Page 1

ASSEMBLY INSTRUCTIONS

90-Day Limited Warranty

If you, as the original owner of this model, discover defects in pans or workmanship wilhin 90 days of purchase, Hobbico will repair or replace it - at the option

of our authorized U.S. repair facility, Hobby Services - without charge. Our liability does not include cost of shipping to us. However, Hobby Services will pay

shipping expenses lo return your model to you. You must provide proof of purchase, such as your original purchase invoice or receipt, for your model's

warranty to be honored. This warranty does not apply to damage or defects caused by misuse or improper assembly, service or shipment. Modifications,

alterations or repair by anyone other than Hobby Services void this warranty. We are sorry, but we cannot be responsible for crash damage and/or resulting

loss of kits. engines, accessories, etc.

Repair Service

Your Avistar must be returned directly to Hobby Services for warranty work. The address is: Hobby Services. Attn: Service Department. 1610 Interstate Drive,

Champaign, II. 61822 Phone: (217) 398-0007. Please follow the instructions below when returning your model. This will help our experienced technicians to

repair and return it as quickly as possible.

1. ALWAYS return your entire system, including airplane and radio.

2. Disconnect the receiver battery switch harness and make sure that the transmitter is turned off Disconnect all batteries and drain all fuel.

3. Include a list of all items returned and a THOROUGH, written explanation of the problem and service needed. If you expect the repair to be covered under

warranty, also include your proof of purchase.

•I.

Include your

full

return

address

and a phone number where

you

can

be

reached during

the

day.

If your model is past the 90-day warranty period or is excluded from warranty coverage, you can still receive repair service through Hobby Services at a

nominal cost. Repair charges and postage may be prepaid or billed COD. Additional postage charges will be applied for non-warraiuy returns All repairs

shipped outside the United States must be prepaid in U.S. funds only All pictures, descriptions and specifications found in this instruction manual and on

the product package arc subject to change without notice. Hobbico maintains no responsibility for inadvertent errors.

Entire contents © Copyright 1999

HCAZ3037 for HCAA2016 V 1.0

Page 2

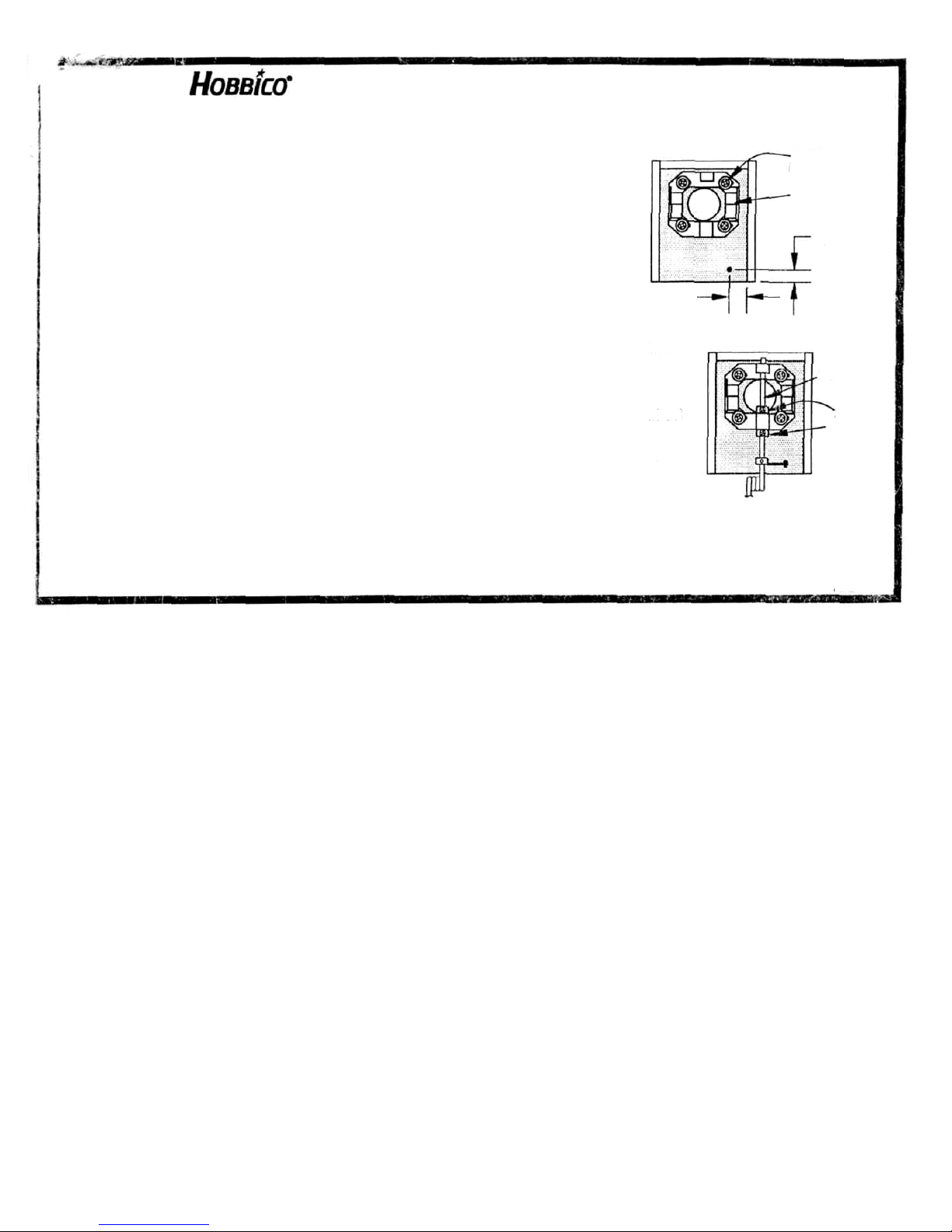

AVISTAR 40 ARF IMPORTANT BUILDING NOTES?

Please make notes of the following points in your instruction manual before beginning assembly.

6-32 X 3/4"

This kit contains an adjustable engine mount. This will allow you mount almost any engine

quickly and easily. To use this mount, please replace the following steps in the manual with

these:

Engine Mount

Machine Screws

1. On page 16, at step 31, drill a hole in the firewall so it is 9/16" in from the right side and

3/8" up from the bottom as shown in the sketch at right.

3/8"

2. On page 17, before step 35, install the engine mount halves by fitting them together and

attaching them to the firewall using four 6-32 x 3/4" machine screws with washers. Do

not tighten completely until later.

9/16"

3. On page 17, at step 36, install the nose gear strut through the steering arm, followed by a 4mm

collar. Next, slide the strut through the lower lug on the engine mount and install a second collar

(see sketch at right). Tighten the collars using 3 x 5mm machine screws.

Nose gear

strut

4. On page 17, at step 37, rotate the steering arm so it is 1/2" away from the firewall with the wheel

pointing straight ahead.

4mm

Collars

5. On page 18, after step 46, once the engine in properly positioned, tighten the engine mount to

the firewall.

6. On page 19, step 47, drill four 7/64" holes at the marks. Do not drill 1/8" holes.

7. On page 19, step 50 will tell you to mount the engine using four 3 x 25mm machine screws with washers and nuts. This hard

ware has been replaced with four #6 x 3/4" sheet metal screws. Simply screw these into the mount to hold the engine in piace.

AV12ADD2

Page 3

You're about to build in just days what took aviation pioneers years—a powered machine that flies.

Specially created for you and other first-time radio control acrobatic pilots, Hobbico's Avistar 40 offers

nearly all the excitement of piloting a real airplane...and develops skills that will take you anywhere you

want in your new hobby.

