Page 1

AAnnyybbuuss®®CCoommmmuunniiccaattoorr™™CCAANN

PPRROOFFIINNEETT®®IIRRTT ((22..3322))

USER MANUAL

SCM-1202-035 1.2 en-US ENGLISH

Page 2

Important User Information

Disclaimer

The information in this document is for informational purposes only. Please inform HMS Industrial Networks of any

inaccuracies or omissions found in this document. HMS Industrial Networks disclaims any responsibility or liability

for any errors that may appear in this document.

HMS Industrial Networks reserves the right to modify its products in line with its policy of continuous product

development. The information in this document shall therefore not be construed as a commitment on the part of

HMS Industrial Networks and is subject to change without notice. HMS Industrial Networks makes no commitment

to update or keep current the information in this document.

The data, examples and illustrations found in this document are included for illustrative purposes and are only

intended to help improve understanding of the functionality and handling of the product. In view of the wide range

of possible applications of the product, and because of the many variables and requirements associated with any

particular implementation, HMS Industrial Networks cannot assume responsibility or liability for actual use based on

the data, examples or illustrations included in this document nor for any damages incurred during installation of the

product. Those responsible for the use of the product must acquire sufficient knowledge in order to ensure that the

product is used correctly in their specific application and that the application meets all performance and safety

requirements including any applicable laws, regulations, codes and standards. Further, HMS Industrial Networks will

under no circumstances assume liability or responsibility for any problems that may arise as a result from the use of

undocumented features or functional side effects found outside the documented scope of the product. The effects

caused by any direct or indirect use of such aspects of the product are undefined and may include e.g. compatibility

issues and stability issues.

®

Anybus

are the property of their respective holders.

is a registered trademark of HMS Industrial Networks AB. All other trademarks mentioned in this document

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 3

Table of Contents

Page

1 Preface ................................................................................................................................. 3

1.1 About This Document .................. .. ................................. ................................. .. ............... 3

1.2 Document history ....................... ..................................................................................... 3

1.3 Document Conventions ............................... .. ....................................................................4

2 Description .......................................................................................................................... 5

2.1 Introduction................ ................................. .. ................................. ................................ 5

2.2 Data Exchange Model ................................................................................. ......................6

2.3 PROFINET IRT Protocol ........................... ................................. .. ................................. ....... 7

2.4 CAN Network Protocol ...... ................................................................................................8

3 Installation......................................................................................................................... 13

3.1 Installation Overview ............... ................................. ...................................................... 13

3.2 Connectors and Indicators ....................... .. ................................. ................................. .. .. 14

3.3 DIN Rail Mounting.. .. ................................. ................................. .. ................................. . 14

3.4 CAN Interface.... .. .......................................................................................................... 16

3.5 PROFINET Interface ........... .. ........................................................................................... 16

3.6 Power Connector ............................... .. ............................... .. ................................. .. ...... 16

3.7 USB Connector ............ ................................. ................................................................. 16

3.8 LED Indicators ....................... ................................. ................................. .. .................... 17

4 Configuration..................................................................................................................... 18

4.1 Configuration Overview.. .. ................................. ................................. .. ........................... 18

4.2 Network Configuration............. ................................. .. ................................. ................... 19

4.3 Web Pages.................................... ................................. .. ................................. ............ 23

5 Anybus Configuration Manager ....................................................................................... 24

5.1 Main Window......................... ................................. .. ................................. ................... 24

5.2 Basic Settings ....................................................................... ................................. .. ...... 25

6 PROFINET Asset Management.......................................................................................... 27

6.1 Asset Management Record ........ .. ................................. .. ............................... .. ................ 27

6.2 Recording and Reading Data .. .......................................................................................... 27

6.3 Supported File Formats ...... .. ................................. .. ................................. ....................... 28

6.4 Supported Asset Management Records.............................. ................................. .. ............. 28

6.5 XML Based Asset Management. ................................. ................................. .. .................... 29

6.6 Binary Based Asset Management .. ................................. .. ............................... .. ................ 32

6.7 Uploading the Asset Management File to the FTP Server.............................................. ......... 36

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 4

A Technical Data ................................................................................................................... 39

A.1 General Specifications............... .. ................................. .. ............................... .. ................ 39

A.2 CAN Interface.... .. .......................................................................................................... 39

A.3 PROFINET IRT Interface ............................................................................................. ...... 39

B Licenses .............................................................................................................................. 40

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 5

Preface 3 (42)

1 Preface

1.1 About This Document

This document describes how to install and configure the Anybus Communicator CAN PROFINET

IRT (2.32) gateway.

For additional related documentation and file downloads, please visit www.anybus.com/support.

1.2 Document history

Version

1.0 2017-02-23

1.1 2017-11-22

1.2 2019-04-11

Date

Description

First release

Updated for new firmware

Added section about PROFINET Asset Management

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 6

Preface 4 (42)

1.3 Document Conventions

Ordered lists are used for instructions that must be carried out in sequence:

1. First do this

2. Then do this

Unordered (bulleted) lists are used for:

• Itemized information

• Instructions that can be carried out in any order

...and for action-result type instructions:

► This action...

→ leads to this result

Bold typeface indicates interactive parts such as connectors and switches on the hardware, or

menus and buttons in a graphical user interface.

Monospaced text is used to indicate program code and other

kinds of data input/output such as configuration scripts.

This is a cross-reference within this document: Document Conventions, p. 4

This is an external link (URL): www.hms-networks.com

This is additional information which may facilitate installation and/or operation.

This instruction must be followed to avoid a risk of reduced functionality and/or damage

to the equipment, or to avoid a network security risk.

Caution

This instruction must be followed to avoid a risk of personal injury.

WARNING

This instruction must be followed to avoid a risk of death or serious injury.

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 7

Description

2 Description

2.1 Introduction

Anybus Communicator CAN PROFINET IRT (2.32) is designed to exchange data between a CAN

subnetwork and a higher level network. The CAN protocol uses individually configurable frames,

offering great flexibility. Through the configuration of CAN frames, the Anybus Communicator

CAN will adapt to a predefined CAN subnetwork. It will be possible to send data to and receive

data from the CAN subnetwork, but also to act as a relay for data on the subnetwork.

The gateway can issue frames cyclically, on change of data, or based on trigger events issued by

the control system of the higher level network. It can also monitor communication on the

subnetwork and notify the higher level network when data has changed.

Anybus Communicator gateways are configured using Anybus Configuration Manager, a family of

configuration tools that have an easy to use graphical interface and that do not require

programming skills.

Anybus Configuration Manager and additional related software and documentation are available

at www.anybus.com/support.

