Operating manual for micro annular gear pumps

mzr-2961, mzr-4661

HNP Mikrosysteme GmbH

Bleicherufer 25

D-19053 Schwerin (Germany)

Telephone: +49 385/52190-301

Telefax: +49 385/52190-333

E-mail: info@hnp-mikrosysteme.de

http://www.hnp-mikrosysteme.de

Last update: April 2018

Impressum

Original instructions

Copyright

HNP Mikrosysteme GmbH

Bleicherufer 25

D-19053 Schwerin

All rights, including translation, reserved.

Without prior explicit written permission of HNP Mikrosysteme GmbH no part

of this manual may be, copied, reproduced or processed.

This manual has been prepared with care. HNP Mikrosysteme does assume no

liability for any errors in this manual and resulting consequences. Likewise, no

liability is assumed direct or subsequent damages arising from an incorrect use

of the devices.

While using micro annular gear pumps, the relevant standards regarding the

specifications of this manual have to be followed.

Subject to change without notice.

Contents Operating manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! i

Contents

1 General Information 1

1.1 Application scope of the pumps 1

1.2 Product information 2

1.3 Measurements 2

1.4 Flow chart 3

1.5 Technical data of the micro annular gear pumps 4

1.6 Technical data of the drive 5

2 Safety instructions 7

2.1 Safety symbols in this operating manual 7

2.2 Staff qualification and training 7

2.3 Safety-conscious work 7

2.4 Safety instructions for the operator 8

2.5 Safety instructions for maintenance, check and

assembly of the pump 8

2.6 Unauthorized pump conversions and spare part

manufacture 8

2.7 Improper modes of operation 9

2.8 General safety instructions 9

3 Transport and intermediate storage 10

3.1 Shipment of the pumps and protection measures 10

3.2 Transport 10

3.3 Intermediate storage 10

4 Description of the pump 11

4.1 Principle of the Micro annular gear pumps 11

4.2 Micro annular gear pump 13

4.3 Materials and liquids 14

4.4 Liquid supply 14

5 Optional modules 16

5.1 By-pass module (optional) 17

6 System integration 19

6.1 Checkup before the first assembly 19

6.2 Mounting of the micro annular gear pump 19

6.3 General instructions for the assembly of the liquid

supply network 20

6.4 Filter selection and use 21

6.5 Operation with terminal box S-G61 22

7 Start Up / Shut Down 26

7.1 Preparing for operation 26

7.2 Startup of the micro annular gear pump 26

7.3 Flushing procedure after use 26

Contents Operating manual mzr-2961, mzr-4661

ii Technical data subject to change without prior notice! Last update: April 2018

7.4 Shutdown of the micro annular gear pump 29

7.4.1 Conservation 31

7.4.2 Dismantling of the system 32

7.5 Trouble shooting 33

7.6 Return of the micro annular gear pump to the

manufacturer 33

8 Accessories for microfluidic systems 34

9 Non-liability clause 34

10 Problems and their removal 35

11 EC Directive 38

11.1 Electromagnetic Compatibility (EMC) 39

11.1.1 EMC Directive and Standards 39

11.1.2 Information on use as intended 40

12 Declarations of conformity 42

13 Service, maintenance and warranty 47

14 Contact person 48

15 Legal information 49

16 Safety information for the return of already

employed micro annular gear pumps and

components 50

16.1 General information 50

16.2 Declaration of media in contact with the micro

annular gear pump 50

16.3 Shipment 50

17 Declaration of media in contact with the micro

annular gear pump and its components 51

18 Appendix 52

1 General Information Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 1

1 General Information

This operation manual contains basic instructions to be followed during

integration, operation and maintenance of the mzr

®

micro annular gear pump.

For this reason it is necessary to read it carefully before any handling of the

device. The present manual should always be kept at the operation site of the

micro annular gear pump.

In case assistance is needed, please indicate the pump type visible on the

housing.

1.1 Application scope of the pumps

The micro annular gear pumps mzr-2961 and mzr-4661 described in this

manual are suitable for continuous delivery of water, watery solutions, solvents,

methanol and varnishes as well as many other liquids.

!

If you intend to handle any aggressive, poisonous or radioactive liquids, you

must conform to safety measures as according to the regulations in force. Any

project concerning handling of corrosive liquids should be previously discussed

with the pump manufacturer.

!

The micro annular gear pumps should not be used for "invasive" medical

applications, in which the liquid having had contact with the pump is reintroduced to the body.

!

Micro annular gear pumps exclusively are provided for use in the industrial

area. A private use is excluded.

!

The micro annular gear pumps must not be used in aircrafts and spacecrafts or

other vehicles without prior consent of the manufacturer.

!

The data concerning resistance of the pumps to manipulated liquids is

elaborated according to the best of HNP Mikrosysteme's knowledge. However,

operating parameters varying from one application case to another, no

warranty for this information can be given.

!

The information given in this manual does not release the customer from

personal obligation to check the integrity, correct choice and suitability of the

pump for the intended use. The use of the micro annular gear pumps should

be conform with technical norms and regulations in force.

If you wish to receive more information than comprised in this manual please

contact directly HNP Mikrosysteme.

1 General Information Operation manual mzr-2961, mzr-4661

2 Technical data subject to change without prior notice! Last update: April 2018

1.2 Product information

This manual is valid for the micro annular gear pumps mzr-2961 and mzr-4661

manufactured by HNP Mikrosysteme GmbH, Bleicherufer 25,

D-19053 Schwerin, Germany.

The bottom line of this manual shows issue and date of issue of the manual.

1.3 Measurements

The pumps are available in two version featuring different liquid connectors.

figure 1 shows the version with Ø 2 mm slip fittings on which flexible tubes

with internal diameter < 2 mm are stuck. figure 2 shows the version with a

manifold assembly, which is screwed and to a preadapted support.

±10

15 0

0,9

+

6,9

1,4

61, 6

-

68,5

2

22

Lage der Abflachungen

zu den Fluidanschlüssen

unbestimmt

2

±0,05

4

±0,05

Lage Anschlusskabel

unbestimmt

Flachbandkabel AWG 26

Stecker nach DIN 41651

.

figure 1 Measurement in configuration slip fittings OD 2 mm

unverli erbare

Zyli nderkopfschr aube M3x12 D I N 91 2

mit fi xierendem O-R i ng 2x1 ,3 FK M

2

7

-

-

±0,5

61 ,8

0

15 0

20

-

0

,1

0,2

±1 ±10

0,1

13,4

30

2

28

22

Stecker nac h DIN 41651

unbestimmt

zu den Fluidanschlüssen

unbestimmt

Lage Anschlusskabel

Flachbandkabel AWG 26

Lage der Abfl achungen

O-Ri ng 2x1

26

4

35

4

2

6,5

.

figure 2 Measurement in configuration with manifold assembly M2.1

1 General Information Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 3

1.4 Flow chart

Liquid water Liquid oil

0

5

10

15

20

0 1 2 3

Differential pressure [bar]

Flow rate [ml/min]

6000

5000

4000

3000

2000

1000

Speed [rpm]

Viscosity 1 mPas

Liquid water

0

5

10

15

20

0

1

2

3

Differential pressure [bar]

Flow rate [ml/min]

6000

5000

4000

3000

2000

1000

Speed [rpm]

Viscosity 16 mPas

Liquid oil

figure 3 Flow charts mzr-2961

Liquid water Liquid oil

0

10

20

30

40

50

60

70

80

0 1

2 3 4 5

Differential pressure [bar]

Flow rate [ml/min]

6000

5000

4000

3000

2000

1000

Speed [rpm]

Viscosity 1 mPas

Liquid water

0

10

20

30

40

50

60

70

80

0 1

2 3 4 5

Differential pressure [bar]

Flow rate [ml/min]

6000

5000

4000

3000

2000

1000

Speed [rpm]

Viscosity 16 mPas

Liquid oil

figure 4 Flow charts mzr-4661

1 General Information Operation manual mzr-2961, mzr-4661

4 Technical data subject to change without prior notice! Last update: April 2018

1.5 Technical data of the micro annular gear pumps

mzr-2961 mzr-4661

Technical data

Displacement volume

3 µl

12 µl

Housing length without fluid connections 62 mm

Housing length with fluid connections Ø 2 mm 69 mm

Diameter 22 mm

Weight 100 g

Internal volume 85 µl

Housing material stainless steel 316L (1.4404), epoxy resin adhesive

Fluid connector material

stainless steel 316L (1.4404), Titan Grade 5

Rotor material tungsten carbide (WC-Ni)

