Hobart Food Machines HS20 Installation Manual

Model HS10

Model HS20

ML-134371

ML-134386

ML-134432

Page 1 - English

Page 21 - French

Page 41 - German

INSTALLATION AND OPERATION MANUAL

MANUEL D’INSTALLATION ET D’UTILISATION

INSTALLATIONS UND BEDIENUNGSANLEITUNG

701 S. RIDGE AVENUE, TROY, OHIO 45374-0001

00-1-937-332-3000 WWW.HOBARTCORP.COM

F 37220 (June 2008)

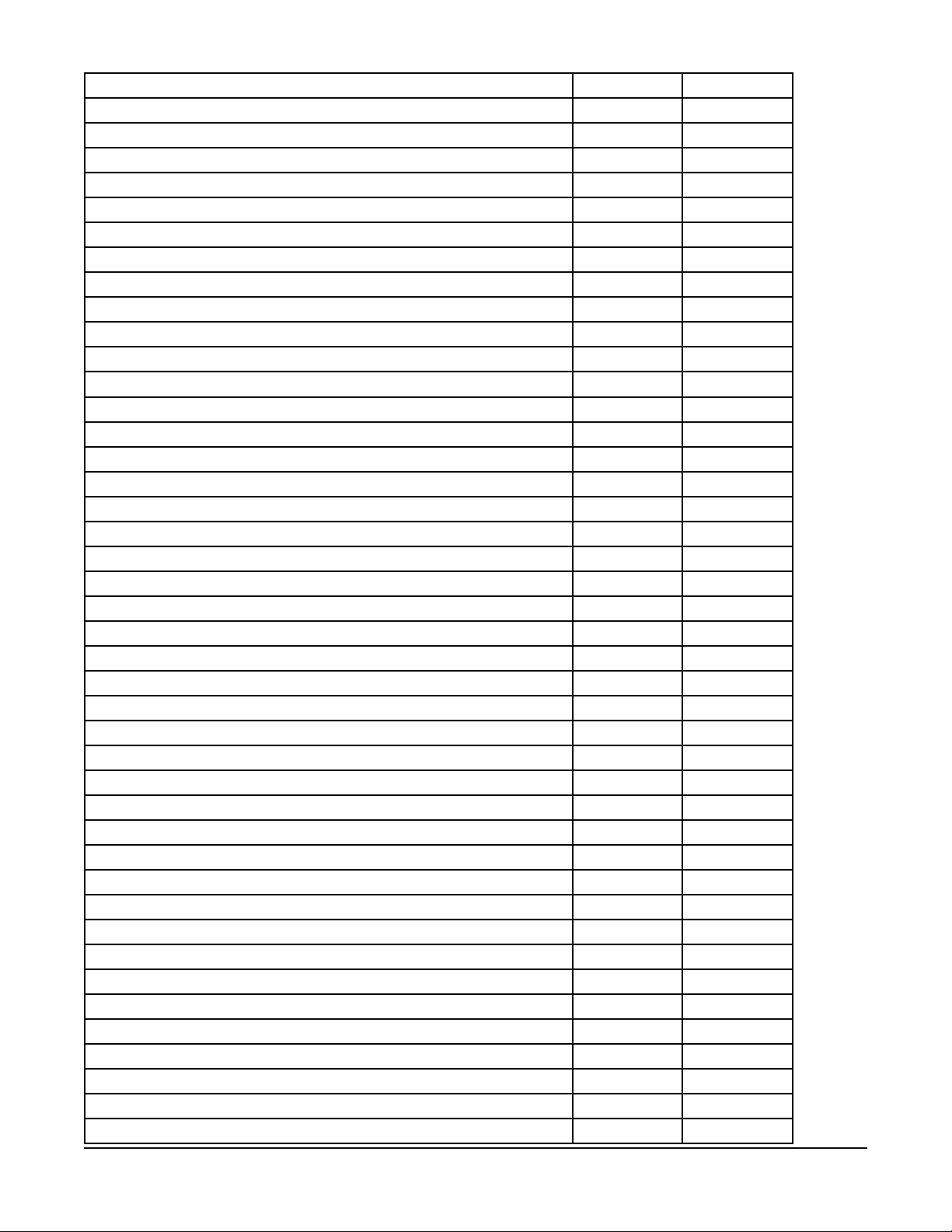

English / Contents

Section Page

Safety Information 1.0 3

Safety Guidelines 1.1 3

Warning Symbols 1.2 3

Liability 1.3 4

Foreword 2.0 4

General Information 3.0 4

Caring for Our Environment 4.0 4

Packing Material 4.1 4

Disposal of Your Old Appliance 4.2 4

Safety Instructions 5.0 5

Dust Hazard 5.1 5

Never 5.2 5

Always 5.3 6

Using the Mixer 6.0 6

Operating for the First Time 6.1 6

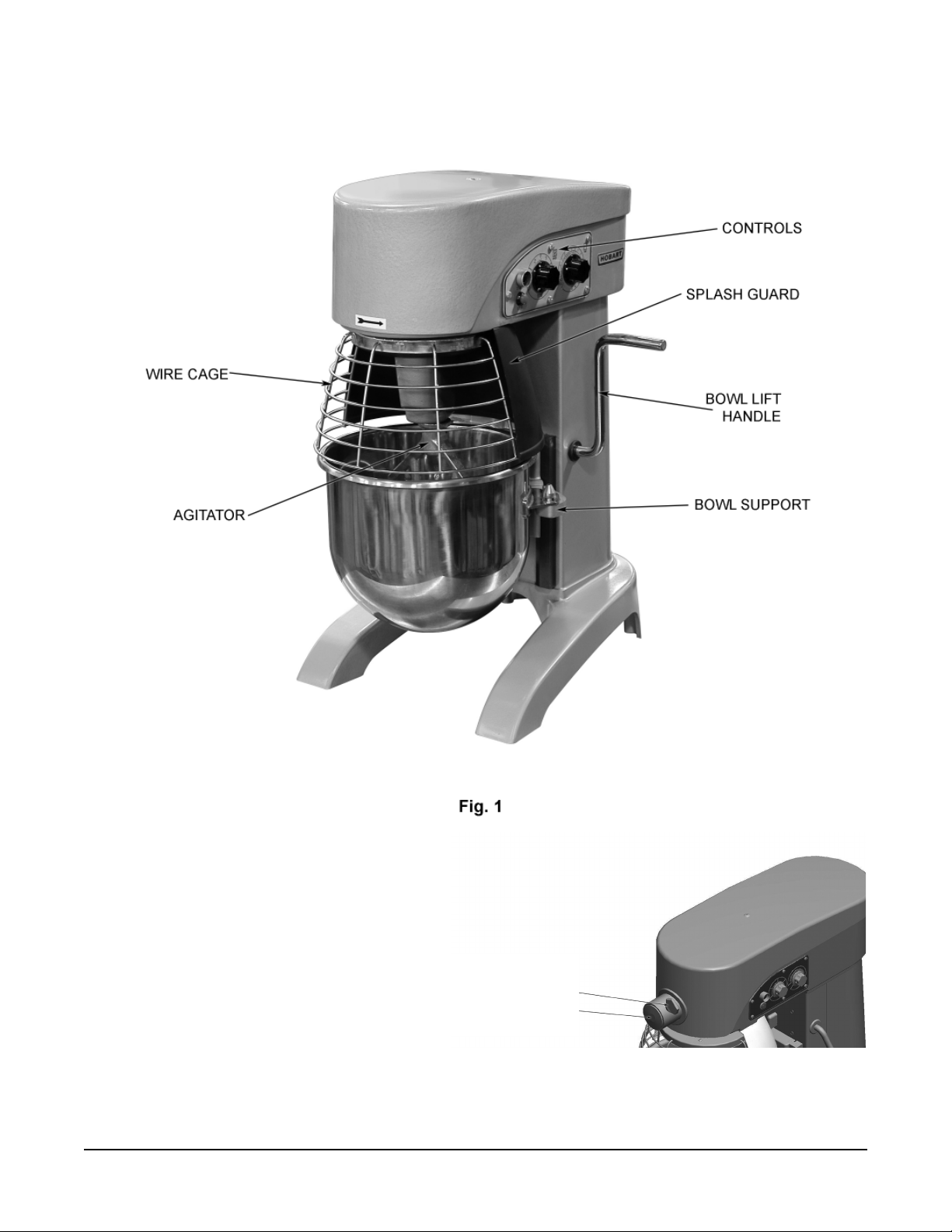

Mixer Component Identifi cation Fig. 1 7

Controls 7.0 8

Bowl Placement 9.0 8

Agitator 10.0 9

Bowl Guard 11.0 9

Remove Bowl Guard 11.1 9

Install Bowl Guard 11.2 9

Mixing Capacity Chart 12.0 10

Agitators 13.0 11

Cleaning 14.0 11

Cleaning After Use 14.1 11

Installation and Commissioning 15.0 12

Technical Information Table 1 14

Unpacking and Handling 16.0 14

Location 17.0 15

Electrical Installation 18.0 15

Operator Training 19.0 15

Mixer Maintenance 20.0 16

Lubrication 20.1 16

Slideways 20.2 16

Planetary Seal 20.3 16

Measure and Adjust Agitator Clearance 20.4 16

Interlock Safety System 20.5 17

Fault Finding 21.0 17

Recommended Spares 22.0 18

Notes 23.0 19

Service Contact Numbers 24.0 20

© Hobart 2008

– 2 –

1.0 SAFETY INFORMATION.

The procedures and precautions contained in this manual are understood to apply to the machinery

