HMS Anybus X-gateway CANopen User Manual

AAnnyybbuuss®®XX--ggaatteewwaayy™™CCAANNooppeenn

PPRROOFFIINNEETT®®IIRRTT ((22..3322))

USER MANUAL

SCM-1202-029 1.2 en-US ENGLISH

®®

Important User Information

Disclaimer

The information in this document is for informational purposes only. Please inform HMS Industrial Networks of any

inaccuracies or omissions found in this document. HMS Industrial Networks disclaims any responsibility or liability

for any errors that may appear in this document.

HMS Industrial Networks reserves the right to modify its products in line with its policy of continuous product

development. The information in this document shall therefore not be construed as a commitment on the part of

HMS Industrial Networks and is subject to change without notice. HMS Industrial Networks makes no commitment

to update or keep current the information in this document.

The data, examples and illustrations found in this document are included for illustrative purposes and are only

intended to help improve understanding of the functionality and handling of the product. In view of the wide range

of possible applications of the product, and because of the many variables and requirements associated with any

particular implementation, HMS Industrial Networks cannot assume responsibility or liability for actual use based on

the data, examples or illustrations included in this document nor for any damages incurred during installation of the

product. Those responsible for the use of the product must acquire sufficient knowledge in order to ensure that the

product is used correctly in their specific application and that the application meets all performance and safety

requirements including any applicable laws, regulations, codes and standards. Further, HMS Industrial Networks will

under no circumstances assume liability or responsibility for any problems that may arise as a result from the use of

undocumented features or functional side effects found outside the documented scope of the product. The effects

caused by any direct or indirect use of such aspects of the product are undefined and may include e.g. compatibility

issues and stability issues.

®

Anybus

are the property of their respective holders.

is a registered trademark of HMS Industrial Networks AB. All other trademarks mentioned in this document

Anybus®X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Table of Contents

Page

1 Preface ................................................................................................................................. 3

1.1 About This Document ............................... ....................................... .......................... .......3

1.2 Document history .......................... .......................... ............. .......................... ............. .... 3

1.3 Document Conventions ........... .......................... .......................... ......................................4

1.4 Document-Specific Conventions......... ..... .......................... ....................................... ........... 4

2 Description .......................................................................................................................... 5

2.1 Introduction............................ ..... .......................... ....................................... ..................5

2.2 Data Exchange ................ .................................. ..... .......................... ................................ 6

2.3 CANopen Functionality. ........ .......................... ............. .......................... ............. ...............7

3 Installation........................................................................................................................... 8

3.1 Installation Overview .... .......................... ............. .......................... ................................... 8

3.2 DIN Rail Mounting..... ............. .......................... .......................... ............. .........................9

3.3 Power Connector ..................... ............. .......................... ....................................... ..........9

3.4 USB Connector ............ .......................... ............. .......................... ................................... 9

3.5 Secondary CANopen Network Interface .................................................. .......................... . 10

3.6 PROFINET IRT Network Interface...... ............. ............. .......................... ............. ................ 11

3.7 LED Indicators ............. .......................... ....................................... ............................... .. 12

4 Configuration..................................................................................................................... 14

4.1 Configuration Overview. .......................... ............. .......................... ................................. 14

4.2 Configuring the Secondary CANopen Network................................... .......................... ........ 15

4.3 Configuring the PROFINET IRT (2.32) Interface......................... .......................... ..... ............. 16

4.4 Enabling Data Exchange ........................................ ............................... ........................... 22

5 PROFINET Asset Management.......................................................................................... 23

5.1 Asset Management Record ................................ .......................... ..... ............................... 23

5.2 Recording and Reading Data ............... .......................... ............. .......................... ............ 23

5.3 Supported File Formats ...... ............. .......................... ....................................... ............... 24

5.4 Supported Asset Management Records....................... .......................... ............. ................ 24

5.5 XML Based Asset Management.. ............. ............. ............. .......................... ...................... 25

5.6 Binary Based Asset Management ........................ ............. ............. ............. ....................... 28

5.7 Uploading the Asset Management File to the FTP Server.... ............................... .................... 32

Anybus®X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

6 CANopen Module Specification........................................................................................ 34

6.1 NMT State Machine.............. ............. .......................... ................................................... 34

6.2 CANopen Data Exchange .. .......................... ............. .......................... .......................... .... 35

6.3 LSS Services ..................................... .......................... ............. .......................... ............ 39

6.4 Error Control .... ....................................... .......................... ............. .......................... ..... 40

6.5 CANopen Emergency Messages ......... ..... .................................. ............................... ......... 41

6.6 CANopen Live List Functionality ................ ............. .......................... ............. .................... 42

7 CANopen Object Implementation .................................................................................... 44

7.1 Static Data Types .............. ..... ....................................... .......................... ....................... 44

7.2 Communication Profile Area ......... ....................................... .......................... ..... ............. 44

7.3 Manufacturer Specific Objects......................... ................................................................. 52

A Technical Data ................................................................................................................... 59

A.1 General Specifications............... ..... .................................. ............................... ................ 59

A.2 Secondary CANopen Network Interface .................................................. .......................... . 59

A.3 Primary PROFINET IRT (2.32) Network Interface ................................ .......................... ........ 59

Anybus®X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Preface 3 (60)

1 Preface

1.1 About This Document

This document describes Anybus X-gateway CANopen PROFINET IRT (2.32).

For additional related documentation and file downloads, please visit www.anybus.com/support.

1.2 Document history

Version

1.0 2017-01-23

1.1 2017-11-22

1.2 2019-04-11

Date

Description

First release

Updated for new firmware

Added section about PROFINET Asset Management

®

Anybus

X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Preface 4 (60)

1.3 Document Conventions

Ordered lists are used for instructions that must be carried out in sequence:

1. First do this

2. Then do this

Unordered (bulleted) lists are used for:

• Itemized information

• Instructions that can be carried out in any order

...and for action-result type instructions:

► This action...

→ leads to this result

Bold typeface indicates interactive parts such as connectors and switches on the hardware, or

menus and buttons in a graphical user interface.

Monospaced text is used to indicate program code and other

kinds of data input/output such as configuration scripts.

This is a cross-reference within this document: Document Conventions, p. 4

This is an external link (URL): www.hms-networks.com

This is additional information which may facilitate installation and/or operation.

This instruction must be followed to avoid a risk of reduced functionality and/or damage

to the equipment, or to avoid a network security risk.

Caution

This instruction must be followed to avoid a risk of personal injury.

WARNING

This instruction must be followed to avoid a risk of death or serious injury.

1.4 Document-Specific Conventions

• Hexadecimal values are represented with the suffix h and a leading zero where needed, e.g.

the hexadecimal value 1F4 is written 01F4h.

• A byte always consists of 8 bits.

Anybus®X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Description

Secondary CANopen network

Primary fieldbus or Ethernet network

SlaveMaster Slave Slave Slave

SlaveSlave Slave Slave Slave

Secondary CANopen network interface

(master or slave)

