Hobart Food Machines KA7E Installation Manual

MODEL KA7E ROTARY OVENS

MODEL

KA7E

SELF-CLEANING, PASS-ThROuGh ML-137701

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

F35521 (May, 2008)

TABLE OF CONTENT

GENERAL ............................................................3

INSTALLATION ........................................................ 4

LOCATION ......................................................4

LEGS, CASTERS OR STAND ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . 4

CONNECTION INFORMATION — GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Legend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Plumbing Connections .........................................5

Chemical Cleaner Supply and Grease Drain Connections ..............6

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PLACING THE ROTOR IN THE OVEN ................................ 8

OPERATION ..........................................................9

OPERATOR CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

PASS-THROUGH CONTROLS ..................................... 10

BEFORE FIRST USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

INITIAL STARTUP ............................................... 11

Power On ............................................... 11

Idle Mode ............................................... 11

Setting the Clock ......................................... 11

Changing Temperature Readings to Celsius .................... 11

SAVING OR VERIFYING A COOK PROGRAM (Program 1 – 9) ........12

PROGRAMMED COOKING (Program 1 – 9) .......................14

MANUAL COOKING (Program 0) ................................ 15

HOLDING CYCLE (SILENCING THE 'END OF CYCLE' ALARM) ....... 16

STOPPING A CYCLE .........................................16

PAUSING A CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

ADDING COOK TIME ......................................... 17

SNOOZING A CYCLE (SILENCING THE 'END OF CYCLE' ALARM) ....17

CLEANING THE TEMPERATURE PROBE (Optional Accessory) . . . . . . . 18

99 PROGRAM FEATURE ......................................18

OPERATOR ID FEATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SUGGESTED ROASTING GUIDELINES .......................... 19

Entering Recipe Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

PREPARING, TYING & SPITTING — CHICKENS ON V-SPITS ..... 20

SPITTING / LOADING ..................................... 22

LOADING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

UNLOADING ACCESSORIES FROM THE OVEN ...................24

EMPTYING THE GREASE CONTAINER .......................... 24

CHANGING THE CHEMICAL BOTTLE . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

AUTOMATIC CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

WIPE DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

REPLACE DRIP STRAINERS PROPERLY . . . . . . . . . . . . . . . . . . . . . . . . 30

WIPE OFF EXTERIOR ........................................30

DELIMING WITH VINEGAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

PUMP TUBE MAINTENANCE ...................................... 33

YEARLY CLEANING .............................................33

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

SERVICE ...................................................... 36

© HOBART, 2008

– 2 –

Installation, Operation and Care of

MODEL KA7E ROTARY OVENS

SAVE THIS MANUAL FOR FUTURE REFERENCE

GENERAL

The KA7E 'seven-spit' rotary oven provides evenly cooked, appealingly roasted

product with combination convection and radiant heat.

A full view, tempered glass door is provided for loading, and an identical pass-through

door is provided on the opposite side for unloading.

• Quartz lighting promotes visual appeal and stimulates customer interest.

• A stainless steel interior is provided for ease of cleaning.

• A pumped drain delivers excess fat to a grease receptacle.

• Automatic self-cleaning thoroughly washes and cleans the oven interior.

• Use only one type of accessory in the oven at any time.

