Hobart Service CUH, CUL Service Manual

SERVICE MANUAL

CENTERLINE DISHWASHER

CUH, High Temp ML-130363

CUL, Low Temp ML-130364

- NOTICE -

This Manual is prepared for the use of trained Hobart Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Hobart Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Hobart Service Technician.

The reproduction, transfer, sale or other use of this manual,

without the express written consent of Hobart, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

A product of Hobart Service 701 S. Ridge Ave Troy, OH 45374

F45743 (0419)

CENTERLINE DISHWASHER

TABLE OF CONTENTS

GENERAL .................................................................................................. 3

INTRODUCTION ....................................................................................... 3

SPECIFICATIONS ...................................................................................... 3

TOOLS ................................................................................................. 4

WALL CHART .......................................................................................... 4

PROGRAMMING CARD ................................................................................ 4

OPERATION ERROR CARD ............................................................................ 5

PROGRAMMING ........................................................................................... 6

PROGRAMMING MENU ................................................................................ 6

CONFIGURATION MENU .............................................................................. 6

ELECTRICAL OPERATION ................................................................................. 8

COMPONENT LOCATION & DESCRIPTION ............................................................ 8

WIRING DIAGRAM ..................................................................................... 9

CONTROL BOARD - WIRE CONNECTIONS ........................................................... 10

SERVICE ADJUSTMENTS AND PROCEDURES ........................................................... 12

HYDRAULIC DIAGRAM (CUH ONLY) .................................................................. 12

WATER FLOW DIAGRAM

............................................................................. 13

REMOVAL AND REPLACEMENT ......................................................................... 14

SERVICE POSITION .................................................................................. 14

BOTTOM PANEL ...................................................................................... 15

FRONT PANEL ....................................................................................... 17

DOOR CATCH ........................................................................................ 18

DOOR SEAL & GASKET .............................................................................. 19

DOOR ................................................................................................ 20

CHEMICAL PUMP MOTORS .......................................................................... 22

WASH PUMP MOTOR ................................................................................ 24

RINSE PUMP MOTOR ................................................................................ 26

TRANSFORMER ...................................................................................... 27

BOOSTER ............................................................................................ 27

TROUBLESHOOTING ..................................................................................... 28

ERROR CODES ...................................................................................... 28

TROUBLESHOOTING DISHWARE .................................................................... 30

© HOBART SERVICE 2019

F45743 (0419) Page 2 of 31

CENTERLINE DISHWASHER - GENERAL

GENERAL

INTRODUCTION

Specified unit is NSF rated, ENERGY STAR® certified Centerline by Hobart high temperature undercounter

dishwasher. Features soft start, two selectable cycles, one standard 2-minute cycle with optional extended cycle

(factory set at 240 seconds); .84 gallons per rack, LED temperature and operator display, service diagnostics,

detergent and rinse aid pumps. Constructed of stainless steel.

MODELS

Model DESCRIPTION

CUH High temperature rinse.

