Page 1

Anybus®CompactCom™B40 Modbus Serial

USER MANUAL

SCM-1202-130 1.1 en-US ENGLISH

Page 2

Important User Information

Disclaimer

The information in this document is for informational purposes only. Please inform HMS Industrial Networks of any

inaccuracies or omissions found in this document. HMS Industrial Networks disclaims any responsibility or liability

for any errors that may appear in this document.

HMS Industrial Networks reserves the right to modify its products in line with its policy of continuous product

development. The information in this document shall therefore not be construed as a commitment on the part of

HMS Industrial Networks and is subject to change without notice. HMS Industrial Networks makes no commitment

to update or keep current the information in this document.

The data, examples and illustrations found in this document are included for illustrative purposes and are only

intended to help improve understanding of the functionality and handling of the product. In view of the wide range

of possible applications of the product, and because of the many variables and requirements associated with any

particular implementation, HMS Industrial Networks cannot assume responsibility or liability for actual use based on

the data, examples or illustrations included in this document nor for any damages incurred during installation of the

product. Those responsible for the use of the product must acquire sufficient knowledge in order to ensure that the

product is used correctly in their specific application and that the application meets all performance and safety

requirements including any applicable laws, regulations, codes and standards. Further, HMS Industrial Networks will

under no circumstances assume liability or responsibility for any problems that may arise as a result from the use of

undocumented features or functional side effects found outside the documented scope of the product. The effects

caused by any direct or indirect use of such aspects of the product are undefined and may include e.g. compatibility

issues and stability issues.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 3

Table of Contents

Page

1 Preface ................................................................................................................................. 3

1.1 About this Document........................................................................................................ 3

1.2 Document History ............................................................................................................ 3

1.3 Document Conventions.....................................................................................................3

1.4 Document Specific Conventions.......................................................................................... 4

1.5 Trademark Information ..................................................................................................... 4

2 About the Anybus CompactCom B40 Modbus Serial........................................................ 5

2.1 General Information ......................................................................................................... 5

2.2 Features ......................................................................................................................... 6

2.3 Overview........................................................................................................................ 6

2.4 How to Use this Manual .................................................................................................... 6

3 Modbus Application Interface............................................................................................ 8

3.1 How To Set Up and Initialize the Modbus Communication ......................................................8

3.2 Supported Modbus Commands ........................................................................................ 10

3.3 Modbus Register Map..................................................................................................... 11

4 Hardware Design ............................................................................................................... 13

4.1 Host Application Interface ............................................................................................... 13

4.2 Network Connector ........................................................................................................ 21

4.3 Network Configuration Switches ....................................................................................... 28

4.4 IO Expansion Mechanism................................................................................................. 29

A Technical Specification...................................................................................................... 31

A.1 Environmental............................................................................................................... 31

A.2 Shock and Vibration ....................................................................................................... 31

A.3 Electrical Characteristics.................................................................................................. 31

A.4 Regulatory Compliance ................................................................................................... 32

B Mechanical Specification .................................................................................................. 33

B.1 Anybus CompactCom B40 Modbus Serial ........................................................................... 33

B.2 Footprint ...................................................................................................................... 34

B.3 Height Restrictions ......................................................................................................... 34

B.4 Network Connector Boards (Optional) ............................................................................... 35

B.5 Connector Board for Fiber Optic Ethernet .......................................................................... 35

B.6 Assembly ...................................................................................................................... 37

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 4

C Firmware Upgrade ............................................................................................................ 39

C.1 Using Firmware Manager II .............................................................................................. 40

C.2 Using FTP ..................................................................................................................... 41

D The Anybus State Machine ............................................................................................... 42

D.1 General Information ....................................................................................................... 42

D.2 State Dependent Actions ................................................................................................. 43

E Implementation Guidelines .............................................................................................. 44

E.1 General ........................................................................................................................ 44

E.2 Example ....................................................................................................................... 44

E.3 Power Supply Considerations ........................................................................................... 45

F Network Interface Examples ............................................................................................ 47

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 5

Preface 3 (48)

1 Preface

1.1 About this Document

This document is intended to provide a good understanding of the functionality offered by the

Anybus CompactCom B40 Modbus Serial.

The reader of this document is expected to be familiar with high level software design and

communication systems in general. The information in this user manual should normally be

sufficient to implement a design. However if advanced network specific functionality is to be

used, in-depth knowledge of network networking internals and/or information from the official

network specifications may be required. In such cases, the persons responsible for the

implementation of this product should either obtain the network specification to gain sufficient

knowledge or limit their implementation in such a way that this is not necessary.

For additional information, please visit the support website at www.anybus.com/support.

1.2 Document History

Version

1.0 2019-04-30

1.1 2019-05-16

Date

1.3 Document Conventions

Ordered lists are used for instructions that must be carried out in sequence:

1. First do this

2. Then do this

Unordered (bulleted) lists are used for:

• Itemized information

• Instructions that can be carried out in any order

...and for action-result type instructions:

► This action...

→ leads to this result

Bold typeface indicates interactive parts such as connectors and switches on the hardware, or

menus and buttons in a graphical user interface.

Monospaced text is used to indicate program code and other

kinds of data input/output such as configuration scripts.

Description

First release

Updated for PROFINET release

This is a cross-reference within this document: Document Conventions, p. 3

This is an external link (URL): www.hms-networks.com

This is additional information which may facilitate installation and/or operation.

This instruction must be followed to avoid a risk of reduced functionality and/or damage

to the equipment, or to avoid a network security risk.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 6

Preface 4 (48)

Caution

This instruction must be followed to avoid a risk of personal injury.

WARNING

This instruction must be followed to avoid a risk of death or serious injury.

1.4 Document Specific Conventions

• The terms “Anybus” or “module” refers to the Anybus CompactCom module.

• The terms “host” or “host application” refer to the device that hosts the Anybus.

• Hexadecimal values are written in the format NNNNh or 0xNNNN, where NNNN is the

hexadecimal value.

• A byte always consists of 8 bits.

• All dimensions in this document have a tolerance of ±0.10 mm unless otherwise stated.

• Outputs are TTL compliant unless otherwise stated.

• Signals which are “pulled to GND” are connected to GND via a resistor.

• Signals which are “pulled to 3V3” are connected to 3V3 via a resistor.

• Signals which are “tied to GND” are directly connected to GND,

• Signals which are “tied to 3V3” are directly connected to 3V3.

1.4.1 Pin Types

The pin types of the connectors are defined in the table below. The pin type may be different

depending on which mode is used.

Pin type

I Input

O Output

I/O Input/Output (bidirectional)

OD Open Drain

Power

Definition

Pin connected directly to module power supply, GND or 3V3

1.5 Trademark Information

Anybus®is a registered trademark of HMS Industrial Networks.

EtherNet/IP is a trademark of ODVA, Inc.

All other trademarks are the property of their respective holders.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 7

About the Anybus CompactCom B40 Modbus Serial 5 (48)

2 About the Anybus CompactCom B40 Modbus Serial

2.1 General Information

The Anybus CompactCom B40 Modbus Serial is a communication solution for simple industrial

field devices. The host application communicates with the product using the Modbus RTU

protocol. The Anybus CompactCom B40 Modbus Serial then communicates the data to the

network. Typical applications are basic level I/O blocks, temperature controllers, measuring

devices, and sensors.

The Anybus CompactCom B40 Modbus Serial software interface is designed to be network

protocol independent, making it possible to support several networking systems using the same

application software code/driver.

The Anybus CompactCom B40 Modbus Serial share footprint and electrical interface with the

other members of the product family, independent of fieldbus or network. The host application

connector provides an interface between the host application (Modbus RTU) and the Anybus

CompactCom, while the network connector provides access to the chosen network. The Anybus

CompactCom acts as a Modbus RTU slave on the host application side.

The Anybus CompactCom 40 family offers a wide range of functionality. For advanced products and

applications, we recommend the standard Anybus CompactCom 40.

For general information about other products using the Anybus CompactCom 40 platform,

consult www.anybus.com/support.

This a class A product. In a domestic environment, this product may cause radio

interference in which case the user may be required to take adequate measures.

This product contains ESD (Electrostatic Discharge) sensitive parts that may be damaged if

ESD control procedures are not followed. Static control precautions are required when

handling the product. Failure to observe this may cause damage to the product.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 8

About the Anybus CompactCom B40 Modbus Serial 6 (48)

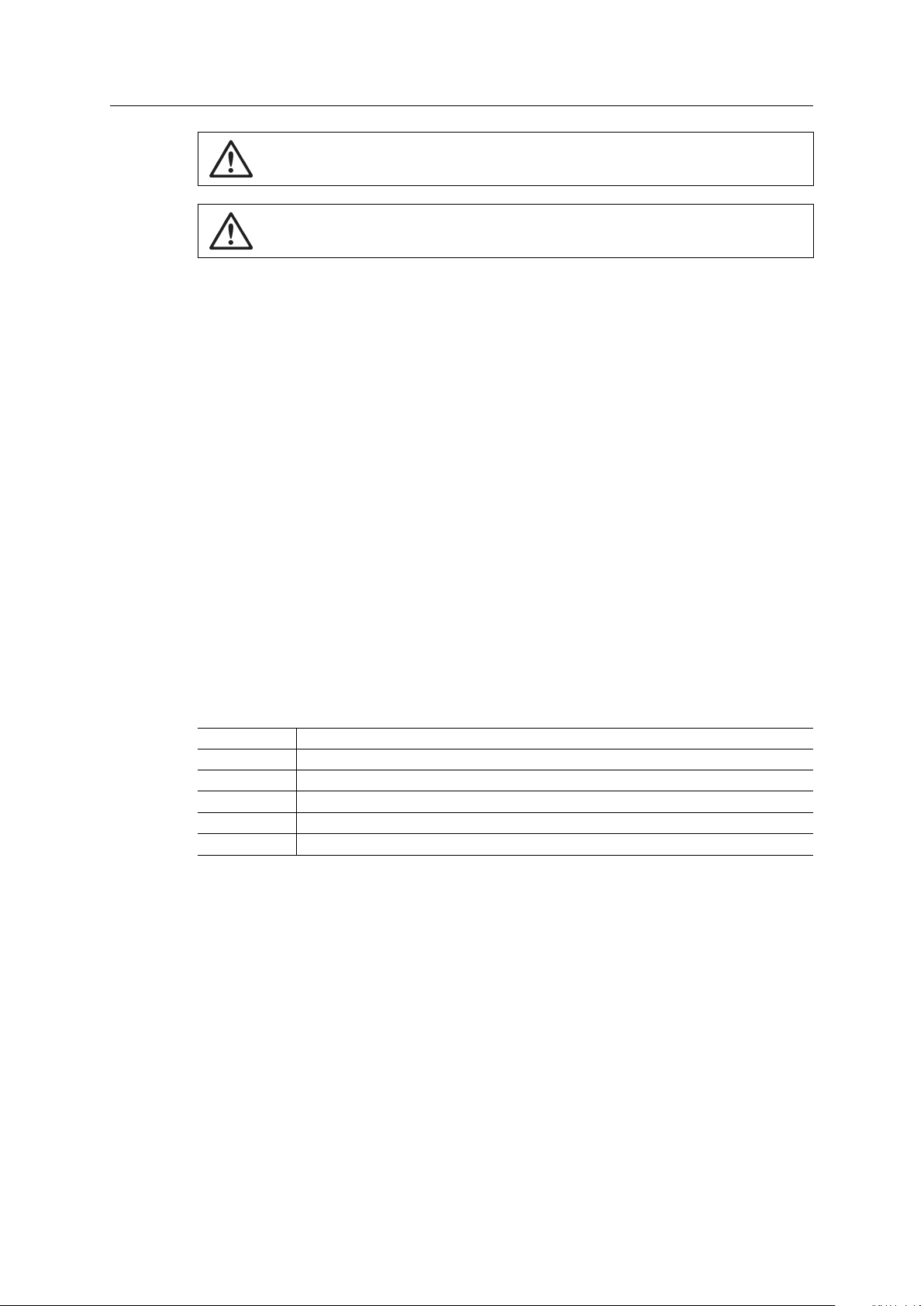

Host processor

with applicaon

Anybus

CompactCom

Modbus

Serial

Process DataData

Industrial Network

Modbus RTU

2.2 Features

• Simple implementation and great connectivity flexibility

• Serial Communications Interface (UART), that can be connected to almost any standard

microcontroller

• Standard Modbus RTU serial protocol

• Galvanic isolation integrated

• Low power consumption

• Control pins for status indications according to each network standard

• Separate network connector board available

• Precompliance tested for network conformance (where applicable).