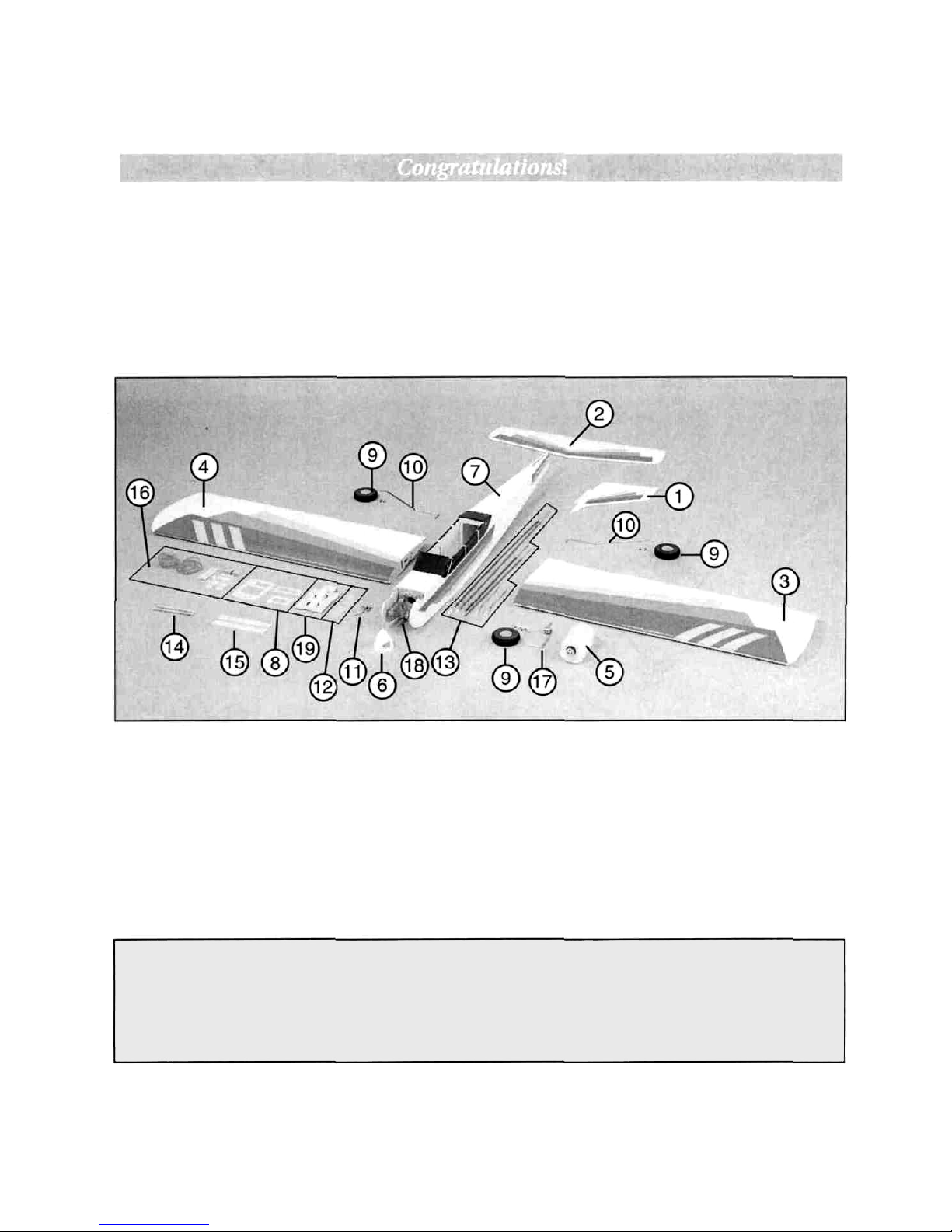

Know Your Model's Parts

Take a moment now to match the box contents with the items listed below. Following the Avistar 40's

assembly instructions will be quite easy if you identify and organize the parts before you begin.

1. RUDDER/FIN (C)

2. STABILIZER/ELEVATOR

(C)

3. LEFT WING PANEL

(A)

4. RIGHT WING PANEL

(A)

5. FUEL TANK (B)

6. SPINNER

(B)

7. FUSELAGE

(B)

8. SERVO TRAY

(B)

9. WHEELS (D)

10.

MAIN LANDING GEAR

(D)

11.

METAL HARDWARE (B)

12.

NYLON HARDWARE

(B)

13.

PUSHRODS (B)

14. WING

DOWELS

(B)

15.

DIHEDRAL BRACES

(A)

16.

HARDWARE (B)

17. NOSE

GEAR

(D)

18. ONE-PIECE ALUMINUM ENGINE MOUNT (B)

19.

BATTERY / RECEIVER TRAY

(B)

Replacement Parts Available

HCAA3030.....Wing Kit (A)

HCAA3031..... Fuselage Kit (B)

HCAA3032.....FinSet(C)

HCAA3033.....Landing Gear Set (D)

() Letter indicates items included in each replacement set.

2

Page 4

Other Items You'll Need

Glues

Choose any 6-minute epoxy, such as Great Planes®

Pro'" Epoxy, which has been formulated especially

for R/C model building. Epoxies offer a strong

bond and a variety of curing times suited for every

step of assembly. You'll also need an instant-setting

CA (cyanoacrylate), a thicker CA+, and a 30-minute

epoxy, plus rubbing alcohol and paper towels for

easy epoxy cleanup.

Hardware

Tools and accessories required for assembly:

Hobby knife Needle nose pliers

#11 knife blades Large Phillips screwdriver

#64 Rubber bands Small Phillips screwdriver

Ruler 3 ft of 3/32" fuel tubing

Drill with drill bits: 1/16", 3/32", and 3/16"

Model Engine

Power your Avistar with any high-quality, .40-size

model engine. The O.S.® .40 LA and SuperTigre®

GS-40 are just a few examples. Look for features

such as easy break-in, easy starting, efficient

carburetion and low maintenance. Check the

manufacturer's recommendations for propellers to

use with your engine.

Radio Equipment

To let you send the commands that control your

Avistar 40's "flight path," you'll need a 4-channel

aircraft radio system with four standard servos.

Many 4-channel radios include just three servos.

You may need to purchase the fourth separately.

The servos and radio receiver will be mounted onboard your model and need to be cushioned from

jolts and vibration. One-half inch thick foam

rubber sheets are available for this purpose.

Getting Ready for Flight

Your Hobbico Avistar 40 trainer is ready for takeoff

in as little as 15-20 hours. Your hobby dealer or

flying instructor can help you decide what

accessories you'll need for flight. Most are one-time

only purchases—and your instructor will probably

allow you to use his field box until you can outfit

your own with a glow plug starter, fuel bulb or

pump, and "chicken stick" or electric starter. You

will need to provide your own fuel. Use glow fuel

with a 10-15% nitro blend to keep your engine

performing at its peak...and your Avistar 40 will

have the power to make you an accomplished pilot!

Other General Items Required:

Masking Tape

Epoxy Brushes

T-Pins

Clothes pins

Sandpaper

Foam Rubber

Mixing Sticks

Felt-Tip Marker

String

Paper Towels

Standard Screwdriver

Thread Locking Compound

Epoxy Mixing Cups Wing Seating Tape

Find A Flying Instructor

The best way to begin flying your Avistar 40 is with

an experienced R/C pilot or flying instructor at

your side. You'll learn faster, relax those in-flight

jitters and avoid risking your model before you're

truly ready to solo.

Where do you find an instructor? Ask at your local

hobby shop. They'll have information about flying

clubs in your area whose membership includes

qualified instructors. You can also join the

Academy of Model Aeronautics (AMA), a 165,000

member-strong national organization with more

than 2,500 chartered clubs across the country.

Through any one of them, instructor training

programs and insured newcomer training are

available. Contact the AMA at the address or phone

number below:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

Toll Free: (800) 435-9262

Fax: (765) 741-0057

Web Site: http://www.modelaircraft.org

3

Page 5

Please follow these safety precautions:

Before you fly

1. Make sure that no other flyers are using your

radio frequency.

2. Your radio transmitter must be the FIRST thing

you turn ON, and the LAST thing you turn OFF.

Fuel storage and care

1. Do not smoke near your engine or fuel.

2. Store all engine fuel in a safe, cool, dry place,

away from children and pets.

3. Always wear safety glasses.

4. Make certain that your glow plug clip is securely

attached to the glow plug—and cannot pop off,

possibly falling into the spinning propeller.

