Hobart Food Machines HFC225 Installation Manual

MODEL HFD/HFC SERIES

ELECTRIC FRYERS

I

N

S

T

R

U

C

T

I

O

N

S

MODELS

HFD40 ML-114624

HFD50 ML-114625

HFD225 ML-114626

HFD85 ML-114627

HFC40 ML-114628

HFC50 ML-114629

HFC225 ML-114630

HFC85 ML-114631

HFO15 ML-114632

HFO21 ML-114633

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

— 1 —

FORM 33637 Rev. B (5-99)

TABLE OF CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Codes and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Leveling the Fryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Before First Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Filling the Fry Tank with Shortening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Adding Solid Shortening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Daily Shortening Addition (All Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Controls — HFD Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Melting Solid Shortening (Model HFD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Turning the HFD Fryer On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Turning the HFD Fryer Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

High Limit Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Frying (All Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Daily Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Shortening Life (All Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Controls — HFC Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

To Begin Melt Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Cooking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Manual Cooking Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Cooking Time Remaining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Successive Product Cooking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

During Slack Periods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Idle Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Operator Advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Using the Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Programming the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Service and Parts Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

— 2 —

Installation, Operation and Care of

MODEL HFD/HFC SERIES ELECTRIC FRYERS

SAVE THESE INSTRUCTIONS FOR FUTURE USE

GENERAL

Hobart HFD/HFC Series Electric Fryers are available in 3 sizes with an array of features and options

for a range of commercial fryer applications. While the overall tank width on the HF40 and HF50 are

the same, the HF50 has a deeper tank area than the HF40.