• Precompliance tested for CE & UL. Contact HMS Industrial Networks for further information.

All Anybus CompactCom 40 Modbus Serial will be precertified for network conformance.

This is done to ensure that the final product can be certified, but it does not necessarily

mean that the final product does not require recertification. Contact HMS Industrial

Networks for further information.

2.3 Overview

The picture below shows the data flow in the Anybus CompactCom B40 Modbus Serial. The

application sets up the Modbus RTU communication, and the Anybus CompactCom maps the

process data to the industrial network/fieldbus.

Fig. 1

2.4 How to Use this Manual

This manual includes the following:

1. The implemented Modbus RTU application interface and how to use it (host application).

2. Instructions on how to indesign the Anybus CompactCom in your product (hardware design).

Network specific configuration, performed from the network, is described in the Anybus

CompactCom 40 Modbus Serial Network Guides.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 9

About the Anybus CompactCom B40 Modbus Serial 7 (48)

2.4.1 Host Application

The Modbus application interface is set up and configured in the same way, independent of

which network the data will be sent to/read from. This process, including an example is

described in Modbus Application Interface, p. 8.

2.4.2 Hardware Design

• When creating your hardware design, refer to Hardware Design, p. 13 for descriptions of

connectors etc. Please note that some inputs should be strapped to ensure correct behavior.

• Dimensions and other mechanical information is presented in Mechanical Specification, p.

33.

• Technical specifications, like temperature limits and electrical specifications, are given in

Technical Specification, p. 31.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 10

Modbus Application Interface 8 (48)

3 Modbus Application Interface

The host application interface of the product consists of a Modbus Serial interface, which

implements a reduced set of registers and commands. The Anybus CompactCom acts as a

Modbus RTU slave.

3.1 How To Set Up and Initialize the Modbus Communication

To set up and initialize the communication between the host application and the network, follow

the steps below. Steps 2 - 6 includes examples of what the Modbus messages can look like.

1. Set Modbus address, baud rate, stop bits, and parity according to Communication Settings,

p. 19.

See Hardware Design, p. 13 for information on how to connect the corresponding pins.

2. Write initial values to the Write Process Data area (registers 0x0000-). (Optional)

Example – Using the Modbus function Write Multiple Holding Registers to set

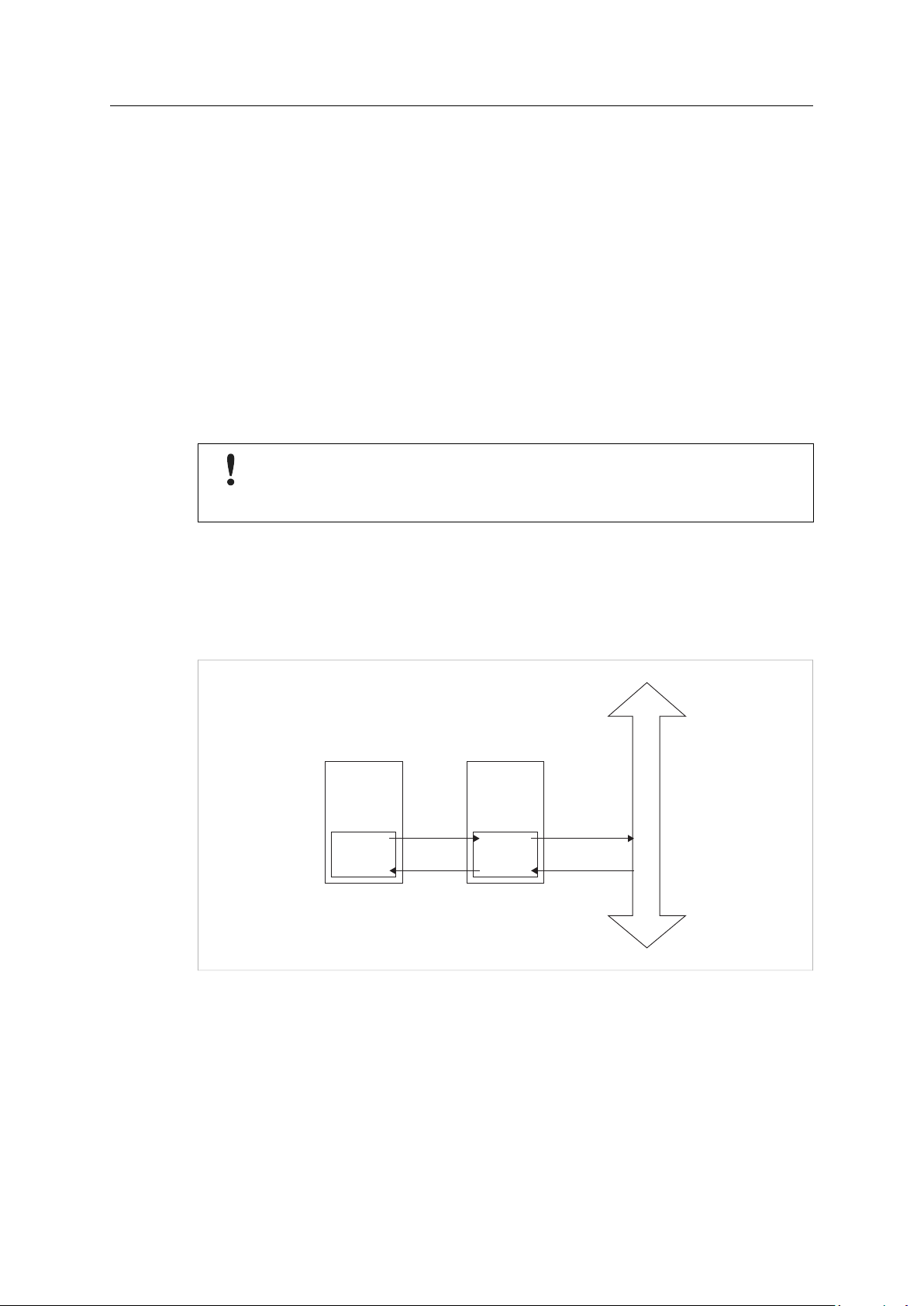

initial values for 10 Write Process Data registers (20 bytes) to CompactCom with address 5.

Address Function Code

0x05 16 0x0000 10 20

Data CRC

Starting

Address

Quantity of

Registers

Byte Count

Register

Values

20 bytes of

data

CRC-16-ANSI

3. Write switch settings to register 0x5200-0x5201, “Application switch 1” and “Application

switch 2”. Optional for networks that do not require these settings.

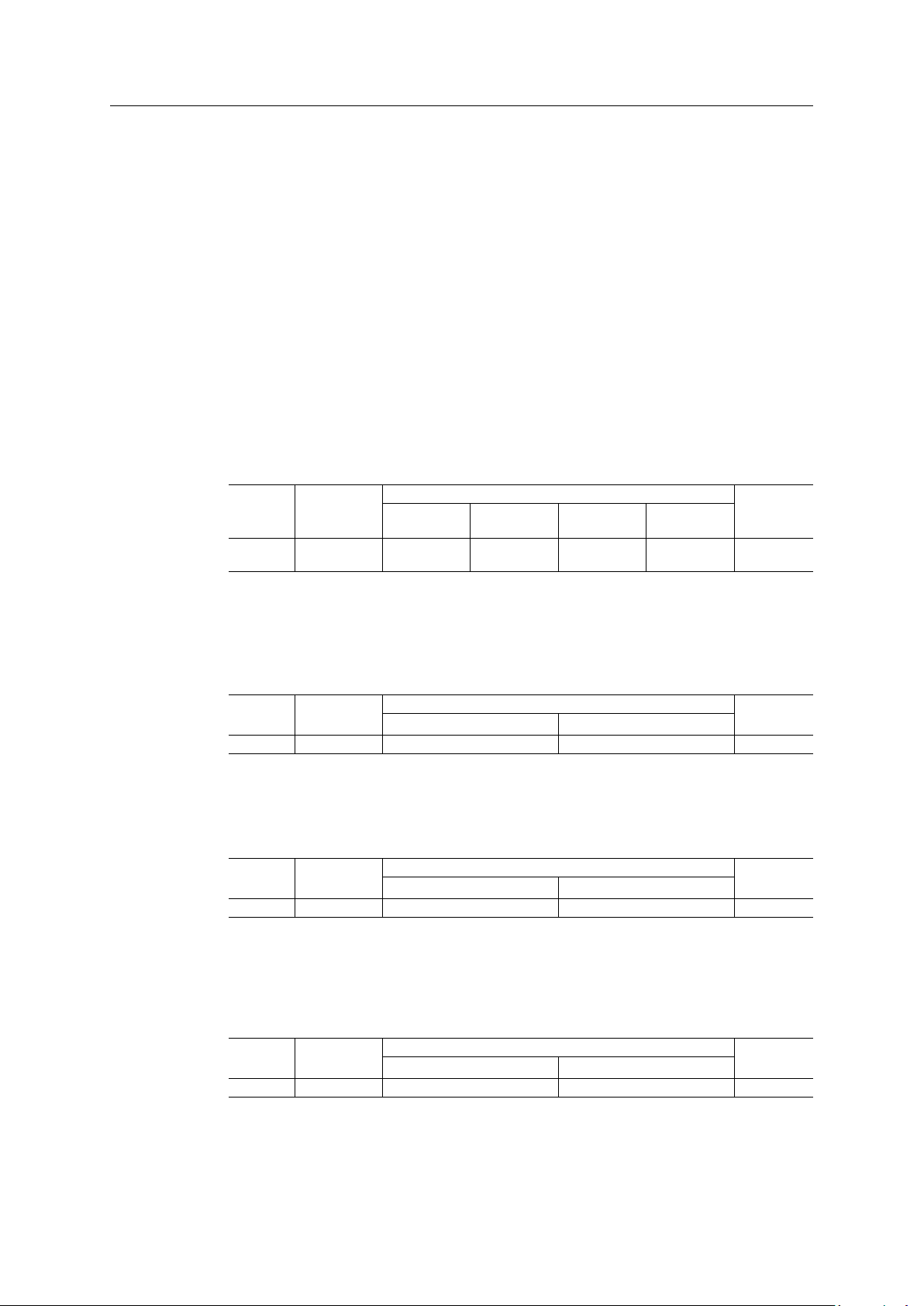

Example – Using the Modbus function Write Single Holding Register to set the

Node Address for a network using a node address for identification. NOTE: Node address 7

will be used on the Industrial Network (e.g. PROFIBUS).