only when it is used in the prescribed manner. If the machinery is used other than in the recommended

manner, the operator will be responsible for his/her own safety and for the safety of the other persons

who may be involved.

The information in this manual has been prepared to assist the operator to understand, maintain, and

operate the mixer. In order to prevent accidents, read, understand and follow all the precautions and

warnings contained in this manual before installation or operating for the fi rst time. This manual must be

studied to obtain a clear understanding of the mixer and its capabilities.

1.1 SAFETY GUIDELINES.

Ensure suffi cient precautions are observed during manual handling of the mixer particularly when mov-

ing into position on installation. Reference must be made to manual handling regulations. The mixer

weights are given in Table 1.

Do not hose or pressure clean this appliance. It is vital to adhere to the cleaning instructions

•

detailed in section 14 of this manual.

Do not remove any covers or loosen any fi ttings whilst the machine is operating.

•

Ensure this manual is kept in an easily accessible place for future reference near the mixer.

•

All operators must be trained in the safe operation of the mixer and attachments.

•

Ensure that the power supply cord has been unplugged before attempting to service or move

•

the mixer.

Rotating machinery and electricity are potentially hazardous and may cause injury if suffi cient

•

precautions are not taken prior to operating or servicing the machine.

Always have your mixer and attachments regularly serviced; at least twice a year, depending on

•

frequency of use.

When mixing products that develop dust care must be taken. Mix the ingredients using the

•

BLEND facility until the dust is eliminated.

Exposure to dust (including fl our) may be harmful to health causing rhinitis (running noses),

•

watering eyes and possibly occupational asthma.

1.2 WARNING SYMBOLS.

To identify the safety messages in this manual, the following symbols have been used:

The "Warning" symbol is found primarily where the corresponding information is

important for the safe use of the machinery.

The electrical hazard symbol is used when there are risks of an electrical nature. Prior to

servicing the machinery, always disconnect the power cable from the mains supply.

– 3 –

1.3 LIABILITY.

Installations and repairs which are not carried out by Authorised technicians or the use of other than

original spare parts, and any technical alterations to the machine, may affect the warranty set out in the

standard conditions of sale.

2.0 FOREWORD.

Hobart reserves the right to alter the design of their products without prior notice. Whilst every effort is

made to ensure this publication refl ects the latest design, the Company cannot guarantee full compli-

ance. Take pride in your HS10/HS20 Mixer - keep it clean and in good mechanical and electrical condition.

3.0 GENERAL INFORMATION.

The information and instructions contained in this manual may not cover all details or variations in the

equipment, nor provide for every eventuality to arise with installation, operation, or maintenance. If additional information is required, please contact your local Hobart offi ce.

The HS10/HS20 Mixers are designed to mix food products as detailed on the specifi cation chart (Sec-

tion 12.0, page 10).

The Hobart 10-litre/20-litre mixers are a bench-type mixer which features a manual bowl lift.

The Hobart 20-litre mixer is optional with a #12 attachment hub. With the use of special agitators, a 10litre bowl may be used on the HS20 mixer.

The machines are rated to operate on the electrical supplies shown in Table 1, page 14.

The Mixer is fi tted with a "no volt release" safety feature to prevent automatic restarting after a supply failure or

disconnection from the mains. The bowl and the guard are interlocked so that when either is not in their correct

operating positions, the mixer will not work. The standard mixer is delivered with guard, bowl and agitators.

4.0 CARING FOR OUR ENVIRONMENT.

4.1 PACKAGING MATERIAL.

The pallet and protective packing material have been selected from

materials that are environmentally friendly for disposal or can normally

be recycled. Instead of throwing them away, please ensure they are recycled.

4.2 DISPOSAL OF YOUR OLD APPLIANCE.

Old appliances contain materials that can be recycled. Please contact your local waste collection centre; scrap merchant or local Hobart offi ce about potential recycling schemes.

– 4 –

5.0 SAFETY INSTRUCTIONS.

A FULLY TRAINED AND COMPETENT PERSON MUST ONLY USE THE MIXER.

The following instructions must be observed when using the mixer.

Note: The mixer must only be used for the purpose it was designed and inline with the supplied operating instructions.

5.1 DUST HAZARD.

In order to minimise any dust hazard follow the instructions detailed below.

When mixing ingredients care must be taken to avoid the inhalation of dust particles e.g. fl our. Refer-

ence should be made to product supplier's data sheets to ensure adequate precautions/protections are

taken.

Items such as fl our must be added in such a manner to avoid dust particles being dispersed into the

local atmosphere.

Carefully slit the bag whilst holding in the lower part of the bowl. When mixing dry ingredient use the

lowest speed to minimise dust emission. Mix the ingredients in the bowl using the lowest speed until the

risk of producing any dust is eliminated.

Fit suitable dust extraction equipment.

5.2 NEVER.

Operate the mixer or attachments if a fault develops or the mixer is unsafe.

•

Wear loose clothing.

•

Attempt to reach into the bowl when mixing.

•

Access rotating parts.

•

Fit the agitator to the mixer without a bowl in place.

•

Leave the agitator on machine without the bowl being fi tted.

•

Use excessive force when operating which could affect the stability of the mixer.

•

Operate the mixer if parts are disassembled.

•

Over ride the safety switches fi tted to the mixer.

•

Open the guard to stop machine.

•

Use the bowl lift to stop machine.

•

Use the mixer in an unsafe condition.

•

– 5 –

•

Clean the mixer with scouring powder or a scouring pad.

•

Clean aluminium agitators in dishwashers.

•

Inhale mixing ingredient dust particles.

5.3 ALWAYS.

• Use the mixer in a well-lit area.

• Ensure the bowl, agitator and guard are correctly fi tted to the mixer.

• Disconnect the mains electricity supply before cleaning the mixer.

• Clean the mixer daily.

• Stop mixer before adding more ingredients.

• Use the stop button to stop machine.

• Clean the bowl and agitators after use.

• Clean the mixer using mild soap and water.

• Service the mixer at least twice a year depending on the frequency of use.

• Use the mixer as intended and inline with the operating instructions.

6.0 USING THE MIXER.

6.1 OPERATING FOR THE FIRST TIME.

Prior to installation, test the electrical service to assure that it agrees with the specifi cations on the ma-

chine data plate.

Place the mixer on a suitable sturdy level surface. There should be adequate space around the mixer

for the user to operate the controls and to install and remove bowls.

Holes are located in the base to permanently secure the mixer, although this is not necessary in normal

installations.

This food mixer is only for professional use by suitably trained persons. Ensure

operators have read and understood this manual and have received adequate training. Moving

agitator in bowl. Keep hands, clothing, and utensils out while in operation. Do not use without

interlocked guard.

