Hobart Food Machines WS-P213 Installation Manual

INSTALLATION & PARTS

INSTRUCTIONS

HOBART

WATER SOFTENING

SYSTEM

WS-P213

- NOTICE This Manual is prepared for the use of trained Hobart Service

Technicians and should not be used by those not properly qualified.

If you have attended a Hobart Service School for this product, you

may be qualified to perform all the procedures described in this

manual.

This manual is not intended to be all encompassing. If you have not

attended a Hobart Service School for this product, you should read,

in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do not

have the necessary tools, instruments and skills should be

performed by a trained Hobart Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Hobart, is prohibited.

A product of HOBART TROY, OHIO 45374

F25312 (January 2009)

TABLE OF CONTENTS

INSTALLATION ............................................................................ 2

DISC SELECTION .......................................................................... 7

REPLACEMENT PARTS ..................................................................... 8

© HOBART 2009

INSTALLATION

SAVE THESE INSTRUCTIONS

1. Determine location to install equipment. Make

sure the unit will be on a flat surface.

2. If sand, silt, or turbidity is present, install a

separate prefilter.

3. Install by-pass valving. Be certain to note the

inlet and outlet arrows on the valve head.

4. Connect the inlet/outlet adapters leading to the

softener using the proper size plumbing.

5. Plumb as necessary to accommodate the bypas valve and to complete the installation.

NOTE: Actual installation of by-pass valving may

vary from installation to installation. Be sure to follow

state and local codes.

NOTE: When installing a plastic component in line, it

is recommended that grounding straps be put in

place before the lines are actually cut to ensure the

ground is never broken.

NOTE: Do not solder brass adapters while inserted

in the module base. Damage to plastic and rubber

parts may result due to the heat. In addition, the

materials used in the soldering process may attack

certain types of plastics.

F25312 (January 2009) Page 2 of 12

NOTE: Care should be taken during the installation

process to assure that solder and flux do not come in

contact with the media tanks, the control module,

and related components.

6. After all plumbing is completed, but before

connecting equipment, flush both the inlet and

outlet lines by opening the by-pass valve and

allowing water to rinse out any debris in the

lines.

7. Locate enclosed kit containing four O-rings, two

pipes with O-rings, and the silicone packet.

Apply a liberal amount of silicone to the four Orings, and the O-rings in the two pipes. Install

the four O-rings on the inlet/outlet adapters.

8. Connect the main tank with softener valve to the

inlet/outlet adapter. The inlet/outlet adapter is

inserted into the control valve and locked in

place by the plastic E-clips.

NOTE: Be certain the E-clips are fully inserted into

the valve. Check to make sure that all three tabs on

the E-clips are fully inserted.

