Page 1

Item # ________________________________

Quantity_______________________________

C.S.I. Section 11400

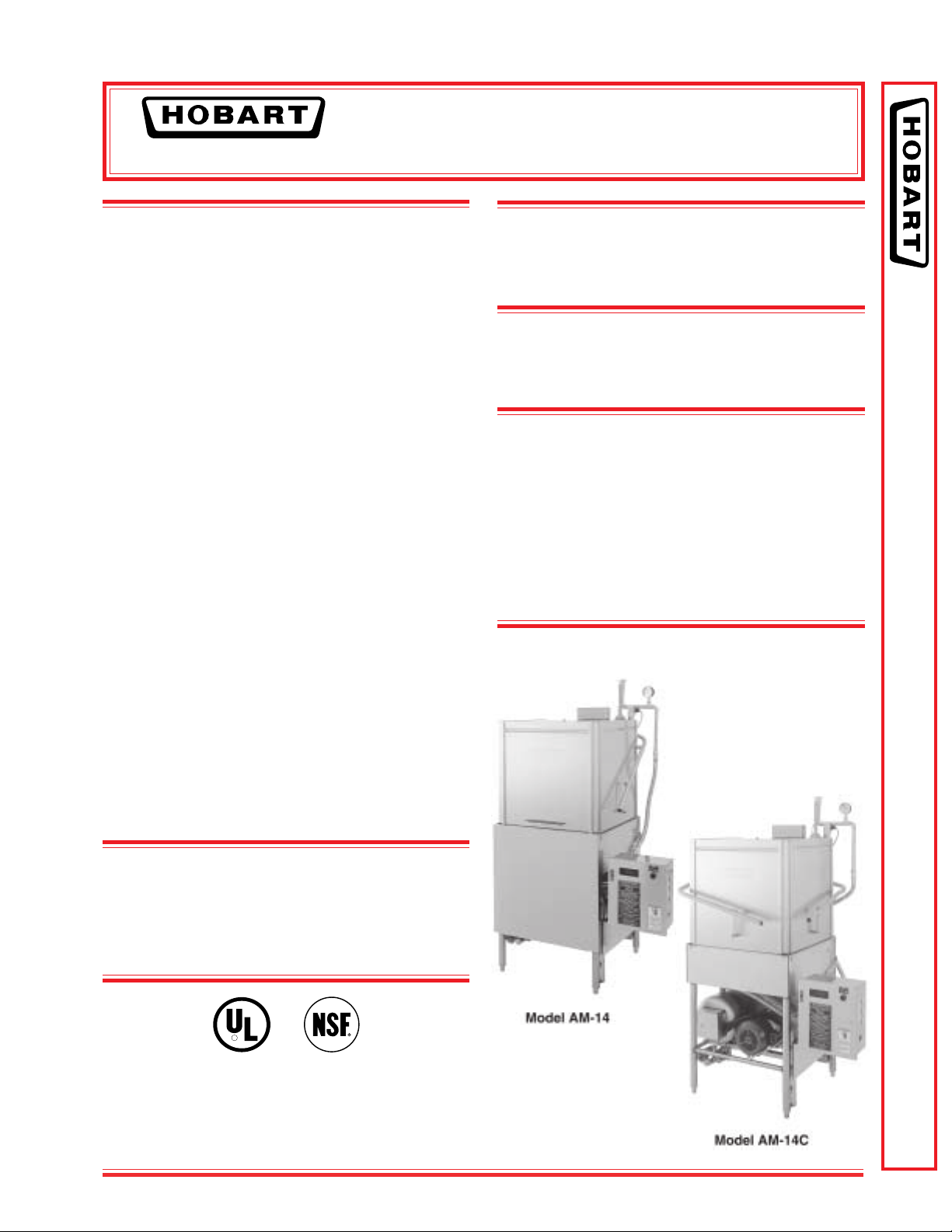

AM-14/AM-14C

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STANDARD FEATURES

■ 53 racks per hour – hot water sanitizing

■ 16 gauge stainless steel tank, chamber, doors,

frame and feet

■ Stainless steel front panel (AM14)