KA7E ACCESSORIES

Type of Spit Qty Whole Chicken Capacity

V-Spit 7 21 - 28

Thermo-Wave Spit 7 21 - 28

Meat Fork Spit 7 28 - 35

5-Position Rack 7 35

4-Position Rack 7 28

Baskets 7 Hold Chicken Parts

– 3 –

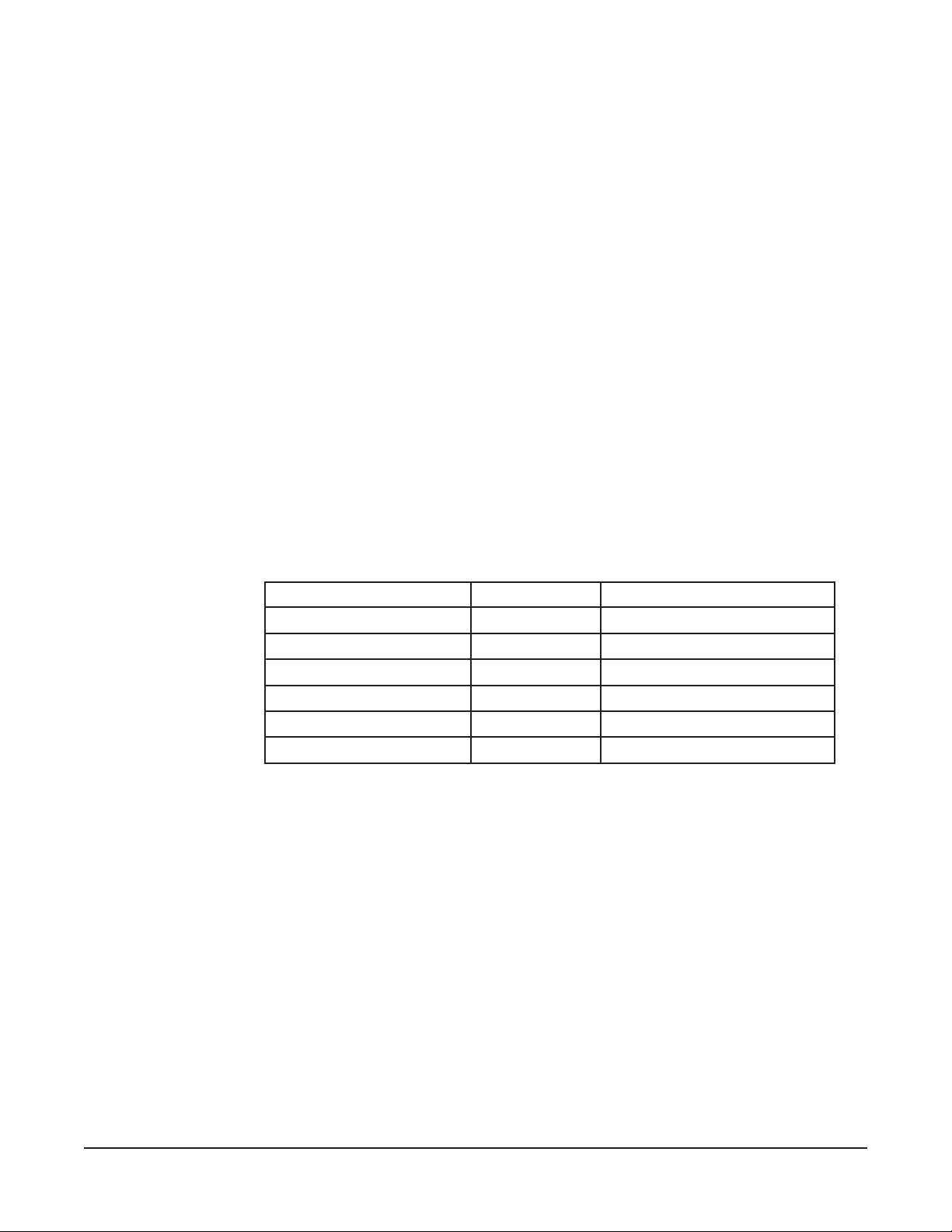

LOCATION

E1

P1

P4

P3

P2

INSTALLATION

Immediately after unpacking the oven, check for possible shipping damage. If the

oven is found to be damaged, save the packaging material and contact the carrier

within 15 days of delivery.

Prior to installation, test the electrical service to make sure that it agrees with the

specications on the machine data plate located at the lower outside corner of the

oven.

The oven must be installed on a level surface within 5 feet of both an open drain

and a hot water supply. The installation location must allow adequate clearances

for servicing and for proper operation. Suitable space is needed for the grease

container and the chemical cleaner supply bottle and for access at the doors. For

stacked and countertop congurations, the minimum clearance on the right side

for plumbing and electrical connections is 3". For out-of-sight, drop-through utility

connection into the stand accessory, 0" clearance is required on all sides. Wood

laminates, veneers, etc. are unsuitable materials for use in areas exposed to self-

cleaning oven, steam and detergents. The rotary oven must not be installed in

high-moisture environments such as meat rooms or where high pressure cleaning

is used.

LEGS, CASTERS OR STAND ACCESSORIES

A set of four 4" tall legs is available as an accessory. Casters are included with the

stacking kit accessory. An oven stand accessory is available; the oven is mounted

on top of the stand.

Tethering is required for units equipped with casters, either on a stand or stacked.

Refer to the Stand or Stacking Kit Instructions for additional installation

information.

CONNECTION INFORMATION — GENERAL

Machine comes standard with utility connections on the right

side (Figs. 1 & 2).

For out-of-sight, drop-through utility connection into the stand

accessory, contact Hobart Service. A drop-through utilities

relocation kit is included with the stand accessory.

Legend (Fig. 1)

E1 Electrical, page 7.

P1 Water Drain, page 5.

P2 Chemical Supply, page 6.

P3 Grease Drain, page 6.

P4 Hot Water Supply, page 5.

