Page 1

Hardware Manual / Software Manual

T100 Development Kit

Manual

Page 2

HMS Technology Center Ravensburg GmbH

Helmut-Vetter-Straße 2

88213 Ravensburg

Germany

Tel.: +49 751 56146-0

Fax: +49 751 56146-29

Internet: www.hms-networks.de

E-Mail: info-ravensburg@hms-networks.de

Support

In case of unsolvable problems with this product please contact HMS in

written form by:

Fax: +49 751 56146-29

E-Mail: support@ixxat.de

Further international support contacts can be found on our webpage

www.ixxat.com/support

Copyright

Duplication (copying, printing, microfilm or other forms) and the electronic

distribution of this document is only allowed with explicit permission of

HMS Technology Center Ravensburg GmbH. HMS Technology Center

Ravensburg GmbH reserves the right to change technical data without

prior announcement. The general business conditions and the regulations

of the license agreement do apply. All rights are reserved.

Registered trademarks

All trademarks mentioned in this document and where applicable third

party registered are absolutely subject to the conditions of each valid

label right and the rights of particular registered proprietor. The absence

of identification of a trademark does not automatically mean that it is not

protected by trademark law.

Document number: 4.01.0300.20100

Version: 1.6 Release

Page 3

Document history

Date

Version

Change

Editor

24.11.17

1.6

Support of IXXAT Safe T100/FSoE

added. Dynamic non-safe ADI

configuration removed. Flow charts (CIP

Safety IP Address) updated. Cycle Time

attribute described for the first time.

K. Angele

Page 4

Content

Copyright HMS TC Ravensburg GmbH

3

T100 Development Kit Manual,

Version 1.6

Document history .................................................................................. 5

Referenced documents ........................................................................ 5

Abbreviations ........................................................................................ 6

1 Overview ......................................................................................... 7

1.1 Anybus CompactCom objects ............................................. 10

1.2 Functional Safety Object ...................................................... 11

2 Power Supply connection ........................................................... 12

3 Address Switches ........................................................................ 13

3.1 PROFIsafe F-Address ........................................................... 13

3.2 CIP Safety IP Address ........................................................... 14

3.3 FSoE Slave Address ............................................................. 17

4 Enable the Safety module ........................................................... 18

4.1 Communication Cycle Time ................................................. 19

5 Non-safe process data handling ................................................. 20

5.1 PROFINET ............................................................................. 21

5.2 EtherNet/IP ............................................................................ 21

5.3 EtherCAT ............................................................................... 21

5.4 Non-safe input data .............................................................. 22

5.5 Non-safe output data ............................................................ 24

6 Network Configuration ................................................................ 26

6.1 PROFINET (GSDML) ............................................................. 26

6.2 EtherNet/IP ............................................................................ 26

6.2.1 Electronic Data Sheet (EDS) ................................................. 26

6.2.2 Configuration Data String ....................................................... 26

6.2.3 PLC Configuration in RSLogix Designer (Studio 5000) ......... 27

6.2.3.1 Device Identity and Connections .............................. 27

6.2.3.2 SCID (Safety Configuration Identifier) ...................... 28

6.2.3.3 Safety Network Number / TUNID ............................. 29

6.3 EtherCAT (ESI) ...................................................................... 29

7 Fault reset button ......................................................................... 30

7.1 Manual Fault Reset ............................................................... 30

7.2 Automatic Fault Reset .......................................................... 30

8 Reset button ................................................................................. 31

Page 5

Content

Copyright HMS TC Ravensburg GmbH

4

T100 Development Kit Manual,

Version 1.6

9 LED indicators.............................................................................. 32

9.1 PROFIsafe ............................................................................. 32

9.2 CIP Safety .............................................................................. 33

9.3 FSoE ...................................................................................... 33

10 Safety I/O Connectors .................................................................. 34

11 Other components ....................................................................... 35

11.1 Jumper ................................................................................... 35

11.2 Switch S1 ............................................................................... 35

11.3 Pin Header JP18 .................................................................... 35

11.4 JTAG Connector ................................................................... 35

11.5 RS232 connector JP7 ........................................................... 35

12 Web page ...................................................................................... 36

13 Wiring Diagram ............................................................................ 37

14 Product Support and Conformity ............................................... 43

14.1 Support .................................................................................. 43

14.2 Returning hardware .............................................................. 43

14.3 Information on EMC .............................................................. 43

14.4 EC Declaration of Conformity .............................................. 44

Appendix A – ADI Configuration ................................ ........................ 45

ADI 1 ............................................................................................. 45

ADI 2 ............................................................................................. 46

Appendix B – Firmware Upgrade ....................................................... 47

Development Kit board ................................................................ 47

Anybus CompactCom .................................................................. 47

T100 .............................................................................................. 47

Page 6

Referenced documents

Copyright HMS TC Ravensburg GmbH

5

T100 Development Kit Manual,

Version 1.6

Referenced documents

[1] Safety Manual for IXXAT Safe T100

[2] Network Guide Anybus CompactCom 40 PROFINET IRT,

Doc. Id. SCM-1202-023 Rev. 1.4

[3] Network Guide Anybus CompactCom 40 EtherNet/IP,

Doc. Id. SCM-1202-031 Rev. 1.1

[4] Network Guide Anybus Compact Com 40 EtherCAT,

Doc. Id. SCM-1202-034 Rev. 1.4

Page 7

Abbreviations

Copyright HMS TC Ravensburg GmbH

6

T100 Development Kit Manual,

Version 1.6

Abbreviations

ABCC Anybus CompactCom – Network communication module with a

protocol independent software interface.

ADI Application Data Instances – Instance of an application input or

output module which can be used to exchange data e.g. with a PLC.

CB Carrier Board – Printed circuit board of the DevKit that is the mounting

base for the T100 and the ABCC

DevKit Development Kit – Abbreviation for this product.

EDS Electronic Data Sheet – ASCII text file that describes the

characteristics of a CIP device and is used by software tools for

device and network configuration.

ESI EtherCAT Slave Information (EtherCAT Devices Description) – A XML

file that describes the characteristic of an EtherCAT device. The file is

used by software tools for device and network configuration.

GSDML General Station Description Markup Language – In an XML based

language this file describes the characteristics of a PROFINET

device.

MDP Modular Device Profile - The Modular Device Profile defines a

modeling of structures within in a device. Mainly the object dictionary

structure and corresponding behavior of the entries is defined by the

MDP. The intention is to provide an easy way for master and

configuration tools to handle the devices.

PLC Programmable Logic Controller – A programmable electronic device

used in industrial automation to provide logic and sequencing controls

for machinery.

SCCRC Safety Configuration CRC – CRC that covers the device configuration

data.

SCTS Safety Configuration Time Stamp – Safety related signature that

identifies the revision of the device configuration.

SCID Safety Configuration Identifier – Combination of the SCCRC and the

SCTS used to uniquely identify a configuration.

TUNID Target Unique Network Identifier – Uniquely identifies a device in a

CIP Safety Network.

UTC Coordinated Universal Time – Base for the definition of the SCTS and

the Safety Network Number in the TUNID.

