Page 1

CAN@net NT

100/200/420

USER MANUAL

4.01.0332.20000 1.8 en-US ENGLISH

Page 2

Important User Information

Disclaimer

The information in this document is for informational purposes only. Please inform HMS Networks of any

inaccuracies or omissions found in this document. HMS Networks disclaims any responsibility or liability for any

errors that may appear in this document.

HMS Networks reserves the right to modify its products in line with its policy of continuous product development.

The information in this document shall therefore not be construed as a commitment on the part of HMS Networks

and is subject to change without notice. HMS Networks makes no commitment to update or keep current the

information in this document.

The data, examples and illustrations found in this document are included for illustrative purposes and are only

intended to help improve understanding of the functionality and handling of the product. In view of the wide range

of possible applications of the product, and because of the many variables and requirements associated with any

particular implementation, HMS Networks cannot assume responsibility or liability for actual use based on the data,

examples or illustrations included in this document nor for any damages incurred during installation of the product.

Those responsible for the use of the product must acquire sufficient knowledge in order to ensure that the product

is used correctly in their specific application and that the application meets all performance and safety requirements

including any applicable laws, regulations, codes and standards. Further, HMS Networks will under no circumstances

assume liability or responsibility for any problems that may arise as a result from the use of undocumented features

or functional side effects found outside the documented scope of the product. The effects caused by any direct or

indirect use of such aspects of the product are undefined and may include e.g. compatibility issues and stability

issues.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 3

Table of Contents

Page

1 User Guide ........................................................................................................................... 3

1.1 Target Audience............................................................................................................... 3

1.2 Related Documents ......... ................................................................................................. 3

1.3 Document History ............................................. ... ............... ... ... ... ............ ... ... ... ............ ... 3

1.4 Trademark Information ..... ... ... ............ ... ... .................. ... ...................................................3

1.5 Conventions....................................................................................................................4

2 Safety Instructions .............................................................................................................. 5

2.1 General Safety Instructions ........... ... ... ... .................. .......................................................... 5

2.2 Intended Use................................................................................................................... 5

3 Scope of Delivery ................................................................................................................ 6

4 Product Description ............................................................................................................ 7

4.1 Features . ... ... ... ............ ... ... ... ......... ... ... ... .................. ... ...................................................7

4.2 Operational Modes .......................................................................................................... 8

4.3 Add-Ons for Customer Specific Expansions ......................................................................... 10

5 Installation......................................................................................................................... 11

5.1 Installing the Software .................................................................................................... 11

5.2 Installing the Hardware ................................................................................................... 11

5.3 Checking and Updating the Firmware ................................................................................ 13

6 Configuration..................................................................................................................... 15

6.1 Connecting Possibilities ............................... ... ... ............... ... ... ... ......... ... ... ... ............... ... .. 15

6.2 Basic Configuration ............................................................................................. ........... 16

6.3 Configuration of Interface Modes (ASCII, VCI, ECI).......................................... .................. ... . 20

6.4 Configuration of Bridge Modes (Local CAN, CAN-Eth-CAN) ................................................ .... 21

6.5 Downloading the Configuration with Linux ....................................................... ... ............... 22

6.6 Reset to Factory Settings ... ... ... ............... ... ..................... ................................................. 23

6.7 Read and erase LOG File..... ... ... ... ............ ... ... ... ............ ... ... .................. ... ........................ 23

7 Operation........................................................................................................................... 24

7.1 Ethernet Port ................................. ... ............... ... ... ... ......... ... ... ... ... ............ ... ... ............. 24

7.2 Mini USB Port................................................... .................. ... ... ............... ... ... ... ......... ... . 24

7.3 Indicators .......................................................................... ..................... ... ............... ... . 25

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 4

8 Default Network Settings ................................................................................................. 27

9 Default TCP/UDP Ports ..................................................................................................... 27

10 Technical Data ................................................................................................................... 27

11 Support/Return Hardware................................................................................................ 28

11.1 Support ........................................................................................................................ 28

11.2 Return Hardware ........................................................................................................... 28

12 Disposal.............................................................................................................................. 28

A Regulatory Compliance ..................................................................................................... 29

A.1 EMC Compliance (CE) ...................... .................. ... ... ............ ... ... ... ... ......... ... ... ... ............. 29

A.2 FCC Compliance Statement ................................................................................... ........... 29

A.3 Disposal and recycling..................................................................................................... 30

B UL Ordinary Locations (Ord.Loc.) ..................................................................................... 31

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 5

User Guide 3 (32)

1 User Guide

Please read the manual carefully. Make sure you fully understand the manual before using the

product.

1.1 Target Audience

This manual addresses trained personnel who are familiar with CAN, CAN FD and the applicable

national standards. The contents of the manual must be made available to any person

authorized to use or operate the product.

1.2 Related Documents

Document

Installation Guide VCI Driver

Software Design Guide CAN@net NT 100/200/420 Generic Protocol for Gateway

Mode

User Manual CAN-Gateway Configurator

User Manual CAN@net NT/CANbridge NT Lua ADK

User Manual CAN@net NT C-API

Author

HMS

HMS

HMS

HMS

HMS

1.3 Document History

Version

1.0

1.1

1.2

1.3

1.4

1.5 January 2019

1.6

1.7

1.8

Date

July 2016 First release

October 2016 Adjusted to new Ixxat CAN-Gateway Configurator

July 2017 Changes in configuration tool, added CAN@net NT 420

November 2017

April 2018 Moved parts of the configuration to user manual of CAN-Gateway Configurator

March 2019 Layout changes

March 2020 Added CAN@net NT 100 and new features, structural changes

December 2020 Added UL listing, adjusted links

Description

Minor corrections

New CAN-Gateway-Configurator version

1.4 Trademark Information

Ixxat®is a registered trademark of HMS Industrial Networks. All other trademarks mentioned in

this document are the property of their respective holders.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 6

User Guide 4 (32)

1.5 Conventions

Instructions and results are structured as follows:

► instruction 1

► instruction 2

→ result 1

→ result 2

Lists are structured as follows:

• item 1

• item 2

Bold typeface indicates interactive parts such as connectors and switches on the hardware, or

menus and buttons in a graphical user interface.

This font is used to indicate program code and other

kinds of data input/output such as configuration scripts.