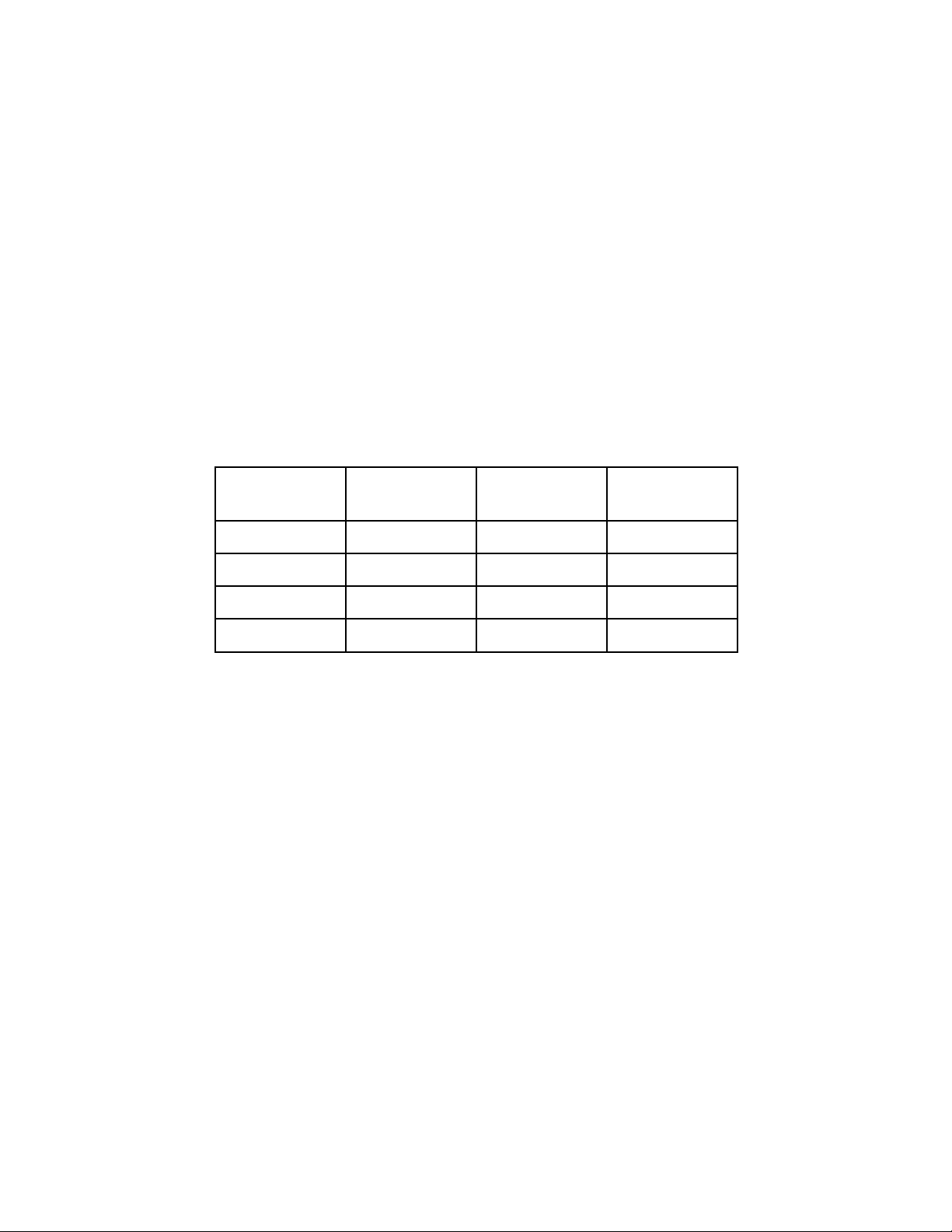

Width Fry Compound

Model KW inches cm Lb. kg

HFD/HFC40 14 & 17 15.5 39.3 35-40 15-18

HFD/HFC50 14, 17 & 21 15.5 39.3 45-50 15-18

HFD/HFC225 14, 17 & 21 15.5 39.3 25 11

HFD/HFC85 24 21.0 53.3 70-85 31-38

Voltage ranges are: 208/240, 3 Phase

220/380, 3 Phase, 4 Wire

240/415, 3 Phase, 4 Wire

480, 3 Phase.

Model HF Series Fryers can be free standing or arranged in batteries of 2 to 5 fryers. The number

preceding the model number of your fryer refers to the number of fryers in a battery. One fryer in a

battery can be a Frymate Dump Station (HFO15 for HF40 and HF50, HFO21 for HF85) (only one per

battery).

HFD Fryers have a solid state thermostat and HFC Fryers have a microprocessor (computer)

thermostat and timer control.

Feature options include Basket Lift(s) with Timer(s); Tri, Twin, or Single Baskets; Filter Ready and

Battery Interplumbing. Finish options include S/S Sides and Casters. S/S Legs are standard.

Your Hobart fryer is constructed and designed to give long satisfactory service, providing it is properly

installed, adjusted and maintained.

The Mobile Filter is covered under a separate Installation and Operation Manual.

— 3 —

HF Series Fryer — Features

Model

HFD 225 Std. N/A N/A

HFD40, HFD50 Std. Solid State Opt. Std. Opt. N/A

HFD85 Std. Opt. Opt.

HFC40, HFC50

HFC85 Std. Opt. Opt.

Model Filter Ready

HFD40/HFC40 Opt. (Use HMF50) Opt. Opt.

HFD50/HFC50 Opt. (Use HMF50) Opt. Opt.

HFD225 Opt. (Use HMF50) Opt. Opt.

HFD85/HFC85 Opt. (Use HMF85) Opt. Opt.

Fat Melt

Cycle Twin Single Tri

Std. Computer Opt.

HF Series Fryer — Construction Features

Thermostat Basket Lift(s)

Battery Battery

Configuration Interplumbing

Basket(s)

Std. Opt. N/A

BATTERY CONFIGURATIONS

Batteries of up to five fryers wide can be configured with any HF Series Fryer or HFO Frymate Dump

Station (either 15

1

⁄2" [39.3 cm] or 21" [53.3 cm] wide). Possible configurations showing positions A thru

E are depicted below:

NOTES:

= Dump Station; = Fryer.

*Indicates filter interplumbing not available.

A mobile filter can be located under any position in a battery if it has been built without an HFO Frymate.

A mobile filter can be located under any position in a battery if the line-up has been built with an HFO Frymate

located at either end of the battery.

When an HFO Frymate is built between two fryers within a battery, the filter is located under the HFO Frymate.

All options and accessories can be used with batteried equipment.

HFO15 is used on Models HF40 or HF50.

HFO21 is used on Model HF85.

