Page 1

Anybus®CompactCom

Host Application Implementation Guide

HMSI-27-334 1.7 en-US ENGLISH

™

Page 2

Important User Information

Disclaimer

The information in this document is for informational purposes only. Please inform HMS Industrial Networks of any

inaccuracies or omissions found in this document. HMS Industrial Networks disclaims any responsibility or liability

for any errors that may appear in this document.

HMS Industrial Networks reserves the right to modify its products in line with its policy of continuous product

development. The information in this document shall therefore not be construed as a commitment on the part of

HMS Industrial Networks and is subject to change without notice. HMS Industrial Networks makes no commitment

to update or keep current the information in this document.

The data, examples and illustrations found in this document are included for illustrative purposes and are only

intended to help improve understanding of the functionality and handling of the product. In view of the wide range

of possible applications of the product, and because of the many variables and requirements associated with any

particular implementation, HMS Industrial Networks cannot assume responsibility or liability for actual use based on

the data, examples or illustrations included in this document nor for any damages incurred during installation of the

product. Those responsible for the use of the product must acquire sufficient knowledge in order to ensure that the

product is used correctly in their specific application and that the application meets all performance and safety

requirements including any applicable laws, regulations, codes and standards. Further, HMS Industrial Networks will

under no circumstances assume liability or responsibility for any problems that may arise as a result from the use of

undocumented features or functional side effects found outside the documented scope of the product. The effects

caused by any direct or indirect use of such aspects of the product are undefined and may include e.g. compatibility

issues and stability issues.

®

Anybus

CompactCom

is a registered trademark of HMS Industrial Networks.

™

is a trademark of HMS Industrial Networks.

All other trademarks are the property of their respective holders.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 3

Table of Contents

Page

1 Preface ................................................................................................................................. 3

1.1 About This Document ........................................................................... ............................3

1.2 Related Documents ............................ .............................................. ................................ 3

1.3 Document history ............................................................................................................ 3

1.4 Document Conventions ......................................... .............................................. .............. 4

2 Introduction......................................................................................................................... 5

2.1 Overview ........................................................................................................................6

2.2 Preparations ................................................................................................................... 7

3 Step One .............................................................................................................................. 8

3.1 System Adaptation and Application Development..................................................................8

3.2 System Set-up ................................................................................................................. 8

3.3 Anybus CompactCom Set-up .............................................................................................. 9

3.4 System Adaptation Functions ........................................................................................... 14

3.5 Object Configuration ... ......................................... .......................................................... 18

3.6 Example Application .................... .............................................. ..................................... 18

4 Step Two ............................................................................................................................ 21

4.1 Adaptations and Customizations .............................................. ......................................... 21

A Software Overview............................................................................................................ 41

A.1 Folders............ ............................................................................................................. 41

A.2 Root Files ..................................................................................................................... 41

A.3 CompactCom Driver Interface (Read Only).......................................................................... 41

A.4 Internal Driver Files (Read Only) ....................................................................................... 42

A.5 System Adaptation Files ........... .............................................. ......................................... 43

B API ...................................................................................................................................... 44

B.1 API Documentation .................. ..... ......................................... ........................................ 44

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 4

C Host Application State Machine....................................................................................... 47

D 30- and 40-series Modules in the Same Application....................................................... 51

D.1 Hardware Design Considerations ...................................................................................... 51

D.2 Module Identification ..................................................................................................... 51

D.3 Enable Supported Communication Interfaces.................................. ..... ............................... 52

D.4 Select Operating Mode ................................................................................................... 52

D.5 Message Data Size ......................................................................................................... 53

D.6 Process Data Size ........................................................................................................... 53

D.7 Supported Data Types............................ .............................................. ........................... 53

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 5

Preface 3 (54)

1 Preface

1.1 About This Document

This document describes the host application example code. It provides a guide for making a

simple implementation and tips for further development.

For additional related documentation and file downloads, please visit www.anybus.com/support.

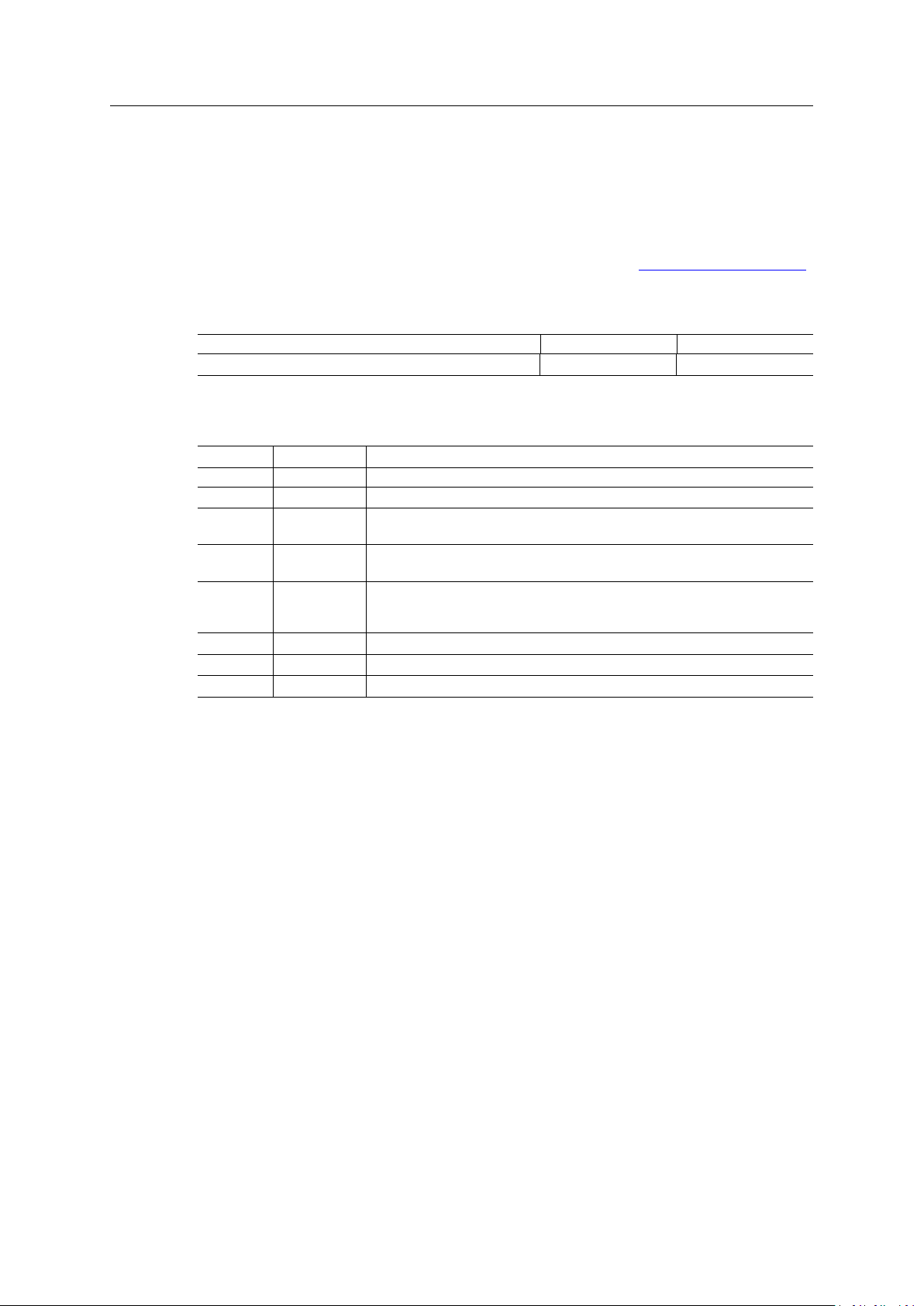

1.2 Related Documents

Document

Anybus CompactCom 40 Software Design Guide

1.3 Document history

Author

HMS HMSI-216-125

Document ID

Version

1.00 2015-11-20

1.10 2016-02-05

1.2 2017-01-10

1.3 2018-01-23

1.4 2018-05-31

1.5 2018-10-16

1.6 2019-02-25

1.7 2020-03-09

Date

Description

New document

Fully revised revision

Converted to DOX

Major updates

Added disclaimer

Changed document type

Updated API description

Added appendix on 30- and 40-series modules in the same application

Minor updates

Minor updates to fit latest software release

Rebranding

Minor updates

®

Anybus

CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 6

Preface 4 (54)

1.4 Document Conventions

Numbered lists indicate tasks that should be carried out in sequence:

1. First do this

2. Then do this

Bulleted lists are used for:

• Tasks that can be carried out in any order

• Itemized information

► An action

→ and a result

User interaction elements (buttons etc.) are indicated with bold text.

Program code and script examples

Cross-reference within this document: Document Conventions, p. 4

External link (URL): www.hms-networks.com

WARNING

Instruction that must be followed to avoid a risk of death or serious injury.

Caution

Instruction that must be followed to avoid a risk of personal injury.

Instruction that must be followed to avoid a risk of reduced functionality and/or damage

to the equipment, or to avoid a network security risk.

Additional information which may facilitate installation and/or operation.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 7

Introduction 5 (54)

2 Introduction

When starting an implementation of the Anybus CompactCom 30 or the Anybus CompactCom

40, host application example code is available to speed up the development process. The host

application example code includes a driver, which acts as glue between the Anybus CompactCom

module and the host application. The driver has an API (Application Programming Interface),

which defines a common interface to the driver. Also included in the example code is an example

application which makes use of the API to form an application that can be used as a base for the

final product.