Fig. 1

– 4 –

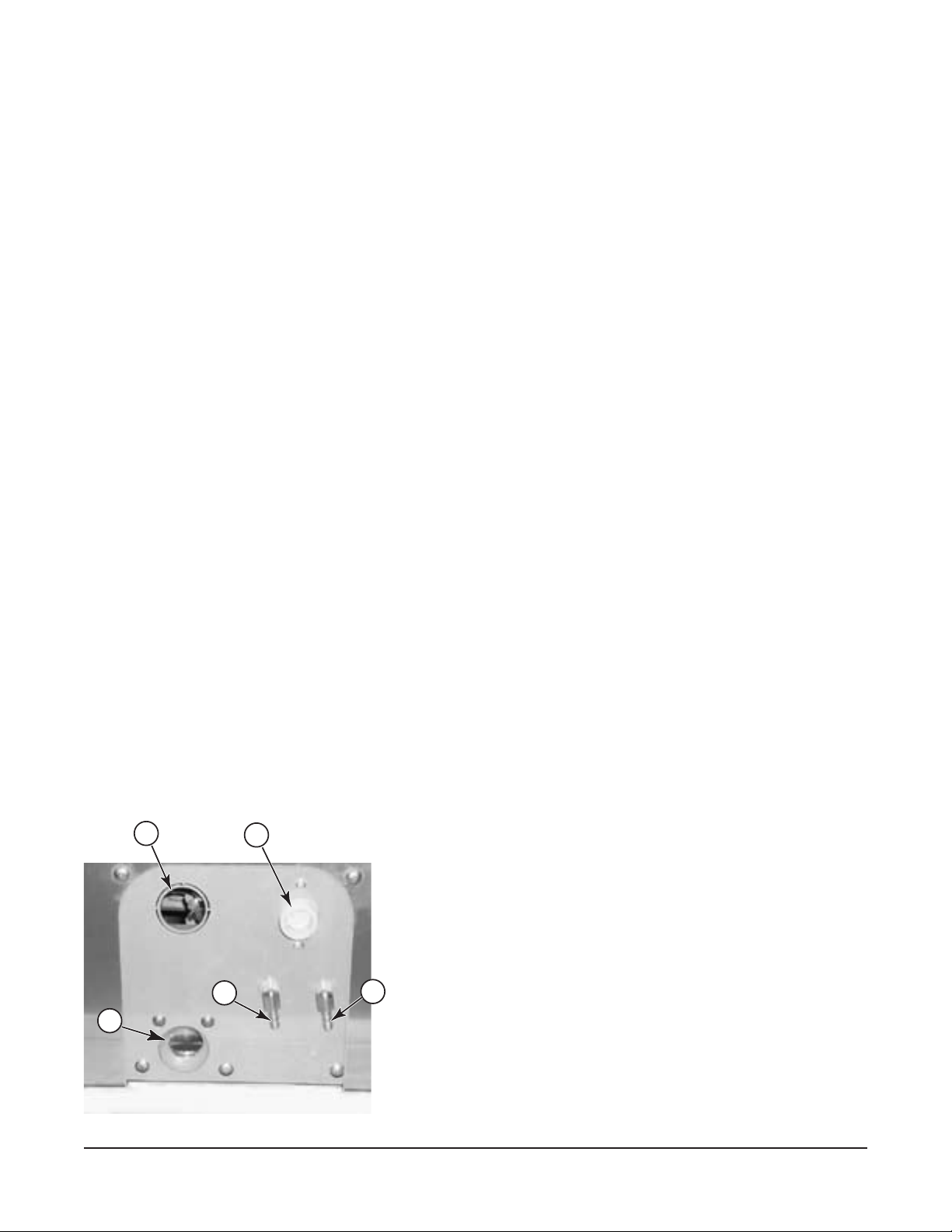

Plumbing Connections

E1 ELECTRICAL

P1 WATER DRAIN

P2 CHEMICAL SUPPLY

P3 GREASE DRAIN

P4 HOT WATER SUPPLY

safety and plumbing codes.

P1 Water Drain — 1" NPT female piped to an open drain. No solid connection.

Output is 140°F maximum at 5 GPM.

P4 Hot Water Supply — 3/4" male hose bib tting. 0.5 GPM, 25 – 50 psi. For proper

operation, use only HOT water, 120°F – 140°F. For installations at the end of a long

hot water line, a second pre-rinse may be required to prime the line. Contact Hobart

service to make any needed parameter changes to Cleaning cycle programming.

The sensors on the machine need to see a small amount of minerals in the water

in order to work properly. But, excessive minerals may cause lime scale build-up.

