Page 1

Item # _____________________________________

Quantity ___________________________________

C.S.I. Section 11400

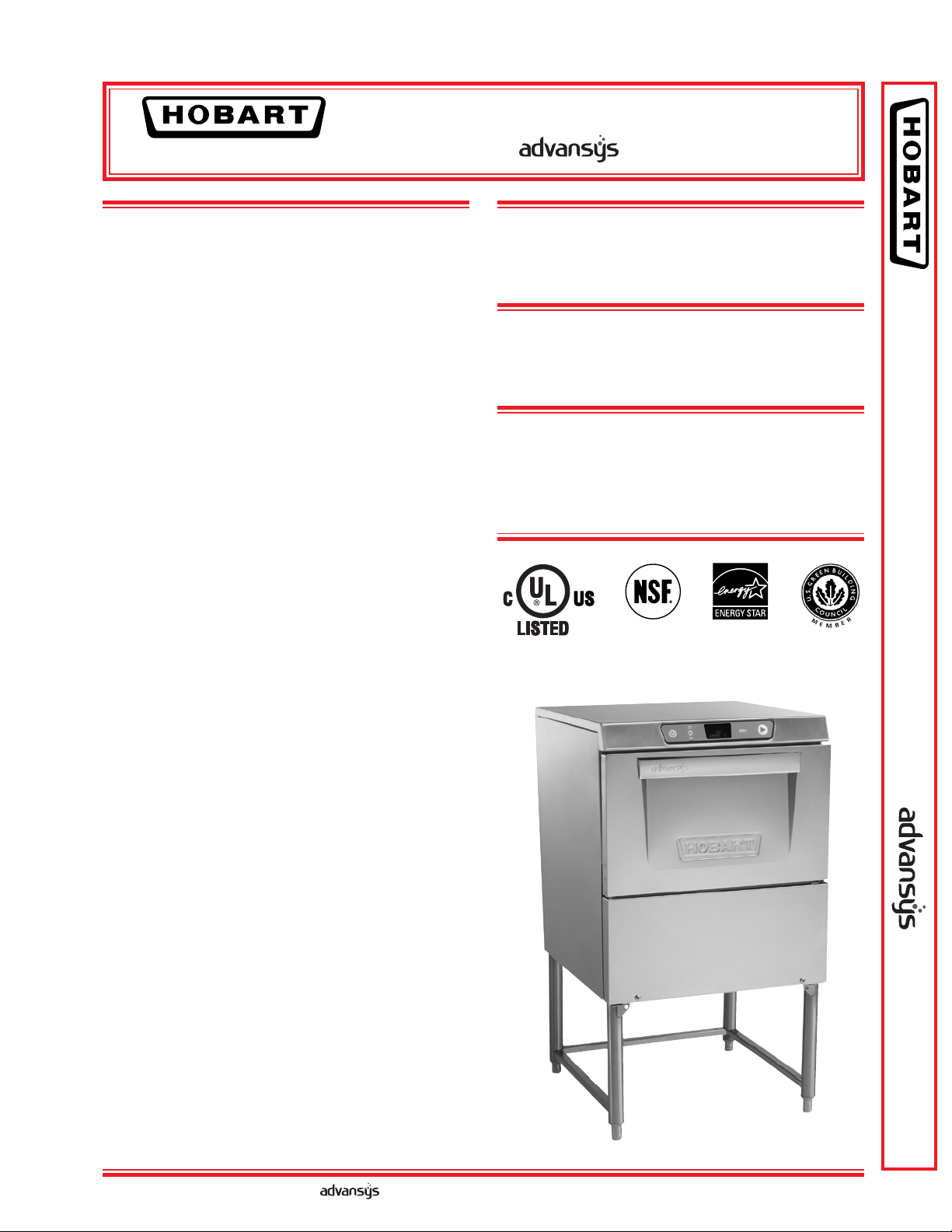

LXGeR and LXGePR

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STANDARD FEATURES

■ Racks per hour Light Normal

LXGeR 30 24

LXGePR 38 29

■ .62 gallons of water per rack – LXGeR

1.14 gallons of water per rack – LXGePR

■ Hot water or chemical sanitation units available

■ Steam Elimination and Energy Recovery (LXGeR

model only)

■ PuriRinse cycle (Potable water rinse to remove

chemical residue) (LXGePR model only)

■ Low chemical alert indicators

■ Sense-A-Temp™ booster heater capable of

70 rise, provided on LXGeR models

■ Chemical pump “auto-prime”