Page 8

Overview

Copyright HMS TC Ravensburg GmbH

7

T100 Development Kit Manual,

Version 1.6

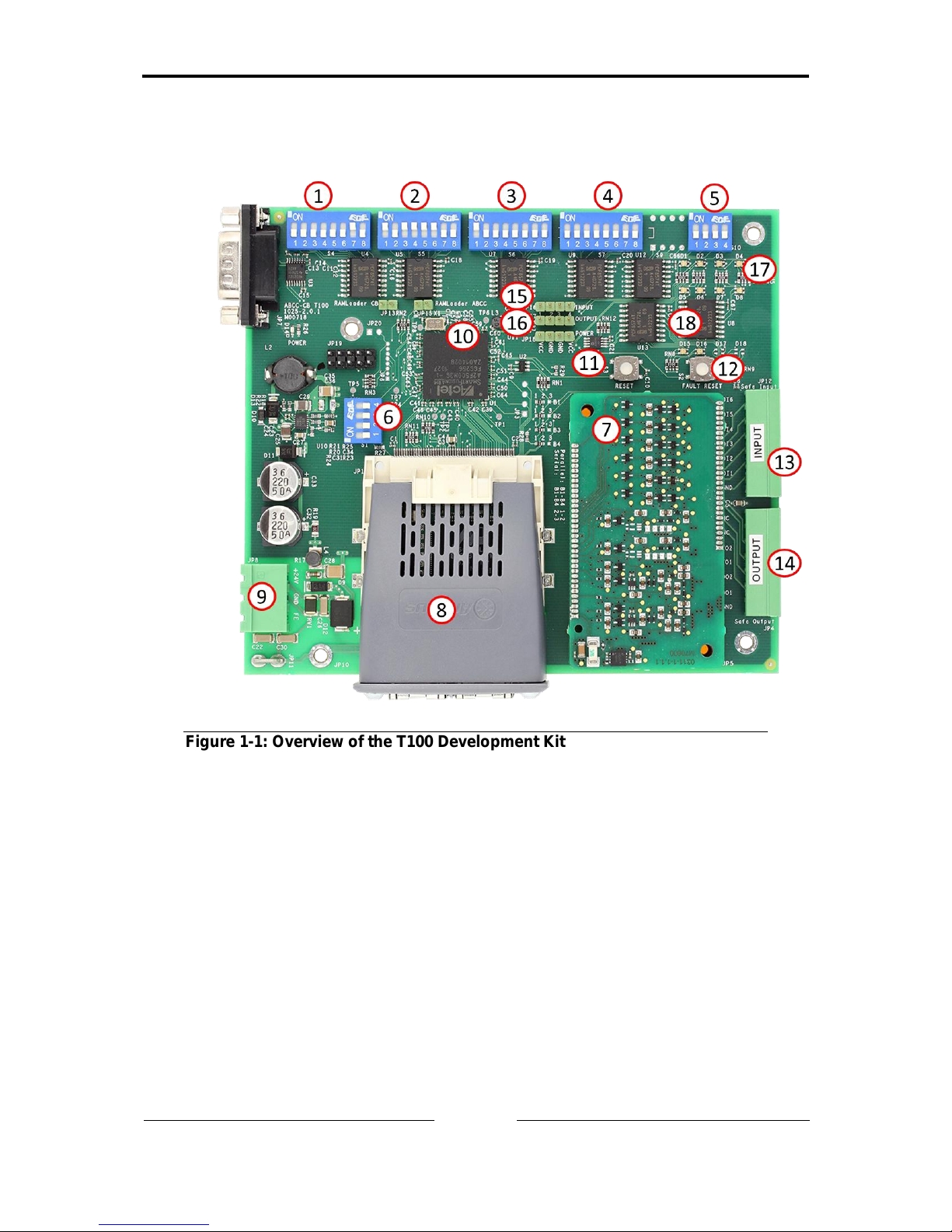

1 Overview

Figure 1-1: Overview of the T100 Development Kit

Page 9

Overview

Copyright HMS TC Ravensburg GmbH

8

T100 Development Kit Manual,

Version 1.6

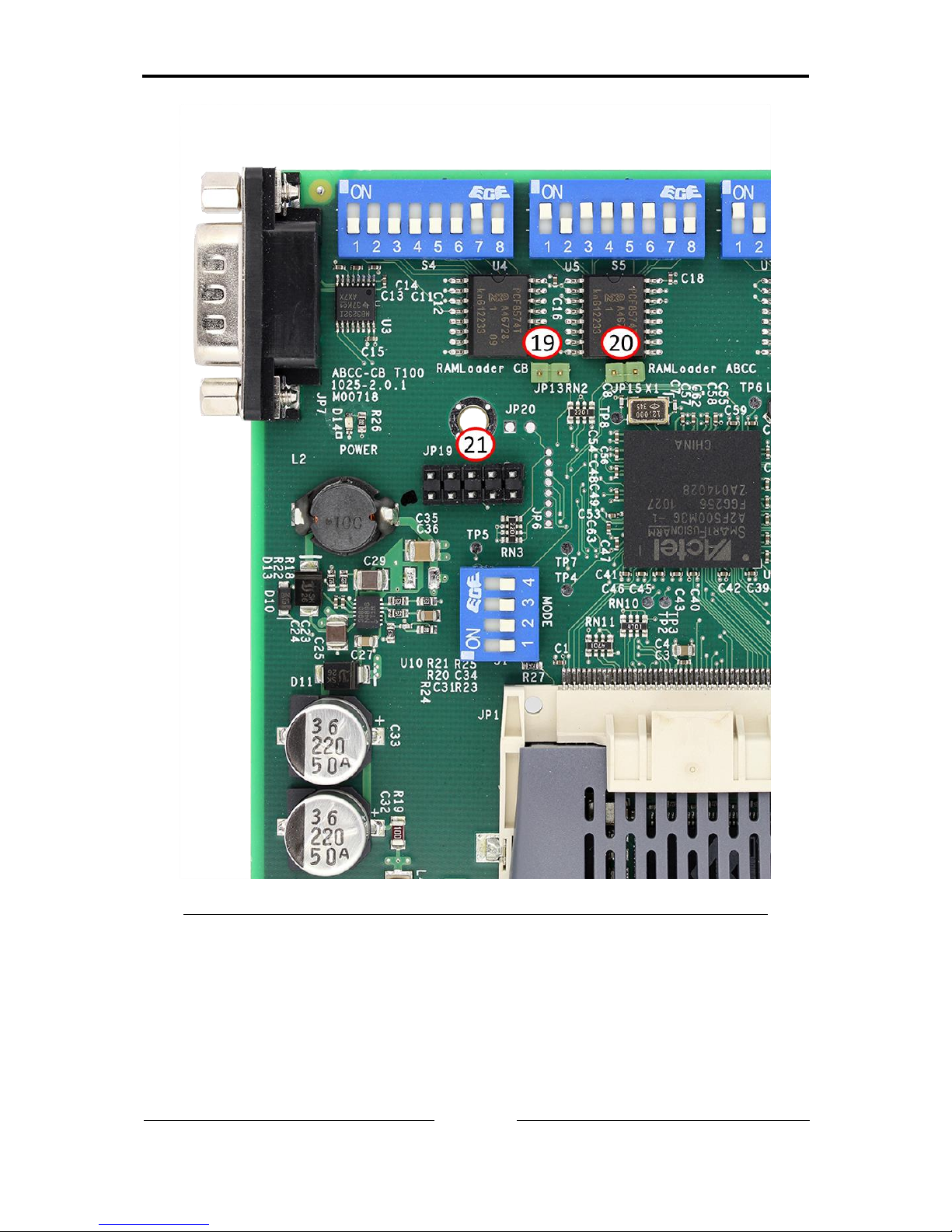

Figure 1-2: Detailed view of the T100 Development Kit

Page 10

Overview

Copyright HMS TC Ravensburg GmbH

9

T100 Development Kit Manual,

Version 1.6

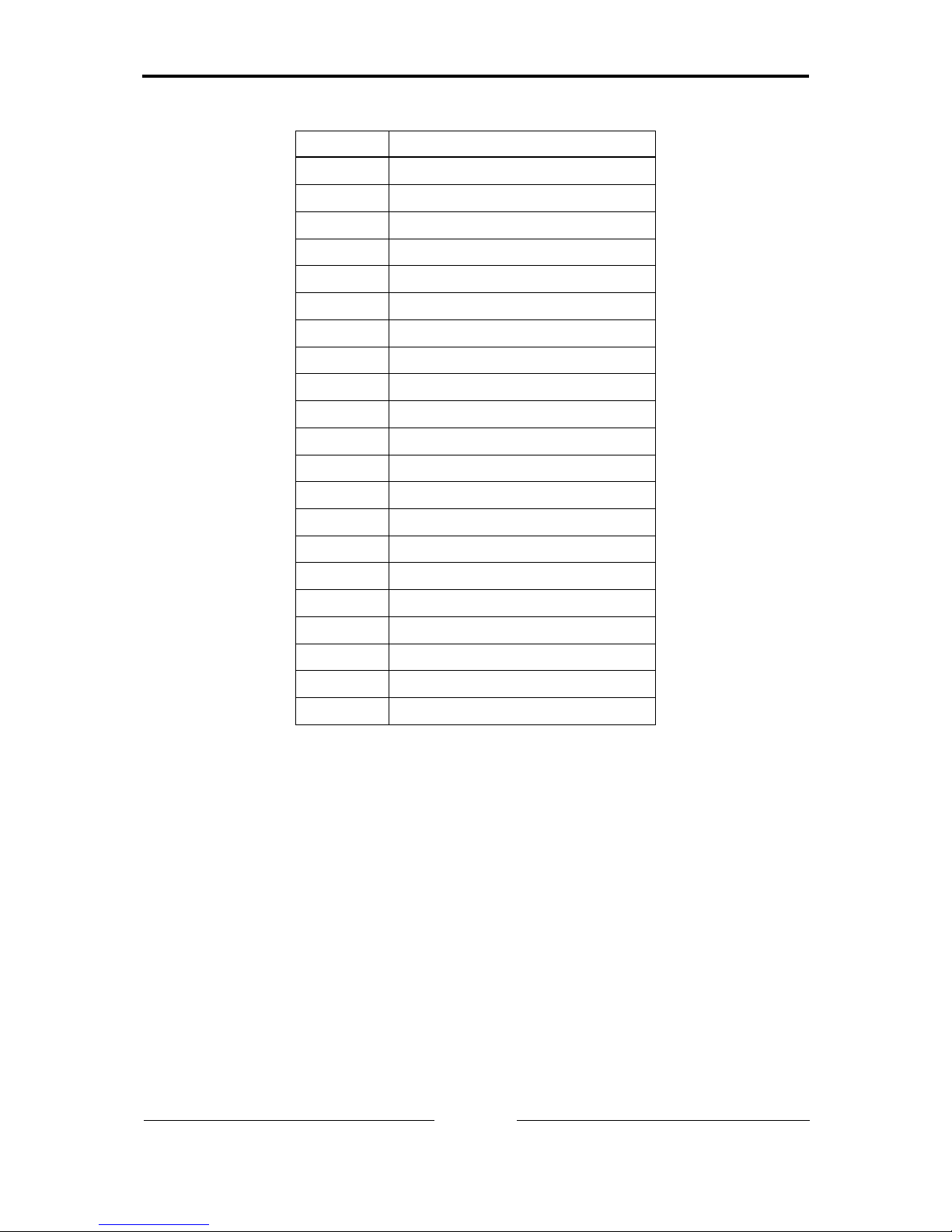

Number

Name

1

Switch S4

2

Switch S5

3

Switch S6

4

Switch S7

5

Switch S10

6

Switch S1

7

Safe T100

8

Anybus CompactCom

9

24V DC Input

10

Host Processor

11

Board Reset

12

Fault Reset

13

Safe Inputs

14

Safe Outputs

15

Non-Safe Inputs JP16

16

Non-Safe Outputs JP17

17

Status LEDs D1-D8

18

User LEDs D15-D16

19

RAMloader CB Jumper 13

20

RAMloader ABCC Jumper 15

21

JTAG Interface JP19