This guide is developed to describe a step-by-step implementation of the Anybus CompactCom driver and

example application. The programmer is requested to have basic knowledge in the Anybus CompactCom

object model and the communication protocol before starting the implementation.

This document is based on the contents of version 3.06 of the host application example code.

The guide is divided into two steps:

Step One: The adaptations needed for the target hardware are done here and a simple application is

developed. The goal with this step is to make sure that the hardware specific code is working and that it

is possible to connect to the network and exchange a limited amount of data.

Step Two: The code is adapted to the target product. The goal with this step is to customize the code

and add to it, to configure the data that will be sent on the network. After this, the application can be

further extended and improved.

The driver is fully OS independent and it can even be used without an operating system, if

required. Furthermore, it can be used for Anybus CompactCom 30 modules as well as Anybus

CompactCom 40 modules. The driver supports multiple operating modes, where selection of one

of the implemented modes can be made at runtime.

It is possible to use modules from the 30- and the 40-series in the same application, see 30- and

40-series Modules in the Same Application, p. 51.

The host application example code is available in different versions for different platforms. When

writing this guide, the platforms depicted below are available.

Each folder contains all files for a specific platform/development environment.

Platform

Generic

Xilinx, MicroZed

ST, STM3240-EVAL

NXP, TWRP1025

HMS, USB II Board Visual Studio Used for the HMS Starter Kit hardware (USB board)

Reference Project/Tool Chain

-

GNU

Keil µVision Used for the STM3240-EVAL evaluation platform

IAR Embedded Workbench Used for the STM3240-EVAL evaluation platform

Code Warrior Used for the NXP TWRP1025 evaluation platform

Description

Can be ported to any platform

Used for the Microzed evaluation platform with

Anybus IP

®

Anybus

CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 8

Introduction 6 (54)

Host Applicaon Objects ADI/Process Data

CompactCom Applicaon Handler Main Loop

Example Applicaon

API

CompactCom Driver

System Adaptaon Layer

Anybus Physical Interface

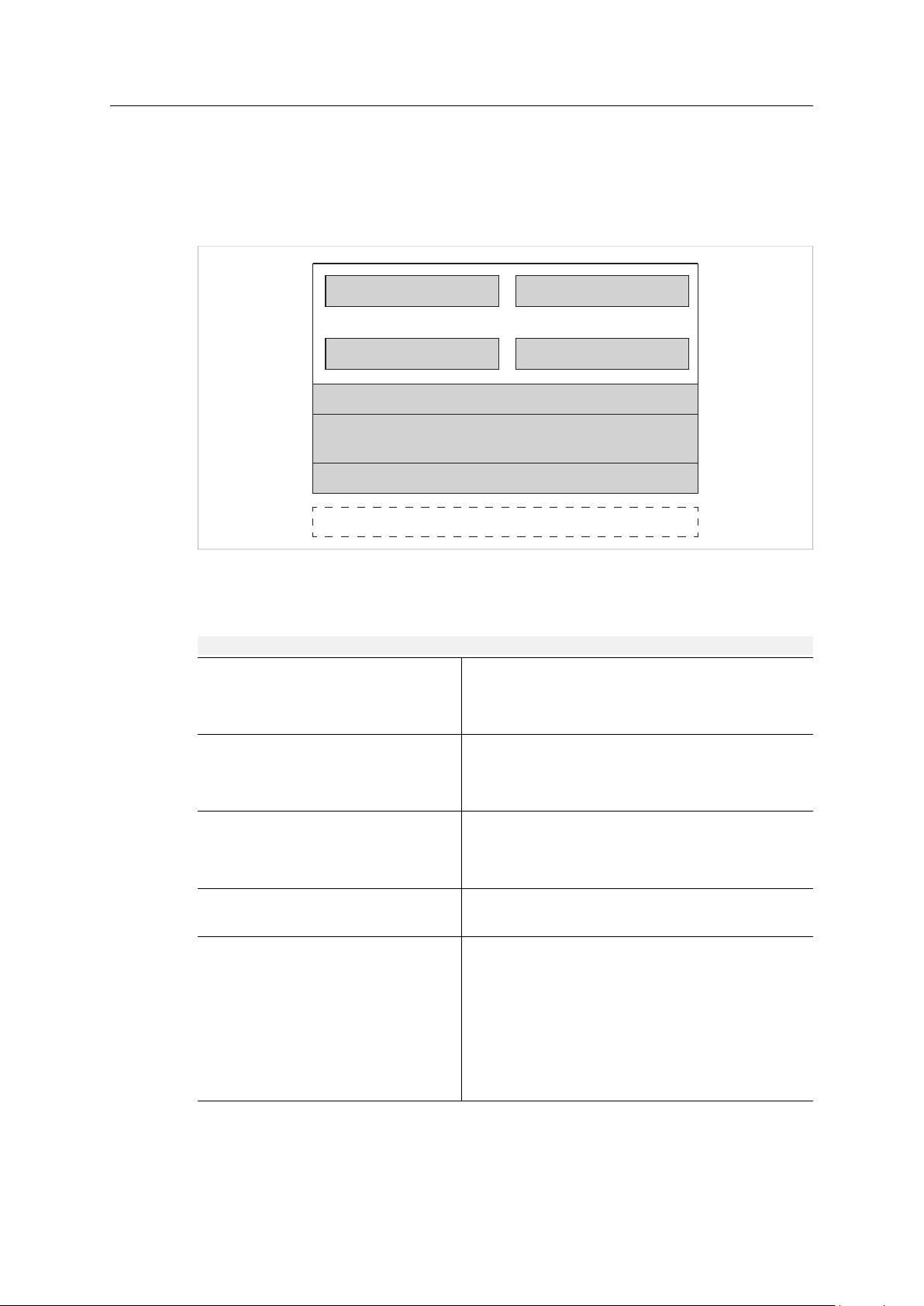

2.1 Overview

Parts of the driver code need to be adapted to the host application platform. This generally

includes functions which access the Anybus host interface, or functions which need to be

adapted to integrate the driver into the host system. The figure below shows the different parts

of the host application example code.

Fig. 1 Software overview

The host application example code is divided into five different folders depending on the

functionality and whether the files need to be adapted or not by the user.

Folder Structure

/abcc_abp (part of the driver - read only)

/abcc_drv (part of the driver - read only)

/abcc_adapt

/abcc_obj

/example_app

Contains all Anybus object and communication protocol definitions.

Files may be updated when new Anybus CompactCom releases are

available.

These files are read only and must not be changed in any way by

the user.

Contains source and header files for the driver.

Files may be updated when new Anybus CompactCom releases are

available.

These files are read only and must not be changed in any way by

the user.

Contains configuration files.

These files must be modified by the user to adapt the driver and

the example code to the system environment. Note: If using

example code adjusted to a specific platform, most of the

adaptations needed in this folder are already completed.

Includes all Anybus host application object implementations.

These files can be modified if needed, for optimization and/or

additional features.

Example application including:

– Main state machine to handle initialization, restart, normal and

error states.

– State machine patterns to show how to send Anybus

CompactCom messages.

– Implementation of callbacks required by the driver.

– Definition of ADIs, Application Data Instances, and default

process data mapping setup.

These files have to be adapted to the application by the

programmer. Additionally they may be modified for optimization

and/or additional features.

®

Anybus

CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 9

Introduction 7 (54)

2.2 Preparations

Before continuing, try to answer as many of the questions below as possible. This will make the

later decisions during implementation easier. It is also good to have access to the hardware

schematics of the target hardware during the implementation.

Step One

Consider the following questions:

• What operating mode, or modes, shall be used in the design?

• What communication interfaces shall be used to communicate with the CompactCom in the

design?

• What networks shall be used in the design?

• Are the networks available in the CompactCom 40 series or is there also a need to use

CompactCom 30 series modules?

• Are the Module Identification pins connected to the host processor?

• Are the Module Detection pins connected to the host processor?

Step Two

Consider the following questions:

• Is the interrupt signal implemented in the hardware?

• What parameters/data shall be communicated on the network in the final product?

– Name

– Data type

– Number of elements

– Read/Write access

– Acyclic access, Cyclic access

– Max/Min/Default values

• Which events (diagnostics) shall be reported on the network?

• What network identification parameters are available? E.g. Vendor ID, Product Code, Id

number etc.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 10

Step One

3 Step One

3.1 System Adaptation and Application Development

When this step is completed you have...

• ...implemented the system specific functions needed to communicate with the Anybus

CompactCom.

• ...compiled the host application example code with default settings.

• ...exchanged data between the host application and the network master/scanner.

3.2 System Set-up

These defines can be found in abcc_adapt/abcc_td.h.

General settings for the system environment, to be used in the driver, are configured here.

3.2.1 Big- or Little Endian

Configure if the host application is a big endian system or a little endian system. Define ABCC_

SYS_BIG_ENDIAN if it is a big endian system. Do not define (leave as default) if the host

application is a little endian system.

8 (54)

#define ABCC_SYS_BIG_ENDIAN /* Big endian host application */

/* #define ABCC_SYS_BIG_ENDIAN */ /* Little endian host application */

3.2.2 16–bit Char System

Configure if the host application is a 16-bit char system or an 8-bit char system (i.e. if the

smallest addressable type is 8-bit or 16-bit). Define ABCC_SYS_16BIT_CHAR if it is a 16-bit

char system. Do not define (leave as default) if it is an 8-bit char system. Configuring of 16-bit

char for an 8-bit char system is not recommended.

