Hobart Welding Products HWC-115A User Manual

OM-185 480B

March 1999

Processes

MIG (GMAW) Welding

Description

Weld Control For Spoolmatic Gun

HWC-115A

From Hobart to You

Thank you and congratulations on choosing Hobart.

Now you can get the job done and get it done right.

We know you don’t have time to do it any other way.

This Owner’s Manual is designed to help you get the

most out of your Hobart products. Please take time

to read the Safety precautions. They will help you

protect yourself against

potential hazards on the

worksite. We’ve made

installation and operation

quick and easy. With Hobart you can count on

years of reliable service with proper

maintenance. And if for some reason the unit

Hobart is registered to the

ISO 9001 Quality System

Standard.

needs repair, there’s a Troubleshooting section

that will help you figure out what the problem

is. The parts list will then help you to decide

which exact part you may need to fix the

problem. Warranty and service information for

your particular model are also provided.

Hobart Welders manufactures a full line

of welders and welding related equipment.

For information on other quality Hobart

products, contact your local Hobart distributor

to receive the latest full line catalog or

individual catalog sheets. To locate your nearest

distributor or service agency call 1-877-Hobart1.

Hobart offers a Technical

Manual which provides

more detailed service and

parts information for your

unit. T o obtain a Technical

Manual, contact your local

distributor. Your distributor

can also supply you with

Welding Process Manuals

such as SMAW, GTAW,

GMAW, and GMA W-P.

SECTION 1 – SAFETY PRECAUTIONS FOR ARC WELDING

OM-185 480 – 2/97

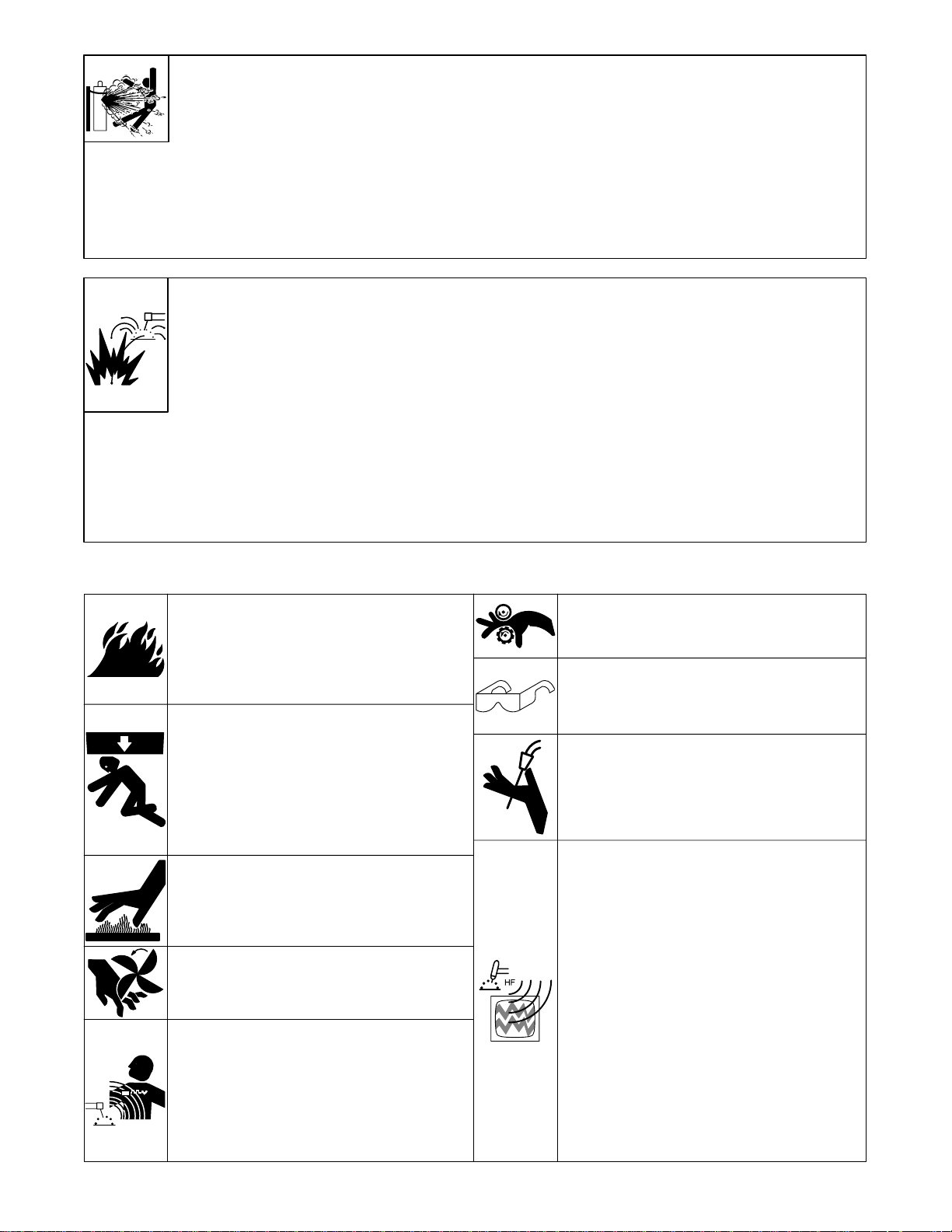

1-1. Symbol Usage

safety_som1 4/95

Means Warning! Watch Out! There are possible hazards with this

procedure! The possible hazards are shown in the adjoining symbols.