– 6 –

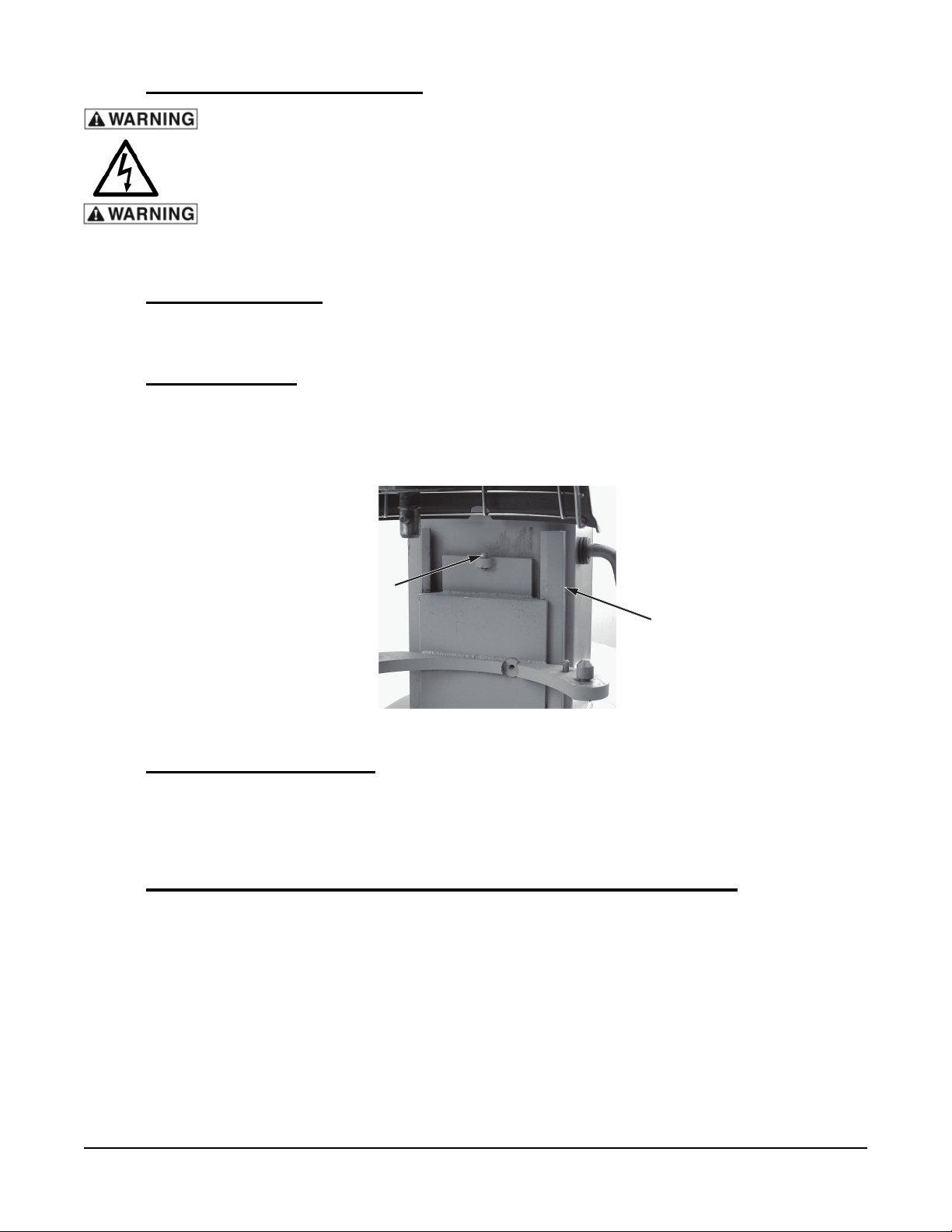

Attachment Hub

Thumb Screw

– 7 –

Plug

Fig. 2 (20 Liter Mixer)

7.0 CONTROLS

Push-button STAR T and STOP buttons control power to the mixer.

•

The Bowl Guard must be in place and closed or the mixer will not operate.

•

If the Bowl Support is not all the way up, the mixer will not operate.

•

STARTS

STARTS

MIXER

MIXER

STOPS

STOPS

MIXER

MIXER

SPEED

SPEED

SELECTOR

SELECTOR

Fig. 3

TIME

TIME

SELECTOR

SELECTOR

The TIMER is used in conjunction with the S

TAR T button for timed mixing operations and will stop the

mixer when the desired time has elapsed.

For Non-Timed Mixing — Set the timer on H

PEED SELECTOR (Fig. 3) is used to change speeds. To change speeds, turn the SPEED SELECTOR to

The S

OLD and use the STOP button to turn the mixer off.

the desired speed. Speed can be set when mixer is on or off.

LEND The slowest speed to incorporate ingredients.

B

Speed 1 (Low) For light dough, heavy batters, or potatoes.

Speed 2 (Medium) For cake batters or some whipping operations.

Speed 3 (Medium-High) For light work, such as whipping cream, beating eggs, or mixing thin

batters.

Speed 4 (High) This speed is for maximum and accelerated air incorporation into light

batches.

The B

OWL LIFT HANDLE (Fig. 1, page 7) is used to raise and lower the bowl. To raise the bowl, rotate the

handle upward; rotating the handle downward lowers the bowl.

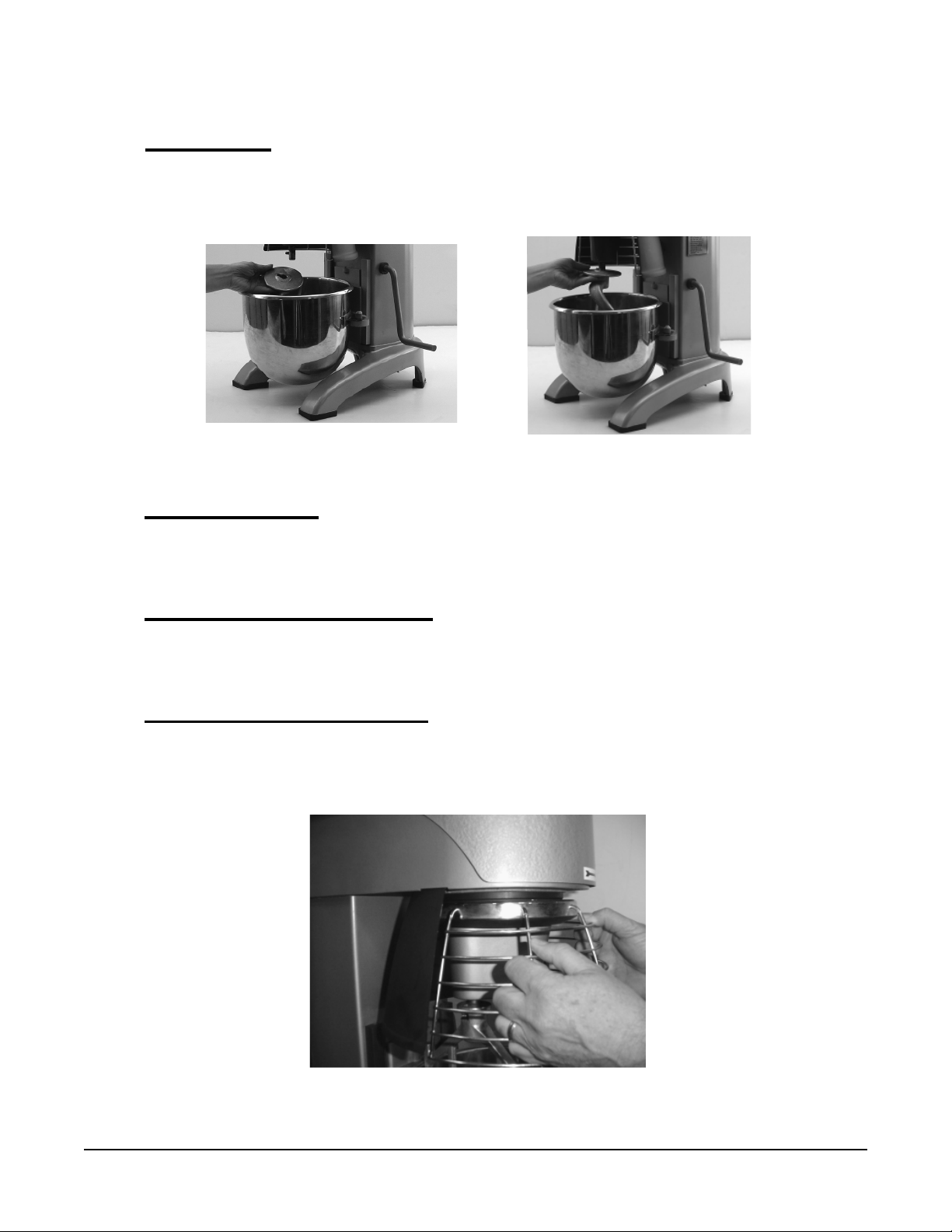

9.0 BOWL PLACEMENT

The bowl must be installed before the agitator. To install the

bowl, fully lower the bowl support (Fig. 4). Position the bowl so two large

holes on bowl tabs are above the bowl pins on the bowl support.