#define ABCC_SYS_16_BIT_CHAR /* 16 bit char system */

/* #define ABCC_SYS_16_BIT_CHAR */ /* 8 bit char system */

3.2.3 Extended Bus Endian Difference

If the endianness for the external parallel data bus differs from the internal data bus endianness,

enable this define. If parallel 16-bit operating mode is not used, this define is ignored.

#define ABCC_CFG_PAR_EXT_BUS_ENDIAN_DIFF (FALSE)

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 11

Step One

3.2.4 Data Types

Define the Data Types for the current system. For 16-bit char systems, all 8-bit types shall be

typed to 16-bit types. The following data types must be defined:

9 (54)

BOOL

BOOL8

INT8

INT16

INT32

UINT8

UINT16

UINT32

FLOAT32

Standard boolean data type.

Standard boolean data type, 8-bit.

Standard signed 8-bit data type.

Standard singed 16-bit data type.

Standard signed 32-bit data type.

Standard unsigned 8-bit data type.

Standard unsigned 16-bit data type.

Standard unsigned 32-bit data type.

Float (according to IEC 60559).

3.3 Anybus CompactCom Set-up

These defines and functions are found in abcc_adapt/abcc_drv_cfg.h. Detailed

descriptions are available in abcc_drv/inc/abcc_cfg.h.

Settings for how to use and communicate with the Anybus CompactCom. Operating mode,

interrupt handling, memory handling etc., are configured here.

3.3.1 Communication Interfaces and Operating Modes

Define the communication interfaces and the operating mode between the host application and

the CompactCom (Parallel, SPI, Serial), that will be used in the implementation. There are several

possibilities to set the operating mode depending on how the host application is intended to

communicate with the Anybus and also depending on how the operating mode is selected by the

user.

• First, define all communication interfaces that will be supported by the implementation. All

interfaces that will be used must be defined here, otherwise an error will be reported later

on. Only define the interfaces that will really be used, since every enabled interface will

increase the compiled code size.

Only for 40-series.

#define ABCC_CFG_DRV_PARALLEL ( TRUE ) /* Parallel, 8/16-bit, event

mode */

#define ABCC_CFG_DRV_SPI ( FALSE ) /* SPI */

For both 30-series and 40-series.

#define ABCC_CFG_DRV_SERIAL ( FALSE ) /* Serial */

#define ABCC_CFG_DRV_PARALLEL_30( TRUE ) /* Parallel, 8-bit, half

duplex */

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 12

Step One

10 (54)

ABCC_CFG_DRV_SERIAL and ABCC_CFG_DRV_PARALLEL_30 use the CompactCom half duplex

communication protocol, with limited data sizes for process data and message data.

• Get the operating mode from external hardware - If the operating mode is set e.g. via a dipswitch connected to the host application processor or via an HMI controller, define the

ABCC_CFG_OP_MODE_GETTABLE and implement the function ABCC_SYS_GetOpmode

() in abcc_adapt/abcc_sys_adapt.c.

#define ABCC_CFG_OP_MODE_GETTABLE ( TRUE )

If not defined, the operating mode defines must be explicitly defined for the specific module

type. (See ABCC_CFG_ABCC_OP_MODE_30 and ABCC_CFG_ABCC_OP_MODE_40

below).

• If the operating mode pins on the CompactCom host connector can be controlled by the

host processor, define ABCC_CFG_OP_MODE_SETTABLE and implement the function

ABCC_SYS_SetOpmode() in abcc_adapt/abcc_sys_adapt.c.

#define ABCC_CFG_OP_MODE_SETTABLE ( TRUE )

If not defined, it is assumed that the operating mode signals of the CompactCom host

connector are fixed or controlled by external hardware, e.g. a dip-switch.

• If only one operating mode per module type (CompactCom 30 and CompactCom 40) is

used, define the operating mode with ABCC_CFG_ABCC_OP_MODE_30 and ABCC_CFG_

ABCC_OP_MODE_40. The available operating modes (ABP_OP_MODE_X) can be found in

abcc_abp/abp.h.

#define ABCC_CFG_ABCC_OP_MODE_30 ABP_OP_MODE_8_BIT_PARALLEL

#define ABCC_CFG_ABCC_OP_MODE_40 ABP_OP_MODE_16_BIT_PARALLEL

If none of these defines are set, ABCC_SYS_GetOpmode() must be implemented to

retrieve the operating mode from external hardware. See

ABCC_CFG_OP_MODE_GETTABLE above.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 13

Step One

3.3.2 Parallel Operating Mode Specifics

If parallel operating mode (8-bit or 16-bit) is not used, this section can be ignored.

If direct access to the CompactCom memory is available (the host controller provides dedicated

signals to access external SRAM), define ABCC_CFG_MEMORY_MAPPED_ACCESS to TRUE and

define the base address with ABCC_CFG_PARALLEL_BASE_ADR (this address must be

defined to suit the host platform).

#define ABCC_CFG_MEMORY_MAPPED_ACCESS ( TRUE )

#define ABCC_CFG_PARALLEL_BASE_ADR ( 0x00000000 )

If direct access to the CompactCom memory is not available, several functions to read and write

data must be implemented in abcc_adapt/abcc_sys_adapt.c (described in abcc_drv/

inc/abcc_sys_adapt_par.h).

The recommendation is to have direct access to the CompactCom memory if possible for a simpler and

most often faster implementation.

3.3.3 SPI Operating Mode Specifics

11 (54)

Only for 40-series. If SPI operating mode is not used, this section can be ignored.

The length of an SPI message fragment in bytes per SPI transaction is defined with ABCC_CFG_

SPI_MSG_FRAG_LEN.

If the ABCC_CFG_SPI_MSG_FRAG_LEN value is less than the largest message to be

transmitted, the sending or receiving of a message may be fragmented and take several SPI

transactions to be completed. Each SPI transaction will have a message field of this length

regardless if a message is present or not. If messages are important the fragment length should

be set to the largest message to avoid fragmentation. If IO data are important the message

fragment length should be set to a smaller value to speed up the SPI transaction.

For high message performance a fragment length up to 1524 octets is supported. The message

header is 12 octets, so 16 or 32 octets will be enough to support small messages without

fragmentation.

#define ABCC_CFG_SPI_MSG_FRAG_LEN ( 16 )

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 14

Step One

3.3.4 Module ID and Module Detect Settings

• If the Module Identification pins (MI) on the CompactCom host connector are not

connected to the host processor, ABCC_CFG_MODULE_ID_PINS_CONN must be defined

as FALSE, and ABCC_CFG_ABCC_MODULE_ID must be defined to the correct

CompactCom module ID that corresponds to the module ID of the used device. If defined, it

shall be set to the correct ABP_MODULE_ID_X definition from abcc_abp/abp.h.

If ABCC_CFG_MODULE_ID_PINS_CONN is defined as TRUE, the function ABCC_SYS_

ReadModuleId() in abcc_adapt/abcc_sys_adapt.c must be implemented.

The recommendation is to connect the Module ID pins on the application connector directly to GPIO-pins

on the host processor and implement the ABCC_SYS_ReadModuleId() function.

#define ABCC_CFG_ABCC_MODULE_ID ABP_MODULE_ID_ACTIVE_ABCC40

#define ABCC_CFG_MODULE_ID_PINS_CONN ( TRUE )

• If the Module Detect pins (MD) in the host application connector are connected to the host

processor, the ABCC_CFG_MOD_DETECT_PINS_CONN shall be set to TRUE and the

ABCC_SYS_ModuleDetect() function in abcc_adapt/abcc_sys_adapt.c must

be implemented.

#define ABCC_CFG_MOD_DETECT_PINS_CONN ( TRUE )

12 (54)

3.3.5 Message and Process Data Settings

Leave the following defines with the default values for now.

#define ABCC_CFG_MAX_NUM_APPL_CMDS

#define ABCC_CFG_MAX_NUM_ABCC_CMDS

#define ABCC_CFG_MAX_MSG_SIZE

#define ABCC_CFG_MAX_PROCESS_DATA_SIZE

#define ABCC_CFG_REMAP_SUPPORT_ENABLED

#define ABCC_CFG_CMD_SEQ_MAX_NUM_RETRIES

#define ABCC_CFG_MAX_NUM_CMD_SEQ

The different platforms can have different default values depending on the available resources.

( 2 )

( 2 )

( 255 )

( 512 )

( FALSE )

( 0 )

( 2 )

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 15

Step One

3.3.6 Interrupt Handling

If the IRQ pin is connected the driver can be configured to check if an event has occurred even if

the interrupt is disabled. It can be used e.g. to detect the CompactCom power up event. Define

ABCC_CFG_POLL_ABCC_IRQ_PIN to enable this functionality, and implement the function

ABCC_SYS_IsAbccInterruptActive() in abcc_adapt/abcc_sys_adapt.c.

#define ABCC_CFG_POLL_ABCC_IRQ_PIN ( TRUE )

In this step, we will not use the interrupt functionality, which means that we will define ABCC_

CFG_INT_ENABLED as FALSE.

If the IRQ pin is not connected, this define must be set to false.

#define ABCC_CFG_INT_ENABLED ( FALSE )

3.3.7 Communication Watchdog Settings

The timeout for the CompactCom communication watchdog is configured with ABCC_CFG_WD_

TIMEOUT_MS. If a timeout occurs, the callback function ABCC_CbfWdTimeout() is called.

The watchdog functionality is only supported by the SPI-, serial- and

parallel30 (half duplex) operating modes.

13 (54)

#define ABCC_CFG_WD_TIMEOUT_MS ( 1000 )

3.3.8 ADI Settings

Leave the following defines with the default values for now.

