Page 1

Item # _____________________________________

R

Quantity ___________________________________

C.S.I. Section 11400

HBA2E DOUBLE RACK

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STANDARD FEATURES

■ Advanced digital programmable control panel

includes:

- Bake/steam timers

- Cool-down mode

- Four stage baking

- Auto on/off control

- Auto vent

- 99 menus

- Energy saving idle mode

■ Heavy duty rack lift with rack jam warning

system utilizing slip clutch feature

■ Soft start rotation system

■ Stainless steel construction

■ Oven body shipped in two main sections for

ease of installation

■ Flush oor with patented adjustable oor

construction provides easy access - no ramp

required

■ Field reversible bake chamber door

■ Hood with plenum for Type II installation

■ Space saving 72" wide x 62" deep footprint

(less canopy)

■ Wide viewing glass (21" W x 57.5" H) with triple

pane glass for reduced heat loss and cooler

working area in front of oven

■ Patented self-contained cast spherical steam

system

■ Pre-plumbed water regulator

■ Built-in rollers and levelers for ease of

installation

■ Single point 10" vent connection

■ Stainless steel “B” style rack lift

■ Capacity - two single racks or one double rack

■ One year parts/labor warranty

OVEN – ELECTRIC

MODEL

❑ HBA2E – Double Rack Oven, Electric

OPTIONS AND ACCESSORIES

❑ Back-up controls

❑ Floor extender kit

❑ Shipped assembled (less canopy/steam

system)

❑ Aluminum or stainless steel oven racks

❑ Hood with grease lters – Type 1 (UL listed to

Standard UL 710 and meets all requirements of

NFPA-96)

❑ “C” style rack lift

❑ Kosher package

❑ 50 Hz available, consult factory for details

Specications, Details and Dimensions on Back.

HBA2E DOUBLE RACK OVEN – ELECTRIC

ANSI/NSF Standard #4

City of LA (M-910049) and State of MA (C3-0606-363)