This group of symbols means Warning! Watch Out! possible ELECTRIC SHOCK, MOVING

PARTS, and HOT PARTS hazards. Consult symbols and related instructions below for necessary

actions to avoid the hazards.

Y Marks a special safety message.

. Means NOTE; not safety related.

1-2. Arc Welding Hazards

WARNING

The symbols shown below are used throughout this manual to call attention to and identify possible

hazards. When you see the symbol, watch out, and follow the related instructions to avoid the hazard. The

safety information given below is only a summary of the more complete safety information found in the

Safety Standards listed in Section 1-4. Read and follow all Safety Standards.

Only qualified persons should install, operate, maintain, and repair this unit.

During operation, keep everybody, especially children, away.

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal

shocks or severe burns. The electrode and work

circuit is electrically live whenever the output is on.

The input power circuit and machine internal

circuits are also live when power is on. In

semiautomatic or automatic wire welding, the wire,

wire reel, drive roll housing, and all metal parts

touching the welding wire are electrically live.

Incorrectly installed or improperly grounded

equipment is a hazard.

1. Do not touch live electrical parts.

2. Wear dry, hole-free insulating gloves and body protection.

3. Insulate yourself from work and ground using dry insulating

mats or covers big enough to prevent any physical contact with

the work or ground.

4. Disconnect input power or stop engine before installing or

servicing this equipment. Lockout/tagout input power according

to OSHA 29 CFR 1910.147 (see Safety Standards).

5. Properly install and ground this equipment according to its

Owner’s Manual and national, state, and local codes.

6. Always verify the supply ground – check and be sure that input

power cord ground wire is properly connected to ground

ARC RAYS can burn eyes and skin;

NOISE can damage hearing; FLYING

SLAG OR SPARKS can injure eyes.

Arc rays from the welding process produce intense

visible and invisible (ultraviolet and infrared) rays

that can burn eyes and skin. Noise from some

processes can damage hearing. Chipping,

grinding, and welds cooling throw off pieces of

NOISE

1. Use approved ear plugs or ear muffs if noise level is high.

metal or slag.

terminal in disconnect box or that cord plug is connected to a

properly grounded receptacle outlet.

7. When making input connections, attach proper grounding

conductor first – double-check connections.

8. Frequently inspect input power cord for damage or bare wiring –

replace cord immediately if damaged – bare wiring can kill.

9. Turn off all equipment when not in use.

10. Do not use worn, damaged, undersized, or poorly spliced

cables.

11. Do not drape cables over your body.

12. If earth grounding of the workpiece is required, ground it directly

with a separate cable – do not use work clamp or work cable.

13. Do not touch electrode if you are in contact with the work,

ground, or another electrode from a different machine.

14. Use only well-maintained equipment. Repair or replace

damaged parts at once. Maintain unit according to manual.

15. Wear a safety harness if working above floor level.

16. Keep all panels and covers securely in place.

17. Clamp work cable with good metal-to-metal contact to

workpiece or worktable as near the weld as practical.

ARC RAYS

2. Wear a welding helmet fitted with a proper shade of filter to

protect your face and eyes when welding or watching (see ANSI

Z49.1 and Z87.1 listed in Safety Standards).

3. Wear approved safety glasses with side shields.

4. Use protective screens or barriers to protect others from flash

and glare; warn others not to watch the arc.

5. Wear protective clothing made from durable, flame-resistant

material (wool and leather) and foot protection.

FUMES AND GASES can be

hazardous to your health.

Welding produces fumes and gases. Breathing

these fumes and gases can be hazardous to your

health.

1. Keep your head out of the fumes. Do not breathe the fumes.

2. If inside, ventilate the area and/or use exhaust at the arc to

remove welding fumes and gases.

3. If ventilation is poor, use an approved air-supplied respirator.

4. Read the Material Safety Data Sheets (MSDSs) and the

manufacturer’s instruction for metals, consumables, coatings,

cleaners, and degreasers.

5. Work in a confined space only if it is well ventilated, or while

wearing an air-supplied respirator. Always have a trained

watchperson nearby . Welding fumes and gases can displace air

and lower the oxygen level causing injury or death. Be sure the

breathing air is safe.