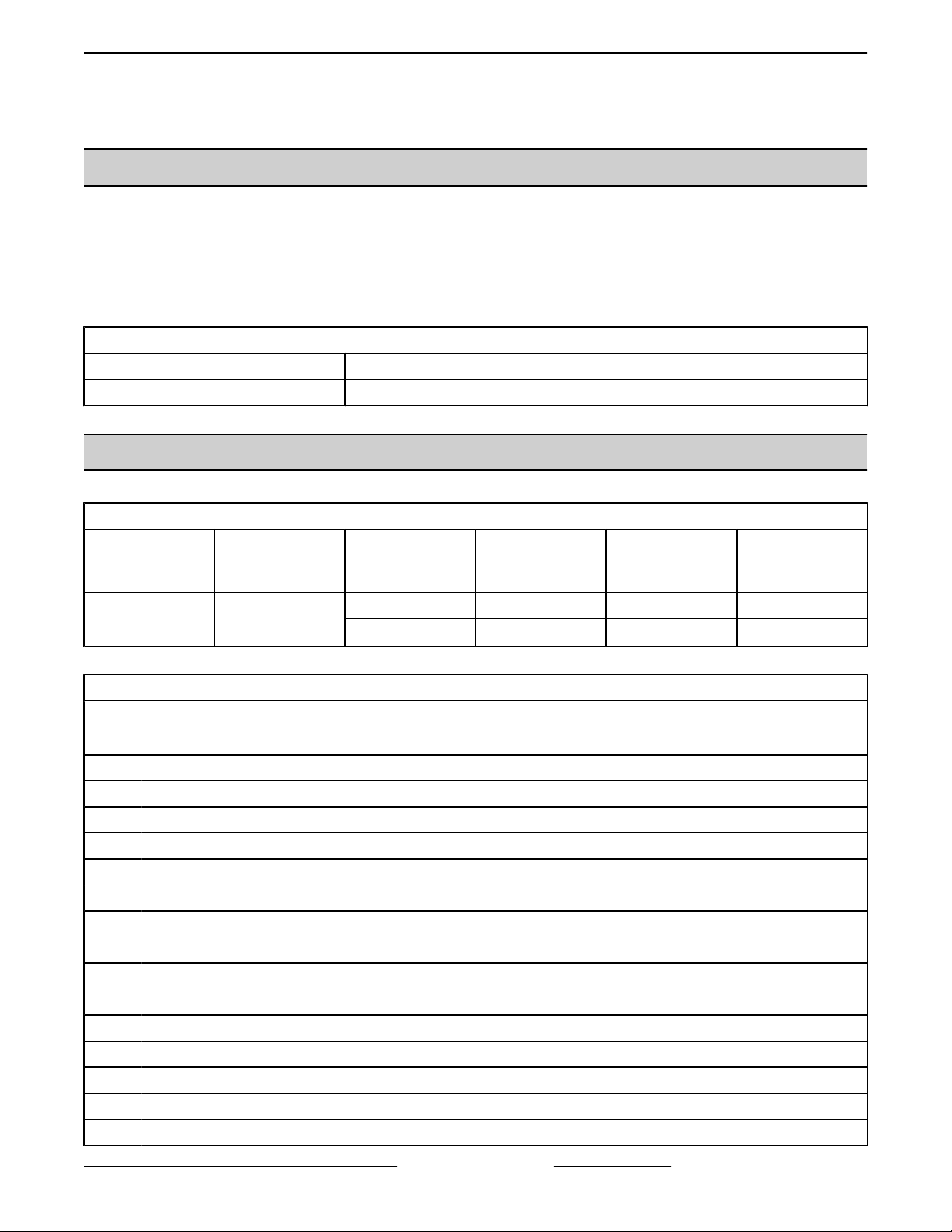

SPECIFICATIONS

STANDARD ELECTRICAL OPTIONS

MODEL HEAT TYPE ELEC SPECS RATED AMPS

CUH

Electric

High Temp Rinse

208/60/1 24.2 30 30

240/60/1 27.5 30 30

MIN SUPPLY

CIRCUIT

AMPACITY

MAXIMUM

PROTECTIVE

DEVICE

Capacities

Cycle Time (seconds) 120

Racks per Hour 24

Tank Capacity - US Gallons 5.3

Motor Horsepower

Wash 0.62

Rinse 0.20

Water Consumption

U.S. Gallons per Hour (maximum use) 20.2

U.S. Gallons per Rack (maximum use) 0.84

Peak Drain Flow - U.S. Gallons 2.8

Temperatures °F

Wash 150°F

Rinse 180°F

Incoming Water Temperature (minimum recommenced) 110°F

SPECIFICATIONS

CUH

High Temp Rinse

Page 3 of 31 F45743 (0419)

CENTERLINE DISHWASHER - GENERAL

SPECIFICATIONS

Heating

Tank Heat, electric (kW) 5.5

Electric Booster (kW) 6.0

Standard 20" x 20" (508 x 508) Rack Complement

Flat 1

Peg 1

Machine Timing

Wash Minimum 90 Sec.