■ Advanced Service diagnostics

■ Clogged wash arm sensing

■ Custom cycle selection – light, normal

■ Automated delime cycle – includes booster

deliming

■ Deep drawn stainless steel tank

■ Microcomputer, top mounted controls with

advanced digital cycle/temperature display

■ Revolving upper and lower anti-clogging wash

arms

■ Snap-in revolving upper and lower rinse arms

■ Removable stainless steel scrap screen

■ Corrosion resistant pump

■ Energy Saver mode

■ Automatic pumped drain

■ 12" door opening

■ Dirty water indicator

■ Automatic ll

■ Detergent, rinse aid and delime pumps standard

(plus sanitizer pump on chemical machine)

■ Electric tank heat

■ One dishrack – one glass/wine rack

■ Customizable “advansys” button to select

favorites function

■ Auto clean cycle washes down inside of

machine at shutdown

GLASSWASHER

MODELS

❑ LXGeR – Energy Recovery

❑ LXGePR – PuriRinse

STANDARD VOLTAGES

❑ 120/208-240(3W)/60/1 (LXGeR model only)

❑ 120/60/1 (LXGePR model only)

ACCESSORIES

❑ Power cord kits

❑ DWT-L X e drain water tempering kit

Specications, Details and Dimensions on Back.

LXGeR and LXGePR GLASSWASHER

F40404 – LXGeR and LXGePR Glasswasher Page 1 of 8

Page 2

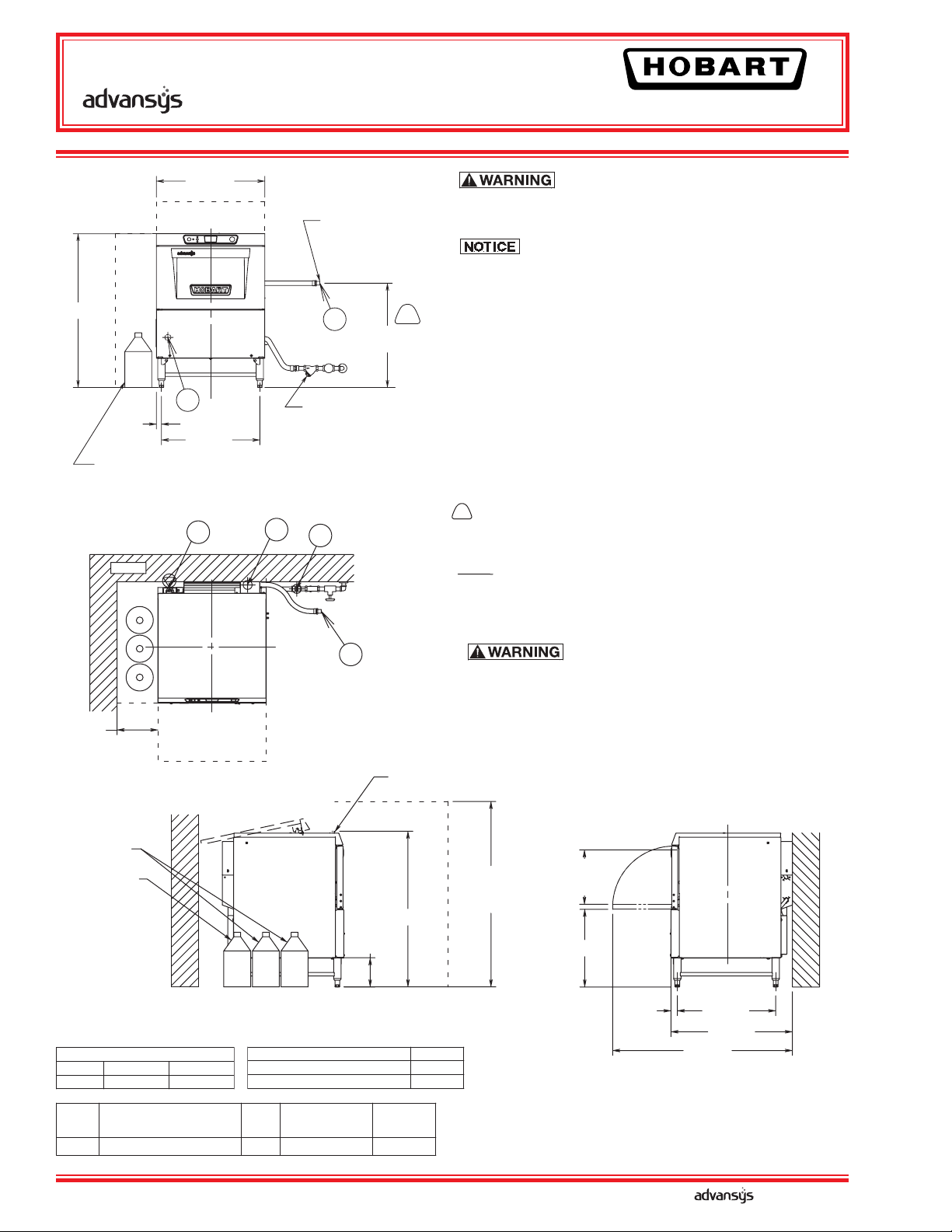

LXGeR SHORT

EITHER SIDE OF MACHINE

23 15/16"