#define ABCC_CFG_STRUCT_DATA_TYPE ( FALSE )

#define ABCC_CFG_ADI_GET_SET_CALLBACK ( FALSE )

#define ABCC_CFG_64BIT_ADI_SUPPORT ( FALSE )

3.3.9 Debug Event Print Settings

For development purposes, a number of debug functions are available for the developer. The

following defines affects debug printouts from the driver. If additional printouts are needed from

the application code, use the ported function ABCC_PORT_DebugPrint() in abcc_adapt/

abcc_sw_port.h.

• Enable or disable the error reporting callback function ABCC_CbfDriverError() with

ABCC_CFG_ERR_REPORTING_ENABLED. The function is described in abcc_drv/inc/

abcc.h.

#define ABCC_CFG_ERR_REPORTING_ENABLED ( TRUE )

• Enable or disable driver support for print out of debug events within the driver with ABCC_

CFG_DEBUG_EVENT_ENABLED. ABCC_PORT_DebugPrint() in abcc_adapt/

abcc_sw_port.h will be used to print debug information.

#define ABCC_CFG_DEBUG_EVENT_ENABLED ( TRUE )

• Enable or disable printout of debug information, such as file name and line number, when

ABCC_CbfDriverError() is called with ABCC_CFG_DEBUG_ERR_ENABLED.

#define ABCC_CFG_DEBUG_ERR_ENABLED ( FALSE )

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 16

Step One

• Enable or disable printout of received and sent messages with ABCC_CFG_DEBUG_

MESSAGING. Related events such as buffer allocation and queuing information is also

printed.

#define ABCC_CFG_DEBUG_MESSAGING ( FALSE )

• Enable or disable printout of command sequencer actions with ABCC_CFG_DEBUG_CMD_

SEQ_ENABLED.

#define ABCC_CFG_DEBUG_CMD_SEQ_ENABLED ( FALSE )

3.3.10 Startup Time

If the CompactCom IRQ pin is connected, ABCC_CFG_STARTUP_TIME_MS will be used as a

timeout while waiting for the CompactCom to become ready for communication. An error

(APPL_MODULE_NOT_ANSWERING) will be reported if the start-up interrupt is not received

within this time. If the interrupt pin is not available ABCC_CFG_STARTUP_TIME_MS will serve

as time to wait before starting to communicate with the CompactCom. If not defined, the default

value is 1500 ms.

#define ABCC_CFG_STARTUP_TIME_MS ( 1500 )

If possible, the recommendation is to use the startup interrupt (option available for the SPI and parallel

communication interfaces).

14 (54)

3.3.11 Sync Settings

Only for 40-series.

Leave the following defines with the default values for now.

#define ABCC_CFG_SYNC_ENABLE ( FALSE )

#define ABCC_CFG_SYNC_MEASUREMENT_IP ( FALSE )

#define ABCC_CFG_SYNC_MEASUREMENT_OP ( FALSE )

3.4 System Adaptation Functions

A number of functions must be implemented for the driver to be able to access the Anybus

CompactCom. The functions shall be implemented in abcc_adapt/abcc_sys_adapt.c.

The functions are described per operating mode in the files specified below.

• General functions: abcc_drv/inc/abcc_sys_adapt.h

• SPI operating mode: abcc_drv/inc/abcc_sys_adapt_spi.h

• Parallel operating mode: abcc_drv/inc/abcc_sys_adapt_par.h

• Serial operating mode: abcc_drv/inc/abcc_sys_adapt_ser.h

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 17

Step One

3.4.1 General Functions

These functions can be found in abcc_drv/inc/abcc_sys_adapt.h.

ABCC_SYS_HwInit()

This function can be used to initiate the hardware required to communicate with the

CompactCom device (e.g. configuring the direction and initial values of used host processor port

pins). This function shall be called once during the power up initialization.

Note: Make sure that the CompactCom is kept in reset state when returning from this function.

ABCC_SYS_Init()

This function is called by the driver at start-up and restart of the driver. If needed, any hardware

or system dependent initialization shall be done here. If not used, leave the function empty.

ABCC_SYS_Close()

Called from the driver if the driver is terminated. If resources were allocated in ABCC_SYS_

Init() it is recommended to close or free them in this function. If not used, leave the function

empty.

ABCC_SYS_HWReset()

This function must be implemented to pull the reset pin on the Anybus CompactCom interface to

low.

15 (54)

ABCC_SYS_HWReleaseReset()

This function must be implemented to set the reset pin on the Anybus CompactCom interface to

high.

ABCC_SYS_AbccInterruptEnable()

For now, interrupt will be disabled. Leave this function empty for now.

ABCC_SYS_AbccInterruptDisable()

For now, interrupt will be disabled. Leave this function empty for now.

ABCC_SYS_IsAbccInterruptActive()

If the interrupt pin (IRQ) is connected to the host processor, this function shall read the interrupt

signal from the CompactCom and return TRUE if the interrupt pin is low (i.e. interrupt is active)

and return FALSE if the interrupt pin is high (i.e. the interrupt is inactive). It is used to enable

polling of the interrupt pin of the CompactCom interface if interrupts are not enabled.

ABCC_SYS_SyncInterruptEnable()

For now, synchronization will be disabled. Leave this function empty for now.

ABCC_SYS_SyncInterruptDisable()

For now, synchronization will be disabled. Leave this function empty for now.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 18

Step One

3.4.2 SPI Operating Mode

Only for 40-series. If SPI operating mode is not used, the functions below are never called, and

this section can be ignored.

These functions can be found in abcc_drv/inc/abcc_sys_adapt_spi.h.

ABCC_SYS_SpiRegDataReceived(ABCC_SYS_SpiDataReceivedCbfType pnDataReceived)

Registers the callback function that shall be called when new data is received (MISO frame

received).

Example:

static ABCC_SYS_SpiDataReceivedCbfType pnDataReadyCbf;

void ABCC_SYS_SpiRegDataReceived( ABCC_SYS_SpiDataReceivedCbfType

pnDataReceived )

{

pnDataReadyCbf = pnDataReceived;

}

ABCC_SYS_SpiSendReceive(void* pxSendDataBuffer, void* pxReceiveDataBuffer, UINT16

iLength)

Handles sending and receiving of data in SPI mode.

16 (54)

Two buffers are provided, one with a MOSI data frame to be sent and one buffer to store the

received MISO frame.

3.4.3 Parallel Operating Mode

These functions can be found in abcc_drv/inc/abcc_sys_adapt_par.h.

If parallel operating mode is not used, the functions below are never called, and this section

can be ignored.

If parallel operating mode is used and ABCC_CFG_MEMORY_MAPPED_ACCESS is defined, this

section can be ignored. See Parallel Operating Mode Specifics for more information about

ABCC_CFG_MEMORY_MAPPED_ACCESS.

ABCC_SYS_ParallelRead()

Reads an amount of octets from the CompactCom memory.

ABCC_SYS_ParallelRead8()

Only used for half duplex parallel operating mode.

Reads an octet from the CompactCom memory.

ABCC_SYS_ParallelRead16()

Reads a word from the CompactCom memory.

ABCC_SYS_ParallelWrite()

Writes an amount of octets to the CompactCom memory.

ABCC_SYS_ParallelWrite8()

Only used for half duplex parallel operating mode.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 19

Step One

Writes an octet to the CompactCom memory.

ABCC_SYS_ParallelWrite16()

Writes a word to the CompactCom memory.

ABCC_SYS_ParallelGetRdPdBuffer()

Get the address to the received read process data.

ABCC_SYS_ParallelGetWrPdBuffer()

Get the address to store the write process data.

3.4.4 SerialOperating Mode

These functions can be found in abcc_drv/inc/abcc_sys_adapt_ser.h.

If serial operating mode is not used, the functions below are never called, and this section can

be ignored.

ABCC_SYS_SerRegDataReceived(ABCC_SYS_SerDataReceivedCbfType pnDataReceived)

Registers a callback function that shall indicate that a new RX telegram has been received on the

serial channel.

17 (54)

Example:

static ABCC_SYS_SerDataReceivedCbfType pnSerDataReadyCbf;

void ABCC_SYS_SerRegDataReceived( ABCC_SYS_SerDataReceivedCbfType

pnDataReceived )

{

pnSerDataReadyCbf = pnDataReceived;

}

ABCC_SYS_SerSendReceive(void* pxTxDataBuffer, void* pxRxDataBuffer, UINT16 iTxSize,

UINT16 iRxSize)

Send TX telegram and prepare for RX telegram reception.

ABCC_SYS_SerRestart(void)

Restart the serial driver. Typically used when a telegram has timed out.

This command flushes all buffers, restarts communication, and starts waiting for a RX telegram

with the length of the latest provided RX telegram length.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 20

Step One

3.5 Object Configuration

For this step, the default settings in the CompactCom will be used. No host application objects

are enabled in the file abcc_adapt/abcc_obj_cfg.h.

In Step Two, the network identification attributes will be customized to fit the target product.

3.6 Example Application

An API layer that defines a common interface for all network applications to the Anybus

CompactCom driver is available. The API is found in abcc_drv/inc/abcc.h. The example

application is provided to give an example of how a standard application implements the

CompactCom driver using the API. It can be used as it is to be able to test the CompactCom

concept and can also be used as a base when implementing the driver into the final application.

3.6.1 ADI and Process Data Mapping

Process data is an integral part of the application. Process data is added to the application by

creating ADIs (Application Data Instances) and mapping them to the desired process data areas

(read or write).

For now, the mapping described in appl_adimap_speed_example.c shall be used. This

means that APPL_ACTIVE_ADI_SETUP in /example_app/appl_adi_config.h is

defined as APPL_ADI_SETUP_SPEED_EXAMPLE.

