Hobart Food Machines SP-600 Service Manual

SUPERVISOR

MANUAL

SP600 ML-028945

SP600P ML-028946

SP600 & SP600P

F-34349 (June 2001)

SP600 Scale System

SP600

Supervisor Manual

Table of Contents

Introduction

Introduction ...........................................................................................................................1-2

FCC Note ................................................................................................................................1-3

Verify Correctness of Weight & Price...................................................................................1-3

Supervisor Manual Overview...............................................................................................1-3

How to Use This Manual.......................................................................................................1-4

General Information

General Information .............................................................................................................2-2

Electrical Connections ...........................................................................................................2-2

Communication Connections................................................................................................2-2

Resetting and Operating........................................................................................................2-3

Using the Keypad...................................................................................................................2-3

Accessing Supervisor Mode..................................................................................................2-4

Using Function Codes............................................................................................................2-4

Scale Setup

Setting Up Your Scale............................................................................................................3-2

Configuring the Time Format ...............................................................................................3-2

Configuring the Date Format................................................................................................3-2

Setting the Date/Time............................................................................................................3-4

Configuring the Scale ID & Store Information....................................................................3-4

Assigning the Scale ID........................................................................................................3-4

Setting Up the Store Name.................................................................................................3-5

Assigning the Store ID .......................................................................................................3-5

Configuring the Weight Symbol & Tare Suffix...................................................................3-6

Configuring the Weight Separator........................................................................................3-6

Configuring the Monetary Symbol & Separator..................................................................3-7

Setting the Display Time.......................................................................................................3-8

Using Operator Identification...............................................................................................3-9

Assigning an Operator ID.....................................................................................................3-9

Configuring the Scale to Accumulate Operator Totals....................................................3-11

Printing Operator Information on a Label.......................................................................3-12

Printing an Operator Access Report ................................................................................3-12

Deleting Operator IDs......................................................................................................3-12

Setting Up Speedkeys..........................................................................................................3-13

Adding a Speedkey..........................................................................................................3-13

Printing a Speedkey Overlay ...........................................................................................3-14

Deleting a Speedkey.........................................................................................................3-15

i © Hobart Corporation, 2001

SP600 Scale System

Classes & Products

Overview................................................................................................................................4-2

Working with Classes............................................................................................................4-2

Using the Hobart Recommended Class Structure.............................................................4-2

Adding a Class ...................................................................................................................4-5

Updating a Class ................................................................................................................4-6

Deleting a Class..................................................................................................................4-6

Working with Products..........................................................................................................4-7

Using an EAN Barcode ......................................................................................................4-7

Configuring EAN...............................................................................................................4-8

Adding a PLU (EAN).........................................................................................................4-9

Updating a PLU (EAN)....................................................................................................4-12

Using a UPC Barcode.......................................................................................................4-15

Adding a PLU (UPC) .......................................................................................................4-15

Updating a PLU (UPC) ....................................................................................................4-20

Updating the Price - ONLY!.............................................................................................4-22

Reviewing a Product........................................................................................................4-22

Printing PLU Files............................................................................................................4-23

Deleting a PLU .................................................................................................................4-23

Working with Support Files................................................................................................4-24

Special Messages..............................................................................................................4-24

Creating a Special Message.............................................................................................4-24

Editing a Special Message...............................................................................................4-25

Copying and Editing a Special Message...........................................................................4-25

Using a Special Message.................................................................................................4-26

Printing Special Messages ..............................................................................................4-26

Deleting a Special Message .............................................................................................4-27

Expanded Text .................................................................................................................4-27

Creating Expanded Text .................................................................................................4-28

Editing Expanded Text...................................................................................................4-28

Copying and Editing Expanded Text...............................................................................4-29

Using Expanded Text.....................................................................................................4-30

Printing Expanded Text .................................................................................................4-30

Deleting Expanded Text .................................................................................................4-31

Modes of Operation

Setting Up Operator Mode....................................................................................................5-2

Wait on a Customer Mode (Default).....................................................................................5-2

PrePack Mode.........................................................................................................................5-2

Additional PrePack Options ..............................................................................................5-3

Accumulate Items Mode........................................................................................................5-4

Setting Up Automatic PLU Lookup......................................................................................5-6

Setting What the Operator Can Override.............................................................................5-6

ii

SP600 Scale System

Labels

Working with Labels .............................................................................................................6-2

Label Stock Styles..................................................................................................................6-2

Butt Cut Labels...................................................................................................................6-2

Continuous Labels .............................................................................................................6-3

Listing Paper ......................................................................................................................6-3

Loading Labels.......................................................................................................................6-4

Label Types ............................................................................................................................6-5

Setting Up the Label..............................................................................................................6-6

Selecting Fields to Print (Selecting Date Line Options) .....................................................6-6

Printing a Header...............................................................................................................6-8

Printing the Product Description.......................................................................................6-9

Printing the Store Name...................................................................................................6-11

Printing Expanded Text ...................................................................................................6-12

Printing a Bar Code..........................................................................................................6-14

Printing the Weight..........................................................................................................6-14

Printing the Unit Price .....................................................................................................6-15

Printing the By Count Quantity.......................................................................................6-15

Printing the Product Life..................................................................................................6-16

Printing the Weight Symbol.............................................................................................6-17

Label Formats.......................................................................................................................6-18

Using 32 mm (1.25 in.) Labels ..........................................................................................6-18

Using 44 mm (1.75 in.) Labels ..........................................................................................6-20

Using 57 mm (2.25 in.) Labels ..........................................................................................6-21

Using 76 mm (3.0 in.) Labels............................................................................................6-23

Using Continuous Labels.................................................................................................6-25

Using Label Formats in Accumulate Items Mode ...........................................................6-26

Using Loadable Labels (RAM Labels) .............................................................................6-32

Totals

Working with Totals..............................................................................................................7-2

Production Totals...................................................................................................................7-2

Viewing Production Totals ................................................................................................7-2

Printing Production Totals.................................................................................................7-3

Clearing Production Totals ................................................................................................7-4

Operator Totals ......................................................................................................................7-4

Viewing Operator Totals....................................................................................................7-5

Printing Operator Totals ....................................................................................................7-5

Clearing Operator Totals....................................................................................................7-6

Backup or Restore

Backup or Restore (Read or Write)........................................................................................8-2

Backing Up to a Disk (Writing).............................................................................................8-3

Restoring from a Disk (Reading)..........................................................................................8-4

Backing Up or Restoring with MiniNet ...............................................................................8-5

Scanning for Bad Records .....................................................................................................8-7

iii

SP600 Scale System

Appendix

Function Codes .....................................................................................................................A-2

Determining the By Count Method...................................................................................A-12

Troubleshooting..................................................................................................................A-14

Service Functions................................................................................................................A-18

Checking ROM & RAM .....................................................................................................A-18

Checking Master ROM....................................................................................................A-18

Checking Slave ROM ......................................................................................................A-18

Checking Master RAM....................................................................................................A-19

Checking Slave RAM ......................................................................................................A-19

Checking the Display .........................................................................................................A-19

Checking the Numeric Display.......................................................................................A-19

Checking the Alpha Display...........................................................................................A-20

Testing the Keyboard .........................................................................................................A-20

Monitoring Sensors ............................................................................................................A-21

Printing Test Labels............................................................................................................A-22

Checking the EEP CRC.......................................................................................................A-22

Printing the Scale Configuration.......................................................................................A-22

Checking the Calibration ...................................................................................................A-23

Checking the Scale Counts.................................................................................................A-23

Testing the Communication Ports .....................................................................................A-23

Testing the Real Time Clock..............................................................................................A-24

