Page 1

SERVICE MA NUAL

HQC45 & 90 SERIES

QUICK CHILLERS

MODEL ML#

HQC45 ML # 124059

HQC45 ML # 124066

HQCF45 ML # 124060

HQCF45 ML # 124067

HQC90 ML # 124063

HQC90 ML # 124068

- NOTICE This Manual is prepared for the use of trained Hobart Service

Technicians and should not be used by those not properly

qualif ied. If you have attended a Hobart Service School for this

product, you may be qualified to perform all the procedures

described in this manual.

Thi s manual is not inten ded to be al l encompassing. If yo u have

not attended a Hobart Service School for this product, you

should read, in its entirety, the repair procedure you wish to

perform to determine if you have the n ecessary t ools,

instruments and skills required to perform the procedure.

Procedures f or which you do not have the necessary t ools,

instruments and skills should be performed by a trained Hobart

Service Technician.

Reproduction or other use of this Manual, without the express

written consent of Hobart Corporation, is prohibited.

A product of HOBART CORP ORATION TROY, O H 45374- 0001

Form 24693 ( M ar c h 2001)

Supercedes F-24664 and F-24603

Page 2

HQC45/HQCF45/HQC90 QUICK CHI LLE R

TABLE OF CONTENTS

GENERAL............................................................................. 3

Introduction ........................................................................ 3

Operation.......................................................................... 3

Cleaning .......................................................................... 3

Tools ............................................................................. 3

Specifications ...................................................................... 4

REMOVAL AND REPLACEMENT OF PARTS ................................................. 5

Covers and Panels ................................................................... 5

Controller Assembly.................................................................. 6

Temperature Sensors ................................................................ 7

Air Sensor ..................................................................... 8

Expansion Valve .................................................................... 8

Door Gasket........................................................................ 9

Heaters ........................................................................... 9

Defrost Heater .................................................................. 9

Door Frame Heater ............................................................. 10

Food Temperature Probe Receptac le ................................................... 10

Condensing Unit Components ......................................................... 11

Compressor ................................................................... 11

Condenser Fan Assembly ......................................................... 11

Condenser Coil ................................................................. 11

Pressure Control................................................................ 12

Filter/Drier .................................................................... 12

Evapor ator Coil .................................................................... 12

Evapor ator Fan .................................................................... 13

Hot Gas Condensate Pan ............................................................. 13

SERVICE PROCEDURES AND ADJUSTMENTS .............................................. 14

Refrigeration Control Adjustments ...................................................... 14

TEV Superheat A djustment ........................................................... 15

Checking for Leaks ................................................................. 15

Evacuating System ................................................................. 16

Charging System ................................................................... 16

System Cl ean Up ................................................................... 17

Serv ice Mode ML-124059, M L- 124060, ML-124063 ......................................... 17

Serv ice Mode ML-124066, M L- 124067, ML-124068 ......................................... 19

Factory Settings Mode ML-124066, M L- 124067, ML-124068 .................................. 22

Software Ver si on M L- 124059, ML-124060, ML-124063 ...................................... 24

Software Ver si on M L- 124066,ML-124067,ML-124068 ....................................... 24

Controll er Serv ice Procedures ML-124059,M L-124060, ML-124063 ............................. 25

Controll er Serv ice Procedures ML-124066, M L-124067, ML-124068 ............................ 27

ELECTRICAL OPERATION .............................................................. 29

Component Locat ion ................................................................ 29

Component Func tion ................................................................ 31

Sequence of O per ation ML-124059, M L- 124060, ML-124063 .................................. 32

Sequence of O per ation ML-124066, M L- 124067, ML-124068 .................................. 33

Schematics ....................................................................... 35

TROUBLESHOOTING .................................................................. 41

System Troubleshooting ............................................................. 41

Product Tr oubleshooting ............................................................. 44

CONDENSED SPARE PARTS LIST ........................................................ 44

© Hobart Corporat ion 2001

Form 24693 ( M ar c h 2001) Page 2 of 44

Page 3

HQC45/HQCF45/HQC90 QUICK CHI LLE R - GENERAL

GENERAL

INTRODUCTION

Chillers are food processing refrigerators designed

for rapidly chilling product from 150° F to

approximately 37° F in approximately 90 mi nutes for

reheating at a later time. Quick Freezers are

designed for r apidly freezing product as well as

rapidly chilling product.

These units aid in preserving food quality, texture

and nutritional value.

All of the information, illustrations and specific ations

contained i n this manual ar e based on the latest

product information availabl e at the time of printing.

OPERATION

Refer to the Instruction manual for specific

operating i nst r uc tions.

CLEANING

TOOLS

Standard

• Standard set of hand tools.

• Temperat ure tester or thermometer.

• VOM with AC current tester.

• Electricall y c onduc tive field service grounding

kit (p/ n TL84919).

Special

• Refri geration Recl aiming E quipment

• Acetylene torch

• Nitrogen bottle with gauges

• Refri geration gauge m anifol d

• Dial-a-charge

• Valve core rem oval tool

• Vacuum pump

Detailed c leaning instr uc tions are incl uded wi th each

unit, however, special care must

condenser coil. The condenser coil must be cleaned

weekly

grease for proper system operation. This can be

done with a v acuum cleaner usi ng a br ush

attachm ent, or a stiff brush or whisk broom. Care

must

fins.

. This surface must be kept free of dirt and

be taken not to damage the condenser coil

be given to the

Form 24693 ( M ar c h 2001)Page 3 of 44

Page 4

HQC45/HQCF45/HQC90 QUICK CHI LLE R - GENERAL

SPECIFICATIONS

DATA

HQC45 HQCF45 HQC90

H.P. 1

BTU/HR 9900 @ 25(F Evaporator

Temp

Refri ger ant Type R-404A R-404A R-404A

Refri ger ant Charge (oz) 160 160 160

Cond Unit Amp Draw (RLA) 1 phase = 8.1A 1 phase = 9.0A 1 phase = 12A

Evapor ator Fans Amp Draw 1.1A 1.1A 1.1A

Voltage 208,240/60/1 208,240/60/1 208,240/60/1

Amps 10.8A 10.8A 13.8A

Optional Voltage N/A N/A 208-240/60/3

Optional Amps N/A N/A 10.4A

1

/

4

8050 @ 0(F Evaporator

Temp

11/

4

13/

4

14700 @ 25(F

Evapor ator Temp

3 phase = 8.6A

Operatin g Data

Refri ger ant R-404A

Ambient Temperature 70(F 100(F

Suction Pressure PSIG

(Chill Mode)

Start of cycle 75 75

End of cycle 28 32

Suction Pressure PSIG

(Freezer Mode)

Start of cycle 55 55

End of cycle 5 6

Discharge Pressure PSIG

Start of cycle 340 420

End of cycle 225 300

DIMENSIONS

(inches)

HQC45

HQC90

HQCF45

Width 32 32

Depth 37 44½

Height 70 77½

Width (cavity ) 28 28

Depth (cavity) 19

Height (cavit y) 27½ 27½

Height to bottom of cavity 27½ 35½

Form 24693 ( M ar c h 2001) Page 4 of 44

1

/

4

26¾

Page 5

HQC45/HQCF45/HQC90 QUICK CHI LLE R - RE M OVAL AND REPLACEME NT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

COVERS AND PANELS

Condensing Unit Covers (Front and Rear)

1. Pull t he c over toward you to pull the V E LCRO

apart at each cor ner of the cover.

Evaporator Cover

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the tracks (HQC90) or the shelves and

back shelf clips f r om the cabinet.

2. Remove the screws that secure the evaporator

cover and remove it from the c abinet.

NOTE:

DISCONNECT THE ELECTRICAL

The ev apor ator fan panel can be opened.

2. Reverse proc edur e to install .

Top and Rear Covers

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the screws from the edges of the top

cover and remove it from the machine.

2. Remove the screws from the edges of the rear

cover and remove it from the machine.

DISCONNECT THE ELECTRICAL

3. Reverse proc edur e to install .

3. Reverse proc edur e to install .

Form 24693 ( M ar c h 2001)Page 5 of 44

Page 6

HQC45/HQCF45/HQC90 QUICK CHI LLE R - RE M OVAL AND REPLACEME NT OF PARTS

CONTROLLER ASSEMBLY

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

CAUTION: Electro-static discharge will damage

the control board. Use a anti-static grounding kit

when servicing the computer con t rol box.

Procedure

1. Remove the top cover as outlined under

"COVERS AND PANELS".

2. Disconnect the plugs from the control box or

control panel.

3. Remove the connectors from t he c ontrol box or

controller, if necessary.

Removable Components

Only fo r ML-124059,ML- 124060,ML-124063

DISCONNECT THE ELECTRICAL

4. Open the door to t he control box or control

panel and remove the screws that secure

computer control box or controller to f r ont of

cabinet.

5. Remove the control box or cont r oller from the

cabinet.