18 (54)

• example_app/appl_adimap_speed_example.c - Simulation of speed and

reference speed.

– ADI 1: "Speed", UINT16, Mapped to Read process data

– ADI 2: "Ref Speed", UINT16, Mapped to Write process data

– Data is manipulated with the function APPL_CyclicalProcessing()

– No structures or callbacks are used.

3.6.2 Main Loop

The main loop is where the execution of the application starts. In the generic project, it is located

in the file named main.c. Below are some guidelines how to implement the main loop.

• ABCC_HwInit() - this function will initiate the hardware required to communicate with

the CompactCom, and shall be called once during the power-up initialization. It must also

make sure that the CompactCom is kept in reset when returning from the function. The

driver can be restarted without calling this function again. ABCC_HwInit() will trigger

the function ABCC_SYS_HwInit() in abcc_adapt/abcc_sys_adapt.c, which

shall be customized to fit the current system. Make sure this function is one of the first

functions called in the main function.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 21

Step One

19 (54)

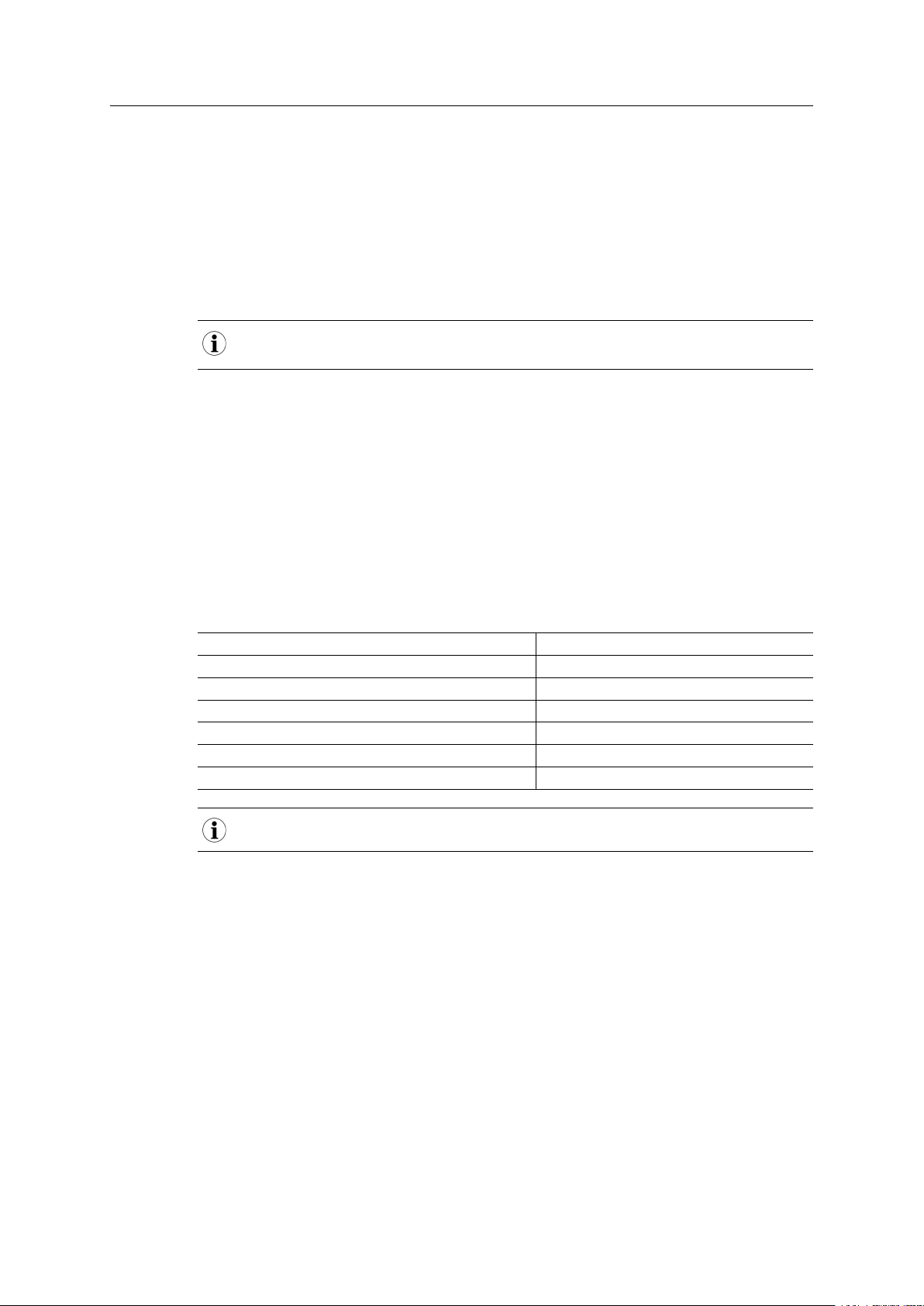

• APPL_HandleAbcc() - This function will run the CompactCom state machine and take

care of reset, run, and shutdown of the driver, and it must be called periodically from the

main loop. A status from the CompactCom driver is returned every time this function is

called.

APPL_MODULE_NO_ERROR

APPL_MODULE_NOT_DETECTED

APPL_MODULE_NOT_SUPPORTED

APPL_MODULE_NOT_ANSWERING

APPL_MODULE_RESET

APPL_MODULE_SHUTDOWN

APPL_MODULE_UNEXPECTED_ERROR

The CompactCom is OK. This is the normal response if everything is

running normal.

No CompactCom is detected. Inform the user.

Unsupported module detected. Inform the user.

Possible reasons: Wrong communication interface selected, defect

module.

Reset requested from the CompactCom. A reset is received from the

network. The application is responsible for restarting the

CompactCom.

Shutdown requested.

Unexpected error occurred. Inform the user. If necessary, put the

outputs in a fail-safe state.

• ABCC_RunTimerSystem() - This function shall be called periodically with a known

period (ms since last call). This can be done either by having a known delay in the main loop

and call the function each iteration, or by setting up a timer interrupt.

This function is responsible for handling all timers for the CompactCom driver. It is

recommended to call this function on a regular basis from a timer interrupt. Without this

function no timeout and watchdog functionality will work.

It is recommended to use a timer interrupt with this function. However, for easier debugging when

implementing, skip the timer interrupt in the beginning.

int main()

{

APPL_AbccHandlerStatusType eAbccHandlerStatus = APPL_MODULE_NO_ERROR;

if (ABCC_HwInit() != ABCC_EC_NO_ERROR )

{

return ( 0 );

}

while ( eAbccHandlerStatus == APPL_MODULE_NO_ERROR )

{

eAbccHandlerStatus = APPL_HandleAbcc();

#if( !USE_TIMER_INTERRUPT )

ABCC_RunTimerSystem( APPL_TIMER_MS );

DelayMs( APPL_TIMER_MS );

#endif

switch( eAbccHandlerStatus )

{

case APPL_MODULE_RESET:

Reset();

break;

default:

break;

}

}

return ( 0 );

}

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 22

Step One

3.6.3 Compile and Run

To compile the project, update the make-file to include all the Anybus CompactCom 40 example

code (all of the five folders described here) and compile.

• /abcc_abp

• /abcc_drv

• /abcc_adapt

• /abcc_obj

• /example_app

Before continuing to Step Two, make sure...

• ...the project compiles without errors.

• ...the host application can communicate with the Anybus CompactCom.

• ...data can be exchanged with the network.

20 (54)

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 23

Step Two

4 Step Two

4.1 Adaptations and Customizations

When this step is completed you have...

• …customized the network identification, e.g. Vendor ID, Product Code, Product Name, etc.

• …created ADI:s for the target product.

• …mapped the ADI:s that shall be exchanged cyclically to process data.

4.1.1 Anybus CompactCom Setup

In Step One, some Anybus CompactCom settings were left at default values. We will revisit some

of those values here.

Message and Process Data Settings

• The number of message commands that can be sent without receiving a response is

configured with ABCC_CFG_MAX_NUM_APPL_CMDS. Increasing this value will of course

increase the possible number of message commands, but it will also consume more RAM

memory.

21 (54)

#define ABCC_CFG_MAX_NUM_APPL_CMDS ( 2 )

• The number of message commands that can be received without sending a response is

configured with ABCC_CFG_MAX_NUM_ABCC_CMDS. Increasing this value will of course

increase the possible number of message commands, but it will also consume more RAM

memory.

#define ABCC_CFG_MAX_NUM_ABCC_CMDS ( 2 )

• The size of the largest message in bytes that will be used is configured with ABCC_CFG_

MAX_MSG_SIZE.

Anybus CompactCom 30 supports 255 bytes messages and Anybus CompactCom 40 supports 1524 bytes

messages. ABCC_CFG_MAX_MSG_SIZE should be set to largest size that will be sent or received. If

this size is not known it recommended to set the maximum supported size.

#define ABCC_CFG_MAX_MSG_SIZE ( 255 )

• The maximum size of the process data in bytes that will be used in either direction is

configured with ABCC_CFG_MAX_PROCESS_DATA_SIZE. The maximum size is

dependent on the type of network that is used. See the corresponding network guide for

the networks to be used.

#define ABCC_CFG_MAX_PROCESS_DATA_SIZE ( 512 )

• Enable or disable driver and Application Data object support for the remap command with

ABCC_CFG_REMAP_SUPPORT_ENABLED. If TRUE the ABCC_CbfRemapDone() needs

to be implemented by the application. The function is described in abcc_drv/inc/

abcc.h.