Checking Country ROM.....................................................................................................A-24

iv

Chapter One: Introduction

♦ Introduction

♦ FCC Note

♦ Verify Correctness of Weight & Price

♦ Supervisor Manual Overview

♦ How to Use This Manual

SP600 Scale System

1-1 Introduction

SP600 Scale System

SP600 & SP600P

Scale Printer System

SAVE THESE INSTRUCTIONS

Introduction

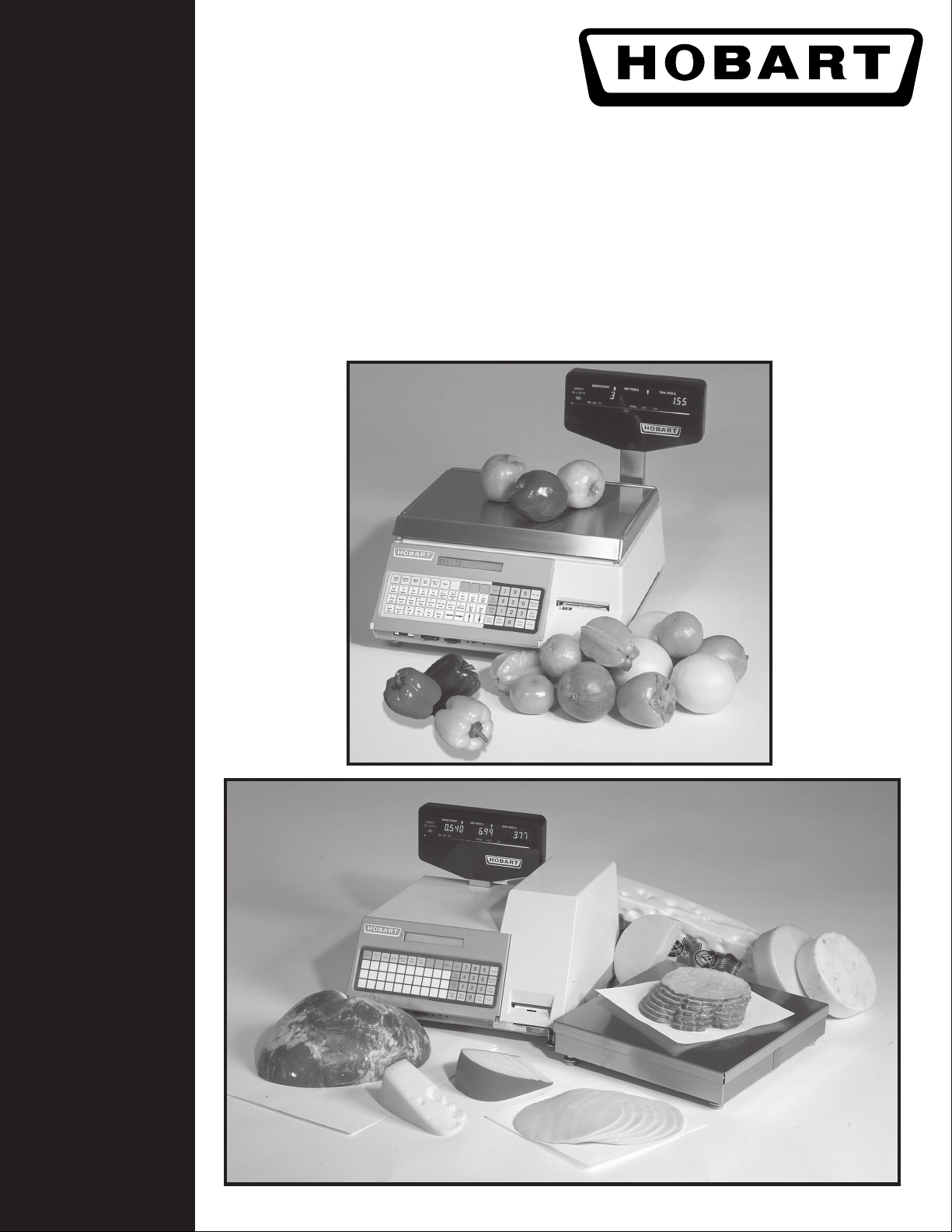

The SP600/SP600P Scale Printer System prints

merchandising labels used to identify price and to code a

variety of supermarket items. EAN or UPC barcode,

description, weight, unit price, total price, packed-on date,

sell by date, and use by date are some of the fields available

on labels. Expanded Text and Special Message fields enable

the SP600 to provide cooking instructions, ingredients

and/or special, promotional information.

The elevated display enables both customer and operator to

view numeric transaction data: Weight, Unit Price and Total

Price for the item.

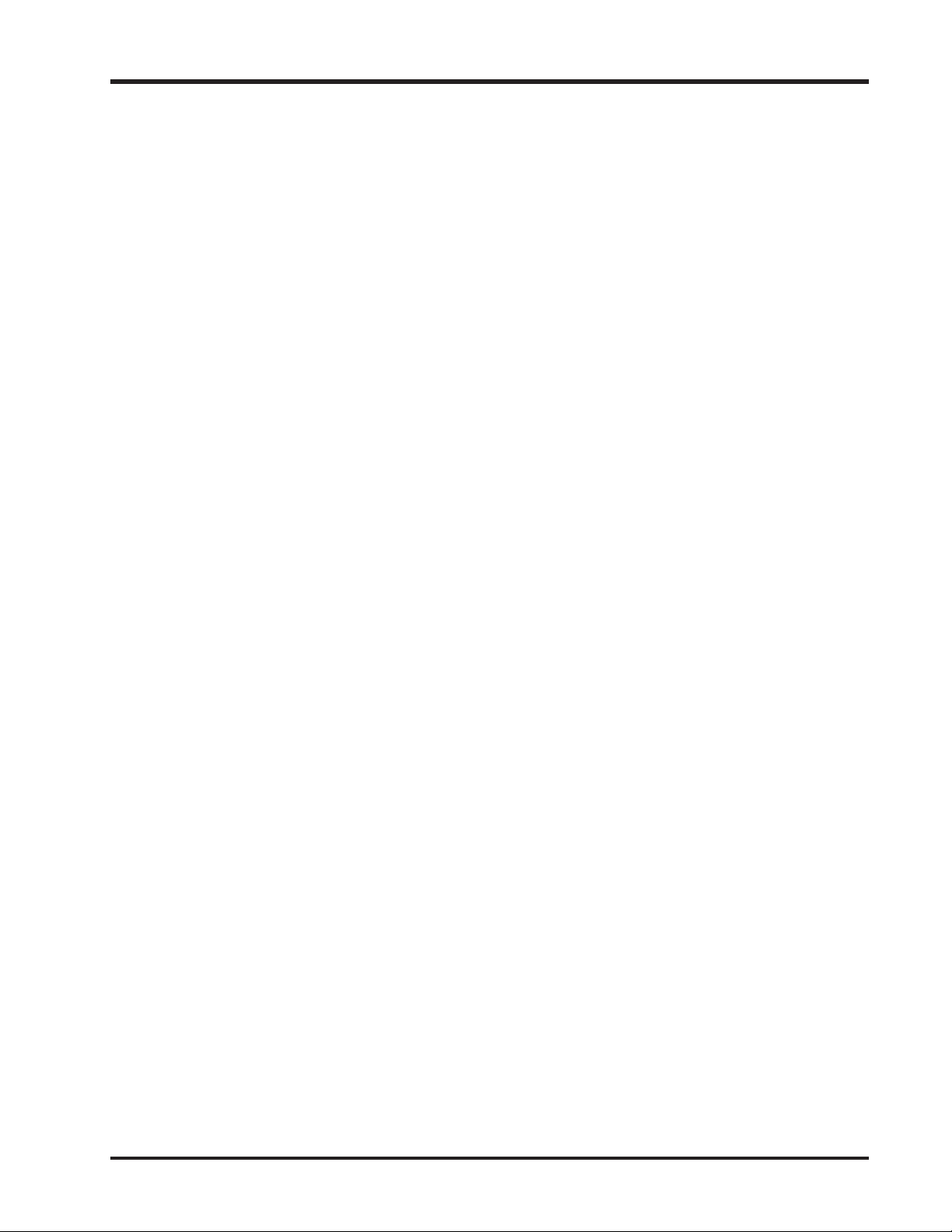

The SP600P can be used as a label printer (if used without a

weigher) or a prepack scale (if connected with a model SPS

or CSWS scale).

When the system is disconnected, memory is maintained by

batteries for a minimum of 100 hours. The batteries

automatically charge when the system is connected to AC

power, whether the scale is in Reset or Operate mode.

Introduction 1-2

SP600 Scale System

FCC Note

Verify Correctness of

Weight & Price

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in

which case the user will be required to correct the

interference at his own expense.