This manual describes the basic functionality and how to use an Anybus

CompactCom (ABCC) with an IXXAT Safe T100/PS, T100/CS or T100/FSoE

module attached. It also describes how the safe and non-safe functionality of

the Development Kit is implemented and used based on a simple I/O demo

application.

The Development Kit consists of a carrier board (CB) hosting an Anybus

CompactCom, an IXXAT Safe T100/PS, T100/CS or T100/FSoE and a host

application microprocessor. For demonstration purposes the host application

microprocessor runs a simple (non-safe) I/O demo. This demo software is also

initializing the IXXAT Safe T100 module via the ABCC object interface which is

described in more details within this manual.

Page 11

Overview

Copyright HMS TC Ravensburg GmbH

10

T100 Development Kit Manual,

Version 1.6

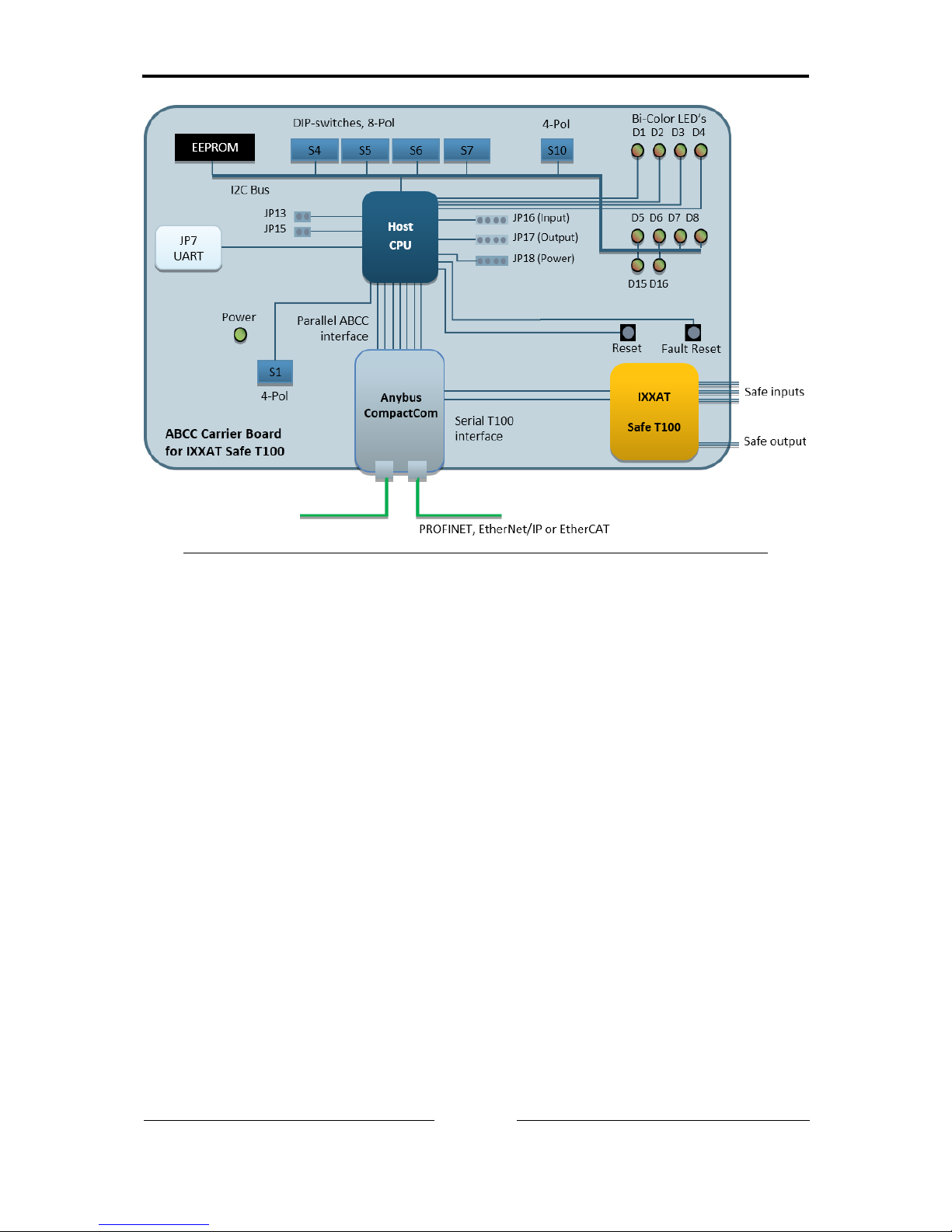

Figure 1-3: Development Kit block diagram

For detailed information about the IXXAT Safe T100 module please refer to

the Safety Manual [1].