Primary network interface

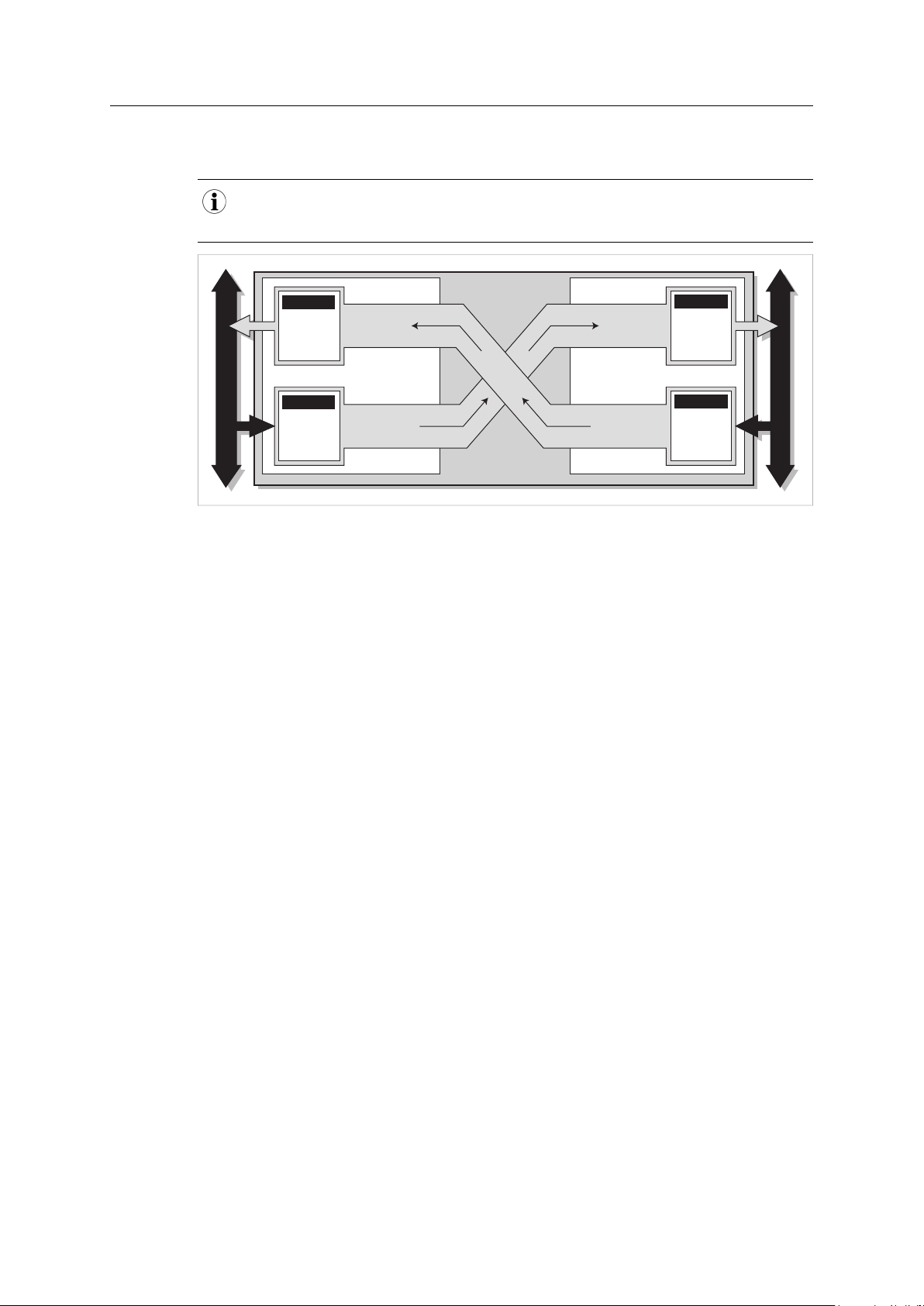

2 Description

2.1 Introduction

Anybus X-gateway CANopen is designed to provide a seamless connection between a primary

fieldbus or Ethernet network and a secondary CANopen sub-network.

The X-gateway transmits I/O data transparently between the two networks. Data from the

primary network is written into CANopen objects that can be mapped into CANopen PDOs or

read via CANopen SDOs, and vice versa. This makes it possible to integrate CANopen devices into

almost any other PLC system and their supported networks.

No proprietary configuration software is needed for Anybus X-gateway CANopen, although

dedicated tools may be required when configuring the primary network. Any standard CANopen

configuration tool can be used to configure the secondary CANopen network interface.

5 (60)

Fig. 1 Networking example

Anybus®X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Description

Primary Network InterfaceSecondary Network Interface

Primary Network

Secondary CANopen Network

Data From

Primary

Network

Data From

Secondary

Network

Data To

Primary

Network

Data To

Secondary

Network

Status Word

Status Word

Control Word

Control Word

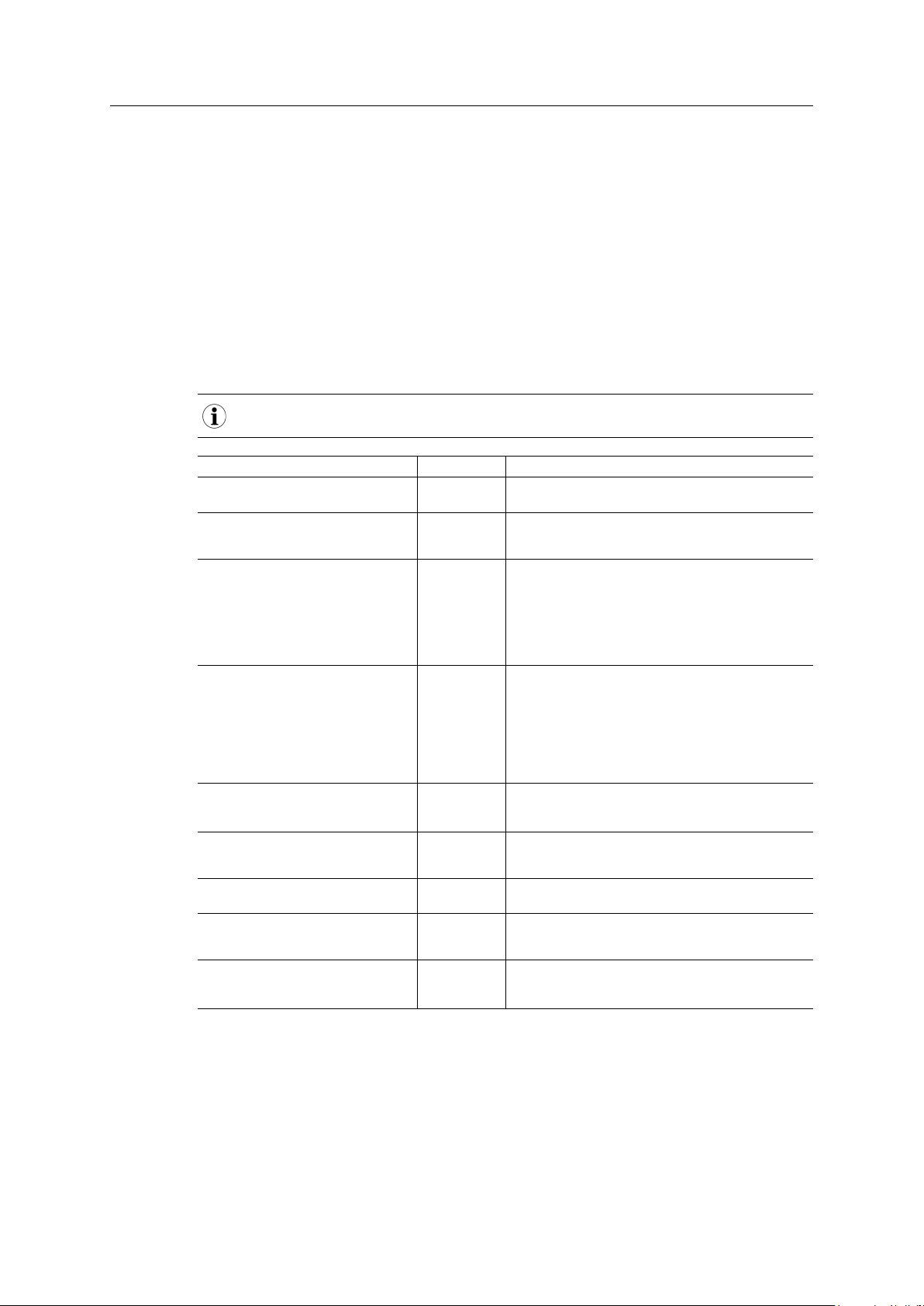

2.2 Data Exchange

The terminology and definitions used for different types of data vary between network types. All data

transported through the Anybus X-gateway CANopen are fast, cyclic data, and will in this document

simply be referred to as “I/O data”.

Fig. 2 Data exchange example

6 (60)

Each of the two network interfaces exchanges data on its network through its own buffer, which

can hold up to 512 bytes of data. The first two bytes in the primary network buffer are reserved

for the Control Word and Status Word, leaving 510 bytes available for I/O data.

The actual amount of data that can be exchanged depend on the application and network used

and may therefore be less than 510 bytes, which is only the maximum size of the buffer.

The Control Word can be used by the master on the primary network to start and stop the

exchange of data, and to reset the X-gateway if needed. The Status Word can be used by the

master to read the status of the secondary CANopen network.

The I/O data exchange is separated from the network data exchange. While the gateway ensures

data consistency (where applicable), it does not feature any mechanisms for synchronisation

between the primary and secondary networks.