Verification of information on labels should be made

routinely. Check the multiplication of price-per-kilogram

(lb) times weight, and check the indicated weight against

printed weight. Weigh the same package several times to

verify consistency. Keep in mind that some packages which

weigh near the middle of the 0.005 kg (0.01 lb.) increment

will normally vary up or down by 0.005 kg (0.01 lb.) Greater

variation than 0.005 kg (0.01 lb.) indicates a need for

adjustment of the system. In such cases, or whenever

necessary, contact your authorized Hobart Service

representative.

Supervisor Manual

Overview

This manual will use the following methods to explain

keystrokes and data entry procedures:

♦ The word PRESS means to press a key on the Control

Panel.

♦ The word TYPE means to press a series of keys on the

control panel and press [ENTER].

♦ The word ENTER means to press the [ENTER] key on

the Control Panel.

♦ Words in uppercase enclosed in brackets (for example

[ENTER]) represent specific keys.

The following special instructions are used in the manual:

☛ Note

A note is information that you need to know, but it is not an

actual step in the procedures.

1-3 Introduction

SP600 Scale System

How to Use This Manual

✎ Tip

A tip is additional information that may be useful when you

are using the scale system.

Look At This

Look At This is information to alert you that you may be

doing something that will permanently alter your scale

system.

Refer to the following sections for information about using

the SP600/SP600P Scale Printer System.

♦ Chapter One: Introduction

♦ Chapter Two: General Information

♦ Chapter Three: Setting Up Your Scale

♦ Chapter Four: Working with Classes/Products

♦ Chapter Five: Setting Operator Mode

♦ Chapter Six: Working with Labels

♦ Chapter Seven: Working with Totals

♦ Chapter Eight: Backup or Restore

♦ Chapter Nine: Appendix

Introduction 1-4

Chapter Two: General Information

♦ General Information

♦ Electrical Connections

♦ Communication Connections

♦ Resetting and Operating

♦ Using the Keypad

♦ Accessing Supervisor Mode

♦ Using Function Codes

SP600 Scale System

2 - 1 General Information

SP600 Scale System

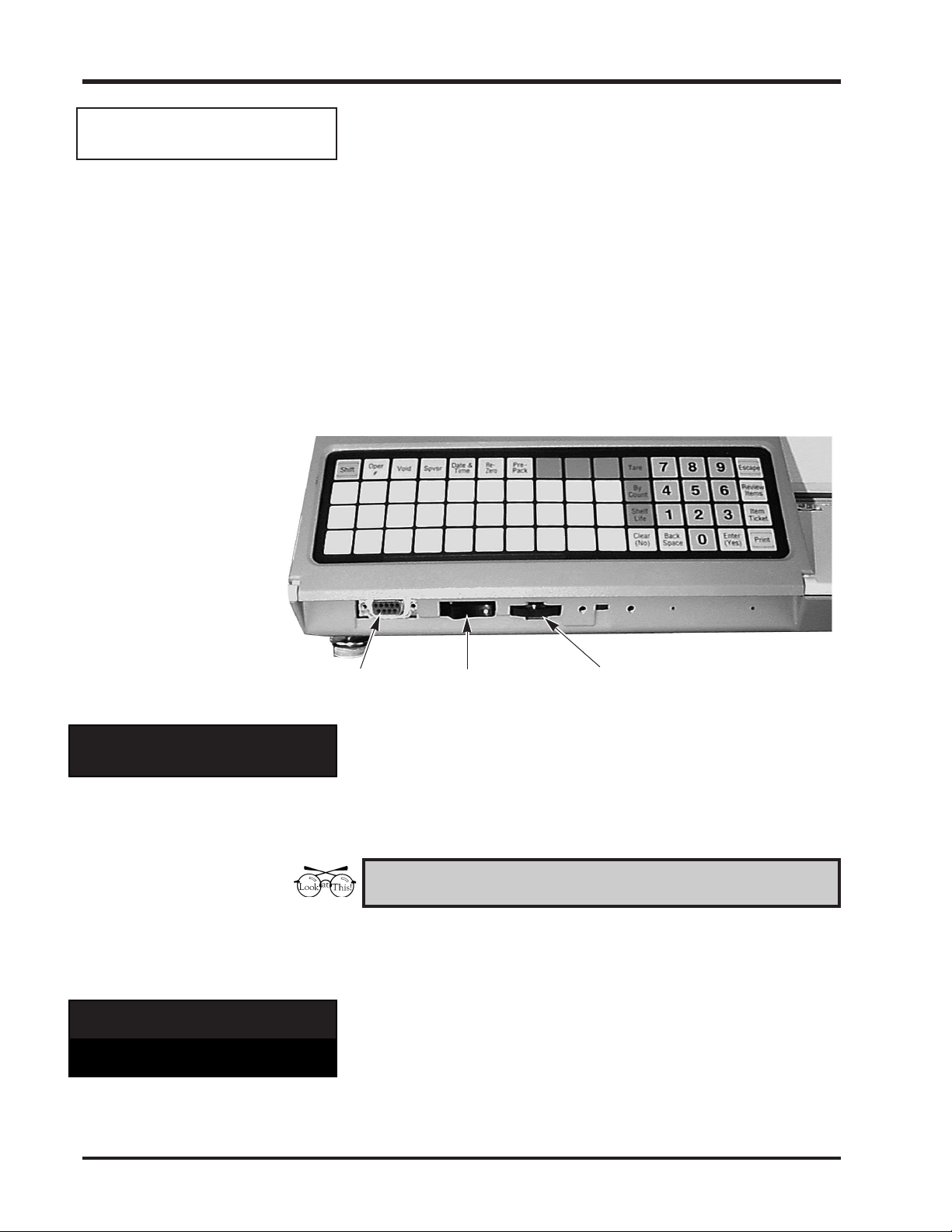

RS-232 PORT

VIEW ANGLE CONTROL

RESET/OPERATE

SWITCH

General Information

The SP600 Scale Printer System is perfect for your over-thecounter weighing applications or for use in backroom meat

applications with the Hobart TWS, HWS or NSW wrapping

machines. This weighing system can handle a broad variety

of products for meat, deli, bakery, produce, fish and cheese

departments.

The scale’s memory is expandable from 0.5 MB to 2.5 MB,

enabling the scale to store information on thousands of

products.

The SP600 Scale System should be installed or moved only

by qualified Hobart-trained service technicians. It can

operate in a temperature range from 32

40

˚C).

˚F to 104˚F (0˚C to

Electrical Connections

Communication

Connections

General Information 2 - 2

The power cord receptacle is located under the SP600 base,

toward the back. The power cord is connected to 120/220 V.,

60/50 Hz., single phase electrical power. Once the SP600 is

plugged in, the system is powered up.

Look At This

Connecting to a power source with a different voltage or

frequency than the scale is configured for may cause

SEVERE damage to the scale.

In addition to the power cord, there is an RS-232 port at the

front of the scale. This port can be used with the Hobart

Disk Player/Recorder or the Hobart External Disk Drive.