Address Function Code

0x05 6 0x5200 7 CRC-16-ANSI

Data CRC

Register Address Register Value

4. Set Offline Action for Read Process Data in register 0x5101 (Clear or No action). (Oprtional)

Example – Using the Modbus function Write Single Holding Register to configure

Clear as the Offline Action for Read Process Data (all data will be 0 if the network is

offline).

Address Function Code

0x05 6 0x5101 0 CRC-16-ANSI

Data CRC

Register Address Register Value

5. Set the size of the Write Process Data area to register 0x5102. Data type (byte or word) is

configured with register 0x5100.

Example – Using the Modbus function Write Single Holding Register to configure

Write Process Data size 20 bytes. Assuming default value of register 0x5100, i.e. data type is

UINT8.

Address Function Code

0x05 6 0x5102 20 CRC-16-ANSI

Data CRC

Register Address Register Value

®

Anybus

CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 11

Modbus Application Interface 9 (48)

6. Set the size of the Read Process Data area to register 0x5103. Data type (byte or word) is

configured with register 0x5100.

Example – Using the Modbus function Write Single Holding Register to configure

Read Process Data size 18 bytes. Assuming default value of register 0x5100, i.e. data type is

UINT8.

Address Function Code

0x05 6 0x5103 18 CRC-16-ANSI

Data CRC

Register Address Register Value

7. The CompactCom is now ready to start communicating with the network master with the

configured settings. Start cyclical read/write of process data to register 0x0000- and 0x1000-.

Also consider to cyclically monitor the values of register 0x0FFD (Anybus Switch Status),

0x0FFE (LED status), and 0x0FFF (Anybus Status).

If a reset request is indicated in the Anybus Status register, the host application must reset

the CompactCom, and start the initialization sequence from step 1. See RESET (Reset Input),

p. 18.

Example – The Modbus function Read/Write Multiple Registers allows you to

both read and write registers with one command. In this example the status registers and

the read process data registers are read, at the same time as the write process data

registers are written.

Command:

Address Function Code

0x05 23 0x0FFD 12 0x0000 10 20

Data CRC

Read

Starting

Address

Quantity

to Read

Write

Starting

Address

Quantity

to Write

Write

Byte

Count

Write

Reg

Values

20 bytes

of data

CRC-16-ANSI

Response:

Address Function Code

0x05 23 24

Data CRC

Read Byte Count Read Reg Values

24 bytes of data

CRC-16-ANSI

The Anybus CompactCom will stay in state SETUP until values have been written to 0x5102 and

0x5103 (items no. 5 and 6 in the list above). The Anybus CompactCom will then change states to

WAIT_PROCESS, and the registers 0x5100-0x5103 will be read-only.

See also ..

• The Anybus State Machine, p. 42

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 12

Modbus Application Interface 10 (48)

3.2 Supported Modbus Commands

# Name

3

4

6

16

23

70

Read multiple registers All mapped to the same register space.

Read input registers

Write single register

Write multiple registers

Read/Write registers

Anybus command Custom Modbus command, see below

Description

3.2.1 Error Handling

• Modbus reads, addressing undefined registers, return zeroes.

• Modbus writes, addressing undefined registers, do not return any error.

• Modbus writes containing invalid data to registers do not return any error.

• Modbus writes, addressing read-only registers, do not return any error.

3.2.2 Endianess

• If 8-bit data types are mapped to Modbus registers, the first byte is mapped to LSB and the

second byte is mapped to MSB of the Modbus register.

3.2.3 Anybus Command (Modbus Function Code 70)

This command can be used to send an Anybus CompactCom message. Allowed content depends

on which network is connected to the Anybus CompactCom. The data field part of the telegram

is composed by concatenating the content for each configuration option to include. Note that

the total amount of configuration options to set is limited to 244 bytes of data. Please refer to

the applicable network appendix for more information.

The content of the telegram will be stored and used at the next startup. It is not necessary to

send this telegram at each startup. Instead it is recommended to send it once to customize the

Anybus CompactCom behavior.

Request format:

0 1 2

3 4 5 6 7 8 9 10–n

Address Function Size Data Field CRC

(Address)

70 66 1 1 0 1 7 0

The content of the data field depends on which network is connected. Please refer to the applicable

network appendix for details.

Size of

Data

Field

0

0-244 bytes of

data,

configuring the

Anybus

CompactCom

behavior

(n+1)(n+2)

(CRC)

Response format

0 1 2 3 4 5 6 7 8 9 10–11

Address Function

(Address)

®

Anybus

CompactCom™B40 Modbus Serial User Manual

70 2 1 1 0 17 0 0 0

Size

CRC

(CRC)

SCM-1202-130 1.1 en-US

Page 13

Modbus Application Interface 11 (48)

3.3 Modbus Register Map

The Modbus register space is designed to allow easy and efficient communication using a single

cyclic read/write Modbus command.

Register#

0x0000 -

0x0FFD

0x0FFE LED status

0x0FFF

0x1000 -

0x5003

Name Access

Write process data

Anybus Switch status Read only Value of INPUT1 and INPUT2 pins.

Anybus status

Read process data Read only Area is updated with new data from Network ONLY when address

Module type Read only Anybus CompactCom 40 (0x0403)

Description

Read/

Write

Read only Bit field holding the current state of the network status LEDs as

Read/

Write

When the last byte of mapped process data is written, data is sent

to the network for consistency reasons.

INPUT1:

INPUT2:

follows:

Bit:

b0:

b1:

b2:

b3:

b4:

b5:

b6:

b7:

b8 - b15

Anybus status register with two additional bits, Reset and Set

Default added.

Bit(s)

0 - 2

3 SUP

4 -13

14

15 Reset

0x1000 is read.

LSB

MSB

Contents:

LED1A status (0=OFF, 1=ON)

LED1B status (0=OFF, 1=ON)

LED2A status (0=OFF, 1=ON)

LED2B status (0=OFF, 1=ON)

LED3A status (0=OFF, 1=ON)

LED3B status (0=OFF, 1=ON)

LED4A status (0=OFF, 1=ON)

LED4B status (0=OFF, 1=ON)

(reserved)

Description

Anybus state (See The Anybus State Machine, p. 42)

0. Setup

1: NW_INIT

2: WAIT_PROCESS

3: IDLE

4: PROCESS_ACTIVE

5: ERROR

6: (reserved)

7: EXCEPTION

0: Module is not supervised

1: Module is supervised by another network device

The SUP bit indicates the overall status of the network

communication. For example, on CIP, this bit indicates

that the master has a connection towards the module.

Exactly how this functionality should be handled, the

offered level of security, and how to correctly activate

it is network specific and often depends on external

circumstances, e.g. configuration of the network as

well as other network devices. Whether use of the

SUP-bit is appropriate must therefore be decided for

each specific application and network.

(reserved)

Set Default

0: No action

1: Application is requested to set “factory default” to

all parameters/settings. Application shall acknowledge

this by writing 1 to this bit to clear it.

0: No action

1: Application is requested to reset the Anybus

CompactCom

®

Anybus

CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 14

Modbus Application Interface 12 (48)

Register#

0x5004

0x5005

Name Access

Network type Read only

Anybus Exception Code Read only

0x5100 Data type

0x5101

0x5102

Offline action

Number of Write

Parameters

0x5103

Number of Read

Parameters

0x5200

0x5201

Application switch 1

Application switch 2

Read/

Write

Read/

Write

Read/

Write

Read/

Write

Read/

Write

Read/

Write

Description

0x0089:

0x009B:

0x00:

0x01:

0x02:

0x03:

0x04.

0x05:

0x06:

0x07:

0x08:

0x09:

0x0A:

0x0B:

0x0C:

PROFINET IRT

EtherNet/IP

No exception

Application timeout

Invalid device address

Invalid communication settings

Major unrecoverable application event

Waiting for application reset

Invalid process data configuration

Invalid application response

NVS memory checksum error

Functional Safety Module error

Insufficient application implementation

Missing serial number

File system is corrupt

Data type of the parameters that are mapped to Write and Read

process data.

UINT8:

UINT16:

0x0004 (Default)

0x0005

R/W in SETUP state.

Read only in other states.

Action taken when the Anybus CompactCom is not in PROCESS_

ACTIVE state.

0x0000:

0x0001:

Clear “Read Process data area”

No action (Default)

R/W in SETUP state.

Read only in other states.

Number of parameters mapped to Write process data.

If the value written is bigger than module can handle, the value will

automatically be adjusted to max possible value (according to

network) after the SETUP state.

R/W in SETUP state. Read only in other states.

Number of parameters mapped to Read process data.

If the value written is bigger than module can handle, the value will

automatically be adjusted to max possible value (according to

network) after the SETUP state.

R/W in SETUP state. Read only in other states.

This register can be used for the node address.

Value written to this register may be defined by DIP switches on

the application. See Network Configuration Switches, p. 28.

This register can be used for defining stop bits and baud rate.

Value written to this register may be defined by DIP switches on

the application. See Network Configuration Switches, p. 28.