6. Do not weld in locations near degreasing, cleaning, or spraying

operations. The heat and rays of the arc can react with vapors to

form highly toxic and irritating gases.

7. Do not weld on coated metals, such as galvanized, lead, or

cadmium plated steel, unless the coating is removed from the

weld area, the area is well ventilated, and if necessary, while

wearing an air-supplied respirator . The coatings and any metals

containing these elements can give off toxic fumes if welded.

OM-185 480 Page 1

CYLINDERS can explode if damaged.

Shielding gas cylinders contain gas under high

pressure. If damaged, a cylinder can explode.

Since gas cylinders are normally part of the welding

process, be sure to treat them carefully.

1. Protect compressed gas cylinders from excessive heat,

mechanical shocks, slag, open flames, sparks, and arcs.

2. Install cylinders in an upright position by securing to a stationary

support or cylinder rack to prevent falling or tipping.

3. Keep cylinders away from any welding or other electrical

circuits.

4. Never drape a welding torch over a gas cylinder.

5. Never allow a welding electrode to touch any cylinder.

6. Never weld on a pressurized cylinder – explosion will result.

7. Use only correct shielding gas cylinders, regulators, hoses, and

fittings designed for the specific application; maintain them and

associated parts in good condition.

8. T urn face away from valve outlet when opening cylinder valve.

9. Keep protective cap in place over valve except when cylinder is

in use or connected for use.

10. Read and follow instructions on compressed gas cylinders,

associated equipment, and CGA publication P-1 listed in Safety

Standards.

WELDING can cause fire or

explosion.

Welding on closed containers, such as tanks,

drums, or pipes, can cause them to blow up. Sparks

can fly off from the welding arc. The flying sparks,

hot workpiece, and hot equipment can cause fires

and burns. Accidental contact of electrode to metal

objects can cause sparks, explosion, overheating,

or fire. Check and be sure the area is safe before

doing any welding.

1. Protect yourself and others from flying sparks and hot metal.

2. Do not weld where flying sparks can strike flammable material.

3. Remove all flammables within 3 5 f t (10.7 m) of the welding arc. If

this is not possible, tightly cover them with approved covers.

4. Be alert that welding sparks and hot materials from welding can

easily go through small cracks and openings to adjacent areas.

5. Watch for fire, and keep a fire extinguisher nearby.

6. Be aware that welding on a ceiling, floor, bulkhead, or partition

can cause fire on the hidden side.

7. Do not weld on closed containers such as tanks, drums, or

pipes, unless they are properly prepared according to AWS F4.1

(see Safety Standards).

8. Connect work cable to the work as close to the welding area as

practical to prevent welding current from traveling long, possibly

unknown paths and causing electric shock and fire hazards.

9. Do not use welder to thaw frozen pipes.

10. Remove stick electrode from holder or cut off welding wire at

contact tip when not in use.

11. Wear oil-free protective garments such as leather gloves, heavy

shirt, cuffless trousers, high shoes, and a cap.

12. Remove any combustibles, such as a butane lighter or matches,

from your person before doing any welding.

1-3. Additional Installation, Operation, And Maintenance Hazards

FIRE OR EXPLOSION can result from

placing unit on, over, or near

combustible surfaces.

1. Do not locate unit on, over, or near combustible

surfaces.

2. Do not install unit near flammables.

FALLING EQUIPMENT can cause

serious personal injury and equipment

damage.

1. Use lifting eye to lift unit only, NOT running gear,

gas cylinders, or any other accessories.

2. Use equipment of adequate capacity to lift unit.

3. If using lift forks to move unit, be sure forks are

long enough to extend beyond opposite side of

unit.

HOT PARTS can cause severe burns.

1. Do not touch hot parts bare handed.

2. Allow cooling period before working on gun or

torch.

MOVING PARTS can cause injury.

1. Keep away from moving parts such as fans.

2. Keep all doors, panels, covers, and guards closed

and securely in place.

MAGNETIC FIELDS FROM HIGH

CURRENTS can affect pacemaker

operation.

1. Pacemaker wearers keep away.

2. Wearers should consult their doctor before going

near arc welding, gouging, or spot welding

operations.

MOVING PARTS can cause injury.

1. Keep away from moving parts.

2. Keep away from pinch points such as drive rolls.

FLYING PIECES OF MET AL or DIRT can

injure eyes.

1. Wear safety glasses with side shields or face

shield.

WELDING WIRE can cause puncture

wounds.

1. Do not press gun trigger until instructed to do so.

2. Do not point gun toward any part of the body, other

people, or any metal when threading welding wire.

HIGH-FREQUENCY RADIATION can

interfere with radio navigation, safety

services, computers, and

communications equipment.

1. Have only qualified persons familiar with

electronic equipment perform this installation.

2. The user is responsible for having a qualified

electrician promptly correct any interference

problem resulting from the installation.