SP600 Scale System

Resetting and

Operating

Using the Keypad

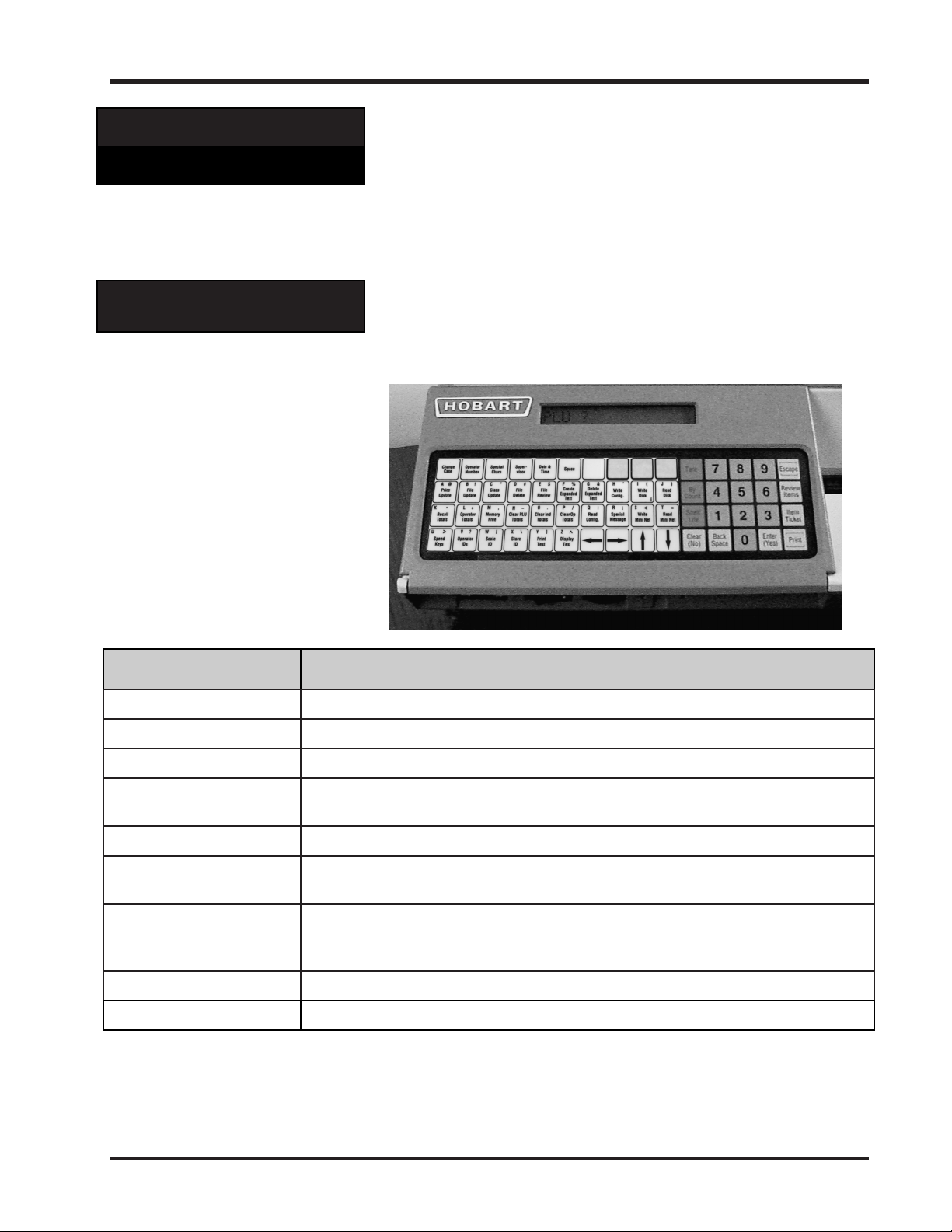

Shown with Supervisor

overlay installed.

The SP600 Scale has power when it is plugged in. Flip the

RESET/OPERATE switch, located on the front of the

system, to switch between reset mode and operate mode.

If you have modified your scale configuration, you must

reset the scale to activate the changes.

The SP600 Scale keypad enables you to enter information

into a field. Refer to the following table for specific key

descriptions.

Key/Highlight Function

Numeric Keypad (0-9) Enables you to enter numeric data.

Backspace Removes the last character when entering data.

Clear Clears data or printer errors. Also used to answer No to many prompts.

Escape Returns you toward the Function Code prompt when in Supervisor Mode.

-- OR -- Returns you to Operator Mode from the Function Code prompt.

Print Enables you to print a label or group of labels.

Enter Enables you to accept the selected data and advance to the next field or screen.

Also used to answer Yes to many prompts.

Arrow Keys UP and DOWN Arrow Keys enable you to move the cursor from field-to-field or

LEFT and RIGHT Arrow Keys enable you to move the cursor from character-tocharacter within a field.

Supervisor Enables you to access the Supervisor Menu.

Alpha Characters* Enable you to enter uppercase or lowercase alpha characters while in a text field.

2 - 3 General Information

SP600 Scale System

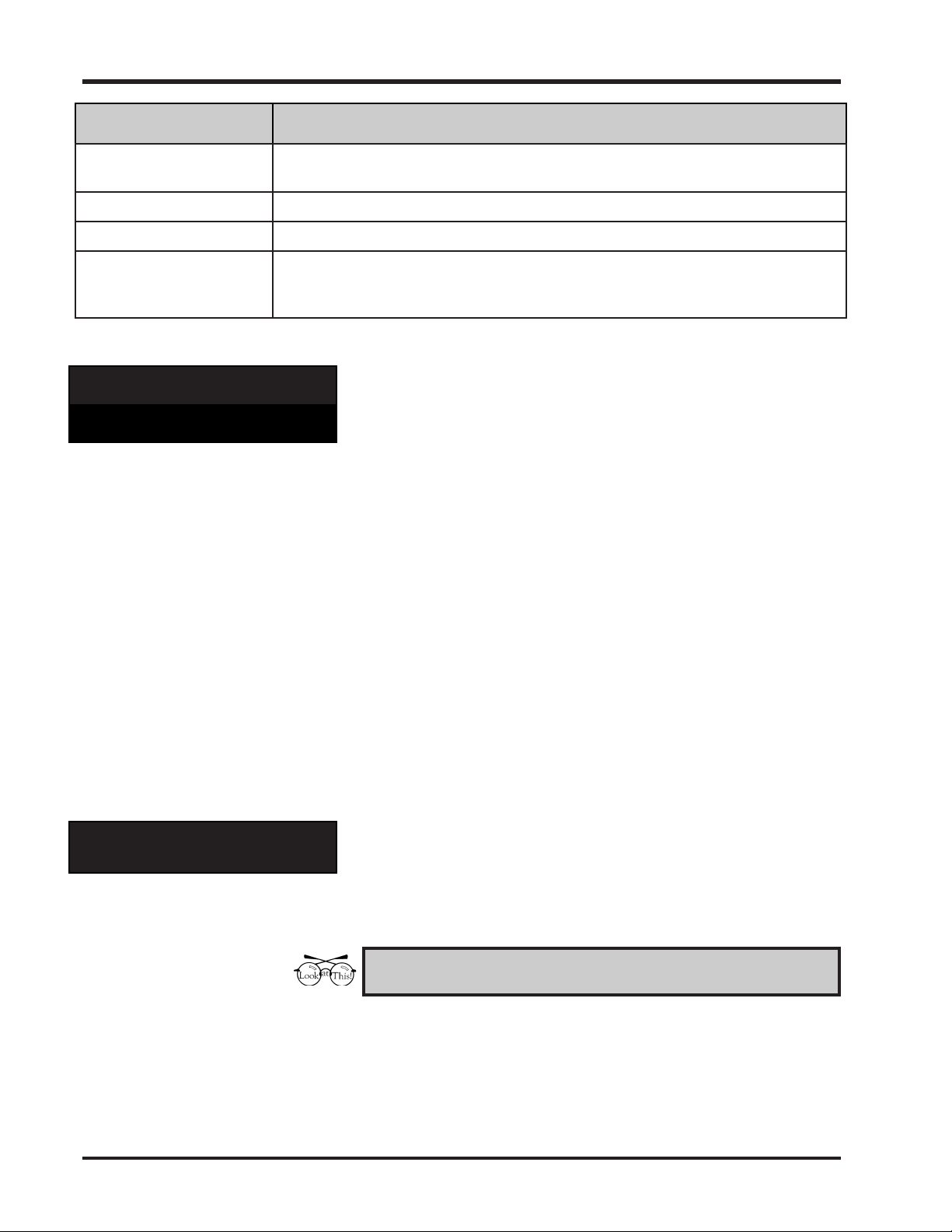

Key/Highlight Function

Special Chars. 1* Press this key to type a special character (found in the upper right corner of each

alpha-key). You must press Special Chars. for each Special Character you type.

Change Case* Enables you to switch between uppercase or lowercase.

Space* Enables you to type (add) a space between words or characters.

Special Chars2* PRESS this key to type a special character (found in the lower right corner of

each alpha-key). You must press Special Chars. for each Special Character you

type.

*Only available in Supervisor Mode.

Accessing Supervisor

Mode

Using Function Codes

You can access Supervisor Mode from the PLU? prompt.

To access Supervisor Mode:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter your

Secret ID. The Function Code prompt displays.

2. From the Function Code prompt (Supervisor Mode), you

can do any of the following:

• Type the two-digit function code.

-- OR --

• Press the [UP ARROW (ÇÇÇÇ)] or [DOWN ARROW

(ÈÈÈÈ)] keys to scroll through the function codes. PRESS

[ENTER] when the function you want displays.

-- OR --

• Press a key from the Supervisor Overlay to select a

scale function.