®

Anybus

CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 15

Hardware Design 13 (48)

Pin 1

Application

interface

Pin 1

Network

interface

Outline of brick

Top view

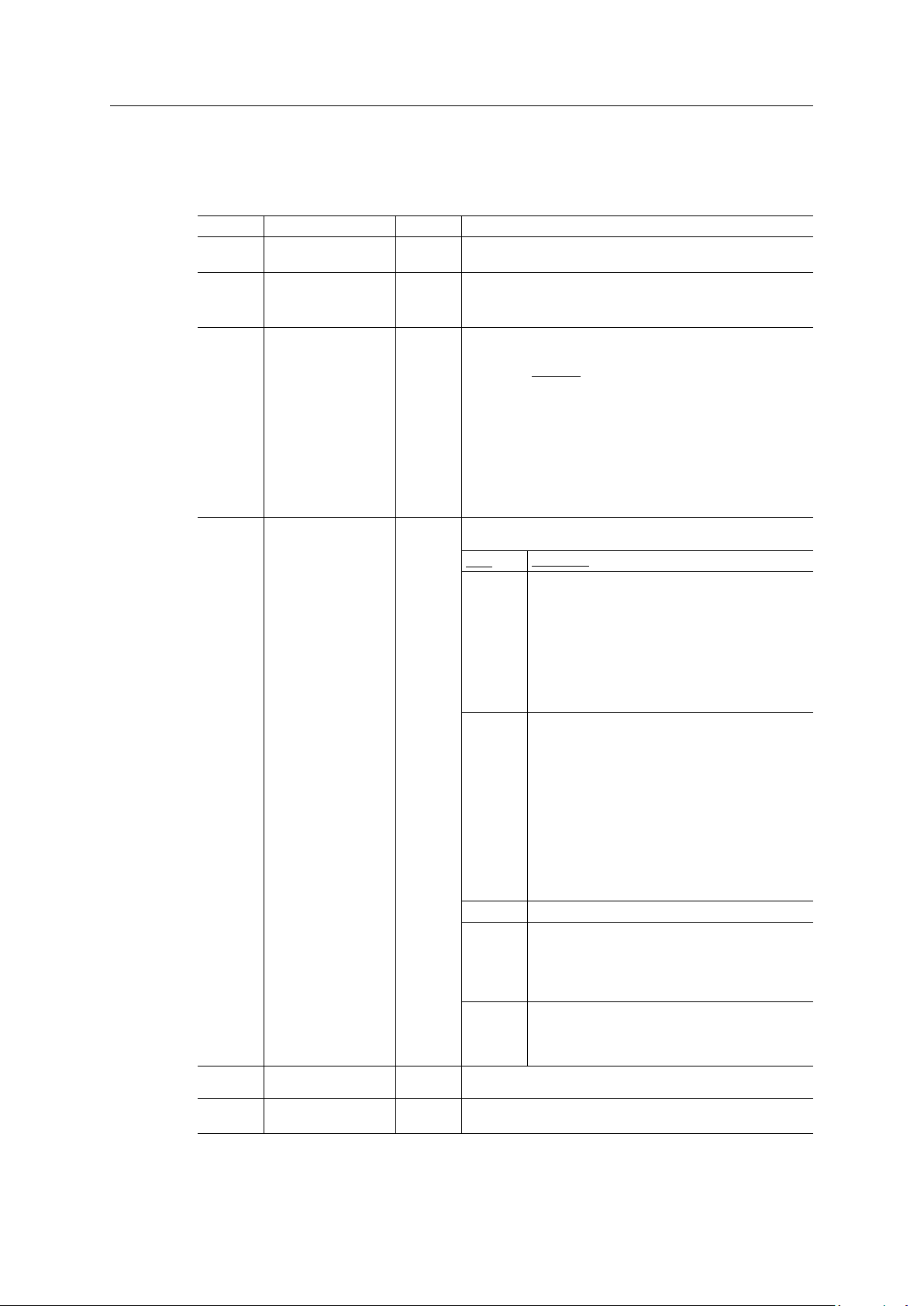

4 Hardware Design

Information needed to design the hardware for a product embedding the Anybus CompactCom

B40 Modbus Serialis presented later in this section. This includes mechanical and electrical

specification, connector pinnings etc. An example on how to design a network interface is also

included. An optional connector board is available.

• For the host application and network interfaces, see Hardware Design, p. 13

• For further implementation guidelines see Implementation Guidelines, p. 44

• For brick dimensions, footprint dimensions and height restrictions, see Mechanical

Specification, p. 33

• For electrical characteristics and other technical specifications, see Technical Specification, p.

31

• The optional connector board is described in Network Connector Boards (Optional), p. 35

• How to mount the Anybus CompactCom on the host application PCB is described in

Assembly, p. 37

• A typical example of how to design the network interface is offered in Network Interface

Examples, p. 47

4.1 Host Application Interface

The host application connector provides an interface between the host application and the

Anybus CompactCom B40 Modbus Serial.

Anybus®CompactCom™B40 Modbus Serial User Manual

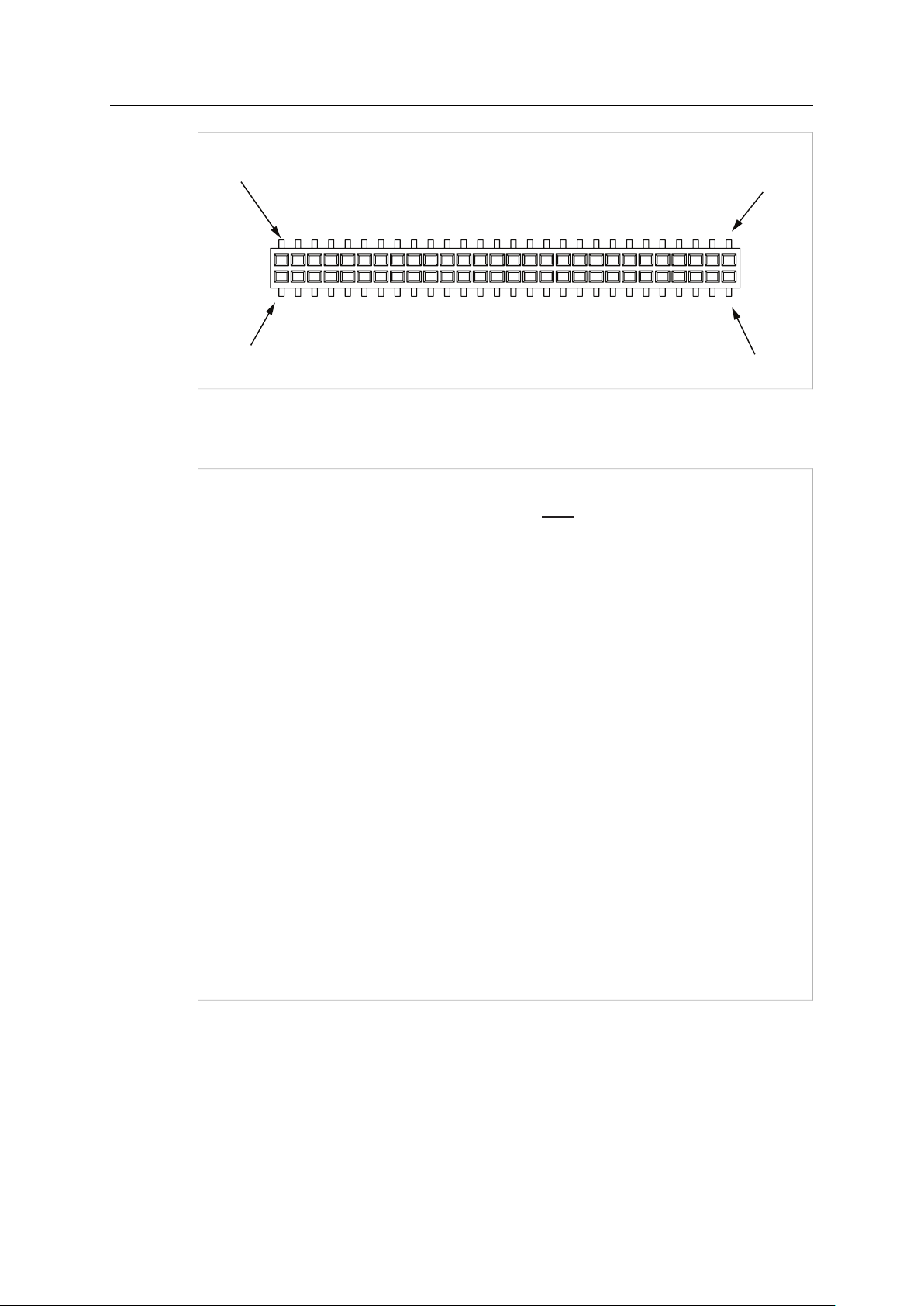

Fig. 2

The connector is implemented by a standard 1.27 mm 56 pin header surface mounted to the

bottom side of the PCB.

SCM-1202-130 1.1 en-US

Page 16

Hardware Design 14 (48)

1

2

56

55

Top view

GND 2 1 3V3

INPUT1_0 4

3 RESET

INPUT1_2 6

5 INPUT1_1

GND 8

7 INPUT1_3

INPUT1_5 10

9 INPUT1_4

INPUT1_7 12

11 INPUT1_6

GND 14

13

16

15

GND 18

17

20

19

INPUT2_6 22

21 INPUT2_7

GND 24

23 INPUT2_5

INPUT2_3 26

25 INPUT2_4

GND 28

27 INPUT2_2

MD0 30

29 INPUT2_1

OM0 32

31 INPUT2_0

GND 34

33 OM1

36

35 OM2

DE 38

37

GND 40

39

42

41

GND 44

43

46

45

48

47

GND 50

49

TX/OM3 52

51 RX

MI0 54

53 MI1

GND 56

55 3V3

Fig. 3

The picture shows the pinning of the mating connector on the host application as seen from the

top.

Anybus®CompactCom™B40 Modbus Serial User Manual

Fig. 4

See Pin Overview, p. 15 for information on how each pin is used.

SCM-1202-130 1.1 en-US

Page 17

Hardware Design 15 (48)

4.1.1 Pin Overview

Presented below is an overview of all pins except GND and 3V3.

The pin types of the connector are defined in Pin Types, p. 4. The pin type may be different

depending on which mode is used.

The pin numbers of the Anybus CompactCom B40 (brick) host application connector are

different from those of the Anybus CompactCom M40 (module) host application

connector.

Pin

Signal

Name

4 INPUT1_0 I

5 INPUT1_1 I

6 INPUT1_2 I

7 INPUT1_3 I

9 INPUT1_4 I

10 INPUT1_5 I

11 INPUT1_6 I

12 INPUT1_7 I

13

(not used)

15 I

16 O, I

17

(not used)

19 I

20

(not used)

31 INPUT2_0 I

29 INPUT2_1 I

27 INPUT2_2 I

26 INPUT2_3 I

25 INPUT2_4 I

23 INPUT2_5 I

22 INPUT2_6 I

21 INPUT2_7 I

49

(not used)

48 O

47 O

46 O

45 O

43 O

42 O

41 O

37

(not used)

39 I

36 I

38 DE O

Type Notes

I

I

O

O

I

These inputs are used to set the Modbus address of the Anybus CompactCom

See Communication Settings, p. 19

The signals can also be used to connect a DIP switch, see IO Expansion Mechanism, p.

29.

Connect directly to GND

Connect directly to 3V3

Leave unconnected

These inputs are used to set baud rate, stop bits, and parity of the Anybus

CompactCom

See Communication Settings, p. 19

The signals can also be used to connect a DIP switch, see IO Expansion Mechanism, p.

29.

Leave unconnected

Connect directly to 3V3

Active high Data Enable for RS485 transceiver

See DE (Data Enable), p. 17

®

Anybus

CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 18

Hardware Design 16 (48)

Pin Signal

Name

51 RX I

52

TX / OM3 I/O

32 OM0 I

33 OM1 I

35 OM2 I

54 MI0 O

53 MI1 O

30 MD0 O

3 RESET I

Type Notes

Receive Input for Modbus communication

• Direction: Host application -> Anybus CompactCom

• Idle state = High

Transmit Output for Modbus communication

• Direction: Anybus CompactCom -> Host application

• Idle state = High

This pin doubles as OM3 strapping input on Anybus CompactCom. Connect a pulldown resistor on the application for this pin in Modbus serial mode. The pull-down

resistor shall have a value between 1 kΩand 2.2 kΩ.