This is a cross-reference within this document: Conventions, p. 4

This is an external link (URL): www.hms-networks.com

Safety advice is structured as follows:

Cause of the hazard!

Consequences of not taking remediate action.

How to avoid the hazard.

Safety signs and signalwords are used dependent on the level of the hazard.

This is additional information which may facilitate installation and/or operation.

This instruction must be followed to avoid a risk of reduced functionality and/or damage

to the equipment, or to avoid a network security risk.

Caution

This instruction must be followed to avoid a risk of personal injury.

WARNING

This instruction must be followed to avoid a risk of death or serious injury.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 7

Safety Instructions 5 (32)

2 Safety Instructions

Risk of interference to radio and television if used in office or home environment!

Use exclusively included accessories. Use exclusively shielded cables.

Make sure that the shield of the interface is connected with the device plug and the plug

on the other side.

Malfunction caused by extension cable!

According to the USB specification connect the interface directly or via an active USB hub

to the computer. Do not use an extension cable.

2.1 General Safety Instructions

► Protect product from moisture and humidity.

► Protect product from too high or too low temperature (see Technical Data, p. 27).

► Protect product from fire.

► Do not paint the product.

► Do not modify or disassemble the product. Service must be carried out by HMS Industrial

Networks.

► Store products in dry and dust-free place.

2.2 Intended Use

The components are used to connect computer systems to CAN and CAN FD networks and to

connect the networks with each other. They are intended for installation on standard DIN rail.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 8

Scope of Delivery 6 (32)

3 Scope of Delivery

Included in scope of delivery:

• CAN@net NT

• 1 x power connector

• 2 x CAN connector (with CAN@net NT 200)

4 x CAN connector (with CAN@net NT 420)

• User Manual CAN@net NT

• Installation Guide VCI Driver

• Mini USB cable

The following is available for download on the CAN@net NT support pages on

www.ixxat.com/support-bridges-gateways:

• CAN-Gateway Configurator

• VCI driver

• User Manual CAN-Gateway Configurator for CAN@net NT and CANbridge NT

• Software Design Guide CAN@net NT 100/200/420 Generic Protocol for Gateway Mode

• User Manual CAN@net NT/CANbridge NT Lua ADK

• User Manual CAN@net NT C-API ixcan

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 9

Product Description 7 (32)

4 Product Description

To use all features the latest version of the CAN-Gateway Configurator as well as the latest firmware of

the CAN@net NT must be installed. For documentation of firmware versions below V6 contact Ixxat

support.

The CAN@net NT hardware provides connectivity to Ethernet and CAN networks with various

operational modes. The CAN@net NT 420 additionally is capable of CAN FD. The application

firmware provides functions to access a CAN bus from virtually every Ethernet TCP/IP host. The

CAN@net NT provides message filtering, based on CAN identifiers, for Bridge and Gateway mode

in the direction from CAN system to TCP/IP network. In the Gateway mode the filter can be

configured by ASCII commands. In the Bridge mode the configuration tool is used to configure

the filter. With the VCI driver the CAN@net NT can be used as a PC interface.

4.1 Features

• CAN@net NT 100: 1 x CAN connections (D-Sub 9 connector)

• CAN@net NT 200: 2 x CAN connections (terminal adapters)

• CAN@net NT 420: 4 x CAN connections (terminal adapters), via the CAN-Gateway

Configurator two connections can be switched between Classic CAN and CAN FD

• 1 x RJ45 Ethernet port, 10/100 Mbit/s

• 1 x mini USB 2.0 port, high-speed

• CAN/CAN FD according to ISO 11898-1:2015

• CAN high speed according to ISO 11898-2:2016

• configuration via USB or Ethernet

• platform independent due to ASCII protocol

• With the CAN-Gateway Configurator a configuration can be created, modified, written to

and read from the target device via USB or Ethernet connection.

The configuration of the following features are described in detail in the User Manual CAN-

Gateway Configurator CANbridge NT & CAN@net NT 100/200/420:

• Classic CAN/CAN FD ID filtering (mapping)

• Classic CAN to CAN FD mapping and CAN FD to Classic CAN mapping (with NT 420)

• J1939 mapping

• cyclic transmission of CAN messages

• MQTT and syslog functionality

• command line program CANGWfile (available for Windows and Linux)

• action rules via if-this-action-then-that-event functionality

• remote access via ASCII protocol

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 10

Product Description 8 (32)