5 (42)

Fig. 1 Anybus Configuration Manager

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 8

Description

Internal Memory

Input Data

(220 bytes)

CAN Subnetwork

Output Data

(220 bytes)

General Data

Higher Level Network

CAN Network:

Fieldbus:

CAN Network:

Fieldbus:

CAN Network:

Fieldbus:

Write Only

Read Only

Read Only

Write Only

Read/Write

-

Input Data Output Data General Data

0x000 0x200

0x0DB 0x2DB

0x400

0x7FF

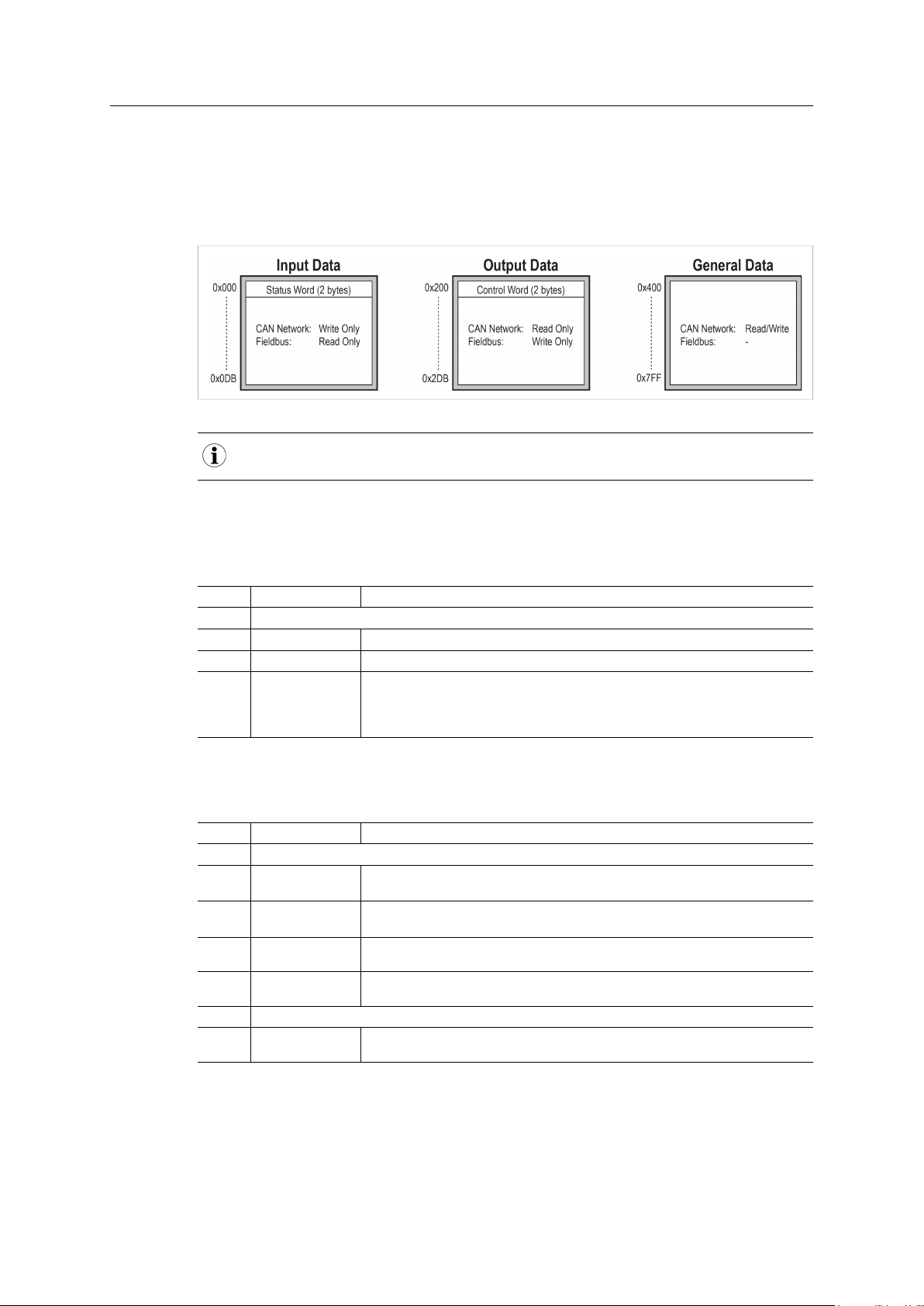

2.2 Data Exchange Model

2.2.1 Overview

The data exchanged on the CAN subnetwork and the data exchanged on the higher level

network reside in the same internal memory in the Anybus Communicator CAN. In order to

exchange data with the CAN subnetwork, the higher level network simply reads and writes data

to memory locations that have been specified in Anybus Configuration Manager. The same

memory locations can then be exchanged on the CAN subnetwork.

6 (42)

Fig. 2 Memory buffer structure

The internal memory buffer is divided into three areas based on their function:

Input Data (220 bytes) This area can be read from by the higher level network.

Output Data (220 bytes) This area can be written to by the higher level network.

General Data

(up to 1024 bytes)

2.2.2 Memory Map

When building the CAN subnetwork configuration in Anybus Configuration Manager the areas in

the memory buffer will be mapped to the following memory locations:

This area cannot be accessed by the higher level network but can be used for

transfers between individual nodes on the subnetwork, or as a general “scratch

pad” for data.

The size of the General Data area is 1024 bytes. How much of that area that will

be used for communication depends on the configuration.

Fig. 3 Memory Map

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

The illustration shows the maximum available data areas in Anybus Communicator CAN. The actual

amount of memory that can be allocated depends on the fieldbus network used.

SCM-1202-035 1.2 en-US

Page 9

Description

2.3 PROFINET IRT Protocol

PROFINET is the open Industrial Ethernet standard for automation from PROFIBUS and PROFINET

International. The PROFINET IRT device provides PROFINET IO Isochronous Real Time

Communication.

PROFINET makes a clear distinction between fast cyclical data, IO Data, and acyclical data,

Record Data. PROFINET IO Data corresponds to what is generally referred to as I/O Data in

Anybus Communicator CAN PROFINET IRT (2.32). PROFINET Record Data is not supported.

Anybus Communicator CAN PROFINET IRT (2.32) acts as a PROFINET device (slave), which means

it can be accessed by a PROFINET controller (master), but will not initiate communication by

itself.

PROFINET IO Data (I/O Data)

PROFINET IO Data is exchanged cyclically and is built up by I/O modules. The actual I/O

configuration is determined by the PROFINET IO Controller. The modules are mapped to the

Input and Output Buffers in the order of their slot number.

The first two bytes of the I/O data area are reserved for the Control Word and the Status Word,

which are used by the IO Controller to control and report status on the nodes on the CAN

subnetwork. The remainder is available for real-time data transfer using PDOs.

7 (42)

GSD File

All PROFINET devices are associated with an XML-based GSD file. This file contains information

about the basic capabilities and configuration options of the device.

The latest version of the GSD file for Anybus Communicator CAN PROFINET IRT (2.32) can be

downloaded from www.anybus.com/support.

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 10

Description

2.4 CAN Network Protocol

2.4.1 General

The CAN protocol is message-based and can exchange up to 8 bytes of data in each message.

The protocol only acts as a data carrier, it is up to each application to define and interpret the

data content of the messages.

Data is exchanged using frames. Each frame has a unique identifier for the data it exchanges,

which also represents the message priority. Anybus Communicator CAN supports both 11-bit

(CAN 2.0A) and 29-bit (CAN 2.0B) identifiers, selected in the configuration.