Set [OM2, OM1, OM0] to [0,1,1]

For more information see Settings , p. 17.

Low at power-up and before reset release.

See Settings , p. 17

Please not that this pin can be used as SYNC pin PROFINET. Used at conformance

testing.

Tied to 3V

See Settings , p. 17

Tied to GND

See Settings , p. 17

See RESET (Reset Input), p. 18

4.1.2 Power Supply Pins

Signal

GND Power 2, 8, 14, 18, 24,

3V3 Power 1, 55

Type

Pin Description

28, 34, 40, 44,

50, 56

Ground

Power and signal ground reference.

3.3 V power supply.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 19

Hardware Design 17 (48)

4.1.3 Settings

Signal Name

OM3

OM2

OM1

OM0

MI0

MI1

MD0 O 30

RX

TX

Type

I

I

I

I

O

O

I

O

Module Detection

This signal is internally connected to GND, and can be used by the host application to detect

whether a module is present or not. When connecting an external pull-up resistor, a low signal

indicates that a module is present.

If not used, leave this signal unconnected.

4.1.4 DE (Data Enable)

Pin Description

52

35

33

32

54

53

51

52

Set [OM3, OM2, OM1, OM0] to [0,0,1,1] for Modbus Serial

operation.

OM3 is used to set operation mode at startup, and requires a

pull-down resistor. It is used as TX output after startup. The pulldown resistor shall have a value between 1 kΩand 2.2 kΩ.

[MI1, MI0] = [1,0] indicates that the Anybus CompactCom

connected comes from the Anybus CompactCom 40-series..

Module Detection

This signal can be used by the host application to determine that

an Anybus CompactCom is inserted into the slot, see Module

Detection, p. 17.

The signal is connected directly to GND on the Anybus

CompactCom.

Serial Communications Signals, used for Modbus Communication.

TX is used as OM3 during setup

The Anybus CompactCom B40 Modbus Serial supports RS485. This signal is then used as an

active high data enable signal for RS485 transceivers.

Signal Name Pin Type Pin Description

DE O 38

Data Enable

Active high signal used for RS485 transceiver.

This signal must be pulled to GND on the host application side to prevent spurious transmissions

during startup.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 20

Hardware Design 18 (48)

Power

/RESET

0V

3.3V

Power

On

Power

Stable

t

B

t

A

V

IL

V

IH

t

t

RESET

t

C

V

IL

V

IH

t

4.1.5 RESET (Reset Input)

Signal Name Pin Type Pin Description

RESET I 3 Reset

The Anybus CompactCom does not feature any internal reset regulation. To establish a reliable

interface, the host application is solely responsible for resetting the Anybus CompactCom when

the supply voltage is out of the specified range.

Power Up

Used to reset the module.

Fig. 5

Powerup time limits are given in the table below:

Symbol

t

A

t

B

Min.

- -

1 ms

Max.

-

Definition

Time until the power supply is stable after power-on; the duration depends

on the power supply design of the host application and is thus beyond the

scope of this document.

Safety margin.

Restart

The reset pulse duration must be at least 10 µs in order for the Anybus CompactCom to properly

recognize a reset.

Fig. 6

Symbol

t

C

Min.

10 µs

Max.

-

Definition

Reset pulse width.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 21

Hardware Design 19 (48)

4.1.6 Communication Settings

The communication settings are configured by the INPUT1 and INPUT2 input pins in the

application interface. Invalid settings results in the Anybus CompactCom entering the state

EXCEPTION.

The Modbus address is configured using INPUT1. Valid range is 1 - 247.

Baud rate, stop bits, and parity are configured using INPUT2, as defined in the tables below.

INPUT2 bits 1..0 value Stop bits, Parity

0 1, Even

1

2 2, None

3 1, None

INPUT2 bits 7..2 value Baud rate

0 - 2

3 9600

4 19200

5 38400

6 57600

7

8 115200

9 625000

10 - 64

1, Odd

(reserved)

(reserved)

(reserved)

®

Anybus

CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 22

Hardware Design 20 (48)

3V3

3V3

INPUT1_2

INPUT1_5

INPUT1_1

INPUT1_0

INPUT1_3

INPUT1_4

INPUT1_7

INPUT1_6

INPUT2_2

INPUT2_5

INPUT2_1

INPUT2_0

INPUT2_3

INPUT2_4

INPUT2_7

INPUT2_6

Modbus address setting = 1

Modbus baud rate setting = 4 (19200)

Modbus stop bit setting = 0 (1 stop bit, even)

Example

The figure shows INPUT1 and INPUT2 signals directly for Modbus communication. INPUT1 signals

are strapped to Modbus address 0x01. INPUT2 signals are set to configure 1 stop bit, even parity

and baud rate 19200.

Fig. 7

®

Anybus

CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 23

Hardware Design 21 (48)

Pin 1

Application

interface

Pin 1

Network

interface

Outline of brick

Top view

1

2

52

51

Top view

4.2 Network Connector

The network connector provides network access to the Anybus CompactCom B40 Modbus Serial.

Fig. 8

The signals from the network connector can be directly routed to the (optional) connector board,

which carries a network connector(s) identical or similar to the ones on the corresponding

Anybus CompactCom M40 module.

Examples on how to design the network access circuitry, when not using the connector board,

are shown in Network Interface Examples, p. 47.

The brick has a standard 1.27 mm 52 pin header surface mounted to the bottom side of the

board as network interface.

Anybus®CompactCom™B40 Modbus Serial User Manual

Fig. 9

The pictures shows the pinning of the corresponding network connector on the host application

board, seen from the top.

SCM-1202-130 1.1 en-US

Page 24

Hardware Design 22 (48)

GND 2 1 3V3

B_1CEN/SDA 4

3 B_1P/RXP

GND 6

5 B_1N/RXN

B_2CEN/SCL 8

7 B_2P/SDP

GND 10

9 B_2N/SDN

B_3CEN 12

11 B_3P/TXEN

GND 14

13 B_3N/TXDIS

B_4CEN/BUSP 16

15 B_4P/TXP

GND 18

17 B_4N/TXN

NW_LED4A 20

19 NW_LED4B

NW_LED3A 22

21 NW_LED3B

NW_LED2A 24

23 NW_LED2B

NW_LED1A 26

25 NW_LED1B

GND 28

27 3V3

A_1CEN/SDA 30

29 A_1P/RXP

GND 32

31 A_1N/RXN

A_2CEN/SCL 34

33 A_2P/SDP

GND 36

35 A_2N/SDN

A_3CEN 38

37 A_3P/TXEN

GND 40

39 A_3N/TXDIS

A_4CEN/BUSP 42

41 A_4P/TXP

GND 44

43 A_4N/TXN

C_RX 46

45 C_TX

C_BUSP 48

47 C_TXEN

GATE2 50

49 GATE1

GND 52

51 3V3

Fig. 10

4.2.1 Overview

Depending on network, the pins have different names and different functionalities. Presented

below is an overview of all pins except GND and 3V3. More detailed descriptions of the signals

are described for each available network/fieldbus version later in this section (4.2). Please note

that at the moment only EtherNet/IP and PROFINET IRT are available.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 25

Hardware Design 23 (48)

Pin Signal Name

Ethernet based

networks, Copper

3 B_1P B_RXP

4 B_1CEN B_SDA

5 B_1N B_RXN

7 B_2P B_SDP

8 B_2CEN B_SCL

9 B_2N B_SDN

11 B_3P B_TXEN

12 B_3CEN

13 B_3N B_XDIS

15 B_4P B_TXP

16 B_4CEN

17 B_4N B_TXN

19 NW_LED4B NW_LED4B NW_LED4B NW_LED4B NW_LED4B

20 NW_LED4A NW_LED4A NW_LED4A NW_LED4A NW_LED4A

21 NW_LED3B NW_LED3B NW_LED3B NW_LED3B NW_LED3B

22 NW_LED3A NW_LED3A NW_LED3A NW_LED3A NW_LED3A

23 NW_LED2B NW_LED2B NW_LED2B NW_LED2B NW_LED2B

24 NW_LED2A NW_LED2A NW_LED2A NW_LED2A NW_LED2A

25 NW_LED1B NW_LED1B NW_LED1B NW_LED1B NW_LED1B

26 NW_LED1A NW_LED1A NW_LED1A NW_LED1A NW_LED1A

29 A_1P A_RXP

30 A_1CEN A_SDA

31 A_1N A_RXN

33 A_2P A_SDP

34 A_2CEN A_SCL

35 A_2N A_SDN

37 A_3P A_TXEN

38 A_3CEN

39 A_3N A_TXDIS

41 A_4P A_TXP

42 A_4CEN

43 A_4N A_TXN

45 C_TX C_TX C_TX

46 C_RX C_RX C_RX

47 C_TXEN C_TXEN

48 C_BUSP_N

49 GATE1 GATE1 GATE1

50 GATE2 GATE2 GATE2

Ethernet based

networks, fiber optic

DeviceNet

PROFIBUS

CC-Link

At the moment the following copper wired Ethernet protocols are available: EtherNet/IP and

PROFINET IRT. The speed of all these protocols is 100 Mb/s (using signal pairs 1-2 of each port).

PROFINET IRT is also available for fiber optic.

The LED signals are active high and should be connected to the respective LEDs via a resistor.

The pin types of the connector are defined in Pin Types, p. 4. The pin types are specified for each

network type on the following pages.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 26

Hardware Design 24 (48)

4.2.2 Power Supply Pins

Signal Name

GND Power 2, 6, 10,

3V3 Power 1, 27, 51

Type

Pin No. Description

14, 18, 28,

32, 36, 40,

44, 52

Ground

Power and signal ground reference.

3.3 V power supply.

4.2.3 How to Connect Unused Network Connector Pins

For Ethernet versions of the Anybus CompactCom B40 Modbus Serial it is recommended to

terminate Ethernet signals in the network interface if one of the Ethernet ports is unused. For

the 10/100 Mb/s hardware version it is sufficient to terminate pair no. 1 and 2, for the port of

concern, while for the 1 Gb/s hardware version this has to be done for pair no. 1, 2, 3, and 4.

Fig. 11

Unused fibre optic connector pins should be connected as follows:

• 100R between TXP and TXN

• 820R between SDN and 3V3, resulting in 2 V on SDN

• 1k5 between SDP and 3V3, resulting in 1.5 V on SDP- Indicates that no signal is received. A

signal amplitude of 0.5 V is appropriate.

• 4k7 between SCL and 3V3

• 4k7 between SDA and 3V3

Other network signals may be left floating when not used.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 27

Hardware Design 25 (48)

4.2.4 Ethernet Based Networks (Copper)

The industrial networks, that use Ethernet for communication, share the same hardware design.