Recommended water hardness, 4 – 6 grains. Minimum conductivity required,

30 MICROMHOS/CM.

Plumbing connections must comply with applicable sanitary,

Fig. 2

– 5 –

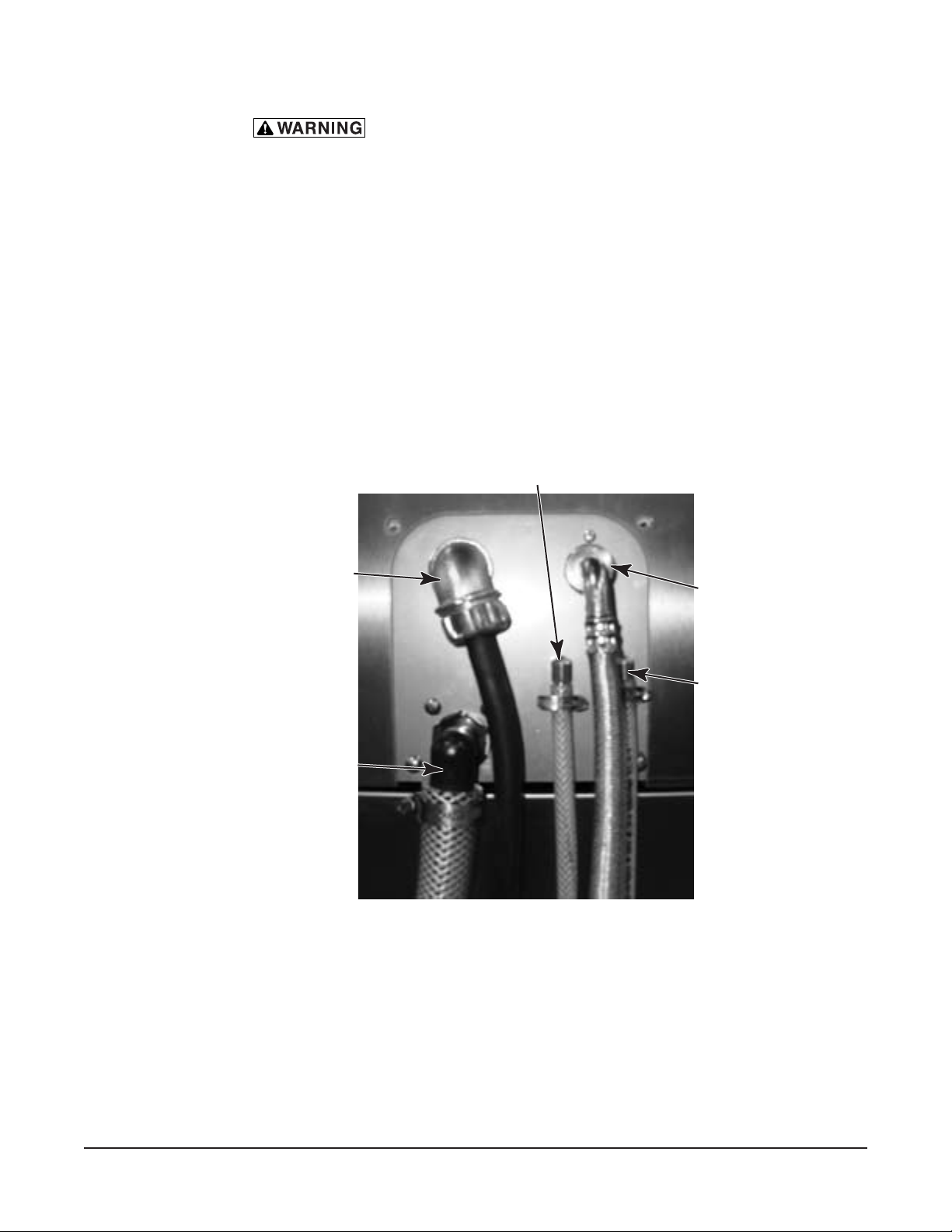

Chemical Cleaner Supply and Grease Drain Connections

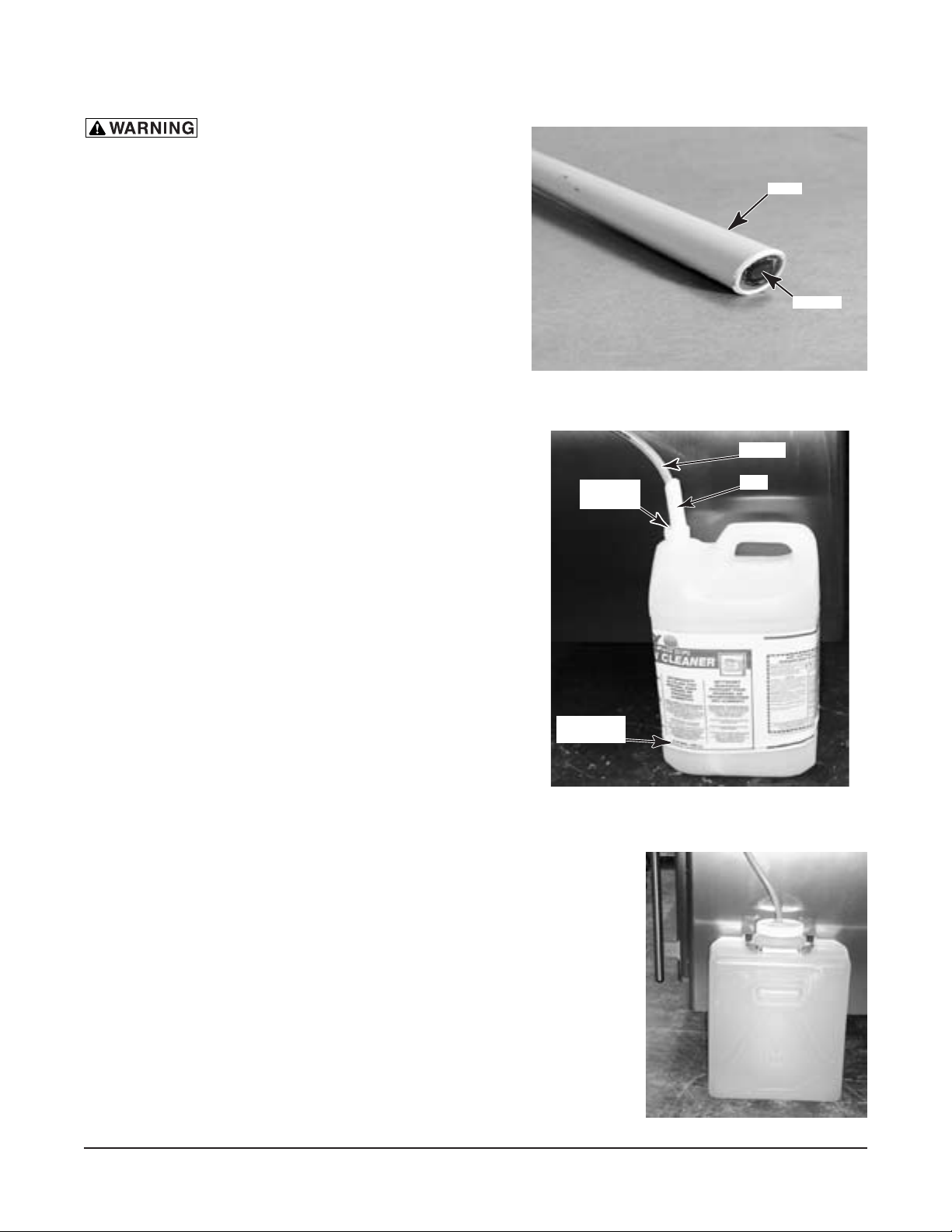

PIPE

TUBING

CAP

REMOVED

TUBING

PIPE

CHEMICAL

CONTAINER

Oven cleaners are corrosive and can

cause chemical burns. Rubber gloves, goggles and

protective clothing are required. Read and follow the

instructions for the oven cleaner.

P2 Chemical Cleaner Supply — Hose barb to accept 1/4"

ID chemically resistant tubing, supplied with oven.

NOTE: Use only Kay Chemical CIP Cleaner or other

approved cleaners for proper operation. Unapproved

chemicals can cause excess foaming, poor dispensing,

poor washing, poor draining and damage to seals and

other components inside the oven. DO NOT use any

chemicals in addition to the approved, self-dispensed

cleaner as hazardous interactions can result.

The amount of chemical that is self-dispensed may need

to be adjusted for various reasons, such as for light or

heavy soil or when using alternative approved cleaners.

Contact Hobart service to make any needed parameter

changes to cleaning cycle programming.

Fig. 3

Hose is 6 feet long, can be cut to suit. A #4 or #6 SST

hose clamp is recommended for the tubing at the barbed

tting.

• Cut a 45° angle on the bottom end of the tubing.