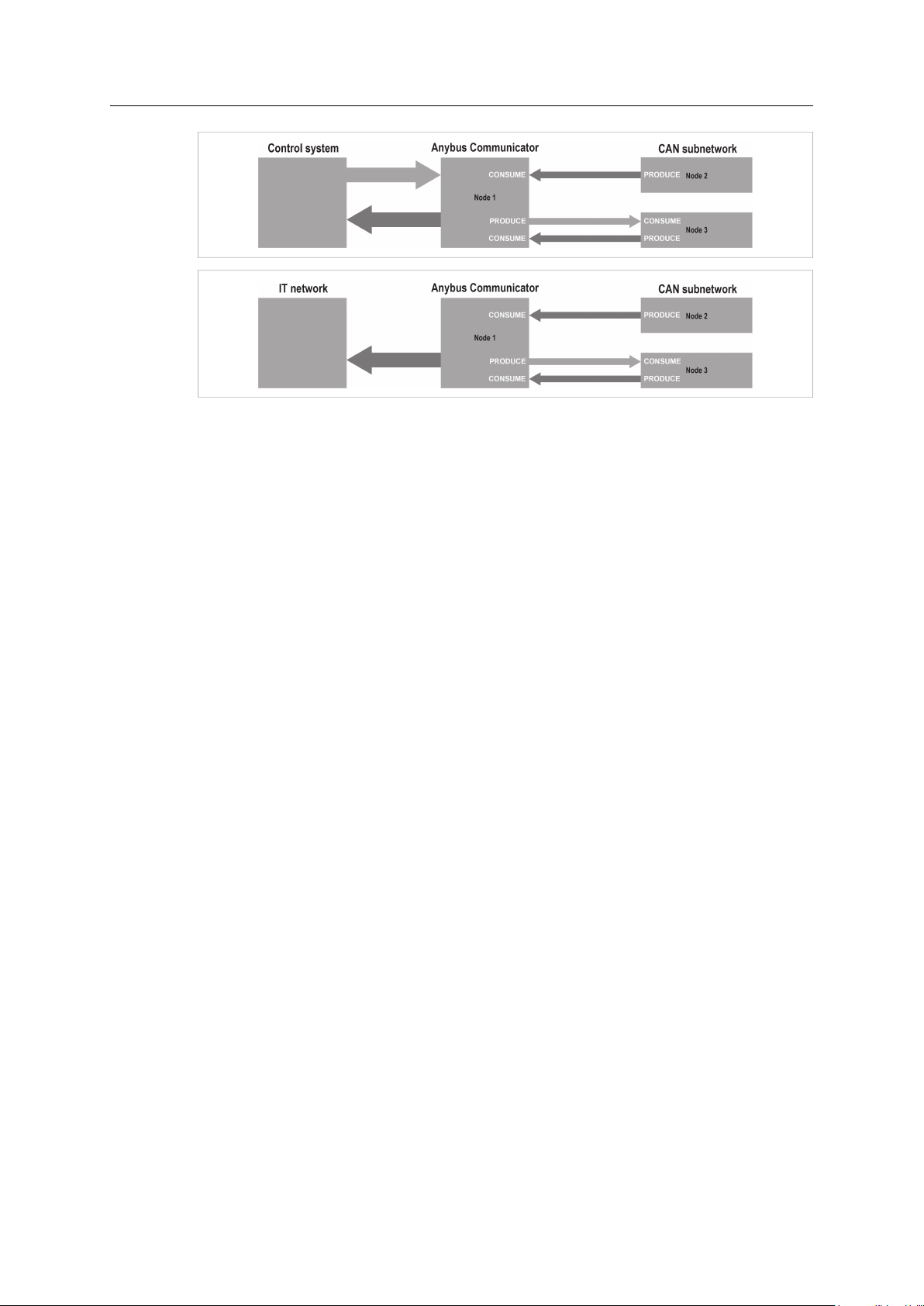

CAN is essentially a produce-consume protocol, where all nodes listen to all messages. The

devices recognize what data to collect by the identifier in the CAN frame. Anybus Communicator

CAN is also able to act as a network master and issue queries that demand responses. Both

methods can be used within the same configuration.

2.4.2 Message Types

Anybus Communicator CAN features three CAN message types: Query-Response, Produce, and

Consume. These message types only specify the basic communication model, not the actual CAN

protocol. All three message types can be used in the same configuration.

8 (42)

Query-Response

The Anybus Communicator CAN here acts as a master on the CAN subnetwork, and

communication takes place in a query-response fashion. The gateway sends a query and expects

a response within a specified timeout.

Fig. 4 Query-Response messaging

Produce and Consume

Here there is no master-slave relationship between the Anybus Communicator CAN and the

subnetwork nodes. Any node, including the gateway, may both produce and consume messages.

Nodes do not have to respond to messages, or wait for a query in order to send one. The

consumed data can be accessed from the higher level network, and vice versa.

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 11

Description

9 (42)

Fig. 5 Produce and Consume messages

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 12

Description

2.4.3 Protocol Building Blocks

The following building blocks are used in Anybus Configuration Manager to describe the

subnetwork communication.

10 (42)

Group

Transaction

Dynamic Transaction

CAN Frames

A group does not represent any specific device on the CAN subnetwork, it is only a

means to structure the transactions that have been defined for the gateway in Anybus

Configuration Manager.

Each group can be associated with any number of transactions, however the total

number of transactions in a configuration is limited to 128.

A transaction consists of one or more CAN frames. Each transaction is associated with a

set of parameters controlling how and when to use it on the subnetwork. There are 5

transaction types: produce, consume, query-response, dynamic produce and dynamic

consume. A group can contain transactions of all three types simultaneously.

A total of 128 transactions can be configured.

A dynamic transaction makes it possible for a network master to change selected

parameters during runtime. The parameters are mapped to the Output or General Data

areas and cannot be changed using Anybus Configuration Manager.

A dynamic transaction can only consist of a single CAN frame which in turn can only hold

one data object.

Only one dynamic produce transaction and one dynamic consume transaction can be

configured.

CAN frames are low level entities used to compose transactions. Each frame carries an

11-bit or 29-bit identifier and can hold up to 8 bytes of data.

A total of 256 CAN frames can be configured.

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 13

Description

2.4.4 Control and Status Words

The optional Control and Status Words can be used to control the startup mode of the Anybus

Communicator CAN and to read the status of the CAN subnetwork. The Control Word is always

mapped to the first two bytes of the output data area, and the Status Word to the first two bytes

of the input data area, with the Least Significant Byte in the first byte (byte 0).

Fig. 6 Memory buffers

The illustration shows the maximum available data areas in Anybus Communicator CAN. The actual

amount of memory that can be allocated depends on the fieldbus network used.

Control Word

The Control Word can be used to reset the CAN controller and to select the startup mode and/or

reboot the Anybus Communicator CAN.

11 (42)

Bit Name

15 - 3

2 Reset CAN

1

0

(reserved)

Reboot module 1 - Reboots the Anybus Communicator CAN (software reset)

Operation mode Sets the start-up operation mode of the Anybus Communicator CAN:

Description

1 - Resets the CAN controller (used when CAN interface is bus off)

0 - Idle (no new data is issued to the CAN subnetwork. Data received from the CAN

subnetwork is sent on to the higher level network.)