F-40016 – HBA2E Double Rack Oven – Electric Page 1 of 2

Page 2

HBA2E DOUBLE RACK

OVEN – ELECTRIC

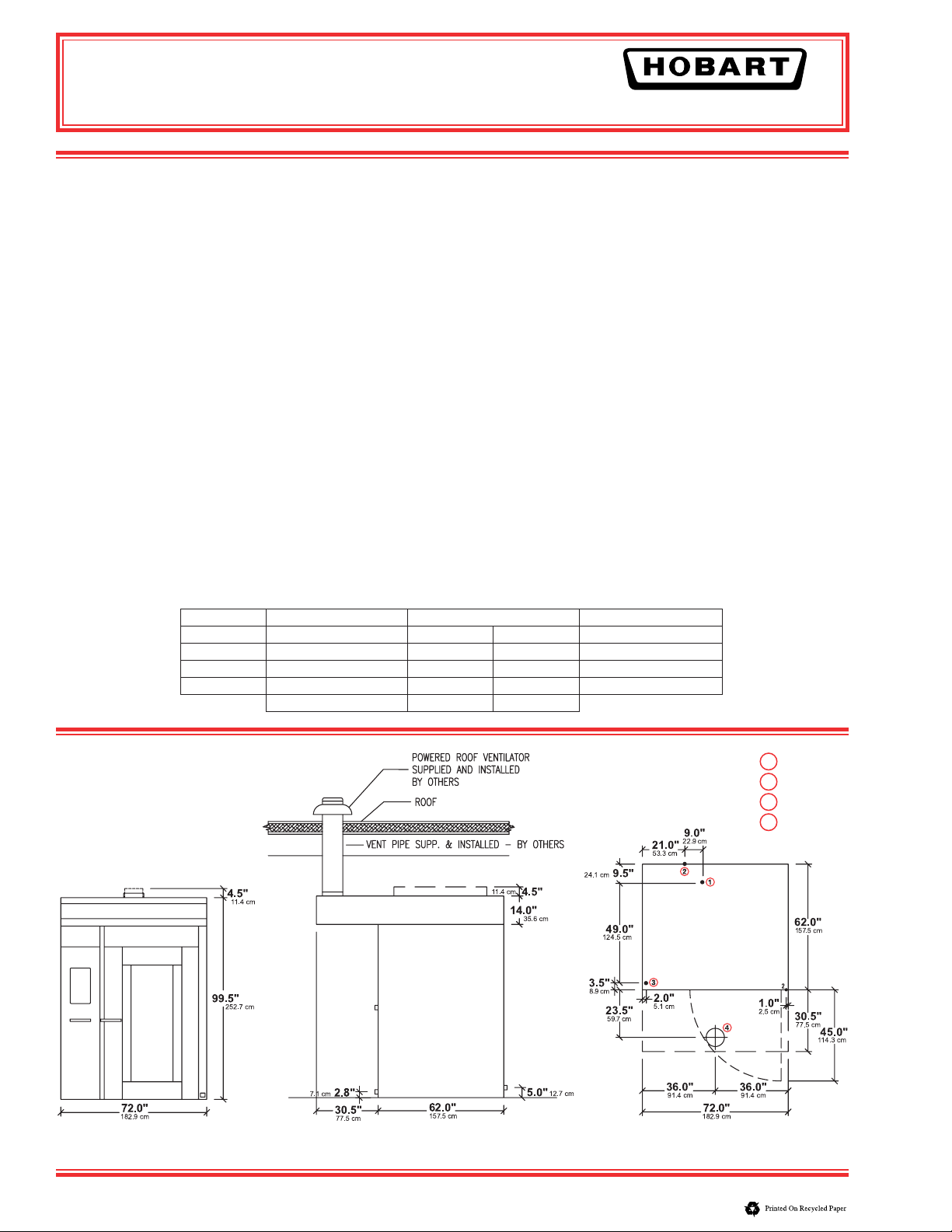

SPECIFICATIONS

1. Water—1⁄2" NPT. Cold water @ 30 psi. minimum @ 3.0 GPM

ow rate. Water supply must have the proper hardness, pH

and chloride concentration. Consult your local Hobart service

ofce, water company and/or water conditioner dealer before

installation.

Recommended water hardness range: 2-4 grains per gallon

Recommended pH range: 7.0 to 8.0

Acceptable range for chloride concentration: 0-30 ppm

2. Drain—Choose either rear or front drain and plug the drain

connection that is not in use. Route to air-gap drain.

Rear drain: 3⁄4" FNPT; Kit is provided to extend drain to left or

right side of oven.

Front drain: 3⁄8" FNPT.

3. Electrical—2 supplies required.

1) 120/60/1 15 amps – dedicated circuit required max. 20A

2) 208/60/3 146.4 amps Heating circuit: 51.3 kW

208-240/60/3 111.4-127.2 amps Heating circuit: 38.5-51.3 kW

440-480/60/3 59.2-64 amps Heating circuit: 43-51.3 kW

Blower Motor 11⁄2 H.P.

4. Hood Vent—10" diameter connection collar. Minimum 900 cfm

(25.5 m3/min) required with 0.6" w.c. (150 Pa) static pressure

drop through hood. Customer to supply duct and ventilator fan

per local code. Oven provided relay with max. 10.0 amp 1⁄2 H.P.

@ 120V output for fan operation.

SECTION W x L x H (CRATED) PALLET WT. (lbs.) / CU. FT. W x D x H (ACTUAL)

Heating 71" x 111" x 47" 1,815 214.4 36" x 62" x 104"

Bake 71" x 111" x 47" 1,670 214.4 36" x 62" x 100"

Hood 23" x 98" x 40" 270 52.2 18" x 72" x 31"

Door 11" x 78" x 50" 280 24.9 44.5" x 5" x 74"

Shipping Total 4,035 505.9

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

NOTES

1. The purchaser is responsible for all installation costs and for

providing: Disposal of packing materials; labor to unload oven

upon arrival; installation mechanics; and all local service

connections including electricity, vents, gas water and drain per

local code. A factory technician or factory authorized installation

technician must supervise and approve any installation. In order

to validate the warranty, the start-up must be performed by an

Authorized Servicer.

2. All services must comply with federal, state and local codes.

3. CAUTION – To reduce the risk of re, the appliance is to be

mounted on oors of non-combustible construction with noncombustible ooring and surface nish and with no combustible

material against the underside thereof, or on non-combustible

slabs or arches having no combustible material against the

underside. IMPORTANT: Do not route utilities (wiring, plumbing,

etc.) in or under the non-combustible oor beneath the oven.

4. For proper installation, oor should be level with 1⁄8" per foot not

to exceed 3⁄4". Floor anchors require minimum of 1" thick solid

oor substrate.

5. Minimum clearances to combustible construction: 0 inches

from sides and back; 18" from top (99.5"). 10 feet minimum

ceiling height for service access and tilt up for installation.

6. Ventilator fan is recommended. Consult local authorities to

determine whether TYPE 1 (grease) or TYPE 2 (vapor) duct will

be required.

7. Actual weight: 3,360 lbs.;

Shipping weight: 4,035 lbs. (freight class 70)

DETAILS AND DIMENSIONS

Highest Point on Oven—104.0" (264.2 cm)

Front View Side View Top View

As continued product improvement is a policy of Hobart, specications are subject to change without notice.

1 Water

2 Drain

3 Electrical

4 Hood Vent

Page 2 of 2 F-40016 – HBA2E Double Rack Oven – Electric

F-40016 (REV. 10/09) LITHO IN U.S.A. (H-01)

Loading...

Loading...