• Cut a 3/4" I.D. PVC pipe, not supplied, about 18" long,

with a 45° angle at each end.

• Put the angled end of the tubing inside the pipe

(Fig. 3) so both angled ends extend to the bottom

of the container (Fig. 4). The pipe prevents the

tubing from curling inside the container and prevents

suctioning against the container bottom.

P3 Grease Drain — Hose barb to accept 1/4" ID high-temperature tubing

supplied with machine, 212°F rated.

Hose is 6 feet long, can be cut to suit. A #4 or #6 SST hose clamp is

recommended for the tubing at the barbed tting.

• Connect the grease drain tubing to the barbed tting, P3.

Fig. 4

• Insert the other end of the grease drain tubing into a suitable

grease vessel, not supplied, similar to the one shown in

Fig. 5.

– 6 –

Fig. 5

Electrical Connection

Electrical and grounding connections must comply with the

applicable portions of the National Electrical Code, ANSI / NFPA 70, latest

edition, and / or other local electrical codes.

Disconnect the electrical power supply to the machine and

follow lockout / tagout procedures.

The electrical connection is E1 (Fig. 1). Make sure that the electrical power supply

agrees with the specications on the oven data plate. Refer to the wiring diagram

located inside the side panel.

Connect the power supply to the terminal block as shown on the wiring diagram.

Inspect and check all wiring and terminal connections for tightness and proper routing

away from any moving parts or pinch points. Carefully replace side panels.

E1 – ELECTRICAL DATA

60 HZ KA7E

VO LTAGE PHASE WAT TAG E AMPERAGE

208 1 9,300 42.8

240 1 9,300 37.7

208 3 9,300 24.7

240 3 9,300 21.8

Field wire electrical connection is 11/4" and/or 11/2" knockout (strain relief not supplied).

Stacked units must be wired independently.

SINGLE PHASE CONNECTION — 208V or 240V

11 21 31 12 7 22 23 13 33

1 2 3 4 5 6 7 8 9 10 11 12

TB1

1 2 3

L1 L2 L3

(3W) THREE PHASE CONNECTION — 208V or 240V

11 21 31 12 22 23 13 33

1 2 3 4 5 6 7 8 9 10 11 12

TB1

1 2 3

L1 L2 L3

– 7 –

PLACING THE ROTOR IN THE OVEN

Do not wrap the rotor or any other parts inside the oven with aluminum

foil. Soft metals can react with oven cleaners, and hazardous interactions can

result.

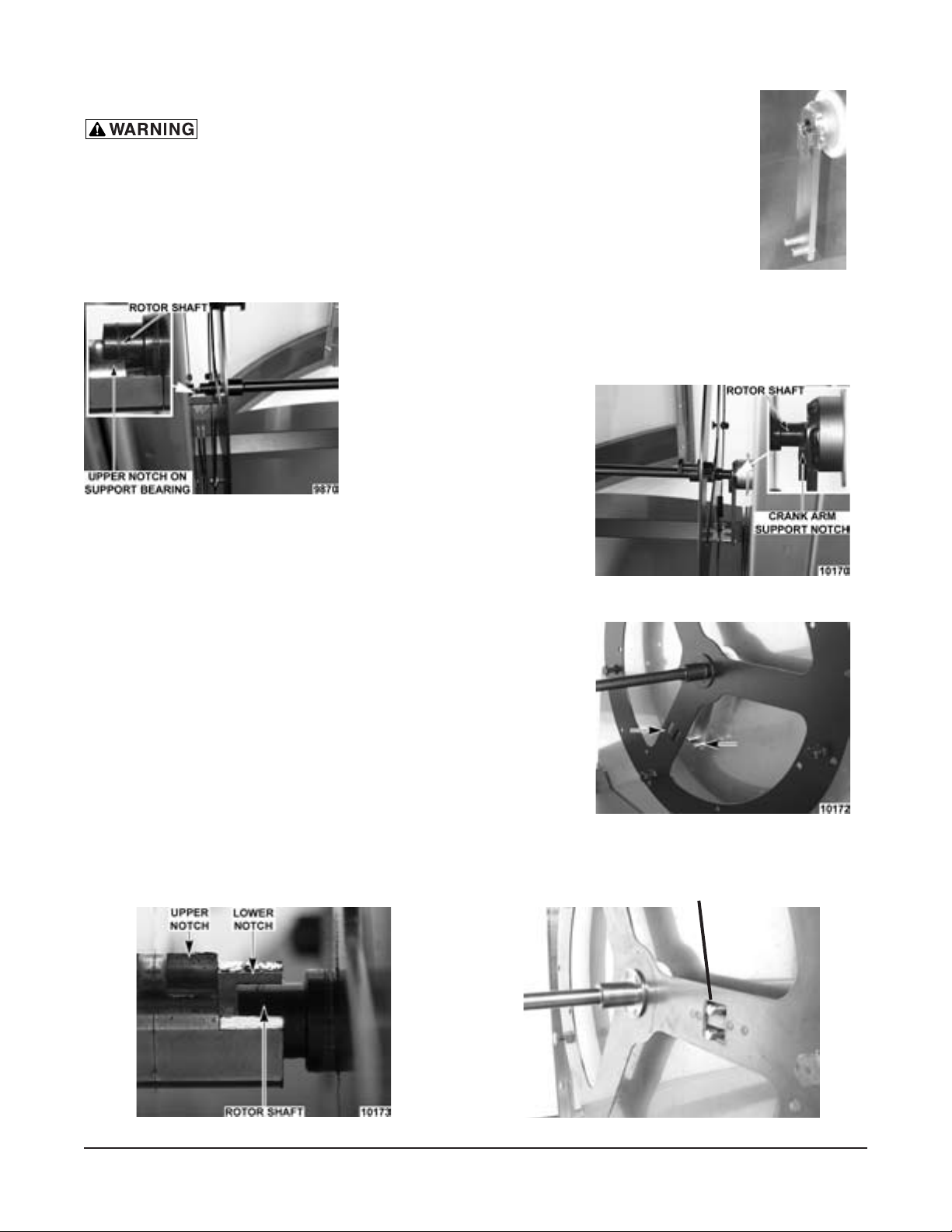

The rotor must properly engage with the drive mechanism. Orient the rotor so that the

end plate with square drive slots is on the same side of the oven as the drive arm.