5. Use a "chicken stick" or electric starter to start

the engine— NOT your fingers.

6. Make sure that the wires from your starter and

glow plug clip cannot become tangled with the

spinning propeller.

7. Do not stand at the side of the propeller when

you start or run the engine. Even at idle speed,

the spinning propeller will be nearly invisible.

8. If any engine adjustments are necessary,

approach the engine only from behind the

spinning propeller.

90-Day Limited Warranty

If you, as the original owner of this model, discover

defects in parts or workmanship within 90 days of

purchase, Hobbico will repair or replace it—at the

option of our authorized U.S. repair facility, Hobby

Services—without charge. Our liability does not

include cost of shipping to us. However, Hobby

Services will pay shipping expenses to return your

model to you.

You must provide proof of purchase, such as your

original purchase invoice or receipt, for your

model's warranty to be honored.

This warranty does not apply to damage or defects

caused by misuse or improper assembly, service or

shipment. Modifications, alterations or repair by

anyone other than Hobby Services voids this

warranty. We are sorry, but we cannot be

responsible for crash damage and/or resulting loss

of kits, engines, accessories, etc.

Repair Service

Your Avistar 40 must be returned directly to Hobby

Services for warranty work. The address is:

Hobby Services,

Attn: Service Department

1610 Interstate Drive, Champaign, IL 61822

Phone: (217) 398-0007

Please follow the instructions when returning your

model. This will help our experienced technicians

to repair and return it as quickly as possible.

1. ALWAYS return your entire system, including

airplane and radio.

2. Disconnect the receiver battery switch harness

and make sure that the transmitter is turned off.

Disconnect all batteries and drain all fuel.

3. Include a list of all items returned and a

THOROUGH, written explanation of the

problem and service needed. If you expect the

repair to be covered under warranty, also

include your proof of purchase.

4. Include your full return address and a phone

number where you can be reached during the day.

If your model is past the 90-day warranty period or

is excluded from warranty coverage, you can still

receive repair service through Hobby Services at a

nominal cost. Repair charges and postage may be

prepaid or billed COD. Additional postage charges

will be applied for non-warranty returns. All

repairs shipped outside the United States must be

prepaid in U.S. funds only.

All pictures, descriptions and specifications

found in this instruction manual and on the

product package are subject to change without

notice. Hobbico maintains no responsibility for

inadvertent errors.

4

Page 6

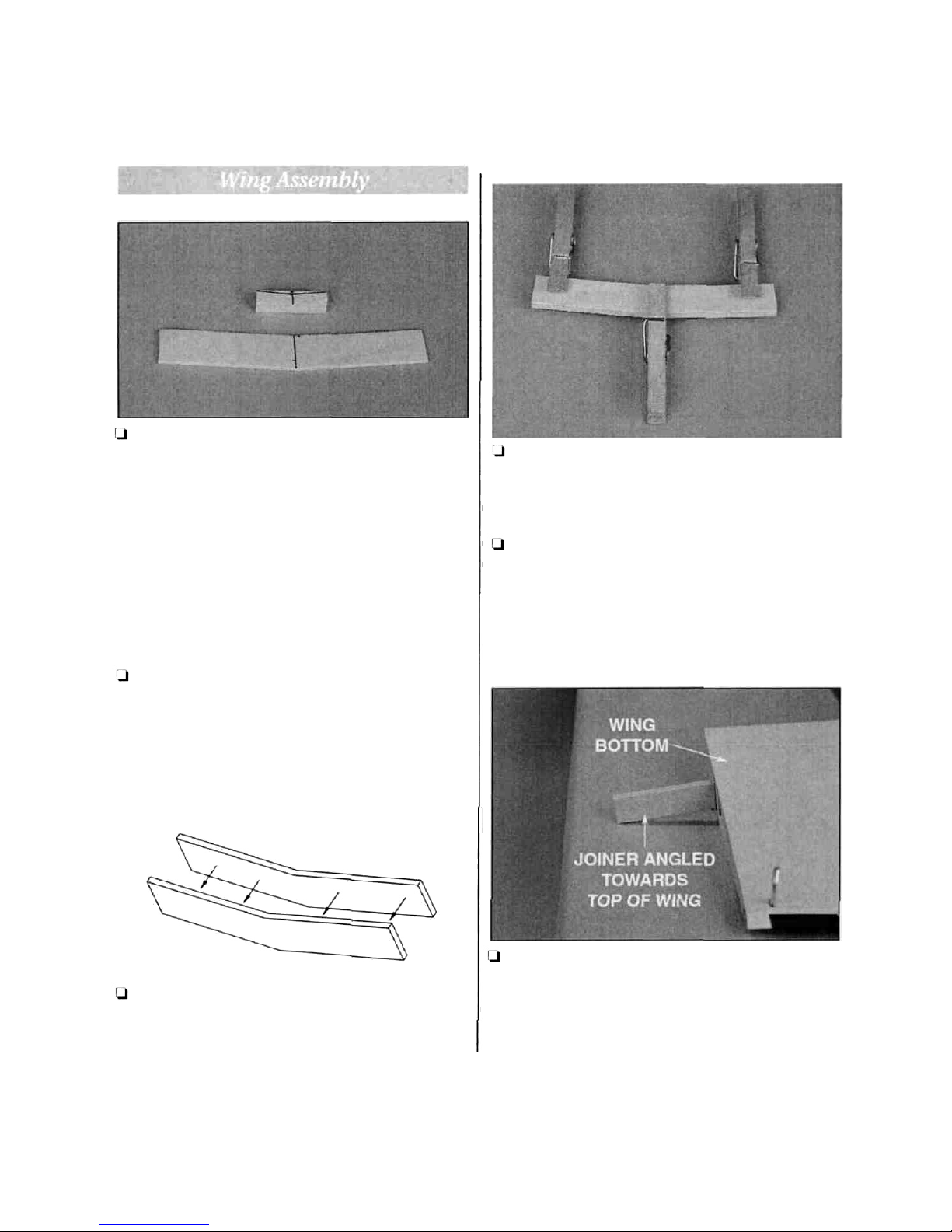

Q Find the two 1/8" (3mm) die-cut plywood wing

joiners. Draw a center line on both sides of the

plywood wing joiners and balsa aileron servo tray

mounting blocks. Use one plywood joiner as a

template to mark the wing dihedral angle on both

of the balsa 5/16" x5/16" x 1-1/2" (8mm x 8mm x

38mm) aileron servo tray mounting blocks. Put

these mounting blocks aside for use later.

Orientation of the wing joiners

Q Arrange the two "V-shaped plywood wing

joiners in the same orientation as they will be

glued together.

Gluing the wing joiner

Q Mix approximately l/4oz. (7.5ml) of30-minute

epoxy. Using a mixing stick or epoxy brush, apply

an even coat of epoxy on one side of a wing joiner.

Stack the other joiner on top of the epoxy.

Clamping the wing joiner

l-l Use three clothes pins to clamp the wing joiners

together firmly. The excess epoxy must be removed

before it cures as described in the next step.

Removing the excess epoxy

l-l Excess epoxy will be squeezed out of the seams

between the joiners and must be removed before

the epoxy is allowed to cure. Use a paper towel and

rubbing alcohol to remove the excess epoxy.

Be careful not to disturb the alignment of the

joiner pieces.

Test fit the wing joiner

After the epoxy has cured and the clothes pins

have been removed, test fit the wing joiner in both

wings by sliding the joiner into the joiner cavity in

the wing. The joiner should slide in with a little

resistance up to the centerline drawn on the both

sides of the joiner.