■ Microcomputer controls with LED

cycle/temperature display

■ Manual by-pass controls

■ Field adjustable control box height

■ Left hand or right hand controls (AM14)

■ 90° controls (AM14C)

■ Revolving upper and lower anti-clogging wash

arms

■ Revolving upper and lower anti-clogging rinse

arms

■ Scrap screen and bucket system

DISHWASHERS

MODELS

❑ AM-14

❑ AM-14C

OPTIONS AT EXTRA COST

❑ 70° rise electric booster heater

❑ Flanged feet

ACCESSORIES

❑ Vent fan control field installed kit (electric heat)

❑3⁄4" pressure regulator valve

❑ Peg rack

❑ Combination racks

❑ Stainless steel tray rack

Specifications, Details and Dimensions on Inside and Back.

■ Self-draining, high efficiency pump with

Ni-resistant impeller

■ Automatic fill

■ Door actuated drain closure

■ Spring counterbalanced doors with nylon door

guides

■ Vent fan control (gas units only)

■ Pass-through or corner installation

■ Hot water or chemical sanitation

VOLTAGE

❑ 208-240/60/1

❑ 208-240/60/3

❑ 480/60/3

R

AM-14/AM-14C DISHWASHERS

Model AM-14C

F-8091 – AM-14/AM-14C Dishwashers Page 1 of 12

Page 2

AM-14/AM-14C

DISHWASHERS

STANDARD DESIGN FEATURES

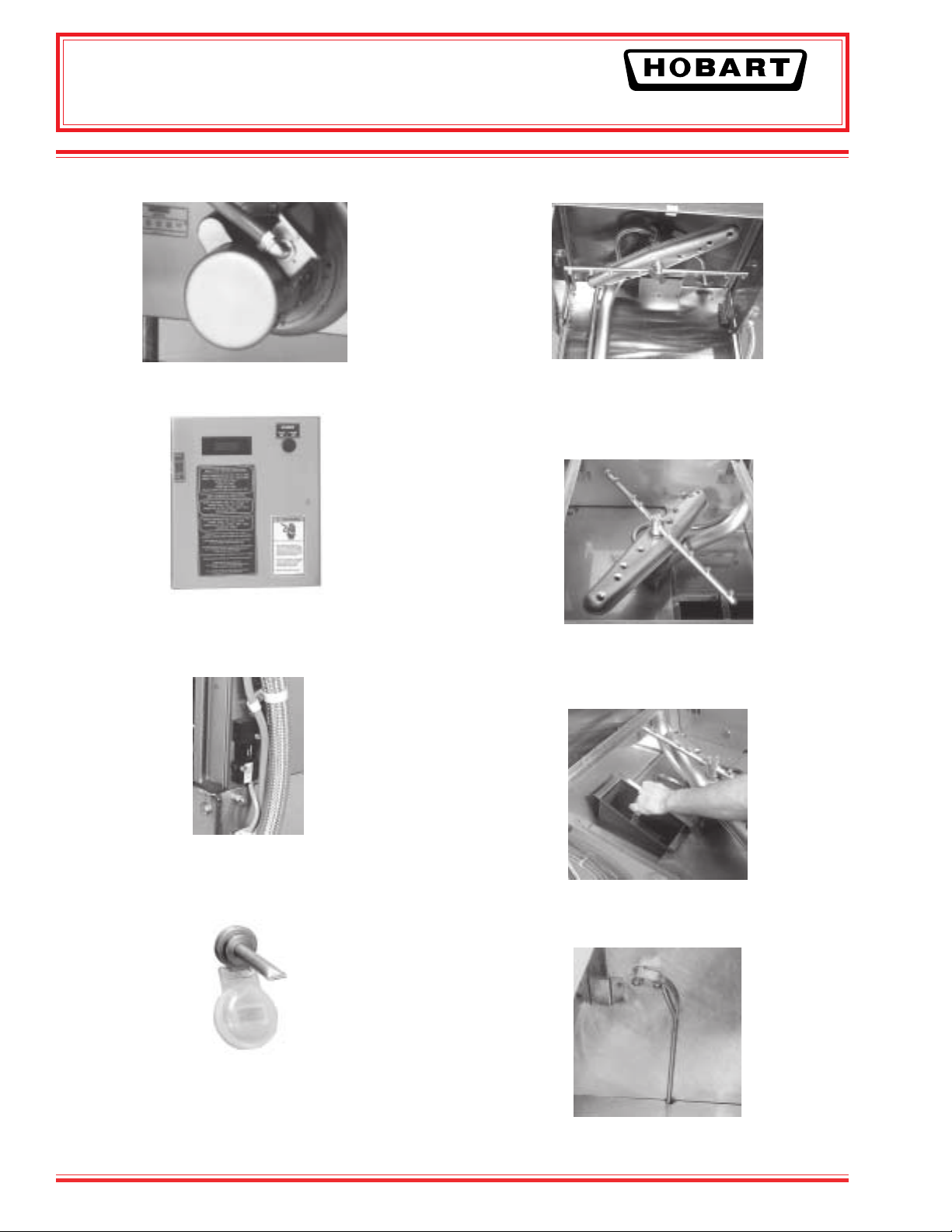

PUMP: High efficiency self-draining pump assures

maximum cleanliness and sanitation.

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

UPPER WASH & RINSE ASSEMBLY: Wash arm – all

stainless steel (Hobart exclusive design) provides

improved washability. Interchangeable with lower wash

arm. Revolving upper rinse arm assures efficient, effective

rinse coverage.

CONTROL BOX: Mounted on right or left side (AM14) or

90° (AM14C) of machine, below table level, to provide

easy access to the microcomputer controls. Field

adjustable in height from table

DOOR CYCLE SWITCH: Automatically starts the washrinse timer program when doors are closed. Door cycle

switch turns off power to pump if doors are opened while

machine is operating and resets timer program to start

position.

11

⁄16" to 1011⁄16".

LOWER WASH AND RINSE ARMS: Wash arm — all

stainless steel, interchangeable with upper wash arm.

Lower revolving rinse arm assures effective rinse

coverage.

REMOVABLE SCRAP BASKET: Stainless steel,

self-flushing strainer pan and removable scrap basket for

easy cleaning.

AUTOMATIC TEMPERATURE CONTROL AND