33 15/16"

RECOMMENDED

SLIDE UNIT FORWARD FOR SERVICE ONLY

TRIM STRIP

CLEARANCE

39 11/16"

12" MAX

LO

MIN

LXGeR

1100 2000

MAX

MODELS:

LXG

T

00-950418

REV B

NOTE: FOR SUPPLY CONNECTIONS, USE COPPER WIRE

ONL

*

ACCESSORY CORD KIT AVAILABLE FOR ALL MACHINES

Do not premix other chemicals and sodium hypochlorite

(liquid bleach). Mixing may cause hazardous gas to form.

Required flowing w

. If pressures higher than

65 PSIG are present

dishmachine (b

Pressure gauge not required on pumped rinse machines.

Important:

If chemical containers are to be placed in cabinet adjacent to machin

is required in the cabinet to run chemical supply lin

P2 DRAIN CONNECTION: 5/8" BARB FITTING WITH 6' LONG HOSE SUPPLIED WITH MACHINE.

CONNECTION INFORMATION

Notes:

Electrical and grounding connections must comply with

the applicable portions of the National Electrical Code

and/or other local electrical codes

Plumbing connections must comply with applicable sanitary,

safety and plumbing codes.

vary, some methods are shown on this drawing.

CHEMICAL BOTTLES

MAY BE LOCATED ON

WALL

GLASSWASHER

1-1/2" TRADE SIZE

PIPE MIN. REDUCED

DOWN TO 3/4" FPT

CONNECTION (BY

CUSTOMER)

P2

23" OR LESS

FLOOR LINE

E1

1 1/8"

21 11/16"

E1

RECOMMENDED WATER

SERVICE ROUGH-IN

1/2" TRADE SIZE

PIPE MIN. W/SHUTOFF

VALVE, LINE STRAINER

& 3/4" MALE GARDEN

HOSE FITTING (BY

CUSTOMER).

P2

P1

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

ater pressure to the dishmachine is 15-65 PSIG

, a pressure regulating valve must be installed in the water line to the

y others).

3

The chemical containers should be placed no higher than 16" above floor.

e.

1. All vertical machine dimensions taken from floor may be increased by .875" or decreased

by .375".

2. Moist air escapes from the door.

Use only moisture resistant materials adjacent to dishmachine sides and top.

3. A vent hood is not recommended above the undercounter dishmachine since it does not

produce excessive vapors.

e, a 1/2" dia. hole

Plumbing notes:

1. Water hammer arrestor (meeting ASSE-1010 Standard or equivalent) to be supplied

(by others) in common water supply line at service connection.

2. Recommended water hardness to be 3 grains or less for best results.

3. If drain hose is looped above a sink, the loop must not exceed 44" AFF.

(AFF = ABOVE FINISHED FLOOR)

LEGEND

E1 E LECTRICAL CONNECTION: 1-3/8" DIA. HOLE FOR 1" TRADE SIZE CONDUIT; 10-5/8" AFF.

P1 SINGLE FILL AND RINSE CONNECTION: 3/4" FEMALE GARDEN HOSE FITTING ON 6' LONG

HOSE SUPPLIED WITH MACHINE.; 55-85°F (COLD) RECOMMENDED FOR LXGeR.

P2

9"

DETERGENT &

RINSE-AID

DELIME

6 7/16"

ADDITIONAL CLEARANCE REQUIRED TO

HEAT OUTPUT, BTU/HR

MODEL

MODEL

Page 2 of 8 F40404 – LXGeR and LXGePR Glasswasher

LATENT

VOLTS/HERTZ/PHASE

120/208-240(3W)/60/1*

SENSIBLE

SHIPPING WEIGHTS

NET WEIGHT OF MACHINE

DOMESTIC SHIPPING WEIGHT

RATED

AMPS

30.5

MIN SUPPLY

CKT CONDUCTOR

AMPACITY

40

(OPTIONAL)

34 3/8"

PROTECTIVE

DEVICE

40LXGeR

LXGeR

165 LBS

185 LBS

.

Drain and fill line configurations

40 15/16"

SERVICE

MIN

Y RATED AT 90°C MINIMUM.