Anybus®X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Description

2.3 CANopen Functionality

The functionality of the secondary CANopen network interface is defined by the following

CANopen specifications:

• KGB Draft Standard 301 version 4.2.0 (Rev. 4.2)

• CiA Draft Standard Proposal 302 Part 1–5.

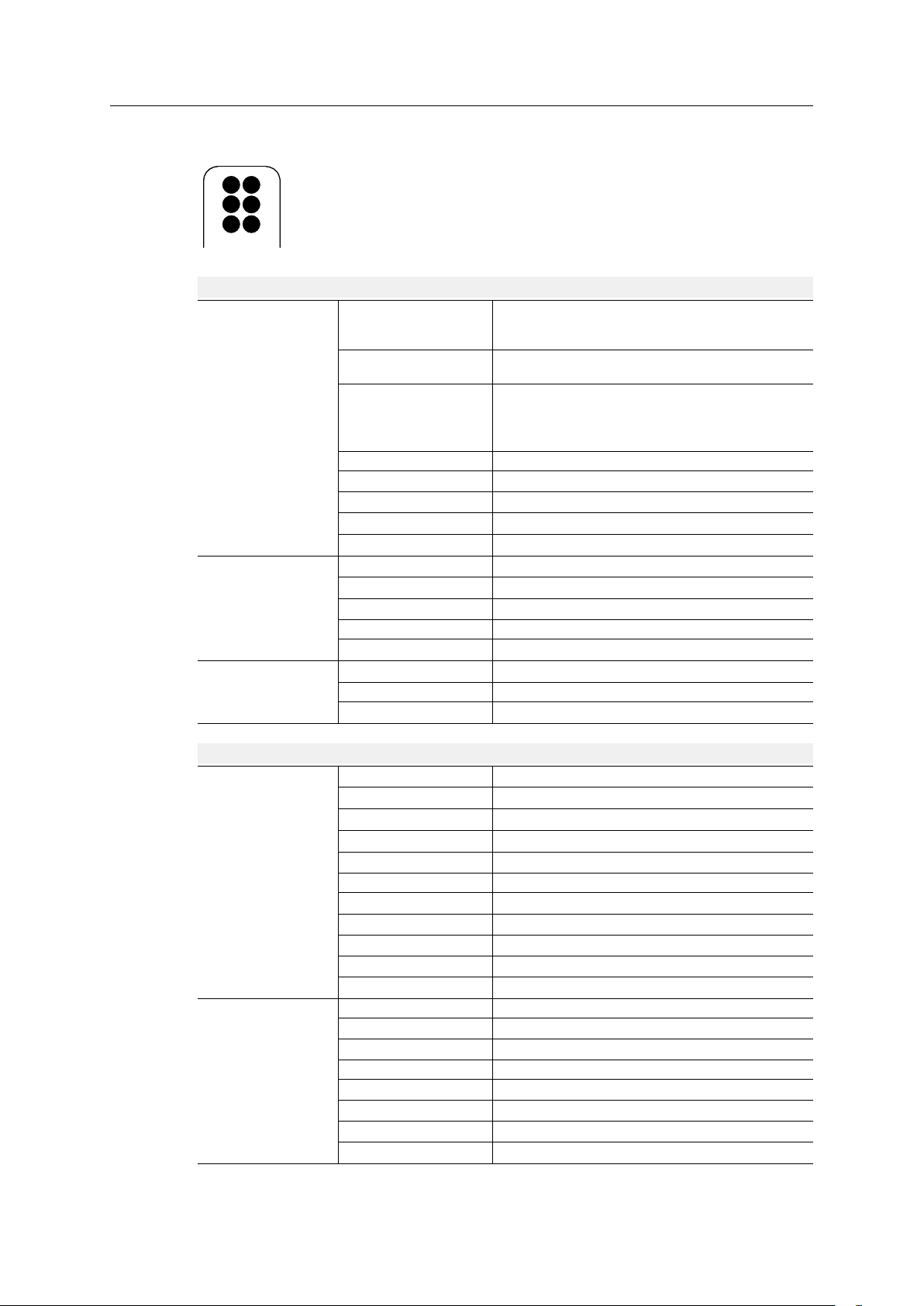

Supported CANopen Services

Communication and parameters in the CANopen protocol are built around åbject. Different

services are used for communication with the objects and for other tasks such as supervising the

network. Which services are available depend on whether the secondary CANopen network

interface is operating as a master or as a slave.

The secondary CANopen network will start up as a slave by default.

7 (60)

Service

NMT (Network Management)

CMT (Configuration Management)

PDO (Process Data Objects)

SDO (Service Data Objects)

SYNC (Synchronization Object)

EMCY (Emergency Object)

LSS (Layer Setting Services)

Heartbeat Mechanism

Node Guarding Protocol

Available in

Master

Master

Master/Slave Used for I/O communication.

Master/Slave

Master/Slave

Master/Slave

Master

Master/Slave

Master/Slave

Description

NMT messages are used to configure, initialize and

monitor the network,and for error handling.

CMT messages are used for configuring CANopen devices.

This primarily involves PDO parameters and mapping of

information.

128 Receive PDOs and 128 Transmit PDOs are

implemented, each being able to transfer up to 8 bytes.

The total number of PDOs that can be used is limited by

the data buffer size.

Supported PDO message types are COS (Change of state),

Cyclic Synchronous, and Acyclic Synchronous.

Used to access and configure objects in the X-gateway and

other network nodes without mapping them to an I/O

(PDO) connection.

SDOs use asynchronous data transmission and can transfer

more than 8 bytes (the limit for a PDO).

Supported SDO message types are Expedited Upload/

Download Protocol and Segmented Upload/Download

Protocol.

Used for synchronizing PDO communication. A master can

be either a producer or a consumer of the synchronization.

A slave can only be a consumer.

Used for error reporting when a fatal error has occurred in

the X-gateway or in other monitored or supervised

modules.

Used by a CANopen master to configure the baud rate and

NodeID of slaves that support LSS.

Allows a device to monitor the status of another node. The

X-gateway can appear both as heartbeat producer and

consumer.

Provides active surveillance of a slave by the master.

Slaves can be configured to expect a node guarding

request from the master.

®

Anybus

X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Installation 8 (60)

A

B

C

D

E

F

3 Installation

This product contains parts that can be damaged by electrostatic discharge (ESD). Use

ESD prevention measures to avoid damage.

3.1 Installation Overview

Basic steps when installing the Anybus X-gateway CANopen:

1. Set the node address and baud rate for the secondary CANopen interface.

2. Set the hardware configuration switches for the primary network interface (if applicable).

3. Mount the gateway on the DIN rail.

4. Connect the primary and secondary networks.

5. Connect the power cable and apply power.

6. Continue to Configuration, p. 14.

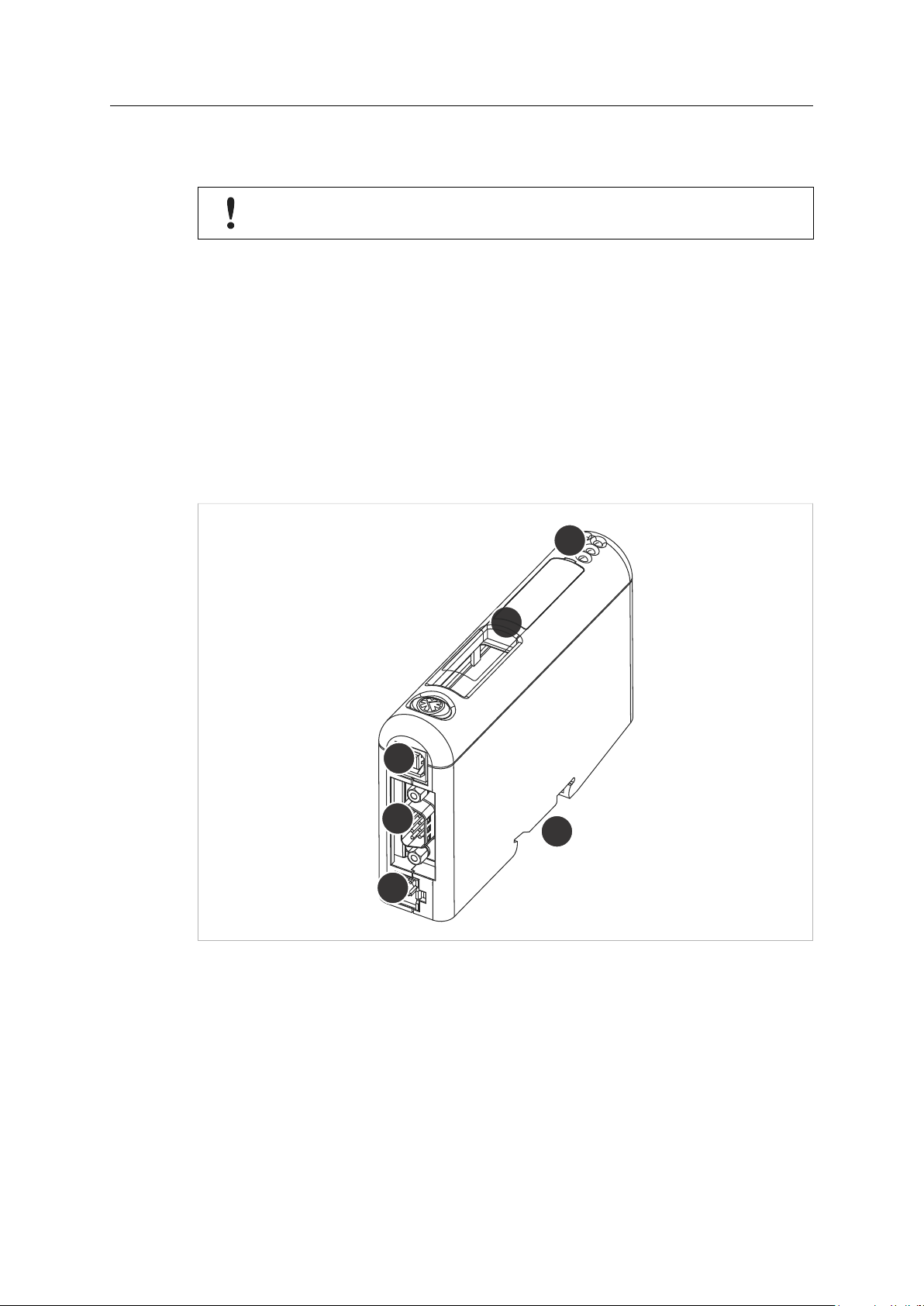

Fig. 3 Connectors, switches and indicators

A

B

C USB connector

D CANopen connector

E Power connector

F

LED indicators

Primary network interface

DIN rail mount

Anybus®X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Installation 9 (60)

1 2

1

2

3

4

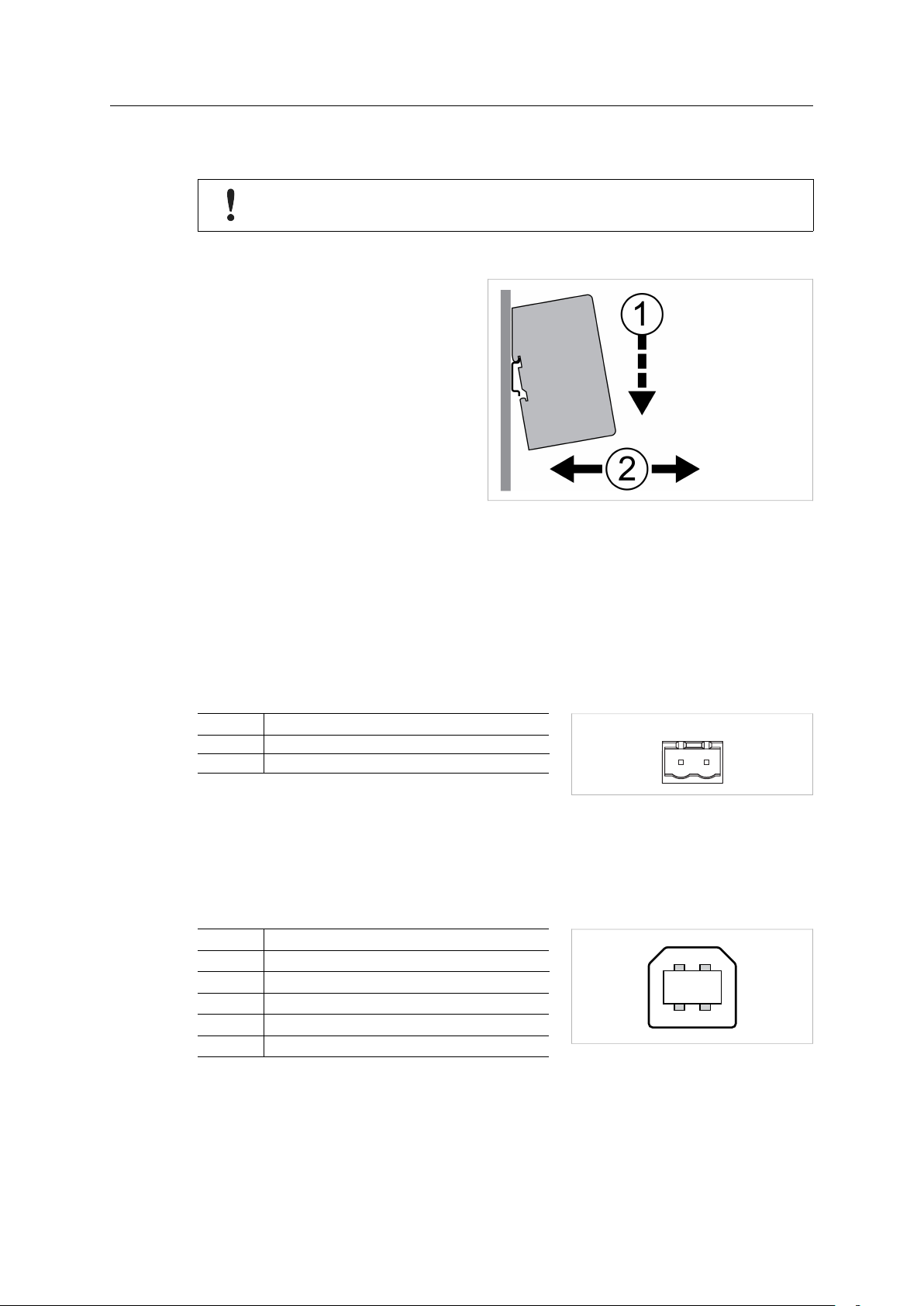

3.2 DIN Rail Mounting

The unit must be electrically grounded through the DIN rail for EMC compliance.

Mount on DIN rail

1. Hook the unit onto the upper lip of

the rail and push gently downwards.

2. Push the unit towards the rail until it

snaps into place.

Fig. 4 Push down to mount or remove

Remove from DIN rail

1. Push the unit gently downwards on the rail.

2. Pull the bottom end of the unit free of the rail and remove it.

3.3 Power Connector

See also Technical Data, p. 59 regarding power supply requirements.

Pin Signal

1 +24 VDC

2

Power Ground

3.4 USB Connector

The USB connector is only used when upgrading the firmware of the unit. It cannot be used for

configuration purposes.

Pin

1 +5 V input

2

3

4

Housing

Signal

USBDM (USB communication)

USBDP (USB communication)

Signal ground

Cable shield

Fig. 5 Power connector

Fig. 6 USB type B connector

®

Anybus

X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Installation 10 (60)

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

ABC

x1

x1 0

+= 42

BC

69

5 1(male)