6. Reverse the procedure to install.

Form 24693 ( M ar c h 2001) Page 6 of 44

Page 7

HQC45/HQCF45/HQC90 QUICK CHI LLE R - RE M OVAL AND REPLACEME NT OF PARTS

Removable Components

Only fo r HQC45 ML-124066, HQCF45 ML-124067,HQ C90 M L-124068

Form 24693 ( M ar c h 2001)Page 7 of 44

Page 8

HQC45/HQCF45/HQC90 QUICK CHI LLE R - RE M OVAL AND REPLACEME NT OF PARTS

TEMPERATURE SENSORS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Air Sensor

1. Remove the evaporator cover as outlined

under "COVERS A ND P A NE LS " .

2. Remove the air t emperature sensor f r om its

locati on in the return air duct.

3. Disconnect the lead wires.

DISCONNECT THE ELECTRICAL

EXPANSION VALVE

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

USE OF REF RIGERANTS. B E CE RTAIN THE

WORK AREA IS WELL VENTILATED. SAFETY

GOGGLES AND GLOVES SHALL BE WORN

SINCE REFRI GERANTS MAY CAUS E B URNS TO

THE SKIN.

1. Pump-down refrigeration system.

WARNING:

LINES WILL CONTAIN PRESSURE.

2. Access the expansion valve through t he front

of the cabinet. The expansion valve is located

behind the evaporator fans.

3. Detach expansion val ve bulb from suct ion line.

4. Remove expansion valve from the l iquid line at

inlet and outlet of valve.

5. Install new expansion valve into inl et line and

fasten bulb to suction line. Initial setting: 3½

turns counterclockwise.

DISCONNECT THE ELECTRICAL

THIS PROCE DURE RE QUIRES THE

AFTER PUMP - DOWN, REFRIGERANT

4. Reverse proc edur e to install .

Coil Sensor

1. Remove the evaporator cover as outlined

under "COVERS A ND P A NE LS " .

2. Remove the air t emperature sensor f r om its

locati on on the evapor ator coil.

3. Disconnect the lead wires.

4. Reverse proc edur e to install .

NOTE:

attached paral lel to suction line and makes

good contact.

NOTE:

the diaphragm of the valve.

NOTE:

changed when this part is replaced.

Make sure expansion valve bulb is

Expansion valve bulb must be lower than

It is recommended that the filter/dr ier be

Form 24693 ( M ar c h 2001) Page 8 of 44

Page 9

HQC45/HQCF45/HQC90 QUICK CHI LLE R - RE M OVAL AND REPLACEME NT OF PARTS

6. Recharge unit and c hec k for leaks.

7. Put unit bac k into operation and check the

superheat as outlined under " TEV

SUPERHEAT ADJUSTMENT" in "SERVICE

PROCEDURES AND ADJUSTMENTS".

DOOR GASKET

1. Select Stand-by Mode.

2. Open door to m aximum position.

3. Remove door gasket by pulling arrow shaped

retaini ng tab from the retai ning channel around

the outer edge of the door.

CAUTION: When handling a new door gasket,

DO NOT

material will stretch at room temperature and

will NOT

4. Position the corners of the gasket at the top

pull on the gasket mat erial. T he gasket

return to its original length.

corners of t he door and push straight in on the

gasket until the arrow tab is lock ed in the

retaini ng channel.

6. Install side by starting at the top and working

down, making sure t he end of the gasket meets

with the edge of the door.

7. Check door for proper operation.

HEATERS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Defrost Heater

1. Remove the evaporator cover as outlined

under "COVERS A ND P A NE LS " .

2. Disconnect wire leads to defrost heater .

3. Unscrew floor brac k et in fr ont of the evaporator

coil.

4. Remove the copper wires holding defrost

heater(s) in place.

DISCONNECT THE ELECTRICAL

5. Start the c enter of t he top and work the gasket

in place from the center to each cor ner .

5. Remove the defr ost heater from the coil being

careful to prevent damage t o c oil f ins.

6. Reverse proc edur e to install .

Form 24693 ( M ar c h 2001)Page 9 of 44

Page 10

HQC45/HQCF45/HQC90 QUICK CHI LLE R - RE M OVAL AND REPLACEME NT OF PARTS

Door Frame Heater

1. Open door past 90°.

2. Remove door frame heater covers fr om the

door frame by gently pr y ing out on the insi de

edge of the cover.

NOTE:

to install.

3. Pull t he door frame heater wire loose from the

Do not bend the covers. They will be difficult

door frame channel.

FOOD TEMPERATURE PROBE

RECEPTACLE

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Turn chiller OFF or select Stand-by Mode were

applicable.

2. Remove the probe recept ac le cov er .

NOTE:

are properly in-place between probe receptacle

housing and cov er.

DISCONNECT THE ELECTRICAL

When installing the cover, insure grommets

4. Disconnect the suppl y lead wires from each

end of the heat er , and the (green) ground lead

wire from one end.

5. Connect lead wires to r eplacement heater.

6. Insert the heater into the door frame channel.

NOTE:

frame.

7. Install heater covers. The horizontal one first.

NOTE:

corners of t he door frame.

8. Check for proper operation of the door and

Form 24693 ( M ar c h 2001) Page 10 of 44

Do not kink heat er wire at the corners of the

A. Hook the inside edge of the heater c over

over the lip of the door frame.

Check positi on of heater cover in the top

B. Use your fingers to push the outside edge

over the outside lip of the heat er c hannel

in the door frame.

C. Repeat for each side.

door frame heater.

3. Unplug the probe.

4. Reverse the procedure to install.

Page 11

HQC45/HQCF45/HQC90 QUICK CHI LLE R - RE M OVAL AND REPLACEME NT OF PARTS

CONDENSING UNIT

COMPONENTS

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Compressor

WARNING:

USE OF REF RIGERANTS. B E CE RTAIN THE

WORK AREA IS WELL VENTILATED. SAFETY

GOGGLES AND GLOVES SHALL BE WORN

SINCE REFRI GERANTS MAY CAUS E B URNS TO

THE SKIN.

1. Remove the condensing uni t cover s as outl ined

under “COVERS AND PANELS”.

2. Evac uate refrigeration system.

NOTE:

mandatory.

3. Disconnect lead wi r es and conduit at the

compressor junction box.

4. Disconnect suction and discharge li nes from

the compressor.

DISCONNECT THE ELECTRICAL

THIS PROCE DURE RE QUIRES THE

The use of reclaiming equipment is

3. Remove the mot or and fan assembly from the

mounti ng bracket.

4. To replace the fan blade only, f ollow steps 4A

& 4B. To replace the motor, perf or m step 4A

and proceed to step 5.

A. Loosen the set screw that secures the fan

blade to the motor shaft and remove the

fan blade from the motor.

B. Install the new fan blade with the set

screws between the motor and the bl ades

and rever se t he pr oc edur e to install .

5. Disconnect the lead wires from the motor .

6. Reverse the procedure to install.

Condenser Coil

WARNING:

USE OF REF RIGERANTS. B E CE RTAIN THE

WORK AREA IS WELL VENTILATED. SAFETY

GOGGLES AND GLOVES SHALL BE WORN

SINCE REFRI GERANTS MAY CAUS E B URNS TO

THE SKIN.

1. Evac uate refrigeration.

NOTE:

mandatory.

2. Remove fan guard and fan shroud from

condensing coil.

THIS PROCE DURE RE QUIRES THE

The use of reclaiming equipment is

5. Remove the compr essor.

6. Install new compressor and connect wire leads

and conduit at c ompressor junction box.

7. Install a new filt er /drier.

8. Evac uate system.

9. Charge system and put unit into operation.

Condenser Fan Assembly

1. Remove the fan guar d from the top of t he

condenser assembly.

3. Disconnect i nlet and outlet lines at the sol der ed

connections nearest t he c ondenser coil.

4. Remove coil from mounting plate.

5. Reverse proc edur e to install c oil, then pr oc eed

to next step.

NOTE:

changed when this part is replaced.

6. Evac uate system.

NOTE:

mandatory.

7. Charge system and put unit into operation.

It is recommended that the filter/dr ier be

The use of reclaiming equipment is

2. Remove the screws from the mounti ng c lamps

on the front and rear of the motor.

Form 24693 ( M ar c h 2001)Page 11 of 44

Page 12

HQC45/HQCF45/HQC90 QUICK CHI LLE R - RE M OVAL AND REPLACEME NT OF PARTS

Pressure Control

WARNING:

USE OF REF RIGERANTS. B E CE RTAIN THE

WORK AREA IS WELL VENTILATED. SAFETY

GOGGLES AND GLOVES SHALL BE WORN

SINCE REFRI GERANTS MAY CAUS E B URNS TO

THE SKIN.

1. Pump-down refrigeration system.

WARNING:

LINES WILL CONTAIN PRESSURE.

2. Front seat the suct ion service valve.

3. Disconnect wire leads to pressure switch.

4. Disconnect capillary tube from c ompressor

fitting.

5. Remove pressure control from mounting

bracket.

6. Replace pressure switch and connect c apillary

tube to com pressor fitt ing.

7. Put unit bac k into operation.

Filter/Drier

WARNING:

USE OF REF RIGERANTS. B E CE RTAIN THE

WORK AREA IS WELL VENTILATED. SAFETY

GOGGLES AND GLOVES SHALL BE WORN

SINCE REFRI GERANTS MAY CAUS E B URNS TO

THE SKIN.