In the following sections the Anybus CompactCom objects and host

application objects containing information related to functional safety are

described. Please consult the Anybus CompactCom 40 Network Guide ([2] for

PROFINET, [3] for EtherNet/IP, [4] for EtherCAT) for detailed information

regarding these objects.

1.1 Anybus CompactCom objects

The Anybus CompactCom contains the main control and configuration objects

which are necessary to activate and configure the IXXAT Safe T100 operation.

These objects can be accessed via the following object references (indices):

Functional Safety Module Object (11h)

Network Configuration Object (04h)

Page 12

Overview

Copyright HMS TC Ravensburg GmbH

11

T100 Development Kit Manual,

Version 1.6

1.2 Functional Safety Object

The Functional Safety Object (E8h) is implemented in the host application

processor. It contains information which is relevant for the host application

process.

Page 13

Power Supply connection

Copyright HMS TC Ravensburg GmbH

12

T100 Development Kit Manual,

Version 1.6

2 Power Supply connection

JP8: 24V DC Input (-15% + 20% according to IEC 61131-2)

and Protective Earth

JP11: Protective Earth

Figure 2-1: Power and Protective Earth connectors

Page 14

Address Switches

Copyright HMS TC Ravensburg GmbH

13

T100 Development Kit Manual,

Version 1.6

3 Address Switches

3.1 PROFIsafe F-Address

The F-address is the PROFIsafe address on the network which must be

configured from the host application before “Setup complete” of the Anybus

CompactCom module state machine. The F-address is located in instance #21

“F-Address” of the Network Configuration object in the Anybus CompactCom

module and must match the F-address configured in the PLC for the system to

work.

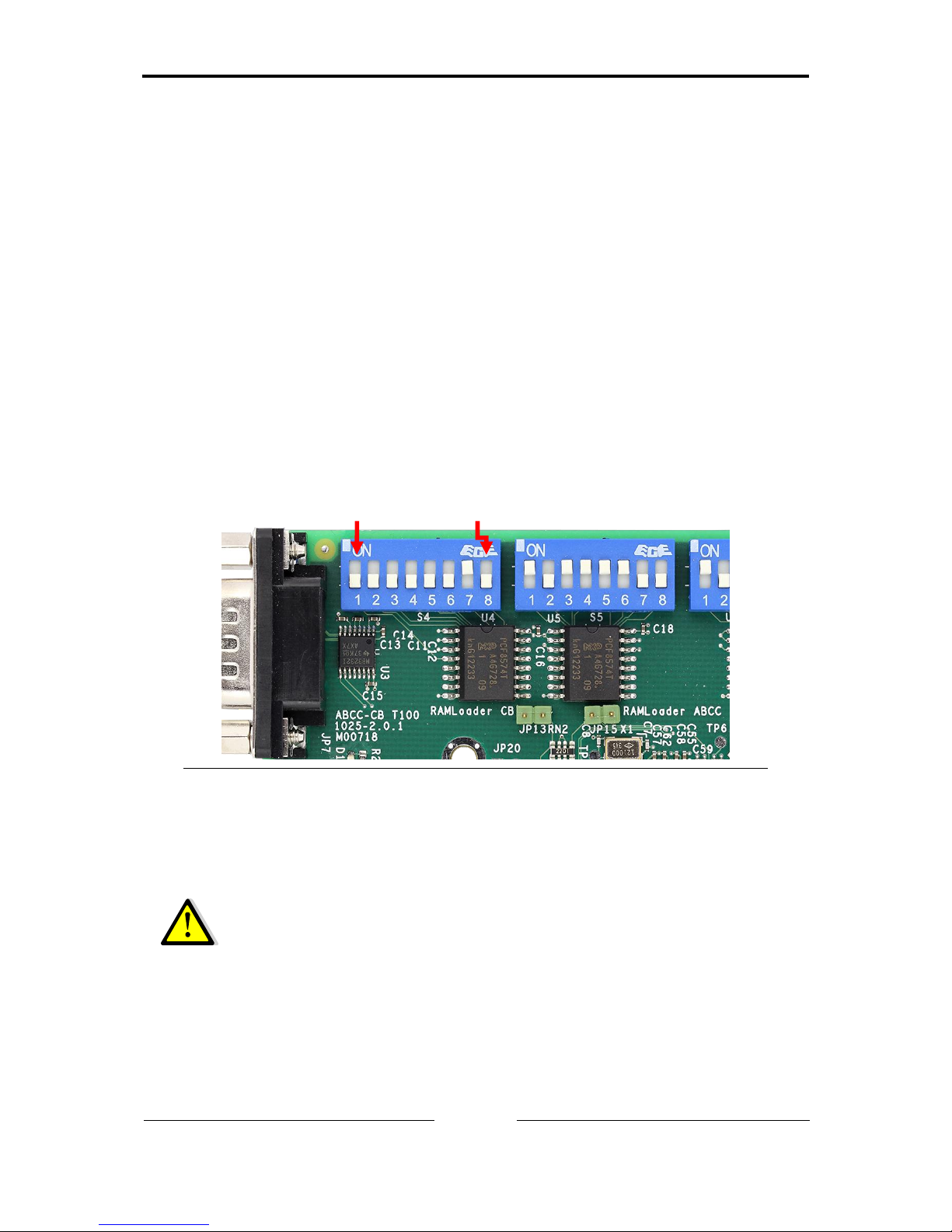

Switches S4 and S5 are used by the Development Kit host application to read

in the value which is then written to the F-Address value attribute. The FAddress is read considering the two DIP-switches as two bytes with the MSB

given by S4 and the LSB given by S5. If the switch lever is down it is

interpreted as OFF/0, if it is up it is interpreted as 1/ON. The range for a valid

F-Address is between 1 and 65534.

Figure 3-1: Switches S4 and S5 to set the PROFIsafe F-Address

Example: The switches in the figure have the F-address 700 – or 00000010

10111100 in binary – configured.

If the F-address value changes (in this case, someone alters S4

and/or S5) during runtime, the new value must be sent from the

host application to the Anybus CompactCom. As the value is only

sent during startup to the IXXAT Safe T100 it will be used after the

next restart of the system.

MSB

LSB

Highest bit

Lowest bit

Page 15

Address Switches

Copyright HMS TC Ravensburg GmbH

14

T100 Development Kit Manual,

Version 1.6

3.2 CIP Safety IP Address

CIP Safety devices can optionally determine their IP-address by means of

hardware switches. In the Development Kit host application Switch S5 is used

for this purpose.

Setting Switch S5 to a value between 1 and 254 indicates that the IP address

of the device is determined by this switch (see Figure 3-2). The IP address of

the device is then set to 192.168.1.switch-value. The subnet mask is set to

255.255.255.0. The default gateway is set either to 192.168.1.1 or (to avoid

equality with the IP address) to 0.0.0.0 in case the switch is set to 1.

For switch settings 0 or 255 the IP address is determined by the Anybus

CompactCom module itself (e.g. DHCP, TCP/IP Object attribute, web server,

etc.).