-- OR --

• PRESS [ESCAPE] to return to the PLU? prompt

(Operator Mode).

Detailed procedures of how to use the supervisor functions

follow throughout this manual.

Use function codes to access any function in the system. A

function code is a number that represents a specific option

in the system. For example, the function code to update a

file is 10. Refer to the Appendix for a detailed list of function

codes and what each one does.

Look At This

Certain countries may not be able to access Function Codes

50 through 53 & 55. To configure these options, contact your

Hobart Service representative.

General Information 2 - 4

Chapter Three: Scale Setup

♦ Setting Up Your Scale

♦ Configuring the Time Format

♦ Configuring the Date Format

♦ Setting the Date/Time

♦ Configuring the Scale ID & Store Information

♦ Assigning the Scale ID

♦ Setting Up the Store Name

♦ Assigning the Store ID

♦ Configuring the Weight Symbol and Tare Suffix

♦ Configuring the Weight Separator

♦ Configuring the Monetary Symbol & Separator

♦ Setting the Display Time

♦ Using Operator Identification

♦ Assigning an Operator ID

♦ Configuring the Scale to Accumulate Operator Totals

♦ Printing Operator Information on a Label

♦ Printing an Operator Access Report

♦ Deleting Operator IDs

♦ Setting Up Speedkeys

♦ Adding a Speedkey

♦ Printing a Speedkey Overlay

♦ Deleting a Speedkey

SP600 Scale System

3 - 1 Scale Setup

SP600 Scale System

p

Setting Up Your Scale

Configuring the Time

Format

Before you can begin setting up your classes, products, etc.,

you should set up your scale to specify how it will operate

on a daily basis.

This section ex

such as:

♦ the Time Format

♦ the Date Format

♦ the actual Date & Time

♦ the Scale ID & Store Information

The SP600 scale system enables you to configure the scale

clock for either 12- or 24-hour mode.

To set the time format:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter

your Secret ID. The Function Code prompt displays.

2. TYPE 53 and PRESS [ENTER]. The Baud Rate prompt

displays.

3. PRESS [UP ARROW (ÇÇÇÇ)] or [DOWN ARROW (ÈÈÈÈ)] until

you see the 12 Hour Cloc prompt.

4. PRESS [CLEAR] to toggle between ON/OFF. Select ON

to use 12 hour mode -- OR -- select OFF to use 24-hour

mode.

5. PRESS [ENTER] to save changes and return to the

Function Code prompt.

lains how to set up general scale information,

Configuring the Date

Format

You can configure eight different date formats which

include the separator.

To set the date format:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter

your Secret ID. The Function Code prompt displays.

2. TYPE 53 and PRESS [ENTER]. The Baud Rate prompt

displays.

3. PRESS [UP ARROW (ÇÇÇÇ)] or [DOWN ARROW (ÈÈÈÈ)] until

you see the Date format? prompt.

4. Refer to the following table for available formats.

Scale Setup 3 - 2

SP600 Scale System

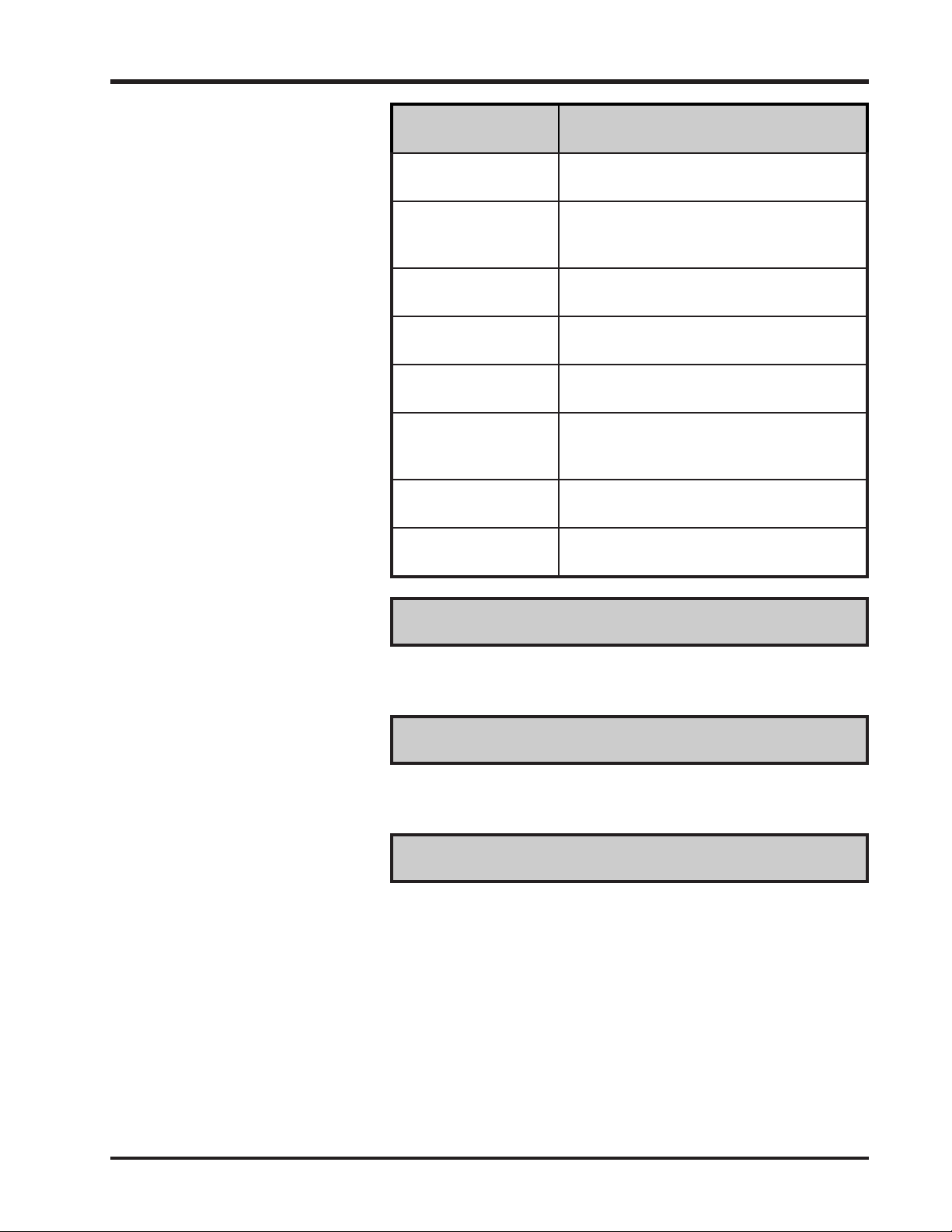

Set to this

Number

To Print this Format

0 24 Jan 97 (Day Month Year)

[separators are two spaces]

1 Jan 24,97 (Month Day, Year)

[separators are one space and one

comma]

2 24/01/97 (Day/Month/Year)

[separators are two forward slashes]

3 01/24/97 (Month/Day/Year)

[separators are two forward slashes]

4 24 Jan 1997 (Day Month Year)

[separators are two spaces]

5 Jan 24, 1997 (Month Day, Year)

[separators are one space and one

comma]

6 24/01/1997 (Day/Month/Year)

[separators are two forward slashes]

7 01/24/1997 (Month/Day/Year)

[separators are two forward slashes]

☛ Note

The scale display defaults to display the date separated by

dashes (i.e., 01-24-97). Depending on the configuration, the

date might print with spaces or backslashes as separators.

☛ Note

The scale will display the two (2) least significant digits of

the year, regardless of configuration settings.

☛ Note

Julian Dates can be configured in the SP600. Contact your

Hobart Service Representative.

3 - 3 Scale Setup

SP600 Scale System

Setting the Date/Time

Set the date and time to specify the accurate date and time.

To set Date/Time:

1. From the PLU? prompt, PRESS [DATE & TIME]. The

system date displays. Be aware that the first time you

power up the scale, you are prompted for the Date and

Time, not for a PLU.

2. PRESS [CLEAR] to clear any existing data; 00-00-00

displays.

3. TYPE the month, day and year or day, month and year

depending on your configuration.

4. PRESS [ENTER] to accept the date and move to the time

prompt.