— 4 —

Field Installable Accessories: Factory Installed Only

• Casters • Fat Melt

• Twin Baskets • Basket Lift

• Single Baskets • S/S Tank

• Tri Baskets (HF85 only) • S/S Sides

• Heat Lamp • Battery Configuration

• S/S Vat Cover • Battery Interplumbing

• Batter Tray

• Tank Skimmer

• Tank Scoop

HFO SERIES FRYMATE (Dump Station)

Model HFO Frymate Dump Station can be configured in batteries with fryers in either 15

1

⁄2" (39.3 cm)

or 21" (53.3 cm) width. Frymate provides a final prep area where excess oil drains away and product

is seasoned, packaged, and kept ready for sale.

HFO Series Frymate — Finish Options

Model HFO15, HFO21 Front Door Sides Legs

Standard Stainless Steel Painted Steel Stainless Steel Legs

Optional Not Applicable Stainless Steel Casters

*Model HFO15 is for use with all HF40, HF50 and HF225 Series Fryers.

Model HFO21 is for use with the HF85 Series Fryers.

HFO Series Frymate — Features

Heat Lamp

Opt. Std. Opt. Opt. Opt. Opt.

*Side liners are not available in batteries with HFO interplumbed Frymates.

Drain Solid Pan Solid Pan Perforated

Tops

Side Liners*

— 5 —

INSTALLATION

Before installing the fryer, verify that the electrical service agrees with the specifications on the fryer

data plate which is located on the inside of the door panel.

UNPACKING

Immediately after unpacking the fryer, check for possible shipping damage. If the fryer is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Do not use the door or its handle to lift or move the fryer.

LOCATION

The fryer may be installed at 0" clearance from the back or side walls. A 16" (40.6 cm) clearance is

required between the fryer and any open top flame burner. Position the fryer for easy accessibility

for service.

INSTALLATION CODES AND STANDARDS

Your Hobart fryer must be installed in accordance with:

1. State and local codes.

2. The National Electrical Code, ANSI/NFPA No. 70 (latest edition). Copies may be obtained from the

National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

3. NFPA Standard #96.

ASSEMBLY

The fryer must be restrained with adequate ties to prevent tipping when installed in order to avoid the

splashing of hot liquid.

Legs

Position fryer in an open space near the final installation area. Tilt fryer on its side, being careful to

avoid scratching the finish. Thread legs into mounting holes provided on bottom of fryer by screwing

in a clockwise rotation until tight.

Carefully raise fryer to its normal position and place it in the installing location.

— 6 —

Casters (Optional)

It is recommended that casters be installed on all batteried appliances. A strain relief is supplied to

protect the electrical supply line.

If it is necessary to disconnect the restraint, unplug electrical supply before disconnection. Reconnect

the restraint before plugging the electrical supply in and returning the fryer to its installation position.

Instructions for installing casters to the fryer are included with the casters.

STRAIN RELIEF

FITTING FOR ELECTRIC

THIS SIDE ONLY.

(Strain relief fitting

supplied by Hobart.

Chain to be supplied by

others.)

PL-53296

Fig. 1

LEVELING

Place a carpenter's level on top of the fryer and level the fryer front-to-back and side-to-side by turning

the adjustable legs.

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE NATIONAL

ELECTRICAL CODE AND/OR OTHER LOCAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH TO INDICATE THAT YOU ARE WORKING ON THE CIRCUIT.

WARNING: APPLIANCES EQUIPPED WITH A FLEXIBLE ELECTRIC SUPPLY CORD ARE

PROVIDED WITH A THREE-PRONG GROUNDING PLUG. IT IS IMPERATIVE THAT THIS PLUG

BE CONNECTED INTO A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. IF THE

RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO NOT

REMOVE THE GROUNDING PRONG FROM THIS PLUG.

— 7 —

Place fryer as near to its final position as possible. Connect 3 phase line to X, Y and Z of terminal block.

I

To reach terminal block, remove electric cover plate from fryer.

For each 15

1

⁄2" (39.3 cm) and 21" (53.3 cm) section, a 3 phase supply line capable of handling the

required KW at the fryer's rated voltage (208, 240, 480) is needed. Refer to the fryer data plate for this

electrical information.

If a fan interlock is needed, it should be connected to 1 and 2 on the 4 pole barrier strip. 1 and 2 go

to a set of dry contacts on the power switch.

— 8 —

Loading...

Loading...