Setting the IP address configuration is done by writing to the Network

Configuration Object (see [3] for details).

For CIP Safety compliant behavior it is necessary to read and evaluate the

switch value during initialization of the Anybus CompactCom module (before

setting the Anybus Object attribute Startup Complete) according to the

example shown in Figure 3-3, but also to continuously sample the switch value

and react on changes. An example for the ongoing switch value evaluation is

shown in Figure 3-4 (“IP Address Change via Switch”).

Additionally the Development Kit host application has to react if the IP address

of the device was changed by network services (e.g. via TCP/IP Object

attribute). An example how to implement this behavior is also shown in Figure

3-4 (“IP Address Change via Network”).

Figure 3-2: Switch S5 to set IP address of the device.

LSB

Highest bit

Lowest bit

Page 16

Address Switches

Copyright HMS TC Ravensburg GmbH

15

T100 Development Kit Manual,

Version 1.6

INIT==255 OR

INIT==0 ?

FALSE

TRUE

Power-On

DHCP Enabled ?

FALSE

TRUE

Read Switch S5

INIT = S5

Get DHCP Status

(Network Configuration Object 04h

DHCP (Inst#6, Attr#5)

Set IP Address to '1'

(Network Configuration Object 04h)

IP: 192.168.1.1 (Inst#3, Attr#5)

Subnet: 255.255.255.0 (Inst#4, Attr#5)

Gateway: 0.0.0.0 (Inst#5, Attr#5)

DHCP: Disabled (Inst#6, Attr#5)

Set IP Address to 'INIT'

(Network Configuration Object 04h)

IP: 192.168.1.INIT (Inst#3, Attr#5)

Subnet: 255.255.255.0 (Inst#4, Attr#5)

Gateway: 192.168.1.1 (Inst#5, Attr#5)

DHCP: Disabled (Inst#6, Attr#5)

INIT==1 ?

FALSE

TRUE

DeviceIpAddr =

192.168.1.INIT

DeviceIpAddr =

192.168.1.1

DeviceIpAddr =

Value

Get IP Address 'Value'

(Network Configuration Object 04h)

IP (Inst#3, Attr#5)

DeviceIpAddr =

0.0.0.0 (unassigned)

IP Settings valid and

used for communication

Use DHCP

Figure 3-3: Determination of the initial IP-address based on Switch S5

Page 17

Address Switches

Copyright HMS TC Ravensburg GmbH

16

T100 Development Kit Manual,

Version 1.6

INIT <> NEW ?

TRUE

Set IP Address to 'NEW'

(Network Configuration Object 04h)

IP: 192.168.1.NEW (Inst#3, Attr#5)

Gateway: 192.168.1.1 (Inst#5, Attr#5)

FALSE

NEW ==255 OR

NEW==0 ?

TRUE

Read Switch S5

NEW = S5

Loop

Set IP Address to 'NEW'

(Network Configuration Object 04h)

IP: 192.168.1.NEW (Inst#3, Attr#5)

Set IP Address to 'INIT'

(Network Configuration Object 04h)

IP: 192.168.1.INIT (Inst#3, Attr#5)

NEW==1 ?

FALSE

Set IP Address to '1'

(Network Configuration Object 04h)

IP: 192.168.1.1 (Inst#3, Attr#5)

Gateway: 0.0.0.0 (Inst#5, Attr#5)

TRUE

Get IP Address 'CfgIpAddr'

(Network Configuration Object 04h IP

(Inst#3, Attr#6)

FALSE

Set IP Address to 'DeviceIpAddr'

(Network Configuration Object 04h)

IP: SafetyIpAddr (Inst#3, Attr#5)

Set IP Address to 'CfgIpAddr'

(Network Configuration Object 04h)

IP: CfgIpAddr (Inst#3, Attr#5)

DeviceIpAddr =

'CfgIpAddr'

IpAddrChangedEvt

TRUE

'DeviceIpAddr' ==

0.0.0.0

'CfgIpAddr' <>

'DeviceIpAddr'

TRUE

TRUE

FALSE

FALSE

FALSE

IP Address Change via Switch

IP Address Change via Network

Triggers 'Abort' request to

T100/CS

NEW IP address is used

after restet

Restore INIT IP address

Triggers 'Abort' request

to T100/CS

IP Address change request

during runtime

Restore IP address

IP assigned for the first

time e.g. by DHCP

Triggers 'Abort' request

to T100/CS

Flag set if Ethernet Host Object

(Instance 1, Attr. 16) is written

Figure 3-4: Cyclic check for IP Address changes

Page 18

Address Switches

Copyright HMS TC Ravensburg GmbH

17

T100 Development Kit Manual,

Version 1.6

3.3 FSoE Slave Address

The FSoE Slave Address is a unique address inside the communication

system which is used to check whether a FSoE Slave is actually addressed.

The FSoE Slave Address must be configured from the host application before

“Setup complete” of the Anybus CompactCom module state machine. The

FSoE Slave Address is located in instance #21 “FSoE Address” of the Network

Configuration object in the Anybus CompactCom module.

Switches S4 and S5 are used by the Development Kit host application to read

in the value which is then written to the FSoE slave address value attribute.

The FSoE Slave Address is read considering the two DIP-switches as two

bytes with the MSB given by S4 and the LSB given by S5. If the switch lever is

down it is interpreted as OFF/0, if it is up it is interpreted as 1/ON. The range

for a valid FSoE Slave Address is between 1 and 65535.

Figure 3-5: Switches S4 and S5 to set the FSoE Slave Address

The FSoE Slave Address is only sent during startup to the IXXAT

Safe T100/FSoE. So changes in the FSoE Slave Address will only

take effect after the next restart of the Development Kit.

MSB

LSB

Highest bit

Lowest bit

Page 19

Enable the Safety module

Copyright HMS TC Ravensburg GmbH

18

T100 Development Kit Manual,

Version 1.6

4 Enable the Safety module

The host application must enable the safety module by implementing the

Functional Safety Object, and respond with TRUE when a request for the

value of the attribute “Safety enabled” is received during the startup sequence.

More information about the Functional Safety Object can be found in the

Anybus CompactCom PROFINET Network Guide (see [2]) respectively

Anybus CompactCom EtherNet/IP Network Guide (see [3]) respectively

Anybus CompactCom EtherCAT Network Guide (see [4]).

To enable the safety functionality of the IXXAT Safe T100 the host application

needs to respond to the Safety enabled attribute request.

- For PROFIsafe additionally the F-address must be set (see chapter 3.1).

- For CIP Safety additionally the Cycle Time attribute shall be

implemented (see chapter 4.1). Furthermore the host application can

assign the IP address (see chapter 3.2).

- For FSoE additionally the FSoE Slave Address must be set (see chapter

3.3).

All other functional safety related attributes shall be considered as non-safe

status information only.

Switch S6:1 is used by the Development Kit host application to decide if the

safety module shall be enabled or not.

Figure 4-1: Switch S6 with safety functionality enabled.

S6:1

Description

OFF

Safety functionality disabled. Value of DIP-switch has only effect

during start-up.

ON

Safety functionality enabled. Value of DIP-switch has only effect

during start-up.

S6:2 to S6:8 are used for internal tests and should stay in default

position OFF.

S6:1

Page 20

Enable the Safety module

Copyright HMS TC Ravensburg GmbH

19

T100 Development Kit Manual,

Version 1.6

4.1 Communication Cycle Time

The Cycle Time attribute (#4) configures the communication cycle time

between Anybus CompactCom and IXXAT Safe T100 in milliseconds.

For CIP Safety the host application needs to respond to the Cycle Time

attribute request with a value of 4ms.

When using PROFIsafe or FSoE there is no need to implement this attribute

because the expected value of 2ms is the default value used by Anybus

CompactCom.