1 - Run (data is exchanged between CAN subnetwork and higher level network.)

Status Word

The Status Word holds information from the CAN subnetwork.

Bit Name

15 - 6

5 CAN overrun 0 - OK

4 Error passive

3

2 Reset CAN

1

0

(reserved)

Bus off

complete

(reserved)

Operation mode 0 - Idle

Description

1 - CAN reception overrun

0 - CAN interface is NOT in error passive state

1 - CAN interface is in error passive state

0 - Bus runnning

1 - Bus off

If set, the CAN controller has been reset (used when CAN interface is bus off)

1 - Run

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 14

Description

2.4.5 Transaction Live List

The optional Transaction Live List consists of a bit array where each bit corresponds to a

transaction on the CAN subnetwork (bit 0 corresponds to transaction 1 etc.). A set bit indicates

normal functionality. The bit is not set if the transaction is non-working or non-existent.

The live list is mapped in the Input data area of the memory, either at the start of the area or

directly after the Status word. From 8 transactions up to 128 transactions in steps of 8 can be

monitored using the live list. This means that up to 16 bytes of the input data area of the

memory can be occupied by the live list.

The latest live list can always be accessed in Anybus Configuration Manager, regardless of

whether the live list is mapped in the input data area or not.

12 (42)

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 15

Installation 13 (42)

3 Installation

This product contains parts that can be damaged by electrostatic discharge (ESD). Use

ESD prevention measures to avoid damage.

3.1 Installation Overview

These are the basic steps for installing Anybus Communicator CAN gateways.

Depending on the fieldbus network type there may also be configuration switches on the Anybus

Communicator CAN that need setting. See the following sections for more information.

Basic installation steps

1. Mount the Anybus Communicator CAN on the DIN rail.

2. Connect the CAN network.

3. Connect the fieldbus network.

4. Configure the fieldbus network interface (if applicable).

5. Connect the power cable and apply power.

6. Connect the USB cable between the gateway and a PC.

7. Download Anybus Configuration Manager from www.anybus.com/support

and install it on the PC following the instructions in the installer.

(Anybus Configuration Manager requires Microsoft

8. Continue to Configuration, p. 18

®

Windows XP or later)

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 16

Installation 14 (42)

3.2 Connectors and Indicators

3.2.1 External Parts

Fig. 7 Overview

1

LED indicators

2

DIN rail mount

3 Power connector

4 CAN connector

5 USB connector

6

PROFINET IRT network interface

3.3 DIN Rail Mounting

The unit must be electrically grounded through the DIN rail for EMC compliance.

Mount on DIN rail

1. Hook the unit onto the upper lip of

the rail and push gently downwards.

2. Push the unit towards the rail until it

snaps into place.

Remove from DIN rail

1. Push the unit gently downwards on the rail.

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

Fig. 8 Push down to mount or remove

SCM-1202-035 1.2 en-US

Page 17

Installation 15 (42)

2. Pull the bottom end of the unit free of the rail and remove it.

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 18

Installation 16 (42)

1 8

1 2

1

2

3

4

69

5 1(male)

3.4 CAN Interface

The CAN network connector is located on the bottom of the unit.

Pin Signal

2 CAN_L

3 CAN_GND

5

6 CAN_GND

7 CAN_H

1, 4, 8, 9

Shield

(reserved)

Fig. 9 CAN connector

3.5 PROFINET Interface

The PROFINET IRT interface contains a dual port Ethernet switch with RJ45 type connectors. The

two ports are labeled LAN 1 and LAN 2.

Pin Function

1 TD+

2 TD-

3 RD+

6 RD-

4, 5, 7, 8

(reserved)

Fig. 10 Ethernet connector (RJ45)

3.6 Power Connector

See also Technical Data, p. 39 regarding power supply requirements.

Pin

1 +24 VDC

2

Signal

Power Ground

3.7 USB Connector

The USB connector is used for connecting the Anybus Communicator CAN to a computer for

uploading and downloading configurations. The USB cable should be removed when not in use.

Pin Signal

1 +5 V input

2

3

4

Housing

USBDM (USB communication)

USBDP (USB communication)

Signal ground

Cable shield

Fig. 11 Power connector

Fig. 12 USB type B connector

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 19

Installation 17 (42)

1 2

3

546

3.8 LED Indicators

The LED indicators provide diagnostic information about data communication and status of the

network interfaces as well as general device status.

LED 1 to 4

LED 5

LED 6 Device status

LED

1 - Network Status Off Offline

2 - Module Status Off No power or initializing

3 - Link/Activity 1

4 - Link/Activity 2

Indication Meaning

Green

Green, 1 flash Online (STOP)

Red Fatal error

Red, 1 flash

Red, 2 flashes IP address error

Red, 3 flashes Configuration error

Alternating red/green

Green

Green, 1 flash

Red Fatal error

Alternating red/green

Off No power or no link detected

Green

Green, flickering

PROFINET IRT network status

CAN network status

– No power

– No connection to IO Controller

Online (RUN)

– Connection to IO Controller

– Connection to IO Controller

– IO Controller in STOP state or IO data bad

– RT synchronization not finished

Station name error

Firmware update in progress

Normal operation

Diagnostic event present

Firmware update in progress

Link OK

Transmitting/receiving data

LED

5 - CAN Subnet Status Off

Device Status

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

Indication Meaning

No power or no CAN communication

Green Running, no errors or timeout

Red. flashing Transaction error, timeout, or CAN subnet stopped

Red Fatal error

Off No power or initializing

Green Running

Green, flashing Idle

Red Fatal error

Alternating red/green

Configuration error

SCM-1202-035 1.2 en-US

Page 20

Configuration 18 (42)

4 Configuration

4.1 Configuration Overview

Device Description Files

A device description file contains a description of a network device, its functions, object

dictionary implementations, etc., and is used when configuring the network interface. The device

description file can be referred to as a DDF, EDS, GSD, etc., depending on the type of network.

The latest versions of the device description files can be downloaded from

www.anybus.com/support.

Basic steps when configuring Anybus Communicator CAN PROFINET IRT (2.32)

1. Install, connect and power up the Anybus Communicator CAN gateway (if you have not

already done so). See also Installation, p. 13.

2. Download Anybus Configuration Manager from www.anybus.com/support and install it.

3. Download the latest device description file for Anybus Communicator CAN PROFINET IRT

(2.32) from www.anybus.com/support.

4. Build your configuration using Anybus Configuration Manager and download it to the

gateway.See Anybus Configuration Manager, p. 24.

5. Install the appropriate device description file in the PROFINET IRT configuration tool.

6. Configure the PROFINET IRT network as required. Make sure that the configuration matches

the configuration present in the Anybus Communicator CAN.

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 21

Configuration 19 (42)

4.2 Network Configuration

To be able to communicate over Ethernet, the PROFINET network interface needs a valid TCP/IP

configuration. This section explains some basic concepts and describes how to configure the

TCP/IP settings using the IPconfig software tool.