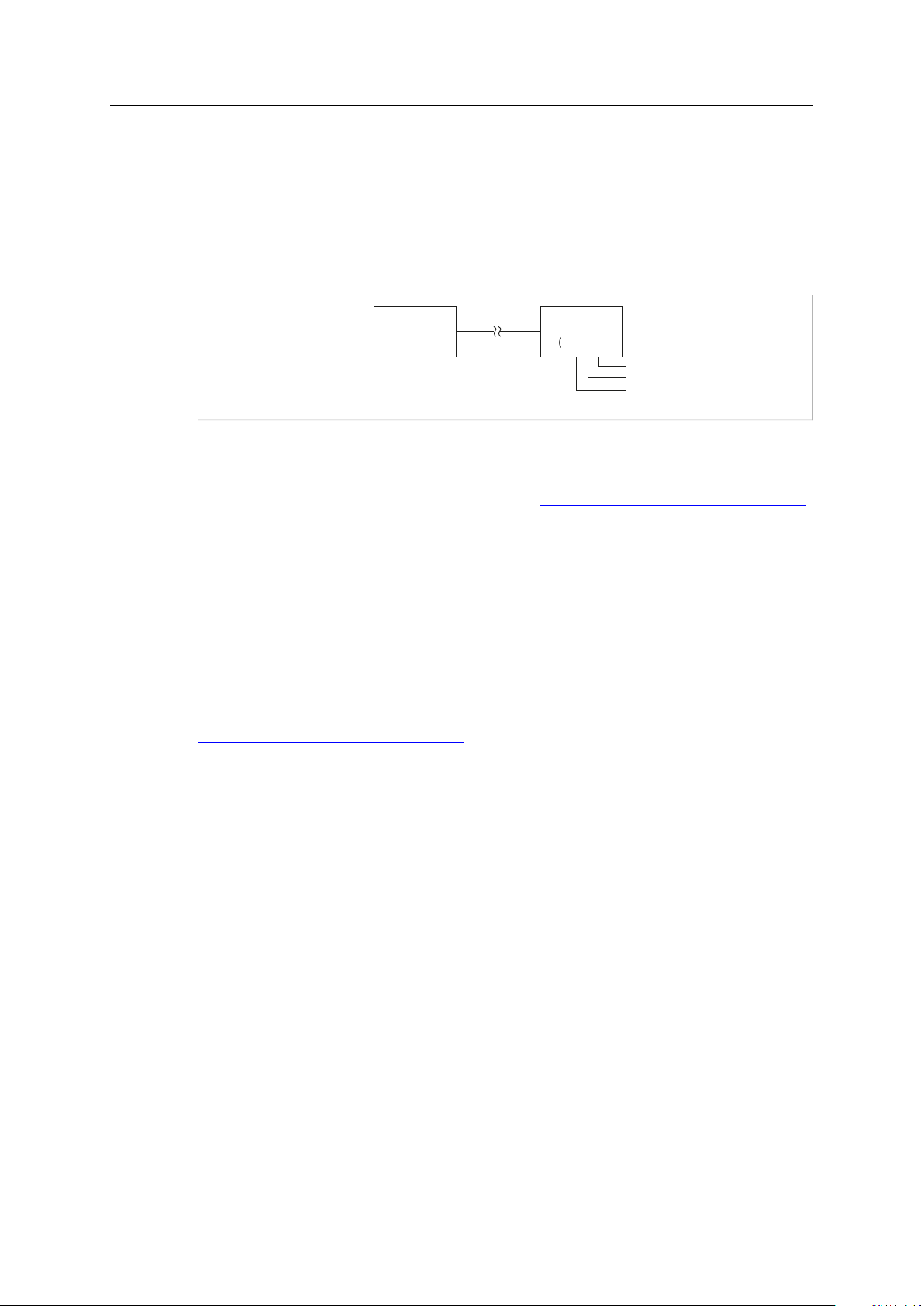

CAN@net NT

(Gateway)

Host System

1

4

3

2

CAN

CAN or CAN-FD

1+2:

3+4:

4.2 Operational Modes

4.2.1 ASCII Gateway Mode

In the Gateway mode, the CAN@net NT is hooked to the local intranet or internet (firewall

needed). This allows a TCP/IP host within the reach of this intranet or internet to connect to the

CAN@net NT and gain control of the CAN system. The Ethernet TCP/IP host can exchange

commands and CAN messages using the ASCII protocol. The server relays the commands and

messages to the CAN bus and vice versa.

Fig. 1 Gateway mode

For information about the communication in Gateway mode and commands that are used to

exchange CAN messages see Software Design Guide CAN@net NT 100/200/420 Generic Protocol

for Gateway Mode on CAN@net NT support pages on www.ixxat.com/support-bridges-gateways.

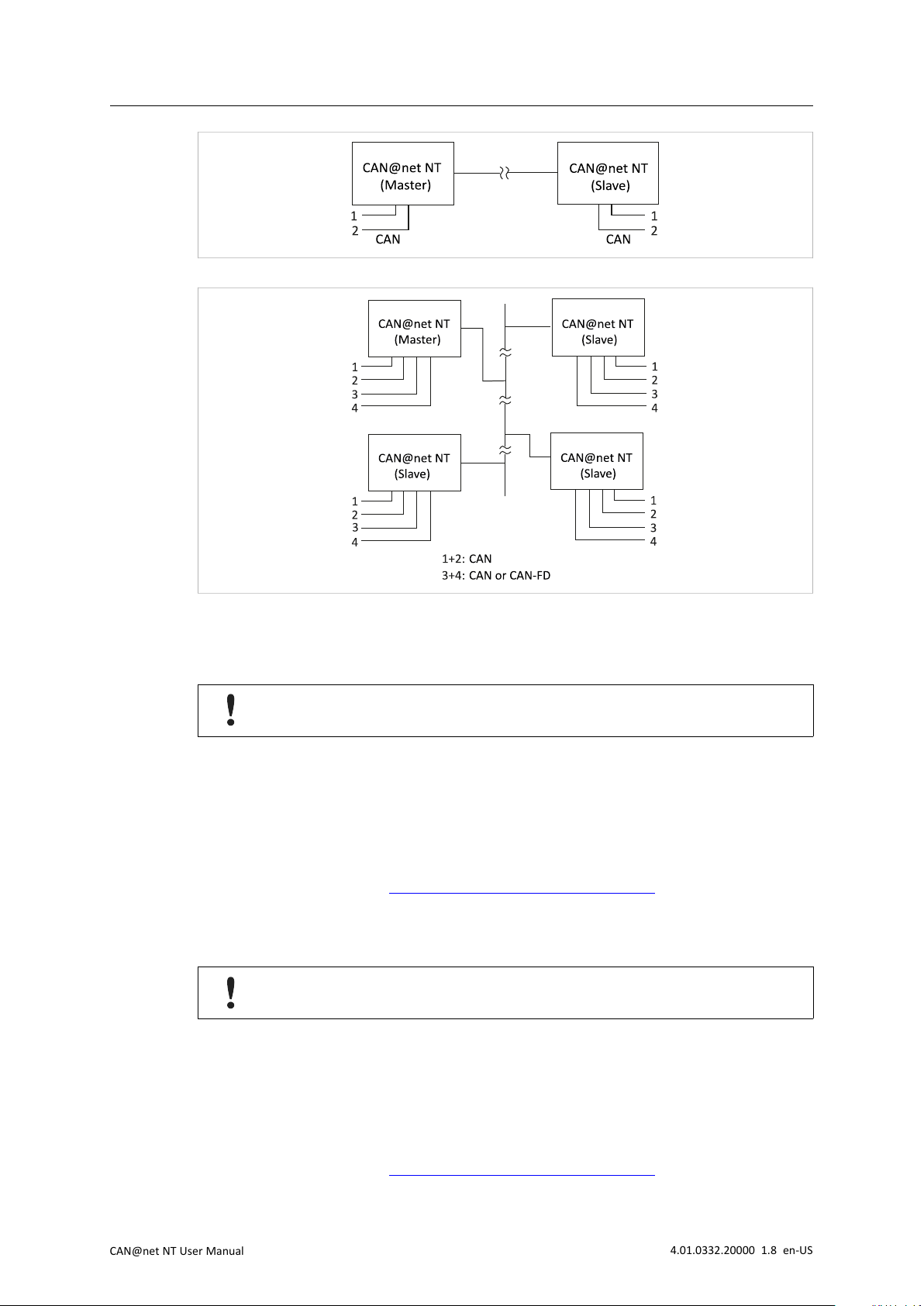

4.2.2 Bridge Modes

A single device can be used as Local CAN Bridge, which allows to map individual messages from

and to each CAN port of the device. The CAN-Ethernet-CAN Bridge mode allows to connect CAN

systems over an Ethernet TCP/IP network, for example the local intranet or the internet (firewall

needed). Minimum two devices are required for a CAN-Ethernet-CAN Bridge. One must be

configured as master and one as slave.