Page 21

Non-safe process data handling

Copyright HMS TC Ravensburg GmbH

20

T100 Development Kit Manual,

Version 1.6

5 Non-safe process data handling

The Development Kit host application configures the Anybus CompactCom

with two Application Data Instances (ADIs) for development purposes, which

describe the data possible to read and write through the network. For the

functional safety module itself, no ADIs are needed. The configuration and

process data mapping of non-safe data of the ADIs can be configured by

switch S7.

The default behavior can be activated by setting S7:1 to ON and the rest of the

switch to OFF. The default behavior enables using of S10 and JP16 for input

data and D15, D16 and JP17 for output data. The exact usage and handling

will be described in the following chapters.

For information about how the ADIs are configured, see Appendix A.

Figure 5-1: Switch S7 to manage non-safe I/O data

S7:1

Description

OFF

Read process data received from the network is copied and sent as

write process data.

ON

Read process data and write process data is mapped.

S7:2 to S7:8 are reserved and should stay in default position OFF.

S7:1

Page 22

Non-safe process data handling

Copyright HMS TC Ravensburg GmbH

21

T100 Development Kit Manual,

Version 1.6

5.1 PROFINET

Figure 5-2: Physical structure of the control

The non-safe output data is assigned to the Module located in Slot 2, while the

non-safe input data is assigned to the Module located in Slot 3.

5.2 EtherNet/IP

Input data is mapped to assembly instance 100 and outputs are mapped to

instance 150. These assembly instances can be used as connection points for

Class 1 connections (Exclusive-Owner / Listen-Only / Input-Only).

Assembly Instance

Description

100

Non-safe input data

103

Heartbeat, Input-Only

104

Heartbeat, Listen-Only

106

Heartbeat, Input-Only Extended

107

Heartbeat, Listen-Only Extended

150

Non-safe output data

5.3 EtherCAT

Figure 5-3: MDP structure of the Device

ABCC

-

ECT

IXXAT

Safe

T100

Slot 1

Output/

Input

Slot 2

…

ABCC

-

PRT

2 - ports

Slot 0

IXXAT

Safe

T100

Slot 1

Output

Module

1 Byte

Slot 2

Input

Module

1 Byte

Slot 3

…

Page 23

Non-safe process data handling

Copyright HMS TC Ravensburg GmbH

22

T100 Development Kit Manual,

Version 1.6

To use safe and non-safe data in parallel, the device implements the Modular

Device Profile (MDP) approach. Here the device is divided into several slots /

modules whereby each module (or function) can occupy several objects inside

its dedicated index area of the global object dictionary. Since the IXXAT Safe

T100/FSoE is always assigned to Slot 1, the non-safe input data and non-safe

output data module is assigned to Slot 2. The host application implements the

default index instance of 0x10, which leads to the following layout:

Slot

Index

PDO

Description

1

0x6000-0x600F

0x1600

Reserved for IXXAT Safe T100/FSoE

0x7000-0x700F

0x1A00

Reserved for IXXAT Safe T100/FSoE

2

0x6010

0x1601

Non-Safe input Data

0x6011-0x601F

---

Reserved

0x7010

0x1A01

Non-safe output data

0x7011-0x701F

---

Reserved

5.4 Non-safe input data

For modes where write process data (controller input) is mapped the value

may be set using the 4-pole DIP-switch S10 and the 4-pin header JP16. The 4

lower bits are represented by JP16 and the 4 higher bits are represented by

S10. The value is repeated for each byte in the write process data.

Bit 0Bit 3Bit 4Bit 7

S10 JP16

Figure 5-4: Input data represented by S10 and JP16

DIP-switch S10 and JP16 are low active. This means that when all switches of

DIP-switch S10 are off, they are interpreted as 1 and when they are on they

are interpreted as 0. Likewise all pins of pin header JP16 are pulled up

internally to 3.3V when not connected (interpreted as 1) and should be

connected to ground to be interpreted as 0.

For example if nothing is connected to JP16 and only S10:1 and S10:4 are on,

the input value is read as 6F, where 6 corresponds to S10 and F corresponds

to JP16.

Page 24

Non-safe process data handling

Copyright HMS TC Ravensburg GmbH

23

T100 Development Kit Manual,

Version 1.6

JP16 is directly connected to a PCF8574T I2C expander (NXP

Semiconductors) that is operated with 3.3V. For more information check the

datasheet of the PCF8574T.

Figure 5-5: Pin-header JP16 and Switch S10 for non-safe input data

Page 25

Non-safe process data handling

Copyright HMS TC Ravensburg GmbH

24

T100 Development Kit Manual,

Version 1.6

5.5 Non-safe output data

For modes where read process data (controller output) is mapped the value is

provided through the LEDs D15 and D16 and the 4-pin header JP17. The 4

lower bits are provided by JP17 and the 4 higher bits are displayed by LEDs

D15 and D16.

Bit 0Bit 3

JP17D16D15

Bit 4/5Bit 6/7

Figure 5-6: Output data represented by D15, D16 and JP17

Bit

LED

Color

4

D16

Green

5

Red

6

D15

Green

7

Red

Bit value 1 is displayed by the LED being off. So if the LEDs are turned on

green and red at once this shall be interpreted as output Bit sequence 0000, if

they are both green the value displayed is 0101 and if the LEDs are red the

value is 1010. If the LEDs are both off the displayed value is 1111.

JP17 is directly connected to a PCF8574T I2C expander (NXP

Semiconductors) that is operated with 3.3V. For more information check the

datasheet of the PCF8574T.

The non-safe outputs are cleared at the following events:

- Startup of the DevKit

- Provider status of the connected IO Controller is set to BAD

(PROFINET)

- RUN-bit is cleared in the 32-bit Run/Idle header of an Exclusive-Owner

connection (EtherNet/IP)

- Anybus CompactCom is in other state than ‘OPERATIONAL’

(EtherCAT)

- Connection loss

Page 26

Non-safe process data handling

Copyright HMS TC Ravensburg GmbH

25

T100 Development Kit Manual,

Version 1.6

Figure 5-7: Pin-header JP17 and LEDs D15 and D16 for non-safe output

data

Page 27

Network Configuration

Copyright HMS TC Ravensburg GmbH

26

T100 Development Kit Manual,

Version 1.6

6 Network Configuration

6.1 PROFINET (GSDML)

The provided Anybus CompactCom PROFINET GSDML-file is used for the

configuration of the IXXAT Safe T100/PS Development Kit in e.g. Siemens

Step7 or TIA configuration tool. The GSDML-file can be customized for the

end product according to the Anybus CompactCom PROFINET Network

Appendix (see [2]).

Special care has to be taken that the GSDML file part describing the safety

configuration objects are not altered or removed when editing the file.

6.2 EtherNet/IP

6.2.1 Electronic Data Sheet (EDS)

An EDS File is provided with the DevKit for the T100/CS. But depending on

the used PLC and toolchain it may not be possible to use this for configuration

purposes.

At the time this manual was written the EDS file is not usable for configuring

an IXXAT Safe T100/CS in Rockwell Studio 5000 Logix Designer. Thus the

settings for configuring the connections to the DevKit must be entered

manually.

6.2.2 Configuration Data String

The host application automatically configures the T100/CS during startup with

the default configuration data string. See [1] chapter 5.4.2 for details.

Page 28

Network Configuration

Copyright HMS TC Ravensburg GmbH

27

T100 Development Kit Manual,

Version 1.6

6.2.3 PLC Configuration in RSLogix Designer (Studio 5000)

6.2.3.1 Device Identity and Connections

The following figure shows an example for setting up connections for safe

inputs and safe outputs as well as non-safe inputs and outputs. The identity

information in the Module Parameters section may be subject to change (e.g.