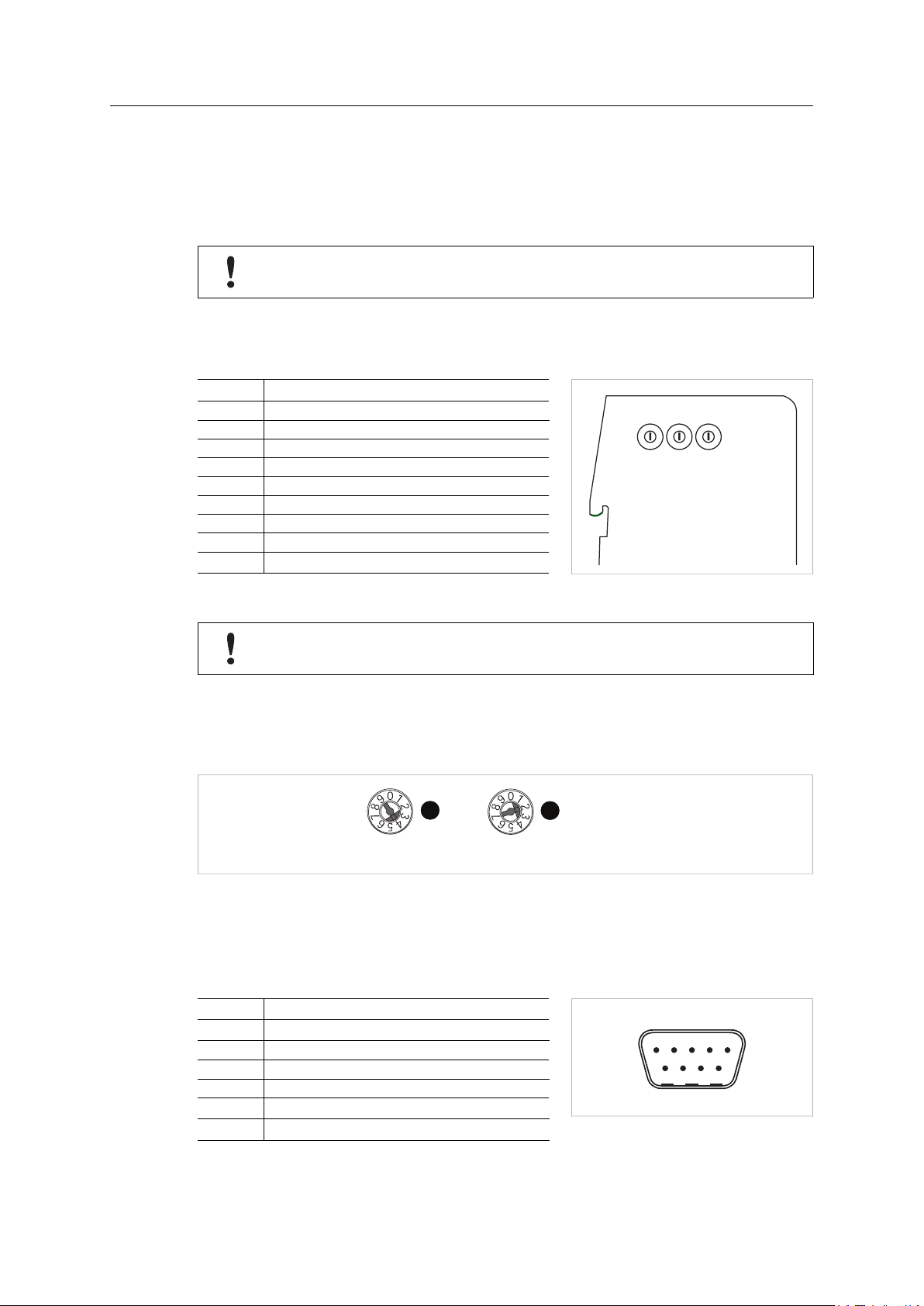

3.5 Secondary CANopen Network Interface

3.5.1 Configuration Switches

Three configuration switches on the side of the unit are used to set the node address and baud

rate for the secondary CANopen network interface.

The node address and baud rate cannot be changed during runtime. The module must be

restarted to make a changed setting take effect.

Baud Rate (Switch A)

The first rotary switch is used to set the operating baud rate.

Setting

Baud Rate (kbit/s)

0 20

1 50

2 125

3 250

4 500

5 800

6 100

7 Auto

8, 9

(not used)

Fig. 7 Configuration switches

Do not select “Auto” if the traffic on the secondary network will be limited, e.g. if there

are only a few nodes or the interface is configured as a master.

Node Adress (Switches B + C)

The second and third switches are used together to set a CANopen node address between 1 and

99. In the following example the node address is set to 42 (4 x 10 + 2 x 1):

Fig. 8 Node address example

3.5.2 CANopen Connector

The secondary network CANopen connector is located on the bottom of the unit. This connector

is also used when downloading the CANopen configuration.

Pin

2 CAN_L

3 CAN GND

5

6 CAN GND

7 CAN_H

1, 4, 8, 9

Anybus®X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

Signal

Shield

(reserved)

Fig. 9 CANopen connector

SCM-1202-029 1.2 en-US

Installation 11 (60)

1 8

LAN 1 LAN 2

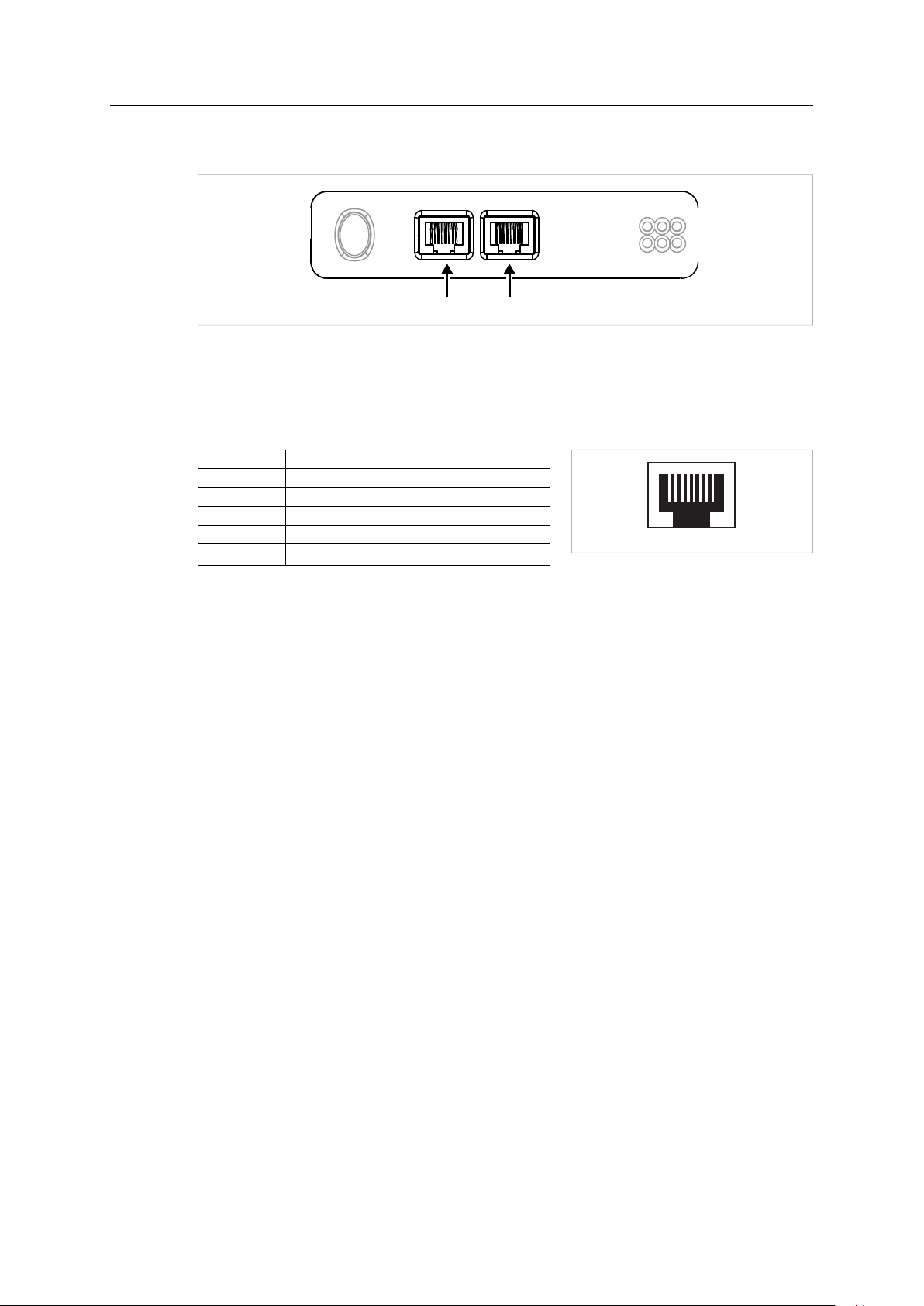

3.6 PROFINET IRT Network Interface

Fig. 10 PROFINET IRT interface

Ethernet Connectors (LAN 1/LAN 2)

The PROFINET IRT interface contains a dual port Ethernet switch with RJ45 type connectors. The

two ports are labeled LAN 1 and LAN 2.