5. PRESS [CLEAR] to clear the existing time.

6. TYPE the hour and minute.

7. PRESS [ENTER]. If the clock is set to 12-hour mode, the

AM? Prompt displays.

8. PRESS [CLEAR] to indicate PM --OR-- [ENTER] to

indicate AM.

☛ Note

Configuring the Scale

ID & Store Information

Assigning the Scale ID

To allow the operator to change the date/time, select ON at

the Op Edit Date prompt in Function Code 51.

The Scale ID & Store Information option enables you to

assign the Store Number, Scale ID and Store Name to your

scale.

Assign the Scale ID to help distinguish between scales in a

department or store. This is an arbitrary number that you

can assign according to your specific needs.

To set up the Scale ID:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter

your Secret ID. The Function Code prompt displays.

2. TYPE 88 and PRESS [ENTER] or PRESS [SCALE ID

The Scale ID prompt displays.

3. TYPE the Scale ID number and PRESS [ENTER]. This

number can be any number from 0 to 99. You

automatically return to the Function Code prompt.

Scale Setup 3 - 4

SP600 Scale System

Setting Up the Store Name

Use the following procedures to enter your store name into

the scale. If a store name is set up, it will always be printed

on the label.

To set up the store name:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter

your Secret ID. The Function Code prompt displays.

2. TYPE 89 and PRESS [ENTER]. The Store Name prompt

displays. If this is the first time you have accessed this

function Record Not Found displays and then the display

clears.

3. TYPE the store name, or information you may want in

the Store Name field of the label. Use the [DOWN

ARROW (ÈÈÈÈ)] to move to the second line of store name, if

applicable.

4. PRESS [ENTER].

☛ Note

You can specify the number of lines and characters through

Function Code 52. For detailed procedures, refer to Working

with Labels.

Assigning the Store ID

Assign the Store ID to help distinguish between stores in a

chain. This is an arbitrary number that you can assign

according to your specific needs.

To set up the Store ID:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter

your Secret ID. The Function Code prompt displays.

2. TYPE 90 and PRESS [ENTER] or PRESS [STORE ID]. The

Store ID prompt displays.

3. TYPE the Store ID number and PRESS [ENTER]. This

number can be any number from 0 to 999999. You

automatically return to the Function Code prompt.

3 - 5 Scale Setup

SP600 Scale System

Configuring the

Weight Symbol & Tare

Suffix

Configuring the

Weight Separator

When you select a weight system, a 2 character weight

symbol is automatically determined (lb. for Avoirdupois or

kg. for Metric). However, a 1 character suffix can be created,

for both the weight and tare, using any character that can be

entered from the keyboard.

To configure the weight symbol suffix:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter

your Secret ID. The Function Code prompt displays.

2. TYPE 52 and PRESS [ENTER]. The Desc Lines prompt

displays.

3. PRESS [UP ARROW (ÇÇÇÇ)] or [DOWN ARROW (ÈÈÈÈ)] until

you see the Wt suffix prompt.

4. TYPE the character you want to use as the weight suffix.

5. PRESS [DOWN ARROW (ÈÈÈÈ)] until you see the Tare

suffix prompt.

6. TYPE the character you want to use as the tare suffix.

7. PRESS [ENTER] to save changes and return to the

Function Code prompt.

To configure the weight delimiter:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter

your Secret ID. The Function Code prompt displays.

2. TYPE 52 and PRESS [ENTER]. The Desc Lines prompt

displays.

3. PRESS [UP ARROW (ÇÇÇÇ)] or [DOWN ARROW (ÈÈÈÈ)] until

you see the WComma/Point prompt.

4. PRESS [CLEAR] to toggle between ON/OFF. The

default is ON.

• Select ON, to use a comma.

• Select OFF, to use a point.

5. PRESS [ENTER] to save changes and return to the

Function Code prompt.

Scale Setup 3 - 6

Configuring the

Monetary Symbol &

Separator

SP600 Scale System

A three-character monetary symbol can be stored in the

scale configuration. You can use any character available on

the keyboard. The symbol will always precede the price.

To configure the monetary symbol prefix:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter

your Secret ID. The Function Code prompt displays.

2. TYPE 52 and PRESS [ENTER]. The Baud Rate prompt

displays.

3. PRESS [UP ARROW (ÇÇÇÇ)] or [DOWN ARROW (ÈÈÈÈ)] until

you see the Money Symbol prompt.

4. TYPE the character(s) you want to use as the monetary

symbol.

5. PRESS [UP ARROW (ÇÇÇÇ)] or [DOWN ARROW (ÈÈÈÈ)] until

you see the Comma/Point prompt.

6. PRESS [CLEAR] to toggle between ON/OFF. The

default is ON.

• Select ON, to use a comma to delimit the whole and

fractional digits.

• Select OFF, to use a point to delimit the whole and

fractional digits..

7. PRESS [ENTER] to save changes and return to the

Function Code prompt.

☛ Note

The SP600 offers the ability to change the location of the

decimal point or comma and to change the number of price

digits.

Unit Price is determined by two configurations: Unit Digits

and Price Decimal. These are used with the following

restrictions:

• Unit Digits is limited to a value between and including 3

and 6.

• Price Decimal is limited to a value between and

including 0 and 3.

The Monetary Separator determines which separator a

decimal point or comma displays and prints.

Total Price is determined by the two configurations: Total

Digits and Price Decimal. These are used with the following

restrictions:

• Price Digits is limited to a value between and including

3 and 7.

• Price Decimal is limited to a value between and

including 0 and 3.

The Monetary Separator determines which separator, a

decimal point of a comma, displays and prints.

These options are configurable by a trained Hobart Service

Representative, only. Contact your local office for details.

3 - 7 Scale Setup

SP600 Scale System

Setting the Display

Time

Set the display time to adjust the time duration between

visual prompts. You can enter 0 to 3000, which is equal to

0 to 3 seconds.

To set the display time:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter

your Secret ID. The Function Code prompt displays.

2. TYPE 51 and PRESS [ENTER]. The Bycnt Metho prompt

displays.

3. PRESS [UP ARROW (ÇÇÇÇ)] or [DOWN ARROW (ÈÈÈÈ)] until

you see the Disply Time prompt.

4. TYPE the setting you want. The factory setting is 500,

which is equal to

5. PRESS [ENTER] to save changes and return to the

Function Code prompt.

1

/2 second.

Scale Setup 3 - 8

SP600 Scale System

Using Operator

Identification

Assigning an Operator ID

Set up an operator’s ID to limit or grant the operator’s access

to various scale Supervisor functions. The operator’s

identification number provides security within each

department, enhancing the integrity of the scale files.

By configuring the scale to prompt the operator before each

transaction, the identification numbers enable you to

accumulate totals and track the operator’s productivity.

This number will often be referred to as a Secret ID. Be

aware that Operator ID and Secret ID are the same.

This section explains how to:

♦ assign an Operator ID

♦ configure the scale to accumulate operator totals

♦ print an operator access report

♦ delete an Operator ID

The Operator ID option enables you to assign a numeric

code that identifies a specific scale operator. When you

assign the Operator ID, you also assign an access code

which specifies the Supervisor functions the operator is

authorized to perform in the scale. A complete explanation

of access levels can be found later in this chapter.

☛ Note

If there is more than one operator, you must assign at least

one person with access level 5 in order to maintain the

Operator ID file. This ID should be set up first.

✎ Tip

Be aware that once you have an ID in the system, you will

always be prompted for the ID to access the Supervisor

Mode.

3 - 9 Scale Setup

SP600 Scale System

y

To assign an Operator ID:

1. PRESS [SUPERVISOR]. If a Secret ID is already set up,

enter

our secret ID. The Function Code prompt displays.

2. TYPE 34 and PRESS [ENTER] or PRESS [OPERATOR

IDs]. The Operator ID prompt displays.

3. TYPE the Operator ID number and PRESS [ENTER]. This

can be any number between 1 and 9999. The ID number

displays with the Access prompt.