Shaft material tungsten carbide (WC-Ni)

Magnet coating material gold

Bearing material ceramics, Al

2O3

Static sealing FKM

optional EPDM, FFKM (Perfluorelastomer)

Performance parameters

Min. flow rate Q (at 400 rpm) 1,2 ml/min* 4,8 ml/min*

Max. flow rate Q (at 6000 rpm) 18 ml/min 72 ml/min

Min. dosage volume 5 µl 10 µl

Max. system pressure 6 bar (87 psi)) (inlet

pressure+differential

pressure)

6 bar (87 psi) (inlet

pressure+differential

pressure)

Differential pressure range

0 – 3 bar (43,5 psi)

0 – 5 bar (72,5 psi)

Viscosity 0.3 – 10 mPas

Liquid temperature -15 … +60 °C

Ambient temperature -15 … +60 °C

Storage temperature

5 … 40 °C

Pulsation of flow (theoretical value) 6 %

NPSHR value 0.5 m

*) Values are specified for oil with viscosity 16 mPas. Differing specifications on request

**) Customized solutions on request.

table 1 Technical data of the micro annular gear pump mzr-4661

Warning

The material properties of a liquid (e.g. viscosity, lubricating property, particle

content, corrosiveness) impacts the technical data and the lifetime of pumps.

Under appropriate conditions the characteristic values may be increased or

decreased.

Warning

If you intend to operate the pump out of the range of the above given

specification, please consult the manufacturer. Modifications may be necessary

to ensure successful operation. Otherwise the pump or the system may be

damaged seriously.

1 General Information Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 5

1.6 Technical data of the drive

The micro annular gear pumps

mzr-2961 and mzr-4661 are provided with a

canned motor with integrate speed controller. The motor uses a high dynamic

of the micro annular gear pump. With the internal control unit it is possible to

manage lower RPM ranges down to 400 RPM. The connection of the motor to

a control unit is simple.

Dimensions

diameter 16 mm

length 43 mm

Data of capacity

Max. voltage 24 V

Max. permanent torque 5 mNm

output power 8,9 W

No-Load speed by 10 V 2500 rpm

max. permanent current 300 mA

Terminal resistor 12,4 Ω

Rotor inductance

0,440 mH

RPM speed range 400 - 6000 rpm

Temperature range -15 ÷ +60 °C

table 2 Technical data of the motor

1

2

6 5

figure 5 Pin configuration of the motor cable

Pin

Description

Value

1 Up 24 V DC (5 - 28)

2 U

mot

24 V DC (6 – 30)

3 GND

4 U

nsoll

0 … 10 V DC;

> 10 V DC - max. U

P

,

Nominal speed value

undefined

5 DIR to earth or

U < 0.5 V = anti-clockwise,

U > 3 V = clockwise

6 FG max. UP, I

max

15 mA)

6 pulses per revolution

table 3 Pin configuration of the motor

!

Electrostatic discharges at the connection pin assignment of the ribbon cable

can result in irreparable damage to the motor.

1 General Information Operation manual mzr-2961, mzr-4661

6 Technical data subject to change without prior notice! Last update: April 2018

While connecting the DC voltage pay attention to the correct polarity,

otherwise electronics may be damaged.

2 Safety instructions Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 7

2 Safety instructions

Please comply not only with the general safety instructions listed below, but

also with specific safety instructions mentioned in the following chapters.

2.1 Safety symbols in this operating manual

Non respect of the safety instructions marked with the following signs

represents danger to people:

Danger symbol High voltage symbol

!

Safety symbol according to

DIN 4844 – W9

Safety symbol according to

DIN 4844 – W8

Non compliance with the safety instructions marked with the following sign

represents a risk of damage to the micro annular gear pump:

Warning

Operating instructions machined directly on the pump such as the indication of

liquid input and output should be followed and kept in a clearly readable

condition.

2.2 Staff qualification and training

The staff operating, servicing, inspecting and assembling the pumps must

evidence the appropriate qualification for these works. Areas of responsibility

and competence as well as monitoring of the staff must be precisely regulated

by the operator in charge. If the personnel do not have the necessary

knowledge, they must be trained and instructed accordingly. If necessary, this

can be implemented by the supplier or the manufacturer on behalf of the

operator. Furthermore, the operator in charge must ensure that the content of

the present manual has been fully understood by the personnel.

2.3 Safety-conscious work

The safety instructions listed in this operating manual, applicable national

regulations concerning accident prevention as well as internal work, operation

and safety regulations of the operator must be complied with.

2 Safety instructions Operation manual mzr-2961, mzr-4661

8 Technical data subject to change without prior notice! Last update: April 2018

2.4 Safety instructions for the operator

The surface temperature of the motor under full load may exceed 60°C. If

needed, this surface should be protected on site against contact in order to

avoid skin burns.

The drive should be protected against dust, water vapor condensation,

humidity, splash water, aggressive gases and liquids. Please provide for an

adequate air ventilation and thus cooling of the motor.

The micro annular gear pump mzr-4661 must not be used in areas exposed to

explosion risks or in proximity of inflammable gases and vapors.

Possible leaks of dangerous liquids (for example from the shaft sealing) should

be guided away in a way not to represent any danger for the personnel and the

environment. The pump should be regularly checked for possible leakage. All

legal requirements in this matter should be complied with.

Take care that all risks resulting from the electric energy are excluded. For

details please refer to the instructions provided by the authorities in charge or

your power supplier.

Warning

Please insure, that the totality of the liquid supply system such as tubes, hoses,

filters etc. are free from dust or dirt particles. Impurities such as metal swarf,

plastic or glass splinters may impair or damage the pump leading to its failure.

Warning

Please, operate the pump with a filter featuring 10 µm or smaller pores. It will

protect the pump.

2.5 Safety instructions for maintenance, check and assembly of the pump

As a rule all maintenance work on the device should be performed when it is at

a standstill. The turning-off procedure described in this manual must be

followed. Pumps delivering liquids hazardous to health must be

decontaminated. Immediately after the work had been completed all safety

equipment and protection measures should be applied.

Before starting the operation, please take notice of the instructions listed in the

chapter 6.5.

Warning

Should a malfunction of the mzr-pump occur, do not dismantle the pump on

your own but contact one of HNP Mikrosysteme service staff for professional

assistance.

2.6 Unauthorized pump conversions and spare part manufacture

Conversions or modification to the device are only permitted with prior consent

of the manufacturer. Original spare parts and accessories authorized by the

manufacturer ensure safety. The use of other parts will annul the liability of the

pump manufacturer for any resulting consequences.

2 Safety instructions Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 9

2.7 Improper modes of operation

The safety of operation of the delivered device can only be insured by correct

use, as described in chapter 1. The limit values given in this manual must not be

exceeded in any case.

2.8 General safety instructions

Please observe the following safety instructions

!

The pump may operate at high pressures. For this reason please use only the

delivered accessories and ensure that the employed fittings and tubing have

been prescribed and approved for these pressures.

!

In order to decrease the pressure, provide the system with a pressure control

valve directing the excess liquid to the storage tank or back to the suction side.

In the case of blockage of the pressure side the operating pressure can

multiply, this can lead to the damage of downstream components.

!

At a standstill, the liquid may flow through the pump in the direction of falling

pressure. In order to avoid this unwanted movement, please integrate nonreturn valves (see accessories). This applies also to elevated liquid containers.

!

Protect the micro annular gear pump and the electric drive against strokes and

shocks.

!

Under normal working conditions the shaft sealing rings integrated in the

pump prevent the liquid from leaking out of the device. The micro annual gear

pumps are "technically leak-proof" however not "hermetically sealed" which

means it may occur that gases or liquids enter to or escape from the pump.

The allowed electrical parameters of the drive must not be exceeded. In

particular an incorrect polarity setting of the supply voltage may lead to

damage of the control unit.