However, the firmware downloaded to the brick is different depending on network. Physically

they use the same set of pins in a similar way. At the moment Anybus CompactCom B40 Modbus

Serial is available for the following Ethernet based networks: EtherNet/IP and PROFINET IRT.

The brick supports dual network ports, signal group A should be connected to the left port (port

1) and signal group B to the right port (port 2) on the connector board, looking at the front, see

Connector Board for Copper Based Ethernet, p. 35

Signal Group Signal Name Type

B B_1P

B_1CEN Power 4

B_1N

B_2P

B_2CEN Power 8

B_2N

B_3P

B_3CEN Power 12

B_3N

B_4P

B_4CEN Power 16

B_4N

A A_1P

A_1CEN Power 30

A_1N

A_2P

A_2CEN Power 34

A_2N

A_3P

A_3CEN Power 38

A_3N

A_4P

A_4CEN Power 42

A_4N

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

Pin

3

5

7

9

11

13

15

17

29

31

33

35

37

39

41

43

Description

First pair, positive signal

Center tap voltage for first pair

First pair, negative signal

Second pair, positive signal

Center tap voltage for second pair

Second pair, negative signal

Third pair, positive signal. Used for Gigabit Ethernet.

Center tap voltage for third pair. Used for Gigabit

Ethernet.

Third pair, negative signal. Used for Gigabit Ethernet.

Fourth pair, positive signal. Used for Gigabit Ethernet.

Center tap voltage for fourth pair. Used for Gigabit

Ethernet.

Forth pair, negative signal. Used for Gigabit Ethernet.

First pair, positive signal

Center tap voltage for first pair

First pair, negative signal

Second pair, positive signal

Center tap voltage for second pair

Second pair, negative signal

Third pair, positive signal. Used for Gigabit Ethernet.

Center tap voltage for third pair. Used for Gigabit

Ethernet.

Third pair, negative signal. Used for Gigabit Ethernet.

Fourth pair, positive signal. Used for Gigabit Ethernet.

Center tap voltage for fourth pair. Used for Gigabit

Ethernet.

Forth pair, negative signal. Used for Gigabit Ethernet.

4.2.5 Ethernet Fiber Optic Networks

Ethernet fiber optic networks use more or less the same pins as copper based Ethernet networks.

The brick supports PROFINET fiber optic network (PROFINET IRT).

The brick supports dual network ports, signal group A is be connected to the left port (port 1)

and signal group B to the right port (port 2)on the connector board, looking at the front, see

Fiber Optic Conenctor LÄNK!!.

If the Anybus CompactCom B40 connector board is not to be used, please study the design

requirements for the Rx and SD channels, see Rx Channel Design Requirements, p. 26 and SD

Channel Design Requirements, p. 27. Furthermore, fiber optic connectors without metal are

preferred in order to minimize EMC disturbance.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 28

Hardware Design 26 (48)

Brick

Trans-

ceiver

Trans-

ceiver

Trans-

ceiver

Brick Brick

AC coupled transceiver DC coupled transceiver DC coupled transceiver with bias current

Signal Group Signal Name

B B_RXP I 3

B_SDA

B_RXN I 5

B_SDP I 7

B_SCL

B_SDN I 9

B_TXEN O 11

B_TXDIS O 13

B_TXP O 15

B_TXN O 17

A A_RXP I 29

A_SDA

A_RXN I 31

A_SDP I 33

A_SCL

A_SDN I 35

A_TXEN O 37

A_TXDIS O 39

A_TXP O 41

A_TXN O 43

Type

I/O

I/O

I/O

I/O

Pin Description

4

8

30

34

Rx, LVPECL positive signal

SDA, I2C data

Rx, LVPECL negative signal

Signal Detect, LVPECL positive signal

SCL, I2C clock

Signal Detect, LVPECL negative signal

Tx enable

TXEN is implemented as the inverse to TXDIS

Tx disable

Tx, LVPECL positive signal

Tx, LVPECL negative signal

Rx, LVPECL positive signal

SDA, I2C data

Rx, LVPECL negative signal

Signal Detect, LVPECL positive signal

SCL, I2C clock

Signal Detect, LVPECL negative signal

Tx enable

TXEN is implemented as the inverse to TXDIS

Tx disable

Tx, LVPECL positive signal

Tx, LVPECL negative signal

The differential signals Rx and Tx should be routed as differential pairs with a characteristic

impedance of 100 Ω differentially.

Rx Channel Design Requirements

The Rx channel is designed for an optical transceiver output that has an AC coupled 100 Ω

differential signal with 100-1000 mV amplitude, e.g. LVPECL (low voltage positive emitter

coupled logic). Each line is terminated with 50 Ω to a common point with a potential of 1.2 V on

the brick.

If a transceiver with a DC coupled output is used, series capacitors are needed to obtain desired

signal levels for the brick. Below is a figure describing three different options to connect a

transceiver output to an Rx channel on the brick:

Fig. 12

The AC coupling capacitors typically have a value of 100 nF. Resistors draining bias current

typically have a value of 150 Ω.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 29

Hardware Design 27 (48)

Brick

Trans-

ceiver

Trans-

ceiver

Trans-

ceiver

Brick Brick

a: Differential

LVPECL output

b: Single ended LVPECL output

If the output is active low:

Connect the output to SDN and

the 820 Ω resistor to SDP .

c: LVCMOS output. If the output is

active low, connect the 1.8 kΩ

resistor to SDN instead.

SD Channel Design Requirements

The SD (signal detect) channel is designed for a transceiver output that has a DC coupled

differential output with 100-1000 mV amplitude. If a transceiver with LVTTL/LVCMOS output is

used, the signal needs to be conditioned using a few resistors, to obtain desired signal levels for

the brick.

Each line is pulled to GND by a 1.27 kΩ resistor on the brick.

Even if the transceiver has a single ended output and the other line is at a fixed reference

potential, it is recommended to route SDN and SDP side by side all the way to the signal

conditioning resistors. This will give the interference, collected by the transmission line, common

mode characteristics, and it can thus be ignored by the differential input, instead of becoming a

differential mode interference that would corrupt the signal.

Below is a figure describing three different ways to connect a transceiver output to an SD

channel of the brick:

Fig. 13

In case a and case b, additional pull-down resistors will be required if the LVPECL outputs require

a certain bias current (> 1 mA) to function.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 30

Hardware Design 28 (48)

Brick

network

interface

G

Y

220 Ω

220 Ω

NW_LED4A

NW_LED4B

4.2.6 LED Indicators

The Anybus CompactCom 40 series supports four bicolored LED indicators.

LED name Pin no.

LED1 26 NW_LED1A Green

25 NW_LED1B

LED2 24 NW_LED2A Green

23 NW_LED2B

LED3 22 NW_LED3A Green

21 NW_LED3B

LED4 20 NW_LED4A Green

19 NW_LED4B

Signal Name

Default color

Red

Red

Yellow

Yellow

Default Functionality

Network status

Module status

All Industrial

Ethernet Networks:

Other: Not used

EtherNet/IP, Modbus

TCP

Other Not used

All Industrial

Ethernet Networks:

Other: Not used

EtherNet/IP, Modbus

TCP

Other Not used

Link/Act for the

network port (port A)

10 Mbit Link/Act for

Link/Act for the

network port (port A)

Link/Act for the

network port (port B)

10 Mbit Link/Act for

Link/Act for the

network port (port B)

All LED outputs are active high and should be connected as shown in the picture below. The

resistor values should be chosen to get even light between different LEDs.

Fig. 14

4.3 Network Configuration Switches

Modbus registers 0x5200 (Application switch 1) and 0x5201 (Application switch 2) can be used

for network configuration. Application switch 1 is generally used to configure the node address

and application switch 2 to configure the network baud rate.

It is recommended to provide means for the end user to set the values of these registers, using

physical switches like DIP switches, rotaries etc. The application is responsible for reading the

switch values and then writing them to Modbus registers 0x5200 (Application switch 1) and

0x5201 (Application switch 2).

If the application processor does not have sufficient input pins to connect physical switches,

there is a mechanism for I/O expansion that can be used. The switches are then connected to

the Anybus CompactCom B40 Modbus Serial instead. For more information see IO Expansion

Mechanism, p. 29.

Please refer to the applicable network appendix for a description of the contents of the registers.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 31

Hardware Design 29 (48)

4.4 IO Expansion Mechanism

If the application is to implement physical switches for network configuration, but does not have

sufficient I/O pins, the switches can be connected to the Anybus CompactCom instead using the

IO Expansion Mechanism. The INPUT1 and INPUT2 pins can then be used both to strap the

Modbus communication settings and to connect the physical switches.

The Anybus CompactCom will sample the INPUT1 and INPUT2 pins to determine the Modbus

communication settings before Modbus communication is performed. When the first Modbus

telegram has been exchanged, the DE signal can be used to alter the INPUT1 and INPUT2 signals

to sample the physical switches. The application processor can then read the INPUT1 and INPUT2

pins in Modbus register 0x0FFD (Anybus switch status) and write back the values to Modbus

registers 0x5200 (Application switch 1) and 0x5201 (Application switch 2).

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 32

Hardware Design 30 (48)

INPUT1_2

INPUT1_5

INPUT1_1

INPUT1_0

INPUT1_3

INPUT1_4

INPUT1_7

INPUT1_6

INPUT2_2

INPUT2_5

INPUT2_1

INPUT2_0

INPUT2_3

INPUT2_4

INPUT2_7

INPUT2_6

Modbus baud rate setting = 4 (19200)

Modbus stop bit setting = 0 (1 stop bit, even)

3V3

3V3

3V3

3V3

SW DIP-8

SW DIP-8

Network address

Network baud rate, stop bits and parity

DE

nReset

CLK

CLR

PRE

D

Q

Q

74LVC74

Modbus address setting = 1

Fig. 15

Anybus

®

CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 33

Appendix A: Technical Specification 31 (48)

A Technical Specification

A.1 Environmental

A.1.1 Operating

-40 to 85° C (-40 to 185° F)

A.1.2 Storage

-40 to 85°C (-40 to 185° F)

A.1.3 Humidity

5 to 95% non-condensing

A.2 Shock and Vibration

A.2.1 Shock

The Anybus CompactCom B40 Modbus Serial is tested according to IEC 68–2–27

• half-sine 30 g, 11 ms, 3 positive and 3 negative shocks in each of three mutually

perpendicular directions

• half-sine 50 g, 11 ms, 3 positive and 3 negative shocks in each of three mutually

perpendicular directions

Connector boards/interface cards are tested for 30 g.

