Hobart Food Machines 6614 Installation Manual

MODEL 6614 MEAT SAW

MODEL

6614 ML-134096

PREVIOUS MODELS COVERED BY THIS MANUAL:

6614 ML-134050

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 34527 Rev. B (August 2011)

Installation, Operation, and Care of

MODEL 6614 MEAT SAW

SAVE THESE INSTRUCTIONS

GENERAL

The 6614 Meat Saw is rugged, durable, and easy to clean. The saw is equipped with a water resistant

3 HP electric motor and direct gear drive transmission that provides a blade speed of 3500 feet per minute.

The carriage (Fig. 1) has stainless steel ball bearings providing easy travel and dependability. The shaped

front edge of the carriage is comfortable to the operator's body even when leaned on during movement.

The carriage lock is standard. The upper pulley cover and bafe are stainless steel.

Table, carriage, pulleys, guides, and wiper assemblies can be quickly removed without tools for ease of

cleaning. Moving parts are enclosed but accessible. The blade is guarded above and below the cutting

zone. The pusher plate is provided to eliminate the need of handling items close to the blade; it can ride

on the right "anged-end" of the carriage so you keep your hands away from the cutting edge of the blade.

For electrical specications above 250 volts, a transformer provides a 115 volt control circuit voltage.

One long-life blade is furnished with each saw as standard equipment. This blade cannot be re-sharpened;

replacement blades are available through your local Hobart Service Ofce.