Warning

Please insure, that the totality of the liquid supply accessories such as tubes,

hoses, filters etc. are absolutely free from dust or dirt particles. Impurities such

as metal swarf, plastic or glass splinters may impair or damage the pump

leading to its failure.

Warning

Please, operate the pump with a filter featuring 10 µm or smaller pores. It will

protect the pump.

While connecting the DC voltage pay attention to the correct polarity,

otherwise electronics may be damaged.

3 Transport and intermediate storage Operation manual mzr-2961, mzr-4661

10 Technical data subject to change without prior notice! Last update: April 2018

3 Transport and intermediate storage

3.1 Shipment of the pumps and protection measures

The pumps leaving the factory are secured against corrosion and shocks. The

inlets and outlets of the pumps are protected with plastic plugs in order to

prevent any foreign bodies from penetrating into the device.

3.2 Transport

In order to avoid any transport-related damage, the package must be protected

against shocks. HNP Mikrosysteme guarantees that all goods leave the factory

in the best condition. Any noticed damage should be reported to the

concerned forwarding agent, authorized dealer or to HNP Mikrosysteme

as manufacturer.

3.3 Intermediate storage

Following points concerning pump storage should be observed:

− necessary conservation procedure (see also chapter 7.4.1)

− the protective caps must be put on

− the pump should not be stored in humid places

− for storage temperature - refer to chapter 1.5 of the present manual

4 Description of the pump Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 11

4 Description of the pump

4.1 Principle of the Micro annular gear pumps

Micro annular gear pumps are positive displacement pumps. They contain two

rotors bearing slightly eccentrically to each other; an externally toothed internal

rotor and an annular, internally toothed external rotor (see figure 6). Due to

their cycloid indenting, the rotors remain interlocked at any time, forming

during rotation a system of several sealed pumping chambers. As the rotors

revolve around their offset axis, the pumping chambers increase on the

induction (suction) side and simultaneously decrease on the delivery side of the

pump (see figure 7). A homogenous flow is generated between the kidney-like

inlet and outlet.

internal

rotor

external

rotor

delivery side

induction side

inlet

outlet

figure 6 Principle of the micro annular gear pump

figure 7 Operating principle of the micro annular gear pump

Reciprocating and rotary pumps have a direct allocation to the fed amount of

the displacement volume V

g

of the pump and its actuator’s number of

revolutions n. The displacement volume describes the volume, which is

theoretically fed with each revolution. The coherence of the flow rate referring

to the formula (= volumetric flow rate) Q of the pump is:

nVQ

gVol

⋅⋅

=

η

The volumetric efficiency

η

Vol

describes the coherence of the actual flow rate

from the theoretical resulting value. Differences occur according to leaking, as

the sealing on the inside of the pump is done over a gap. The volumetric

4 Description of the pump Operation manual mzr-2961, mzr-4661

12 Technical data subject to change without prior notice! Last update: April 2018

efficiency is dependent on the media and the pressure against which it has to

be fed.

Example: The pump mzr-4661 feeds with its displacement volume of 12 µl with

3000 RPM and a volumetric efficiency of 100 % referring to the abovementioned formula the flow rate of 36 ml/min. The following table shows the

volumetric displacement in dependence to the number of revolutions (

η

Vol

=

100 %).

mzr-2961 mzr-4661

Speed

[rpm]

Q [ml/min] Q [ml/h] Q [ml/min] Q [ml/h]

500 1,5 90 6 360

1000 3 180 12 720

2000 6 360 24 1440

3000 9 540 36 2160

4000 12 720 72 2880

5000 15 900 60 3600

6000 18 1080 72 4320

table 4 Theoretical flow rate of the micro annular gear pumps

The pressure, which the pump has to generate, is given by the construction of

the fluidic system and the results of the hydrostatic pressure and the hydraulic

resistants (given by tubes, contractions etc.).

The viscosity of the pumping liquid has an important influence on the

volumetric efficiency. The volumetric efficiency increases with higher viscosity

according to the smaller disengagement through the gaps of the pump.

Cavitation is an effect, which can reduce the volumetric efficiency from in a

specific ceiling speed. With increasing viscosity (e.g.> 500 mPas), this ceiling

speed is lower. This is the result of the media specified underflow of the steam

pressure in the induction port of the pump, in which gases are building up in

the pump.

The specific feature of the

mzr-pumps is their highly precise design, as well as

the guarantee of high accumulator pressure and high accuracy in flow rate and

dosage. Therefore, space width and transverse space width of the rotors as well

as the interspace to the adjacent case parts lie in the range of just a few

micrometers. This precession is at the same time the criteria to achieve a

volumetric efficiency in the range of approx. 100 %.

The micro annular gear pump head has an inscription on the front side (see

figure 8). The induction connection is marked with the letter »S«, the pressure

connection with the letter »D«. An arrow on the front side of the pump

indicates the inherent turning direction of the shaft.

4 Description of the pump Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 13

liquid inlet

(suction side)

liquid outlet

(pressure side)

figure 8 Indication of the turning direction and fluidic connections on the front of the micro annular gear pump

4.2 Micro annular gear pump

The micro annular gear pumps

mzr-2961 and mzr-4661 is provided with an

actuator equipped with a canned motor. The motor works high dynamically

and is recommended for dosage operation of the micro annular gear pump.

With this control unit it is possible to manage lower RPM ranges down to

400 RPM. For operating, it is recommended to use a power source of 24 V

(with a power rating of 2,5 A).

figure 9 Measures of the micro annular gear pump

The mzr-micro annular gear pump consists of the micro annular gear pump

head, the coupling unit and an actuator. The pump head is equipped with two

fluidic connector bore holes and a shaft for actuation of the rotors. The

coupling unit serves as connection between the pump head and the actuator as

well as to mount the micro annular gear pump.

The actuators used may be protected against dust, condensing moisture,

humidity, splashing, aggressive gases and liquids. Ensure sufficient ventilation

and therefore cooling of the motors.

The preferred position to assemble the micro annular gear pump is horizontal.

To avoid intruding fluids you may lay the pump under the actuator in vertical

operation.

The mechanical assembly of the pump may not be done over the fluidic

connectors or the motor.

4 Description of the pump Operation manual mzr-2961, mzr-4661

14 Technical data subject to change without prior notice! Last update: April 2018

4.3 Materials and liquids

The components of the micro annular gear pump heads are manufactured of

tungsten carbide (with 10% nickel binder) and nickel bronze.

The liquid resistance is to be checked in single cases. Feeding of non-lubricant

liquid reduces the service life of the micro annular gear pumps.

4.4 Liquid supply

We are able to supply the micro annular gear pump head in two kinds.

Slip fittings

The micro annular gear pump head is equipped with two front slip fittings with

OD 2 mm for connection of flexible tubes with the ID < 2 mm (such as 1/8"

hose).

The suction side is indicated with the letter »S« the delivery side with

the letter »D«. An arrow in the front of the pump indicates the operating

direction of the shaft.

In order to prevent foreign bodies from penetrating into the pump, the liquid

inlet and outlet are protected by plastic caps. Please remove them before you

assemble the pump.

Manifold assembly M2.1

The micro annular gear pump with manifold assembly has been designed for

integration into systems. The benefit of the manifold assembly is diminished

cubage for easier integration of the micro annular gear pump and higher

pressure resistance.

4 Description of the pump Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 15

figure 10 Drawing manifold assembly M2.1 (figure with mzr-4661)

figure 11 Dimensions configuration version

5 Optional modules Operation manual mzr-2961, mzr-4661

16 Technical data subject to change without prior notice! Last update: April 2018

5 Optional modules

The spectrum of applications of the magnetic hermetic micro annular gear

pump series may be expanded by using different additional modules. The

modules allow for special dosage tasks, which could otherwise not be

accomplished with a standard pump version. The modules may be combined

with each other and with almost all available pump heads and motor versions.

− By-pass module for the delivery of minimal constant flow rates down to the

nanoliter range (see chapter 5.1)

Due to specific requirements of each application the configuration of a given

pump version should be discussed with the technical service. Additional

customized modules may be designed on demand.