STEP 1: Stop the drive arm so it is in the down position (Fig. 6).

STEP 2: Place the rotor shaft onto upper notch of support bearing

on the non-drive side of the oven (Fig. 7).

Fig. 7

Fig. 6

STEP 3: Place the drive side of the rotor shaft on the drive arm

support notch (Fig. 8).

STEP 4: Turn the rotor, lining up the square drive slots on

the rotor end plate with the pins on the drive arm

(Fig. 9).

STEP 5: Nudge rotor toward the drive arm. Non-drive end

of rotor shaft falls into the lower portion of support

bearing hub (Fig. 10). Drive end of rotor shaft is driven

into center hole of drive arm.

STEP 6: Rotor is now in normal operating position (Fig. 11).

Fig. 8

Fig. 9

MOTOR DRIVE PINS THROUGH DRIVE

SLOTS ON ROTOR END PLATE

– 8 –

Fig. 11Fig. 10

Hot glass, grease and parts can cause burns. Use care when operating and servicing

ROTATE

the oven.

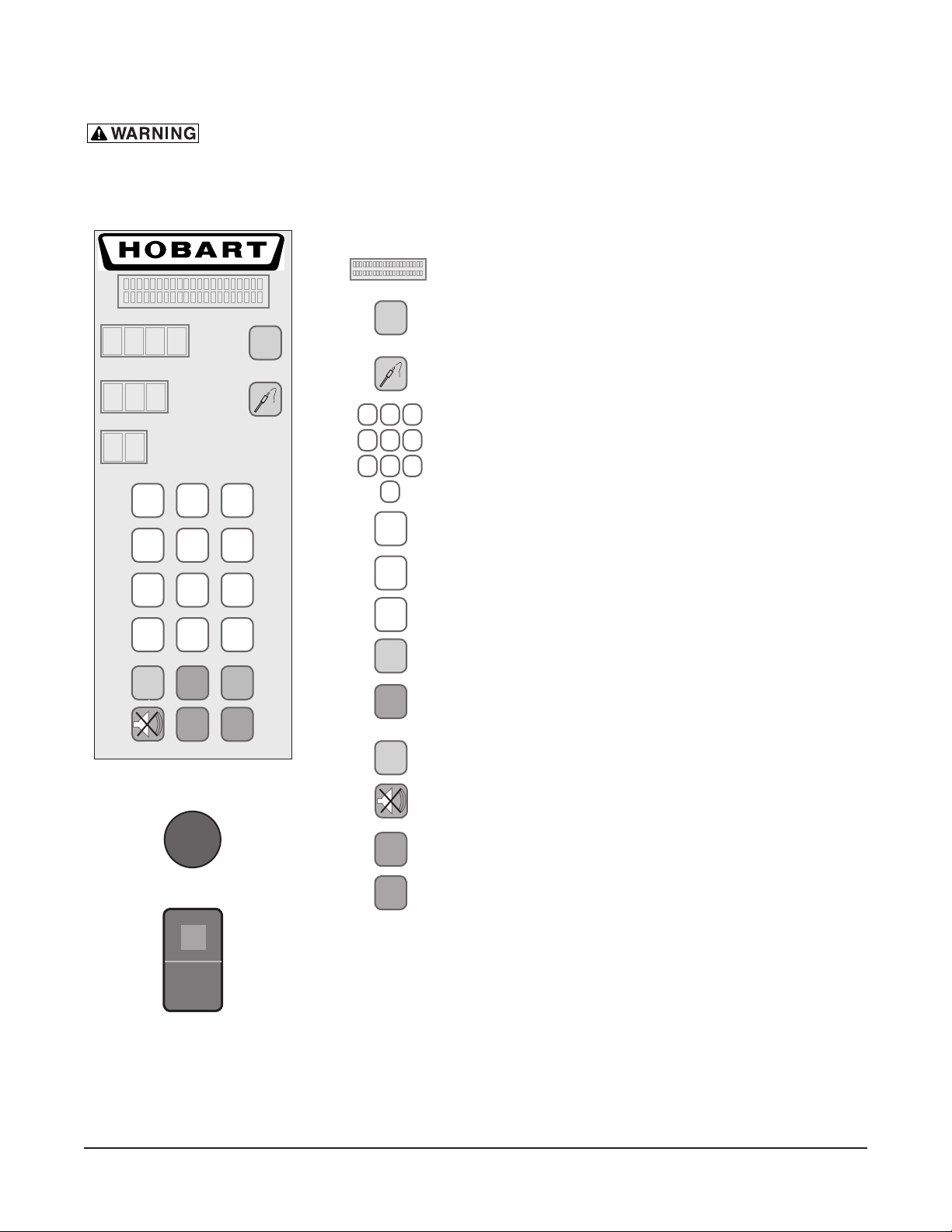

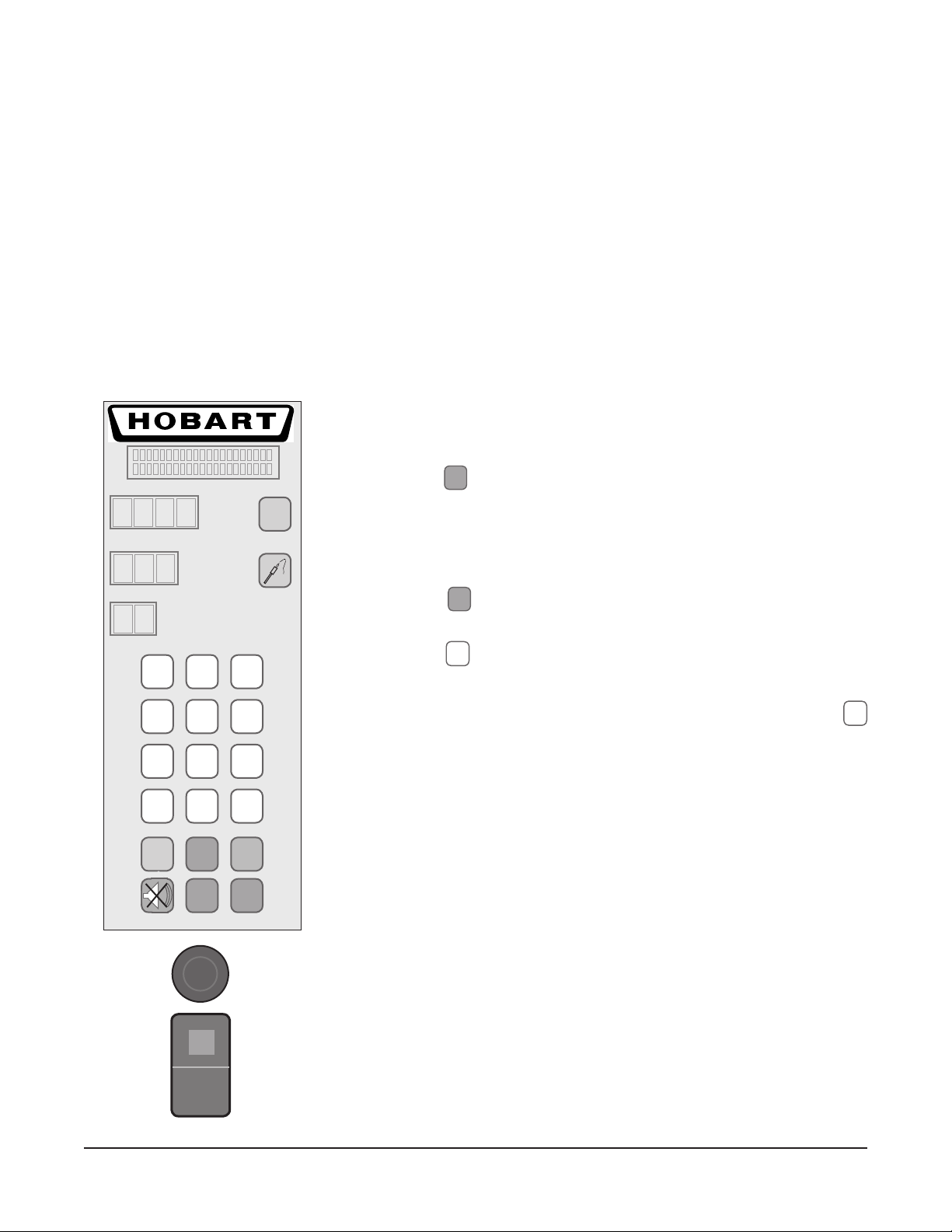

OPERATOR CONTROLS (Fig. 12)

OPERATION

MESSAGE — Provides instructions.

CENTER

TIME

TEMPERATURE

PROGRAM

1 2 3

4 5 6

7 8 9

CLEAR

START

AM

•

PM

•

F

•

C

•

STEP

1 • 2 • 3 • 4

MANUAL

ENTER

0

STOP

P

CLEAN

CLOCK

•

ADD

5

ADD

5

1 2 3

4 5 6

7 8 9

0

CLEAR