Rinse Minimum 15 Sec.

Standard Tools

Standard set of hand tools.

•

CUH

High Temp Rinse

TOOLS

• Metric set of hand tools.

• VOM with measuring micro amp current tester. Any VOM with minimum of CAT III 600V, CE certified. Sensitivity

of at least 20,000 ohms per volt can be used. In addition, meter leads must also be a minimum of CAT III 600V.

• Clamp on type amp meter with minimum of NFPA-70E CAT III 600V, UL/CSA/TUV listed.

• Temperature tester (thermocouple type).

• Field service grounding kit.

Special Tools

• EW-199069 – Door Shim.

• EW-199070 – Door Side Shim.

• EW-199061 – Drain Body.

• EW-199067 – Lower Manifold Nut.

• EW-199068 – Upper Manifold Nut.

WALL CHART

Centerline Wall Chart

PROGRAMMING CARD

Programming Card

F45743 (0419) Page 4 of 31

Operation Error Card

CENTERLINE DISHWASHER - GENERAL

OPERATION ERROR CARD

Page 5 of 31 F45743 (0419)

CENTERLINE DISHWASHER - PROGRAMMING

PROGRAMMING

PROGRAMMING MENU

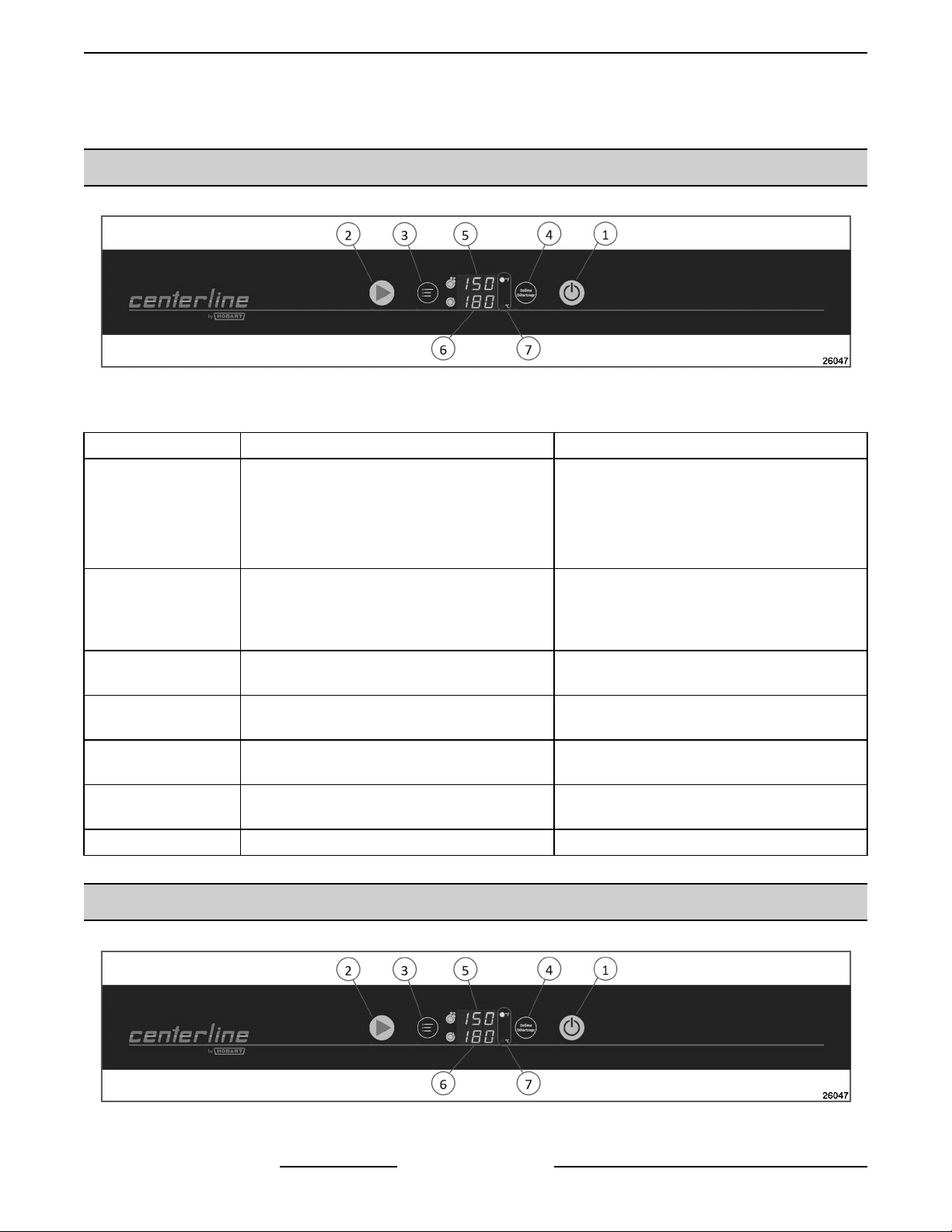

Fig. 1

ITEM NAME DESCRIPTION

Pressing this button switches the machine

on, fills and heats the wash tank.

1 Power / Drain Button

2 Start Button

3 Menu Button

4 Delime Button

5 Temperature Display, Wash Tank

6 Temperature Display, Rinse

7 Temperature Units LED lights for °F or °C.

Pressing and holding (3 seconds) activates

self-cleaning

switches the machine off automatically.

Pressing this button starts the wash cycle. If

pressed a 2nd time within 10 seconds of the