THIS SYSTEM REQUIRES THREE POWER WIRES WHICH INCLUDES

A CURRENT CARRYING NEUTRAL, AN ADDITIONAL FOURTH WIRE

MUST BE PROVIDED FOR MACHINE GROUND.

ADING

HEIGHT

17"

1 3/8"

21 11/16"

26 13/16"

eR SHOR

Page 3

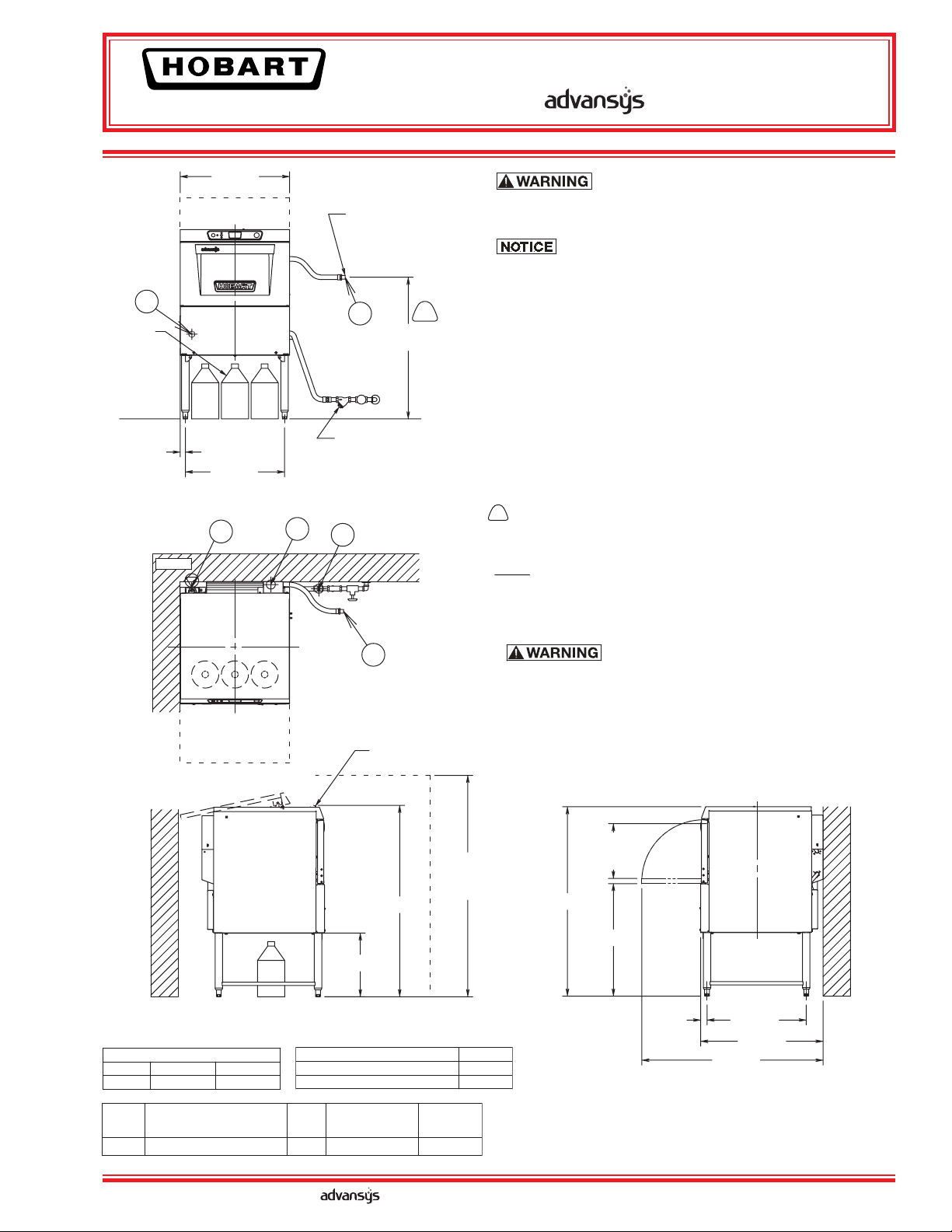

LXGeR TALL

NOTE: FOR SUPPLY CONNECTIONS, USE COPPER WIRE

ONL

*

S

ACCESSORY CORD KIT AVAILABLE FOR ALL MACHINES

SLIDE UNIT FORWARD FOR SERVICE ONLY

TRIM STRIP

E

23 15/16"

CUSTOMER).