When Ethernet communication has been established the TCP/IP settings can also be changed

from the web interface. See Web Pages, p. 23.

4.2.1 Basic TCP/IP Concepts

IP Address

The IP address is used to identify each node on a TCP/IP network. IP addresses are written as

four decimal integers (0–255) separated by dots, where each integer represents the binary value

of one byte of the IP address. This is known as dot-decimal notation.

Example: 10000000 00001010 00000010 00011110 is written as 128.10.2.30

The following IP addresses are reserved for special purposes and cannot be used:

0.n.n.n

127.n.n.n

n.n.n.0

n.n.n.255

First byte zero — used for broadcast messages

First byte 127 — used for loopback addresses to the local host

Last byte zero — identifies a whole network/subnet

Last byte 255 — used for broadcast messages

Subnet Mask

The IP address is divided into three parts: Net ID, Subnet ID and Host ID. A subnet mask is a 32bit binary pattern, where a set bit allocates a bit for Network/Subnet ID, and a cleared bit

allocates a bit for the Host ID. The subnet mask is usually written in dot-decimal notation.

Example: To make the IP address 128.10.2.30 belong to subnet 128.10.2, the subnet

mask must be 255.255.255.0.

Default Gateway

For devices to be able to communicate over Ethernet they must either belong to the same

subnet or communicate via a gateway or router.

A gateway or router routes communication between networks, i.e. it enables the nodes on one

network to access the nodes on another. The default gateway address in the TCP/IP settings of

your product specifies the IP address of the gateway or router on the local network.

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 22

Configuration 20 (42)

4.2.2 TCP/IP Configuration

Installing the IPconfig Utility

IPconfig is a Windows-based tool for configuration of TCP/IP settings in HMS devices. The tool

will detect all compatible and active HMS devices on the local network.

1. Download IPconfig from www.anybus.com/support.

2. Unpack the contents of the zip archive and run the installer program.

Scanning for Connected Devices

When IPconfig is started it will automatically scan all available local networks for HMS devices.

Detected devices will be listed in the main window. To refresh the list, click on Scan.

Fig. 13 IPconfig main window

IP

SN

GW

DHCP

Version Firmware version

Type

MAC

IP address of the device

Subnet mask

Default gateway

Automatically managed IP configuration

Product name

Ethernet MAC address (System ID)

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 23

Configuration 21 (42)

Ethernet Configuration

To change the IP settings for a device, double-click on the entry in the main window or right-click

on it and select Configuration.

Fig. 14 Ethernet configuration

Enter static IP settings as required, or select DHCP if using dynamic IP addressing.

Do not enable DHCP if there is no DHCP server available on the network.

You can add a name for the device in the Hostname field. Only characters a–z, A–Z, 0–9 and _

(underscore) are allowed.

The default password for changing IP settings is blank (no password). If a password has been set

for the device you must enter it to be able to change the settings.

To set a new password, check the Change password box and enter the current password in the

Password field, then enter the new password in the New password field.

For security reasons the default password should always be changed.

Click on Set to save the new settings. The device will reboot automatically.

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 24

Configuration 22 (42)

IPconfig Settings

Additional settings for IPconfig can be accessed by clicking on Settings.

Fig. 15 IPconfig settings

Network Interface

Check this option to select a specific network interface to use when scanning for devices from a

computer which has more than one interface. If this option is left unchecked, all available

networks will be scanned.

Internal DHCP Server

If a device has been set to use DHCP but there is no DHCP server on the network, the device may

not be detected by IPconfig. To recover access to the device an internal DHCP server in IPconfig

can be temporarily activated:

1. Click the checkbox for Internal DHCP Server, then click OK. IPconfig will automatically

refresh the scan and list the missing device in the main window.

2. Select the device and configure it to use static IP addressing instead of DHCP.

3. Disable the internal DHCP server.

Do not enable the internal DHCP server if there is already an active DHCP server on the

network.

4.2.3 DCP (Discovery and Control Protocol)

Anybus Communicator CAN PROFINET IRT (2.32) PROFINET IRT supports the DCP protocol, which

allows a PROFINET IO Controller/Supervisor to change the network settings during runtime.

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 25

Configuration 23 (42)

4.3 Web Pages

Network configuration settings and status of the PROFINET IRT network interface can be

accessed by pointing a web browser to the IP address of the interface.

Module Overview

Fig. 16 Overview tab

Provides basic information about the Anybus Communicator CAN including the serial number

and the installed firmware version.

Network Status

Fig. 17 Status tab

Displays an overview of the current network status.

Network Configuration

Fig. 18 Configuration tab

Provides access to the TCP/IP network settings. These parameters can also be configured using

the IPconfig tool.

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 26

Anybus Configuration Manager 24 (42)