#define ABCC_CFG_REMAP_SUPPORT_ENABLED ( FALSE )

• The maximum number of allowed simultaneous message command sequences when using

the message command sequencer.

#define ABCC_CFG_MAX_NUM_CMD_SEQ ( 2 )

• Configure the number of retries the message command sequencer shall do if there is no

buffer available, before an error is reported.

#define ABCC_CFG_CMD_SEQ_MAX_NUM_RETRIES ( 0 )

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 24

Step Two

22 (54)

Interrupt Handling

The Anybus CompactCom driver can be used either with the interrupt functionality enabled or

disabled.

• Define if the CompactCom IRQ pin shall be used along with an interrupt routine by defining

ABCC_CFG_INT_ENABLED. The IRQ pin can be used in both parallel mode and SPI mode.

The function ABCC_ISR() shall be called from inside the CompactCom interrupt routine. If

the interrupt is flank triggered, the interrupt shall be acknowledged before ABCC_ISR() is

called.

#define ABCC_CFG_INT_ENABLED ( FALSE )

• If parallel mode is not used, this define can be ignored. Configure which interrupts that

shall be enabled when using parallel mode with the ABCC_CFG_INT_ENABLE_MASK_

PAR define. The available options are defined in abcc_abp/abp.h (INT MASK Register).

If an event is not notified via the CompactCom interrupt, it must be polled by the driver

function ABCC_RunDriver() (called by example_app/APPL_HandleAbcc()). If

not defined, the default mask is 0.

#define ABCC_CFG_INT_ENABLE_MASK_PAR ( ABP_INTMASK_RDPDIEN | ABP_

INTMASK_STATUSIEN | ABP_INTMASK_RDMSGIEN | ABP_INTMASK_WRMSGIEN |

ABP_INTMASK_ANBRIEN )

• ABCC_CFG_HANDLE_INT_IN_ISR_MASK defines what interrupt events for the Anybus

CompactCom that are handled in interrupt context. Events that are enabled in the interrupt

enable mask (ABCC_CFG_INT_ENABLE_MASK_X) but not configured to be handled by

the ISR will be translated to a bit field of ABCC_ISR_EVENT_X definitions (defined in

abcc_drv/inc/abcc.h) and forwarded to the user via the ABCC_CbfEvent()

callback. Only applicable for parallel 8/16-bit operating mode.

If not defined, the value will be 0, i.e. no events are handled by the ISR.

#define ABCC_CFG_HANDLE_INT_IN_ISR_MASK ( ABP_INTMASK_RDPDIEN )

ADI Settings

• Enable ADI-support for structured data types with ABCC_CFG_STRUCT_DATA_TYPE. This

define will affect the AD_AdiEntryType in abcc_drv/inc/abcc_ad_if.h, used for

defining the user ADI:s. If defined, the required memory usage will increase, i.e. it should

only be defined if structured data types are needed.

#define ABCC_CFG_STRUCT_DATA_TYPE ( FALSE )

• Enable or disable driver support for triggering of callback notifications each time an ADI is

read or written with ABCC_CFG_ADI_GET_SET_CALLBACK. This define will affect the

AD_AdiEntryType in abcc_drv/inc/abcc_ad_if.h, used for defining the user

ADI:s. If an ADI is read by the network the callback is invoked before the action. If an ADI is

written by the network the callback is invoked after the action.

#define ABCC_CFG_ADI_GET_SET_CALLBACK ( FALSE )

• Enable or disable support for 64-bit data types in the Application Data object with ABCC_

CFG_64BIT_ADI_SUPPORT.

#define ABCC_CFG_64BIT_ADI_SUPPORT ( FALSE )

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 25

Step Two

23 (54)

Sync Settings

Only for 40–series.

• Enable or disable driver support for sync. If TRUE, the abcc_CbfSyncIsr() must be

implemented by the application.

#define ABCC_CFG_SYNC_ENABLE ( TRUE )

• ABCC_SYS_SyncInterruptEnable()

Enables the sync interrupt triggered by the sync-pin on the application interface (MIO/SYNC).

This function will be called by the driver to enable the sync interrupt.

Only used when synchronization functionality is enabled.

• ABCC_SYS_SyncInterruptDisable()

Disables the sync interrupt triggered by the sync-pin on the application interface (MIO/

SYNC). This function will be called by the driver to disable the sync interrupt.

Only used when synchronization functionality is enabled.

If sync is not used or if the code is compiled for release, the following defines shall be disabled.

The sync measurement functions are used to measuring the input processing time and the

output processing time used in a sync application.

• Enable or disable driver support for measurement of input processing time (used for sync)

with ABCC_CFG_SYNC_MEASUREMENT_IP. This define is used during development by

activating it and compiling special test versions of the product. When ABCC_CFG_SYNC_

MEASUREMENT_IP is TRUE ABCC_SYS_GpioReset() is called when the WRPD has

been sent. If running in SPI operating mode it is instead called when ABCC_

SpiRunDriver() has finished sending data to the Anybus. When ABCC_CFG_SYNC_

MEASUREMENT_IP is TRUE, ABCC_GpioSet() needs to be called at the Input Capture

Point.

#define ABCC_CFG_SYNC_MEASUREMENT_IP ( FALSE )

• Enable or disable driver support for measurement of output processing time (used for sync)

with ABCC_CFG_SYNC_MEASUREMENT_OP. This define is used during development by

activating it and compiling special test versions of the product. When ABCC_CFG_SYNC_

MEASUREMENT_OP is TRUE, ABCC_SYS_GpioSet() is called from the RDPDI interrupt.

When ABCC_CFG_SYNC_MEASUREMENT_OP is TRUE ABCC_GpioReset() needs to

be called at the Output Valid Point.

#define ABCC_CFG_SYNC_MEASUREMENT_OP ( FALSE )

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 26

Step Two

4.1.2 System Adaptation Functions

These functions can be found in abcc_adapt/abcc_sys_adapt.c.

If interrupts will be used in Step Two, implement the following functions.

• ABCC_SYS_AbccInterruptEnable()

Enable the CompactCom HW interrupt (IRQ_N pin on the application interface). This

function will be called by the driver when the CompactCom interrupt shall be enabled.

If ABCC_CFG_INT_ENABLED is not defined in abcc_adapt/abcc_drv_cfg.h, this

function does not need to be implemented.

• ABCC_SYS_AbccInterruptDisable()

Disable CompactCom HW interrupt (IRQ_N pin on the application interface).

If ABCC_CFG_INT_ENABLED is not defined in abcc_adapt/abcc_drv_cfg.h, this

function does not need to be implemented.

24 (54)

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 27

Step Two

4.1.3 Network Identification

So far, all network settings have been left disabled and the product has identified itself as an

HMS product, using default values. Now it is time to customize the network identification

settings.

Host Application Objects — Networks

Define the networks to be supported by the implementation by defining their respective host

application object in the file abcc_adapt/abcc_obj_cfg.h. Further implementations of

the host application objects are done in the abcc_obj folder where each object has its own cand h-files.

Example:

#define PRT_OBJ_ENABLE ( TRUE )

#define EIP_OBJ_ENABLE ( FALSE )

#define EPL_OBJ_ENABLE ( TRUE )

The identity related attributes for each enabled network object are parameters that must be set

by the application. They are all related to how the device is identified on the network. If the

attribute is enabled (TRUE), the value will be used. If the attribute is disabled (FALSE), the

attribute's default value will be used. These settings can be found in abcc_adapt/abcc_

identification.h.

25 (54)

Example:

/*---------------------------------------------------------------------------** Ethernet Powerlink (0xE9)

**---------------------------------------------------------------------------*/

#if EPL_OBJ_ENABLE

/*

** Attribute 1: Vendor ID (UINT32 - 0x00000000-0xFFFFFFFF)

*/

#ifndef EPL_IA_VENDOR_ID_ENABLE

#define EPL_IA_VENDOR_ID_ENABLE TRUE

#define EPL_IA_VENDOR_ID_VALUE 0xFFFFFFFF

#endif

/*

** Attribute 2: Product Code type (UINT32 - 0x00000000-0xFFFFFFFF)

*/

#ifndef EPL_IA_PRODUCT_CODE_ENABLE

#define EPL_IA_PRODUCT_CODE_ENABLE TRUE

#define EPL_IA_PRODUCT_CODE_VALUE 0xFFFFFFFF

#endif

It is also possible to define a function instead of a constant to generate the value. The serial number is a

good example of where a function would be suitable. In the example below, the serial number is set

during production in a specific memory area, and here the same number is fetched:

extern char* GetSerialNumberFromProductionArea(void);

#define PRT_IA_IM_SERIAL_NBR_ENABLE TRUE

#define PRT_IA_IM_SERIAL_NBR_VALUE GetSerialNumberFromProductionArea()

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 28

Step Two

26 (54)

Host Application Objects — Other

In abcc_adapt/abcc_obj_cfg.h, define all other host application objects that shall be

supported by the implementation. If not supported, leave the value as FALSE.

Example:

#define ETN_OBJ_ENABLE ( TRUE )

#define SYNC_OBJ_ENABLE ( FALSE )

Host Application Objects — Advanced

The file abcc_adapt/abcc_obj_cfg.h contains all attributes for all supported host

objects, except for those already defined in abcc_adapt/abcc_identification.h. All

attributes in this file are disabled by default. Network specific services are labelled "not

supported" by default, and if desired they need to be implemented in the application.

The file abcc_adapt/abcc_platform_cfg.h can be used to override defines for objects and

attributes in the files abcc_adapt/abcc_obj_cfg.h, abcc_adapt/abcc_identification.

h and abcc_adapt/abcc_drv_cfg.h.