RECOMMENDED

DETERGENT

RINSE-AID

& DELIME

BO

BE LOCA

UNDER

MACHINE

LXGeR

1100 2000

MODELS:

LXG

LL

00-950418

REV B

P2 DRAIN CONNECTION: 5/8" BARB FITTING WITH 6' LONG HOSE SUPPLIED WITH MACHINE.

CONNECTION INFORMATION

Electrical and grounding connections must comply with

the applicable portions of the National Electrical Code

and/or other local electrical codes

Plumbing connections must comply with applicable sanitar

safety and plumbing codes.

vary, some methods are shown on this drawing.

Required flowing w

. If pressures higher than

65 PSIG are present

dishmachine (b

Pressure gauge not required on pumped rinse machines.

Important:

If chemical containers are to be placed in cabinet adjacent to machin

is required in the cabinet to run chemical supply line.

Do not premix other chemicals and sodium hypochlorite

(liquid bleach). Mixing may cause hazardous gas to form.

Notes:

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

E1

,

TTLES MAY

TED

THE

FLOOR LINE

1 1/8"

21 11/16"

E1

WALL

P2

1-1/2" TRADE SIZE

PIPE MIN. REDUCED

DOWN TO 3/4" FPT

CONNECTION (BY

CUSTOMER)

P2

31" OR LESS

RECOMMENDED WATER

SERVICE ROUGH-IN

1/2" TRADE SIZE

PIPE MIN. W/SHUTOFF

VALVE, LINE STRAINER

& 3/4" MALE GARDEN

HOSE FITTING (BY

P1

GLASSWASHER

ater pressure to the dishmachine is 15-65 PSIG

, a pressure regulating valve must be installed in the water line to the

y others).

3

The chemical containers should be placed no higher than 24" above floor.

1. All vertical machine dimensions taken from floor may be increased by .875" or decreased

by .375".

2. Moist air escapes from the door.

Use only moisture resistant materials adjacent to dishmachine sides and top.

3. A vent hood is not recommended above the undercounter dishmachine since it does not

produce excessive vapors.

e, a 1/2" dia. hole

Plumbing notes:

1. Water hammer arrestor (meeting ASSE-1010 Standard or equivalent) to be supplied

(by others) in common water supply line at service connection.

2. Recommended water hardness to be 3 grains or less for best results.

3. If drain hose is looped above a sink, the loop must not exceed 51" AFF.

(AFF = ABOVE FINISHED FLOOR)

LEGEND

E1 E LECTRICAL CONNECTION: 1-3/8" DIA. HOLE FOR 1" TRADE SIZE CONDUIT; 18-1/8" AFF.

P1 SINGLE FILL AND RINSE CONNECTION: 3/4" FEMALE GARDEN HOSE FITTING ON 6' LONG

HOSE SUPPLIED WITH MACHINE.; 55-85°F (COLD) RECOMMENDED FOR LXGeR.

P2

ADDITIONAL CLEARANCE REQUIRED TO

HEAT OUTPUT, BTU/HR

MODEL

MODEL

LATENT

VOLTS/HERTZ/PHASE

120/208-240(3W)/60/1*

SENSIBLE

F40404 – LXGeR and LXGePR Glasswasher Page 3 of 8

13 15/16"

SHIPPING WEIGHTS

NET WEIGHT OF MACHINE

DOMESTIC SHIPPING WEIGHT

RATED

AMPS

30.5

MIN SUPPLY

CKT CONDUCTOR

AMPACITY

40

(OPTIONAL)

41 7/8"

48 7/16"

SERVICE

CLEARANC

MIN

MAX

PROTECTIVE

DEVICE

40LXGeR

LXGeR

165 LBS

185 LBS

.

Drain and fill line configurations

12" MAX

LOADING

HEIGHT

41 7/16"

24 1/2"

1 3/8"

Y RATED AT 90°C MINIMUM.

THIS SYSTEM REQUIRES THREE POWER WIRES WHICH INCLUDE

A CURRENT CARRYING NEUTRAL, AN ADDITIONAL FOURTH WIRE

MUST BE PROVIDED FOR MACHINE GROUND.

21 11/16"

26 13/16"

39 11/16"

y,

eR TA

Page 4

LXGePR SHORT

23 15/16"

33 15/16"

SLIDE UNIT FORWARD FOR SERVICE ONLY

TRIM STRIP

DETERGENT

RINSE-AID

E

LXGePR

1900 800

170 LBS

DOMESTIC SHIPPING WEIGHT

NOTE: FOR SUPPLY CONNECTIONS, USE COPPER WIRE

ONL

ACCESSORY CORD KIT AVAILABLE FOR ALL MACHINES

MODELS:

LXG

T

00-950419

REV B

Do not premix other chemicals and sodium hypochlorite

(liquid bleach). Mixing may cause hazardous gas to form.