first press, the extended wash cycle is

activated.

Pressing this button enters the configuration

menu.

Pressing and holding this button (3 seconds)

initiates the deliming cycle.

Displays wash tank temperature while

machine is in ready state or in a wash cycle.

Displays rinse temperature only when rinse is

active.

cycle, drains machine, and then

CONFIGURATION MENU

Fig. 2

F45743 (0419) Page 6 of 31

CENTERLINE DISHWASHER - PROGRAMMING

ITEM NAME ITEM NAME

1 Power / Drain Button 5 Temperature Display, Wash Tank

2 Start Button 6 Temperature Display, Rinse

3 Menu Button 7 Temperature Units

4 Delime Button

1. Push and hold Power button to turn off machine.

2. While

3. With machine off and door open, press and hold "Menu" and "Delime" button simultaneously until display

4. Close door.

5. Press "Start" button until display reads 23 parameter.

6. Press "Delime" button to select 23 parameter.

7. Press "Power" button for 3 seconds, to select dishwasher parameter.

8. Press and hold "Power" button for 5 seconds to set parameter. LED light under Power button will flash indicating

9. Open door to exit program.

machine is draining, push and hold Power button within 20 seconds, until machine powers off and drain

stops.

changes.

NOTE: Verify LED lights, located underneath the buttons, are lit up.

• 01 = Cold Unit Program (CUL)

• 02 = Hot Unit Program (CUH)

selection is complete.

Page 7 of 31 F45743 (0419)