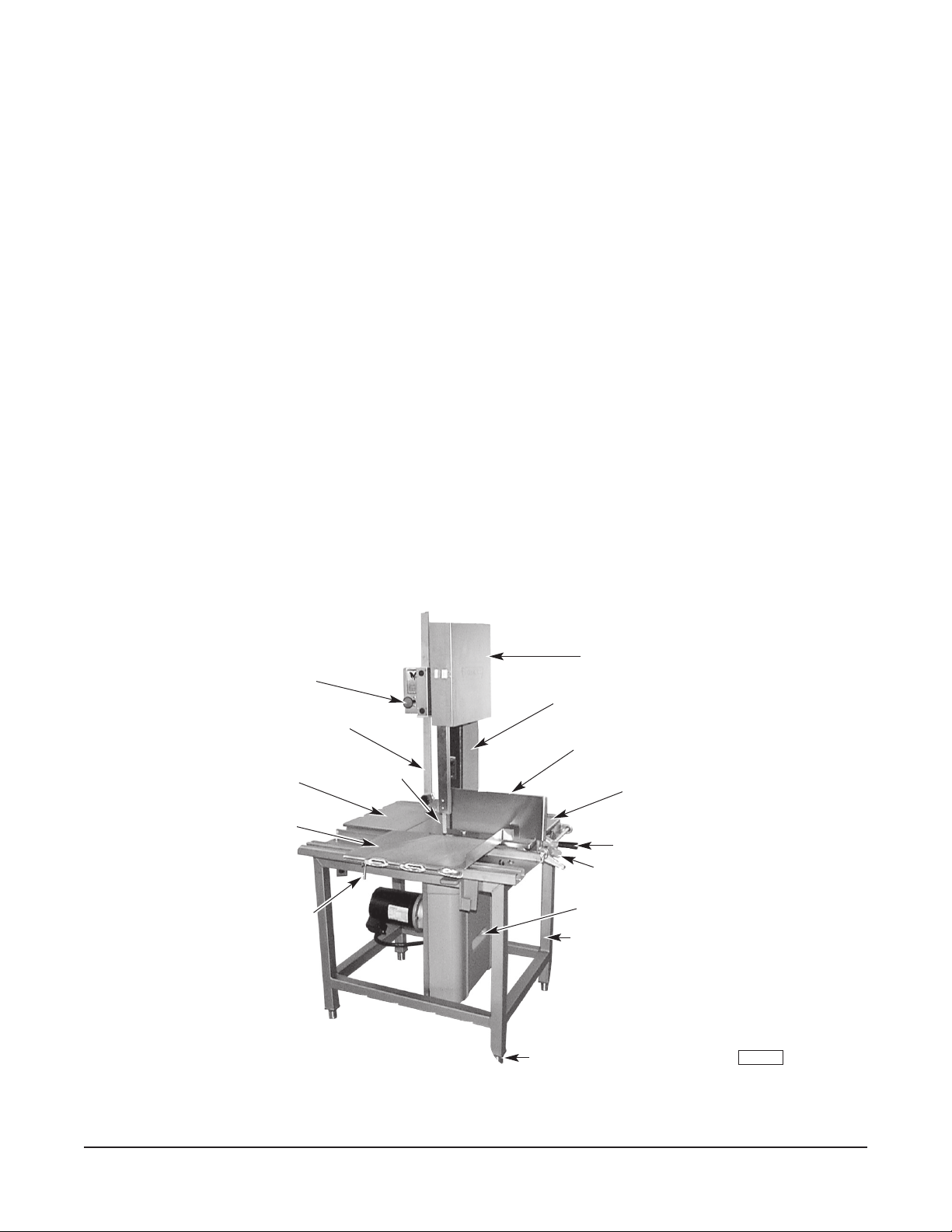

SWITCH KNOB

UPPER GUIDE AND GUARD

TABLE (LEFT)

CARRIAGE

CARRIAGE LOCK

SAW BLADE

Fig. 1

UPPER PULLEYCOVER

COLUMN GUARD

GAUGE PLATE

LOWER COVER (SCRAP PA N)

LEGS

FEET

TABLE (RIGHT)

GAUGE PLATE HANDLE

LOCK LEVER

PL-41501-1

© HOBART, 1995, 2000

– 2 –

INSTALLATION

PL-52107

Hand Knob

Upper Guide

and Guard

UNPACKING AND ASSEMBLY

Immediately after unpacking the meat saw, check for possible shipping damage. If the meat saw is found

to be damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, test the electrical service to make sure it agrees with the specications on the machine

data plate located on the column.