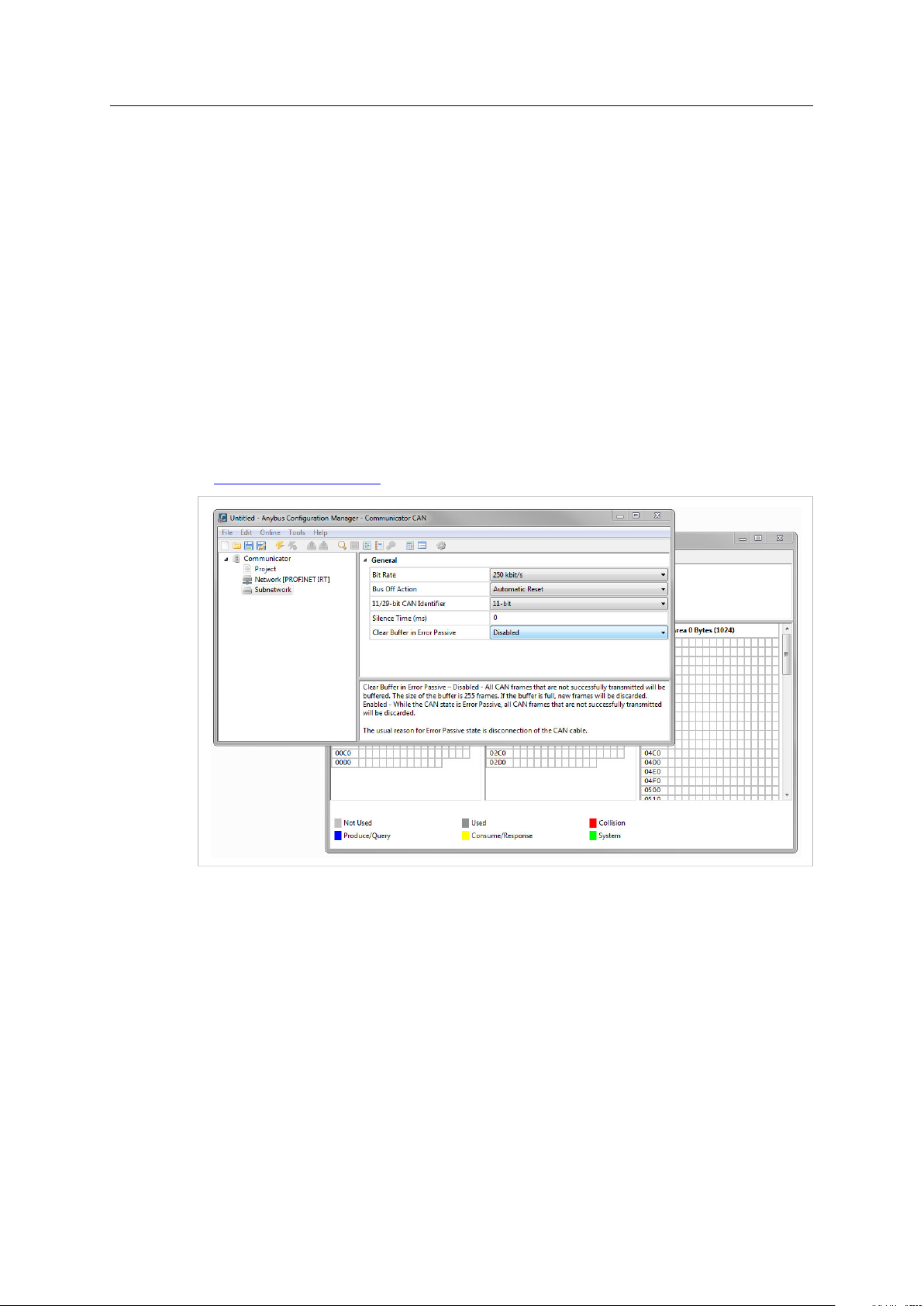

5 Anybus Configuration Manager

5.1 Main Window

Fig. 19 Anybus Configuration Manager - Communicator CAN

1: Menus and Toolbar

The most common menu commands can also be carried out by clicking on a button in the toolbar.

Moving the mouse cursor over a toolbar button will display a tooltip explaining its function.

2: Parameter List

Lists the parameters or options related to the currently selected entry in the Navigation Tree.

Values can be selected from a dropdown menu or entered manually depending on the parameter.

Values can be specified in either decimal or hexadecimal format.

Example: The decimal value 42 can also be entered as 0x2A.

Moving the mouse cursor over a parameter in this window will show a help text in the

Information Window explaining how to use the parameter.

3: Information Window

Displays a help text describing the current parameter.

4: Navigation Tree

A hierarchic tree view of the configuration, divided into three main sections:

Project

Network Settings for the higher level network

Subnetwork Settings for the CAN subnetwork

Information about the current configuration project

Select an entry to display its available parameters in the Parameter List. Right-click on the entry

to show additional options.

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 27

Anybus Configuration Manager 25 (42)

5.2 Basic Settings

For more detailed explanations of each configuration setting, see the help texts in the

Information Window.

5.2.1 Project

Used to store project information such as project name, project creator, version and description.

5.2.2 Network Settings

General

During startup the fieldbus interface is initialized to fit the configuration created in Anybus

Configuration Manager. Some initialization parameters can optionally be set manually to provide

better control over how the data shall be treated by the Anybus Communicator CAN.

Network Type

The higher level network type must be selected here in order to create a valid configuration.

5.2.3 Communicator Settings

Additional settings for the Anybus Communicator CAN.

General

Parameter Comment

Control/Status Word If enabled, the Control/Status Word will occupy the first two bytes of the Output/Input

Start-up Operation Mode Decides the start-up mode of the CAN subnetwork if the Control Word is enabled.

Transaction Live List

Statistics

Parameter Comment

Counters

Receive Counter Address Enter the address in the input data area where the receive counter shall be mapped. The

Transmit Counter Address Enter the address in the input data area where the transmit counter shall be mapped.

areas of the memory.

To avoid memory address collisions this parameter should be enabled before adding

frames to the configuration.

If the Transaction Live List is enabled it is mapped from the beginning of the input area

or, if the Control/Status Word is enabled, after the Status Word. It is possible to map

from 8 to 128 transactions, in steps of 8. Each transaction is represented by a bit that

tells the system whether the transaction is alive or not.

The receive counter and the transmit counter count successful CAN messages on the

subnetwork. If enabled, the counters can be mapped to the input data area. The first

free address in the input data area is selected by default. The counters can be disabled

and enabled separately.

To avoid memory address collisions this parameter should be enabled before adding

frames to the configuration.

The messages are counted only if they have been configured in Anybus Configuration

Manager.

receive counter occupies 2 bytes.

The transmit counter occupies 2 bytes.

Fatal Event

Parameter

Action

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

Values

Stay in Safe-State In case of a fatal software event, the Anybus Communicator

Software Reset In case of a fatal software event, the software will be reset and

Comment

CAN will be locked in the safe state.

the Anybus Communicator CAN will be restarted.

SCM-1202-035 1.2 en-US

Page 28

Anybus Configuration Manager 26 (42)

5.2.4 Subnetwork Settings

Settings for the CAN subnetwork.

Parameter

Bit Rate

Bus Off Action

11/29-bit CAN Identifier

Silence Time (ms)

Clear Buffer in Error Passive

Values

20 kbit/s

50 kbit/s

100 kbit/s

125 kbit/s

200 kbit/s

250 kbit/s

500 kbit/s

800 kbit/s

1000 kbit/s

No Action

Automatic Reset

11 bit

29 bit

0 - 65535

Disabled/Enabled

Comment

Select the bit rate on the CAN subnetwork.

Select what will happen to the CAN controller when the CAN

subnetwork goes bus off.

When the Control/Status Word is enabled this parameter will

be disabled (No Action).

Select CAN identifier size on the subnetwork

If there are configured transactions when this parameter is

changed, the following will happen:

• A change from 11 bit to 29 bit identifier will cause the

identifier to be padded with zeroes up to 29 bits, keeping

the 11 bits at the same location.

• A change from 29 bit to 11 bit identifier will cause the

upper 18 bits to be deleted and the lower 11 bits kept.

This may in some cases cause faulty CAN identifiers.

Default = 0 (disabled)

The minimum time that must elapse between the end of a

message and the beginning of the next message. If a device on

the CAN subnetwork is slow and/or does not have a message

queue, it may be necessary to enter a delay between the

messages to ensure that they are handled correctly. The delay

is set in milliseconds.

Disabled: All CAN frames that are not successfully transmitted

will be buffered. The size of the buffer is 255 frames. If the

buffer is full, new frames will be discarded.

Enabled: While the CAN state is Error Passive, all CAN frames

that are not successfully transmitted will be discarded.

The usual reason for Error Passive state is disconnection of the

CAN cable.

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 29

PROFINET Asset Management

6 PROFINET Asset Management

6.1 Asset Management Record

With the asset management record functionality data about the assets available on a non

PROFINET network can be recorded and read out over a PROFINET network.

Together with the Identification & Maintenance data functionality an extensive registration of

devices and machines is possible, even in facilities where the devices are not installed in the

PROFINET environment.

Factory owners and system integrators can collect data about devices installed beyond the

Anybus gateway.

The recorded data can be used as basis for the design of easier maintenance and operation

processes, despite the increasing complexity of processes and associated machines.