Required flowing w

. If pressures higher than

65 PSIG are present

dishmachine (b

Pressure gauge not required on pumped rinse machines.

Important:

If chemical containers are to be placed in cabinet adjacent to machin

is required in the cabinet to run chemical supply lin

Use only 6% or 8.4% sodium hypochlorite (liquid bleach) as sanitizing chemical to insure

proper operation of dishmachine

Certain materials including silver plat

h

Notes:

P2 DRAIN CONNECTION: 5/8" BARB FITTING WITH 6' LONG HOSE SUPPLIED WITH MACHINE.

CONNECTION INFORMATION

Electrical and grounding connections must comply with

the applicable portions of the National Electrical Code

and/or other local electrical codes

Plumbing connections must comply with applicable sanitary,

safety and plumbing codes

vary, some methods are shown on this drawing.

38 7/16"

12" MAX

LO

E1

1 1/8"

21 11/16"

CHEMICAL BOTTLES

MAY BE LOCATED ON

EITHER SIDE OF MACHINE

WALL

GLASSWASHER

1-1/2" TRADE SIZE

PIPE MIN. REDUCED

DOWN TO 3/4" FPT

CONNECTION (BY

CUSTOMER)

P2

RECOMMENDED

23" OR LESS

FLOOR LINE

RECOMMENDED WATER

SERVICE ROUGH-IN

1/2" TRADE SIZE

PIPE MIN. W/SHUTOFF

VALVE, LINE STRAINER

& 3/4" MALE GARDEN

HOSE FITTING (BY

CUSTOMER).

E1

P2

P1

P2

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

ater pressure to the dishmachine is 15-65 PSIG

, a pressure regulating valve must be installed in the water line to the

y others).

3

The chemical containers should be placed no higher than 16" above floor.

e.

.

ypochlorite (liquid bleach). See instructional manual.

1. All vertical machine dimensions taken from floor may be increased by .875" or decreased

by .375".

2. Moist air escapes from the door.

Use only moisture resistant materials adjacent to dishmachine sides and top.

3. A vent hood is not recommended above the undercounter dishmachine since it does not

produce excessive vapors.

e, aluminum and pewter are attacked by sodium

e, a 1/2" dia. hole

Plumbing notes:

1. Water hammer arrestor (meeting ASSE-1010 Standard or equivalent) to be supplied

(by others) in common water supply line at service connection.

2. Recommended water hardness to be 3 grains or less for best results.

3. If drain hose is looped above a sink, the loop must not exceed 44" AFF.

(AFF = ABOVE FINISHED FLOOR)

LEGEND

E1 E LECTRICAL CONNECTION: 1-3/8" DIA. HOLE FOR 1" TRADE SIZE CONDUIT; 10-5/8" AFF.

P1 SINGLE FILL AND RINSE CONNECTION: 3/4" FEMALE GARDEN HOSE FITTING ON 6' LONG

HOSE SUPPLIED WITH MACHINE.;

120°F WATER MIN. FOR LXGePR, 140°F RECOMMENDED.

9"

MIN

&

CHLORINE

SANITIZER

DELIME

(ADDITIONAL

CLEARANCE

MAY BE

REQUIRED)

ADDITIONAL CLEARANCE REQUIRED TO

HEAT OUTPUT, BTU/HR

MODEL

MODEL

LXGePR

Page 4 of 8 F40404 – LXGeR and LXGePR Glasswasher

LATENT

VOLTS/HERTZ/PHASE

120/60/1

SENSIBLE

SHIPPING WEIGHTS

NET WEIGHT OF MACHINE

RATED

AMPS

15.4

MIN SUPPLY

CKT CONDUCTOR

AMPACITY

6 7/16"

20

(OPTIONAL)

34 3/8"

MAX

PROTECTIVE

DEVICE

20

LXGePR

150 LBS

40 15/16"

SERVICE

CLEARANC

MIN

Y RATED AT 90°C MINIMUM.

ADING

HEIGHT

17"

.

. Drain and fill line configurations

1 3/8"

21 11/16"

25 9/16"

ePR SHOR

Page 5

LXGePR TALL

P2 DRAIN CONNECTION: 5/8" BARB FITTING WITH 6' LONG HOSE SUPPLIED WITH MACHINE.

CONNECTION INFORMATION

Electrical and grounding connections must comply with

the applicable portions of the National Electrical Code

and/or other local electrical codes

Plumbing connections must comply with applicable sanitary,

safety and plumbing codes

vary, some methods are shown on this drawing.