MANUAL

0

ENTER

START

P

STOP

ADD 5 — Adds 5 minutes to the current step of the

program each time it is pressed.

PROBE — Displays temperature, external meat

probe.

0 – 9 — Number keys enter numeric values.

CLEAR — Clears time or temperature entry .

MANUAL 0 — Enter a MANUAL Program.

ENTER — Accepts time or temperature entry.

START — Begins cooking cycle.

PROGRAM — Enters program mode to modify a cook

program; press P for 3 seconds.

STOP — Stops cycle.

ON

OFF

Fig. 12

SILENCE — Silences beeper.

CLOCK

CLEAN

CLOCK — Sets the clock for time of day.

CLEAN — Initiates AUTOMATIC CLEANING, refer

to pages 26 – 31.

ROTATE — Rotor on/off, pauses cooking cycle;

pauses cleaning cycle.

MAIN POWER SWITCH — Turns oven and controls on or off.

– 9 –

PASS-THROUGH CONTROLS (Fig. 13)

DOOR JAM

SNOOZE — Adds 10 minutes to the previous step of the program

SNOOZE

SILENCE — Silences the beeper.

STOP

STOP — Stops the cycle.

and silences the beeper. Snooze is active only when the

beeper is sounding at the end of a cook cycle. Snooze is

not active during the cook cycle, during Hold or after the

Stop or Silence buttons have been pressed.

ROTATE — Rotor on/off, pauses cooking cycle; pauses the cleaning

cycle.