Revision).

Figure 6-1: RSLogix Designer Identity and Connection Settings

Page 29

Network Configuration

Copyright HMS TC Ravensburg GmbH

28

T100 Development Kit Manual,

Version 1.6

6.2.3.2 SCID (Safety Configuration Identifier)

An SCID check can be activated on the Safety tab. When the Configuration

Signature check box is activated the PLC will send a Type 2a SafetyOpen

(SCID check active). Figure 6-3 shows the SCID of the DevKit default

configuration data string.

The value in the ID field represents the SCCRC whereas the SCTS can be

entered as a Date and Time value. Please note that the time is entered in the

local time zone of the PC and is being converted to UTC by RSLogix. The

example below was generated in the time zone CEST (UTC + 2h). Thus the

value actually transmitted is 36 000 000 ms (10:00:00.000).

Figure 6-2: RSLogix Designer Configuration Signature Settings

Page 30

Network Configuration

Copyright HMS TC Ravensburg GmbH

29

T100 Development Kit Manual,

Version 1.6

6.2.3.3 Safety Network Number / TUNID

After a download of the above configuration the connection of the PLC may fail

because the TUNID is not yet set (e.g. MS LED blinking red). While being

online click then the button with the 3 dots besides the Safety Network Number

(see Figure 6-1). In the windows that opens enter the Safety Network Number

(time-based or manual) and click “Set”. This will initiate a Propose_TUNID and

Apply_TUNID sequence to assign the TUNID.

Figure 6-3: Setting the TUNID in RSLogix Designer

6.3 EtherCAT (ESI)

An EDS-file is provided with the DevKit for the IXXAT Safe T100/FSoE. The

file is used for the device and network configuration and can be customized for

the end product.

Special care has to be taken that the ESI-file part describing the safety objects

is not altered or removed when editing the file.

Page 31

Fault reset button

Copyright HMS TC Ravensburg GmbH

30

T100 Development Kit Manual,

Version 1.6

7 Fault reset button

The IXXAT Safe T100/PS and the IXXAT Safe T100/FSoE supports only the

Manual Fault Reset mode whereas for the T100/CS this mode is the default

behavior, but is changeable to Automatic Fault Reset mode in the

configuration parameters.

7.1 Manual Fault Reset

When in the Manual Fault Reset mode, the IXXAT Safe T100 module has

entered the fail-state for any of the safe in- or outputs (e.g. due to failed

consistency or clock signal checks). In this case an error confirmation has to

be sent to recover from this error.

There are two ways of sending this error confirmation. The first one is via the

safety PLC and the second one is using the Fault Reset button operated by

the host application. When pressing the Fault Reset button while a fail-state is

present, the IXXAT Safe T100 module will reactivate the safe in- or output

again. If the error which caused the fail-state is still present, the safety module

will immediately enter the fail-state again. Otherwise the normal operation of

the safe in- and outputs is continued.

Figure 7-1: Fault reset button

When pressing the fault reset button, the “Error_Confirmation”-command in the

Functional Safety Module Object is requested from the Anybus CompactCom

module by the host application. As a consequence, the Anybus CompactCom

module sends an error confirmation command to the IXXAT Safe T100 module

which clears all pending channel-errors at once.

7.2 Automatic Fault Reset

This mode only exists for the IXXAT Safe T100/CS. In this mode the Fault

Reset button is inactive. Instead the fault reset behavior is determined by the

Safety Discrete Input Point Objects and Safety Discrete Output Point Objects.

This means that after the input or output returns to the inactive state and after

the corresponding error latch time has expired the fault is reset automatically

and the input or output enters the normal operation again.

Page 32

Reset button

Copyright HMS TC Ravensburg GmbH

31

T100 Development Kit Manual,

Version 1.6

8 Reset button

When pressing the reset button a complete reset of the whole Development Kit

board is performed including the Host processor, the Anybus CompactCom

and the T100.

Figure 8-1: Reset button

Page 33

LED indicators

Copyright HMS TC Ravensburg GmbH

32

T100 Development Kit Manual,

Version 1.6

9 LED indicators

Figure 9-1: LEDs D1 to D8

LEDs D1 and D2 show in red different error codes according to the following

table, where D1 corresponds to the highest bit and D4 to the lowest bit.

D1

D2

Description

OFF

OFF

No error

OFF

ON

ABCC error response or unknown/unsupported network

ON

OFF

Reserved

ON

ON

FATAL ABCC error

LEDs D3 and D4 are reserved for future use and are thus not relevant.

LEDs D5, D6, D7 and D8 reflect the value of the State attribute (#1) of the

Anybus CompactCom Functional Safety Module Object in green color. D5

corresponds to the highest bit and D8 to the lowest bit.

LEDs D5-D8 are all lit red if it is not possible to read out the State

from the Functional Safety Module Object.

9.1 PROFIsafe

The following table shows the possible patterns for the states of the T100/PS.

D5

D6

D7

D8

Description

OFF

OFF

OFF

OFF

Boot

OFF

OFF

OFF

ON

Selftest, Initialization

OFF

OFF

ON

OFF

Parametrization: Wait for F-Address

OFF

OFF

ON

ON

Run

OFF

ON

OFF

OFF

Parameterization:

Wait and Check F- and I-Parameter

ON

ON

ON

ON

Error / Safe State

Page 34

LED indicators

Copyright HMS TC Ravensburg GmbH

33

T100 Development Kit Manual,

Version 1.6

9.2 CIP Safety

The following table shows the possible patterns for the states of the T100/CS.

D5

D6

D7

D8

Description

OFF

OFF

OFF

OFF

BOOT

OFF

OFF

ON

OFF

WAIT_INIT

OFF

OFF

ON

ON

WAIT_TUNID

OFF

ON

OFF

OFF

WAIT_CONFIG

OFF

ON

OFF

ON

INVALID_CONFIG

OFF

ON

ON

OFF

IDLE

ON

OFF

OFF

OFF

EXEC_PROD_ONLY

ON

OFF

OFF

ON

EXEC_CONS_ONLY

ON

OFF

ON

OFF

EXEC_PROD_AND_CONS

ON

ON

OFF

OFF

WAIT_RESET

ON

ON

OFF

ON

INVALID_NODEID

ON

ON

ON

ON

FAILSAFE

9.3 FSoE

The following table shows the possible patterns for the states of the

T100/FSoE.

D5

D6

D7

D8

Description

OFF

OFF

OFF

OFF

BOOT

OFF

OFF

ON

OFF

WAIT_FOR_SADR

OFF

OFF

ON

ON

WAIT_FOR_INIT_LEAVE

OFF

ON

OFF

OFF

PRE_OPERATIONAL

OFF

ON

OFF

ON

SAFE_OPERATIONAL

OFF

ON

ON

ON

WAIT_FOR_FSOE_DATA

ON

OFF

OFF

OFF

FSOE_DATA

ON

ON

ON

ON

FAILSAFE

Page 35

Safety I/O Connectors

Copyright HMS TC Ravensburg GmbH

34

T100 Development Kit Manual,

Version 1.6

10 Safety I/O Connectors

The connectors for safe input and output are connected directly to the Safe

T100 module. See the safety manual [1] for detailed information.

Figure 10-1: Safe Inputs and Safe Outputs

Note that all IXXAT Safe T100 in- and outputs are 24V types.

Therefore they shall never be connected directly to the in- and

outputs of the Development Kit described in section 5.

Safe Input

Safe Output

Page 36

Other components

Copyright HMS TC Ravensburg GmbH

35

T100 Development Kit Manual,

Version 1.6

11 Other components

11.1 Jumper

JP13 is used for software upgrades by HMS. Closing JP13 during power-up

activates the serial bootloader of the host application microprocessor. See also

section 11.5.