Pump-down refrigeration system.

WARNING:

LINES WILL CONTAIN PRESSURE.

1. Remove fi lter/drier from liquid line.

THIS PROCE DURE RE QUIRES THE

AFTER PUMP - DOWN, REFRIGERANT

THIS PROCE DURE RE QUIRES THE

AFTER PUMP - DOWN, REFRIGERANT

EVAPORATOR COIL

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

USE OF REF RIGERANTS. B E CE RTAIN THE

WORK AREA IS WELL VENTILATED. SAFETY

GOGGLES AND GLOVES SHALL BE WORN

SINCE REFRI GERANTS MAY CAUS E B URNS TO

THE SKIN.

1. Remove the evaporator cover and top cover as

outlined under "COVERS AND PANE LS " .

2. Pump-down system.

WARNING:

LINES WILL CONTAIN PRESSURE.

3. Remove the defr ost heaters as outlined under

“DEFROST HEATERS”.

4. Disconnect the suct ion line at the soldered joint

closest to the coil.

NOTE:

mandatory.

5. Disconnect the liquid line at the expansion

valve.

6. Remove the screws from the coil mounting

bracket.

7. Pull t he coil out of the cabi net through the front.

8. Reverse proc edur e to install c oil, then pr oc eed

to next step.

DISCONNECT THE ELECTRICAL

THIS PROCE DURE RE QUIRES THE

AFTER PUMP - DOWN, REFRIGERANT

The use of reclaiming equipment is

NOTE:

changed when this part is replaced.

9. Evac uate system.

10. Charge system and put unit into operation.

2. Install a new filt er /drier.

3. Evac uate system.

NOTE:

mandatory.

4. Charge system and put unit into operation.

Form 24693 ( M ar c h 2001) Page 12 of 44

The use of reclaiming equipment is

It is recommended that the filter/dr ier be

Page 13

HQC45/HQCF45/HQC90 QUICK CHI LLE R - RE M OVAL AND REPLACEME NT OF PARTS

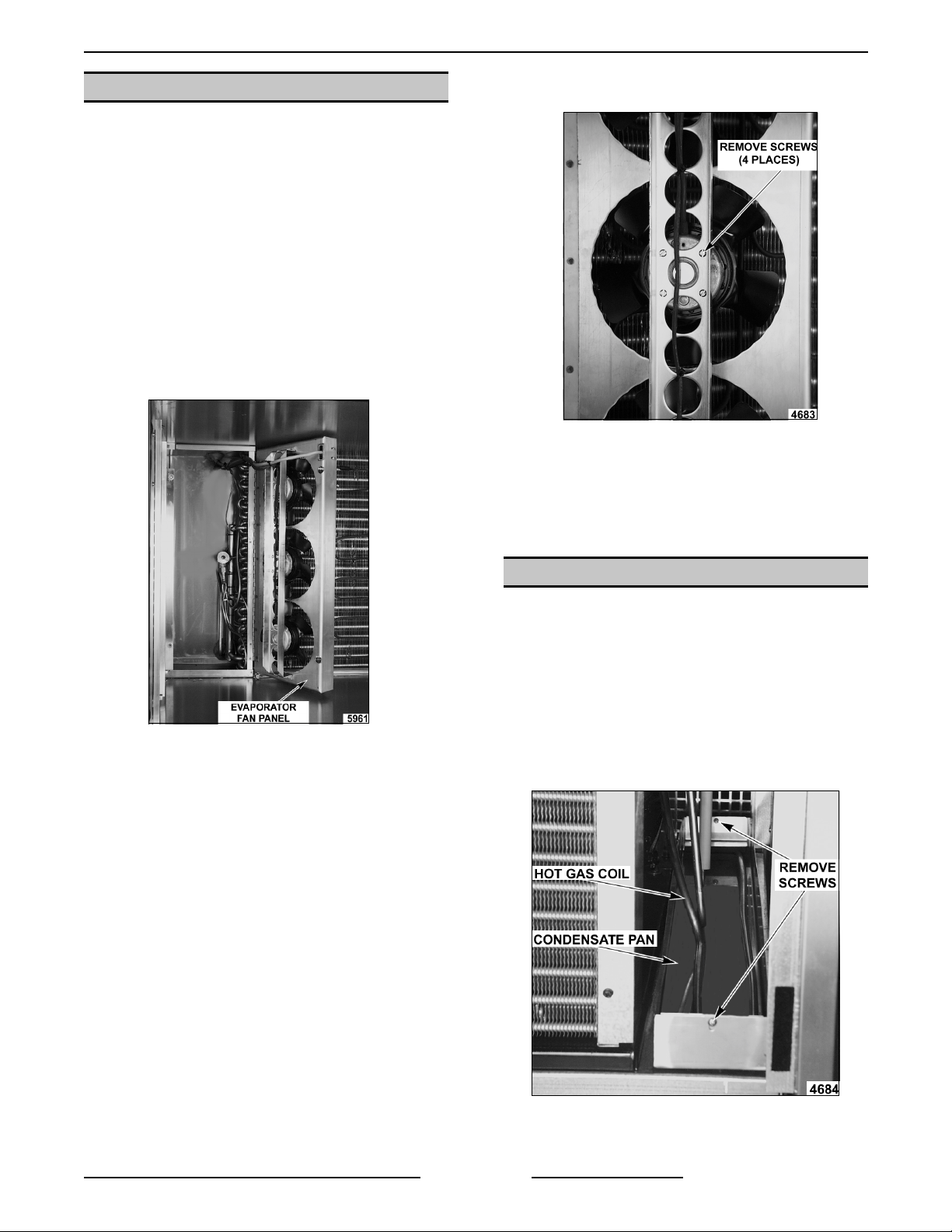

EVAPORATOR FAN

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

1. Remove the top and rear c overs as outlined

under “COVERS AND PANELS”.

2. Remove the tracks or shel ves fr om the cabinet

and remove the shelf clips from the left r ear

shelf support.

3. Remove the evaporator cover and open the

evaporator fan panel as out lined

under"COVERS A ND P A NE LS " .

DISCONNECT THE ELECTRICAL

5. Remove the bolts that secure the evaporator

fan from the housing panel.

6. Remove the fan from the cabinet.

CAUTION: Do not attempt t o disassembly motor

or remove fan blades from mo t or, blades are not

available as a service part.

7. Reverse the procedure to install.

4. Disconnect the lead wires at the junction box

on the top of the unit and pull them into the

cavity with the fan.

HOT GAS CONDENSATE PAN

1. Remove the condensing uni t cover as outlined

under “COVERS AND PANELS”.

2. Remove the bolts that secure the hot gas coil

from the pan.

CAUTION: Do not damage the coil during

removal.

3. Lift the hot gas coil out of t he pan.

4. Lift the hot gas pan to pull the Velcr o apar t

from the pan to the uni t.

5. Reverse proc edur e to install .

Form 24693 ( M ar c h 2001)Page 13 of 44

Page 14

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

SERVICE PROCEDURES AND A DJUSTMENTS

WARNING:

MEASUREMENTS WHILE THE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT

ALL TIMES. IF TEST POINTS ARE NOT EASI LY ACCESSIBLE, DISCONNECT POWER, ATTACH TEST

EQUIPMENT AND REAPPLY POWER TO TEST .

Expansion Valve

1. Access the expansion valve behind t he

evaporator fans.

2. Remove seal cap from the side of the

expansion valve.

3. Turn adjusting stem cloc k wise and seat valve.

4. Turn adjusting stem 2-1/2 t ur ns

counterclockwise. This is the initial setting.

5. Reassemble unit and c hec k for proper

operation.

Dual Pressure Co ntrol

CERTAIN PROCEDURES IN THIS SECTION REQUIRE ELECTRICAL TEST OR

REFRIGERATION CONTROL

ADJUSTMENTS

CPR Valve

Only fo r HQC45 ML124059, HQCF 45 ML124060,

HQC90 ML124063

1. Remove the rear condensing unit cover.

2. Remove the insulation fr om the valve.

1. Turn low pressure adjustm ent "cut-i n" screw to

10

the initial setting of

2. Turn diff adj ust ment screw to the initial setting

12

psi.

of

3. Turn high pressure adjustment "cut- out" screw

to the initial setting of

psi.

440

psi.

3. Connect the pressure gauge to the suct ion port

of the compressor.

4. Operate the cabinet with the door open or with

hot product.

5. Adjust the CPR valve so the maxim um

55

pressure is

psig.

4. Check for proper operation.

Form 24693 ( M ar c h 2001) Page 14 of 44

Page 15

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

TEV SUPERHEAT ADJUSTMENT

Introduction

Superheat is the heat that the refrigerant vapor absorbs above the boiling point. P r oper adjustment of the

superheat will optimize system performance.

Helpful Hints

• Adjustment s normally take 10-15 mi nutes before f ull impact on the system.

• 8-10 degrees F is a desirable superheat at coil out let.