Pin Function

1 TD+

2 TD-

3 RD+

6 RD-

4, 5, 7, 8

(reserved)

Fig. 11 Ethernet connector (RJ45)

Anybus®X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Installation 12 (60)

1 2

3

546

3.7 LED Indicators

LED 1 to 4

LED 5

LED 6 Device operation status

Primary network interface status

Secondary CANopen network interface status

LED Indicators – Primary PROFINET IRT Network Interface

1 - Network Status Off Offline

Green

Green, 1 flash Online (STOP)

Red Fatal error

Red, 1 flash

Red, 2 flashes IP address error

Red, 3 flashes Configuration error

Alternating red/green

2 - Module Status Off No power or initializing

Green

Green, 1 flash

Red Fatal error

Alternating red/green

3 - Link/Activity 1

4 - Link/Activity 2

Off No power or no link detected

Green

Green, flickering

– No power

– No connection to IO Controller

Online (RUN)

– Connection to IO Controller

– Connection to IO Controller

– IO Controller in STOP state or IO data bad

– RT synchronization not finished

Station name error

Firmware update in progress

Normal operation

Diagnostic event present

Firmware update in progress

Link OK

Transmitting/receiving data

LED Indicators – Secondary CANopen Network Interface & Device Status

5 - CANopen Status

6 - Device Status

Off

Flickering red/green

Green

Green, 1 flash Stopped state

Green, blinking Pre-operational state

Red Bus off

Red, 1 flash Warning limit reached

Red, 2 flashes Error control event

Red, 3 flashes

Red, 4 flashes

Red, blinking Configuration error

Off Power off

Green Running

Green, 1 flash

Red Fatal error

Red, 1 flash Initialization error

Red, 2 flashes

Red, 3 flashes Hardware failure

Red, 4 flashes Invalid switch settings

No power

LSS services in progress

Operational state

Sync error

Data communication timeout

Bootup

Timeout error

®

Anybus

X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Installation 13 (60)

On

Off

50 ms

50 ms

Flickering

LED

On

Off

Blinking

LED

200 ms

200 ms

On

Off

Single flash

LED

200 ms

1000 ms

On

Off

Double flash

LED

200 ms

1000 ms

200 ms

200 ms

On

Off

Quadruple flash

LED

200 ms

1000 ms

200 ms

200 ms

200 ms 200 ms 200 ms 200 ms

On

Off

Triple flash

LED

200 ms

1000 ms

200 ms

200 ms

200 ms 200 ms

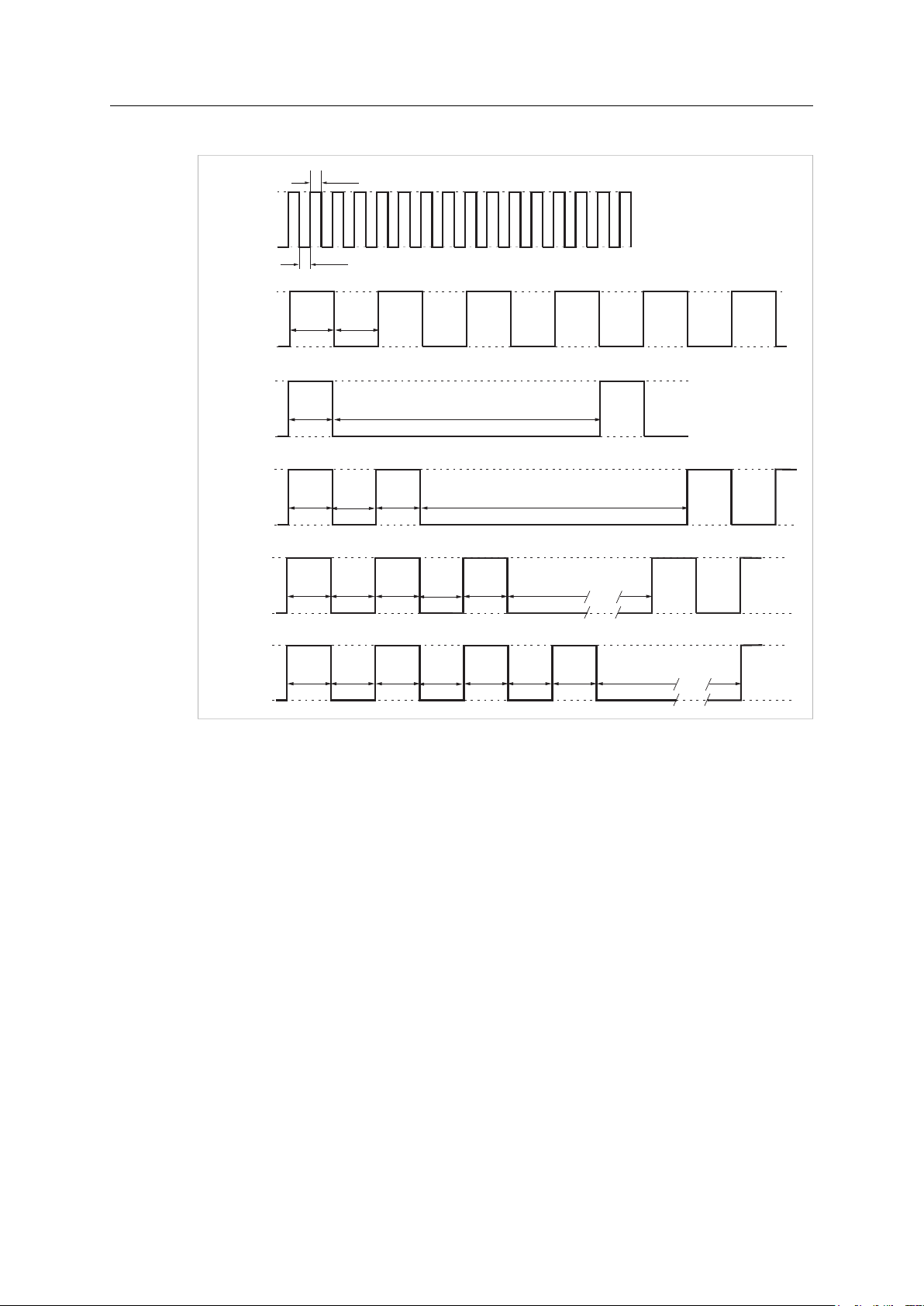

LED Indicator Timing Intervals

Fig. 12 LED indicator timing intervals

®

Anybus

X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Configuration 14 (60)

4 Configuration

4.1 Configuration Overview

Device Description Files

A device description file contains a description of a network device, its functions, object

dictionary implementations, etc., and is used when configuring the network interface. The device

description file can be referred to as an EDS, GSD, DDF, etc., depending on the type of network.

The latest versions of the device description files to use with Anybus X-gateway CANopen can be

downloaded from www.anybus.com/support.

Basic steps when configuring Anybus X-gateway CANopen

The secondary network interface should be configured first. The gateway must then be

power cycled before configuring the primary network interface.

1. Determine the amount of data that should be transferred. This value will be entered in the

secondary CANopen network interface configuration.

2. Configure the secondary CANopen network interface.

See Configuring the Secondary CANopen Network, p. 15.

3. Power cycle the X-gateway.

4. Configure the primary network interface.

See Configuring the PROFINET IRT (2.32) Interface, p. 16.