For detailed descriptions of the features in the different modes (e.g. MQTT, Action Rules, cyclic

transmission) and information about the configuration see User Manual CAN-Gateway

Configurator CANbridge NT & CAN@net NT 100/200/420 on the support pages on

www.ixxat.com/support-bridges-gateways.

Possible Bridge Modes with CAN@net NT 100:

• Local CAN Bridge

• CAN-Ethernet-CAN Bridge with 2 devices

Possible Bridge Modes with CAN@net NT 200:

• Local CAN Bridge

• CAN-Ethernet-CAN Bridge with 2 devices

Possible Bridge Modes with CAN@net NT 420:

• Local CAN Bridge

• CAN-Ethernet-CAN Bridge with 2 devices

• CAN-Ethernet-CAN Bridge with 3 devices

• CAN-Ethernet-CAN Bridge with 4 devices

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 11

Product Description 9 (32)

CAN

CAN@net NT

(Slave)

CAN@net NT

(Master)

2

1

2

CAN

CAN

CAN@net NT

(Slave)

CAN@net NT

(Master)

CAN or CAN-FD

1

4

3

2

1+2:

3+4:

1

4

3

2

CAN@net NT

(Slave)

1

4

3

2

CAN@net NT

(Slave)

1

4

3

2

Fig. 2 CAN-Ethernet-CAN Bridge with 2 devices (NT 200)

Fig. 3 CAN-Ethernet-CAN Bridge with 4 devices (NT 420)

4.2.3 VCI Interface Mode

The VCI interface mode is only possible via Ethernet.

With the VCI driver the CAN@net NT can be used as a PC interface with Windows. All VCI-based

Ixxat tools as well as customer-specific applications based on the VCI driver can be used. The VCI

driver offers the possibility to communicate with up to 128 CAN@net NT devices via LAN or

internet. The CAN@net NT 420 additionally is capable of CAN FD.

For information about the communication in the VCI mode and commands that are used to

exchange CAN messages see Software Design Guides in the VCI download package (available on

the product support pages on www.ixxat.com/support-bridges-gateways).

4.2.4 ECI Interface Mode

The ECI interface mode is only possible via Ethernet.

With the ECI driver the CAN@net NT can be used as a PC interface with Linux. All ECI-based Ixxat

tools as well as customer-specific applications based on the ECI driver can be used. The ECI driver

offers the possibility to communicate with up to 32 CAN@net NT devices via LAN or internet. The

CAN@net NT 420 additionally is capable of CAN FD.

For information about the communication in the ECI mode and commands that are used to

exchange CAN messages see Software Design Guides in the ECI download package (available on

the product support pages on www.ixxat.com/support-bridges-gateways).

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 12

Product Description 10 (32)

4.3 Add-Ons for Customer Specific Expansions

4.3.1 Lua ADK

With the Lua Application Development Kit customer specific Lua scripts can be executed on the

CAN@net NTin operational modes Local Bridge or CAN-Eth-CAN bridge. By using the Lua ADK for

handling and processing of communication data the functionality of the standard application can

be expanded.

For more information about the Lua ADK see User Manual CAN@net NT/CANbridge NT Lua ADK

on the product support pages on www.ixxat.com/support-bridges-gateways.

4.3.2 C-API ixcan

The CAN API for C uses the ASCII protocol interface to access the CAN@net NT. The C-API ixcan

converts the API calls into corresponding ASCII commands according to the ASCII Gateway Mode

of the CAN@net NT. With the application that uses the C-API ixcan the CAN@net NT can be

accessed exclusively or in shared access with a Bridge configuration.

For more information about the C-API ixcan see User Manual CAN@net NT C-API ixcan on the

product support pages on www.ixxat.com/support-bridges-gateways.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 13

Installation 11 (32)

3

1

2

4 5

5 Installation

5.1 Installing the Software

To create a configuration for the CAN@net NT, the CAN-Gateway Configurator running on a

Windows system and the Ixxat VCI driver are needed.

The VCI driver is constantly improved and expanded! Check if a newer version is available within the

product support pages on www.ixxat.com/support.

The CAN-Gateway Configurator is constantly improved and expanded! Check if a newer version is

available within the product support pages on www.ixxat.com/support-bridges-gateways.

► Install the latest VCI driver on a Windows computer (see Installation Guide VCI Driver).

► Download the CAN-Gateway Configurator CANbridge NT & CAN@net NT 100/200/420

package from the product support pages on www.ixxat.com/support-bridges-gateways.

→ By default the package is stored in C:\Program Files\HMS\Ixxat CANGWconfig.

► Start the Ixxat CanGWconfig Setup.

→ Installation wizard starts automatically.

► Follow the instructions in installation program.

► In Windows Start menu open folder Ixxat CANGWconfig and start CAN-Gateway

Configurator V6.

5.2 Installing the Hardware

Fig. 4 Connectors

The CAN@net NT 100 has one D-Sub 9 CAN connector on the front.

1

CAN 1 (CAN@net NT 200/420)

2

CAN 2 (CAN@net NT 200/420)

3 Power connector

4

CAN 3 (CAN@net NT 420)

5

CAN 4 (CAN@net NT 420)

► Make sure that the cross-sectional area of the cable is larger than or equal to 0.14 mm2resp.

25 AWG.

► To remove the connector, use screwdriver or similar tool.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 14

Installation 12 (32)

► Connect the CAN cables.

► Connect the power supply.

► Plug the connector into the housing.