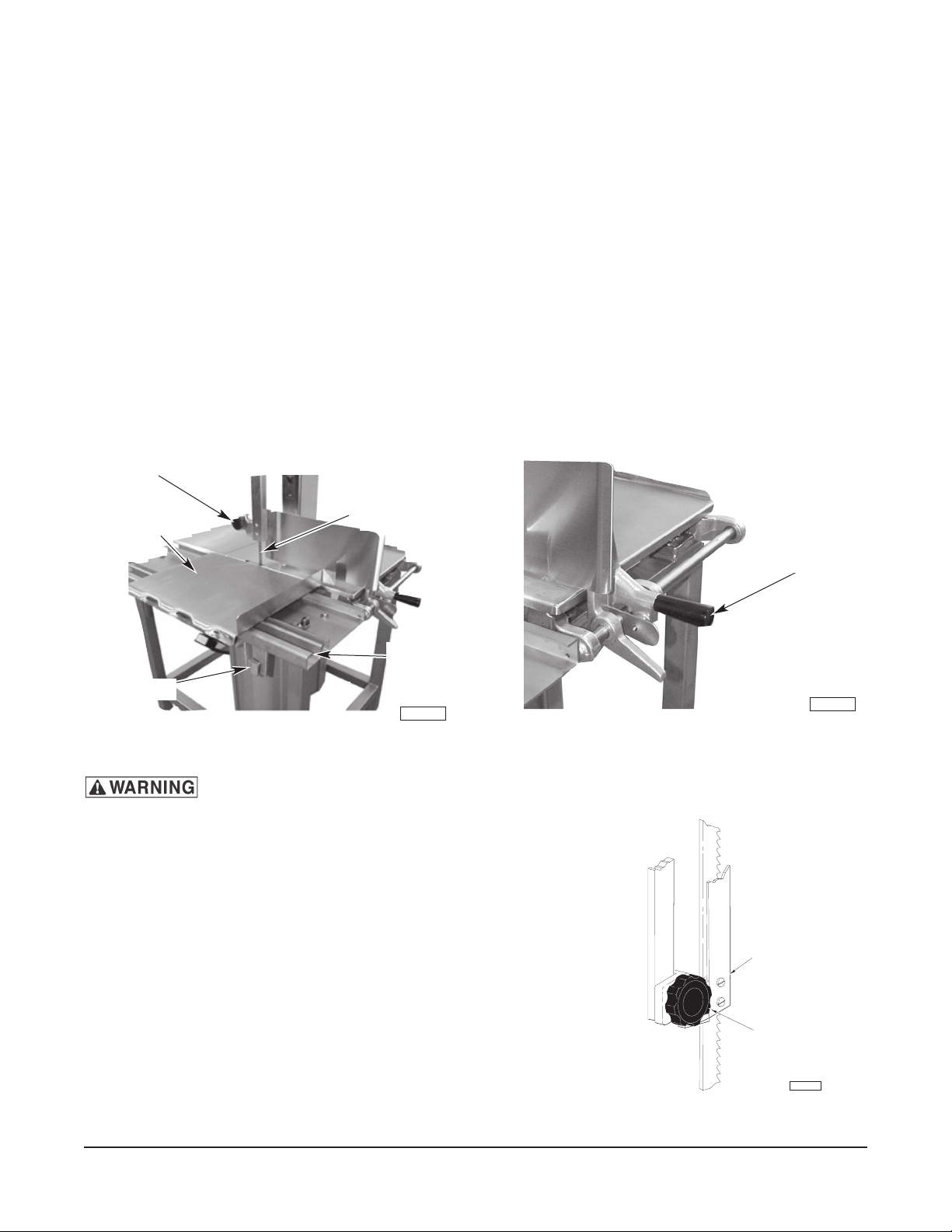

Packed in a packet attached to the table compartment are the pusher plate and the gauge plate handle.

Place the pusher plate in its storage location under the carriage support (Fig. 2). Assemble the gauge

plate handle to the gauge plate support by screwing the stud into the threaded hole (Fig. 3).

LEVELING

Place the saw in its operating location. Using a spirit level, level the meat saw front-to-back and side-toside by turning the threaded feet in or out.

HAND KNOB

SAW BLADE

CARRIAGE

CARRIAGE

SUPPORT

PUSHER PLATE

PL-41502-1

Fig. 2 Fig. 3

Disconnect the electrical power to the machine and follow lockout / tagout

procedures.

SAW BLADE

The saw blade must be installed so the teeth point to the right

and down (Fig. 4).

UPPER GUIDE AND GUARD ASSEMBLY

When the saw is off, the hand knob (Fig. 4) can be used to raise

or lower the upper guide and guard assembly so the cutting

zone is only as high as necessary for the piece being cut. The

hand knob is not loosened during raising or lowering — it should

remain tightly secure.