Do not premix other chemicals and sodium hypochlorite

(liquid bleach). Mixing may cause hazardous gas to form.

Required flowing w

. If pressures higher than

65 PSIG are present

dishmachine (b

Pressure gauge not required on pumped rinse machines.

Important:

If chemical containers are to be placed in cabinet adjacent to machin

is required in the cabinet to run chemical supply lin

Use only 6% or 8.4% sodium hypochlorite (liquid bleach) as sanitizing chemical to insure

proper operation of dishmachine

Certain materials including silver plat

h

Notes:

23 15/16"

CUSTOMER).

RECOMMENDED

DETERGEN

RINSE-AI

CHLORINE

SANITIZE

& DELIME

BO

BE LOCA

UNDER

MACHINE

SLIDE UNIT FORWARD FOR SERVICE ONLY

TRIM STRIP

E

MODELS:

LXG

LL

00-950419

REV B

LXGePR

1900 800

170 LBS

DOMESTIC SHIPPING WEIGHT

NOTE: FOR SUPPLY CONNECTIONS, USE COPPER WIRE

ONL

ACCESSORY CORD KIT AVAILABLE FOR ALL MACHINES

41 7/16

38 7/16"

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

E1

T,

D,

R

TTLES MAY

TED

THE

1 1/8"

21 11/16"

E1

WALL

P2

1-1/2" TRADE SIZE

PIPE MIN. REDUCED

DOWN TO 3/4" FPT

CONNECTION (BY

CUSTOMER)

P2

FLOOR LINE

RECOMMENDED WATER

SERVICE ROUGH-IN

1/2" TRADE SIZE

PIPE MIN. W/SHUTOFF

VALVE, LINE STRAINER

& 3/4" MALE GARDEN

HOSE FITTING (BY

3

31" OR LESS

P1

P2

GLASSWASHER

ater pressure to the dishmachine is 15-65 PSIG

, a pressure regulating valve must be installed in the water line to the

y others).

The chemical containers should be placed no higher than 24" above floor.

e.

.

ypochlorite (liquid bleach). See instructional manual.

1. All vertical machine dimensions taken from floor may be increased by .875" or decreased

by .375".

2. Moist air escapes from the door.

Use only moisture resistant materials adjacent to dishmachine sides and top.

3. A vent hood is not recommended above the undercounter dishmachine since it does not

produce excessive vapors.

e, aluminum and pewter are attacked by sodium

Plumbing notes:

1. Water hammer arrestor (meeting ASSE-1010 Standard or equivalent) to be supplied

(by others) in common water supply line at service connection.

2. Recommended water hardness to be 3 grains or less for best results.

3. If drain hose is looped above a sink, the loop must not exceed 51" AFF.

(AFF = ABOVE FINISHED FLOOR)

LEGEND

E1 E LECTRICAL CONNECTION: 1-3/8" DIA. HOLE FOR 1" TRADE SIZE CONDUIT; 18-1/8" AFF.

P1 SINGLE FILL AND RINSE CONNECTION: 3/4" FEMALE GARDEN HOSE FITTING ON 6' LONG

HOSE SUPPLIED WITH MACHINE.;

120°F WATER MIN. FOR LXGePR, 140°F RECOMMENDED.

e, a 1/2" dia. hole

(OPTIONAL)

13 15/16"

ADDITIONAL CLEARANCE REQUIRED TO

HEAT OUTPUT, BTU/HR

MODEL

MODEL

LXGePR

LATENT

VOLTS/HERTZ/PHASE

120/60/1

SENSIBLE

SHIPPING WEIGHTS

NET WEIGHT OF MACHINE

RATED

AMPS

15.4

MIN SUPPLY

CKT CONDUCTOR

AMPACITY

20

F40404 – LXGeR and LXGePR Glasswasher Page 5 of 8

41 7/8"

48 7/16"

SERVICE

CLEARANC

MIN

MAX

PROTECTIVE

DEVICE

20

LXGePR

150 LBS

12" MAX

LOADING

HEIGHT

"

24 1/2"

Y RATED AT 90°C MINIMUM.

.

. Drain and fill line configurations

1 3/8"

21 11/16"

25 9/16"

ePR TA

Page 6

LXGeR and LXGePR

GLASSWASHER

SPECIFICATIONS

DESIGN: Front opening, equipped for installation in either

freestanding or undercounter-type operations.

CONSTRUCTION: 300 series stainless steel tank, door

and top panel.

PUMP: Centrifugal-type, integral with motor, horizontally

mounted. Pump capacity 38 gpm.

MOTOR: Single phase, furnished for all electrical specications. Factory sealed lubrication. Inherent overload

protection with auto reset.