10 Liter Mixer - Lower the bowl onto the bowl pins then turn clockwise until

stopped in locked position.

20 Liter Mixer - Lower the bowl onto the bowl pins then turn counter clockwise until stopped in locked

position.

– 8 –

Fig. 4

10.0 AGITATOR

To install an agitator (Fig. 1, page 7), the bowl must be installed and fully lowered. Place the agitator in

the bowl, push it up on the agitator shaft, and turn it clockwise to seat the shaft pin in the slot of the

agitator shank.

Fig. 5Fig. 5

11.0 BOWL GUARD

Bowl guard must be in position and closed in order to mix. If bowl guard is opened during the mixing,

mixer will stop.

11.1 REMOVE BOWL GUARD

Lower the bowl support and remove agitator before removing bowl guard. Hold bowl guard with both

hands and pull downward gently to release bowl guard from retaining groove.

11.2 INSTALL BOWL GUARD

Hold bowl guard with both hands and gently push upward until bowl guard is latched onto the retaining

groove and can be rotated freely.

Fig. 6

– 9 –

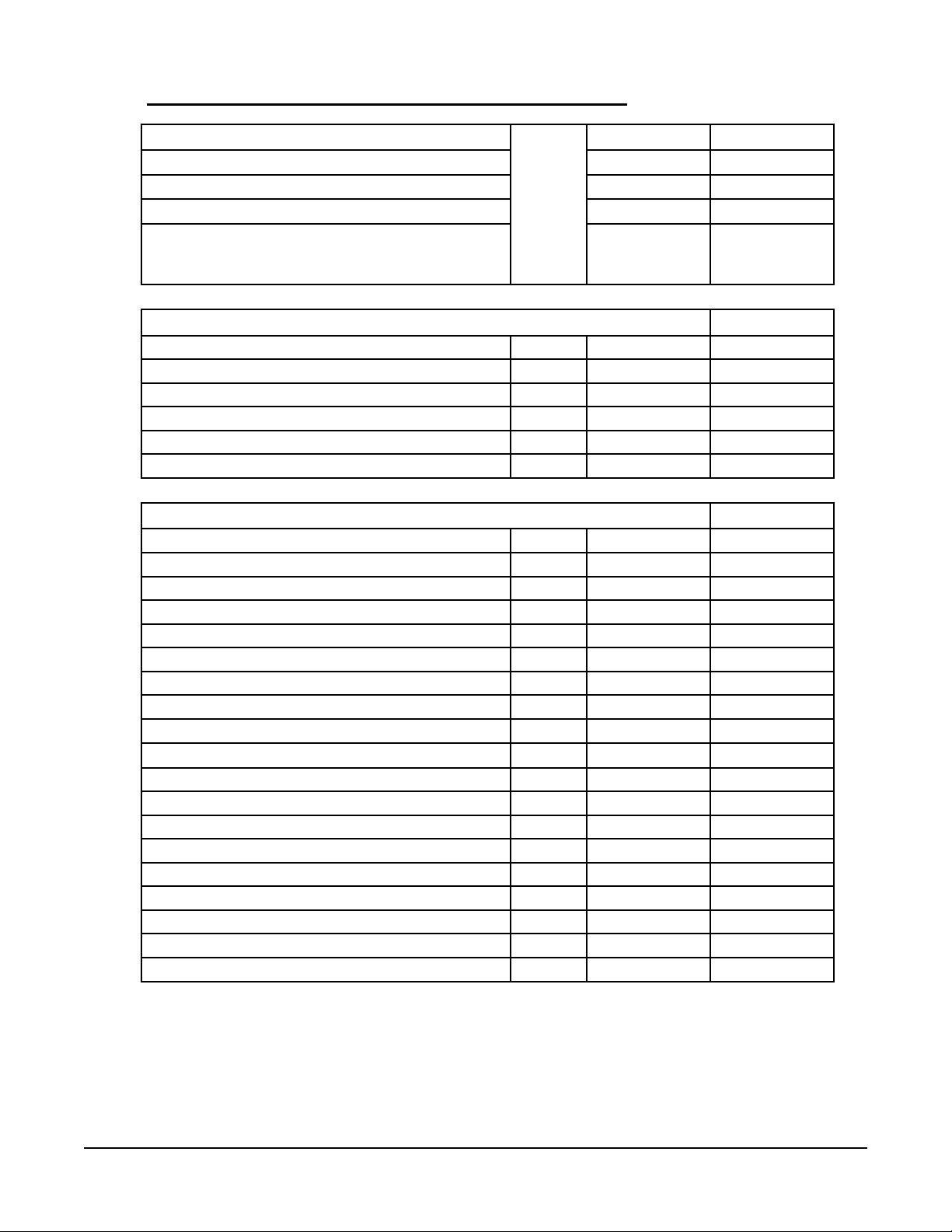

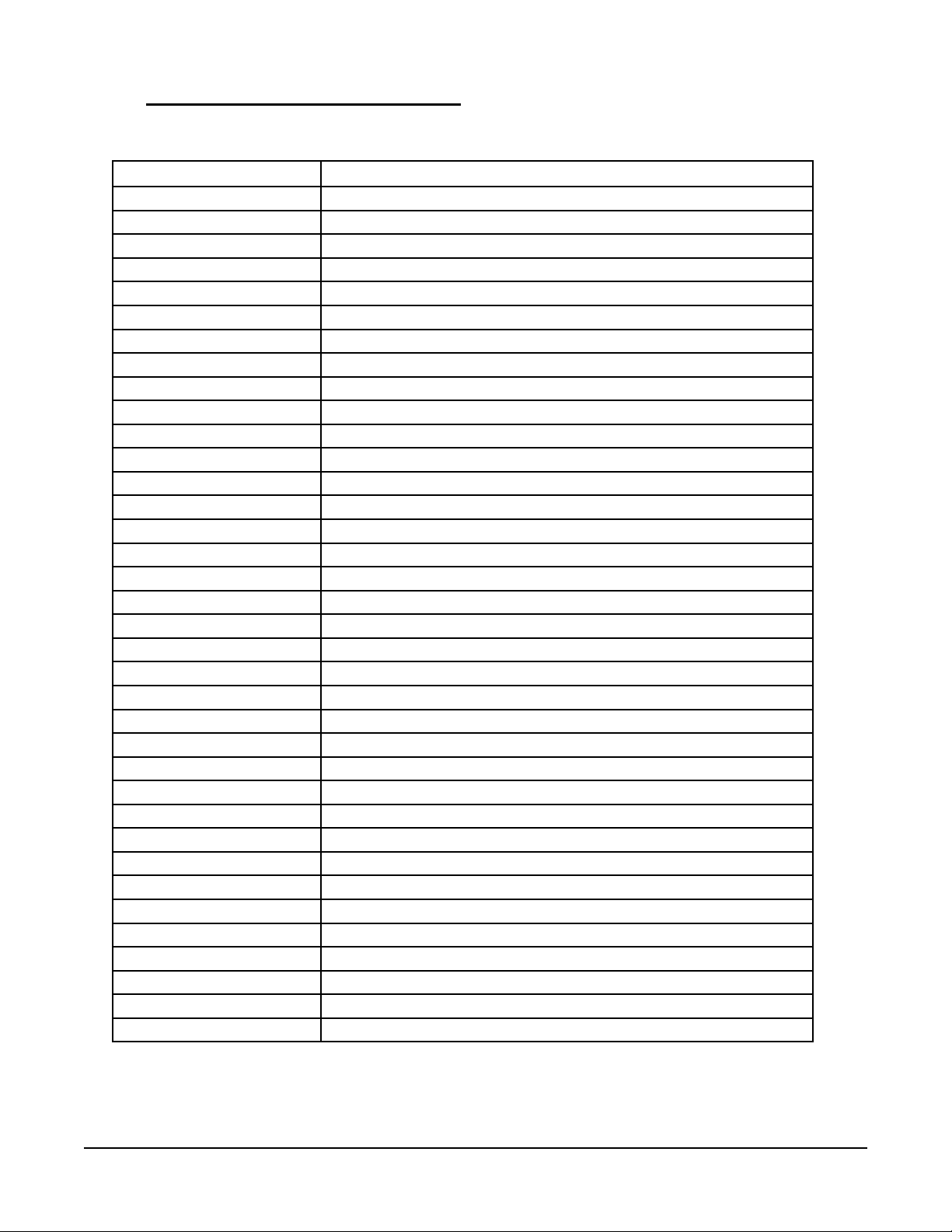

12.0 Mixing Bowl Capacity Chart - HS10/HS20

Capacity of Bowl (Qts. Liquid)

Model HS10 HS20

Motor (HP) .45 .45

Small Bowls Available as Extras

Overall Space Required (Floor) 13 21/32W X

Agitators

Suitable

for

Opera-

tion

10-Quart 20-Quart

17 47/64W X

17 9/32D X 25

5/8H

23 1/8D X 31

11/32H

Kitchen Materials Capacity Chart (Finished Materials)

Egg Whites (pt.) D 1 pt. 2 pts.