POSITIVE LOW-LEVEL WATER PROTECTION: The

stainless steel probe contains a thermistor sensor for

water temperature control and a reed switch works in

conjunction with the float (below the probe) for positive

low-level water protection.

AUTOMATIC DRAIN SHUT-OFF: Door actuated,

automatically closes drain when doors are lowered.

Page 2 of 12 F-8091 – AM-14/AM-14C Dishwashers

Page 3

AM-14/AM-14C

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

DISHWASHERS

MICROCOMPUTER CONTROLS FOR RELIABILITY AND PERFORMANCE

The new microcomputer control provides LED digital display of cycle (Fill, Wash, Rinse) and temperature. Built-in, self

diagnostics makes service fast and easy, if it should ever be needed.

The AM-14 is field convertible to either hot water or low temperature chemical sanitizing and features “flexible timing for

special applications”. Capacity varies from 52 racks per hour to 80 racks per hour depending on operating mode.

Unit has equal capacity to some two-rack fill and dump dishwashers, but requires only half the space and consumes

less water.

STANDARD EQUIPMENT

1 H.P. Magnetically Controlled Motor 208-240/60/1, 208-240/60/3 and 480/60/3 * 200-240/50/3, 380-415/50/3

all with solid state motor protection all with solid state motor protection

Choice of Heat Electric with automatic temperature Gas immersion tube style with energy-saving

control solid state ignition, temperature control and

Control System Microcomputer control system 13KW, 70° rise electric hot water

Door cycle switchs booster heater

Solid state water temperature sensor Left or right hand mounted control panel

Positive low water protection

Stainless steel water-protected control box

and switching

Magnetic power switch

LED display on control box for monitoring

wash and final rinse temperatures

Manual override switches for wash and rinse

Construction 16 gauge welded stainless steel

tank, legs and frame unit

16 gauge welded stainless steel

upper chamber

Model AM-14 - 3 door, straight thru

with inspection door and stainless

steel “snap-in” front enclosure panel

Model AM-14C - 2 door for corner installations

Racks Peg compartment,

OPTIONAL ACCESSORY GROUPS

(at extra cost)

stainless steel flue

Plate racks, glass and

silverware racks

(*These electrical specs not submitted for UL Listing)