5

Page 7

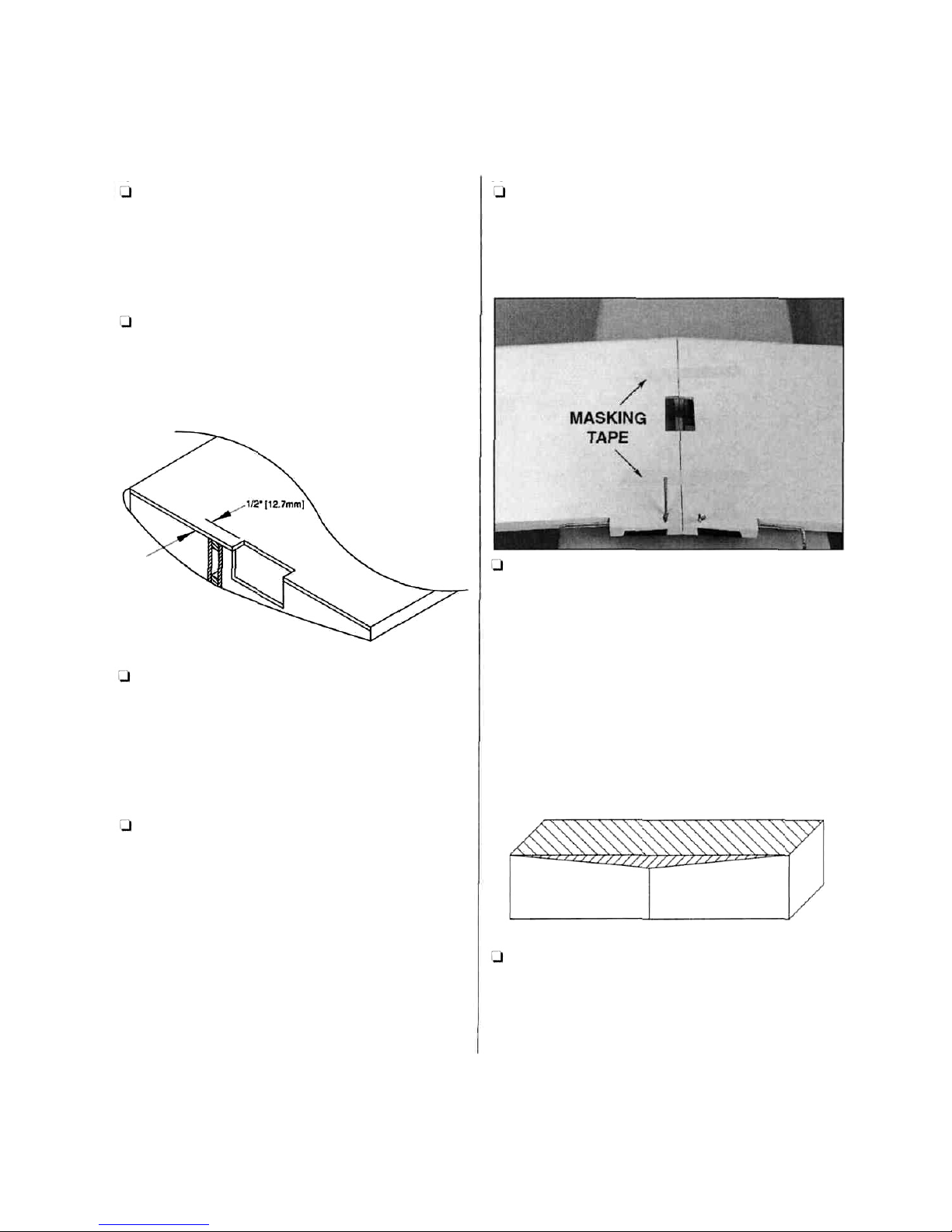

Sanding the joiner

Cl If the wing joiner will not Fit in the cavity, lightly

sand the excess epoxy and uneven surface joints

from the joiner edges and sides. Caution: A snug fit

is desirable between the joiner and the wing cavity.

Do not sand excessively.

Viewing the wing dihedral

Cl Pay close attention to the orientation of the wing

joiner in relation to the dihedral of the wings.

Marking the wing cavity

1-1 Lay the wing halves on the work surface with the

flat side facing up. Remove the precut balsa from the

root rib. Using the measurements in the sketch, trim

away the balsa sheeting from the bottom of the wing

to allow for the installation of the aileron servo.

Gluing the joiner in the wing

1-1 Mix l/4oz. (7.5ml) of 30-minute epoxy to glue

the joiner into one wing half. Use a mixing stick or

epoxy brush to apply epoxy to all four sides of the

joiner cavity wall. Insert the joiner into the cavity

up to the centerline marked on the joiner plate. Be

sure you are installing the joiner in the correct

orientation to the wing. It should angle upwards

when installed correctly. Clean the excess epoxy

from the wing root rib. You must be sure all the

excess glue is removed from the wing root or the

wings will not fit together correctly. Allow enough

time for the epoxy to fully cure before proceeding

to the next step.

Applying the epoxy

l-l Mix l/2oz. (14.5ml) of 30-minute epoxy and

apply to the wing root rib and inside the joiner

cavity of the second wing half.

Joining the wing halves

Q Assemble the two wing halves with the tightest

seam possible. No gaps should be showing between

the two wing halves. Clean the excess epoxy from

the outside of the wing using a paper towel and

rubbing alcohol. Tape the wing halves together with

masking tape. Set the wing aside to cure.

Cutting the mounting blocks

l-l Find the aileron servo tray and the two balsa

servo tray mounting blocks and position them

with the marked dihedral line up. Using a sharp

hobby knife, cut the angle out of the block. This

angle will be placed against the wing when the

servo tray is installed.