To override a define, just add the desired defines to the abcc_adapt/abcc_platform_cfg.h file

or use the global defines section in the development environment.

If not used, leave the file empty.

4.1.4 Software Platform Porting

These functions can be found in abcc_adapt/abcc_sw_port.h.

The driver uses a number of functions, like memory copying functions, print functions, and

functions for critical sections, which can be optimized for the current software platform. These

functions can be found in the file abcc_adapt/abcc_sw_port.h (described in abcc_

drv/inc/abcc_port.h). The default example code can be used as-is, but it should be

optimized (recommended) for the desired platform later in the implementation project.

ABCC_PORT_DebugPrint()

Used by the driver for debug prints such as events or error debug information. If not defined the

driver will be silent. Debug prints can e.g. be sent to a serial terminal or be saved to a logfile.

Critical Section Functions

Critical sections are used when there is a risk of resource conflicts or race conditions between

CompactCom interrupt handler context and the application thread.

The following macros are used to implement the critical sections:

• ABCC_PORT_UseCritical()

• ABCC_PORT_EnterCritical()

• ABCC_PORT_ExitCritical()

• ABCC_PORT_TIMER_UseCritical()

• ABCC_PORT_TIMER_EnterCritical()

• ABCC_PORT_TIMER_ExitCritical()

Depending on the configuration of the driver there are different requirements on the critical

section implementation. Please choose the most suitable implementation from the numbered

list below. The first statement that is true will choose the requirement.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 29

Step Two

27 (54)

1. The first three macros above need to be implemented if any of the statements below are

true.

– Any message handling is done within interrupt context.

Requirements:

– The implementation must support that a critical section is entered from interrupt

context. ABCC_PORT_UseCritical() should be used for any declarations needed

in advance by ABCC_PORT_EnterCritical().

– When entering the critical section the required interrupts i.e. any interrupt that may

lead to driver access, must be disabled. When leaving the critical section the interrupt

configuration must be restored to the previous state.

2. ABCC_PORT_EnterCritical() and ABCC_PORT_ExitCritical() need to be

implemented if any of the statements below are true.

– The application is accessing the CompactCom driver message interface from different

processes or threads without protecting the message interface on a higher level

(semaphores or similar).

Requirement:

– When entering the critical section the required interrupts i.e. any interrupt that may

lead to driver access, must be disabled. When leaving the critical section the interrupts

must be enabled again.

3. If none of the above is true, no implementation is required.

If the application is calling ABCC_RunTimerSystem() from a timer interrupt, the last three timerspecific macros also need to be defined. If left undefined by the application in abcc_sw_port.h,

these will assume the same definition as the corresponding three macros specified above:

Requirements:

• ABCC_PORT_TIMER_UseCritical() should be used for any declarations needed in advance by

ABCC_PORT_TIMER_EnterCritical().

• When entering the critical section, the required interrupts i.e. any interrupt that may lead

to driver access, specifically the timer system, must be disabled. When leaving the critical

section the interrupt configuration must be restored to the previous state.

ABCC_PORT_UseCritical()

If any preparation is needed before calling ABCC_PORT_EnterCritical() or ABCC_

PORT_ExitCritical(), this macro is used to add platform specific necessities.

ABCC_PORT_EnterCritical()

This function is called by the driver when there is a possibility of internal resource conflicts

between the CompactCom interrupt handler and the application thread or main loop. The

function temporarily disables interrupts to avoid conflict. Note that all interrupts that could lead

to a driver access need to be disabled.

ABCC_PORT_ExitCritical()

Restore interrupts to the state they were before ABCC_PORT_EnterCritical() was called.

ABCC_PORT_TIMER_UseCritical()

If any preparation is needed before calling ABCC_PORT_TIMER_EnterCritical() or

ABCC_PORT_TIMER_ExitCritical(), this macro is used to add platform specific

necessities.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 30

Step Two

28 (54)

ABCC_PORT_TIMER_EnterCritical()

Disables timer based interrupts, if they are not already disabled.

ABCC_PORT_TIMER_ExitCritical()

Restore interrupts to the state they were before ABCC_PORT_TIMER_EnterCritical()

was called.

ABCC_PORT_MemCopy()

Copy a number of octets, from the source pointer to the destination pointer.

ABCC_PORT_StrCpyToNative()

Copy a packed string to a native formatted string.

ABCC_PORT_StrCpyToPacked()

Copy a native formatted string to a packed string.

ABCC_PORT_CopyOctets()

Copy octet aligned buffer.

ABCC_PORT_Copy8()

Copy 8 bits from a source to a destination. For a 16 bit char platform octet alignment support

(the octet offset is odd) need to be considered when porting this macro.

ABCC_PORT_Copy16()

Copy 16 bits from a source to a destination. Octet alignment support (the octet offset is odd)

need to be considered when porting this macro.

ABCC_PORT_Copy32()

Copy 32 bits from a source to a destination. Octet alignment support (the octet offset is odd)

need to be considered when porting this macro.

ABCC_PORT_Copy64()

Copy 64 bits from a source to a destination. Octet alignment support (the octet offset is odd)

need to be considered when porting this macro.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 31

Step Two

4.1.5 Example Application

ADI:s and Process Data Mapping

In Step One, the example ADI mapping appl_adimap_speed_example.h was used. In the

example application there are ADI mapping examples included, which exemplify different types

of ADI:s.

Only one mapping can be used at a time. The map that is currently used in the application is

configured in the file example_app/appl_adi_config.h, by defining APPL_ACTIVE_

ADI_SETUP to the ADI mapping to be used. For detailed information about how to set up the

ADIs, see abcc_drv/abcc_ad_if.h.

• example_app/appl_adimap_speed_example.h – Simulation of speed and

reference speed.

29 (54)

ADI

ADI 1

ADI 2

Description

"Speed", UINT16 (mapped to input data)

"Ref Speed", UINT16 (mapped to output data)

– Data manipulated with the function APPL_CyclicalProcessing().

– No structures or callbacks are used.

• example_app/appl_adimap_simple16.c – This map loops 32 16-bit words.

ADI

ADI 1

ADI 2

Description

32 element array of UINT16 (mapped to input data)

32 element array of UINT16 (mapped to output data)

– The ADIs are mapped to process data in each direction..

– The data is looped since both ADIs refer to the same data place holder.

– No structures or callbacks are used.

• example_app/appl_adimap_separate16.c - Example of how get/set callbacks can

be used.

ADI

ADI 10

ADI 11

ADI 12

Description

32 element array of UINT16 (mapped to output data)

32 element array of UINT16 (mapped to input data)

UINT16 (not mapped to process data)

– ADIs 10 and 11 are mapped on process data in each direction.

– A callback is used when the network reads ADI 11. This callback will increment the

value of ADI 12 by one.

– A callback is used when the network writes ADI 10. This callback copies the value of

ADI 10 to ADI 11.

ABCC_CFG_ADI_GET_SET_CALLBACK has to be enabled in abcc_adapt/abcc_drv_cfg.h

since callbacks are used. See ADI Settings for more information.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 32

Step Two

30 (54)

• example_app/appl_adimap_alltypes.c - Example of how structured data types

and bit data types can be used

ADI

ADI 20

ADI 21

ADI 22

ADI 23

ADI 24

ADI 25

ADI 26

ADI 27

ADI 28

ADI 29

ADI 30

ADI 31

ADI 32

ADI 33

ADI 34

ADI 35

ADI 36

ADI 37

ADI 38

ADI 39

Description

UINT32 (mapped to output data)

UINT32 (mapped to input data)

SINT32 (mapped to output data)

SINT32 (mapped to input data)

UINT16 (mapped to output data)

UINT16 (mapped to input data)

SINT16 (mapped to output data)

SINT16 (mapped to input data)

BITS16 (mapped to output data)

BITS16 (mapped to input data)

UINT8 (mapped to output data)

UINT8 (mapped to input data)

SINT8 (mapped to output data)

SINT8 (mapped to input data)

PAD8 (mapped to output data, reserved space, no data)

PAD8 (mapped to input data, reserved space, no data)

BIT7 (mapped to output data)

BIT7 (mapped to input data)

Struct (mapped to output data)

Struct (mapped to input data)

ABCC_CFG_STRUCT_DATA_TYPE has to be enabled in abcc_adapt/abcc_drv_cfg.h since

structures are used. See ADI Settings for more information.

No specific functionality is implemented to manipulate with the data in this example.

• example_app/appl_adimap_asm.c

Example of an ADI setup with assembly mapping instances.

• example_app/appl_adimap_sync.c

Simple example of how to handle ADI values in a sync application.

• example_app/appl_adimap_verif.c

Used for internal tests at HMS Industrial Networks.

• example_app/adimap_bacnet.c

BACnet specific ADI example.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 33

Step Two

31 (54)

The examples implement the following steps that shall be customized to fit the actual

implementation:

• ADI Entry List - The ADI:s (i.e. the data instances that will be used in the implementation)

must be defined as an AD_AdiEntryType in an ADI entry list. All parameters related to

an ADI are specified here.

ADI Entry Item

iInstance

pabName Name of ADI (character string, ADI instance attribute #1). If NULL, a zero length name will be

bDataType

bNumOfElements For arrays: number of elements of the data type specified in bDataType.

bDesc Entry descriptor. Bit values according to the following configurations:

Description

ADI instance number (1-65535). 0 is reserved for Class.

returned.