Mashed Potatoes (lbs.) B 8 lbs. 15 lbs.

Mayonnaise (Qts. of Oil) B or D 4 qts. 9 lbs.

Meringue (Qty. of Water) D 3/4 pt. 1 1/2 pts.

Waffl e or Hot Cake Batter (qt.) B 4 qts. 8 qts.

Whipped Cream (qt.) D 2 qts. 4 qts.

Bake Shop Materials

Cake, Angel Food (8-10 oz. cake) (lb.) B 7 1/2 lbs. 15 lbs.

Cake, Box or Slab or Layer (lb.) B 10 lbs. 20 lbs.

Cake, Cup (doz.) B 18 doz. 30 lbs.

Cake, Pound (lb.) B 15 lbs. 21 lbs.

Cake, Sponge (lb.) B 6 lbs. 12 lbs.

Cookies, Sugar (lbs.) B 9 lbs. 15 lbs.

Dough, Bread or Roll (Lt-Med) 60% AR § (lb.) ED 12 lbs.** 25 lbs.**

Dough, Heavy Bread 55% AR § (lb.) ED 5 lbs.** 10 lbs.**

Dough, Pie (lb.) B 12 lbs. 18 lbs.

Dough, Thin Pizza 40% AR (max mix time 5 min.) § ED 4 lbs.** 9 lbs.**

Dough, Medium Pizza 50% AR § ED 5 lbs.** 10 lbs.**

Dough, Thick Pizza 60% AR § ED 8 lbs.** 20 lbs.**

Dough, Raised Donut 65% AR (lb.) ED 4 1/2 + lbs. 9 + lbs.

Dough, Whole Wheat 70% AR ED 8 lbs.** 20 lbs.**

Eggs & Sugar for Sponge Cake (lb.) B 4 lbs. 8 lbs.

Icing, Fondant (lb.) B 6 lbs. 12 lbs.

Icing, Marshmallow (lb.) B 1 lbs. 2 lbs.

Shortening & Sugar, Creamed (lb.) B 8 lbs. 16 lbs.

Pasta, Basic Egg Noodle (max mix time 5 min.) (lb.) ED 3 lbs. 5 lbs.

ABBREVIATIONS - AGITATORS

SUITABLE FOR OPERATION

B - Flat Beater

D - Wire Whip

ED - Dough Arm

** 1st Speed

+ 2nd Speed

NOTE: % AR (% Absorption Ratio)

= Water weight divided by fl our weight X 100%.

Capacity depends on moisture content of dough.

Above capacity based on 12% fl our moisture and

o

F water temperature.

70

§ If high gluten fl our is used, reduce above dough

batch size by 10%.

– 10 –

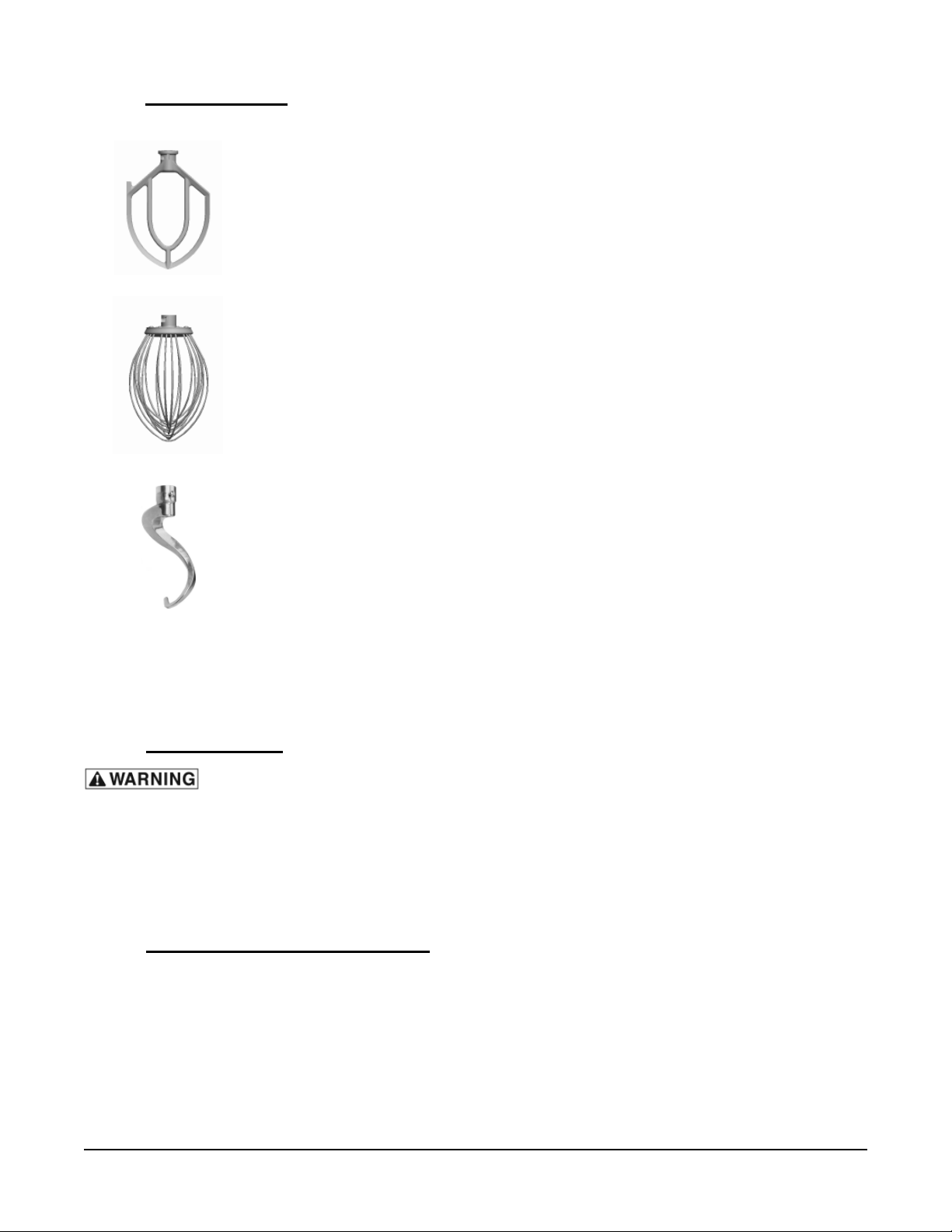

13.0 AGITATORS

The B Flat Beater is a multi-purpose agitator used for mashing potatoes or

other vegetables, and mixing cakes, batters or icings. It is also used in industrial

applications for any product requiring a creaming or rubbing action and uniform

dispersion of ingredients. Use fi rst speed for starting most operations; medium

speed for fi nishing.

The D Wire Whip is designed for maximum blending of air into light products.

Uses include: whipping cream, beating egg whites, mixing very light icings, meringues and all similar applications. The D Wire Whip is most commonly used in

third and fourth speed.

The ED Dough Hook is used for mixing most bread, roll and pizza dough, which

require folding, and stretching action for best development. These agitators are

suitable for use on all yeast raised doughs and commonly used in fi rst or second

speed.

14.0 CLEANING.

Cleaning New Mixer Bowls and Accessories - Before using the fi rst time, thor-

oughly wash new mixer bowls and agitators (beaters, whips and dough hooks). Wash in hot

water and a mild detergent solution, rinsing with either a mild soda or vinegar solution, and

thoroughly rinse with clear water. Also follow this cleaning procedure for bowls and agitators

before whipping egg whites or whole eggs.

14.1 CLEANING AFTER USE.

After use, clean the mixing bowl and agitators with hot water, using a suitable non-abrasive detergent

and soft bristle brush. (Flushing the bowl with hot water immediately after use will ease the cleaning).