A.2.2 Sinusoidal Vibration

The Anybus CompactCom B40 Modbus Serial is tested according to IEC 68–2–6

Frequency range: 10–500 Hz

Amplitude 10–49 Hz:

Acceleration 50–500 Hz

Sweep rate:

0.35 mm

5 g

1 oct/min

10 double sweep in each of the three mutually perpendicular directions

A.3 Electrical Characteristics

Failure to follow the requirements may lead to permanent hardware damage

It is recommended for Anybus CompactCom B40 Modbus Serial users to make sure that each

signal controlling the Anybus CompactCom B40 Modbus Serial has a drive strength enough to

fulfill level and timing constraints even if the signal is loaded with 20 pF in parallel with 2.2 kΩ to

GND or 3V3.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 34

Appendix A: Technical Specification 32 (48)

A.3.1 Operating Conditions

Symbol

3V3

GND Ground reference 0.00 0.00 0.00 V

I

IN

V

IH

V

IL

I

OH

I

OL

V

OH

V

OL

I

OH

(NW_

LEDx)

Parameter

Supply Voltage (DC)

Ripple (AC)

Current consumption

(also including network

interfaces and network

status LEDs)

Input High Voltage

Input Low Voltage

Current, Output High

Current, Output Low

Output High Voltage

Output Low Voltage

Output Current ,

network LEDs

Pin

Types

PWR

I, BI

O, BI

O 20 mA

Conditions Min.

3.15 3.30 3.45 V

- - ± 100 mV

Class A - - 250 mA

Class B - - 500 mA

Class C - - 1000 mA

-

-

= -4mA 2.4

I

OH

= 4mA

I

OL

2.0

-0.3

-8.0

- -

Typ.

-

-

-

- -

Max. Unit

3.45 V

0.8 V

8.0 mA

0.4 V

I= Input, CMOS (3.3V)

O= Output, CMOS (3.3V)

BI= Bidirectional, Tristate

PWR= Power supply inputs

V

A.4 Regulatory Compliance

EMC Compliance (CE)

Since the Anybus CompactCom is considered a component for embedded applications it cannot

be CE-marked as an end product.

However the Anybus CompactCom 40 family is pre-compliance tested in a typical installation

providing that all modules are conforming to the EMC directive in this installation.

The EMC pre-testing has been conducted according to the following standards:

Emission: EN61000-6-4 EN55016-2-3 Radiated emission

EN55022 Conducted emission

Immunity: EN61000-6-2 EN61000-4-2 Electrostatic discharge

EN61000-4-3 Radiated immunity

EN61000-4-4 Fast transients/burst

EN61000-4-5 Surge immunity

EN61000-4-6 Conducted immunity

Since all Anybus CompactCom B40 Modbus Serial modules have been evaluated according to the

EMC directive through above standards, this serves as a base for our customers when certifying

Anybus CompactCom B40 Modbus Serial based products.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 35

Appendix B: Mechanical Specification 33 (48)

36

36

33

13

2x

3,2

1,5 ± 0,25

2,3 ± 0,25

27 ± 0,20 4,5 ± 0,20

1,27 ± 0,05

1,27

2x26p

2x28p

8=max module height

Pin 1

Application

interface

Pin 1

Network

interface

Bottom view

B Mechanical Specification

This is a class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

This product contains parts that can be damaged by electrostatic discharge (ESD). Use

ESD prevention measures to avoid damage.

All dimensions are in millimeters, tolerance ±0.10 mm, unless otherwise stated.

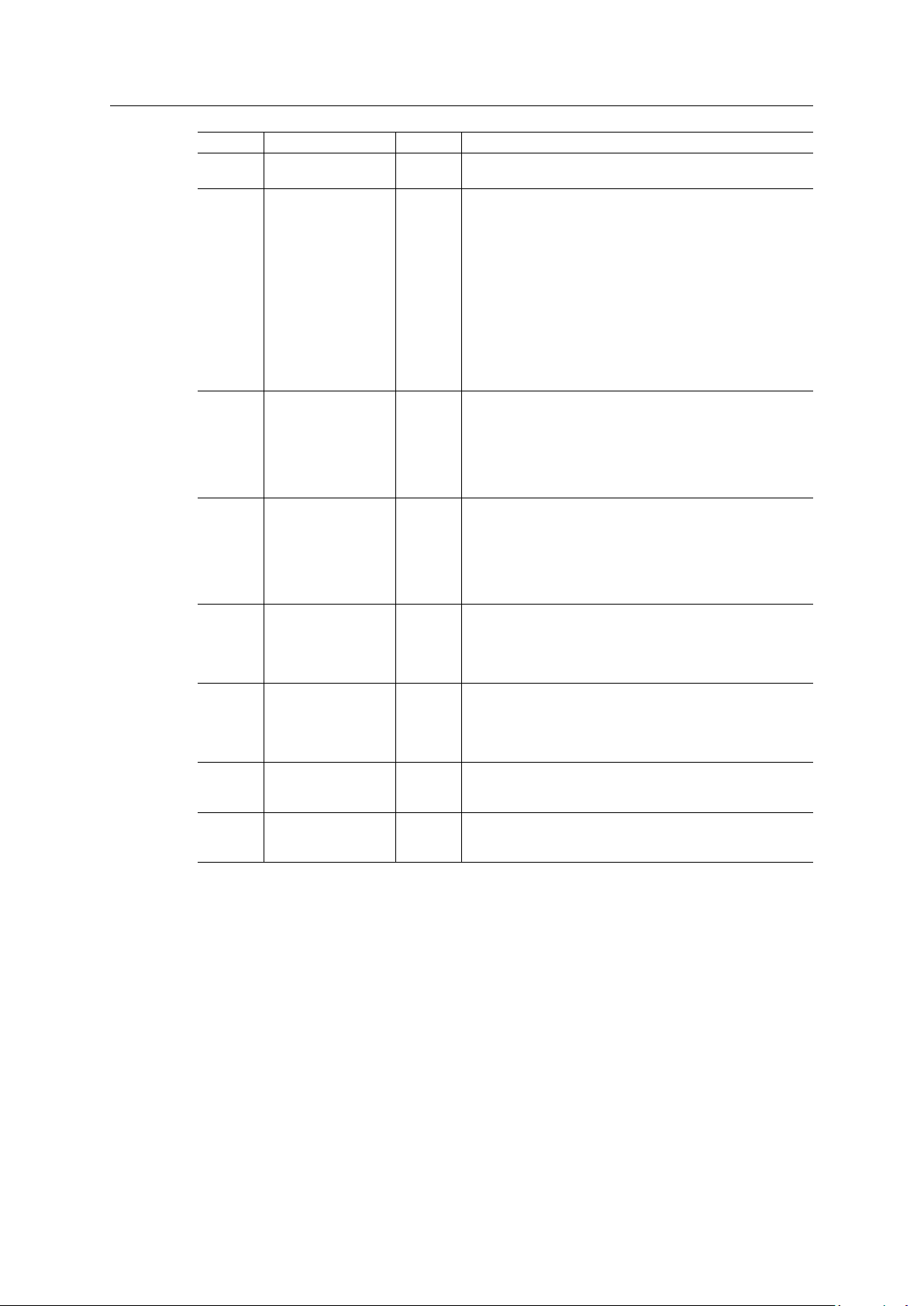

B.1 Anybus CompactCom B40 Modbus Serial

The dimensions for the Anybus CompactCom B40 Modbus Serial are given in the picture below.

Fig. 16

Anybus

®

CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 36

Appendix B: Mechanical Specification 34 (48)

33

2xM3

27

8,5

Pin 1

Application

interface

Pin 1

Network

interface

Outline of brick

Top view

1.5

2.3

27 4.5

8 = max module height

B.2 Footprint

The Anybus CompactCom is connected to the host application board through the host

application interface connector and a network interface connector. The footprint for the Anybus

CompactCom is shown in the picture below.

B.3 Height Restrictions

Fig. 17

All dimensions are in millimeters

Fig. 18

The maximum height occupied by onboard components of the Anybus module is 8 mm. To ensure

isolation, it is recommended to add an additional 2.5 mm on top of these dimensions.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 37

Appendix B: Mechanical Specification 35 (48)

1,5 ± 0,25

2,3 ± 0,25

3,5 ± 0,20

2,9 12,7

37,8

15,6

40

20

18

32

35

3,2

B.4 Network Connector Boards (Optional)

B.4.1 Connector Board for Copper Based Ethernet

The connector board for the copper based Ethernet network interfaces carries two RJ45

connectors.

Fig. 19

B.5 Connector Board for Fiber Optic Ethernet

The connector board for the Fiber Optic Ethernet network interface carries two fibre optic

transceivers.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 38

Appendix B: Mechanical Specification 36 (48)

1,5 ± 0,25

2,3 ± 0,25

3,5 ± 0,20

2,9 13,2

40,3

16,8

20

40

18

32

44,5

3,2

Fig. 20

Anybus

®

CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 39

Appendix B: Mechanical Specification 37 (48)

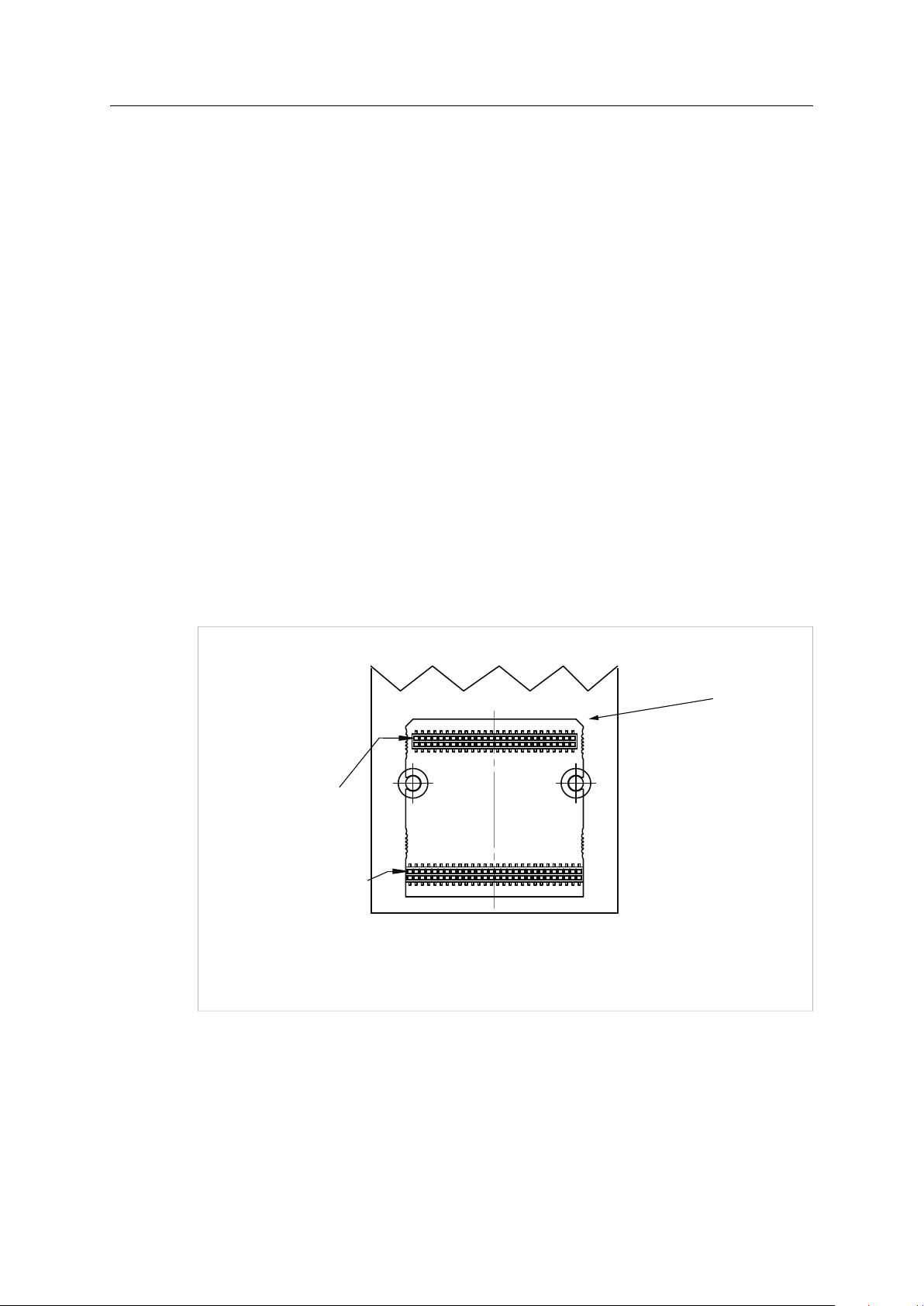

B.6 Assembly

The Anybus CompactCom B40 Modbus Serial and the connector board are mounted separately

on to the host application board. The connector board has to be secured using a screw, joining

