Place the dial into the proper “R/C BATT” position to match

the battery being tested; 4.8V is for 4-cell packs, 6.0V is for 5cell packs, and 9.6V is for 8-cell packs. Note: The meter

automatically applies a 250mA load to the battery under

test any time the dial is one of these three positions. This

is to test the battery under a similar load to that typically

drawn by most R/C transmitters or flight systems to see

if the battery is capable of operating under load.

3. Connect the probes to the battery to be tested. Make certain

the black probe is connected to the negative (-) terminal on

the battery (usually a black or brown wire) and the red probe

is connected to the positive (+) terminal (red wire).

WARNING: Do not allow the black and red probes, or the

battery’s positive (+ red) or negative (-) leads to touch at any

13

Page 14

time. Permanent damage to the meter or equipment under

test could result and void the warranty. It is highly

recommended to remove the battery from either the Tx or Rx

before testing. Inaccurate readings could result as a failure to

follow these instructions.

4. If the measured voltage exceeds the rating for that battery, the

2-color LED on the far left of the meter will illuminate green to

indicate the battery is “OK” to use. The LED will illuminate a

red color to indicate the battery is not O.K. and requires a

charge “CHG” prior to use. WARNING: In no way does this

function accurately indicate the precise amount of capacity

remaining in the battery. The only way to attain such

information is by using a cycler. This function simply provides

an indication of the instantaneous state of charge of the

battery and its ability to withstand a load condition, and should

not be used to gauge the amount of safe flying time left on the

batteries.

This meter has a built-in auto-off timer that will turn off the meter if

no activity has occurred within 15 minutes. This is to maximize the

lifespan of the battery. Sleep mode can occur when the dial is

adjusted to any setting except the “OFF” position. To revive the

meter during sleep mode, simply rotate the dial to another

selection and the LCD should illuminate indicating the meter

is ready.

WARNING: Sleep mode simply turns off the meter’s display

circuitry but does not disconnect the input jacks from internal

electrical connections. While in sleep mode, make sure the probes

SLEEP MODE

14

Page 15

are not touching any live electrical circuitry to prevent accidental

short circuits and possible damage to the meter and/or other

equipment. It is always important to keep the probes completely

clear of any live electrical circuitry when not in use.

Problem: LCD is fading or does not display - battery indicator

illuminates on LCD.

Possible Cause and Cure: Internal 9V battery going dead,

replace battery.

Problem: LCD always reads “1.---”.

Possible Cause and Cure:

· Range selection too low, adjust dial to next highest selection.

· For diodes, probes are backwards, reverse probes on diode.

· For diodes, diode may be defective, discard diode.

· Poor connection with probes, recheck all connections.

Problem: LCD always reads a negative value.

Possible Cause and Cure: Probes are backwards, either

disconnect

probes from device under test and connect in reverse to the

meter ’s jacks or reverse probes on device being measured.

Problem: “R/C Batt” LED will not go red.

Possible Cause and Cure: Range selection in wrong position,

adjust dial up to the proper setting.

Problem: “R/C Batt” LED will not go green.

Possible Cause and Cure:

· Range selection in wrong position, adjust dial down to the proper

setting.

· Defective battery under test, may need to be cycled or replaced.

TROUBLESHOOTING GUIDE

15

Page 16

Problem: Display always reads “.000” in current ranges.

Possible Cause and Cure: Internal fuse blown, replace fuse.

Problem: Display behaves strangely, readings are

incomprehensible.

Possible Cause and Cure:

· Dial in wrong setting or range, disconnect probes and adjust dial

to proper position.

· Probes are in wrong jacks, disconnect probes from equipment

under test and move to proper jacks.

· Poor connection with probes, recheck all connections.

· Frayed or broken probe, replace probe.

· Range selection too high, move dial to lower setting for better

accuracy.

· Internal problem with meter, return to Hobby Services for repair.

1 YEAR LIMITED WARRANTY

HOBBICO warrants this product to be free from defects in materials and

workmanship for a period of one (1) year from the date of purchase. During that

period, we will repair or replace, at our option, any product that does not meet

these standards. You will be required to provide proof of purchase (receipt or

invoice).

If, during the 1 year warranty period, your HOBBICO product shows defects

caused by abuse, misuse, or accident, it will be repaired or replaced at our

option, at a service charge not greater than 50% of the current retail list price.

Be sure to include your daytime phone number in case we need to contact you

about your repair.

Under no circumstances will the purchaser be entitled to consequential or

incidental damages as a result of using this product.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

If you attempt to disassemble or repair this unit yourself it may void the

warranty.

For service to your HOBBICO product, either in or out of warranty, send it

post paid and insured to:

Hobby Services

1610 Interstate Drive

Champaign, IL 61822

(217) 398-0007

Internet: www.hobbico.com

E-mail: productsupport@hobbico.com

16

Loading...

Loading...