5 Optional modules Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 17

5.1 By-pass module (optional)

The by-pass module allows constant minimal volume dosage with flow rates in

the nanoliter range. The technology is based on the division of flow generated

by the micro annular gear pump, according to the relationship of fluidic

resistance of two predefined capillaries. The micro annular gear pump

generates a master circulation from which a side dosage current is derived. This

micro flow capillary allows to obtain flow rates starting at 1 µl/h. The minimal

and the maximal flow rate may differ by a factor of 1000 (dynamic factor). In

order to determine the lower flow rate limit, both capillaries need to be

carefully configured. It is possible to obtain flow rates between 1 and

10,000 µl/h.

The by-pass module assures dosage of minimal amounts of liquids at a very

high constancy of flow and a pressure-resistant flow rate.

figure 12 The by-pass module example with mzr-2521

Performance parameters

Operating flow rate range 1 – 10,000 µl/h

Differential pressure range 0 – 3 bar

Max. applied inlet pressure 1 bar

Pulsation

<1 %

Operating temperature -20 … +60 °C

Viscosity range 0.5 – 100 mPas

Fluid connections − Liquid intake: tube or hose, OD 1/8“

− Master capillary: tube, OD 1/8“ (return line to the tank)

− Side current capillary: tube, OD 1/16“ (dosage capillary)

Wetted parts

stainless steel 316L, PEEK

Measurements approx. 32 x 25 mm (by-pass module without pump)

Weight approx. 140 g (by-pass module without pump)

table 5 Technical data of the by-pass module

5 Optional modules Operation manual mzr-2961, mzr-4661

18 Technical data subject to change without prior notice! Last update: April 2018

figure 13 Construction of a by-pass module with mzr-2521

Working principle

The by-pass module shown in the figure 13 divides the flow generated by the

micro annular gear pump into master and side circulation. The module serves at

the same time as a support and fixture for the micro annular gear pump. The

selection and configuration of the different components of the system is

calculated by a PC. The master circulation capillary (the tube going back to the

liquid tank) and the pump are selected and configured for each customerspecific dosage task. In this way the pump operates with the desired volumetric

efficiency and can generate pressures reaching beyond the required pressure

level. Depending on the difference of pressures between the delivery side of the

pump and the system, a side current capillary is designed and precisely adjusted

so that the desired minimal flow rate is obtained at its outlet. The flow charts of

the by-pass module are verified before the shipment.

Flow chart examples

Flow rate range 100 – 9000 µl/h Flow rate range 0.6 – 4.4 µl/h

0

2000

4000

6000

8000

10000

0 1000 2000 3000 4000 5000 6000 7000 8000 9000

Antriebsdrehzahl n [U/min]

Volumenstrom Q [µl/h]

0,0

1,0

2,0

3,0

4,0

5,0

0 1000 2000 3000 4000 5000 6000 7000 8000 9000

Antriebsdrehzahl n [U/min]

Volumenstrom Q [µl/h]

Master capillary

ID: 0.25…0.5

mm

Length: 80…300

mm

Side capillary

ID:

0.064…0.25 mm

Leng

th: 80…500 mm

mzr-2521 / mzr-2921

By

-pass socket stainless steel 316L

with a manifold assembly,

fixture openings 4 x M3 (

22 mm)

Return line to

the liquid tank

Inlet port of

the pump

Customized nano/micro flow,

starting at 1 µl/h

6 System integration Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 19

6 System integration

6.1 Checkup before the first assembly

Inspect the pumps for potential damage during the shipment (see chapter 3.2).

Please check according to the following points if the right pump type has been

delivered:

− Compatibility with the delivered liquid

− Viscosity range

− Pump performance (displacement volume, dosage volumes, operating

pressures)

− Operating temperature range

!

If you notice any difference between the required and the delivered pump

type, please contact HNP Mikrosysteme. Do not put the pump into operation

without prior approval.

6.2 Mounting of the micro annular gear pump

The fixing of the micro annular gear pump can be vertical or horizontal. To

prevent possible entry of liquid, mounted the level of the motor be above the

level of the pump head.

Warning

Install the pump in such a way that in case of failure no liquid can enter to the

motor or controller.

!

If the pump is mounted flexibly or dosing tasks require change of pump

position, please fasten the cable with an adapted cable tie at the motor in

order to avoid strain. If the pump is moved over a longer time, the cable may

break at its connection to the motor.

!

Take precautions that in case of leakage no surrounding objects or

environment will be exposed to danger.

!

The motor must be protected against humidity, dust or sweat.

6 System integration Operation manual mzr-2961, mzr-4661

20 Technical data subject to change without prior notice! Last update: April 2018

6.3 General instructions for the assembly of the liquid supply network

Foreign bodies and dirt particles can block the micro annular gear pump and

lead to its damage.

Warning

Please note that all the components of the liquid supply system should be

clean and flush them if needed before pump installation. Remember to remove

all remaining splinters or swarf from connection fittings, rests from liquid

containers and any dirt from valves, tubing and filters.

Warning

Operate the pump with a filter featuring 10 µm or smaller pores. The filter

protects the pump from particles and dirt.

!

If the pump is connected once again with a hose that has already been used,

the enlarged ending of the hose should be cut off in order to prevent it from

slipping off and the liquid from flowing out of the connection.

Assembly of the tubing and piping system

1. Please cut the tubing rectangular with a hose cutter. If metal pipes are used

an intensive cleaning procedure is necessary. After machining the pipes

have to be cleaned and flushed very carefully. Smallest swarfs within the

fluidic system can cause failure of the micro annular gear pump.

2. Connect the fittings with the tubing respectively the pipe work according to

the attached installation instruction.

!

Please note that the correct assembly of tubes respectively pipes with the

pump head is a necessary condition to secure the right direction of flow. When

you want to operate the pump in reverse direction please contact

HNP Mikrosysteme since this is not possible in any application.

3. The suction line should be installed ascending to the pump for better

degassing. The suction line should be designed as short as possible. The

inner diameter of the suction line should be large to guarantee good

priming of the liquid. At the planning of the pipe system take care of

possibilities for degassing.

4. Operate the micro annular gear pump always with a filter with a pore size

of 10 µm or smaller. The filter prevents that particles or solids penetrate

into the pump what can cause major damage.

5. Avoid dry running of the pump. Make sure that the liquid flow is not

interrupted.

6 System integration Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 21

6.4 Filter selection and use

In majority of cases it is recommended to integrate a filter on the suction side

of the micro annular gear pump to ensure its secure operation. The

recommended filter pore or mesh size should not exceed 10 µm. The

penetration of particles or swarf that could cause a blockage or damage to the

pump can only be avoided by using an adapted filter.

HNP Mikrosysteme offers a choice of standard filters covering a broad spectrum

of applications. You may count on our assistance for the selection of the most

suitable filter.

In order to select the best adapted filter, such operating parameters as the flow

rate, the viscosity and the degree of pollution of the liquid will be needed. An

increase in at least one of the mentioned terms will require the use of a bigger

filtering element or pressurization of the delivered liquid. In case no suitable

filter for the given high-viscosity liquid can be found, it is possible to use a filter

with slightly larger pore size. Prior discussion with HNP Mikrosysteme is here

recommended. A filter with larger pores is still better than no filter at all. As an

alternative solution an already filtered liquid may be used.

Warning

Because filters have a large internal volume, it is recommended to fill in the

filter and the induction (suction) tubing with already filtered liquid in order to

avoid a too long dry run of the pump during the first operation.

Warning

Please control regularly the filtering elements for pollution. Cleanse regularly

the filter or replace it with a new one. A polluted filter may considerably

decrease the volumetric efficiency of a pump. Furthermore, because of the

cavitation effects dosage imprecision and even pump damage may occur.

Warning

A too small filter (too little filtering surface) may considerably decrease the

volumetric efficiency of the micro annular gear pump. What is more, because

of the cavitation effects dosage imprecision and even pump damage may

occur.

6 System integration Operation manual mzr-2961, mzr-4661

22 Technical data subject to change without prior notice! Last update: April 2018

6.5 Operation with terminal box S-G61

The micro annular gear pump is connected via the Terminal Box S-G61. This

enables an easy startup of the pump due to:

− the possibility to connect the voltage supply with the delivered screw clamp

terminal

− speed set via potentiometer

− analog voltage input 0-10 V for speed controller

− Change the speed setting via jumpers

− Direction input

− Frequency output (FG), on status LED to indicate the operating status

(normal / fault) or optional output error on existing screw

− Internal reverse polarity protection

In order to operate the pump a supplementary source of 24 VDC will be

required. The ampacity of the voltage source should amount to around 2 A for

the micro annular pumps mzr-2961 and mzr-4661.