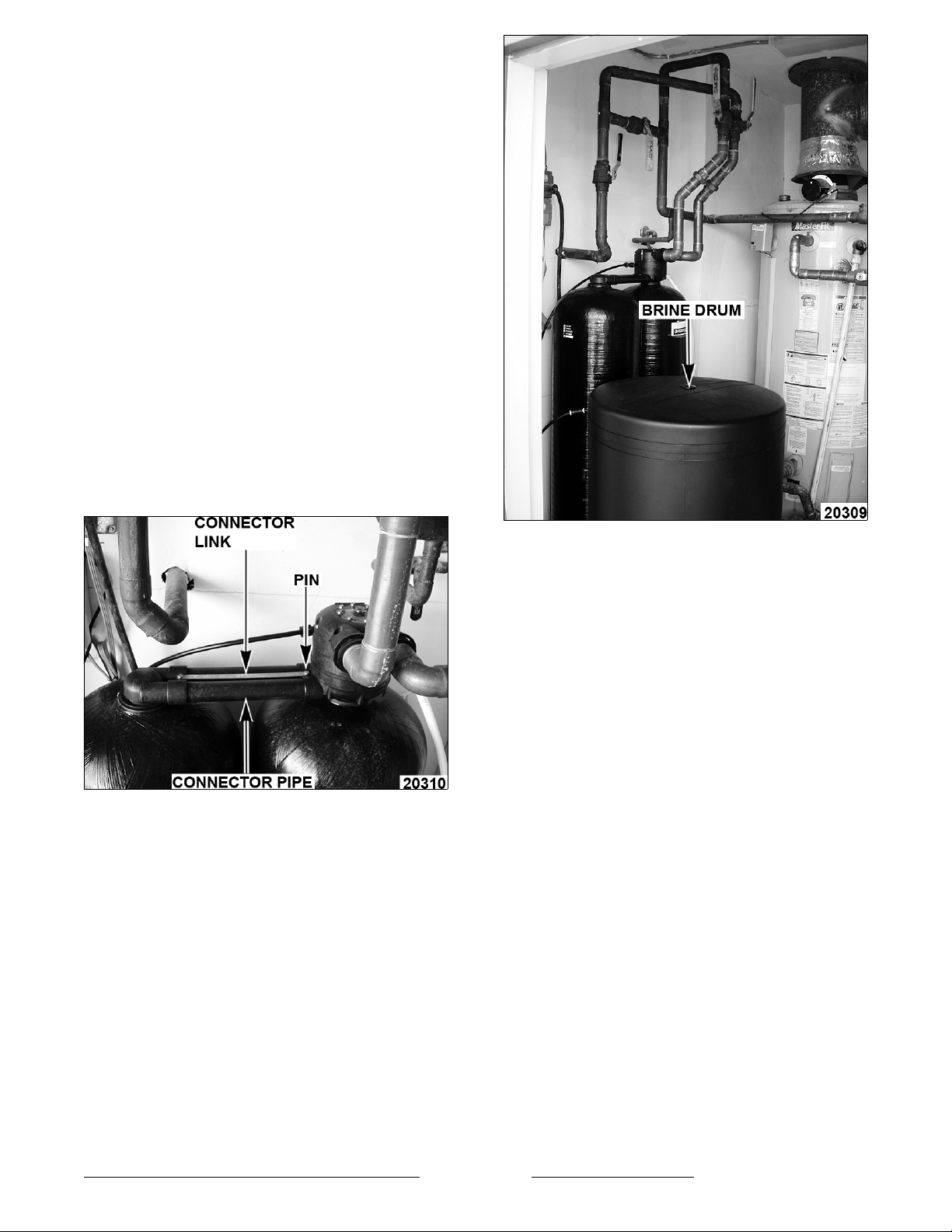

9. Connect the remote tank to the main tank using

connector pipes, connector links and connector

pins.

NOTE: Always use both links and pins.

10. Run a drain line to the discharge point.

NOTE: Follow state and local codes.

11. Before connecting unit, check for obstructions

or kinks. Apply Teflon tape to pipe threads on

side of softener valve, and install the two fittings

supplied. Connect drain line to valve.

NOTE: An air gap must be provided for all drain

lines. Check state and local plumbing codes for

proper setup of drain line air gaps.

NOTE: In Hobart Softeners, the brine drum mixes

and stores a solution of salt or potassium chloride for

regeneration of the softener media. During the brine

rinse cycle, this solution is drawn from the brine

drum and through the media to regenerate it.

The brine drum contains an adjustment to draw the

correct amount of salt or potassium chloride solution

for each cycle. This adjustment is made in two

places, the adjuster tube and the float cup.

NOTE: The adjuster tube measures the amount of

solution that is drawn from the brine drum into the

softener during the brine rinse cycle. The float cup

height determines how much softened water flows

back into the brine drum to prepare for the next

regeneration.

The adjuster tube is set by cutting and removing tabs

on both sides of the tube. Cut across each tab

horizontally, following the channel in the plastic.

Break off each tab individually until the proper setting

is reached. The remaining number or letter imprinted

on the tab determines the correct setting.

NOTE: On drain lines that must travel more than 8

feet up and 30 feet over, it is best to take the 5/8"

drain line that fits the valve and attach it in a larger

diameter line or pipe.

12. Position the brine drum.

F25312 (January 2009)Page 3 of 12

NOTE: The float cup height determines how much

softened water flows back into the brine drum to

prepare for the next regeneration.

The float cup is set by adjusting its height above the

bottom of the Brine Valve Assembly. By removing

the brine valve assembly and resting it on a flat

surface, the height of the float cup can be measured

with a ruler.

The height is measured from the base of the brine

valve assembly to the top of the float cup.

NOTE: Standard settings are defined by markings on

the rod of the brine valve assembly. Where the

predefined settings are not adequate, the actual float

cup height must be measured and the setting must

be measured and set according to the measured

float cup height.

Determining the correct brine valve setting for a

particular application is a three step process:

1. Determine the compensated hardness. This

requires a hardness test and an iron test on raw

water at the application site. Compensated

hardness is calculated by multiplying the ferrous

iron (in ppm) by 3 and adding it to the grains of

hardness.

F25312 (January 2009) Page 4 of 12

Loading...

Loading...