F-8091 – AM-14/AM-14C Dishwashers Page 3 of 12

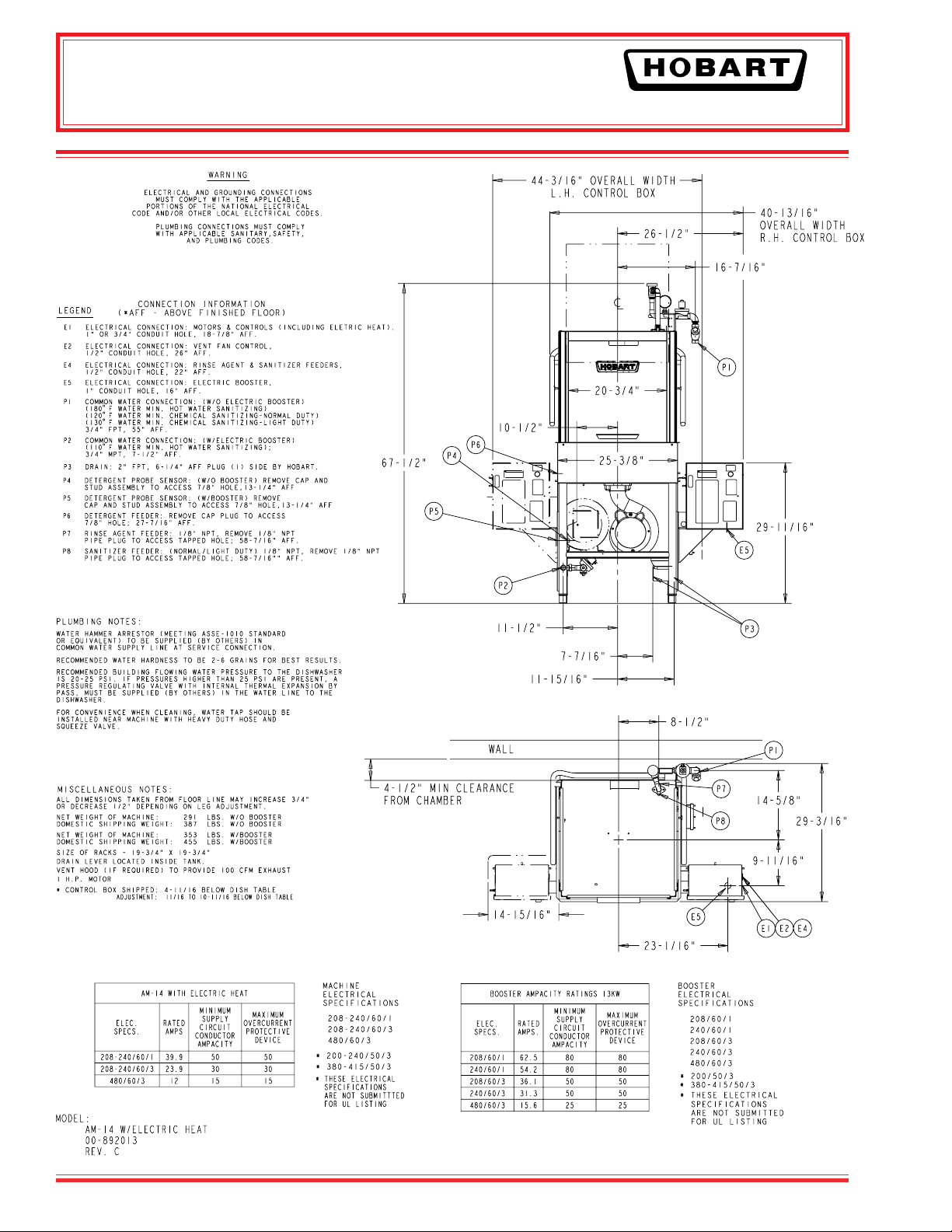

Page 4

AM-14

ELECTRIC

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 4 of 12 F-8091 – AM-14/AM-14C Dishwashers