• Check suction l ine temperature and discharge line temperat ure after any superheat adjustment.

Procedure

1. Access the expansion valve.

2. While the unit is cooling and evaporator fan panel c losed, take suction pressure at the compressor inlet or

(CPR valve outlet t ap were appl icable) and temperature readings at the outlet of the evaporator c oil.

NOTE:

3. Using the Temperature Pressure Chart, c onvert the pressure reading taken i n step 2 into a tem per ature.

4. Subtract t he converted temperat ur e from step 3 from the measured temperature in step 2. This is the

superheat.

A. To increase superheat, turn adjusting stem clockwise.

B. To decrease superheat, tur n adjusting stem c ounterclockwise.

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

USE OF REF RIGERANTS. B E CE RTAIN THE

WORK AREA IS WELL VENTILATED. SAFETY

GOGGLES AND GLOVES SHALL BE WORN

SINCE REFRI GERANTS MAY CAUS E B URNS TO

THE SKIN.

1. Access the refr igeration system.

NOTE:

current EPA guidelines.

The closer to the evaporator outlet, the more acc ur ate the readings.

TEMPERAT URE P RE S S URE CHA RT R-404A

Temperat ure in ° Fahrenhei t Pressure in lb/in²

F lb/in²

(

-41 4.0 -20 16.0 0 33.0 20 56.0 40 85.0

-35 7.0 -5 28.0 5 38.0 25 62.0 45 95.0

-30 10.0 -15 20.0 10 44.0 30 70.0 50 105.0

-25 13.0 -10 24.0 16 50.0 35 78.0 55 115.0

CHECKING FOR LEAKS

DISCONNECT THE ELECTRICAL

THIS PROCE DURE RE QUIRES THE

Recover remaining refrigerant based on

F lb/in²

(

F lb/in²

(

F lb/in²

(

2. Connect the low (blue) side of gauge manif old

to schrader valve.

3. Connect ref rigerant bottle to center of gauge

manifold and open valve on bottle to purge

hose to manifold gauge.

4. Open v alve on low side of gauge m anifol d and

charge system with a small amount of R-22

refrigerant (1 to 2 ounces).

5. Close bottle valve and gauge valve.

6. Disconnect refrigerant bottle and connect

nitrogen bottle.

7. Set output valve on nit rogen bottle t o equal the

appropriate pr essure, for the design rat ed

refrigerant at 100°F on the P/T chart .

NOTE:

See system data plate for desi gn r efrigerant.

F lb/in²

(

Form 24693 ( M ar c h 2001)Page 15 of 44

Page 16

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

8. Open nitrogen bottle valve and gauge manifold

valve (low side) and allow pressure to equalize.

9. Shut off both valves and disconnect the

nitrogen bottle.

10. Using a leak detector, check for leaks at all

tubing connect ions.

A. If any leaks are detected, r epair leak and

recheck f or leaks.

B. If no leaks are discovered, evacuate

system as outlined under " EVACUATING

SYSTEM".

NOTE:

future system diagnostic s.

11. Charge system as outlined under "CHARGING

Install a permanent hi gh si de ac c ess port for

SYSTEM".

EVACUATING SYSTEM

Introduction

Refri geration reclaiming equipment is required.

Our goal i n system ev ac uation is to remove all the

non-condensing contaminates as possible. No

evacuation met hod will remove 100% of the

moistur e and air from within t he r efrigeration cir c uit.

Because of this, guidelines and methods must be

developed and adhered to ensuring onl y har mless

amounts of c ontaminants remain i n the system.

Guidelines

• Use only a two stage vac uum pump (2 CF M or

greater) and el ec tronic m icron gauge.

• Set output valve on nitr ogen bottle to equal the

appropriate pr essure, for the design rat ed

refrigerant at 100°F on the P/T chart .

WARNING:

USE OF REF RIGERANTS. B E CE RTAIN THE

WORK AREA IS WELL VENTILATED. SAFETY

GOGGLES AND GLOVES SHALL BE WORN

SINCE REFRI GERANTS MAY CAUS E B URNS TO

THE SKIN.

1. Access the refr igeration system.

2. Connect low (blue) si de of gauge manifold to

schrader v alve on c ompressor access line and

high (red) side of gauge manifold to schrader

valve on filter/drier line.

NOTE:

permanent sweat on tap.

3. Connect center line of gauge manifold to

vacuum pump.

4. Turn vacuum pump on and open both sides of

gauge manifold.

5. Pull a vacuum to 200 mi c r ons.

6. Charge system and check for proper operat ion.

THIS PROCE DURE RE QUIRES THE

If t her e is no high side access, install a

CHARGING SYSTEM

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

WARNING:

USE OF REF RIGERANTS. B E CE RTAIN THE

WORK AREA IS WELL VENTILATED. SAFETY

GOGGLES AND GLOVES SHALL BE WORN

SINCE REFRI GERANTS MAY CAUS E B URNS TO

THE SKIN.

1. Access the refr igeration system.

DISCONNECT THE ELECTRICAL

THIS PROCE DURE RE QUIRES THE

• Evacuate from high and low sides of system.

• No chemical additive or alcohols are to be used

to "dry up" a system.

• Blow down of system with DRY NITROGEN

prior to evacuation is acceptabl e and many

times desirable. See "SYSTEM CLEAN UP".

• Evacuate to 200 mi c rons of merc ur y .

Procedure

WARNING:

POWER TO T HE MACHINE AT THE MAIN

CIRCUIT BO X. P LA CE A TAG ON THE CI RCUIT

BOX INDICATING THE CIRCUIT IS BEING

SERVICED.

Form 24693 ( M ar c h 2001) Page 16 of 44

DISCONNECT THE ELECTRICAL

2. Be sure refrigeration system is checked f or

3. Connect high side of gauge manifold to the

NOTE:

side to prevent liquid ref r igerant f r om reaching t he

compressor.

4. Connect ref rigerant bottle to center c onnec tion

5. Purge the hose fr om the refrigerant t ank to the

leaks and properly evacuated before chargi ng

as outlined under "LEAK CHECK" and

"EVACUATING SYSTEM".

liqui d line (make certain both valves on the

gauge manifold are closed).

Put ini tial char ge to system through the high

of gauge m anifol d (check the refrigerant bottle

to confirm direction for li quid).

manifold gauge.

Page 17

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

6. Open high side of gauge mani fold and al low

appropriate amount of r efrigerant to flow into

the refr igeration system.

A. Shut off gauge and bottle valves when this

has been accomplished.

7. Disconnect the hose from the r ec eiver valve.

8. Reconnect power to the unit and check for

proper operati on and high pressure leaks.

NOTE:

superheat and operating pr essures. Through low

side of system.

9. Disconnect power to the unit, repl ac e any

10. Reconnec t power to the unit.

Adjust charge as needed based on

panels and cov ers removed.

SYSTEM CLEAN UP

Introduction

When a r efriger ation system i s accessed in service,

some degree of system clean up i s required. There

are two levels of clean up:

• Basic - Conduct proc edur e as outlined under

"EVACUATING SYSTEM" and incorporating a

drier change, this is recommended only when

system exposure is limited.

• Massive - The use of Polyol Ester (POE) oil in

systems using R-134a and R-404a, as well as

in many other applic ations, require that ev er y

system failure be tr eated as a Massive cl eanup.

Massive Contamination

If a compressor burn out or failure has occurr ed, do

not install a new compressor until the clean-up

procedure has been completed.

If a massive moisture cont amination or POE oil

breakdown has occurred, rem ove the old

compressor as outli ned under "CONDENSING UNIT

COMPONENTS" in "REMOVAL AND

REPLACEMENT OF PARTS" dr ain the oil and hold

for installation.

1. Recover refri ger ant based on current EPA

guidelines.

2. Remove fi lter/drier and meter ing device.

NOTE:

assumed that the metering device is restricted after

a contamination. These devic es

clean and reused.

3. Flush high and low sides of refrigeration system

4. Reassemble refrigeration system to inc lude

NOTE:

system while welding is mandatory to prevent

oxidat ion/carbon pl ating that will lead to further

contamination.

In POE oi l applic ations, it shoul d always be

can not

with Nitrogen to displace any t r apped oil and

contaminates.

compressor, 032 size liquid line drier and new

metering device.

The use of low flow Nitrogen t hr ough the

be flushed

NOTE:

when moisture cont amination is present. The

suction dri er shoul d be r emov ed within 48 hours of

installation to prevent further performance issues.

Also instal l a new liquid line drier for maximum

system clean up.

5. Replace new oil into the compressor.

6. Purge system with Nitrogen f or 5 minutes.

7. Evac uate system f or 30 minutes.

8. Repeat steps 5 and 7 two additional times.

NOTE:

less.

9. Charge the system as outlined under

10. Replace any panels and covers removed.

11. Reconnec t power and check for pr oper

The use of a suction drier is recommended

Pressure should be applied t o the high side and

allowed to vent through the port on top of the

compressor.

The final vacuum should be 200 microns or

"CHARGING SYSTEM".

operation.