ROTATE

Fig. 13

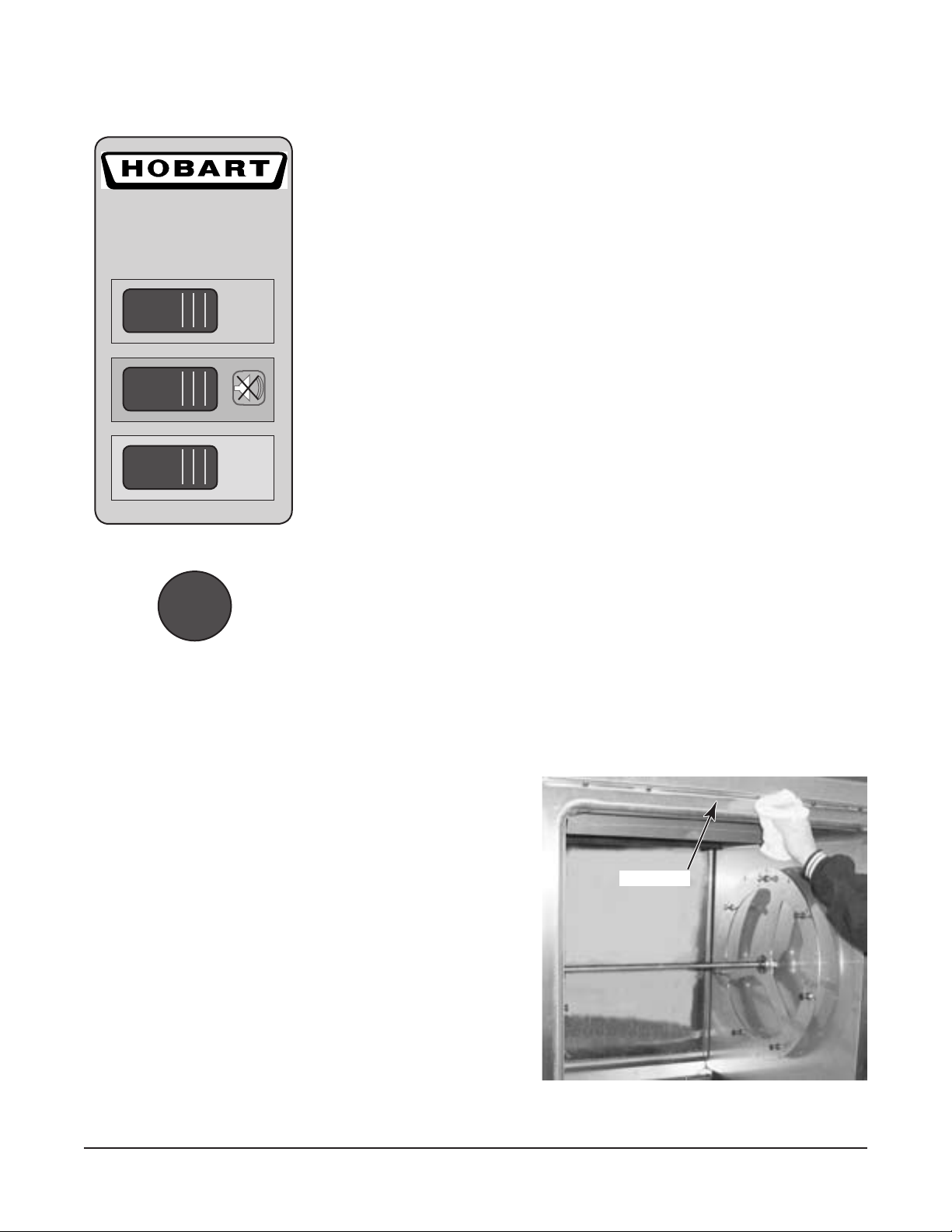

BEFORE FIRST USE

Oven must be burned in to release any odors that might

result from heating the new oven surfaces.

1. Wipe off oven and accessories with a damp or clean

soapy cloth, both inside and outside (Fig. 14). Wipe

clean any soapy residue with a clean damp cloth;

allow to dry.

2. Operate oven at maximum temperature setting of

482°F for 45 minutes. Smoke with an unpleasant

odor will normally be given off during this burn-in

period.

– 10 –

Fig. 14

INITIAL STARTUP

TIME

•

9:25

TEMPERATURE

PROGRAM

P0

•

F

•

C

•

STEP

1 • 2 • 3 • 4

1 2 3

Power On

Idle Mode

Setting the Clock

AM

ADD

PM

5

•

Toggle the Main Power switch on the front panel of the oven to the ON

position; the red indicator light on the switch comes on (Fig. 15).

When the oven is rst turned on, the display shows the time of day

and the last operated program number. Any programmed steps for

the selected program are indicated by illuminated step LEDs. The

interior oven lights are off.

The oven's clock is preset at the factory to run two 12-hour cycles

for A.M. and P.M. as standard. The clock can be reprogrammed to

run as a 24-hour clock by your Hobart service technician.

To set the clock, begin from idle mode.

• Press

CLOCK

.

The time display goes blank.

The AM or PM light blinks.

• Enter the time of day (HH:MM) using the number keys.

• Press

CLOCK

to toggle A.M. or P.M. (not necessary if clock is

programmed for 24-hour operation).

• Press

ENTER

to accept a valid entry. The control returns to idle

mode.

4 5 6

7 8 9

MANUAL

0

START

P

CLOCK

ON

OFF

Fig. 15

ENTERCLEAR

STOP

CLEAN

• If a nonvalid value such as 10:95 is in the time display when

is pressed, the beeper sounds twice and the time display goes

blank.

Changing Temperature Readings to Celsius

The oven is preprogrammed for temperatures to read in Fahrenheit

degrees as standard. The oven can be reprogrammed for Celsius

temperature readings by your local Hobart Service ofce.

ENTER

– 11 –

Loading...

Loading...