6.2 Recording and Reading Data

An asset management file containing all the assets and their corresponding data on the non

PROFINET network is created and uploaded via an FTP server to the Gateway file system.

The asset management file can be transferred from a computer connected to a PROFINET

network.

27 (42)

Fig. 20 The Asset Management Default Mode

By using the superposed parameter channel mode it is also possible to transfer the asset

management file from a PLC connected to a non PROFINET network.

For further details about the superposed parameter channel mode, please refer to

www.anybus.com/support.

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 30

PROFINET Asset Management

Record Data

Data about the assets on the non PROFINET network is recorded and stored in an XML file or an

binary file.

Read Data

Each time an instance is requested the asset management data is read out over the PROFINET

network.

The recorded asset management data can be downloaded to a computer connected to the

PROFINET network.

6.3 Supported File Formats

The following file formats are supported for the asset management file.

28 (42)

Format

XML XML Version 1.0

Binary file

Little-endian

Version

N/A

6.4 Supported Asset Management Records

Supported asset management records:

• Unique ID

• Location

• Hardware Revision

• Annotation

• Order ID

• Serial Number

• Software Revision

• Serial Number

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 31

PROFINET Asset Management

6.5 XML Based Asset Management

6.5.1 Creating the Asset Management XML File

Creating the asset management XML file:

1. List all assets and their corresponding data on the non PROFINET network.

2. Create an XML file that include one asset management record for each asset.

Repeat all the attributes after each other.

3. When all attributes are listed, close the element by using a closing entry.

4. Name the XML file asset_mgmt.

6.5.2 XML File Size Limitation

The size of the asset management file may not exceed 95 kb.

Up to 32 instances can be added.

In order to keep the file size small, consider the following:

29 (42)

• Keep strings as short as possible.

• Do not pad with empty spaces for strings.

• Try to use as few spaces as possible for indentation in the file.

• The number of white-space also affects the file size.

• Avoid using optional name strings.

6.5.3 XML Attribute Name and Data Format

The order of the elements is significant for the XML schema to work with the Anybus Gateways.

If the XML schema is incorrect, the XML file will not work and no data will be recorded.

When creating the XML file, add the elements and their attributes in the same order as the

attribute names are listed in the table below.

Each element consists of a series of attributes and their various data.

Each attribute is described by one entry.

The supported attribute names are specified in the table.

Example 1: XML element including an attribute with the location record.

<AbccAttribute>

<Name Value="Location Type"/>

<Attribute Value="3"/>

<Data Value="1"/>

</AbccAttribute>

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 32

PROFINET Asset Management

Attribute Name and Data Format

Attribute Name

AM info Type

Location Type

AM Type Identification

IM Hardware Revision

IM Annotation

IM Order ID String of length X Maximum number of elements in array: 64.

IM Serial Number String of length X Maximum number of elements in array: 16.

AM Software Revision String of length X Maximum number of elements in array: 64.

AM Hardware Revision String of length X Maximum number of elements in array: 64.

IM Software Revision

IM Unique Identifier Array of Unsigned 8

Location LT

Location SS

AM Device Identification

30 (42)

Data Format

Unsigned 8 The value can be set in either of two formats, 0x12 or 18.

Unsigned 16 The value can be set in either of two formats, 0x1234 or

String of length X Maximum number of elements in array: 64.

String

Length is 16

Array of Unsigned 16

Length is up to 12

elements.

Array of Unsigned 16

Length is 4.

Description

4660.

Format of the string shall be C.X.Y.Z.

C is one character.

X, Y and Z represent a value between 0 and 255.

X – Major version

Y – Minor version

Z – Internal

Format of the value shall be 0xXX;0xYY…0xZZ.

16 values in hex-format, where each value is separated by a

“;”.

Format of the value shall be 0xXXXX;0xYYYY…0xZZZZ.

Up to 12 values in hex-format, where each value is separated

by a “;”.

Format of the value shall be 0xXXXX;0xYYYY…0xZZZZ.

4 values in hex-format, where each value is separated by a “;”.

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 33

PROFINET Asset Management

6.5.4 Asset Management XML File Structure Example

The code example presented below can be used as a guide when creating the asset management

XML file.

31 (42)

Fig. 21 Asset management XML file structure example

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 34

PROFINET Asset Management

6.6 Binary Based Asset Management

6.6.1 Creating the Asset Management Binary File

Creating the asset management binary file:

1. List all assets and their corresponding data on the non PROFINET network.

2. Create an Binary file that include a asset management record for each asset.

Repeat all the attributes after each other.

3. When all attributes are listed, close the element by using a closing entry.

4. Name the bin file asset_mgmt.

6.6.2 Binary File Size Limitation

The size of the asset management file may not exceed 12 kb.

32 instances can be added, instance 1 to 32.

32 (42)

In order to keep the file size small, consider the following:

• Keep strings as short as possible.

• Do not pad with empty spaces for strings.

6.6.3 Binary File Header

Omitted attributes are disabled or set to their default value.

The size of the file header is 70 bytes.

The supported file headers are specified in the table.

Supported File Headers

File Header Byte Number

File format

version

File checksum

Byte offset to

Instance 1

Byte offset to

Instance 2

Byte offset to

Instance 32

Instance data

0-1 UINT16

2-5 UINT32

6-7 UINT16

8-9

68-69

70-x

Data Type Comment

Version number of the file format.

Set to 0.

Used for version control of the file.

Not used by the gateway.

If not used, the field must be set to zero.

Byte offset to the start of the data describing Asset

management Instance X.

Set to zero if instance is not used.

N/A

Data for the instance(s), as specified below.

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 35

PROFINET Asset Management

6.6.4 Binary Instance Data

Each instance consists of a series of attributes and their respective data.

Attribute Description

Each attribute is described by one entry.

33 (42)

Attribute Description Byte number

Attribute number

Data length

Attribute data

0 UINT8

1 UINT8

2–x

Data type Comment

Depends on the

attribute being

described.

Attribute Closure Description

Use a closing entry to close the instance data.

Attribute Description Byte number

Closure

0–1 UINT16

Data type Comment

Attribute number of the data being described.

Optional checksum.

Shall represent the number of data bytes

following.

Not used by the gateway.

Data for the attribute.

Format shall be as described for the data-type.

Not needed for strings padding or termination.

Data-field which tell that there will not follow

any more attributes for this instance.

Set to value 0xFFFF.

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 36

PROFINET Asset Management

Attribute Name and Data Format

Supported attribute names and data formats.

Attribute Name and Data Format

Attribute Name

AM info Type

Location Type

AM Type Identification

IM Hardware Revision

IM Annotation

IM Order ID String of length X Maximum number of elements in array: 64.

IM Serial Number String of length X Maximum number of elements in array: 16.

AM Software Revision String of length X Maximum number of elements in array: 64.

AM Hardware Revision String of length X Maximum number of elements in array: 64

IM Software Revision Array of Unsigned 8

IM Unique Identifier Array of Unsigned 8

Location LT

Location SS

AM Device Identification

Data Format

Unsigned 8 The value is set as one byte value.

Unsigned 16 The value is set with two bytes, little-endian format.

String of length X Maximum number of elements in array: 64.