Page 5

AM-14

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

ELECTRIC

F-8091 – AM-14/AM-14C Dishwashers Page 5 of 12

Page 6

AM-14

GAS

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 6 of 12 F-8091 – AM-14/AM-14C Dishwashers

Page 7

AM-14

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

GAS

F-8091 – AM-14/AM-14C Dishwashers Page 7 of 12

Page 8

AM-14C

ELECTRIC

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 8 of 12 F-8091 – AM-14/AM-14C Dishwashers

Page 9

AM-14C

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

ELECTRIC

F-8091 – AM-14/AM-14C Dishwashers Page 9 of 12

Page 10

AM-14C

GAS

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 10 of 12 F-8091 – AM-14/AM-14C Dishwashers

Page 11

AM-14C

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

GAS

F-8091 – AM-14/AM-14C Dishwashers Page 11 of 12

Page 12

AM-14/AM-14C

DISHWASHERS

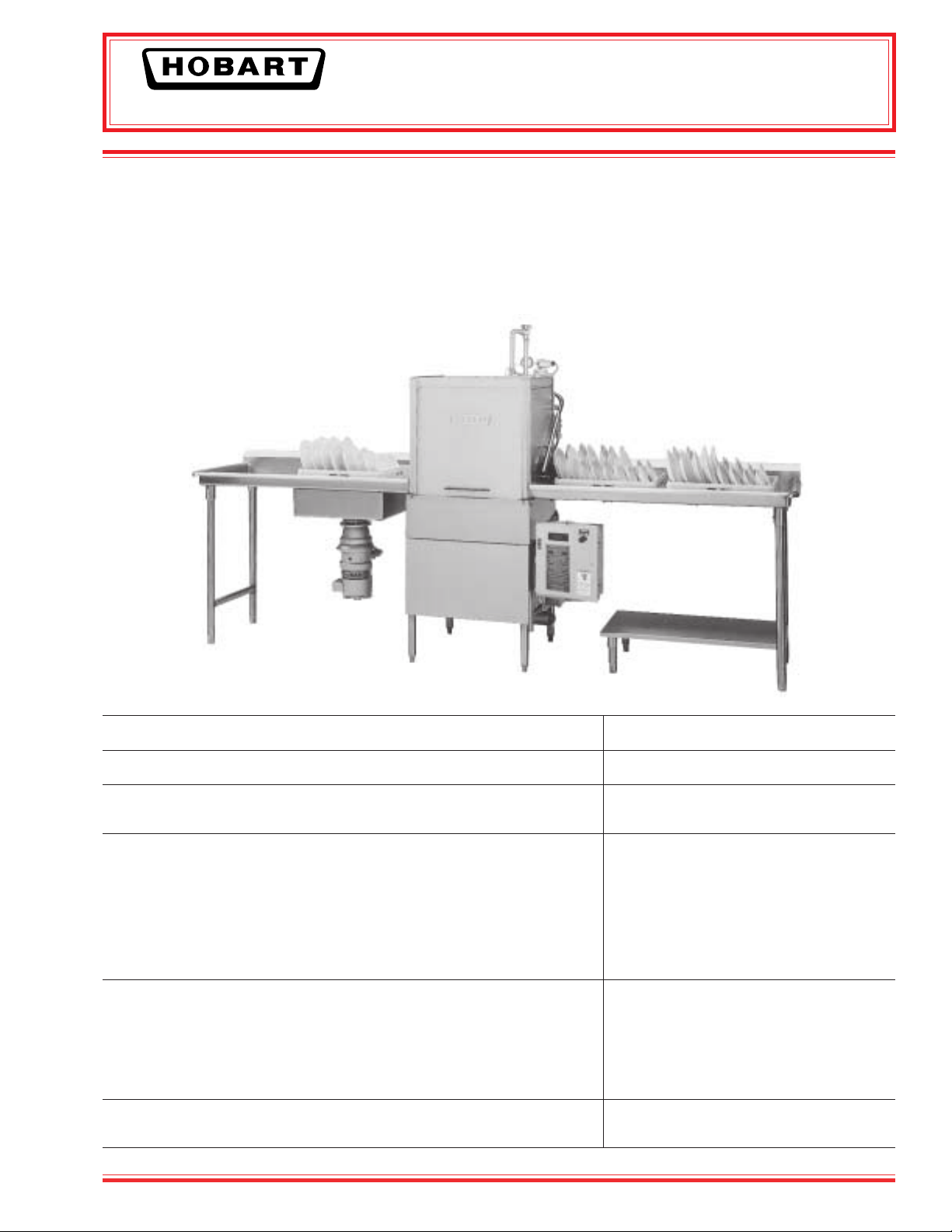

The microcomputer-based control system is built into the AM-14

Series Dishwashers. Model AM-14 is for straight-thru operation with

a third (front) door for inspection, and AM-14C for corner installation.

Each is available in standard electrical specifications of 208-240/60/1,

208-240/60/3, 480/60/3 and all are equipped with a reduced voltage

pilot circuit transformer.

*CAUTION: CERTAIN MATERIALS, INCLUDING SILVER,

ALUMINUM AND PEWTER ARE ATTACKED BY SODIUM

HYPOCHLORITE (LIQUID BLEACH) IN THE CHEMICAL

SANITIZING DISHWASHER MODE OF OPERATION. WATER

HARDNESS MUST BE CONTROLLED TO 2-6 GR. FOR BEST

RESULTS.

CONSTRUCTION: Tank and wash chamber constructed of

#16 gauge stainless steel, arc-welded. Unitized welded stainless

steel tank, frame and stainless steel feet. Wash chamber and front

of tank above motor compartment are polished satin finish. Stainless

steel snap-in front panel – no fasteners required.

DOOR LIFT: Doors coupled by stainless steel door handle, spring

counterbalanced (except the front inspection door). All doors guided

for ease of operation and long life.

PUMP: With Ni-Resist impeller, integral with motor assures alignment

and quiet operation. Pump shaft seal with stainless steel parts and a

carbon ceramic sealing interface. Easily removable impeller housing