68 mm

57 mm

60 mm

3

0 mm

2

4 mm

Ø3,2 (2x)

4

5 mm

54 mm

mzr-pump

GNDDIRA

n_in

SGND

10 V out

F

G

24 VDC

K1K7

figure 14 Measurements of the Terminal Box S-G61

6-pole pump

connection

Potentiometer

Pin bar for jumper

Screw clamp

connections

LED-

operating

status

6 System integration Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 23

Technical data

General technical data

Terminalbox S-G61

Power supply electronic U 24 (5 ... 28 V) V DC

Power supply electronic coil UB 24 (6 ... 28 V) V DC

Max. continuous output current I

dauer

1,5 * A

Max. peak output current I

max

1 A

Total standby current Iel 0,02 A

Speed range

1000 … 6000 *

rpm

Output voltage for external use 10 V out 10

max. 200 mA

V

Nominal input speed An_in 10-Bit AD-converter

Voltage range 0 … 10 V

Potentiometer 10 kΩ (Pegel 0 … 10 V)

Sense of rotation (input) DIR low 0 … 0,5 or GND ⇒

counterclockwise

high 3 … UB or open ⇒ clockwise

V

Input resistance Rin ≥ 10 kΩ

Digital output FG Output frequency

max. 50 mA, high 16 … U

B

:

Number of pulses 6 lines per revolution

Weight with housing 35 g

* Values limited in the control unit with corresponding software

table 6 General technical data

Nr. Configuration Nr. Configuration

K1 24 VDC 1 U

P

K2 GND 2 U

Mot

6

1

2

5

K3 DIR 3 GND

K4 An_in 4 U

nsoll

K5 SGND 5 DIR

K6 10 V out 6 FG

K7 FG

table 7 Configuration of the screw connections Configuration of the 6-pole motor connector

0 ... 10 V

Poti

table 8 Jumper configuration for the analog speed input

6 System integration Operation manual mzr-2961, mzr-4661

24 Technical data subject to change without prior notice! Last update: April 2018

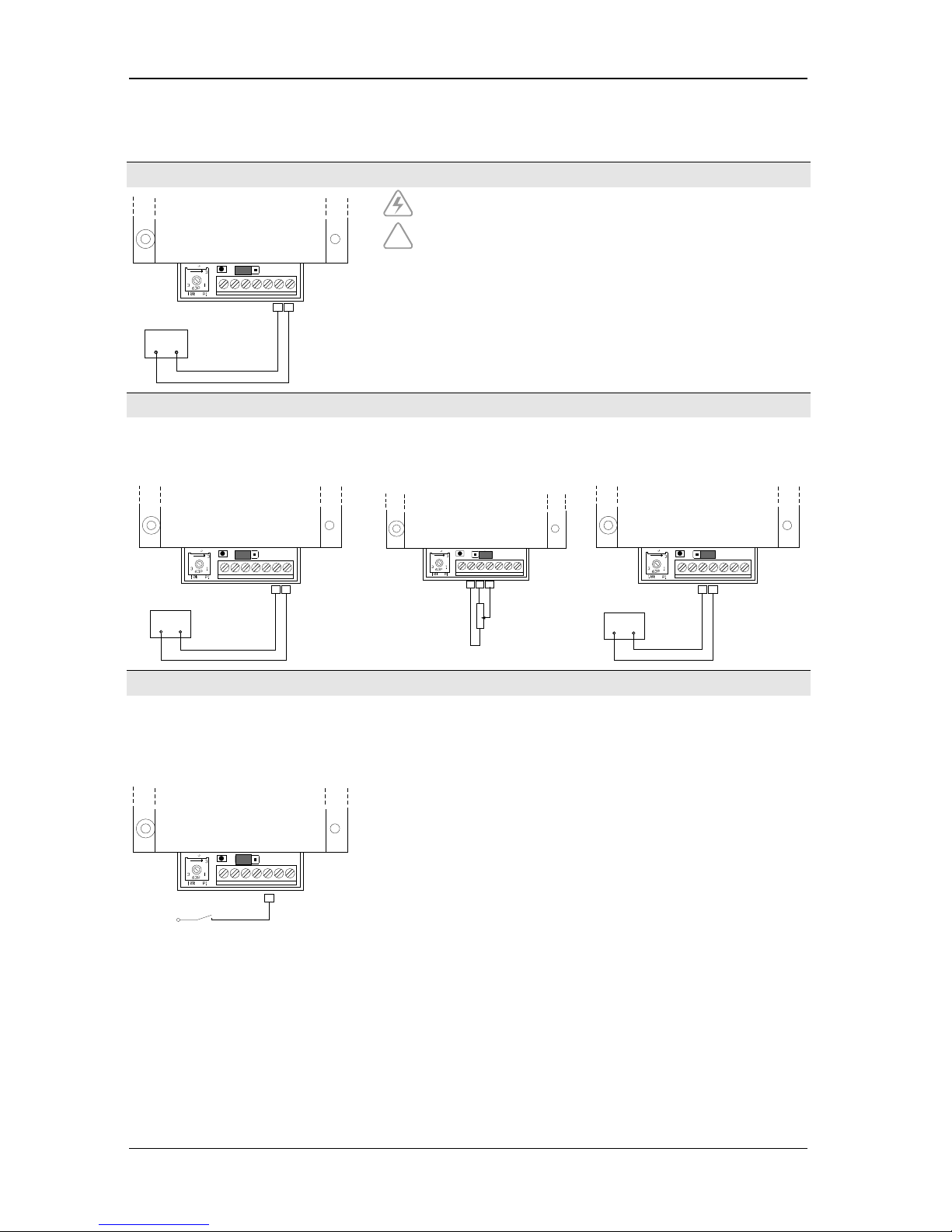

Startup of the micro annular gear pump

Voltage supply

K1K2

Voltage supply

+

–

10...30 VDC

GNDDIR

An_in

S

GND

10 V out

FG

24 VDC

P1

!

Pay attention to the correct polarity of the voltage supply, otherwise

electronics will be damaged.

The length of voltage supply cable should not exceed 10 m, or the

control unit could be damaged by inductance overvoltage.

Analog nominal signal

Potentiometer internal operating mode Potentiometer external operating

mode

0 … 10 V operating mode

connected with jumper pins P3 and P2 connected with the jumper pins P2 and P1 connected with the jumper pins P2 and P1

K1K2

Voltage supply

+

–

10...30 VDC

GND

DIRA

n_in

SGND

10 V out

FG

24 VDC

P1

10 κΩ

K4K5K6

GND

DIR

An_in

SGND

10 V out

FG

24 VDC

P1

K4K5

Sollwert 0...10 V

+

–

GND

DIR

An_in

SGND

10 V out

FG

24 VDC

P1

Digital inputs

Sense of rotation input

− High-Pegel (3 V… U

B

) or open: pump

turn clockwise (to the right)

− Low-Pegel (0 … 0,5 V) oder GND:

Pump turn counterclockwise (to the left)

K3

4...24 VDC

GND

DIR

An_in

SGND

10 V out

FG

24 VDC

P1

6 System integration Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 25

Digital output

Speed signal output

Digital output: 6 lines per revolution

K7

FG

GNDDIR

An_in

SGND

10 V out

FG

2

4 VDC

P1

7 Start Up / Shut Down Operation manual mzr-2961, mzr-4661

26 Technical data subject to change without prior notice! Last update: April 2018

7 Start Up / Shut Down

7.1 Preparing for operation

After the liquid supply system had been completed, please check once again

the operating conditions of the micro annular gear pump as according to the

following points:

− Are the inlet and outlet tubes or hoses correctly connected?

− Is the entire liquid supply system clean - that means free of particles, foreign

bodies, pollution or swarf?

− Has a filter been installed on the suction side?

− Has a sufficient amount of the right liquid been supplied?

− The pump does not run the risk of a longer dry operation?

− The entire liquid supply system has been checked for leakage?

− Is it possible to stop the pump by an emergency switch if an unexpected

malfunction occurs at the first start?