SERVICE MODE ML-124059,

ML-124060, ML-124063

The Service Mode allows service per sonal to

exerci se t he loads and monitor the input of the

Control i ndependently to det er mine if the Control,

the electr o-mechanic al components and the

refrigeration system are operating proper ly.

WARNING:

THE CONTROL BOX BE OPEN WHILE THE

POWER IS SUPPLIED TO T HE MACHINE.

EXERCISE EXTREME CAUTION AT ALL TIMES.

1. The unit must be in the idle mode.

2. Open the control box.

3. Locate the service switch on t he c ontrol board.

Push and hold the service switch, then push the

9 key on the keyboard. A maintenance menu

will be displayed.

THIS PROCE DURE RE QUIRES THAT

Form 24693 ( M ar c h 2001)Page 17 of 44

Page 18

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

Maintenance M enu = 1 = Inputs, 2 = Outputs, 3 = Clock, 4=Printer

INPUTS

Press

1 Front door switch on or off S tatus of input

yes External defrost on or off

yes External defrost on or off

yes Spare switch input on or off S tatus of input

yes AIR temp. - PROBE 1 - PROBE 2. PROBE 3 - PROBE 4 - COIL temp.

yes AIR temp. - PROBE 1 - PROBE 2. PROBE 3 - PROBE 4 - COIL temp.

yes Current Probe Not used

yes

no

Press

2 Defrost heater s = off 0 = off, 1 = on Watch LED 2 on control board

yes Evaporator fan = off 0 = off, 1 = on Watch LED 5 on control board

yes Solenoid valves = on 0 = off, 1 = on Watch LED 3 & 4 on control board

yes Freezer sol enoid = off 0 = off, 1 = on Watch Led 3 (Not used)

yes Remote alarm = off 0 = off, 1 = on Watch LED 1 on control board

yes Buzzer = off 0 = off, 1 = on Audible signal

yes

no

Return to front door switch

Maintenance M enu

Defrost heater s

Maintenance M enu

Display

(Top Line)

Display

(Top Line)

OUTPUTS

Display

(Bottom Line)

Display

(Bottom Line)

Explanation

Status of input

(Not used)

Status of input

(Not used)

Analog to di gital values

for probes

Fahrenheit values for

probes

Explanation

CLOCK

Press

3 Enter new time current ti me setting in memory.

yes Enter new time HR:MN:SC / 0 = AM 1 = PM

yes Enter new date current date setting in memory.

yes

no

Press 4 - Display will flash “SENDING TEST PATTERN TO PRINTER” and return to t he maintenance menu.

If t her e is an error in the pr int operati on, a message will be displayed.

If t he er ror occurs during the test print sequence, t hat error will only be displayed if print is selected again.

Form 24693 ( M ar c h 2001) Page 18 of 44

Enter new time

Maintenance M enu

Display

(Top Line)

Display

(Bottom Line)

PRINTER

Explanation

Use number keys to change t ime

(hrs/ mins/sec)

Use number keys to change dat e

(mo/day/yr)

Page 19

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

SERVICE MODE

ML-124066, ML-124067,

ML-124068

The Service Mode allows service per sonal to exercise the loads and monitor the input of the Control

independently to determine if the Control, the electro-mechanical components and the r efrigeration system are

operating proper ly.

WARNING:

SUPPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL TIMES.

CAUTION: Electro-static discharge will damage the control board. Use a anti-static grounding kit when

servicing t he computer control b ox.

1. Turn power off to the uni t.

2. Loosen the control panel screws and swing open control panel to gain access to servi c e mode switch.

THIS PROCE DURE RE QUIRES THAT THE CONTROL BO X BE OPEN WHILE THE POWER I S

3. Locate the service mode switch on the back of

control boar d, press and hold switch while

turning power ON to chiller. The following

menu will be displayed.

NOTE:

power OFF and back O N to display user main

menu.

To exi t the serv ice mode at any time, turn

LAST DATE OF SERVICE

00/00/00

< UPDATE

< SET CLOCK NEXT >

A. Pressing the button besi de UP DA TE sets

last date of service date to current date. If

date is INVALID, set clock to current date

and tim e.

B. SET CLOCK - Displays set clock menu to

change the last date of service.

SET CLOCK MONTH

XX/XX/XX XX:XX

< BACK NEXT>

< CANCEL ENTER

1) Pr essing the button beside BACK or

NEXT toggles through sel ec tion

options:

MONTH/DAY/YEAR/HOUR/MINUTE.

2) Pr essing the button beside the up or

down arrows changes the selected

date or time numbers.

3) Pr essing the button beside ENTE R

saves the new date and time selected

and displays on the l ast date of

servi ce menu.

4) Pr essing the button beside CANCEL

does not save any change to date or

tim e and return to the last date of

servi ce menu.

Form 24693 ( M ar c h 2001)Page 19 of 44

Page 20

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

C. NEXT- With the last date of service menu

displayed, pr essing t he button beside

NEXT the following service m enu will be

displayed.

< SERVICE MENU DOOR >

< REFR/AIR DEF/COIL >

< PROBES/ALARM FANS >

< PRINTER DISPLAY >

NOTE:

From service menu, the following Ser vic e

modes can be selected:

• SERVICE MENU - Diagnostic test.

• REFR/AIR - Refriger ation System and A ir

probe test.

• PROBES/ALARM - View current probes

reading and change status of ALARM output.

• DISPLAY - Illuminates entire display.

• DOORS - Displays status (OPEN or CLOSED)

• DEF/COIL - Defrost System and Coil probe

test.

• FANS - Tests Fan outputs

• PRINTERS – Sends test pattern to printer(s).

D. SERVICE MENU - Diagnostic test.

< DIAGNOSTIC MAXIMUM >

< RUN CYCLES MINIMUM >

< SINCE DEF. FAILURE >

CYCLES

CLEAR >

5) Pr essing the button beside MINIMUM

displays (in the lower lef t corner of

the display) the minimum air

temperat ure in cabinet .

6) Pr essing the button beside FAILURE

displays (in the lower lef t corner of

the display) the failure since last

servi ce cleared. I f there i s more than

one failure, pressing the lower left

button will cycle through all failures.

Below is a complete list of all possible

failures.

DEFR HEAT= Defrost heater

malfunction.

SYSTEM FAIL= Chiller not cooling

properly.

OVER TEMP= Internal air

temperat ure exceeds 150°F.

CONTROL= Control board

malfunction.

INTERRUPTE D= A chilling cycle has

been interrupted either by loss of

main power or inadvertently switching

power switch OFF.

PROBE= One of the probes have

malfunctioned: Air, Coil, or Pr oduc t.

PRINTER= P r inter not responding or

out of paper/label.

7) Pr essing the button beside CLEAR

clears the curr ent item .

E. REFR/AIR – Refrigeration System and A ir

probe test.

NOTE:

The selected item will have a flashing "<" or

">" beside it.

1) Pr essing the button beside

DIAGNOSTIC returns to the service

menu.

2) Pr essing the button beside RUN

CYCLES displays (in the lower left

corner of the display) t he number of

cycles ran since last cleared.

3) Pr essing the button beside SINCE

DEF. displ ays (in the lower left corner

of the display) the number of cycles

ran since last defrost.

4) Pr essing the button beside

MAXIMUM displays (in the lower left

corner of the display) t he maxi mum

air temperature in c abinet.

Form 24693 ( M ar c h 2001) Page 20 of 44

REFRIGERATION TEST:

< REFR: OFF

AIR TEMP: 14°F

< COMP USAGE BACK>

1) Pr essing the button beside REFR c an

test the com pressor function. The

options for the REFR are: O FF, ON,

or ON&FANS.

OFF= Refrigeration not operational.

ON= Refrigeration operational .

ON&FANS= Refri ger ation and

evaporator fans operational.

2) T he c urrent Air temperature inside

the cavity i s also displayed.

Page 21

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

3) T he servic e menu can be reached by

pressing the button beside B A CK and

all outputs will return to their off state.

4) COMP USAGE – Displays days &

hours since the last cleaning of

condensor coil.

NOTE:

After c leaning the condensor coil,

press the button beside cl eaned c oil to

reset the day & hour bot h to read 0.

5) T he pr evious menu can be reached

by pressing the button besi de B A CK

and all outputs will return to their off

state.

F. PROBES/ALARM – View curr ent probes

reading and change status of ALARM

output.

PRODUCT P ROBE TEMP S :

1 74°F 73°F 3

2 73°F

< ALARM = OFF BACK>

1) T his screen displays the value of

each product probe. If no value(s)

shown find the source of the problem.

2) T he alarm out put can also be

changed from OFF to ON.

3) Pr essing B A CK displays the serv ice

menu and the al arm output r eturns to

the off state.

G. DISPLAY – Illuminates entire display, see

below. Pressing any key will return to the

servi ce menu. This option can also be

used as a test for the key pad, since any

key press will return to the previous menu.

H. DOORS – Displays status (OPEN or

CLOSED).

DOOR INPUTS:

OPEN/CLOSED

BACK >

NOTE:

Cycling the door open and closed shows the

status of compartment door. If not find the source of

the problem.

1) Pr essing B A CK displays the serv ice

menu.