The shield of the CAN connector is connected to the device ground and the PE on the back of the

device (DIN rail) via a 1 MΩ resistor and a 10 nF capacitor. To achieve highest interference

immunity, ground the shield of the CAN cable.

5.2.1 Power Connector

Pin Allocation

Pin no.

1

2 V-

3

4

Signal

V+ (+9 V to +36 V DC)

—

—

5.2.2 CAN and CAN FD Connectors

Pin Allocation of Terminal Adapters

Pin no.

1

2

3 CAN GND

4

Signal

CAN high

CAN low

Shield

If a D-Sub 9 connector is used for the terminal adapters, observe the pin allocation of the D-Sub

9 connector.

Pin Allocation of D-Sub 9 Connector (CAN@net NT 100 and Adapter)

Pin no. Signal

1

2

3 CAN GND

4

5

6

7

8

9

—

CAN low

—

Shield

—

CAN high

—

—

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 15

Installation 13 (32)

5.3 Checking and Updating the Firmware

5.3.1 Checking the Device Firmware

► Make sure, that the latest VCI driver is installed.

► Make sure, that the device is correctly connected to the host computer and to power supply.

► Make sure that the latest CAN-Gateway Configurator is installed (check within product

support pages on www.ixxat.com/support-bridges-gateways).

► Start the Ixxat CAN-Gateway Configurator.

► Open menu Scan and select All Ixxat devices.

→ Connected devices and firmware version of the devices are shown.

5.3.2 Updating the Device Firmware

Whether updating is permitted via Ethernet or a password is needed, is defined in the

security settings of the CAN-Gateway Configurator. The default password is IXXAT. For

more information see user manual CAN-Gateway Configurator.

The firmware is constantly improved and expanded! Check if a newer firmware version is available

within the product support pages on www.ixxat.com/support-bridges-gateways.

To use all features the latest firmware versions of the CAN-Gateway Configurator and of the

CAN@net NT must be installed.

If the current firmware of the CAN@net NT in use is V4 or older:

► See update package on the product support pages on

www.ixxat.com/support-bridges-gateways for information about updating to V5 or contact

Ixxat support.

If the current firmware of the CAN@net NT in use is V5 or V6:

► Check if newer firmware is available on the product support pages on

www.ixxat.com/support-bridges-gateways.

► Download and unzip the update package.

► Make sure, that the device is connected to power supply.

► Connect the device to the computer via USB.

► Make sure that the latest CAN-Gateway Configurator is installed (check within product

support pages on www.ixxat.com/support-bridges-gateways).

► Start the CAN-Gateway Configurator.

► In drop down list Select device type select the device in use.

► In drop down list Select device version select the current firmware version of the device V5

or V6.

► Scan for devices with button Scan and select the device in use in the combo box Target

Device.

► Click button Connect

CAN@net NT User Manual

The device is only found if the selected firmware version matches the firmware version of

the connected device.

.

4.01.0332.20000 1.8 en-US

Page 16

Installation 14 (32)

► Open menu Target and select Read configuration from target.

► Save the configuration on the computer.

► Open menu Target and select Update Firmware.

► Select the update file.

→ Firmware of the connected device is updated.

► In the status window check if the update is completed successfully.

► If the device was updated from V5 to V6 , select V6 in drop-down list Select device version.

► If using a V5 configuration, open menu File and select Convert V5 to V6 to convert the

configuration to the latest version.

► Write the saved configuration to the device.

HMS recommends to verify configurations that are converted from V5 to V6, to make sure that all

settings are working correctly.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 17

Configuration 15 (32)

PC

10.41.18.3

CAN@net N T

169.254.163.109

CAN@net N T

192.168.1.23

CAN@net N T

10.41.18.10

CAN@net N T

10.41.18.5

CAN@net N T

a.b.c.d

Router

USB

10.41.18.1

192.168.1.1

1

2

3

4

ETH

6 Configuration

The security settings set via the CAN-Gateway Configurator define if changing the

configuration via Ethernet is possible and if a password is needed to change to

configuration. The default password is IXXAT. For more information see user manual

CAN-Gateway Configurator.

6.1 Connecting Possibilities

There are different possibilities to connect the CAN@net NT. Depending on the type of

connection different ways of configuring the IP address and the device are necessary.

Fig. 5 Types of connection

The following ways of connecting the devices for the configuration are possible:

• (1) via USB (recommended for the first configuration of the device)

• (2) via Ethernet in a local network

• (3) via Ethernet in a local network with an unknown or invalid IP address

• (4) via Router (IP address of device has to be known)

Malfunction caused by extension cable!

According to the USB specification connect the interface directly or via an active USB hub

to the computer. Do not use an extension cable.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 18

Configuration 16 (32)

3 4 5 6 7 8 9 10 1 1 122

1

13 14

6.2 Basic Configuration

It is possible to add information about the configuration in fields Author, Configuration Name and

Additional Info in the configuration tree entry Info.

It is possible to create and save a configuration without a connected device. Saved configurations can be

downloaded to connected CAN NT devices with Windows and Linux by using the Command Line Tool (see

Downloading the Configuration with Linux, p. 22).

Fig. 6 CAN-Gateway Configurator

1

Information about target device (STS reflects Power LED of device)

2

Drop-down list Select device type

3

Drop-down list Select device version

4

Drop-down list Select operational mode

5 Button New

6 Button Open

7 Button Save

8 Button Save as

9

Button Verify

10 Button Scan

11

Combo box Target device

12 Button Connect

13

Button Write to

14

Button Read from

6.2.1 Connecting the Device in the CAN-Gateway Configurator

The different CAN@net NT types 100, 200 and 420 can not be combined. For CANEthernet-CAN Bridges use either NT 100 devices, NT 200 devices, or NT 420 devices.

To use all features the latest firmware versions of the CAN-Gateway Configurator and the

CAN@net NT must be installed.

► Make sure, that the latest VCI driver is installed.

► Make sure, that the device is installed correctly (see Installing the Hardware, p. 11).

► Connect a device to the host computer (see Connecting Possibilities, p. 15).

► Make sure, that the latest firmware is on the device (see Checking and Updating the

Firmware, p. 13).

► Make sure, that the latest CAN-Gateway Configurator is installed (check within product

support pages on www.ixxat.com/support-bridges-gateways).

► Start the CAN-Gateway Configurator.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 19

Configuration 17 (32)

► To identify the connected devices and the firmware version, open menu Scan and select All

Ixxat devices.