6

Page 8

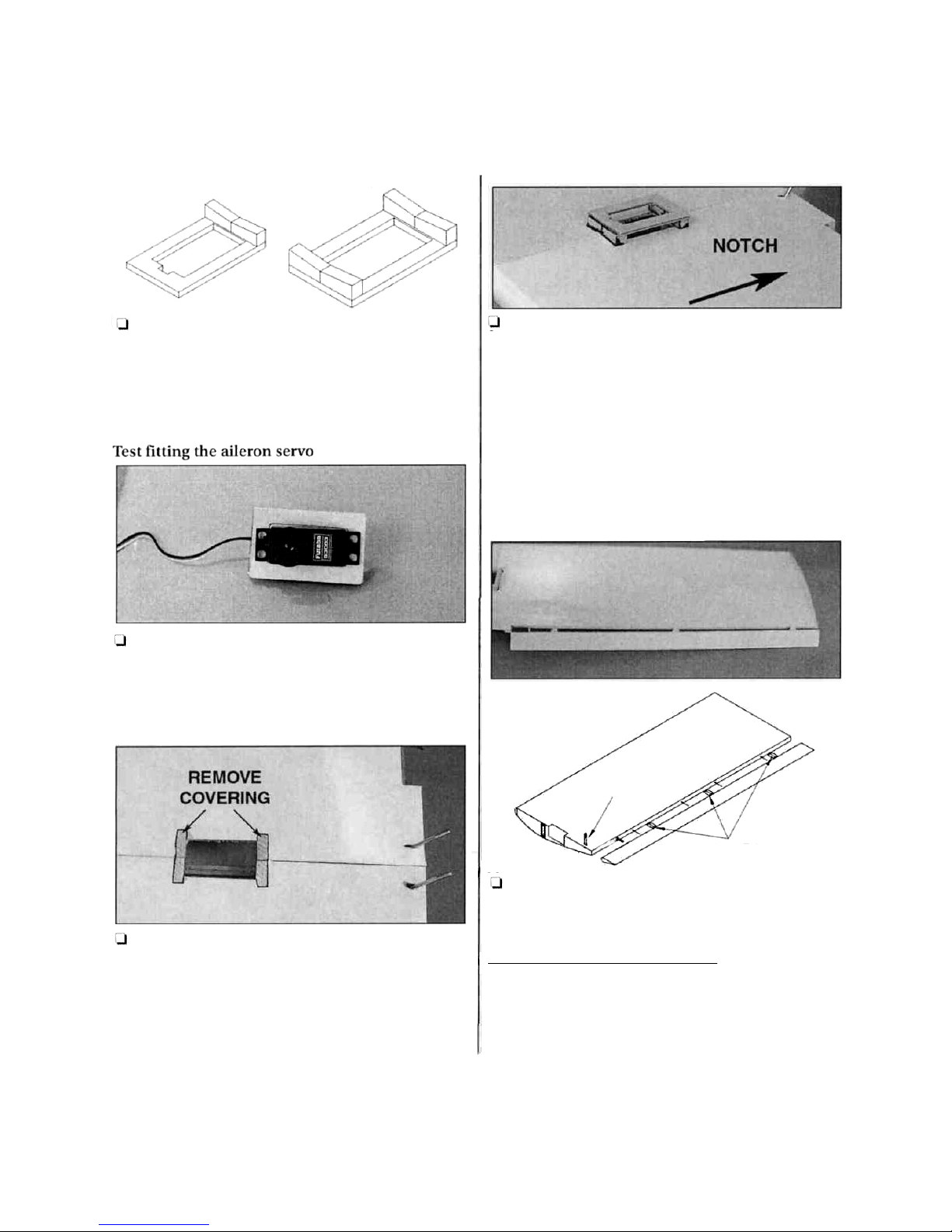

Assembling the servo tray

Q Apply thick CA+ to the flat side of the balsa servo

tray mounting block. Place the mounting block on

the aileron servo tray next to the servo

opening-not on the outer edge of the tray. Note the

positioning of the dihedral angle in relation to the

servo tray.

Q Test fit the aileron servo into the servo tray and

the hole cut in the bottom side of the wing. Enlarge

either hole, if needed, with a hobby knife or a finetoothed file until a proper fit is achieved.

Removing the covering

Q Position the aileron servo tray so it is centered

over the opening made in the wing. Using a felt-tip

marker, trace the outside of the servo tray

mounting block onto the wing. Use a sharp hobby

knife to remove the covering for the mounting

blocks. Use care not to cut into the underlying

balsa of the wing, as this may weaken the wing.

Installing the servo tray

J Mix l/8oz. (3.5ml) of 6-minute epoxy to glue the

servo tray to the bottom side of the wing. Apply

equal amounts of epoxy to the mounting blocks on

both ends of the servo tray. Attach the servo tray on

the bottom of the wing with the servo wire harness

notch facing the trailing edge of the wing. The

mounting blocks should be attached to the wing

sheeting where the covering was removed and not

to the plastic wing covering. Allow the epoxy to

fully cure before proceeding to the next step.

Aileron installation

HINGES

TORQUE

ROD

l-l Test fit the ailerons on the wing with the hinges

installed. Check for free movement in both

directions. There should be no binding. Use a

toothpick to push 30-minute epoxy down the

torque-rod holes in each aileron. Fit the aileron in

place. There should Be virtually no gap when the

aileron is fully seated. If the aileron will not fully

seat, use a hobby knife to clean the hinge slots and

try it again. Glue in the hinges by wicking 4 drops

of thin CA into each side of the hinges.

7

Page 9

Page 10

Installing the servo tray Constructing the tail section

Mix l/8oz. (3.5ml) of 6-minute epoxy to glue the

servo tray into the fuselage. Apply epoxy to all

fuselage parts that will come in contact with the

servo tray.

Q Locate the horizontal stabilizer slot under the

covering on the tail section of the fuselage by

pressing lightly with your finger. The slot will be

located on both sides of the tail. Using a hobby

knife, carefully remove the covering exposing the

slots. Note: Do not cut into the balsa wood

sheeting around the slot.

Installing the wing dowels

LI The wing dowel holes are predrilled. Locate the

four round holes (two on each side of the fuselage)

and remove the covering over each hole. Insert the

two wood dowels into the fuselage. The shorter

dowel is installed towards the tail of the airplane.

Install the dowel caps onto the dowels using four

2.5mm x 8mm sheet metal screws. You may need to

hold one screw with a pliers while installing the

other side.

Vertical stabilizer slot covering

Q Using your finger, locate the vertical stabilizer

slot on the top of the fuselage. Remove the

covering with a hobby knife in the same manner as

for the horizontal stabilizer slots. This will allow

better viewing access when centering the

horizontal stabilizer.

Finding the centerline

A

A

Q Locate the horizontal stabilizer and draw a

centerline on the side with the three color graphics.

Insert the stabilizer into the tail section with the line

showing through the vertical stabilizer slot.

9

Page 11

Preparing to install the stabilizer

EQUAL MEASUREMENTS

Q Attach a piece of string with a pin to the center of

the firewall as shown. The string should be a

minimum of 31-1/2" (800mm) in length. Stretch

the string to the corner of the horizontal stabilizer.

The distance from the pin to the horizontal

stabilizer must be the same on both sides. This

method will adjust the horizontal stabilizer to a

90" angle to the centerline of the aircraft.

Tracing the fuselage outline

U Using a felt-tip pen, trace a line around the tail of

the airplane on the top and bottom of the

horizontal stabilizer.

Removing the covering

Q Using a sharp hobby knife, cut 1/32" [1mm]

inside the lines made with the felt-tip pen and

remove the covering from the center of the

horizontal stabilizer. Do not cut into the balsa

sheeting on the horizontal stabilizer.

Installing the stabilizer

Q Mix l/4oz. (7.5ml) of30-minute epoxy to install

the horizontal stabilizer. Using a mixing stick,

place glue inside the horizontal stabilizer slot on

all sides including the horizontal stabilizer mount.

Insert the horizontal stabilizer and clean off the

excess epoxy that squeezes out of the joint with a

paper towel and rubbing alcohol. Adjust alignment

as shown in the previous step. Set the fuselage

aside to cure.

Preparing the vertical stabilizer

Q Locate the vertical stabilizer. Draw a line on both

sides even with the bottom of the fin as shown in

the sketch. Cutting 1/32" (1mm) below the line and

through the covering only, remove the covering

from the base of the vertical fin.

Important: Do not cut into the balsa fin root.

T-PIN

STRING

STRING

10

Page 12

Installing the vertical stabilizer

90°

90°

Fin

Alignment 90°

Sketch

Q Mix l/4oz. (7.5ml) of 30-minute epoxy to glue

the vertical stabilizer in place. Using a mixing stick,

apply epoxy to the top of the horizontal stabilizer

through the vertical stabilizer slot. Apply epoxy to

the sides and bottom surfaces of the fin base that

have balsa wood exposed. Insert the vertical

stabilizer into the slot, making sure the fin root is

seated firmly on the horizontal stabilizer. Check for

a perpendicular angle between the fin and the

stabilizer when viewed from the back. It is critical

that the fin remains perpendicular while the epoxy

is curing. Masking tape may be required to hold

the fin during this time.

Installing the rudder and elevator hinges

Q Test fit the rudder and elevator on the fin and

stabilizer with the hinges installed. Use the sketch

in "Installing the Ailerons" as a guide. Check for

free movement in both directions. There should be

no binding. Glue in the hinges by wicking 4 drops

of thin CA into each side of the hinges.

Locations of the control horns

l-l Note the locations and alignment of the control

horns in both the photo and the illustration before

marking and drilling.

Control horn alignment

HINGE LINE

CORRECT INCORRECT

11

Page 13

Attaching the elevator control horn

Locating the rudder exit hole

Locate a nylon control horn. Place the horn on

the bottom of the elevator. Position it 1" (25.4mm)

from center and aligned with the leading edge as

shown in the sketch and photo. Mark the two holes

with a felt-tip pen. The holes of the control horn

should line-up with the gap between the rudder

and the vertical stabilizer. Drill two 1/16" (1.5mm)

holes through the balsa elevator. Insert two 2-56 x

5/8" machine screws through the control horn and

elevator into the control horn back plate on the

opposite side of the elevator. Tighten the screws

but do not crush the balsa.

QThe precut rudder pushrod exit hole is located on

the same side as the rudder control horn, under the

covering. Locate the exit hole by gently running

your finger down the top of the fuselage. Using a

hobby knife, remove the covering from the rudder

pushrod exit hole. Do not remove the covering from

the exit hole on the opposite side.