Length is 4

Length is 16

Array of Unsigned 16

Length is up to 12

elements.

Array of Unsigned 16

Length is 4.

Description

First byte is a character.

Bytes 2, 3 and 4 represent the version in the format X.Y.Z

where X, Y and Z represent a value between 0 and 255.

C is one character.

X, Y and Z represent a value between 0 and 255.

X – Major version

Y – Minor version

Z – Internal

Format is 16 bytes.

Each Unsigned 16 comprises two bytes, where each two bytes

form an Unsigned 16 in little-endian format.

The number of Unsigned 16’s can be up to 12, placed directly

after each other

Each Unsigned 16 comprises two bytes, where each two bytes

form an Unsigned 16 in little-endian format.

The number of Unsigned 16’s shall be 4, placed directly after

each other.

34 (42)

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 37

PROFINET Asset Management

6.6.5 Asset Management Binary File Example

The binary file structure example presented below can be used as a guide when creating the

asset management binary file.

Only instance 1 is supported.

For instance 1, only attribute 1 and 2 are defined.

35 (42)

Fig. 22 Binary file example

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 38

PROFINET Asset Management

6.7 Uploading the Asset Management File to the FTP Server

Use Windows Explorer or a standard FTP client to transfer the asset management file to the FTP

server.

When the superposed parameter channel function is enabled, transfer the asset management

file via a PLC connected to the network where the gateway is installed.

6.7.1 Transferring the Asset Management File from Windows Explorer

Transfer the asset management file, XML or binary file, to the FTP server using Windows Explorer.

Before You Begin

Use only one of the file formats, XML format or binary format.

Only upload one single file on the FTP server.

• Name the asset management file: asset_mgmt

• The default port is FTP port 21.

36 (42)

• Make sure that the gateway and your computer are connected to the PROFINET network to

be used.

Procedure

Fig. 23 The FTP Server root folder

1. Open an Windows Explorer Window.

2. Click to select the Address bar.

3. Enter ftp://Username:Password@IPaddress.

– Replace “Username” and “Password” with a valid username and password combination.

– Replace ‘IPaddress’ with the IP address of the PROFINET interface.

4. Press Enter.

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 39

PROFINET Asset Management

Fig. 24 Application folder with an asset_mgmt.xml file

5. Open the application folder and save the asset management file, XML or Binary file, in the

folder.

37 (42)

Anybus®Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 40

This page intentionally left blank

Page 41

Appendix A: Technical Data 39 (42)

A Technical Data

A.1 General Specifications

Model name Anybus Communicator CAN PROFINET IRT (2.32)

Order code

Dimensions (L x W x H)

Weight

Operating temperature

Storage temperature

Humidity range 5–95 % RH, non-condensing (IEC 60068-2-30)

Power supply 24 V ±10 % DC regulated power source

Current consumption

Galvanic isolation Yes, on both network sides

Mechanical rating

Mounting

Certifications

AB7328

120 x 75 x 27 mm

150 g

-25 to +55 °C (IEC 60068-2-1 and IEC 60068-2-2)

-40 to +85 °C (IEC 60068-2-1 and IEC 60068-2-2)

Typical: 100 mA @ 24 VDC

Maximum: 250 mA @ 24 VDC

IP20, NEMA rating 1

DIN rail (EN 50022)

Network shield conductance via DIN rail

CE

A.2 CAN Interface

Maximum baud rate

CAN connector

CAN specification CAN 1.0, 2.0A and 2.0B

A.3 PROFINET IRT Interface

PROFINET specification

PROFINET functionality Isochronous Real-Time (IRT) communication

Isochronous cycle times

Maximum I/O data

Ethernet

1 Mbit/s

D-sub 9 Male (included)

2.32

Conformance supporting Class A, B and C

Media Redundancy Protocol (MRP) support

Discovery and Configuration Protocol (DCP) support

Acyclic Data exchange (Record Data Requests)

Asset Management

0.250 ms to 16 ms

Up to 512 byte in each direction

100 Mbit/s, full duplex (fixed)

Dual port cut-through switch, RJ45 connectors

Ethernet Transport Provider support

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 42

Appendix B: Licenses 40 (42)

B Licenses

This product includes software developed by Carnegie Mellon, the Massachusetts Institute of Technology, the University

of California, and RSA Data Security:

Copyright 1986 by Carnegie Mellon.

Copyright 1983,1984,1985 by the Massachusetts Institute of Technology

Copyright © 1988 Stephen Deering.

Copyright © 1982, 1985, 1986, 1992, 1993 The Regents of the University of California. All rights reserved.

This code is derived from software contributed to Berkeley by Stephen Deering of Stanford University.

Redistribution and use in source and binary forms, with or without modification, are permitted provided that the

following conditions are met:

• Redistributions of source code must retain the above copyright notice, this list of conditions and the following

disclaimer.

• Redistributions in binary form must reproduce the above copyright notice, this list of conditions and the following

disclaimer in the documentation and/or other materials provided with the distribution.

• Neither the name of the University nor the names of its contributors may be used to endorse or promote products

derived from this software without specific prior written permission.

THIS SOFTWARE IS PROVIDED BY THE REGENTS AND CONTRIBUTORS “AS IS” AND ANY EXPRESS OR IMPLIED

WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE REGENTS OR CONTRIBUTORS BE LIABLE FOR ANY

DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED

TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS

INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR

TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF

ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

*****************************************************************************

Copyright © 1990-2, RSA Data Security, Inc. All rights reserved.

License to copy and use this software is granted provided that it is identified as the “RSA Data Security, Inc. MD4

Message-Digest Algorithm” in all material mentioning or referencing this software or this function.

License is also granted to make and use derivative works provided that such works are identified as “derived from the

RSA Data Security, Inc. MD4 Message-Digest Algorithm” in all material mentioning or referencing the derived work.

RSA Data Security, Inc. makes no representations concerning either the merchantability of this software or the suitability

of this software for any particular purpose. It is provided “as is” without express or implied warranty of any kind.

These notices must be retained in any copies of any part of this documentation and/or software.

*****************************************************************************

Copyright © 1991-2, RSA Data Security, Inc. Created 1991. All rights reserved.

License to copy and use this software is granted provided that it is identified as the “RSA Data Security, Inc. MD5

Message-Digest Algorithm” in all material mentioning or referencing this software or this function.

License is also granted to make and use derivative works provided that such works are identified as “derived from the

RSA Data Security, Inc. MD5 Message-Digest Algorithm” in all material mentioning or referencing the derived work.

RSA Data Security, Inc. makes no representations concerning either the merchantability of this software or the suitability

of this software for any particular purpose. It is provided “as is” without express or implied warranty of any kind.

These notices must be retained in any copies of any part of this documentation and/or software.

®

Anybus

Communicator™CAN PROFINET®IRT (2.32) User Manual

SCM-1202-035 1.2 en-US

Page 43

This page intentionally left blank

Page 44

last page

© 2019 HMS Industrial Networks

Box 4126

300 04 Halmstad, Sweden

info@hms.se SCM-1202-035 1.2 en-US / 2019-04-12 / 12861

Loading...

Loading...