permits ease of inspection. Capacity 160 GPM. Pump is completely

self-draining.

MOTOR: Built for Hobart, 1 H.P., with inherent thermal protection,

grease-packed ball bearings, splashproof design, ventilated.

Single-phase is capacitor-start, induction-run type. Three-phase is

squirrel-cage, induction type.

MICROCOMPUTER CONTROL SYSTEM: Hobart microcomputer

controls, assembled within water-protected enclosure, provide built-in

performance and reliability.

The microcomputer control, switches and contactors are housed in a

single stainless steel enclosure, mounted on right-hand or left-hand

side (AM14) or 90° (AM14C) of dishwasher below table level. Control

enclosure is field adjustable to an alternate lower position of 1011⁄16"

from table. The line voltage electrical components are completely

wired with 105°C, 600V thermoplastic insulated wire with stranded

conductors and routed through listed electrical conduit. Low-voltage

electrical components are wired with type ST cord. Line disconnect

switch NOT furnished.

CYCLE OPERATION: The microcomputer timing program is started

by closing the doors, which actuates the door cycle switch. The

microcomputer energizes the wash pump motor contactor during the

wash portion of the program. After the wash, a dwell permits the

upper wash manifold to drain. At the end of the dwell, the final rinse

solenoid valve is energized, after the final rinse valve closes,

Sani-Dwell (Hot Water Mode only) permits sanitization to continue.

The Rinse LED remains on during this period, completing the

program. If the microcomputer is interrupted during a cycle by the

door-cycle switch, the microcomputer is reset to the beginning of the

program. Hot Water Sanitizing – 62 seconds (AM14: 53 Racks/hr.;

AM14C: 52 Racks/hr.): 40 Second Wash, 4 Second Dwell, 9 Second

Rinse, 9 Second Sani-Dwell. Chemical Sanitizing (Normal Duty) –

53 Seconds (AM14: 62 Racks/hr.; AM14C: 60 Racks/hr.):

40 Second Wash, 4 Second Dwell, 9 Second Rinse. Chemical

Sanitizing (Light Duty) – 40 Seconds (AM14: 80 Racks/hr.;

AM14C: 76 Racks/hr.): 27 Second Wash, 4 Second Dwell, 9 Second

Rinse (130°F Minimum). All of the above programs and many more

can be pre-selected by your Hobart service technician.