Cutting the elevator exit hole

Installing the rudder horn

Locate the other nylon control horn. Place the

control horn on the left side of the rudder, 1" (25mm)

from the top of the hinged stabilizer as shown in the

photo on the previous page. Mark the two holes with

a felt-tip pen. Drill two 1/16" (1.5mm) holes through

the rudder. Use two machine screws 2-56 x 5/8" to

attach the control horn.

Q The precut elevator pushrod exit hole is located

on the same side of the fuselage as the elevator

control horn, beneath the covering. Locate the exit

hole by gently running your finger down the side of

the fuselage over the covering. Using a hobby knife,

remove the covering from the elevator pushrod

exit hole. Do not remove the covering from the exit

hole on the opposite side of the fuselage.

12

Page 14

Installing the landing gear

Q On the bottom of the fuselage, 9-3/4" (248mm)

from the engine compartment, there is a channel

located under the covering. Locate this channel by

running your finger over the covering on the bottom

of the fuselage. Using a hobby knife remove the

covering from this channel. To protect the channel

from fuel damage, place several drops of thin CA

along the channel and wipe with a paper towel.

Installing the struts

Q Locate the two chromed landing struts and place

them in the pre-drilled holes inside the channel on

the bottom side of the fuselage. Place two nylon

landing gear straps over the landing gear struts. Using

a felt-tip pen, mark the location of the strap

mounting holes onto the bottom of the fuselage. Drill

the four holes using a 1/16" (1.5mm) drill bit. Mount

the nylon landing gear straps using four #2x3/8" selftapping screws to the bottom of the fuselage over the

struts. The struts should be flush with the bottom of

the fuselage.

Mounting the wheels

Q Locate two foam wheels and four wheel collars.

Place one wheel collar on each strut and secure its

location using a 6-32 set screw. Place the wheel onto

the strut, followed by another wheel collar. Secure the

additional wheel collar with another 6-32 set screw.

In total, you will have two wheel collars, two 6-32 set

screws and one wheel on each strut.

Q Locate the aluminum engine mount and attach

it to the firewall using four 6-32 x 3/4" machine

screws and four #6 washers. The flat side of the

engine mount will be towards the top of the

fuselage as shown in the drawing and photo. Use

thread locking compound on the screws to make

sure they won't vibrate loose. Attach the nose gear

mount to the firewall using two 6-32 x 3/4"

machine screws.

Installing the nose gear

1-1 Place a wheel collar onto the nose gear strut.

Insert the nose gear stem into the plastic nose gear

13

Page 15

holding bracket on the fuselage firewall. Press a

5/32" wheel collar into the nylon steering arm.

Make sure the hole in the arm lines up with the

hole in the wheel collar. Place the nylon steering

arm between the plastic bracket and motor mount.

Slide the nose gear stem into the motor mount.

Lock the steering arm onto the flat spot of the nose

gear by tightening the socket head screw on the

front of the arm. Insert a 14-1/8" (359mm) pushrod

tube through the hole into the fuselage. The

pushrod tube must be flush with the firewall for

the steering to work properly. Wick thin CA around

the pushrod guide tube.

Installing the pushrod

Q Locate the 17-1/2" (445mm) wire control rod (no

threads) and make a 90-degree bend in one end

1/2" from the end. Remove the steering arm from

the nose gear assembly. Insert the bend into the

inside hole of the steering control horn from the

bottom. Slide the pushrod wire into the guide tube

and reassemble the nose gear assembly. Trim the

remaining arm to allow for maximum steering.

Throttle control guide

Q Insert the remaining plastic pushrod guide tube

into the predrilled hole in the engine compartment

firewall. Leaving 1/4" (6mm) of the tube showing,

glue the throttle control tube into the firewall using

thin CA.

Insert the control rod

Q Install a 14-1/8" (360mm) pushrod tube into the

firewall for the throttle pushrod. Leave 1" (25mm) of

the pushrod tube to extend forward of the firewall.

Secure the pushrod tube using thin CA. Thread a

clevis onto the 17-1/2" (440mm) pushrod using the

same technique as the aileron pushrods. Insert the

pushrod into the tube as shown in the photo.

l-l Locate the two aluminum tubes that are used in

the fuel tank.

Bending the pressure line

Q Being careful not to kink the tube, bend one end

of the longer tube to a 70 degree angle. It may be

helpful to find a rigid object that can be used as a

form to bend the tube around. Leave 1-1/2"

(38mm) of straight tube at one end so it can easily

be inserted through the tank plug.

14

Page 16

Assembling the tank plug Installing the tank

U Locate the two stopper plates. Push the aluminum

tubes through the smaller stopper disc and the back

of the rubber plug. Place the larger stopper disc on

the opposite side and insert the 3 x 20mm machine

screw through the larger disc, the rubber plug and

then into the smaller disc. Do not tighten the screw

at this time.

Final fuel tank assembly

Q Locate the metal fuel pick-up weight (often

referred to as the "clunk weight") and the medium

silicone fuel tubing. Insert the fuel pick-up weight

onto the fuel tubing. Compare the length of the

fuel tank to the length of the fuel tubing and cut

the tubing so that the fuel pick-up weight on the

end of the fuel tubing will not touch the end of the

fuel tank. The plug assembly can now be inserted

into the tank. The pressure tube should be

adjusted so the tube is pointed straight up just

under the top of the tank.

Caution: The pressure tube should be close but not

touching the top of the tank because the flow of fuel

may be interrupted and cause the engine to quit.

The stopper discs on the rubber plug can be

tightened by turning the screw. Do not over tighten

the stopper plates or damage to the tank may occur.

(-1 Insert the fuel tank into the fuselage as shown in

the photo.

Orientation of the fuel ports

1-1 Note the locations of the fuel tubes. Cut two fuel

line lengths, pressure line 4-1/2" (114mm) and fuel

line 4" (101mm), from medium silicone fuel line

(not included). Place the cut fuel lines over the

correct tubes.

Mounting the engine

1-1 The photo shows an O.S. 40 LA engine mounted.

Secure the engine by using two engine mounting

15

Page 17

brackets, four 4 x 15mm screws, four 4mm lock

washers and four 4mm nuts. The engine centerline

must be in line with the fuselage centerline. Place

the engine on the mount and secure the engine with

the engine brackets. The lock washers should be

located on top of the bracket under the head of the

screw. The screws are secured by four 4mm nuts.

Note: Thread locking compound is recommended

for use on the engine mounting screws. Attach the

clevis to the throttle arm in the hole closest to the

center of the arm.

Attaching the muffler

Q Locate the muffler and mount it to the engine by

using the screws included with the engine. The

exhaust outlet should be pointing down and away

from the fuselage. Use the instructions included

with the engine to make this adjustment.

Running the fuel line

Q Run the fuel lines to the proper locations on the

engine (fuel line to the fuel inlet, pressure line to

the muffler).

Mounting the propeller and spinner

Q Slide the spinner backplate onto the crankshaft of

the engine. Align the propeller with the two alignment

pegs on the backplate. Secure the propeller and

backplate to the engine using the washer and nut

included with the engine. Use a wrench to tighten the

nut. If the nut is even slightly loose, the propeller

could come off and become a hazard.

Final spinner assembly

Q Place the spinner cone onto the backplate until

they snap together. They must be aligned correctly

for a proper fit. The spinner cone must not come in

contact with the prop or fatigue and fracture of the

prop may occur over a period of time. Insert both

2 x 12mm self-tapping screws into the spinner and

tighten firmly,

Radio Installation

Installing the receiver and battery

Q Wrap both the receiver and battery pack in foam

rubber (not included). Using the supplied hook and

loop material, attach the receiver and battery pack

to the radio gear tray using the photo as a guide.

Alignment Pegs

Alignment Pegs

16

Page 18

Installing the switch

Q Cut a rectangular switch hole in the side of the

fuselage opposite the exhaust using a hobby knife.