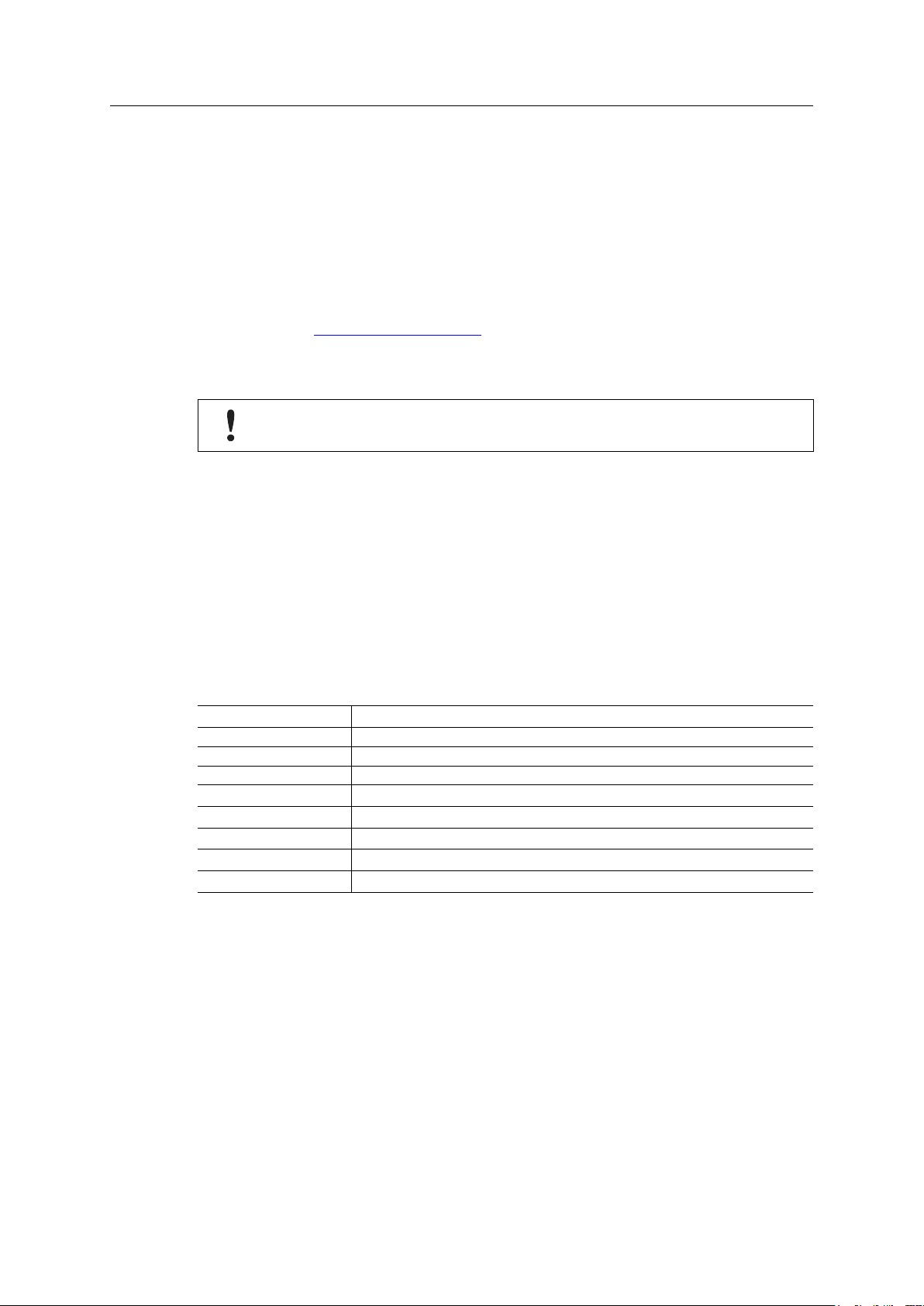

Module Identification

Anybus X-gateway CANopen will identify itself on the network as follows:

Description Value

Vendor Code

Vendor Name “HMS Networks”

Product Code

Product Type

Product Type String “Communications Adapter”

Product Name “Anybus X-gateway CANopen”

Catalog “Anybus X-gateway CANopen”

Desc Text

90

51

12

“Anybus X-gateway CANopen”

®

Anybus

X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Configuration 15 (60)

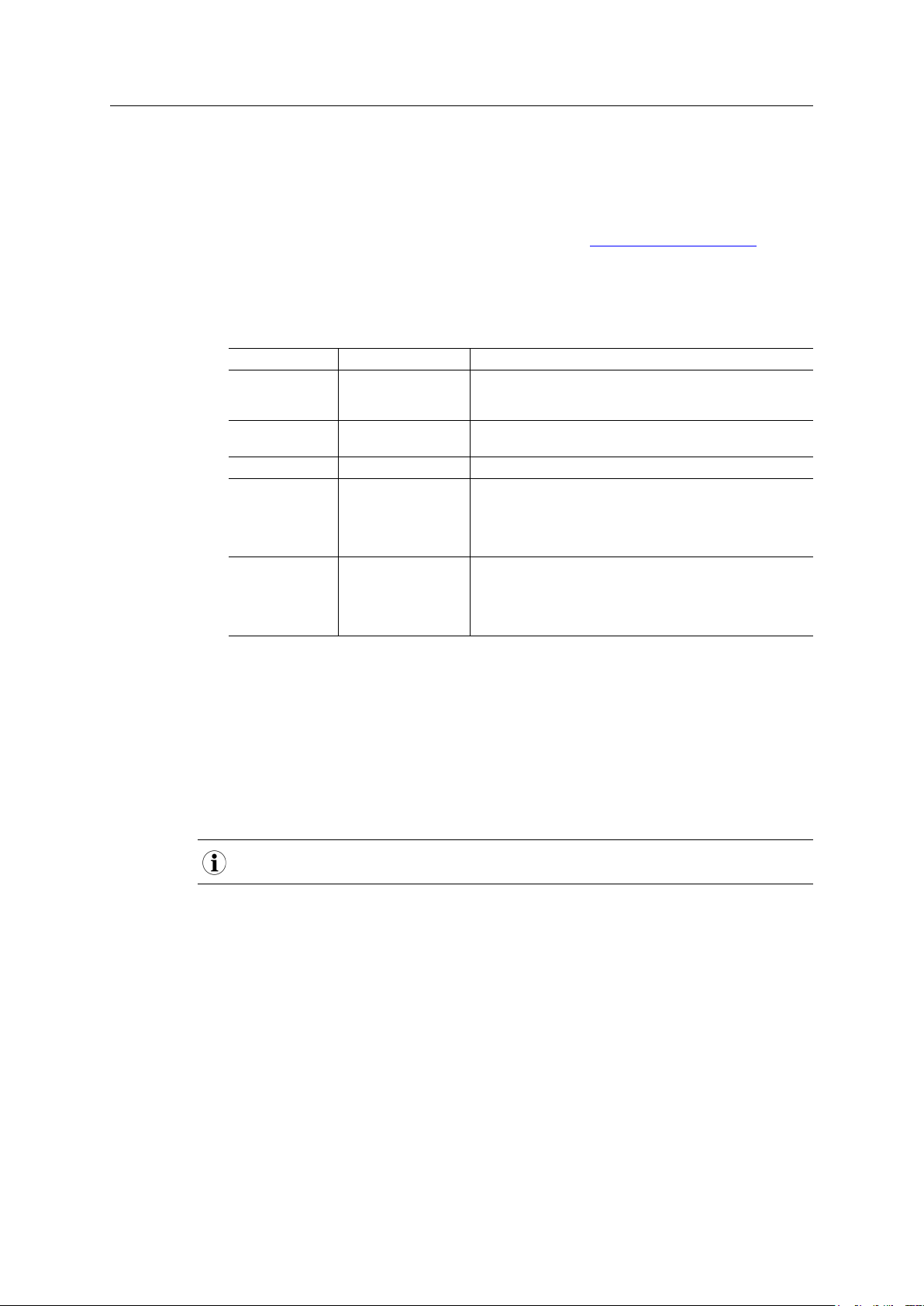

4.2 Configuring the Secondary CANopen Network

This is a generic description of the basic steps in configuring the secondary CANopen network

interface using an external CANopen configuration tool. For instructions on how to create and

apply a configuration, please refer to the documentation for the configuration tool used.

1. Download the Anybus X-gateway CANopen EDS file from www.anybus.com/support.

2. Prepare EDS files for the other nodes on the secondary CANopen network.

3. Open the CANopen configuration tool and upload the EDS files to it.

4. Configure the following parameters in the Anybus X-gateway CANopen:

Parameter

NodeID

Baud Rate

Master/Slave

Input Data Size

(object 3000h)

Output Data Size

(object 3001h)

Value range

1 to 127

20, 50, 125, 250, 500,

800, 1000, Auto

Master or Slave Default = Slave. See also NMT Start-up, 1F80h, p. 48.

2 to 512

2 to 512

Comment

NodeID 1 to 99 can be set with the configuration switches.

NodeID 99 to 127 can only be be set using a configuration tool or

from the CANopen network.

Set with configuration switch.

Auto should only be used when configured as a slave.

Size of the data transmitted to the primary network.

Bytes 0 and 1 are reserved for the Status Word, leaving a

maximum of 510 bytes available for data. The actual maximum

data size depends on the primary network.

Default = 16 bytes (14 bytes data + 2 bytes Status Word).