Note: Do not clean the aluminium agitators in a dishwasher.

The mixer should be thoroughly cleaned daily. Do not use a hose to clean the mixer; it should be

washed with a clean, damp cloth. The base allows ample room for cleaning under the mixer. For

cleaning the Bowl Guard, refer to Section 11.1.

– 11 –

15.0 INSTALLATION AND COMMISSIONING.

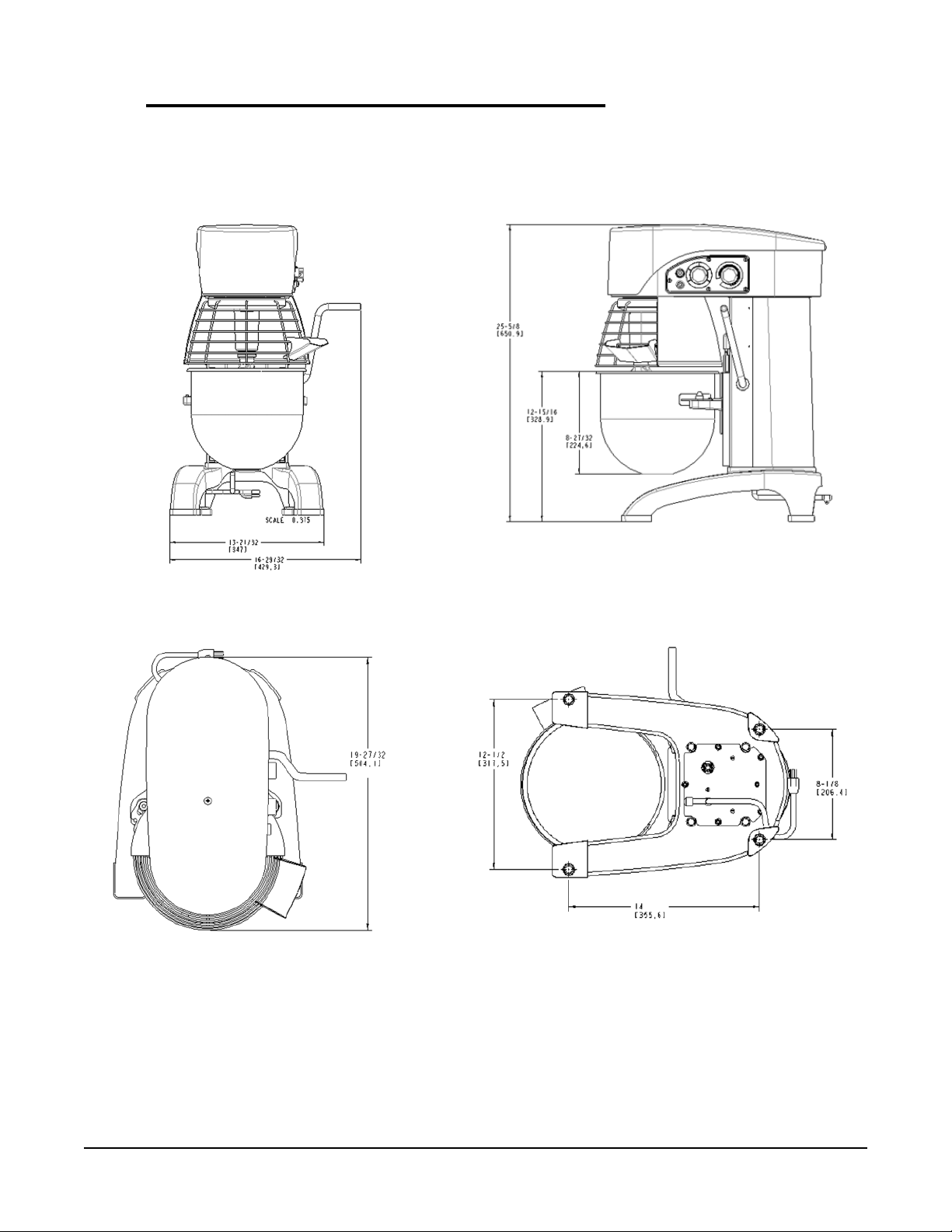

Fig. 7 (HS10)Fig. 7 (HS10)

– 12 –

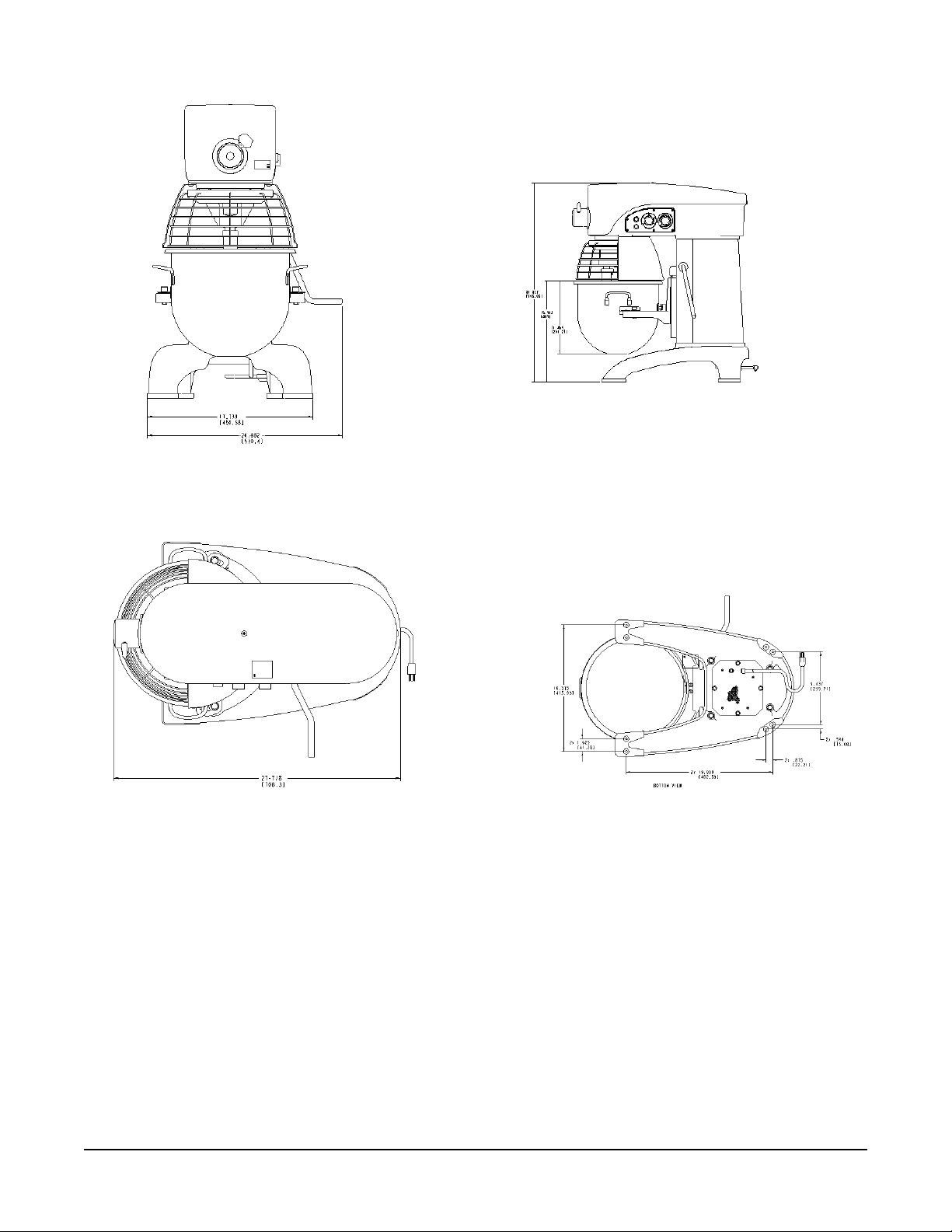

Fig. 8 (HS20)

Overall Dimensions:

A 10-litre bowl and agitator are available.

A variety of attachments, agitators, and accessories are available. These are described in Section 13.0

(page 11) of this manual.