Locate the receiver switch harness in the radio

system and remove the face plate. Place the switch

into the hole with the switch facing outward. Put

the face plate over the switch and mark the screw

holes with a felt-tip marker using the plate as a

template. Drill the screw mounting holes using a

1/16" (1.5mm) drill bit. Install the switch from the

inside of the fuselage with the "on" position toward

the rear of the plane. If the switch should get hit

while the plane is moving forward, it would not

turn the receiver off. Secure the switch using the

two screws supplied with the switch.

Preparing the servos

Q Remove the servo arms and wheels from the three

servos. Install the rubber grommets that came with

the radio system onto the servos, following the

instructions included with your radio system.

Servo installation

1-1 Install the three servos from your radio system as

shown in the photo. Refer to the radio manufacturer's

manual for more detailed instructions. Notice the

location and orientation of each servo as well as the

switch location.

Antenna Routing

STRAIN RELIEF

INSIDE FUSELAGE

ANTENNA HOLDER

AT

THE

TOP

OF

THE

VERTICAL STABILIZER

CUT

CUT

RUBBER

BAND

Q Drill a 1/16" (1.5mm) exit hole in the center of the

rear window 1" (25.4mm) down from the edge of the

radio compartment. Route the antenna under the

plywood servo tray and up through the exit hole. Do

not cut the antenna wire. The receiver is tuned to a

specific length of antenna. Use a medium T-pin to

attach a rubber band to the top portion of the

vertical stabilizer. Tie the antenna to the rubber

band using tension to keep the antenna tight. Use

caution not to damage the antenna. A servo horn

can be cut and used to hold the antenna in place at

both ends with less likelihood of damage to the

antenna wire.

Q Locate the two 21-3/4" (555mm) outer pushrod

tubes. Slide the tubes into the fuselage from the

elevator and rudder pushrod exits. Enlarge the

exits to allow the tubes to slide in easily. Don't glue

the tubes at this time.

Q Center the ailerons, then mark the pushrods at

the point where they meet the holes in the servo

arm. Make a 90 degree bend down in the wires at

this mark.

T-PIN

17

Page 19

Q Cut off the excess wire 3/8" (9.5mm) above the

bend. Enlarge the servo horn holes with a 5/64"

(2mm) drill bit. Insert the bent wire pushrods into

the servo horn from the upper side, then secure

them with Nylon FasLink Pushrod Keepers.

Q Thread clevises onto the 26-3/4" (680mm)

pushrods using the same technique as the aileron

pushrods. Insert the pushrods into the rudder and

elevator pushrod tubes as shown in the photo.

Attach the clevises for both the elevator and rudder

to the control horns as shown. (Both clevises are

attached in the same locations.)

Q

0 Center the elevator, then mark the pushrod

where it crosses the servo horn hole. Enlarge the

servo horn hole with a 5/64" (2mm) drill bit. Make

a 90 degree bend in the pushrod at the mark (you

may want to disconnect the clevis from the elevator

control horn to pull the pushrod wire out of the

fuselage to make it easier to bend). Cut off the

excess wire 3/8" (9.5mm) above the bend. Insert the

bent wire through the enlarged hole in the servo

horn. Secure it in place with a nylon FasLink.

Q Repeat the above step for the rudder pushrod.

1-1 Adjust the height of the pushrod support so the

pushrods can move freely without binding. Glue the

brace into position using medium CA. Slide the

pushrod tubes so 1/8" (3mm) extends forward of

the pushrod support. Glue the pushrod tubes to the

brace using thin CA. Be very careful not to get CA

into the tubes and accidentally glue the pushrod

wires to the tubes. Glue the pushrod tubes to the

fuselage using medium CA.

l-l With the radio on, move the throttle trim lever

and control stick to the closed position, by pulling

them back (or downward) all the way. Manually

close the throttle on the carburetor completely.

Tighten the set screw on the pushrod connector.

Check throttle operation with the radio and make

adjustments to the linkage as necessary for smooth

operation from fully closed to fully open. Use the

appropriate holes in the servo horn and throttle

arm to provide the correct amount of throttle

movement and to prevent the servo from binding

at its end points.

Q Install the nose wheel using the same technique

as the main wheels. Center the nose wheel and

tighten the screw on the pushrod connector for the

nose wheel steering.

18

Page 20

NOTE: This section is VERY important and must

NOT be omitted! A model that is not properly

balanced will be unstable and possibly unflyable.

Q Use a felt tip pen or a narrow strip of tape to

accurately mark the balance point on the bottom of

the wing near both sides of the fuselage. The

balance point (CG) on the Avistar 40 is located

3-1/4" (83mm) back from the leading edge. This is

the point at which your model should balance for

your first flights. Later, you may experiment by

shifting the balance up to 5/16" (8mm) forward or

back to change the flying characteristics. Moving

the balance forward may improve the smoothness

and arrow-like tracking, but it may require more

speed for takeoff and make it more difficult to slow

down for landing. Moving the balance aft makes the

model more agile with a lighter and snappier feel.

Please start at the location we recommend and do

not at any time balance your model outside the

recommended range.

Plug the aileron servo into the receiver. Mount the

wing to the fuselage with #64 rubber bands. The

engine, muffler, propeller and fuel tank should also

be mounted for the C.G. check.

With the fuel tank empty and the wing attached to

the fuselage, lift the model with your finger tips at

the balance point. If the tail drops when you lift,

the model is "tail heavy" and you must move the

battery and/or the receiver toward the nose to

achieve balance. If the nose drops, it's "nose heavy"

and you must move the battery and/or receiver

toward the tail to achieve balance. The C.G. is

always determined with the fuel tank empty.

Balance the model by shifting the receiver battery

and receiver, then test again. When balance is

obtained note the position of the of the receiver,

and the battery pack. If the balance cannot be

achieved by positioning the battery and receiver,

you may add stick-on lead weight to the tail or

nose if required.

Confirm that the battery and receiver are securely

wrapped in foam and secured so they cannot shift

during flight or a rough landing.

IMPORTANT: After the model is 100% complete,

recheck the balance.

IMPORTANT: Go back and check your installation.

Be sure that all servo screws, horns and other

components are secure. Confirm that you have

installed the retainers on the screw lock connectors.

Apply a strip of 1/16" (1.5mm) thick foam wing-

seating tape (not included) to the wing saddle.

This tape provides a seal against dirt and exhaust

oil and cushions the wing from vibration.

4-CHANNEL RADIO SETUP

(STANDARD MODE 2)

ELEVATOR MOVES UP

RIGHT AILERON MOVES UP

LEFT AILERON MOVES DOWN

RUDDER MOVES RIGHT

CARBURETOR WIDE OPEN

Q Check the direction of all control functions. They

must all move in the direction shown in the sketch.

If not, change the position of the reversing

switches on your transmitter.

3-1/4" (83mm)

19

Page 21

Control Surface Throws

We recommend the following throws:

NOTE: Control throw (movement) is measured

at the trailing edge of the elevator, rudder and

ailerons. Hold a ruler vertically on your

workbench or block it up on books to make

these measurements.

ELEVATOR: 3/8" up

3/8" down

RUDDER:

3/4" right 3/4" left

AILERONS: 5/16" up 5/16" down

NOTE: The balance and control throws for the

Avistar 40 have been thoroughly tested and

represent the settings at which the Avistar 40

flies best. Please set up your Avistar 40 to the

specifications listed. If, after a few flights, you

would like to adjust the throws to suit your

taste, that's fine. Remember, "more is not better."

Note: If your radio system does not feature

Adjustable Travel Volume (ATV's), you will have to

mechanically adjust control surface throw.

Q Control throw adjustment: If you move the clevis

at the control horn on the control surface toward

the outermost hole, you will decrease the amount

of throw. If you move the clevis to a hole nearer the

control surface you will increase the amount of

throw. If these adjustments do not provide the

desired throws, you may need to work with a

combination of adjustments by repositioning the

pushrod at the servo. If you move the pushrod

toward the splined shaft on the servo arm, it will

decrease the control surface throw - outward will

increase it.

Ground Stance

NOSE

TOO HIGH

NOSE

TOO LOW

LEVEL

Q "Eyeball" the side of the fuselage from 6 - 10 feet

away. If necessary adjust the height of the nose by

raising or lowering the nose gear wire so that your

model will sit pretty much level, as shown in

the sketches.