7.2 Startup of the micro annular gear pump

− Switch on the voltage supply. The micro annular gear pump can now be put

into operation by turning the potentiometer knob, by sending a nominal

external voltage signal.

− Start the filling in of the pump at low or middle speed (1000 - 3000 rpm).

Warning

Avoid dry operation of the pump over a longer time. The pump should be

filled in before it is put into operation.

7.3 Flushing procedure after use

After each service the micro annular gear pump should be carefully flushed

with a non-corrosive, filtered and particle-free flushing liquid (see table 9 /

table 10). During the flushing procedure the pump should operate at about

3000 rpm and if possible against a low pressure (that can be obtained by using

a restrictor, a capillary or similar). The flushing liquid must be compatible with

the delivered liquid and be suitable for solving the remaining liquid rests.

Depending on the application for example water, or isopropanol may be used.

If you have doubts whether a liquid is suitable for this function or not, please

ask the manufacturer of the liquid or HNP Mikrosysteme.

7 Start Up / Shut Down Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 27

Flush the pump

Selection of flushing

liquid (FL)

Drain the pump

Right

flushing

liquid

Is the

pump

resistant?

no

no

yes

yes

Flushing cycle

End of flushing

cycle

figure 15 Flushing procedure

Warning

Liquids remaining in the pump may crystallize, coagulate or lead to corrosion

and as a consequence impair the work of the micro annular gear pump.

Warning

Please make sure that the pump components and particularly O-rings and

sealing are resistant to the employed flushing liquid (see table 10).

Warning

The flushing liquid (solvent) and the recommended duration of the flushing

procedure depend on the delivered liquid (see table 9). The indicated flushing

liquids are simple recommendations and should therefore be checked by the

user as to their compatibility and suitability.

!

Regulations concerning the use of substances dangerous to health should be

followed!

see table 10 (Resistance of the sealing materials)

see table 9 (Selection of the flushing liquid)

see table 9 (Selection of the flushing liquid)

7 Start Up / Shut Down Operation manual mzr-2961, mzr-4661

28 Technical data subject to change without prior notice! Last update: April 2018

Nature of the handled liquid Flushing cycle

[min]

Suitable flushing liquid

1 Oils, fats, plastifiers 15-20 isopropanol, ethanol, acetone, benzine

2 Solvents (polar + nonpolar) 5-10 isopropanol, ethanol

3 Other organic liquids 10-15 isopropanol , ethanol

4 Refrigerating and cooling agents 15-20 isopropanol, ethanol

5 Neutral watery solutions 20-25 isopropanol, ethanol

6 Basic solutions 25-30 DI-water (deionized water)

7 Organic acids 30-40 isopropanol, ethanol

8 Weak mineral acids 25-30 DI- water

9

Strong mineral acids

35-45

DI- water

10 Strong oxidizing liquids 35-45 DI- water

11 Paints, varnishes, adhesives 50-60 Not specified - for further information

please contact HNP Mikrosysteme.

table 9 Selection of the flushing liquid (solvent) and the duration of the flushing cycle depending on the delivered

liquid.

Warning

Please make sure that the pump components and particularly O-rings and

sealing are resistant to the employed flushing liquid (see table 10).

Shaft sealing O-ring material

Flushing liquid

PTFE (Teflon®),

graphite-

reinforced

UHMWPE FPM

(Viton®)

EPDM FFPM

acetone 0 0 3 0

0

benzene 0 3 1 3 0

benzyl alcohol 0 - 0 2 0

benzine 0 0 0 3 0

butanol 0 - 1 0 0

dimethyl sulfoxide (DMSO) 0 0 3 0 0

ethanol 0 0 0 0 0

isopropanol 0 0 0 0 0

methanol 0 0 2 0 0

methylethylketone (MEK)

0 0 3 1 0

oil / fine mechanics oil 0 0 0 3 0

styrene 0 - 1 3 1

toluene 0 1 2 3 0

water 0 0 0 0 0

xylene 0 1 2 3 0

Legend: 0 ... good suitability 1 ... suitability 2 ... conditional suitability 3 ... labile - ... not specified

table 10 Resistance of the sealing materials depending on the flushing liquid (solvent)

7 Start Up / Shut Down Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 29

7.4 Shutdown of the micro annular gear pump

During the shutdown of the pump the following steps should be followed

− Flush the pump with a filtered and particle-free flushing liquid (solvent)

(see chapter 7.3)

− After the flushing procedure decrease speed of the pump to 0 rpm

− Fill the pump with a suitable conservation liquid (see chapter 7.4.1)

− Remove the pump from the system (see chapter 7.4.2)

By proceeding as shown in the diagram (see figure 16) you may prepare the

pump for a longer standstill.

7 Start Up / Shut Down Operation manual mzr-2961, mzr-4661

30 Technical data subject to change without prior notice! Last update: April 2018

Legend

FL = flushing liquid

CL = conservation liquid

End of test/operation

Drain the pump

Pump

requires

flushing?

Flushing cycle

Is the

pump

clean?

Selection of

conservation liquid

(CL)

Delivery of

solvents

manipulated

liquid =

conservation

liquid

Flush the pump

Selection of flushing

liquid (FL)

Drain the pump

Right

flushing

liquid

Is the

pump

resistant?

Selection of conservation

liquid (CL)

CL

adequate

Is the CL

compatible

with pump

Is the CL

compatible

with the

last FL ?

Nature of

the CL

Let the gas through

the pump

Fill in CL

Desinstall the

pump

Close the liquid

ports

End of conservation

procedure

New operation after

the conservation

procedure

liquid

yes

no

no

no

no

no

no

no

yes

yes

yes

yes

yes

yes

gaseous

no

yes

Flushing cycle

End of flushing

cycle

End of CL

selection

figure 16 Shutdown procedure

see table 9

see table 10

see table 10

see table 11

7 Start Up / Shut Down Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 31

7.4.1 Conservation

If the micro annular gear pump operates at irregular intervals or for other

reasons should be put out of operation for a longer period, it should, after

service and flushing procedure (see chapter 7.3), be filled in with a suitable

conservation liquid.

The conservation liquid may be selected from the table 11 depending on the

duration of the standstill and the resistance of the pump to the manipulated

liquid (table 10). The indicated conservation liquids are simple

recommendations and should therefore be checked by the user as to their

compatibility and suitability. The figure 17 presents the diagram of conservation

liquid selection.

Remark: This diagram is repeated as a part of the figure 16 »Shutdown

procedure«.

After the cleansing procedure the pump should be filled with a suitable

conservation agent. You will find a choice of possible conservation liquids in

the table 11.

Selection of conservation

liquid (CL)

CL

adequate

Is the CL

compatible

with pump

Is the CL

compatible

with the

last FL ?

yes

no

no

no

yes

yes

figure 17 Selection of the conservation liquid (CL)

see table 10 (resistance of the sealing materials)

see table 11 (Selection of conservation liquid)

7 Start Up / Shut Down Operation manual mzr-2961, mzr-4661

32 Technical data subject to change without prior notice! Last update: April 2018

Liquids

Solubility in

water

Compatibility

with the

delivered liquid

Duration of

storage Breakaway

torque Toxicology Viscosity Description

isopropanol + + o o o + solvent for organic compounds, cosmetics, essential oils,

waxes and esters, antifreezers, antiseptic agents

acetone + + o o o + solvent for a number of organic compounds, unlimited

solubility in water, dissolves natural and synthetic resins, fats,

oils and commonly used plastifiers

ethanol + + o o o + solvent for organic compounds, fats, oils and resins

DI-water

+ + - - + + solvent for many organic and mineral liquids

fine mechanics

oil

- - + + + + cleansing and protective action (dissolves fats, tar, rubber or

adhesive substances, protects against corrosion)

hydraulic oil - - + + + - lubricating and preserving properties (Warning: may resinate

or deteriorate with time)

nitrogen - + + + o + is not a solvent, may leave deposits after drying out

air /

compressed air

+ + + + + is not a solvent, may leave deposits after drying out

Legend: + ... good/suitable o ... satisfactory; - ... bad/inadequate

table 11 Selection of the conservation liquid

In order to prevent dust particles and foreign bodies from penetrating into the

pump or the conservation liquid from leaking out, please secure the liquid input

and output with the delivered protective plugs or screws.