– 13 –

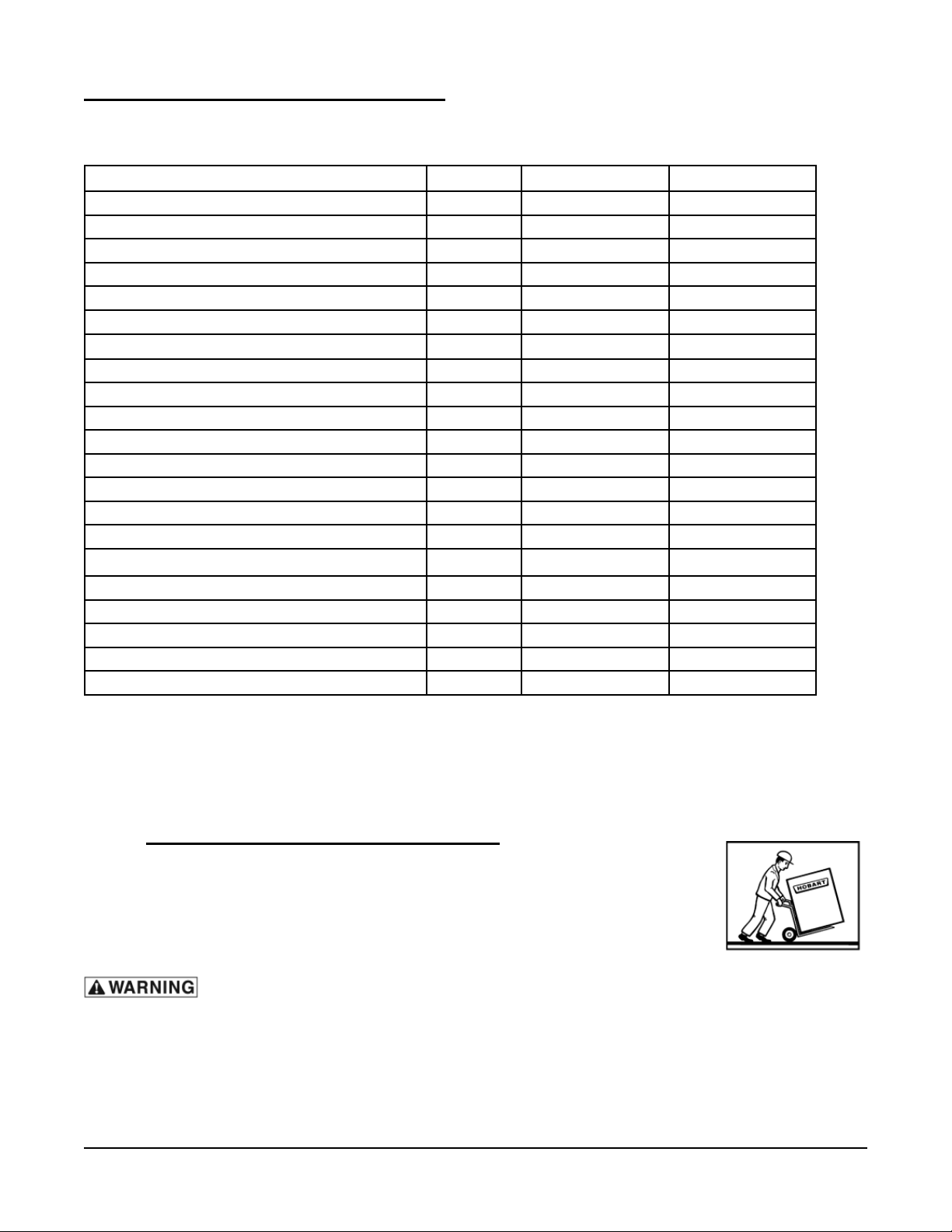

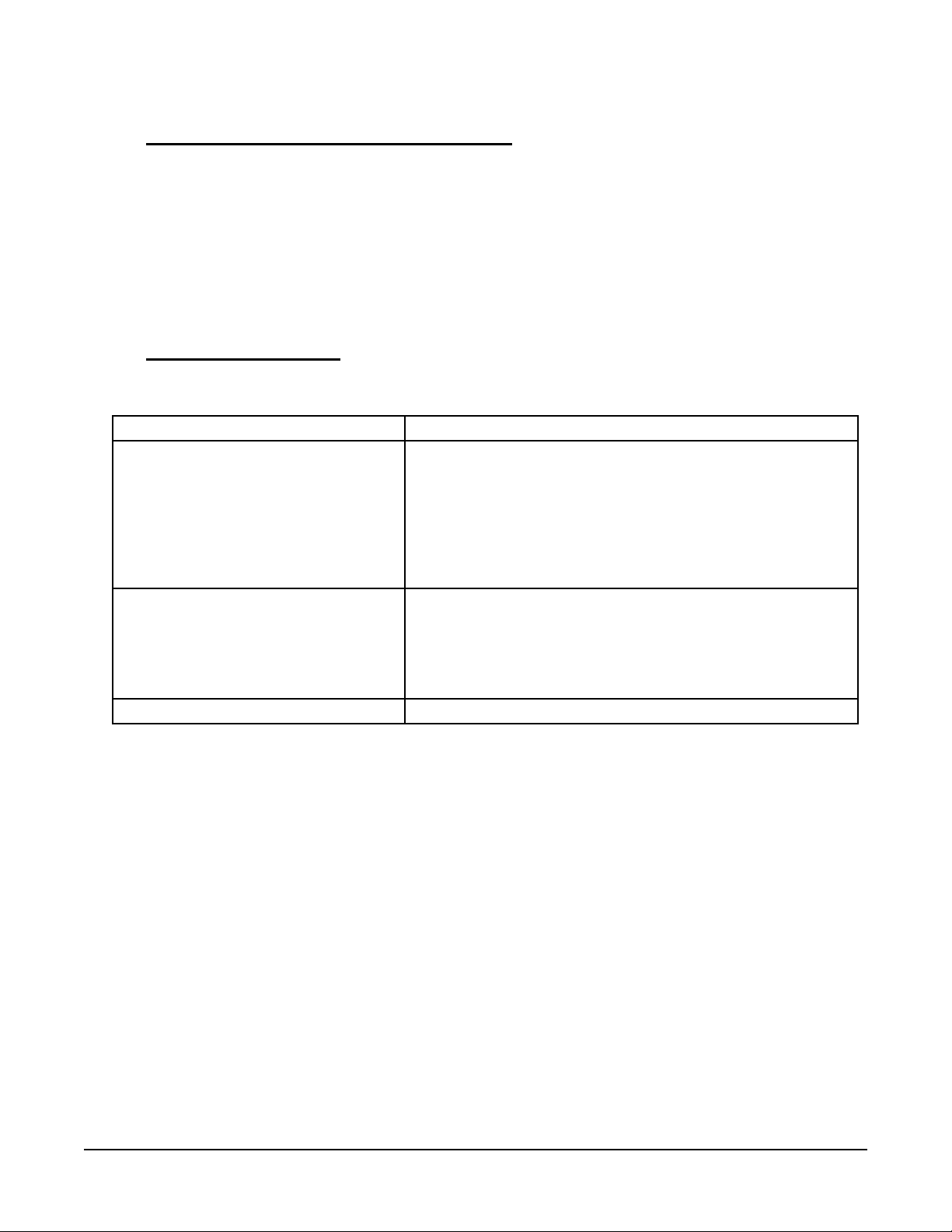

Table 1. Technical Information.

Description Units HS10 HS20

Mixer power kW (hp) 0.34 (0.45) 0.56 (0.75)

Maximum speed of rotating part (50Hz) rpm 2500 3700

Nominal electrical supply 1 ph Volts 200-240 200-240

Full load current at above voltage 1 ph Amps 2.9 5.5

Locked rotor current at above voltage 1 ph Amps 10 12

Recommended fuse size 230v/1 ph/50Hz Amps 10 8

Minimum ambient temperature

Maximum ambient temperature

Planetary grease - - - light coat on gears light coat on gears

Transmission case lubricating grease capacity Kg (lbs) - - - 0.55 (1.21)

Mixer weight (Bowl Included) Kg (lbs) 85.7 (189) 97.1 (214)

Bowl weight (10 litre) Kg (lbs) 1.41 (3.1) - - Bowl weight (20 litre) Kg (lbs) - - - 3.3 (7.2)

Agitator weight (10 litre beater) Kg (lbs) 0.95 (2.1) - - Agitator weight (20 litre beater) Kg (lbs) - - - 1.0 (2.3)

Noise level dB (A) less than70## less than70##

o

C0 0

o

C40 40

Shipping weight (Bowl included) kg (Lbs) 92.5 (204) 136.5 (301)

Shipping dimensions (carton) LxWxH cm 62.8 x 57.8 x 87.3 81.3 x 78.7 x 106.7

Storage conditions. Temperature and humidity.oC, % RH +5 to +38, 85 +5 to +38, 85

Class of appliance Class 1# Class 1#

Enclosure IP rating IP32 IP32

# Refer to Section 18.0

## In accordance with EN-ISO 12001:1996.

16.0 UNPACKING AND HANDLING.

Wherever possible the food mixer should be transported to the installation position

in the packaging provided to avoid damage. Do not use a sharp knife to cut into the

box as damage to the machine may occur. Check for possible shipping damage. If

the unit is found to be damaged, save the packaging material and contact your

nearest Hobart sales offi ce.