GAUGE PLATE HANDLE

PL-41503-1

Fig. 4

– 3 –

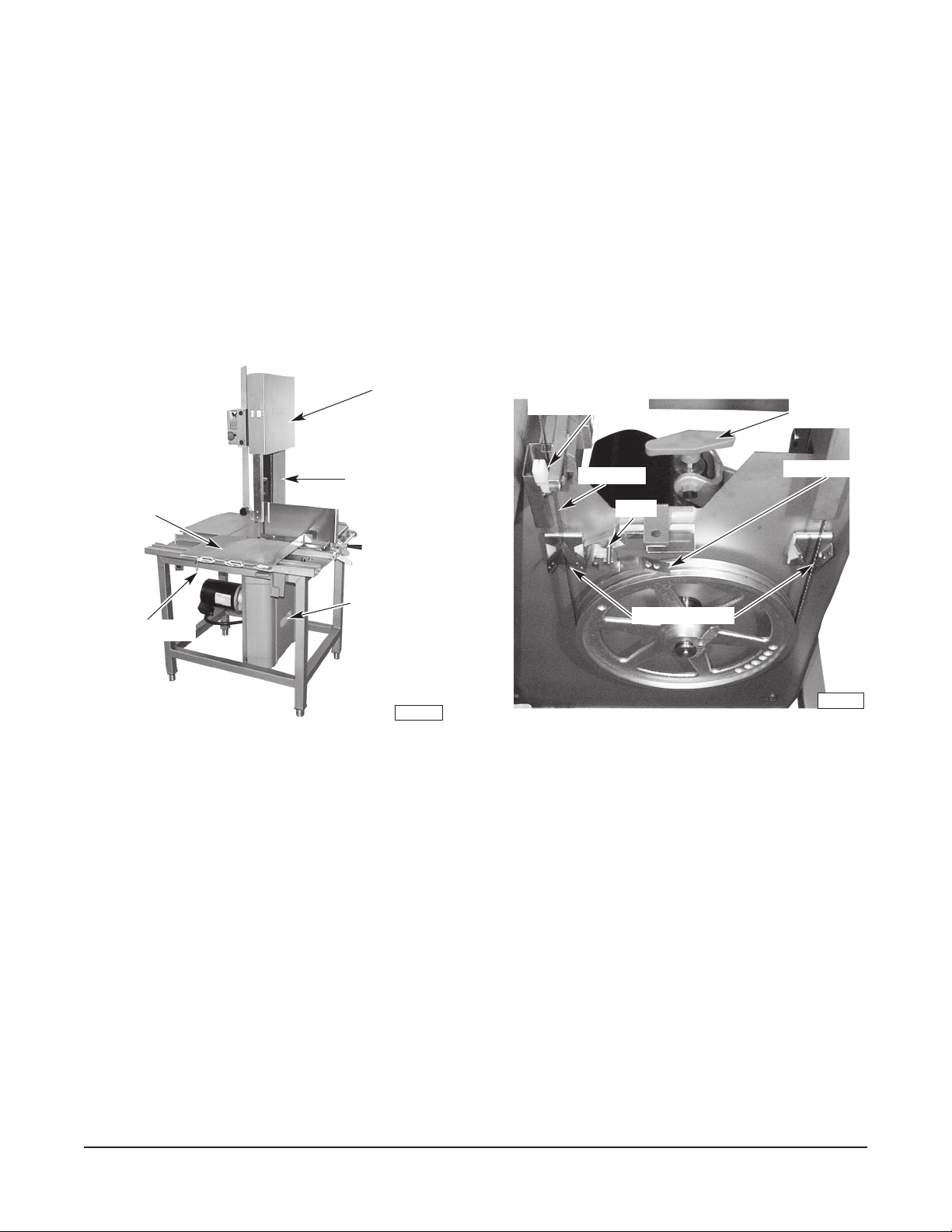

UPPER PULLEY COVER (STAINLESS STEEL)

The stainless steel upper pulley cover (Fig. 5) should be installed on the two hinge pins of the stainless

steel upper pulley bafe and securely latched during saw use. To remove the stainless steel upper pulley

cover for cleaning, unlatch and open the stainless steel upper pulley cover; then, lift straight up off the

hinge pins.

LOWER COVER (SCRAP PAN)

During use, the lower cover (Fig. 5) acts as a scrap pan, accumulating bone dust and debris from the

blade scrapers and pulley wiper that are located on the lower panel (Fig. 6). To remove the lower cover

(scrap pan) for cleaning, release the clip at the top; pull out and lift the lower cover from the groove at the

bottom of the lower panel.

UPPER PULLEYCOVER

LOWER BLADE GUIDE

TENSION

ADJUSTER

PULLEY WIPER

PL-41505-1

CARRIAGE

CARRIAGE LOCK

COLUMN GUARD

LOWER COVER

(SCRAP PAN)

PL--41504-1

Fig. 5 Fig. 6

SAW BLADE

BLOCK

BLADE SCRAPERS

BLADE SCRAPERS

Two blade scrapers wipe the blade during sawing to accumulate bone dust and debris inside the lower

cover (scrap pan). The front scraper points up and the rear scraper points down (Fig. 6). After the blade

is removed, the scrapers can slide off their mounting blocks for cleaning.

PULLEY WIPER

The pulley wiper (Fig. 6) scrapes bone dust or debris from the lower pulley during use. The pulley wiper

can be removed for cleaning by springing the wiper up and sliding it off the pins.

– 4 –

Loading...

Loading...