Warning

Water or deionized water (DI-water) should not be used as conservation

agents. These liquids germinate already after a few days and build a biofilm

which can later block the pump.

7.4.2 Dismantling of the system

− Put the drive out of operation by turning down speed to 0 rpm and by

switching off the voltage supply. Make sure that the procedure described in

the chapter 7.3 has been completed.

− Now that the pump has been stopped you may remove it from the system.

− Protect the inlet and outlet openings of the pump with adapted protective

caps or screws.

7 Start Up / Shut Down Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 33

7.5 Trouble shooting

If the pump does not start to operate or stops the operation abruptly, please

proceed as follows:

Try to liberate the micro annular gear pump:

− by turning the potentiometer knob back and forth or by sending an analog

voltage signal

− via the control software

− by pressing with a syringe a suitable flushing liquid (see table 9 and table 10)

through the micro annular gear pump

− by changing the operating direction of the pump.

If these measures turn out to be ineffective, please contact the service staff of

HNP Mikrosysteme (see chapter 11) and send the pump back to the

manufacturer for inspection.

Warning

You should under no condition try to dismantle the pump by yourself. This

may cause damage to the pump components and consequently annul your

warranty claims.

7.6 Return of the micro annular gear pump to the manufacturer

For the return of a micro annular gear pump and components that have already

been employed, please follow the instructions:

− drain any remaining rests of the delivered liquid from the pump

− flush the pump with an adapted solvent

− remove the filter elements from integrated or loosely delivered filters

− protect all openings against dust with the delivered protective plugs or

screws

− return the pump in its original packing

The service personnel which carries out the repair should be informed about

the condition of the used micro annular gear pump. This is done by means of

the "Declaration of media in contact with the micro annular gear pump and

components" (see chapter 17). This form may also be downloaded from the

web site www.hnp-mikrosysteme.de/download.

!

The "Declaration of media in contact with the micro annular gear pump and

components" must imperatively be filled in. The nature of liquid which entered

into contact with the micro annular gear pump and the components must be

specified.

In case of non-compliance, the sender will be liable for any resulting injure to

persons or any object damage.

8 Accessories for microfluidic systems Operation manual mzr-2961, mzr-4661

34 Technical data subject to change without prior notice! Last update: April 2018

8 Accessories for microfluidic systems

The accessory range for the liquid delivery systems of HNP Mikrosysteme

comprises complementary equipment such as supplementary modules, hoses,

tubing, fluid connection fittings, filters and non-return valves that are best

adapted to your micro annular gear pump. We will eagerly share our long date

experience as far as component selection is concerned.

9 Non-liability clause

HNP Mikrosysteme GmbH shall not be liable for damages resulting form the

non-respect of instructions comprised in this operating manual.

It remains at the responsibility of the user to conform to all laws, rules and

regulations in force. This applies above all to the handling of aggressive,

poisonous, corrosive and other dangerous liquids as well as to the

electromagnetic compatibility (EMC).

10 Problems and their removal Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 35

10 Problems and their removal

Disturbance Cause Solution

1 The pump does not start operation.

No power supply

Check the power supply.

2 The pump does not deliver any

liquid.

No liquid in the primary tank. Fill the recipient/tank with liquid.

Presence of air or gas in the pump The pump cannot run dry against the system

pressure. Fill in the pump at no pressure or at

reduced system pressure.

Malfunction of the liquid supply system

(such as in the delivery tube or hose, the

needle or external non-return valve)

Check the components for possible

disturbances to be eliminated. Cleanse the

accessories if needed.

Failure of the electric installation. Check the electric installation for the correct

cable configuration, loose contacts, etc.

The pump did not receive the start signal or

start conditions are not fulfilled.

Check if the start conditions have been

fulfilled start signals (PLC, start input) and the

programming.

Read the operating manual for the motor

control unit.

3 The pump does not start to operate. The pump does not take in the liquid. The tubing on the suction side is too long or

has a too small internal diameter (a too low

NPSHA value).

The tubing or the fluid connection on the

suction side are not tight. Please check the

intake connection and the tubing.

Air bubbles in the system

(tubes, valves, ...)

If the viscosity of the liquid is too high, apply

pressure on the suction side.

Check the pressure exerted on the primary

liquid tank.

An external non-return valve does not open.

Check the non-return valves.

Submit the non-return valve to a higher

pressure, so that the pump may fill in.

4 The motor turns, but the pump

does not operate.

No liquid in the pump Fill the pump with liquid.

Air bubbles in the liquid supply system

(tubing, valves, ...)

Fill the pump and the liquid supply system

with liquid.

The non-return valve does not open. Rinse the non-return valve.

Blocked delivery tubing or needle Cleanse, flush or exchange the delivery

tubing or dosage needle.

The coupling between the motor and the

pump is out of position.

Return the pump to the manufacturer.

The pump shaft is broken. Return the pump to the manufacturer.

5 The pump is filled with liquid, but

does not pump it.

Adapt the motor current of the control.

Contact the manufacturer of the pump.

Presence of particles in the delivered liquid

or blockage of the pump

Check the motor error status with the Motion

Manager software.

Try to liberate the pump by making it operate

in a reverse direction for 1 s with

- 1000 rpm.

Flush the pump with a syringe.

Return the pump to the manufacturer for

cleansing. Use a filter, flush the liquid delivery

system.

The non-return valve does not open. Rinse the non-return valve.

Blockage of the delivery tubing or the Cleanse, flush or exchange the delivery

10 Problems and their removal Operation manual mzr-2961, mzr-4661

36 Technical data subject to change without prior notice! Last update: April 2018

Disturbance Cause Solution

needle tubing or the needle.

Air bubbles in the liquid delivery system

(tubing, valves)

Fill in the pump and the liquid delivery system

with liquid.

6 Dosage volume does not

correspond to the desired values.

Air bubbles in the liquid delivery system

(tubing, valves ,...) and the pump

Vent the liquid delivery system and check for

untight fluid connections.

Pump shows cavitation. Too long or too narrow intake tubing.

Shorten the intake tubing or change the

position of the pump.

Polluted or too small filter Change the filter to a new or bigger one.

The non-return valve does not open. Rinse the non-return valve.

7 Speed of the pump cannot be

adjusted.

Defective electric installation Check the electric installation for correct

cable configuration and loose contacts.

Defective drive control Return the drive control unit to the

manufacturer.

Encoder cable disconnected The motor works at high speed. Check the

installation, return the pump to the

manufacturer for checkup.

8 Liquid drops from the dosing

needle.

The non-return valve does not close. Rinse the non-return valve.

Too high pressure on the primary liquid

tank

Stop the delivery of compressed air on the

primary liquid tank.

The liquid tank is at a higher level than the

dosing needle.

Place the liquid tank at the same or slightly

lower level as the pump.

9 Liquid leaks out of the sealing

module.

Too high pressure on the sealing liquid

supply cartridge or defective sealing

Stop pressurizing the sealing liquid supply

cartridge. If needed return the pump to the

manufacturer.

10 Dosage volume decreases with

time.

Polluted filter Exchange the filter.

Deposits in the pump Flush the pump or return it to the

manufacturer for dismantling and cleaning.

The pump is worn after a long operating

period or after use with abrasive liquids.

New definition of the calibration factor of the

pump, by modifying the pump characteristics

graph necessary.

11 Leakage from the pump The sealing does not function correctly. Return the pump to the manufacturer.

12 Leakage from the coupling

assembly

Defective shaft seal Return the pump to the manufacturer in

order to change the shaft sealing.

13 Leakage from the fluid connections Untight locking rings Exchange or tighten the fluid connections,

exchange the fluid connection.

14 Air bubbles on the delivery side. Loose fluid connections (particularly on the

induction (suction) side)

Check and tighten the fluid connections.

The shaft seal is untight or worn. Return the pump to the manufacturer.

15 The error status of the pump cannot

be retrieved.

No connection with the pump Check the supplied voltage.

Check the connection of the interface with

the null-modem cable. Replace the cable if

needed.

The motor control unit does not respond. Turn off the voltage supply for a short time,

then turn it on again. Start the pump

automatically with the integrated control

unit.

16 Minimal leakage during standstill No error, cause relative to the operating

principle

Use a non-return valve.