FE (functional earth) on the connector board to FE on the host application board. The screw

holes of the Anybus CompactCom B40 Modbus Serial are not connected to FE, but to GND. If

suggested components are used, the Anybus CompactCom B40 Modbus Serial can be mounted

without screws in a low vibration environment, see Shock and Vibration, p. 31 for more

information.

The Anybus CompactCom B40 Modbus Serial can either be connected to the application board

using headers, or soldered directly to the host application PCB.

Fig. 21

Suggested components

Header Application interface Samtec CLP-128-02-L-D (56 pin)

Network interface Samtec CLP-126-02-L-D (52 pin)

Stand-off (M3)

Pemnet SMTSO-M3-4-ET

The screw standoffs are typically 4 mm tall. If the Anybus CompactCom B40 Modbus Serial and

connector board are to be soldered directly to the host application board, standoffs should be 2

mm tall. Outer diameter may be 6 mm max. The standoffs should not extend outside the screw

mount pads.

Recommended torque is 0.2 Nm. Locking paint can be used to secure the screws against

loosening.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 40

Appendix B: Mechanical Specification 38 (48)

33

2xM3

M3

27

8,5 14,5

Pin 1

Application

interface

Pin 1

Network

interface

Pin 1

Network

interface

PCB layout

Standoffs, typ. 4 mm

FE

Outline of brick

Outline of

connector board

M3: Standoff with internal thread, size M3

Top view

Top view

Fig. 22

®

Anybus

CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 41

Appendix C: Firmware Upgrade 39 (48)

C Firmware Upgrade

Download and upgrade of network communication firmware for a specific fieldbus or industrial

network can be performed in different ways, depending on which Anybus CompactCom B40

Modbus Serial that is to be upgraded.

Ethernet versions with FTP

enabled

Ethernet versions with FTP

disabled

Fieldbus versions

Use the Firmware Manager II tool or download the firmware to the designated folder in

the file system.

Unplug the Anybus CompactCom from the host application pcb and use the Anybus

CompactCom 40 Starter Kit to perform the firmware upgrade. See the starter kit

documentation for further information.

®

Anybus

CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 42

Appendix C: Firmware Upgrade 40 (48)

C.1 Using Firmware Manager II

This tool is available without cost from www.anybus.com and can be downloaded from the

product pages. It can be used to download new firmware for any Ethernet Anybus CompactCom

B40 Modbus Serial. Please note that FTP has to be enabled.

Fig. 23

Using the tool, perform the following steps to download new firmware to the module.

1. Connect a computer with the Firmware Manager II software installed to the network

containing the module.

2. Start the Firmware Manager II tool.

3. Scan the network and find the module.

4. Click the Firmware Repository icon in the menu, to open the Firmware Repository window.

Drag the firmware folder into the window to add the new firmware to the repository. Close

the Firmware Repository window.

5. In the scan window, under the “Available Networks” tab, select the appropriate firmware

for the module. Click the Change Network button. A confirmation window will appear. Click

Yes to start the download of the new firmware. Please make sure that download is

completely finished before continuing.

6. After download, a restart of the module is needed to install the new firmware. If the

application allows it, it is possible to restart the module via the Restart Module button in

the Firmware Manager II tool. If the application does not allow restart from the network, a

manual restart of the module is needed.

For more information, see the help file in the Firmware Manager II software.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 43

Appendix C: Firmware Upgrade 41 (48)

C.2 Using FTP

If the module supports FTP, this can be used to access the file system and upload the new

firmware directly to the /firmware directory. The next time the module is started the firmware

will be upgraded. After the firmware is installed, the firmware file is deleted from the /firmware

directory.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 44

Appendix D: The Anybus State Machine 42 (48)

SETUP

(00h)

WAIT_PROCESS

(02h)

PROCESS_ACTIVE

(04h)

IDLE

(03h)

EXCEPTION

(07h)

(Power up)

(From all states)

ERROR

(05h)

NW_INIT

(01h)

D The Anybus State Machine

D.1 General Information

A fundamental part of the Anybus CompactCom B40 Modbus Serial is the Anybus State Machine.

The state machine shall be regarded as a Moore machine; i.e. the host application is not required

to keep track of all state transitions, however it is expected to perform certain tasks in each state

Fig. 24

®

Anybus

CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 45

Appendix D: The Anybus State Machine 43 (48)

D.2 State Dependent Actions

The expected actions for each state are listed below.

State

SETUP

NW_INIT

WAIT_PROCESS

IDLE

PROCESS_ACTIVE

ERROR

EXCEPTION

The host application must keep the Write Process Data updated in NW_INIT (initial data),

WAIT_PROCESS, IDLE, ERROR and PROCESS_ACTIVE since this data is buffered by the

Anybus CompactCom, and may be sent to the network after a state shift.

Description Expected Actions

Anybus CompactCom Setup in progress.

The Anybus CompactCom module is currently performing

network-related initialization tasks.

The network Process Data channel is temporarily inactive. The host application shall

The network interface is idle. The exact interpretation of this

state is network specific. Depending on the configuration in

the offline action register, the Read Process Data may be either

updated or static (unchanged), unless “offline action” is set to

“clear”, in which case the Read Process Data is cleared in this

state.

Normal data handling is possible Perform normal data

There is at least one serious network error.

The module has ceased all network participation due to a host

application related error.

This state is unrecoverable, i.e. the module must be restarted

in order to be able to exchange network data.

regard the Read Process

Data as not valid.

The host application may

act upon the Read Process

Data, or go to an idle state.

handling.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 46

Appendix E: Implementation Guidelines 44 (48)

Host Application

CPU (3.3V)

3V3

3V3

3V3

OM0

OM1

OM2

Tx/OM3

Rx

IRQ

RESET

MI0/SYNC

MI1

MD

Rx

Tx

GPIO5

GPIO6

GPIO7

GPIO8

GPIO10

INPUT2_0

INPUT2_1

INPUT2_2

INPUT2_3

INPUT2_4

INPUT2_5

INPUT2_6

INPUT2_7

3V3 3V3

INPUT1_0

INPUT1_1

INPUT1_2

INPUT1_3

INPUT1_4

INPUT1_5

INPUT1_6

INPUT1_7

Modbus address,

either strapped

or from switch

Number of stop bits,

parity and baud rate

strapped

or from switch

E Implementation Guidelines

E.1 General

This appendix provides an example of a possible implementation for the Anybus CompactCom

B40 Modbus Serial.

There are many different processors with different functionality available on the market today.

The implementation in this appendix is to be regarded as an example that is designed for one

single type of processor. Other hardware interfaces may require adjustments for timing, different

functionality etc. It is important to fully understand the interface to take correct design decisions

in order to obtain a stable and reliable design.

E.2 Example

The example in the figure below shows an implementation with Modbus Serial communication.

Anybus

Fig. 25

®

CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 47

Appendix E: Implementation Guidelines 45 (48)

E.3 Power Supply Considerations

E.3.1 General

The Anybus CompactCom 40 platform in itself is designed to be extremely power efficient. The

exact power requirements for a particular networking system will however vary a lot depending

on the components used in the actual bus circuitry.

While some systems usually require less than 250 mA of supply current at 3.3 V, some high

performance networks, or networks which require the use of legacy ASIC technology, will

consume up to 500 mA, or in rare cases even as much as 1000 mA.

As an aid when designing the power supply electronics, the networks have been divided into

classes based on their power consumption as follows.

• Class A: less than 250 mA

• Class B: up to 500 mA

• Class C: up to 1000 mA

Please note that the power supply classifications take into account that the power budget is

shared with a full fieldbus circuitry, e.g. the appropriate connector board and NW_LEDs with

maximized consumption (20 mA each).

The following table lists the currently supported networking systems and their corresponding

class.

Network Class A Class B Class C

DeviceNet X

PROFIBUS X

CANopen X

EtherCAT

PROFINET 2-Port X

PROFINET FO 2-Port X

Ethernet/IP 2-Port

EtherNet POWERLINK

Common Ethernet

CC-Link

Modbus-TCP 2-Port

CC-Link IE Field

BACnet/IP

X

X

X

X

X

X

X

X

A power supply designed to fulfill Class A requirements (250 mA), will be able to support all

networks belonging to class A, but none of the networks in Class B and C.

A power supply designed to fulfill Class C requirements, will be able to support all networks.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 48

Appendix E: Implementation Guidelines 46 (48)

3V3

GND

C1

3.3 V

GND

5V

SS14

BAV70

22uF

(6.3V)

4k7

LT1767

10uH

100nF

(16V)

100nF

(16V)

1,5nF

(50V)

10uF

(6.3V)

Vin

FB

Vsw

GND

Vc

SHDN

SYNC

BOOST

VDD (3.3V)

GND

C1

C2

E.3.2 Bypass Capacitance

The power supply inputs must have adequate bypass capacitance for high-frequency noise

suppression. It is therefore recommended to add extra bulk capacitors near preferably all the

power supply inputs (or at least two):

Reference

C1

Fig. 26

E.3.3 3.3 V Regulation

The following example uses the LT1767 from Linear Technology to provide a stable 3.3 V power

source for the module. Note that all capacitors in this example are of ceramic type.

Value (Ceramic)

10 µF / 6.3 V

Fig. 27

For detailed information regarding this example, consult the data sheet for the LT1767 (Linear

Technology).

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 49

Appendix F: Network Interface Examples 47 (48)

F Network Interface Examples

This section offers a typical example of how to design the network interface.

Anybus®CompactCom™B40 Modbus Serial User Manual

SCM-1202-130 1.1 en-US

Page 50

5

4

3

2

1

Design Example

10 and 100 Mbit Ethernet

Network Interface