The HS10/HS20 mixer is a heavy object and must be correctly handled and lifted

to avoid personal injury. Refer to Table 1 for weights and dimensions. For UK installations refer

to the Manual Handling Operations Regulations 1992 and HSE guidance notes for manual handling.

With the machine in the vicinity of its fi nal position, remove from outer carton. Remove mounting bolts

under skid attached to mixer base. Remove mixer from skid forking from the side of unit. When moving unit, always fork from side of unit.

– 14 –

Care must be taken during this operation to ensure:

a.

All required safety measures are taken to ensure correct lifting and handling to avoid risk of

injury through dropping, falling and tilting.

No damage occurs to the machine, which could impair the normal operation.

b.

17.0 LOCATION.

The mixer is not suitable for outdoor installation and must not be installed where

a water jet could be used for cleaning. The mixer must only be operated by trained staff and

must be installed in an area where the use and maintenance is restricted to trained personnel.

The mixer must be installed on a horizontal fl at surface level to a minimum of 1mm in 1 metre side to

side and front to back. Select a suitable fl at level surface that can support the weight of the mixer and

bowl contents when full (refer to Table 1 for weights and dimensions). In areas where stability may be

an issue, the machine should be secured in position.

Ensure there is suffi cient space around the mixer for the user to operate the controls and to install

and remove bowls. The area above and to the rear side of the mixer should allow the top and bottom

covers to be removed for routine maintenance and servicing. Servicing may be more diffi cult because

of reduced clearances and you should always check that equipment specifi cations permit the close

proximity of other equipment. Refer to Figs. 7 and 8, pages 12 and 13 for the overall dimensions of the

mixer and the clearance required to accommodate the bowl.

18.0 ELECTRICAL INSTALLATION.

The electrical installation of the mixer must conform to the local electricity board regulations.

When installed in the United Kingdom the installation must be in accordance with the current edition of the IEE Regulations for electrical equipment in buildings and must conform to

the requirements of the Electricity at work act.

A competent person must carry out the electrical installation.

The technical data shown in Table 1, page 14 details the electrical requirements for the mixer. Ensure

that the electrical power supply agrees with the machine specifi cation prior to connection.

The mixer is equipped with a three-wire power supply cord ready for installation of an appropriate

grounding-type attachment plug. The plug and its mating receptacle must be properly grounded. Contact an electrician. Provide proper fuse or circuit breaker protection.

19.0 OPERATOR TRAINING.

Take time to explain the correct operation and cleaning of the HS10/HS20 mixer to the users referring

to this manual. Leave this manual with the operator and explain that it is important to use it for further

reference.

– 15 –

20.0 MIXER MAINTENANCE.

A

A

A Hobart trained and competent person should carry out servicing.

Do not remove any covers or loosen any fi ttings while the mixer is operating. Ensure the

electrical supply has been isolated before attempting to service or move the mixer.

Unplug machine power cord before beginning any maintenance procedures.

20.1 LUBRICATION.

20.2 SLIDEWAYS.

The slideways (Fig. 9) should be lubricated approximately twice a year. To reach these areas, fully

lower the bowl support. Wipe a thin coat of Lubriplate 630AA on the bowl pad area of the bowl supports

and on each slideway. Refer to the recommended spare parts section for Lubriplate grease part number.

djusting Screw

djusting Screw

Slideway

Slideway

Fig. 9

20.3 PLANETARY SEAL.

Seal requires occasional lubrication.

20.4 MEASURE AND ADJUST AGITATOR CLEARANCE.

A proper clearance between the bowl and agitator is important since an excessive clearance will affect

mixer performance and since contact between the bowl and agitator will damage these components.

Therefore, agitator clearance should be checked periodically. Proper agitator clearance between the

bowl and B fl at agitator, at the bottom of the bowl, is 9.5 mm (.0375 in.).

To check clearance, pour enough fl our into the bowl to cover the bottom of the bowl. With the bowl

raised and locked in the mixing position, make sure that agitator does not contact the bowl, then briefl y

operate the mixer at the lowest speed. Turn off the mixer, disconnect the electrical power supply, and

measure the depth of fl our at several points around the bottom of the bowl where the agitator has

traced a path.

If adjustment is needed, use the adjusting screw, as shown in Fig. 9, to adjust the bowl up or down.

– 16 –

20.5 INTERLOCK SAFETY SYSTEM.

Regular inspection of the mixer safety system is necessary to check the operation of the bowl, guard

and bowl support interlock switches. This must be performed no less than once a year.

A spare parts manual is available on request from Hobart Spare Parts Distribution Centre. For continued safe and reliable operation of this mixer, it is recommended that servicing is only carried out by

Hobart trained service personnel.

21.0 FAULT FINDING.

Symptoms Possible Causes

Mixer will not start. Branch circuit protector is in open position - check fuse or

disconnect switch.

Mixer is overloaded.

Wire cage is not in the closed position.

Bowl is not in up (mix) position.

Timer is not properly set to HOLD or not away from OFF

position.

Agitator touches bowl. Improper agitator clearance - see Mixer Maintenance for

Adjustments.

Stop screw is not adjusted properly - see Mixer Maintenance for Adjustments.

Agitator is not installed properly.

Planetary seal squeaks. Seal requires occasional lubrication - see Maintenance.

– 17 –

22.0 RECOMMENDED SPARES.

Part Number Description

00-916864 Switch - Start HS10

00-917447 Switch - Start - HS20

00-916932 Switch - Stop Assembly HS10

00-917448 Switch - Stop - HS20

00-917141 Knob

00-916867-2 Motor - DC 180V

00-917400 Motor - DC 90V

00-916984 Cage - Weldment HS10

00-917151 Cage - Weldment HS20

00-916982 Ring, Drip

00-917152 Ring, Drip HS20

00-917184 Holder, Reed Switch

00-916902-4 Switch, Reed-fused Assembly

00-916842 Bowl - 10 Litre

00-917080 Bowl - 20 Litre

00-916986-2 "B" Beater - 10 Litre

00-23126-00003 "B" Beater

00-916916 "D" Wire Whip - 10 Litre

00-275897-00004 Wire Whip - 20 Litre (HS20)

00-478189 "ED" Dough Arm - 10 Litre

00-477561-00002 "ED" Dough Arm - 20 Litre (HS20)

00-23440 Bowl, SST (12 Litre) HS20

00-23502-00002 Beater HS20

00-917106 Ingredient Chute

00-917320 Ingredient Chute (20 Litre) HS20

00-917321 Ingredient Chute (12 Litre) HS20

00-478106 Belt, Poly V HS10

00-916901 10 Litre PCB, Speed Select

00-917029 20 Litre PCB, Speed Select

00-916931 Switch, Reset 220V

00-917185 Magnet

00-917186 Holder, Magnet

00-917260 Cord, Strain Relief

00-478191-2 Speed Control 180V

00-916988-2 Timer, 230V, 60 Hz, 15 Min

00-917147-1 Filter, Power Line

– 18 –

23.0 NOTES.

– 19 –

24.0 SERVICE CONTACT NUMBERS.

Hobart trained service technicians strategically located throughout the UK are prepared to give you fast,

effi cient and reliable service. Protect your investment by having a Hobart inspection contract, which as-

sures the continued, effi cient operation of your Hobart machines, spares and accessories. For disposal

of mixer, contact Hobart Service Centre for return details.

For further details please contact: -

Department Telephone Facsimile

SALES: 07002 101 101 02088 864 396

SERVICE 07002 202 202 01733 371 709

SPARES 07002 303 303 01733 371 332

Continued product improvement is a Hobart UK policy, specifi cations may change without notice.

Hobart UK

Hobart House, 51 The Bourne,

Southgate, London N14 6RT

Tel: 07002 101101 Fax 0208 886 4396

F-37220 (June 2008)

– 20 –

Loading...

Loading...