3. If notified by the FCC about interference, stop

using the equipment at once.

4. Have the installation regularly checked and

maintained.

5. Keep high-frequency source doors and panels

tightly shut, keep spark gaps at correct setting,

and use grounding and shielding to minimize the

possibility of interference.

OM-185 480 Page 2

OVERUSE can cause OVERHEATED

EQUIPMENT.

1. Allow cooling period.

2. Reduce current or reduce duty cycle before

starting to weld again.

3. Follow rated duty cycle.

STATIC ELECTRICITY can damage parts

on circuit boards.

1. Put on grounded wrist strap BEFORE handling

boards or parts.

2. Use proper static-proof bags and boxes to store,

move, or ship PC boards.

1-4. Principal Safety Standards

SIGNIFICANT DC VOLTAGE exists after

removal of input power on inverters.

1. Turn Off inverter, disconnect input power, and

discharge input capacitors according to

instructions in Maintenance Section before

touching any parts.

BUILDUP OF SHIELDING GAS can harm

health or kill.

1. Shut of f shielding gas supply when not in use.

Safety in Welding and Cutting, ANSI Standard Z49.1, from

American Welding Society , 550 N.W . LeJeune Rd, Miami FL 33126

Safety and Health Standards, OSHA 29 CFR 1910, from

Superintendent of Documents, U.S. Government Printing Office,

Washington, D.C. 20402.

Recommended Safe Practices for the Preparation for Welding and

Cutting of Containers That Have Held Hazardous Substances,

American Welding Society Standard AWS F4.1, from American

Welding Society, 550 N.W. LeJeune Rd, Miami, FL 33126

National Electrical Code, NFPA Standard 70, from National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

1-5. EMF Information

Considerations About Welding And The Effects Of Low Frequency

Electric And Magnetic Fields

The following is a quotation from the General Conclusions Section

of the U.S. Congress, Office of Technology Assessment, Biological

Effects of Power Frequency Electric & Magnetic Fields –

Background Paper, OTA-BP-E-53 (Washington, DC: U.S.

Government Printing Office, May 1989): “. . . there is now a very

large volume of scientific findings based on experiments at the

cellular level and from studies with animals and people which clearly

establish that low frequency magnetic fields can interact with, and

produce changes in, biological systems. While most of this work is of

very high quality, the results are complex. Current scientific

understanding does not yet allow us to interpret the evidence in a

single coherent framework. Even more frustrating, it does not yet

allow us to draw definite conclusions about questions of possible

risk or to o ffer clear science-based advice on strategies to minimize

or avoid potential risks.”

Safe Handling of Compressed Gases in Cylinders, CGA Pamphlet

P-1, from Compressed Gas Association, 1235 Jefferson Davis

Highway, Suite 501, Arlington, VA 22202.

Code for Safety in Welding and Cutting, CSA Standard W117.2,

from Canadian Standards Association, Standards Sales, 178

Rexdale Boulevard, Rexdale, Ontario, Canada M9W 1R3.

Safe Practices For Occupation And Educational Eye And Face

Protection, ANSI Standard Z87.1, from American National

Standards Institute, 1430 Broadway, New York, NY 10018.

Cutting And Welding Processes, NFPA Standard 51B, from

National Fire Protection Association, Batterymarch Park, Quincy,

MA 02269.

To reduce magnetic fields in the workplace, use the following

procedures:

1. Keep cables close together by twisting or taping them.

2. Arrange cables to one side and away from the operator.

3. Do not coil or drape cables around the body.

4. Keep welding power source and cables as far away as

practical.

5. Connect work clamp to workpiece as close to the weld as

possible.

About Pacemakers:

The above procedures are also recommended for pacemaker

wearers. Consult your doctor for complete information.

OM-185 480 Page 3

SECTION 2 – INSTALLATION

2-1. Typical Process Connections

NOTE

Constant current and/or

constant voltage transformer

and engine-driven DC power

sources. If the power source

does not have a weld output

contactor, the optional

contactor kit should be

ordered.

Weld Power Cable (Not Included)

10 ft (3 m) Contactor Cord

10 ft (3 m) 115 VAC Power Cord

Use gun Owner’s Manual when making connections.

115 Volt

Control

2-2. Gun/Feeder Connections

40 ft (12 m) Gas Hose

30 ft (9 m) Control Cord

30 ft (9 m) Weld Power Cable

Voltage Sensing Lead For CC Mode

Work

1 Gun Control Receptacle

2 Weld Power Grommet

3 Regulator/Flowmeter

2

4 Gas Fitting

Tools Needed:

3

5/8, 3/4 in

Left Side

Wrapper Off

4

1

2

Ref. ST-149 966-C / Ref. ST-149 549-B / Ref. S-0621-C

OM-185 480 Page 4

Loading...

Loading...