CENTERLINE DISHWASHER - ELECTRICAL OPERATION

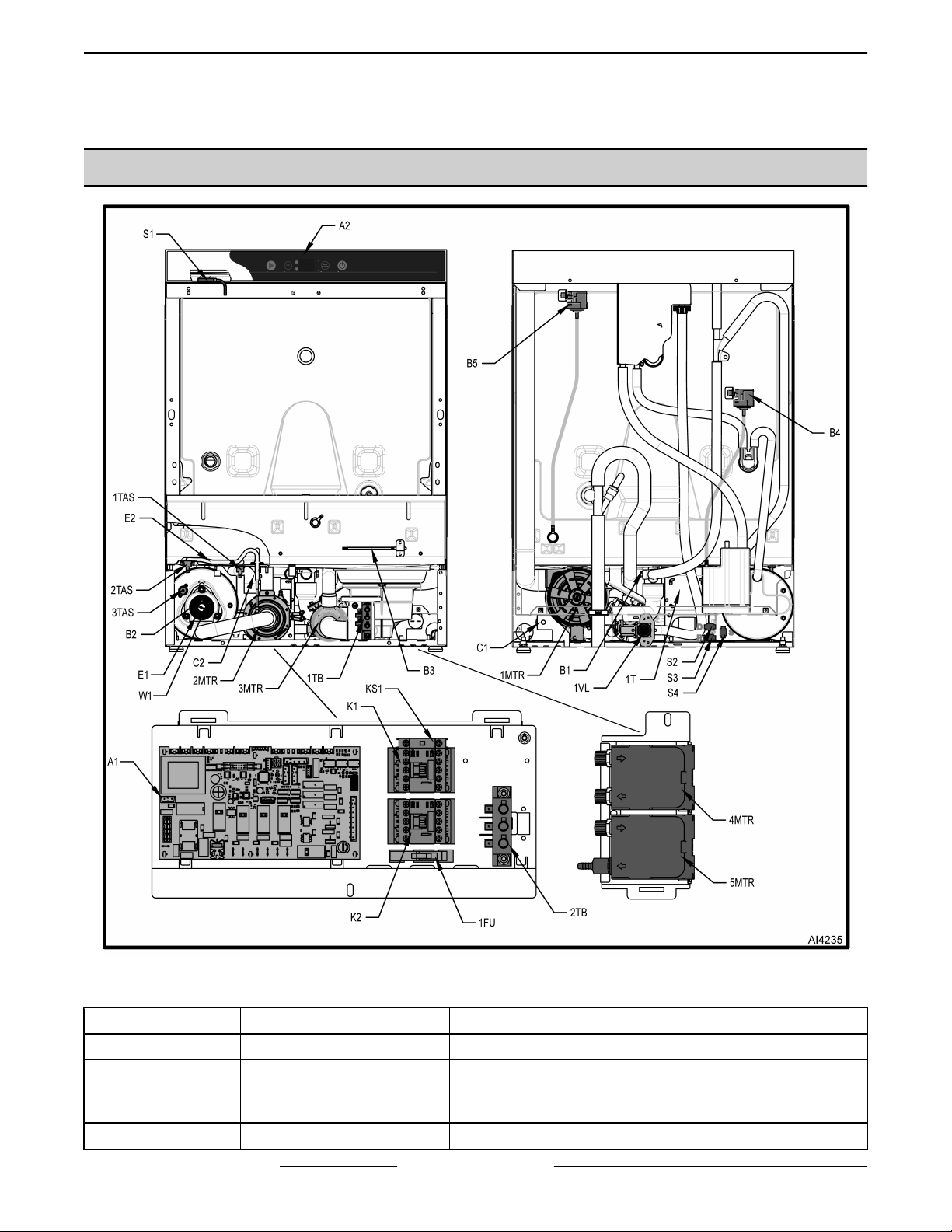

ELECTRICAL OPERATION

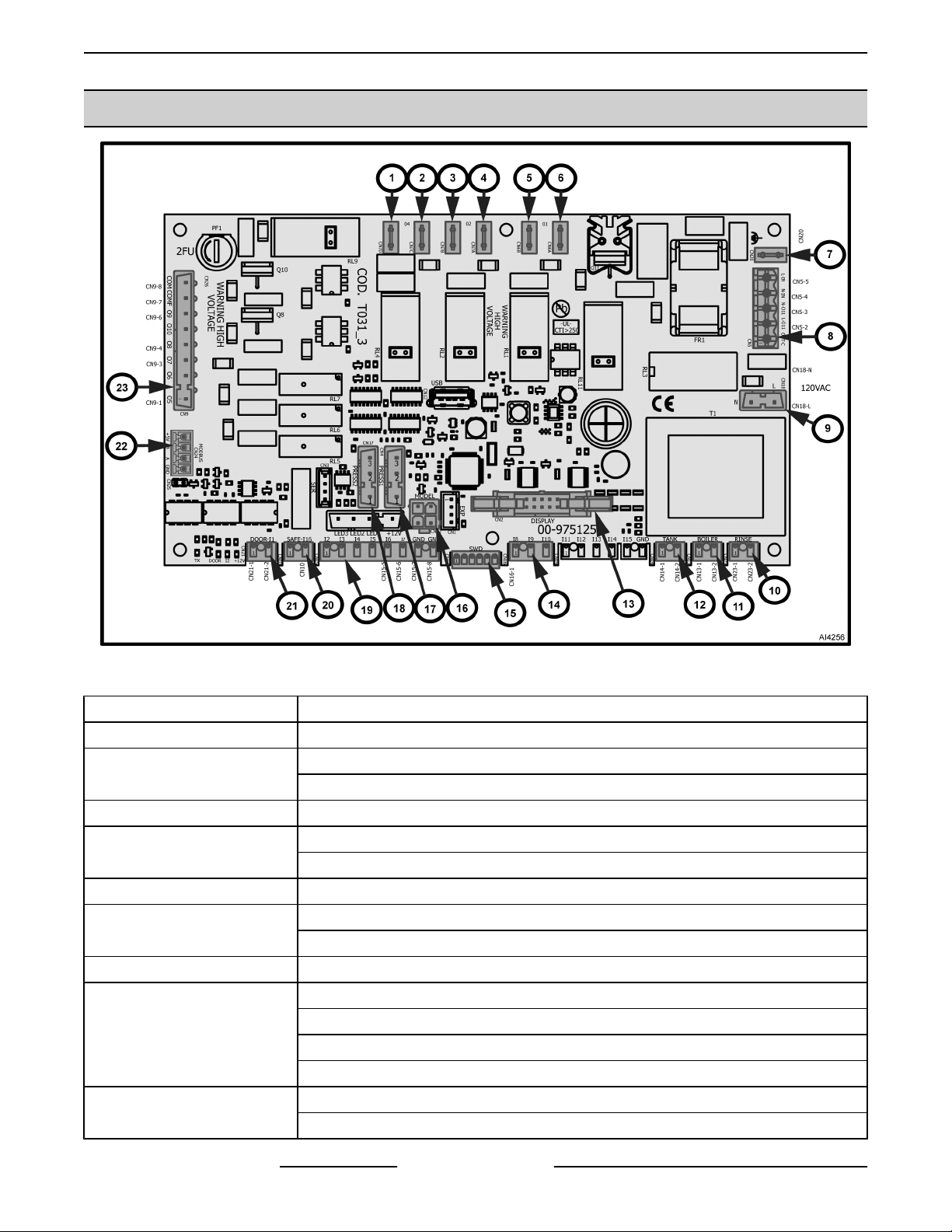

COMPONENT LOCATION & DESCRIPTION

Fig. 3

CALLOUT COMPONENT NAME DEFINITION

A1 Control Board Controls operation of dishwasher.

Provides user interface to control board. Visual display

A2 User Interface

B1 Rinse Probe Measures final rinse tank temperature.

F45743 (0419) Page 8 of 31

shown in window of keypad. Shows machine operation and

programming.

CENTERLINE DISHWASHER - ELECTRICAL OPERATION

CALLOUT COMPONENT NAME DEFINITION

B2 Booster Temp Probe Measures booster tank temperature.

B3 Tank Temp Probe Measures wash tank temperature.

B4 Booster Pressure Sensor

B5 Tank Pressure Sensor

C1 Wash Pump Capacitor

C2 Rinse Pump Capacitor

E1 Booster Heater Heats water in booster.

E2 Tank Heating Element Heats water in tank.

1FU Control Fuse Protects control board and overload from power surges.

K1 Booster Contactor Controls power to booster heater.

K2 Tank Contactor Controls power to tank heater.

KS1 Control Contactor Switch Controls power to tank heater thermostats (1TAS & 2TAS).

1MTR Wash Pump Motor Drives wash pump, which pumps for wash cycles.