I. DEF/COIL – Defrost System and Coil

probe test.

DEFROST TEST:

< HEATER = OFF

COIL TEMP = 76°F

BACK >

1) T he defrost heat can be turned OFF

or ON by pressing the heat er button.

OFF= Defrost heater should not be

energize.

ON= Defrost heater should energi z e

and coil t emperature should sl owly

increase.

2) T he c oil temperature is al so

displayed. If not find the source of the

problem.

NOTE:

If t he screen does not display as shown

display board needs repl ac ed. If display does not

return to the servic e menu then keypad needs

replaced.

3) Pr essing B A CK displays the serv ice

menu and turns the heater off.

Form 24693 ( M ar c h 2001)Page 21 of 44

Page 22

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

J. FANS – Tests Fan out puts.

FAN MODE TE S T:

< FAN = NONE

FAN DOOR = CLOSED

1) Pr essing the FANS button test the

evaporator fans f unction. T he options

for FA NS ar e: NONE, SET 1, SET2

and BOTH.

NONE= All evaporator f ans deenergized.

SET1= T his is the low air flow mode

for the soft chill mode. Only one

evaporator fan energized. If not find

the source of t he problem.

SET2= T wo evaporator fans

energized. I f not find the source of

the problem.

BOTH= A ll evaporator fans

energized. I f not find the source of

the problem.

2) Pr essing B A CK displays the serv ice

menu and turns the fan(s) off.

BACK >

K. PRINTERS – Sends test print out t o

printer(s).

PRINTER TEST:

< RECORD: READY

< LABEL: READY

NOTE:

is not an option.

LABEL: READY not displayed i f label printer

1) Pr essing t he button beside RECORD

sends a test print out t o the paper

printer. The READY changes to

RUNNING, then t o SUCCESS if the

print finishes successfully. Other wise

ERROR is display ed and find the

source of the pr oblem.

2) I f the Label pr inter option is installed,

the LABEL test can be ran by

pressing the button beside LABEL to

send a test print out .

3) Pr essing B A CK displays the serv ice

menu.

BACK >

FACTORY SETTINGS MODE

ML-124066, ML-124067,

ML-124068

WARNING:

SUPPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL TIMES.

CAUTION: Electro-static discharge will damage the control board. Use a anti-static grounding kit when

servicing t he computer control b ox.

1. Turn power OFF to the unit.

THIS PROCE DURE RE QUIRES THAT THE CONTROL BO X BE OPEN WHILE THE POWER I S

Form 24693 ( M ar c h 2001) Page 22 of 44

Page 23

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

2. Loosen the control panel screws and swing open control panel to gain access to factor y settings mode

switch.

3. Locate the factory settings mode switch on the back of display board, press and hold switch while tur ning

power ON to chiller. The following factory settings menu will be displayed.

FACTORY SETT I NGS

VERSION:

S/N:

<RESET NEXT>

BACK DOOR [NO]

LABEL PRINTER [NO]

FAN IN HLD [CYCLE]

<BACK NEXT>

BLASTING DIFF [4]

HOLDING DIFF [4]

((F

((F

ANTI-SHORT [3]

<BACK NEXT>

DEFROST TIME [20]

DEFR. TEMP [50]

DEFR. INTVL [6] HR

((F

<BACK NEXT>

4. Enter the uni ts serial number by sel ec ting the left arrow nex t to

changes which digit to edit in serial number, and the up arrow increments

the v alue of the sel ected digit.

RESET- Resets all the parameters to the factory preset values, and

erases all recorded cycles in memory.

NEXT- Continues to the next factory setting menu.

5. BACK DOOR- Is not an option, selec t no.

6. LABEL PRINTER- Options are:

OFF= No label printer.

ON= Individual label s.

CNT= Continuous labels.

7. FANS IN HLD- [CYCLE] F ans are defaulted to cycle ON and OFF.

Select [ C ONT] f or c ontinuous fan operat ion during hold mode.

8. BLASTING DIFF- Blasting different ial is the t emperature difference

between the set point t emperature and the ac tual tem per ature for opening

the compressor solenoid when in chill or freeze mode.

9. HOLDING DIFF- Is the temperature di ffer enc e for hold mode.

10. ANTI SHORT- Is the minimum time bet ween cl osi ng and opening the

compressor solenoid.

11. DEFROST TI M E - Is the length of defrost t ime in minutes.

12. DEFROST TEM P - Is the set point for the coil temperature.

13. DEFROST INT V L- Is the time interval bet ween automatic defrosts.

S/N

ENTER SE CURITY CODE

FOR NEXT SETTINGS:

[0000000]

<EXIT ENTER>

INCORRECT CODE!

PLEASE CALL HOBART

FOR ASSISTANCE

NEXT>

MACH. MODEL [HQC]

MACHINE SIZE [45]

SOFT FREEZE [NO]

<BACK NEXT>

14. T he security code is t he last seven di gits of the serial number reversed.

The left arrow selects which digit to adjust, and the up arrow increments

the v alue of the selected digi t.

15. Pr ess Enter to continue to secur ed options or Exit to exit the factory

settings mode.

16. I f the inc or r ec t security code was entered, the following screen will be

displayed.

17. MA CH. MODEL- Sel ec t the type of model either HQC or HQCF

NOTE:

18. MA CHINE SIZE- S elect the machine size ei ther 45 or 90

NOTE:

Do not select HQF, FQC, FQF, or F QCF model s.

Do not select any other size than actual chiller size.

19. SOFT FREEZE- Allows chiller to perform a soft freeze.

NOTE:

This should remain NO unless instruc ted otherwise.

Form 24693 ( M ar c h 2001)Page 23 of 44

Page 24

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

FREEZE MAX [20]

SFT FRZ MIN [-5]

DEFROST TYPE [EL E]

<BACK NEXT>

((F

((F

20. F RE E ZE MAX- Is the maximum selectable value for freezing t he HQCF

model chiller.

21. SOFT FRZ M IN- Is the minimum selectabl e value for soft freeze.

22. DEFROST TYPE- Is selection for chiller to defrost by [ELE] (defrost

heating element) or [ GAS] (refrigeration compressor).

NOTE:

This should remain [ELE] unless instructed otherwise.

FACTORY SETT I NGS

DO YOU WISH TO SAVE

THESE NEW SETT I NGS?

<NO YES>

SAVING SETTINGS

PLEASE WAIT. . .

FACTORY SETT I NGS

SETUP IS COMPLETE!

RESTART CONTROL LER

23. YES- Sav es the settings to memory.

24. NO - E xit wit hout saving c hanges.

25. This display will be shown while the settings are being saved.

26. When the sett ings have been saved, restart the controller by turning

power OFF then back ON.

SOFTWARE VERSION

ML-124059,ML-124060,ML-124063

SOFTWARE VERSION

ML-124066,ML-124067,ML-124068

The control program sof tware version can be

determined by pressing the 0 key when the m ain

menu is displayed. The displ ay will show "REV 2.1";

“MODEL2"; “PUSH 0 TO EXIT”.

version)

on the E-Prom. The E-Pr om is locat ed on the

control boar d in the control box.

IMPORTANT NOTE:

could af fect the oper ation of the Chiller.

check the software version before servicing t his unit

or calling for technical assistance.

Form 24693 ( M ar c h 2001) Page 24 of 44

The version will match the version printed

Any change in the software

(2L is the current

ALWAYS

The control program sof tware version is displayed

during initial ization when unit is turned on. The

display will show the chiller model number and the

current sof tware version number.

Smart Chill

HQC 45 or 90

INITIALIZING

VERSION: X.XX

Page 25

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

CONTROLLER SERVICE

PROCEDURES

ML-124059,ML-124060,

ML-124063

Control ler Board

The control ler board has a series of LEDs to assist

in troubl eshooting. When the LED is l it, the

component should be energized.

LED COMPONENT LED COMPONENT

1 Remote Alarm 5 E vaporator Fan

2 Defrost Heater 6 Controller*

3 NOT USED 7 NOT USED

4 Refrigeration

Solenoid

*LED #6 blink s on and off at one second intervals

when the controller board is energized.

The service switch is loc ated near the center of the

board. The buzzer loudness pot is located near t he

center of the board, below the buzzer .

8 NOT USED

Voltage check for +5VDC to Printer Board

1. Check for +5 VDC on pins J3-15, J3- 16, J3-17.

2. Check for 0V on pins J3-18, J3-19, J 3- 20.

Voltage check for +5VDC to Display.

1. Check for +5VDC between J1-1 and J1-2 on

controller board.

2. Check these pins at cable connections J1 and

P1.

Printer Board

The printer board monitors the speed of the paper

feeding through the printhead.

If t he speed i s not nor mal, “Pri nter Error” i s shown

on the display. A paper jam or a mechanical

problem wi th the printer c an be the cause.

To reset the printer you must r emov e the power

from the unit for a minimum of five seconds. If the

power is removed from the unit for less than ten

minutes, it will return to the point in the cycle at

which the int er r uption occurred.

.

Voltage check for 13.5 (±1.5) VDC to Control ler

Board if LED 6 is not flashing.