JP15 is currently unused.

11.2 Switch S1

Switch S1 is currently unused.

11.3 Pin Header JP18

Pin 1 and 4 are connected to 3.3V. Pin 2 and 3 are connected to ground.

Figure 11-1: Pin header JP18

11.4 JTAG Connector

JP19 is the JTAG interface of the host application microprocessor.

11.5 RS232 connector JP7

JP7 is used for internal software upgrades of the host application

microprocessor by HMS. After activating the serial bootloader (see section

11.1) this interface is used to download new firmware.

Page 37

Web page

Copyright HMS TC Ravensburg GmbH

36

T100 Development Kit Manual,

Version 1.6

12 Web page

When accessing the Anybus CompactCom with a browser it is possible to read

out software versions, uptime of the Anybus CompactCom and other helpful

information. To do so enter the IP of the Anybus CompactCom in the address

field of a browser of your choice – for example Firefox. You will have the

possibility to view the parameter data, which includes the version of the Host

firmware. The network interface contains information about the Anybus

CompactCom.

Page 38

Wiring Diagram

Copyright HMS TC Ravensburg GmbH

37

T100 Development Kit Manual,

Version 1.6

13 Wiring Diagram

Figure 13-1: Wiring Diagram

Page 39

Wiring Diagram

Copyright HMS TC Ravensburg GmbH

38

T100 Development Kit Manual,

Version 1.6

Page 40

Wiring Diagram

Copyright HMS TC Ravensburg GmbH

39

T100 Development Kit Manual,

Version 1.6

Figure 13-2: Wiring Diagram

Page 41

Wiring Diagram

Copyright HMS TC Ravensburg GmbH

40

T100 Development Kit Manual,

Version 1.6

Figure 13-3: Wiring Diagram

Page 42

Wiring Diagram

Copyright HMS TC Ravensburg GmbH

41

T100 Development Kit Manual,

Version 1.6

Figure 13-4: Wiring Diagram

Page 43

Wiring Diagram

Copyright HMS TC Ravensburg GmbH

42

T100 Development Kit Manual,

Version 1.6

Figure 13-5: Wiring Diagram

Page 44

Product Support and Conformity

Copyright HMS TC Ravensburg GmbH

43

T100 Development Kit Manual,

Version 1.6

14 Product Support and Conformity

14.1 Support

For more information on our products, FAQ lists and installation tips, please

refer to the support area on our homepage (http://www.ixxat.de). There you

will also find information on current product versions and available updates.

14.2 Returning hardware

If it is necessary to return hardware to us, please download the relevant RMA

form from our homepage and follow the instructions on this form.

14.3 Information on EMC

The product is a class A device according to EN 55011. If the product is used

in office or home environment radio interference can occur under certain

conditions. To ensure faultless operation of the device, the following

instructions must be followed due to technical requirements of EMC:

▪ use only the included accessories

▪ the shield of the interfaces must be connected with the device plug and

with the plug on the other side

Page 45

Product Support and Conformity

Copyright HMS TC Ravensburg GmbH

44

T100 Development Kit Manual,

Version 1.6

14.4 EC Declaration of Conformity

IXXAT Automation declares, that the product:

Anybus CompactCOM carrier board T100 (1025-2.0.1)

with the article number: 022381-B

complies with the EU directive 2004/108/EC.

Applied harmonized standards: EN 61000-4-2:2009

EN 61000-4-3:2006+A1:2008

EN 61000-4-4:2013

EN 61000-4-5:2006

EN 61000-4-6:2010

EN 61000-4-11:2010

EN 61000-6-2:2005

EN 61000-6-4:2011

IEC 61326-3-1:2008

13.08.2014, Dipl.-Ing. Christian Schlegel, Managing Director

HMS Technology Center Ravensburg GmbH

Helmut-Vetter-Strasse 2

88213 Ravensburg

Page 46

Appendix A – ADI Configuration

Copyright HMS TC Ravensburg GmbH

45

T100 Development Kit Manual,

Version 1.6

Appendix A – ADI Configuration

The Application Data Object (#254) hosts the following Object Attributes:

#

Name

Value

1

Name

“Application Data”

2

Revision

2

3

Number of instances

4 4 Highest instance number

4

11

Number of read process data map-able instances

1

12

Number of write process data map-able instances

1

ADI 1

#

Name

Access

Rule

Data type

Value

1

Name

Get

Array of

CHAR

“Unsafe Output Data”

2

Data type

Get

UINT8

UINT8

3

Number of

elements

Get

UINT8

1

4

Descriptor

Get

UINT8

Bit field describing the access

rights, etc. of instance value

bit 0: 0 = NO get access

bit 1: 1 = Set access

bit 2: 0 - Reserved

bit 3: 0 = Write process data

mapping NOT possible

bit 4: 1 = Read process data

mapping possible

5

Value

Get

UINT8

Depending on switch S7, see

chapter 5.

6

Max value

Get

UINT8

255

7

Min value

Get

UINT8

0

8

Default

value

Get

UINT8

0

The Application Data Instance 1 is mapped to Write Process Data.

Page 47

Appendix A – ADI Configuration

Copyright HMS TC Ravensburg GmbH

46

T100 Development Kit Manual,

Version 1.6

ADI 2

#

Name

Access

Rule

Data type

Value

1

Name

Get

Array of

CHAR

“Unsafe Input Data”

2

Data type

Get

UINT8

UINT8

3

Number of

elements

Get

UINT8

UINT8

4

Descriptor

Get

UINT8

Bit field describing the access

rights, etc. of instance value

bit 0: 1 = Get access

bit 1: 0 = NO set access

bit 2: 0 - Reserved

bit 3: 1 = Write process data

mapping possible

bit 4: 0 = Read process data

mapping NOT possible

5

Value

Get

UINT8

Depending on switch S7, see

chapter 5.

6

Max value

Get

UINT8

255

7

Min value

Get

UINT8

0

8

Default

value

Get

UINT8

0

The Application Data Instance 2 is mapped to Read Process Data.

Page 48

Appendix B – Firmware Upgrade

Copyright HMS TC Ravensburg GmbH

47

T100 Development Kit Manual,

Version 1.6

Appendix B – Firmware Upgrade

Development Kit board

The update of the host software is possible using the serial interface (see

section 11.5). For more information about the update process and the required

tools and firmware contact the HMS support team

(https://www.ixxat.com/support).

Anybus CompactCom

It is very important that the following steps are performed in correct order.

Otherwise the module may be unusable and must be sent back to HMS for

recovery.

1. Initialize the module (power it).

2. Download the file *.hms (30 series) or *.hiff (40 series) via FTP to the

module root (30 series) or the firmware folder (40 series). To download

the file to the ABCC, windows explorer (not internet explorer) may be

used. In the address bar, enter “ftp://aa.bb.cc.dd” without quotes, where

aa.bb.cc.dd is the IP address of the Anybus CompactCom. Then drag

the firmware file to this explorer window. Alternatively the HMS

Firmware Manager II can be used to execute the firmware update.

3. After reboot (power off and on), the MS LEDs will start toggling

green/red. In the 30 series modules this toggling sequence is followed

by approximately 10 seconds of no LED activity. When the LED test

sequence is displayed, it is OK to power cycle the Development Kit. Do

not turn off the power before the LED test sequence of the MS and NS

LED (both LEDs first green, then red) is shown. When updating a 40

series module it must be waited until all Anybus CompactCom LEDs are

turned off before rebooting.

4. Power cycle the module. With a 30 series module wait until the MS LED

flashes green/red. This may take up to 1 minute, the LED will then be

turned off and the format of the file system will begin. This can take up

to another minute. (Do absolutely not turn off the power during this

time!)

5. Update complete!

T100

See [1].

Loading...

Loading...