→ Connected devices and firmware version of the devices are shown.

→ Devices that are connected via a router are not found. IP address and device firmware

version must be known.

→ Devices with an unknown or invalid IP address are not found (for more information see

Scanning for Devices with Unknown IP Addresses, p. 18).

► If the connected device is not found, see Scanning for Devices with Unknown IP Addresses, p.

18 for more information.

► Select the type of CAN@net NT in use in drop-down list Select device type (2).

► Select the firmware version of the device in drop-down list Select device version (3).

► Select the desired operational mode for the device in use in drop-down list Select

operational mode (4).

► Click button Scan (10) and select the device in use in combo box Target Device (11).

or

If the device is connected via a router, enter the IP address (see Default Network Settings, p.

27) in combo box Target Device (11).

► Click button Connect (12) to connect the selected device.

► For ASCII Gateway and VCI Interface mode make sure that the IP address is in the range of

the network in which the device is integrated (see Changing IP Address and Device Name, p.

19).

► For CAN-Ethernet-CAN bridge make sure that the IP addresses of all devices of the bridge

are in the same IP range (see Changing IP Address and Device Name, p. 19).

► To create a new project file, click button New (5).

or

To change an existing configuration, click button Read from (14) and save the configuration.

► Configure the device in the selected mode (see Configuration of Interface Modes (ASCII, VCI,

ECI), p. 20 or Configuration of Bridge Modes (Local CAN, CAN-Eth-CAN), p. 21).

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 20

Configuration 18 (32)

6.2.2 Scanning for Devices with Unknown IP Addresses

If the IP address of a device that is connected via Ethernet is unknown or invalid in the local

network, the device can be found via menu Scan — IP configuration.

Device is only found by scanning, if correct device type and firmware version are selected.

Make sure, that device type and firmware version are selected according to the

connected device.

HMS Industrial Networksrecommends to use a static IP address.

► Select the type of CAN@net NT in use in drop-down list Select device type (2).

► Select the firmware version of the device in drop-down list Select device version (3).

► Open menu Scan and select IP configuration.

→ CAN-Gateway Configurator scans automatically for connected devices of predefined

type and firmware version.

→ Connected devices of the selected type and firmware version are shown.

Fig. 7 IP configuration

► Select the desired device in the drop-down list Target device.

► If necessary define a new IP address.

► Make sure that the IP address is in the range of the network in which the device is

integrated.

► Define the network settings.

► Enter password (default: IXXAT) in field Device password.

► To write the new IP configuration to the target device click button Save.

► Connect the device in CAN-Gateway Configurator (see Connecting the Device in the CAN-

Gateway Configurator, p. 16).

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 21

Configuration 19 (32)

6.2.3 Changing IP Address and Device Name

HMS Industrial Networks recommends to use a static IP address.

► Make sure that the device is connected in the CAN-Gateway Configurator (see Connecting

the Device in the CAN-Gateway Configurator, p. 16).

► Open menu Target and select Change IP configuration.

→ Window IP Configuration is opened.

► Make sure that the serial number in drop-down list Target device points to the connected

device.

► To change the IP address, define the network settings.

► To change the device name, enter a new device name in field Device name.

► Enter password (default: IXXAT) in field Device password.

► To write the new IP configuration to the target device click button Save.

► Connect the device again in CAN-Gateway Configurator (see Connecting the Device in the

CAN-Gateway Configurator, p. 16).

HMS Industrial Networks recommends to change the default password. See User Manual CAN-Gateway

Configurator for more information.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 22

Configuration 20 (32)

6.3 Configuration of Interface Modes (ASCII, VCI, ECI)

The VCI interface mode can only be operated via Ethernet. Configuration is possible via

USB.

Fig. 8 ASCII Gateway Mode

► Make sure, that the device is connected to the network (see Connecting Possibilities, p. 15)

and to the CAN-Gateway Configurator (see Connecting the Device in the CAN-Gateway

Configurator, p. 16).

► In drop-down list (1) select the desired interface operational mode.

► In the configuration tree (5) select Interface.

► If checkbox Only for specified device (6) is enabled, enter the serial number of the device to

which the configuration can be written.

If ASCII Gateway Mode is selected:

► Configure the protocol line ending (4).

► Define the IP port (4).

► If checkbox Expert Mode (7) is enabled, select the desired settings (for more

information see User Manual CAN-Gateway Configurator).

► To write the configuration to the device, click button Write to (3).

or

► Click button Save or Save as (2) to save the configuration.

► To exchange messages in the Gateway mode, use ASCII commands (for more information

see Software Design Guide CAN@net NT 100/200/420 Generic Protocol for Gateway Mode

on product support pages on www.ixxat.com/support-bridges-gateways).

► In the VCI interface mode configure the Device Server (for more information see Installation

Guide VCI Driver included in VCI download package on

www.ixxat.com/support-bridges-gateways.

► In the ECI interface mode see Software Design Guides in the ECI download package

(included in ECI download package on www.ixxat.com/support-bridges-gateways) for

information about the communication in the ECI mode and commands that are used to

exchange CAN messages.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 23

Configuration 21 (32)

6.4 Configuration of Bridge Modes (Local CAN, CAN-Eth-CAN)

In the CAN-Ethernet-CAN Bridge mode each device can be configured differently. But to build a Bridge

configuration all devices must be configured in one configuration file. The configuration has to be set

completely for all devices (Master, Slave 1 to 3) and then the complete configuration has to be

downloaded to each device. In the Local CAN Bridge mode only one device is connected and has to be

configured.

Exclusively one master device is allowed in the Bridge mode.

Fig. 9 CAN-Gateway Configurator CAN@net NT 420

For more information about the setting possibilities (e.g. general settings, baud rate, MQTT) and

descriptions of the further configuration possibilities (e.g. J1939 Mapping, cyclic transmission)

see User Manual CAN-Gateway Configurator on www.ixxat.com/support-bridges-gateways.

► Make sure, that the Master device is connected to the network (see Connecting Possibilities,

p. 15) and to the CAN-Gateway Configurator (see Connecting the Device in the CANGateway Configurator, p. 16).

► In drop-down list (1) select the desired bridge operational mode.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 24

Configuration 22 (32)

► Configure the following for the Master and for each Slave in use:

► In the configuration tree select General (8) and enter the IP address of the device for

CAN-Ethernet-CAN bridges (4).