1. Check between TP 8 & 9 on hi gh voltage board

for 13.5 V DC.

2. Check the cable connections between the high

voltage board and the controller board.

A. Pins 5 & 6 are ground on J2 (high voltage

board) and J6 (contr oller board).

B. Pins 3 & 4 are +12VDC on J 2 ( high

voltage board) and J6 (controller boar d) .

C. Check these pins at cable connections

P17, J10/P10, P 9/J9, and P6.

1. Inspect the printer for a paper jam or roll

feeding incorrectly.

2. Remove the paper f rom the printer and reload

the paper.

3. Reset the controller and try to print.

4. If t he er ror occurs again and its not a paper

problem, replace the pr inter board.

Form 24693 ( M ar c h 2001)Page 25 of 44

Page 26

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

Keypad

1. Disconnect P2 from J2 on the controller board.

2. Perform a conti nuity test between the pin numbers (P2) for the appropriate key.

3. Use the 200 scale on a digi tal met er . When the key is pressed, the readi ng shoul d be between 15 and 40

ohms.

Power/Hi gh Voltage Board

The power board has a series of LEDs lamps and

test points to assist in troubleshooti ng.

When the LED or lam p is lit, the component shoul d

be energized.

LAMP

L1 Refrigeration

L2 Evaporator

LED COMPONENT LED COMPONENT

1 Power Board 3 NOT USED

2 Remote Alarm

COMPONENT LAMP COMPONENT

L3 Heater control

Solenoid

L4 NOT USED

Fan

TEST

COMPONENT VOLTAGE

POINT

1 L2 Supply Vol tage

2 Neutral Line 0 V

3 Local Solenoid 120 V

4 Fan Control 120 V

5 Heater Control 120 V

6 Remote S olenoid 120 V

7 Not Used

8 Print er & Controller + 12 V

9 Chassis & Signal

0 V

Ground

10 L1 Supply Voltage

Form 24693 ( M ar c h 2001) Page 26 of 44

Page 27

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

CONTROLLER SERVICE

PROCEDURES

ML-124066, ML-124067,

ML-124068

Control ler Board

The control ler board has two LED's to assist in troubleshooting. LED (D2 P OWER) is lit= indic ates that power is

supplied to the controll er boar d. LED (D1) is f lashing= indicates that I/O board and control board are

comm unicating. If not , check all har ness connections to communication cables going between I/O & controller

boards. LED (D13) is not used.

Form 24693 ( M ar c h 2001)Page 27 of 44

Page 28

HQC45/HQCF45/HQC90 QUICK CHI LLE R - S E RV ICE PROCEDURES AND ADJ U S TMENTS

I/O Board

The I/O board has a series of LED's and test points to assist in troubleshooti ng. When the LED is li t, the

component should be energized or input open.

LED COMPONENT LED COMPONENT TEST

POINT

COMPONENT VOLTAGE

D1 F r ont Door D8 Defr ost Heater TP1 Relays +12VDC

D2 NO T USED D9 Low Fan TP 2 Logic Circuit +5VDC

D3 F an Door D10 High Fan TP3 Ground 0V

D4 Compressor

Solenoid

D11 Alarm J17, J18 Triac Compressor

Solenoid

0.75 - 2VAC

voltage drop

J15, J16 Triac Defrost Heater 0.75 - 2V A C

voltage drop

NOTE:

Voltage drop readings to be measured

while specified com ponent is energized.

Form 24693 ( M ar c h 2001) Page 28 of 44

Page 29

HQC45/HQCF45/HQC90 QUICK CHI LLE R - E LE CTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT LOCATION

Only fo r HQC45 ML-124059, HQCF45 ML-124060, HQ C90 M L-124063

Form 24693 ( M ar c h 2001)Page 29 of 44

Page 30

HQC45/HQCF45/HQC90 QUICK CHI LLE R - E LE CTRICAL OPERATION

Only fo r HQC45 ML-124066, HQCF45 ML-124067, HQ C90 M L-124068

Form 24693 ( M ar c h 2001) Page 30 of 44

Page 31

HQC45/HQCF45/HQC90 QUICK CHI LLE R - E LE CTRICAL OPERATION

COMPONENT FUNCTION

Compressor ...............

Condenser Fan ............

Dual Pressure Co ntrol .......

Start Capacitor.............

Run Capacitor .............

Thermal Overload ..........

Relay ....................

Evaporator Fan ............

Defrost Heater .............

Air Temperature Sensor .....

Coil Temperature Sensor ....

Food Temperature Probe ....

Front Door Switch ..........

Fan Door Switch ...........

Solenoid Valve.............

Door Perimeter Heater.......

Door Heater Thermostat .....

Controller.................

Power Supply Boards .......

I/O Board .................

Main Contactor ............

Main Switch ...............

Over Temp . Thermo st at

(manual reset) .............

Safety Thermostat

(manual reset) .............

Pumps ref rigerant thr ough r efrigeration li nes and components.

Draws air across condenser coil to aid in removing heat from the refrigerant

and moves air across compressor to aid in cooling the compr essor.

Low side monitor s suction pressure at compressor. Shut s compressor off

when low pressure setting is reached (cut-out). Al lows compressor to run

when pressure rises to cut-in setting.

High side monitors discharge pressure at compressor. Shuts compr essor off

when high pressure setting is reached (c ut-out). Allows compressor to run

when pressure returns to cut-in sett ing.

The differential is the difference in pressure between opened and closed

states of the pressure switch.

Wired in series with the start windings to help start compr essor m otor .

Continually in circuit t o help compressor motor during operat ion.

Removes power from c ompressor if the internal temperatur e of the

compressor becom es too high (auto reset).

Senses current of r un winding of compressor motor. Nor mally open c ontacts

close when the run winding draws a high am per age at start and brings the

start capaci tor and start windings into the circ uit. As the motor reaches

operating speed (l ess amper age through run winding), the normal ly open

contacts open and removes the start capacitor and star t windings from the

circuit.

Draws air from the cabinet and mov es the air through the evaporator c oil. Air

should blow air toward the door .

Defrosts evaporator coil and prevents water droplets from evaporator coil

from freezing before t hey c an dr ain to the condensate pan. Operates only

during defrost cycle.

Monitors ai r temperature inside cabinet.

Monitors the suction l ine temperature at evaporator duri ng defrost cycle.

Monitors temperature of food product .

Monitors door for open or closed posit ion. Evaporator fans stop when door is

open.

Monitors evaporator fan compartment door for open or closed position.

Evapor ator fans will not start if the switch is open. Refrigerant system

operation stops after 30 seconds switch has been open.

Normally closed. When energi z ed ,allows refrigerant to flow from receiver to

evaporator coil .

Prev ents condensate from forming on door f r ame.

Monitors door frame t emperature. Opens circuit to door frame heater if the

door frame temper ature exceeds the set poi nt.

Performs the following f unc tions:

A. Displays all data for the current mode of operation.

B. Cycles refrigeration system to maintain cabinet temperature.

C. Monitors power failures.

D. Monitors door positi on.

Controls power to I/O board and printer(s).

Performs the following f unc tions:

A. Cycles defrost heaters during defrost cycle.

B. Cycles compressor solenoid to maintain c abinet tem perature.

C. Monitors AC monitor to determine loss of power.

D. Closes alarm contact to signal external al ar m dev ice, af ter a malfuncti on

detected.

E. Monit ors door switch position.

F. Monitors fan door switch.

Controls power to unit electrical cir c uits once main switch is closed.

Controls power to m ain contactor when safety thermostat is closed.

Removes power from all com ponents including the controller.

Monitors cabinet air temperature. Opens circuit to main c ontactor if cabinet

temperat ure exceeds 155°F.

Monitors cabinet air temperature. Opens circuit to main c ontactor if cabinet

temperat ure exceeds 155°F.

Form 24693 ( M ar c h 2001)Page 31 of 44

Page 32

HQC45/HQCF45/HQC90 QUICK CHI LLE R - E LE CTRICAL OPERATION

SEQUENCE OF OPERATION

ML-124059, ML-124060,

ML-124063

NOTE:

(ML-124063) schematics will be used to explain the

electrical sequence of oper ation.

Refrigeration System

1. The controller must be in a chill or hold mode.

2. The controller monitors the air temperature and

3. The low pressure switch closes with the rise in

4. The expansion valve m onitors the evaporator

5. The controller senses the air temperature

6. Compressor conti nues to r un. Low pressure

7. Unit is cycled by controller.

Idle Mode

1. Conditions

2. Main switch closed.

3. Controll er goes through power up self

HQC45 (ML-124059,ML-124060) HQC90

senses a need for cooling.

A. The relay that control s the sol enoid valve

is energized.

1) Solenoid valve is energized and

refrigerant f lows to the evaporator.

pressure.

A. The compressor motor is energiz ed and

refrigerant is pum ped through the system.

superheat and meter s the amount of r efrigerant

entering the evaporator.

requirements have been met.

A. De-energizes the relay that cont r ols the

solenoid valve.

1) Solenoid valve is de-energiz ed and

closes. Refr igerant f low to the

evaporator stops.

control opens as pressure drops.