Place the liquid tank at the same or slightly

lower level as the pump.

17 Excess temperature The surface of the pump is hot. Clean the surface of the pump, rinse the

pump.

The pump operates with difficulty. The pump should be flushed.

Particles in the delivered liquid or deposits

in the pump

The operation of the pump should

immediately be stopped! Return the pump to

10 Problems and their removal Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 37

Disturbance Cause Solution

the manufacturer for cleansing.

Noise of beveling The operation of the pump should

immediately be stopped! Return the pump to

the manufacturer for cleansing and repair.

The motor surface or the motor interior are

too hot.

High temperature indicator in the drive is on.

The motor has been shut down by the

thermistor. Return the pump to the

manufacturer.

18 The pump is noisy. Wear out of the pump or defective

components.

Do not continue to operate the pump, return

it to the manufacturer for maintenance.

19 Overcurrent Particles in the delivered liquid Rinse the pump.

The pump operates with difficulty. Dosing needle is damaged. Needle should be

cleansed, flushed or exchanged.

Tubing on the delivery side, dosing needle or

the non-return valve is blocked. Cleanse,

flush or exchange the components.

Deposits inside the pump. Flush the pump. If necessary return the pump

to the manufacturer.

20 Undervoltage Voltage supply < 12 VDC Check the power supply 24 VDC

21 Overvoltage Voltage supply > 28 VDC Check the power supply 24 VDC. The drive

control unit may be damaged. Return the

pump to the manufacturer.

table 12 Problem shooting

!

If a disturbance that has not been mentioned in the above list, or that makes

the use of the micro annular gear pump unsafe appears, please stop the

operation of the pump without delay and contact HNP Mikrosysteme (see

chapter 11). If needed return the pump to the manufacturer for checkup.

11 EC Directive Operation manual mzr-2961, mzr-4661

38 Technical data subject to change without prior notice! Last update: April 2018

11 EC Directive

A Directive or EC Directive is a legal instrument of the European Community

addressing at the member states and forcing them to implement specific

regulations or targets. Leastwise, micro annular gear pumps are covered, by the

scope of application of the following Directives: The following directives are of

importance for the user of the described micro annular gear pumps:

Low-Voltage Directive (2014/35/EU)

The Low-Voltage Directive is not relevant for micro annular gear pumps

described in this manual, because the supply voltage is limited to a maximum of

30 VDC.

Machinery Directive (2006/42/EU)

A micro annular gear pump is a machine and is consequently covered by this

Directive. However, it may be a part of a machine or installation.

EMC Directive (2014/30/EU)

The Directive on Electromagnetic Compatibility (EMC) applies to all electronic

and electrical devices, installations and systems. Consequently, the Motion

Controller of the micro annular gear pump is covered by the EMC Directive.

RoHS Directive

(2011/65/EU)

To our knowledge our products delivered to you do not contain substances or

applications in concentrations that are forbidden by this directive. No

substances contain our products delivered to you after our current knowledge

in concentrations or application, the

placing on the market in products

according to the valid requirements forbade to the Directive.

WEEE Directive (2002/96/EU)

Disposal of micro annular gear pumps has to be environmentally sound.

All materials and liquids have to be recycled in accordance with the relevant

regulations. Electrical parts can not be disposed of as household waste. They

have to be delivered to designated collection points.

11 EC Directive Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 39

REACH regulation (EC) No. 1907/2006

HNP Mikrosysteme is not a manufacturer or importer of chemical substances

subjected to registration, but in terms of regulation, a downstream user. As

downstream user, we conduct the necessary communication with our suppliers

to ensure future deliveries of all components necessary to us. We will notify you

of all relevant, changes in our products, their availability and the quality of

parts/products delivered by us within our business and coordinate the

appropriate action in individual cases with you. Previous inspection did not

show any limitation in the supply of material from our upstream suppliers.

11.1 Electromagnetic Compatibility (EMC)

Electromagnetic compatibility is defined as the ability of a electric or electronic

device to function satisfactorily as intended in its electromagnetic environment

without introducing intolerable electromagnetic disturbances in that

environment.

11.1.1 EMC Directive and Standards

Comformity was proven by proof of compliance with the following harmonized

standards by the company Dr. Fritz Faulhaber:

− EN 61000-6-4 (10/01): Generic standards – Emission standard for industrial

environments

− EN 61000-6-2 (10/01): Generic standards – Immunity for industrial

environments

These standards prescribe certain standardised tests for the emittedinterference and interference-immunity tests. The following tests are required

due to the connections on the controller:

Generic Standard on Emitted

Interference:

Description

EN 55011 (05/98)+A1(08/99)+A2(09/02): Radio disturbance characteristics

Generic Standard on Interference

Immunity

EN 61000-4-2 (05/95)+A1(4/98)+A2(02/01): Electrostatic discharge immunity test

EN 61000-4-3 (04/02)+A1(10/02): Radiated, radio-frequency, electromagnetic field immunity

test

EN 61000-4-4 (09/04): Electrical fast transient/burst immunity test

EN 61000-4-5 (03/95)+A1(02/01

Surge immunity test

EN 61000-4-6 (07/96)+A1(02/01): Immunity to conducted disturbances, induced by radio-

frequency fields

EN 61000-4-8 (09/93)+A1(02/01): Power frequency magnetic field immunity test

Table 1 Standards Summary

All tests were conducted successfully.

11 EC Directive Operation manual mzr-2961, mzr-4661

40 Technical data subject to change without prior notice! Last update: April 2018

11.1.2 Information on use as intended

For micro annular gear pumps, note the following:

Requirement for the intended operation is the operation according to the

technical data and the manual.

Restrictions

If the micro annular gear pumps are used at home, in business or in commerce

or in small businesses, appropriate measures must be taken to ensure that

emitted interferences are below the permitted limit a values!

11 EC Directive Operation manual mzr-2961, mzr-4661

Last update: April 2018 Technical data subject to change without prior notice! 41

12 Declarations of conformity Operation manual mzr-2961, mzr-4661

42 Technical data subject to change without prior notice! Last update: April 2018

12 Declarations of conformity

The delivered micro annular gear pump falls within scope of the following EC

directives:

− Machinery Directive (2006/42/EU)

− EMC Directive (2014/30/EU)

You may request the declarations of conformity for the micro annular gear

pumps from us separately.

EC-manufacturer’s certificate

(following Machinery Directive 2006/42/EU)

We hereby declare that the following micro annular gear pump of the magnetic

hermetic series:

mzr-2961, mzr-4661

are intended for installation into another machinery/plant and that start of

operation is forbidden until it is identified that the machinery/plant into which

these micro annular gear pumps shall be installed corresponds to the

regulations of the EC guidelines regarding safety and health requirements.

We confirm the conformity of the product described above to the following

standards in terms of applied directives

− Machinery Directive (2006/42/EU)

Applied standards are particularly

DIN EN 809 DIN EN 60204-1 DIN EN 294

DIN EN ISO 12100 part 1 DIN EN 953

DIN EN ISO 12100 part 2 UVV

This statement does not warrant any characteristics in terms of product liability.

Please note the safety instructions in the manual.

Mr. Lutz Nowotka, HNP Mikrosysteme GmbH, Bleicherufer 25, D-19053

Schwerin is authorised to compile the technical file according to Annex VII A.

Date: 17 May 2013

Signature manufacturer:

Dr. Thomas Weisener

CEO

EC-manufacturer’s certificate

(following EMC Directive 2014/30/EU)

We hereby declare that the following micro annular gear pump of the magnetic

hermetic series:

mzr-2961, mzr-4661

are intended for installation into another machinery/plant and that start of

operation is forbidden till it is identified that the machinery/plant into which

these micro annular gear pumps shall be installed corresponds to the

regulations of the EC guidelines regarding safety and health requirements.

We confirm the conformity of the product described above to the following

standards in terms of applied directives

− EMC Directive (2014/30/EU)

Applied standards are particularly

EN 61000-6-4 (10/01): Generic standards – Emission standard for

industrial environments

EN 61000-6-2 (10/01): Generic standards – Immunity for industrial

environments

This statement does not warrant any characteristics in terms of product liability.

Please note the safety instructions in the manual.

Date: 19 April 2016

Signature manufacturer:

Dr. Thomas Weisener

CEO