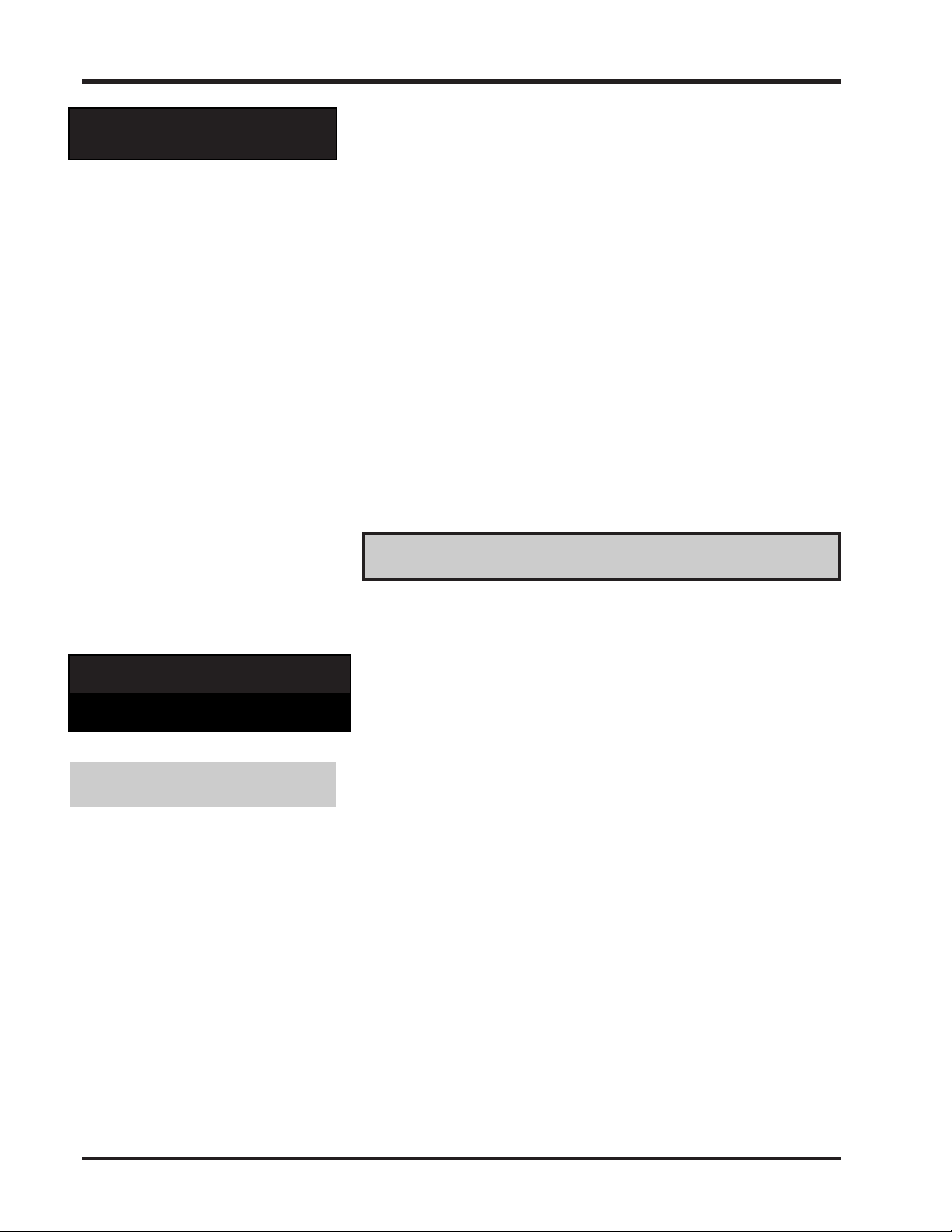

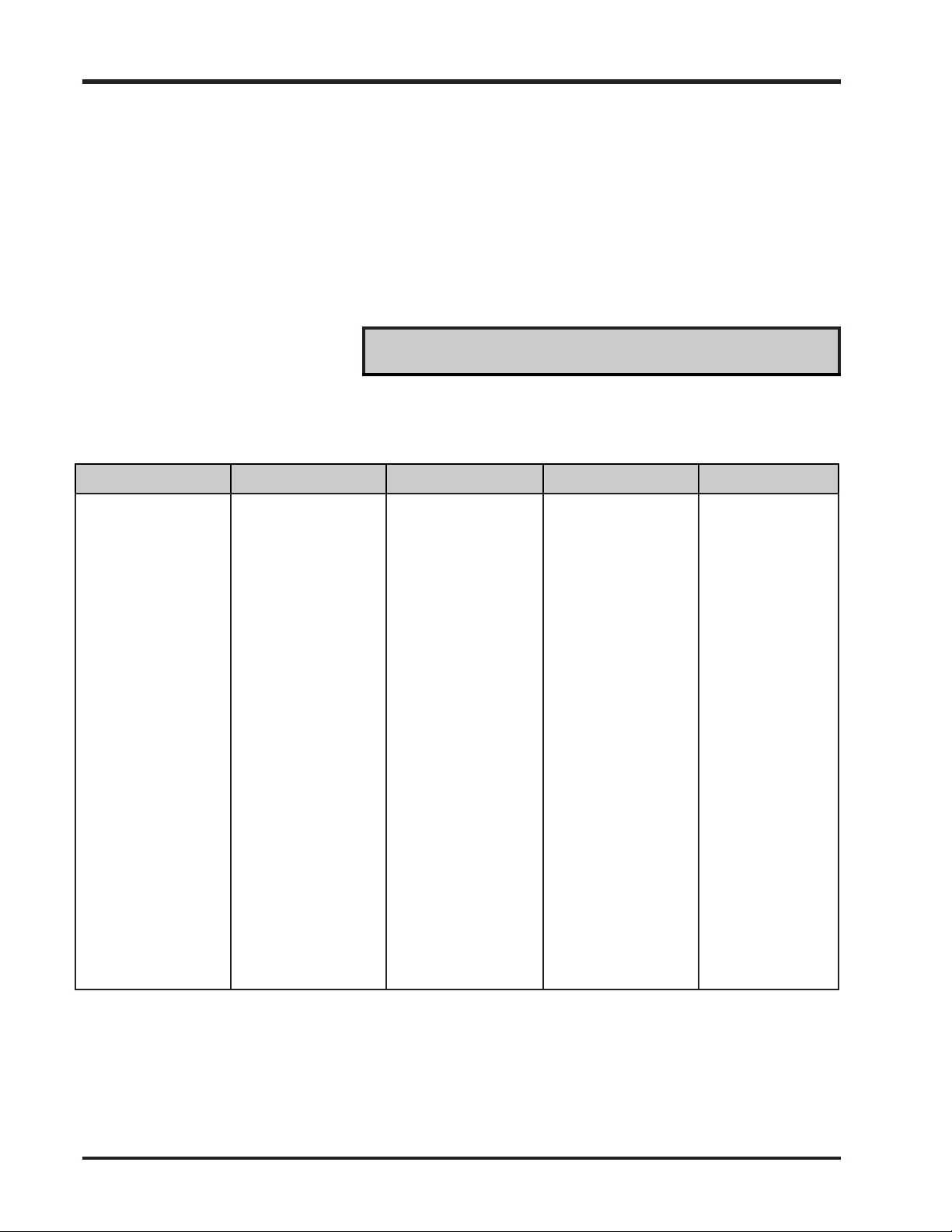

4. TYPE the access code for the operator. Refer to the

following table for the access level of the functions you

want.

☛ Note

Remember, if you select an upper level access code, you can

access all functions from lower levels. Level 1 is for basic

scale operations only; no access to any Supervisor Functions.

File Maintenance Totals Scale Setup Scale Service Configuration

Price Update (4)

File Update (4)

Class Update (4)

File Delete (4)

File Review (2)

Special Message (4)

Expanded Text (4)

Del Expanded Text

(4)

Write Disk (2)

Read Disk (2)

Write Config (2)

Read Config (2)

Bad Record Scan (2)

Write Mini (2)

Read Mini (2)

Delete All (5)

Recall of Tot (3)

Operator Totals (3)

Clear PLU Tot (3)

Clear Ind Totals (3)

Clear Op Totals (3)

Def Speed Key (2)

Operator ID (5)

Scale ID (3)

Store Name (3)

Store ID (3)

Master ROM Check

(5)

Slave ROM Check

(5)

Master RAM Check

(5)

Slave RAM Check

(5)

Numeric Display (5)

Alpha Display (5)

Keyboard Test (5)

Monitor Sensors (5)

Prt Test Label (5)

EEP CRC Check (5)

Print Config (5)

Calibration Date (5)

Scale Counts (5)

Communications (5)

Misc Config (5)

Text Config (5)

Comm Config (5)

Print Config (5)

Memory Free (2)

Scale Setup 3 - 10

Real Time Clock (5)

SP600 Scale System

y

5. After you have typed the access code, PRESS [DOWN

ARROW (ÈÈÈÈ)] to access the first line of description.