Once the correct ground stance is established,

tighten the screws on both the steering arm and

wheel collar on the flat spot of the nose gear wire to

lock the nose gear strut in position. Use thread lock

on both screws.

It is a good practice to periodically check the ground

stance of your Avistar 40 - especially after a hard

landing. The wire landing gear is designed to absorb

shock from rough landings but occasionally may

need to be bent back into position.

Charge the Batteries

Follow the battery charging procedures in your

radio instruction manual. You should always

charge your transmitter and receiver batteries the

night before you go flying and at other times as

recommended by the radio manufacturer.

Balance the Propeller

Balance your propellers carefully before flying. An

unbalanced prop is the single most significant

cause of vibration. Not only will engine mounting

screws and bolts vibrate out, possibly with

disastrous effect, but vibration will also damage

your radio receiver and battery. Vibration will

cause your fuel to foam, which will, in turn, cause

your engine to run lean or quit.

We use a Top Flite' Precision Magnetic Prop

Balancer'" (#TOPQ5700) in the workshop and keep

a Great Planes Fingertip Balancer" (#GPMQ5000)

in our flight box.

20

Page 22

Find a Safe Place to Fly

The best place to fly your R/C model is an AMA

(Academy of Model Aeronautics) chartered club

field. Ask your hobby shop dealer if there is such a

club in your area and join. Club fields are set up for

R/C flying and that makes your outing safer and

more enjoyable. The AMA also can tell you the

name of a club in your area. We recommend that

you join AMA and a local club so you can have a

safe place to fly and have insurance to cover you in

case of a flying accident (The AMA address is listed

on page 3 of this instruction book).

If a club and its flying site are not available, you

need to find a large, grassy area at least 6 miles

away from any other R/C radio operation like R/C

boats and R/C cars and away from houses,

buildings and streets. A schoolyard may look

inviting but it is too close to people, power lines

and possible radio interference.

Ground Check the Model

If you are not thoroughly familiar with the

operation of R/C models, ask an experienced

modeler to check that you have installed the radio

correctly and all the control surfaces do what they

are supposed to. The engine operation also must

be checked and the engine "broken-in" on the

ground by running the engine for at least two tanks

of fuel. Follow the engine manufacturer's

recommendations for break-in. Check to make

sure all screws remain tight, that the hinges are

secure and that the prop is on tight.

Range Check Your Radio

Whenever you go to the flying field, you need to

check the operational range of the radio before the

first flight of the day. First, make sure no one else is

on your frequency (channel). With your transmitter

antenna collapsed and the receiver and transmitter

on, you should be able to walk at least 100 feet away

from the model and still have control. Have a friend

stand by your model and, while you work the

controls, tell you what the control surfaces are

doing. Repeat this test with the engine running at

various speeds with a helper holding the model. If

the control surfaces are not always acting correctly,

do not fly! Find and correct the problem first. Look

for loose servo connections or corrosion, loose

bolts that may cause vibration, a defective on/off

switch, low battery voltage or a defective cell, a

damaged receiver antenna, or a receiver crystal that

may have been damaged from a previous crash.

Engine Safety Precautions

NOTE: Failure to follow these safety precautions

may result in severe injury to yourself and others.

Keep all engine fuel in a safe place, away from high

heat, sparks or flames as fuel is very flammable. Do

not smoke near the engine or fuel; and remember

that the engine exhaust gives off a great deal of

deadly carbon monoxide. Do not run the engine in

a closed room or garage.

Get help from an experienced pilot when learning

to operate engines.

Use safety glasses when starting or running engines

and make all engine adjustments from behind the

rotating propeller.

Do not run the engine in an area of loose gravel or

sand; the propeller may throw such material in

your face or eyes.

Keep your face and body as well as all spectators

away from the plane of rotation of the propeller as

you start and run the engine.

Keep items such as these away from the prop:

loose clothing, shirt sleeves, ties, scarfs, long hair

or loose objects such as pencils, screw drivers that

may fall out of shirt or jacket pockets into the prop.

Use a "chicken stick" device or electric starter;

follow instructions supplied with the starter or

stick. Make certain the glow plug clip or connector

is secure so that it will not pop off or otherwise get

into the running propeller.

The engine gets hot! Do not touch it during or after

operation. Make sure fuel lines are in good

condition so fuel will not leak onto a hot engine

causing a fire.

21

Page 23

Page 24

Page 25

Your first flights should consist of mostly straight

and level flight with gentle turns to keep the model

over the field. These flights will give you practice at

coordinating your control inputs and maintaining

the proper orientation of the airplane. As

mentioned earlier, turns are accomplished by

banking the aircraft with the ailerons, then gently

adding some back stick (up elevator). Enough back

stick should be held in to keep the aircraft at a

constant altitude. To stop turning, apply opposite

aileron (or rudder) to level the wings, then release

the sticks. There is a memory aid that may help

keep you out of trouble when the plane is flying

toward you - "put the stick under the low wing." In

other words, move the stick in the direction of the

low wing to raise that wing. When you are

comfortable flying the aircraft, you can practice

using the rudder along with the ailerons to

"coordinate" the turns - usually, a small amount of

rudder applied in the direction of the turn will

keep the tail following in the exact same track as

the nose.

The most common mistake when learning to fly is

"over control." Think of pressure instead of large

movements of the control sticks. Remember all

Avistar 40's will recover from almost any over

control situation within 50 - 100 feet if you simply

let go of the sticks.

Add and practice one maneuver at a time, learning

how your Avistar 40 behaves in each maneuver.

After you have several flights on your Avistar 40, it's

time to reward yourself with your first acrobatic

maneuver - a

loop.

Climb to a safe altitude and

turn into the wind. Apply full throttle, level the

wings, then slowly pull back on the elevator stick to

about 1/2 to 3/4 up elevator (depending on your

throws) and hold this control input. After you go

over the top and start down the back side of the

loop, pull the throttle back to about half. This will

keep the stresses on the airplane low and the

airspeed relatively constant. Keep holding "up"

elevator until the plane is level, then slowly release

the sticks. You're done! It's really that easy!

CAUTION (THIS APPLIES TO ALL R/C

AIRPLANES): If, while flying, you notice any

unusual sounds, such as a low-pitched "buzz",

this may indicate control surface "flutter".

Because flutter can quickly destroy components

of your airplane, any time you detect flutter you

must immediately cut the throttle and land the

airplane! Check all servo grommets for

deterioration (this will indicate which surface

fluttered) and make sure all pushrod linkages

are slop-free. If it fluttered once, it will probably

flutter again under similar circumstances unless

you can eliminate the slop or flexing in the

linkages. Here are some things which can result

in flutter: Excessive hinge gap; Not mounting

control horns solidly; Sloppy fit of clevis pin in

horn; Elasticity present in flexible plastic

pushrods; Side-play of pushrod in guide tube

caused by tight bends; Sloppy fit of Z-bend in

servo arm; Insufficient glue used when gluing in

the elevator joiner wire or aileron torque rod;

Excessive flexing of aileron, caused by using too

soft balsa aileron; Excessive "play" or "backlash"

in servo gears; and Insecure servo mounting.

Landing

When it's time to land, fly a normal landing

pattern and approach as follows: Reduce the

power to about 1/4 and fly a downwind leg far

enough out from the runway to allow you to make

a gentle 180 degree turn. As you make the turn into

the wind for your final approach, pull the throttle

back to idle. The Avistar 40 has a lot of lift so you

will need a slow, reliable idle in order to achieve

a nice, slow landing. Allow the plane to keep

descending on a gradual glide slope until you are

about 3 feet off the runway. Gradually apply a little

up elevator to flare for landing. You should apply

just enough up elevator to hold the plane just off

the runway while the excess speed bleeds off. The

Avistar 40 should settle onto the runway for a slow,

slightly nose-high landing.

Good luck and have fun flying your Avistar 40, but

always stay in control and fly in a safe manner.

Loading...

Loading...