A. Compressor mot or de- ener gized.

A. Unit connect ed to correct volt age.

B. Safety thermostat c losed.

C. Fan door switch c losed.

D. Front door switch closed.

A. Main contactor energized, c ontacts close.

1) Door heater energized.

2) Cont r oller energized.

3) Power to condensing unit cont r ols.

diagnostics and di spl ay s main menu.

Hold Mode

1. Unit is i n IDLE mode.

2. Hold mode is selected.

NOTE:

run. One tracks the time in the hold mode and the

other track s the time sinc e the last defr ost ( hold

mode has a defrost every six hours).

NOTE:

set-up menus.

NOTE:

operation, the evaporator fans and refrigeration

system will shut down.

3. Hold mode is termi nated by pressing the stop

NOTE:

operator with the def rost cycle in progress, the

defrost mode will continue until completion before

going into IDLE MODE.

Manual Chiller / Freezer Mode

1. Unit is i n IDLE mode.

2. Manual chill is selected and a tim e is entered.

3. For the first 2/3 of the chilling time, the

4. For the last 1/3 of the cycle, if “surface

NOTE:

chill operation, the evaporator fans and refri ger ation

system will shut down.

When the hold mode is selected, two ti mers

A. The refrigeration system will cycle on the

air temperature of the cabinet.

1) “On” at t he set point plus differ ential.

2) “Off” when set point reached.

Set point and differential are selected i n the

If t he c abinet door is opened during

B. The hold m ode has an aut omatic defrost

cycle aft er every six hours of operation in

the hold m ode.

1) When the defrost cycle is complete

and the unit returns to the hold mode,

the ev apor ator fans will not operate

until the coil temperature is below

25°F.

key.

If t he HOLD MODE is terminated by the

A. Unit reverts back to st ep 2.

refrigeration system will cycle on the blasting

air temperature set point.

A. “On” at the set point pl us di ffer ential.

B. “Off” when set point reac hed.

protection” has been selected, the refrigerat ion

system will cycle on the new blasting air

temperat ure set point of 28(F. If “surface

protection” is not selected, the set point

remains the same unt il the end of the cycle.

If t he c abinet door is opened during manual

Form 24693 ( M ar c h 2001) Page 32 of 44

Page 33

HQC45/HQCF45/HQC90 QUICK CHI LLE R - E LE CTRICAL OPERATION

5. Manual chill mode is terminated when time

expires.

A. Buzzer sounds for 2 minutes.

6. If t he end of the m anual chill cycle is not

acknowledge by pressing the yes key, the unit

will enter the hold mode.

A. If t he end of the m anual chill cycle is

acknowledge by pressing the yes key, the

unit will enter the idle mode.

Automatic Chiller / Freezer Mode

1. Unit is i n IDLE mode.

2. Automatic chill is selected.

NOTE:

chill operation, the evaporator fans and refri ger ation

system will shut down.

3. Auto chill mode is terminated when all the

NOTE:

temperat ure of each probe as they r eac h the set

temperat ure and the buzzer sounds for 2 minutes

(unless the MUTE key is pressed).

Defrost Mode

1. The defrost mode can be entered manually

2. Defrost cycle is 20 minutes i n length or until the

NOTE:

evaporator fans will not operate until the c oil

temperat ure is below 25°F.

Operational Mode Error Codes

If t he c abinet door is opened during manual

product probes reach the target chill

temperature.

An asterisk will be displayed next to the

A. If t he end of the automatic ch ill cycl e i s not

acknowledge by pressing the yes key, the

unit will enter the hold mode.

B. If t he end of the automatic ch ill cycl e i s

acknowledge by pressing the yes key, the

unit will enter the idle mode.

from the idle mode or automatical ly from the

hold mode.

coil t emperature reac hes 50°F.

A. If t he defrost mode was entered from t he

hold mode, the unit will return to the hold

mode.

When the unit returns to the hold m ode, the

B. If t he defrost mode was entered from t he

idle mode, the buzzer sounds f or two

minut es unless the yes key or the mute

key is pressed.

MESSAGE EXPLANATION

Printer Error Paper speed too slow

Cooling too slow Air temperature can not be

greater than 44°F 30 minutes

into the hold cycle.

SEQUENCE OF OPERATION

ML-124066, ML-124067,

ML-124068

NOTE:

HQC90 ML-124068 schematics will be used to

explain the electrical sequence of operation.

Refrigeration System

1. The controller must be in a chill or hold mode.

2. The controller monitors the air temperature and

3. The low pressure switch closes with the rise in

4. The expansion valve m onitors the evaporator

5. The controller senses the air temperature

6. Compressor conti nues to r un. Low pressure

7. Unit is cycled by controller.

Idle Mode

1. Conditions

2. Main switch closed.

3. Controll er goes through power up self

HQC45 ML-124066, HQCF45 ML-124067,

senses a need for cooling.

A. The relay that control s the sol enoid valve

is energized.

1) Solenoid valve is energized and

refrigerant f lows to the evaporator.

pressure.

A. The compressor motor is energiz ed and

refrigerant is pum ped through the system.

superheat and meter s the amount of r efrigerant

entering the evaporator.

requirements have been met.

A. De-energizes the relay that cont r ols the

solenoid valve.

1) Solenoid valve is de-energiz ed and

closes. Refr igerant f low to the

evaporator stops.

control opens as pressure drops.

A. Compressor mot or de- ener gized.

A. Unit connect ed to correct volt age.

B. Safety thermostat c losed.

C. Fan door switch c losed.

D. Front door switch closed.

A. Main contactor energized, c ontacts close.

1) Door heater energized.

2) Cont r oller energized.

3) Power to condensing unit cont r ols.

diagnostics and di spl ay s main menu.

Form 24693 ( M ar c h 2001)Page 33 of 44

Page 34

HQC45/HQCF45/HQC90 QUICK CHI LLE R - E LE CTRICAL OPERATION

Hold Mode

Product can be held at chil led temperature by

selecting hold mode from m ain menu. Unit will also

go into hold mode automatically when all active

probes have reac hed the target temperature when in

"By Temp" mode. I f a "By T ime" mode selected the

unit enters hold mode automatical ly aft er the tim e

has expired.

1. Unit is i n IDLE mode.

2. Hold mode is selected.

NOTE:

When the hold mode is selected, two ti mers

run. One tracks the time in the hold mode and the

other track s the time sinc e the last defr ost ( hold

mode def r ost s at a pr ogr amable interval).

A. The refrigeration system will cycle on the

air temperature of the cabinet.

1) “On” at t he set point plus differ ential.

2) “Off” when set point reached.

NOTE:

Set point and differential are selected i n the

factor y set - up menus.

NOTE:

If t he c abinet door is opened during

operation, the evaporator fans and refrigeration

system will shut down.

B. The hold m ode has an aut omatic defrost

cycle after a programable interval of

operation i n the hold mode.

1) When the defrost cycle is complete

and the unit returns to the hold mode,

the ev apor ator fans will not operate

until the coil temperature is below

25°F.

3. Hold mode is termi nated by pressing the exit

key.

NOTE:

If t he HOLD MODE is terminated by the

operator with the def rost cycle in progress, the

defrost mode will continue until completion before

going into IDLE MODE.

A. Unit reverts back to st ep 2.

"By Time" Chiller / Freezer Mode

1. Unit is i n IDLE mode.

2. Chill type is selected and a cycle tim e is

entered then start k ey pr essed.

3. The refrigeration system will cycle on the

blasting air temperature set point.

A. “On” at the set point pl us di ffer ential.

B. “Off” when set point reac hed.

4. If “soft chill” has been selected, the

refrigeration system will cycle on the new

blasting air temperature set point. If “chill” was

selected, the set point remains the same until

the end of t he cycle.

NOTE:

If t he c abinet door is opened during By Time

chill operation, the evaporator fans and refri ger ation

system will shut down.

5. Chill mode is terminated when time expires.

A. Buzzer sounds until muted.

6. At the end of the chill cycle the unit will enter

the hold m ode.

A. If t he end of the chill cycle is acknowledge

by pressing the stop/reset key , the unit will

enter the idle mode.

"By Temp" Chiller / Freezer Mode

1. Unit is i n IDLE mode.

2. Chill type is selected and a target tem per ature

is entered then start key pressed and probe

selected.

3. The refrigeration system will cycle on the

blasting air temperature set point.

NOTE:

If t he c abinet door is opened during By

Temp chill operation, t he evaporator fans and

refrigeration system will shut down.

4. Chill mode is terminated when all the product

probes reach the target c hill temperature.

NOTE:

Once the temperature of the probe reaches

the target temperature display will alternate with

"DONE", and the buzzer will sound unless muted.

A. At the end of the chill cycle the unit will

enter the idle mode.

"By Product" Chiller / Freezer Mode

1. Unit is i n IDLE mode.

2. Product type is selected.

3. Chill type is selected and a target tem per ature

is entered then start key pressed and probe

selected.

4. The refrigeration system will cycle on the

blasting air temperature set point.

NOTE:

If t he c abinet door is opened during By