PRESS [DOWN ARROW (ÈÈÈÈ)] again to access the second

line of description. Each Operator ID can have up to two

lines of description, 10 characters per line.

6. PRESS [ENTER] to save the Operator ID and return to

the Operator ID prompt.

7. PRESS [UP ARROW (ÇÇÇÇ)] or [DOWN ARROW (ÈÈÈÈ)] to

move to the previous or next Operator ID.

-- OR --

TYPE another number and PRESS [ENTER] to add or

review another Operator ID.

-- OR -PRESS [ESCAPE] to return to the Function Code prompt.

Configuring the Scale to

Accumulate Operator Totals

Although you have assigned access levels for each operator,

you must configure the scale to accumulate the totals, if you

want to collect Operator Totals.

To configure for Operator Totals:

1. PRESS [SUPERVISOR]. If a Secret ID is already set up,

enter

2. TYPE 51 and PRESS [ENTER]. The Bycnt Metho prompt

displays.

3. PRESS [DOWN ARROW (ÈÈÈÈ)] until the Op Sign On

prompt displays.

4. Turn the option ON. (PRESS [CLEAR] to toggle between

ON and OFF.) Turn this on so the scale will prompt the

Operator for an ID to begin using the scale.

5. PRESS [DOWN ARROW (ÈÈÈÈ)] until the OP Totals prompt

displays.

6. Turn the option ON. (PRESS [CLEAR] to toggle between

ON and OFF.) Turning this on enables the scale to

accumulate and save the Operator Totals.

7. PRESS [ENTER] to save changes and return to the

Function Code prompt.

our secret ID. The Function Code prompt displays.

☛ Note

To accumulate the most accurate Operator Totals, you

should also turn the Forced Logon option on. When used in

conjunction with Op Sign On, the scale prompts the operator

for an ID each time the operator wants to access a PLU.

To access the Forced Logon option:

A. From the Op Sign On prompt, PRESS [DOWN ARROW

(ÈÈÈÈ)] until the Forced Logon prompt displays.

B. Turn the option ON. (PRESS [CLEAR] to toggle between

ON and OFF.)

3 - 11 Scale Setup

SP600 Scale System

Printing Operator

Information on a Label

The scale can be configured to print the Operator Name or

Operator ID number on a label. Select a Date Line Option

which contains the Operator field. The options which

contain Operator fields are 4, 8, 9, and 10. (Refer to Setting

Up the Date Line Options for detailed procedures.)

Your scale can be configured to print either the ID number

or the name but it will not print both.

☛ Note

When the Forced Logon option is used in conjunction with

Op Sign On the scale prompts the Operator for an ID each

time they want to access a PLU.

To access the Forced Logon option:

A. From the Function Code prompt, TYPE 51 and PRESS

[ENTER]. The Bycnt Metho prompt displays.

B. PRESS [DOWN ARROW (ÈÈÈÈ)] until the Forced Logon

prompt displays.

C. Turn the option ON. (PRESS [CLEAR] to toggle between

ON and OFF.)

Printing an Operator Access

Report

Deleting Operator IDs

Print a list of Operators’ access information. You may want

to do this to verify the IDs and access codes which exist in

the system. You must use continuous label stock or listing

paper.

To print an Operator access report:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter your

Secret ID. The Function Code prompt displays.

2. TYPE 34 and PRESS [ENTER] or PRESS [OPERATOR

IDs]. The Operator ID prompt displays.

3. PRESS [PRINT] to print all Operator IDs.

4. PRESS [ESCAPE] to return to the Function Code prompt.

Delete an Operator ID to permanently remove it from the

system.

☛ Note

Although you delete an operator, the totals for that operator

will remain in the scale until you delete the totals.

Scale Setup 3 - 12

SP600 Scale System

To delete an Operator ID:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter your

Secret ID. The Function Code prompt displays.

2. TYPE your Operator ID (if required) and PRESS

[ENTER]. The Function Code prompt displays.

3. TYPE 34 and PRESS [ENTER] or PRESS [OPERATOR

IDs]. The Operator ID prompt displays.

4. TYPE the Operator ID number that you want to delete

and PRESS [ENTER]. The ID number displays followed

by the Access Code.

5. TYPE 0 (zero) for the access code and PRESS [ENTER].

Deleted flashes followed by the Operator ID prompt.

6. PRESS [UP ARROW (ÇÇÇÇ)] or [DOWN ARROW (ÈÈÈÈ)] to

move to the previous or next Operator ID. -- OR -- PRESS

[ESCAPE] to return to the Function Code prompt.

Setting Up Speedkeys

Adding a Speedkey

Speedkeys are used to quickly access the fastest-moving

items with minimal keystrokes or to quickly access an

operator ID. Different Speedkeys can be assigned for each

scale, even if they are within the same department.

Speedkeys enable operators to enter a PLU number or log

onto a scale by pressing a single key. SP600 scales offer 30

Speedkeys.

☛ Note

Before you can add an Operator ID as a Speedkey, you must

turn on the Op Sign On option (in Function Code 51).

Note

If you assign a PLU number that does not exist in the

system, the message RECORD NOT FOUND flashes

followed by the Key prompt. This is telling you that the PLU

is assigned to the Speedkey, but you must add the PLU

record to the database.

To add a Speedkey:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter your

Secret ID. The Function Code prompt displays.

2. TYPE 30 and PRESS [ENTER] or PRESS [SPEED KEYS].

The Key prompt displays.

3 - 13 Scale Setup

SP600 Scale System

3. PRESS a key on the keyboard. Keys which can be

assigned as Speedkeys are [A] to [Z] and the arrow keys.

The Key prompt is now followed by the letter you

selected and the PLU prompt.

4. To assign a PLU to this Speedkey, TYPE the PLU

number.

-- OR --

To assign an operator ID to this Speedkey, PRESS

[OPERATOR NUMBER] and enter the ID number.

5. PRESS [DOWN ARROW (ÈÈÈÈ)]. The Description prompt

displays the description for the PLU or Operator ID,

which Speedkey represents.

6. PRESS [ENTER] to save the Speedkey and return to the

Key prompt.

7. PRESS [ESCAPE] to return to the Function Code prompt.

Printing a Speedkey Overlay

Print a Speedkey overlay to place over the bottom 3 rows of

keys on the keyboard (replacing the Supervisor overlay).

You must have continuous label stock or listing paper

loaded before you can print a Speedkey overlay. If you are

using continuous label stock, remember to load the label

stock so that the backing paper remains attached.

To print a Speedkey overlay:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter your

Secret ID. The Function Code prompt displays.

2. TYPE 30 and PRESS [ENTER] or PRESS [SPEED KEYS].

The Key prompt displays.

3. PRESS [PRINT].

✎ Tip

You can change the size that the Speedkeys print on the

Speedkey overlay through Function Code 51.

To change the size:

A. From the Function Code prompt TYPE 51 and PRESS

[ENTER]. The Bycnt Metho prompt displays.

B. PRESS [DOWN ARROW (ÈÈÈÈ)] until the SpeedKeySize

prompt displays.

C. TYPE 0 to 3 and PRESS [ENTER] to increase or decrease

the Speedkey size. Each number increases/decreases the

width of the Speedkeys by approximately 2 mm.

Scale Setup 3 - 14

SP600 Scale System

Deleting a Speedkey

Delete a Speedkey to permanently remove it from the

system.

To delete a Speedkey:

1. PRESS [SUPERVISOR]. If a Secret ID is set up, enter your

Secret ID. The Function Code prompt displays.

2. TYPE 30 and PRESS [ENTER] or PRESS [SPEED KEYS].

The Key prompt displays.

3. PRESS the Speedkey on the keyboard. The Speedkey and

its assignment display.

4. PRESS [CLEAR] followed by [ENTER]. Key Deleted

flashes followed by the Key prompt.

5. PRESS [ESCAPE] to return to the Function Code prompt.

3 - 15 Scale Setup

Loading...

Loading...