2MTR Rinse Pump Motor Drives rinse pump, which pumps for rinse cycles.

3MTR Drain Pump Motor Drives drain pump, which pumps drain cycles.

4MTR Det. Pump

5MTR Rinse Aid Pump Drives rinse aid pump, which pumps rinse aid into machine.

S1 Door Switch Disables wash and rinse pumps while door is open.

S2 Det. Level Sensor Detects presence of detergent in tube.

S3 Rinse Aid Level Sensor Detects presence of rinse aid in tube.

S4 Sanitizer Level Sensor Detects presence of sanitizer in tube

1T Transformer

1TAS Tank Thermostat Tank temp sensor.

2TAS Tank Thermostat Tank temp sensor.

3TAS Booster Thermostat Booster temp sensor.

1TB Terminal Block Connects incoming line voltage to controls.

2TB Terminal Block Connects group neutral.

1VL Fill Valve

W1

Booster Heating Element

Bridge

Supplies mV reading for water level in booster. Acceptable

range: 0.5 - 0.78 mV.

Supplies mV reading for water level in tank. Acceptable

range: 0.5 - 0.73 mV.

Drives detergent pump, which pumps detergent into

machine.

Transforms primary voltage down to secondary voltage

(120VAC).

When energized, allows water to enter the holding tank or

booster.

Jumpers booster elements.

Centerline Wiring Diagram

WIRING DIAGRAM

Page 9 of 31 F45743 (0419)

CENTERLINE DISHWASHER - ELECTRICAL OPERATION

CONTROL BOARD - WIRE CONNECTIONS

Fig. 4

CALLOUT DESCRIPTION

1 To rinse pump motor.

2

3 To tank overtemp (1TAS).

4

5 To booster overtemp (3TAS).

6

7 CN20 connects to ground.

8

9

From main power through fuse (1FU).

CN7C connects to CN5-5.

CN7A connects to CN9-8 (COM).

CN7A connects to CN6A.

CN6A connects to CN7A.

CN6A connects to CN18L.

CN5-2 connects to wash pump motor (1MTR).

CN5-3 connects to wash pump motor (1MTR).

CN5-4 connects to 2TB-L.

CN5-5 connects to CN7C.

CN18-L connects to CN6A.

CN18-N connects to 2TB-N.

F45743 (0419) Page 10 of 31

CENTERLINE DISHWASHER - ELECTRICAL OPERATION

CALLOUT DESCRIPTION

10

11

12

13 Connects to display / user interface.

14 CN16-1 connects to sanitizer level sensor connector S4.

15 Not used.

16 CN22 - designated jumper.

17 PRESS1 to booster pressure sensor.

18 PRESS2 to tank pressure sensor.

19

20 CN10 jumpered.

21

22 MODBUS communications.

23

CN23-1 connects to rinse probe.

CN23-2 connects to rinse probe.

CN13-1 connects to booster temp probe CN13.

CN13-2 connects to booster temp probe CN13.

CN14-1 connects to tank temp probe CN14.

CN14-2 connects to tank temp probe CN14.

CN15-5 connects to rinse aid level sensor connector S3.

CN15-6 connects to detergent level sensor connector S2.

CN15-7 connects to detergent level sensor connector S2.

CN15-8 connects to rinse aid level sensor connector S3.

CN21-1 connects to door switch CN21.

CN21-2 connects to door switch CN21.

CN9-1 connects to fill valve.

CN9-3 connects to detergent pump motor.

CN9-4 connects to rinse aid pump motor.

CN9-6 connects to drain pump.

CN9-7 connects to transformer (1T-X1).

CN9-8 connects to CN7A.

NOTE:

board. 120VAC power from transformer X1 comes into board on CN9-7, goes

through PF1 fuse (2FU), comes back out on CN9-8 and then runs to tank heat board

relay, booster heat board relay, and then board power (CN18).

CN9-7 (COMF) and CN9-8 (COM) are connected to fuse 2FU (PF1) on the

Page 11 of 31 F45743 (0419)

Loading...

Loading...