► Define the general settings (5).

► In the configuration tree select CAN Ports (8) and configure the baud rate settings for

all ports in use (6).

► Configure further settings if desired (MQTT, Syslog, Action Rules, etc.) (8).

► Configure the mapping table (7).

Only messages that are entered in the mapping table are forwarded. By default, no filter

is set and all messages are rejected.

► To write the configuration to the device, click button Write to (3).

or

► Click button Save or Save as (2) to save the configuration.

► For the CAN-Ethernet-CAN Bridge connect the devices one after another and download the

configuration to each device.

► Observe that for the configuration of a CAN-Ethernet-CAN Bridge each device must be

configured with the same configuration file. If the configuration is changed, the new

configuration file has to be downloaded again to all devices.

6.5 Downloading the Configuration with Linux

The basic configurations, like the selection of the operating mode, can only be created with the

CAN-Gateway Configurator with Windows. A configuration can be created and saved without a

connected device and can then be downloaded to connected CAN NT devices with Linux by using

the Command Line Tool that is included in the scope of delivery.

► To be able to read and write configurations on CAN NT devices, copy the included file

60-bgi.rules to the folder /etc/udev/rules.d/ (root access required).

► To activate the new rules, execute the following command:

udevadm control - -reload-rules

► To download a saved configuration file to CAN NT devices, start the Command Line Tool

cangwfile without parameters.

→ Output shows the syntax, examples and all possible commands.

► Write the configuration to the target device (see User Manual CAN-Gateway Configurator

for more information about the Command Line Tool).

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 25

Configuration 23 (32)

6.6 Reset to Factory Settings

It is possible to reset the configuration of a connected device to factory settings.

Fig. 10 Menu Reset to factory settings

► Make sure that the device is connected via USB.

► Open menu Target and select Reset to Factory Settings.

► Click button Yes to confirm the reset.

6.7 Read and erase LOG File

In case of an error the device writes the error in a log file. The log file can be read from the

device, saved as a txt file and send to the Ixxat support if needed.

► Open menu Target and select Read and erase LOG file.

→ Window Save Log File As is opened.

► Define a file name and save the file.

→ .txt-file is created and saved.

→ Configuration file is saved.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 26

Operation

1452

3

9

8 7

610

7 Operation

Fig. 11 Ports and LEDs

1 Status LED

2 Power LED

3 Mini USB port

4 CAN LEDs 1 to 4

5 User LED

6

Ethernet LED

7

Link speed LED

8

Ethernet port

9

Link/Activity LED

10

CAN connector D-Sub 9 (CAN@net NT 100)

24 (32)

7.1 Ethernet Port

Designed as standard RJ45 port with pin allocation according to Ethernet standard. Because of

the Ethernet PHY auto-crossover feature the device can be connected with a crossover cable or

with a one-to-one network cable.

The shield of the port is connected to the ground of the printed board via a 1 nF capacitor.

Pin Allocation Ethernet Port

Pin no.

1 TX+

2 TX-

3 RX+

4

5

6 RX-

7

8

7.2 Mini USB Port

Provided to connect the device for configuration.

Signal

Connected to pin 5

Connected to pin 4

Connected to pin 8

Connected to pin 7

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 27

Operation

7.3 Indicators

7.3.1 Power LED

Indicates the status of the power supply.

25 (32)

LED state

Off

Green Power

7.3.2 Status LED

Indicates the device status.

LED state

Off Device not ready No firmware, application firmware not started

Green flashing (1 Hz) Application firmware started Device in Operational state

Red/green flashing

Green/orange flashing

Orange flashing (1 Hz) Automatic baud rate detection or

Red flashing

7.3.3 User LED

Indicates the primary application status and is different, depending on the operating mode.

Description

No power

Description

Configuration file error Rewriting of configuration to device necessary

Device in Configuring state

Lua ADK in remote mode

Device error

Comments

Possible causes: device not connected to power supply,

fuse of device damaged, internal power supply

damaged, power supply not sufficient

Device fully functional

Comments

—

Ongoing automatic baud rate detection, or Lua ADK in

remote mode

Application signals a device error, error in configuration

or no configuration. Read log file for more information

(see Read and erase LOG File, p. 23).

Bridge

In the Bridge mode the User LED can be configured with user defined settings via Action Rules.

See User Manual CAN-Gateway Configurator for more information.

VCI Interface

The User LED is not used.

ASCII Gateway

LED state

Orange/Green flashing

Green flashing Connection monitoring activated Heartbeat mechanism to monitor the connection (PING

7.3.4 Ethernet LED

Indicates the Ethernet communication status.

LED state

Off No Ethernet communication Possible causes: device unsuccessfully initialized, device

Green flashing

Orange flashing

Description

No connection monitoring

Description

TCP/IP packet transmitted

successfully

TCP/IP packet not transmitted

TCP/IP congestion

Comments

—

REQUEST, PING RESPONSE)

Comments

not connected to Ethernet or no communication

Communication was successful

Bad or slow TCP/IP connection, messages can not be

transmitted to CAN and are jammed

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 28

Operation

7.3.5 Link Speed LED

The yellow LED indicates the link speed.

26 (32)

LED state

Off

Orange

7.3.6 Link/Activity LED

Indicates connection status of the Ethernet interface.

LED state

Off No link detected No connection to Ethernet network, Network cable

Green

Green flashing

7.3.7 CAN LED

CAN 1-4 LEDs indicate the status of the corresponding CAN interface.

LED state

Off

Orange flashing Indicates a state of the automatic

Green flashing

Green CAN communication

Red flashing

Red Bus off CAN controller is in Bus Off state, no CAN

Description

10 MBit/s

100 MBit/s

Description

Link Ethernet connection established, no communication

Activity

Description

No CAN communication No connection to CAN

baud rate detection

CAN communication

CAN communication, CAN

controller in Error state

Comments

damaged

present

Ethernet connection established, communication

present

Comments

See User Manual CAN Gateway Configurator

LED is triggered with each CAN message

Device in Operational state, no messages on CAN bus

CAN controller in Error Warning or Error Passive state,

reception/transmission of CAN messages possible

communication possible

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 29

Default Network Settings 27 (32)

8 Default Network Settings

Network parameter Default setting Remark

IP Mode

IP Address

Subnet Mask

Standard Gateway

Device Name CAN@net NT

Device password

Static

169.254.y.x

y = ((device serial number - 800 000) DIV 254) MOD 256

x = ((device serial number - 800 000) MOD 254) +1

255.255.0.0

0.0.0.0

IXXAT

Like APIPA if no DHCP server is

available. By scanning the

network, all available devices

can be found.