WASH AND RINSE CYCLE: Complete automatic type,

controlled by solid-state electronics. Cycle may be interrupted any time by opening door. Cycle continues when

door is closed.

• Initial cycle lls wash tank, to be recirculated each wash

cycle. Some wash water is drained off before rinse

cycle. Rinse cycle refreshes wash water and tank heat.

RINSE PUMP: Powered by a single phase motor, the rinse

pump is made of high strength engineered composite

material.

BLOWER: The blower is a 60mm x 300mm tangential

wheel powered by a 2-pole single phase motor for quiet

and reliable operation, LXGeR only.

CONDENSER COIL: The condensing system uses a tube

and n coil constructed of copper and corrosion resistant

aluminum. The condenser coil allows for energy recovery from waste heat in the moisture laden air that would

normally escape into the environment after a dishwashing

cycle, L XGeR o nly.

RINSE AND SANITATION:

• LXGeR: Sanitation is accomplished by means of a

built-in booster heater designed to raise temperature of

water to a minimum of 180°F from an incoming water

temperature of 55°F.

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

• LXGePR: Sanitation is accomplished by injection of

proper amount of sodium hypochlorite solution (liquid

bleach) into nal rinse water to achieve a minimum

of 50PPM sanitizing solution. Injection of sodium

hypochlorite is accomplished by a built-in sanitizing

chemical pump. Minimum required hot water temperature is 120°F.

– Potable water rinse to remove chemical residue.

– To be used with sanitizer approved for use with post

sanitizing rinse

• CHECK SANITIZER CONCENTRATION: PuriRinse

must be off (hold Wash button for 5 seconds). Verify

that there is sufcient chemical supply. Run cycle

and use test strips on wetted surface of glasses after

cycle is complete. If concentration is below minimum

required, contact your local Hobart Service ofce.

ENERGY RECOVERY: Heat energy is recovered from the

condensation of vapors in the chamber at the end of each

cycle. This pre-heats the water for the next rinse cycle

from 55°F up to 140°F.

PUMPED DRAIN: Machine automatically drains water

through a built-in pump. Maximum 38" drain height

permitted.

ELECTRIC BOOSTER HEATER: 4.9 KW electric booster

with Sense-A-Temp™ technology adequately sized to

raise 55°F inlet water to 180°F, with the aid of the energy

recovery system.

RACKING: Machines accommodate racks from 10" x 20"

to 20" x 20".

NOTE: Certain materials, including silver, aluminum and

pewter are attacked by Sodium Hypochlorite solution in

the chemical sanitizing mode of operation.

SPECIFICATIONS: Listed by Underwriters Laboratories

Inc. and NSF International.

Page 6 of 8 F40404 – LXGeR and LXGePR Glasswasher

Page 7

LXGeR and LXGePR

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

LXGePR LXGeR

MACHINE RATINGS

Light Normal Light

Racks per Hour Rate 38 29 30

Dishes per Hour (25 per Rack Avg.) 950 725 750

Glasses per Hour (36 per Rack Avg.) 136 8 1044 1080

Controls Microcomputer

Tank Capacity - Gallons 2.9

Overall Dimensions - H x W x D (Short) 343⁄8 " x 2315⁄16" x 259⁄16" 343⁄8 " x 2315⁄16" x 2613⁄16"

Overall Dimensions - H x W x D (Tall) 417⁄8 " x 2315⁄16" x 259⁄16" 417⁄8 " x 2315⁄16" x 2613⁄16"

Cycle Time - Seconds 94 124 120

Tank H e at 1.8 KW

Electric Booster Heater N/A 4.9 KW

Water Usage Per Rack - Gallons 1.14 .62

Drain Design Pumped

Door Opening Height 12"

Detergent Pump Standard

Rinse-Aid Pump Standard

Delime Pump Standard

Sanitizer Pump Standard N/A

Chemical Prime (auto prime) Standard

Peak Drain Flow - GPM 4.0

Advanced Service Diagnostics Standard

Advanced Cleaning Cycle Standard

70°Rise Sense-A-Temp™ Booster Heater N/A Standard

Incoming Water Temperature Required (minimum) 120° 55°

GLASSWASHER

Normal

24

600

864

146

F40404 – LXGeR and LXGePR Glasswasher Page 7 of 8

Page 8

LXGeR and LXGePR

GLASSWASHER

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

As continued product improvement is a policy of Hobart, specications are subject to change without notice.

Page 8 of 8 F40404 – LXGeR and LXGePR Glasswasher

F40404 (02/15) LITHO IN U.S.A. (H-01)

Loading...

Loading...