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

WASH: Hobart revolving stainless steel wash arms with unrestricted

openings above and below provide thorough distribution of water jets

to all dishware surfaces. Arms are easily removable for cleaning and

are interchangeable. Stainless steel tubing manifold connects upper

and lower spray system.

RINSE: Upper revolving rinse arm with eight rinse spray nozzles.

The stainless steel upper and lower rinse arms are easily removable

without tools. Lower revolving rinse arm with eight nozzles lifts out for

inspection. Diaphragm-type rinse control solenoid valve mounted

outside machine. Machine is equipped with special hot water vacuum

breaker on downstream side of rinse valve – mounted 6" above

uppermost rinse opening. Easy open brass line strainer furnished.

FILL: Microcomputer controlled fill valve installed on upstream side

of rinse vacuum breaker. Ratio fill method is used giving the correct

fill at any flowing water pressure. (20 PSIG necessary for proper

rinsing.)

DRAIN AND OVERFLOW: Large bell type automatic overflow and

drain valve controlled from inside of machine. Drain automatically

closed by lowering doors. Drain seal is large diameter, high

temperature “O” ring. Cover for overflow is integral part of stainless

steel strainer system.

STRAINER SYSTEM: Equipped with large, exclusive self-flushing,

easily removable perforated stainless steel strainer and large

capacity soil basket. Submerged soil basket minimizes frequent

removal and cleaning.

HEATING EQUIPMENT: Standard tank heat is 5KW electric

immersion heating element. Regulated power immersion tube gas

burner system is optional at extra cost. A solid-state ignitor board

controls the gas valve and provides flame ignition. A transformer

steps the control circuit voltage down to 24 volts to power the ignitor

board and gas valves. Gas Heated Dishwasher: For natural gas, gas

pressure (customer connection) not to exceed 7" W.C. For liquified

petroleum, gas pressure to burner (customer connection) not to

exceed 11" W.C. If gas pressure is higher than 7" W.C. natural or

11" W.C. LP, a pressure regulating valve must be supplied (by

others) in the gas line to the dishwasher. Water temperature

regulation is controlled by thermistor sensor in combination with

microcomputer controls. The tank heat and positive low water

protection microcomputer circuits are automatically activated when

the main power switch is turned “on”. If tank is accidentally drained,

low water protection device automatically turns heat off. Gas

immersion tube is additionally protected by a high limit device

mounted on the surface of the tube. These features are standard with

the Hobart Microcomputer Control System.

STANDARD EQUIPMENT: In addition to the standard features listed

on the front are the following–latest design door cycle switch, ratio fill,

stainless steel adjustable feet. Adjustable height control panel.

Chamber, tank and all doors of 16 gauge stainless steel. Detergent

injector and sensing connections provided as well as connection in fill

line for rinse agent and sanitizer dispensing. Manual by-pass switch.

OPTIONAL EQUIPMENT AT EXTRA COST – ELECTRIC

BOOSTER HEATER: Electric booster adequately sized to raise

110°F inlet water to 180°F (not available on gas heat machines).

Pressure gauge for incoming water.

CONTROLS: Optional 90° controls on C models.

ACCESSORIES: 193⁄4" x 193⁄4" Peg and Combination All-Plastic

Dishracks. Desirable functional accessories can be furnished at

added cost. See listed options and accessories on this specification

sheet. Write to the factory for special requirements not listed above.

As continued product improvement is a policy of Hobart, specifications are subject to change without notice.

As continued product improvement is a policy of Hobart, specifications are subject to change without notice.

Page 12 of 12 F-8091 – AM-14/AM-14C Dishwashers

F-8091 (REV. 8/03) LITHO IN U.S.A. (H-01)

Printed On Recycled Paper

Loading...

Loading...