Transmitted MD5-encrypted

9 Default TCP/UDP Ports

CAN@net PC

CAN Gateway Configurator Device scan and IP configuration:

VCI

Gateway (ASCII Interface)

Bridge (CAN-Ethernet-CAN)

15000/udp

Device configuration (via TCP):

19229/tcp

19229/tcp 1024-65535/tcp

19228/tcp 1024-65535/tcp

Slave: 19239/tcp

Master: 1024-65535/tcp

Device scan and IP configuration:

15001/udp

Device configuration (via TCP):

1024-65535/tcp

—

10 Technical Data

Ethernet Interface

Dimensions 114.5 x 99 x 22.5 mm

Weight

Operating temperature -40 °C to +85 °C

Storage temperature

Power supply 9 V to 36 V DC with overvoltage and polarity protection

Current consumption

Housing material Polyamide

Galvanic isolation 1 kV DC for 1 sec

Protection class

CAN transceiver (CAN 1/CAN2)

CAN FD transceiver (CAN3/CAN4 withCAN@net NT 420)

Max. number of bus nodes

CAN bus termination resistor

CAN baud rates Classic CAN: 5 to 1000 kBaud

CAN pass through delay Local CAN Bridge: 15-25 μs

Startup time after power on

Processing time in Bridge mode

Startup time

10/100 MBit/s, twisted pair

Approx. 150 g

-40 °C to +85 °C

Typically 110 mA at 24 V input voltage,

typically 230 mA at 12 V input voltage

IP20

SN65HVD251

MCP2562FDT

120

None

CAN FD: 5 to 8000 kBaud

CAN-Ethernet-CAN Bridge: 4-6 ms

< 1 s

30 000-40 000 msg/s

Firmware v5.1.3: min. 540 ms (configuration size 5 kB),

max. 1080 ms (configuration size 140 kB)

Firmware v6.0.0: min. 250 ms (configuration size 5 kB),

max. 790 ms (configuration size 140 kB)

Ethernet connection might add up to 1–2 seconds

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 30

Support/Return Hardware

11 Support/Return Hardware

11.1 Support

► To contact support, go to www.ixxat.com/technical-support/contact-technical-support.

► Scroll down and click button mysupport.hms.se to register a support case.

11.2 Return Hardware

► On www.ixxat.com/support/product-returns click button Portal to access the support portal.

► In the support portal select Submit Product Return (RMA).

► Read the information and click Create RMA Case.

► Register a support account and sign in.

► Fill in the form for warranty claims and repair.

► Print out the Product Return Number (PRN resp. RMA).

► Pack product in a physically- and ESD-safe way, use original packaging if possible.

► Enclose PRN number.

28 (32)

► Observe further notes on www.ixxat.com.

► Return hardware.

12 Disposal

► Dispose of product according to national laws and regulations.

► Observe further notes about disposal of products on www.ixxat.com.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 31

Appendix A: Regulatory Compliance 29 (32)

A Regulatory Compliance

A.1 EMC Compliance (CE)

The product is in compliance with the Electromagnetic Compatibility Directive. More information

and the Declaration of Conformity is found at www.ixxat.com.

A.2 FCC Compliance Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

• This device may not cause harmful interference.

• This device must accept any interference received, including interference that may cause

undesired operation.

Product name

Model

Responsible party HMS Industrial Networks Inc

Address 35 E. Wacker Dr, Suite 1700

Phone

Any changes or modifications not expressly approved by HMS Industrial Networks could

void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and the receiver.

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

CAN@net NT

100/ 200/420

Chicago , IL 60601

+1 312 829 0601

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 32

Appendix A: Regulatory Compliance 30 (32)

A.3 Disposal and recycling

You must dispose of this product properly according to local laws and regulations. Because this

product contains electronic components, it must be disposed of separately from household

waste. When this product reaches its end of life, contact local authorities to learn about disposal

and recycling options, or simply drop it off at your local HMS office or return it to HMS.

For more information, see www.hms-networks.com.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 33

Appendix B: UL Ordinary Locations (Ord.Loc.) 31 (32)

B UL Ordinary Locations (Ord.Loc.)

CAN@net NT devices are certified for use in ordinary locations in compliance with the following

standard:

• UL 62368-1 & CAN/CSA C22.2 No. 62368-1-14, Audio/video, information and

communication technology equipment Part 1: Safety requirements

The certification number of the certified devices according to OrdLoc certification is:

• E466303

According to the standards listed above, the devices are certified with the following marking:

Intended Use

The components are used to connect computer systems to CAN and CAN FD networks and to

connect the networks with each other. They are intended for installation on standard DIN rail.

Risk of interference to radio and television if used in office or home environment!

Use exclusively included accessories. Use exclusively shielded cables.

Make sure that the shield of the interface is connected with the device plug and the plug

on the other side.

Protect product from moisture and humidity.

Protect product from too high or too low temperature, and from fire.

Utilisation prévue

Les composants sont utilisés pour connecter les systèmes informatiques aux réseaux CAN et CAN

FD et pour connecter les réseaux entre eux. Ils sont destinés à être installés sur un rail DIN

standard.

Risque d’interférence avec la radio et la télévision si elles sont utilisées au bureau ou à la

maison !

Utilisez exclusivement les accessoires inclus. Utilisez exclusivement des câbles blindés.

Vérifiez que le blindage de l’interface est connecté avec la prise de l’appareil et la prise

de l’autre côté.

Protégez le produit de l’humidité.

Le produit ne doit pas être soumis à des températures extrêmes et doit être protégé

contre tout risque d’incendie.

CAN@net NT User Manual

4.01.0332.20000 1.8 en-US

Page 34

last page

© 2020 HMS Industrial Networks

Box 4126

300 04 Halmstad, Sweden

info@hms.se 4.01.0332.20000 1.8 en-US / 2020-12-02 / 20953

Loading...

Loading...