Size of the data received from the primary network.

Bytes 0 and 1 are reserved for the Control Word, leaving a

maximum of 510 bytes available for data. The actual maximum

data size depends on the primary network.

Default = 16 bytes (14 bytes data + 2 bytes Control Word).

5. Configure the other CANopen nodes as needed. Make sure that each node uses the same

baud rate and has a unique NodeID.

6. Download the configuration from the tool to each CANopen node.

The configuration can be downloaded individually to each node, or as a Concise DCF file to

the CANopen master which will then configure the slaves.

7. Power cycle the X-gateway.

8. Continue to Configuring the PROFINET IRT (2.32) Interface, p. 16.

The secondary CANopen network will start up as a slave by default.

Anybus®X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Configuration 16 (60)

4.3 Configuring the PROFINET IRT (2.32) Interface

The secondary network interface should always be configured first. The gateway must

then be power cycled before configuring the primary network interface.

The primary network interface of the X-gateway must be configured with the configuration tool

used for the network it is connected to. The choice of configuration tool depends on the type of

network, the application, and the master used on the primary network.

Application notes describing how to configure primary network interfaces in Anybus X-gateway

CANopen with some of the most common tools can be found at www.anybus.com/support.

4.3.1 PROFINET Data Exchange

PROFINET is the open Industrial Ethernet standard for automation from PROFIBUS and PROFINET

International. The PROFINET IRT device provides PROFINET IO Isochronous Real Time

Communication.

PROFINET makes a clear distinction between fast cyclical data, IO Data, and acyclical data,

Record Data. PROFINET IO Data corresponds to what is generally referred to as I/O Data in

Anybus X-gateway CANopen. PROFINET Record Data is not supported.

PROFINET IO Data (I/O Data)

PROFINET IO Data is exchanged cyclically and is built up by I/O modules. The actual I/O

configuration is determined by the PROFINET IO Controller. The modules are mapped to the

Input and Output Buffers in the order of their slot number.

The first two bytes of the I/O data area are reserved for the Control Word and the Status Word,

which are used by the IO Controller to control and report status on the nodes on the secondary

CANopen network. The remainder is available for real-time data transfer using PDOs.

The amount of data exchanged as I/O data is specified when configuring the CANopen master

interface. The data arriving from the CANopen master is completely transparent. The

interpretation must be defined by the master on the primary network.

GSD File

All PROFINET devices are associated with an XML-based GSD file. This file contains information

about the basic capabilities and configuration options of the device.

The latest version of the GSD file for Anybus X-gateway CANopen can be downloaded from

www.anybus.com/support.

Anybus®X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Configuration 17 (60)

4.3.2 Network Configuration

To be able to communicate over Ethernet the network interface needs a valid TCP/IP

configuration. This section explains some basic concepts and describes how to configure the

TCP/IP settings in Anybus X-gateway CANopen using the IPconfig software tool.

When Ethernet communication has been established the TCP/IP settings can also be changed

from the web interface. See Web Pages, p. 21.

Basic TCP/IP Concepts

IP Address

The IP address is used to identify each node on a TCP/IP network. IP addresses are written as

four decimal integers (0–255) separated by dots, where each integer represents the binary value

of one byte of the IP address. This is known as dot-decimal notation.

Example: 10000000 00001010 00000010 00011110 is written as 128.10.2.30

The following IP addresses are reserved for special purposes and cannot be used:

0.n.n.n

127.n.n.n

n.n.n.0

n.n.n.255

First byte zero — used for broadcast messages

First byte 127 — used for loopback addresses to the local host

Last byte zero — identifies a whole network/subnet

Last byte 255 — used for broadcast messages

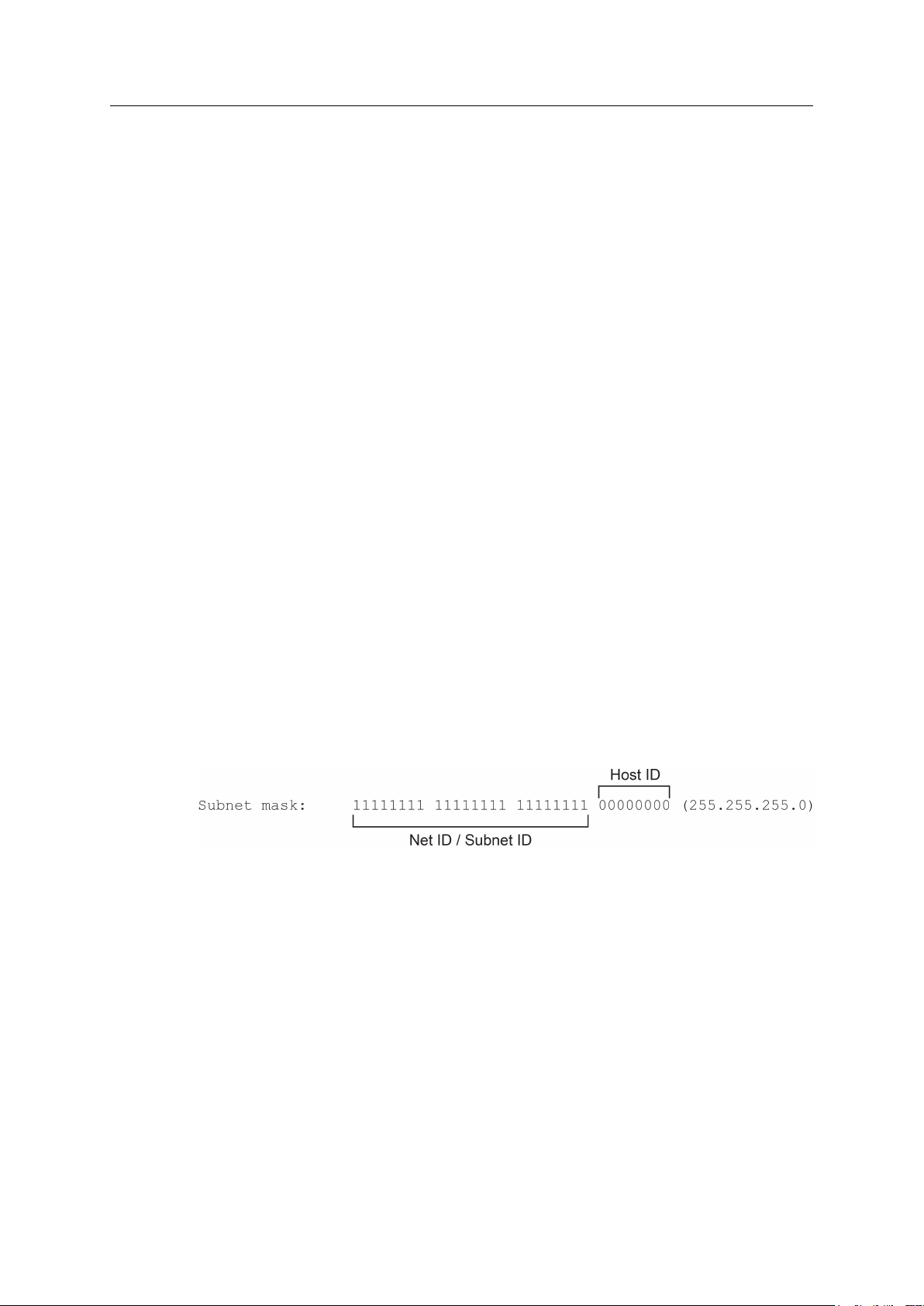

Subnet Mask

The IP address is divided into three parts: Net ID, Subnet ID and Host ID. A subnet mask is a 32bit binary pattern, where a set bit allocates a bit for Network/Subnet ID, and a cleared bit

allocates a bit for the Host ID. The subnet mask is usually written in dot-decimal notation.

Example: To make the IP address 128.10.2.30 belong to subnet 128.10.2, the subnet

mask must be 255.255.255.0.

Default Gateway

For devices to be able to communicate over Ethernet they must either belong to the same

subnet or communicate via a gateway or router.

A gateway or router routes communication between networks, i.e. it enables the nodes on one

network to access the nodes on another. The default gateway address in the TCP/IP settings of

your product specifies the IP address of the gateway or router on the local network.

Anybus®X-gateway™CANopen®PROFINET®IRT (2.32) User Manual

SCM-1202-029 1.2 en-US

Loading...

Loading...