ABP_BOOL:

ABP_SINT8:

ABP_SINT16:

ABP_SINT32:

ABP_UINT8:

ABP_UNIT16:

ABP_UINT32:

ABP_CHAR:

ABP_ENUM:

ABP_SINT64:

ABP_UINT64:

ABP_FLOAT:

ABP_OCTET

ABP_BITS8

ABP_BITS16

ABP_BITS32

ABP_BIT1

ABP_BIT2

:

ABP_BIT7

ABP_PAD0

ABP_PAD1

:

ABP_PAD16

DONT_CARE

For structured data types: number of elements in the structure.

ABP_APPD_DESCR_GET_ACCESS: Get service is allowed on value attribute.

ABP_APPD_DESCR_SET_ACCESS: Set service is allowed on value attribute.

ABP_APPD_DESCR_MAPPABLE_WRITE_PD: ADI is mappable on write process data.

ABP_APPD_DESCR_MAPPABLE_READ_PD: ADI is mappable on read process data.

Boolean

Signed 8 bit integer

Signed 16 bit integer

Signed 32 bit integer

Unsigned 8 bit integer

Unsigned 16 bit integer

Unsigned 32 bit integer

Character

Enumeration

Signed 64 bit integer

Unsigned 64 bit integer

Floating point value (32 bits)

Undefined 8 bit data (Only 40-series)

8 bit bit field (Only 40-series)

16 bit bit field (Only 40-series)

32 bit bit field (Only 40-series)

1 bit bit field (Only 40-series)

2 bit bit field (Only 40-series)

:

7 bit bit field (Only 40-series)

0 pad bit field (Only 40-series)

1 pad bit field (Only 40-series)

:

16 pad bit field (Only 40-series)

Use for structured data types

pxValuePtr Pointer to local value variable. The type is dependent on bDataType.

pxValuePropPtr

psStruct

pnGetAdiValue Pointer to an ABCC_GetAdiValueFuncType called when getting an ADI value. (Optional)

pnSetAdivalue Pointer to an ABCC_SetAdiValueFuncType called when setting an ADI value. (Optional)

®

Anybus

CompactCom™Host Application Implementation Guide

The descriptors can be logically OR:ed together.

In the example, ALL_ACCESS is all of the above logically OR:ed together.

Note: Ignored for structured data types

Note: Ignored for structured data types

Pointer to local value properties struct, if NULL, no properties are applied (max/min/default).

The type is dependent on bDataType. The use of max/min/default for acyclic messaging

must be enabled in the Application Data Object (AD_IA_MIN_MAX_DEFAULT_ENABLE) in

abcc_adapt/abcc_obj_cfg.h.

Note: Ignored for structured data types

Pointer to an AD_StructDataType. Set to NULL for non structured data types. This field is

enabled by defining ABCC_CFG_STRUCT_DATA_TYPE. (Optional, Only 40-series)

HMSI-27-334 1.7 en-US

Page 34

Step Two

The different ADI entries in the example code are defined as "const", i.e. the information will be saved in

ROM. However, sometimes it is not known at compile time what the ADI list shall look like. In that case,

the const declaration must be removed, and the ADI entry structure must be filled out before calling

ABCC_RunDriver(). The information will then be saved in RAM.

For use of structured data types in an ADI, see the example in abcc_drv/inc/abcc_ad_if.h.

• Write and Read Process Data Mapping - ADI:s that shall be mapped as process data are

mapped with AD_MapType. There is one combined list for both read process data and

write process data.

Data Mapping Item Description

iInstance

eDir

bNumElem Number of elements to map. Can only be > 1 for arrays or structures.

bElemStartIndex Element start index within an array or structure. If the ADI is not an array or structure,

ADI number of the ADI to map (see ADI Entry List above)

Direction of map. Set to PD_END_MAP to indicate end of default map list.

AD_DEFAULT_MAP_ALL_ELEM indicates that all elements shall be mapped.

If instance == AD_MAP_PAD_ADI, bNumElem indicates number of bits to pad with.

enter 0

The mappings are done in the order they will show up on the network.

32 (54)

Note: The mapping sequence is terminated by AD_MAP_END_ENTRY, which MUST be

present at the end of the list. During the setup sequence, the Anybus CompactCom driver

will ask for this information by invoking ABCC_CbfAdiMappingReq().

Example:

/* ADI instance no, direction, number of elements in ADI to be mapped,

index of starting element in ADI to be mapped */

AD_MapType APPL_asAdObjDefaultMap[]

{

{ 3, PD_WRITE, AD_MAP_ALL_ELEM , 0 },

{ 5, PD_WRITE, AD_MAP_ALL_ELEM , 0 },

{ 6, PD_WRITE, AD_MAP_ALL_ELEM , 0 },

{ 1, PD_READ, AD_MAP_ALL_ELEM , 0 },

{ 2, PD_READ, AD_MAP_ALL_ELEM , 0 },

{ 500, PD_WRITE, AD_MAP_ALL_ELEM , 0 },

{ 501, PD_WRITE, AD_MAP_ALL_ELEM , 0 },

{ 502, PD_WRITE, AD_MAP_ALL_ELEM , 0 },

{ 4, PD_READ, AD_MAP_ALL_ELEM , 0 },

{ 503, PD_READ, AD_MAP_ALL_ELEM , 0 },

{ AD_MAP_END_ENTRY}

};

See example of usage in abcc_drv/inc/abcc_ad_if.h.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 35

Step Two

33 (54)

Process Data Callbacks

There are two callback functions related to the update of the process data that must be

implemented to inform the host that the read process data has been received from the network

or that it is time to update the write process data. An example is available in example_app/

appl_abcc_handler.c.

• BOOL ABCC_CbfUpdateWriteProcessData( void* pxWritePd) - Updates the

current write process data. The data must be copied into the buffer (pxWritePd) before

returning from the function.

• void ABCC_CbfNewReadPd( void* pxReadPd) - Called when new process data has

been received from the network. The process data needs to be copied to the application

ADI:s (from the buffer pxReadPd) before returning from the function.

As seen below, in the example code, they both call on a service in the Application Data object to

update the information. These functions works, in general, for any process data map, but they

are also slow because of all considerations needed for the general case. For better performance,

please consider writing application specific update functions.

Example:

void ABCC_CbfNewReadPd( void* pxReadPd )

{

/*

** AD_UpdatePdReadData is a general function that updates all ADI:s according

** to current map.

** If the ADI mapping is fixed there is potential for doing that in a more

** optimized way, for example by using memcpy.

*/

AD_UpdatePdReadData( pxReadPd );

}

BOOL ABCC_CbfUpdateWriteProcessData( void* pxWritePd )

{

/*

** AD_UpdatePdWriteData is a general function that updates all ADI:s according

** to current map.

** If the ADI mapping is fixed there is potential for doing that in a more

** optimized way, for example by using memcpy.

*/

return( AD_UpdatePdWriteData( pxWritePd ) );

}

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 36

Step Two

34 (54)

Event Handling

Only 40-series.

In event mode, all events can be configured to be forwarded to the user via the ABCC_

CbfEvent() interface using the configuration defines below, located in the file abcc_drv_

cfg.h.

#define ABCC_CFG_INT_ENABLE_MASK_PAR (ABP_INTMASK_RDPDIEN | ABP_

INTMASK_RDMSGIEN)

#define ABCC_CFG_HANDLE_INT_IN_ISR_MASK (ABP_INTMASK_RDPDIEN)

The configuration above will enable read message and read process data interrupts, but only the

read process data callbacks will be executed in interrupt context directly by the driver. The read

message event will be forwarded to the application by calling the function ABCC_CbfEvent().

This will reduce the amount of work done in the ISR which causes jitter in the process data

handling. Other configurations will of course be possible to set by the user, to increase

performance for any event. At this point the user can trigger the handling of the event from any

chosen context.

If the messaging is fully event driven and messages are sent in an interrupt context, please consider

implementing the critical section porting in abcc_adapt/abcc_sw_port.h. The critical section

functions are described in abcc_drv/inc/abcc_port.h

Example:

void ABCC_CbfEvent( UINT16 iEvents )

{

if( iEvents & ABCC_EVENT_RDMSGI )

{

ABCC_fRdMsgEvent = TRUE;

}

}

The code above illustrates how a task (below) can be triggered by the driver event callback.

volatile BOOL ABCC_fRdMsgEvent = FALSE;

void Task( void )

{

ABCC_fRdMsgEvent = FALSE;

while ( 1 )

{

if( ABCC_fRdMsgEvent )

{

ABCC_fRdMsgEvent = FALSE;

ABCC_TriggerReceiveMessage();

}

}

}

This code depicts a task that handles receive message events.

Anybus®CompactCom™Host Application Implementation Guide

HMSI-27-334 1.7 en-US

Page 37

Step Two

CompactCom driver Anybus CompactCom module

Host application (Interrupt

context)

ReadMessage()

WriteMessage

ABCCInterrupt()

ABCC_Isr()

ABCC_CbfReceiveMsg(msgBuer)

ABCC_SendRespMsg(msgBuer)

Note that this call is

done in interrupt context.

#dene ABCC_CFG_INT_ENABLED ( TRUE )

#dene ABCC_CFG_INT_ENABLE_MASK_PAR ( ABP_INTMASK_RDMSGIEN )

#dene ABCC_CFG_HANDLE_INT_IN_ISR_MASK ( ABP_INTMASK_RDMSGIEN )

CompactCom driver

Anybus CompactCom module

Host application (Interrupt

context)

ReadMessage()

The received message can

be handled in chosen context.

Host application (other

context)

TriggerOtherContext()

ABCCInterrupt()

ABCC_Isr()

End of ISR

ABCC_CbfEvent()

ABCC_CbfReceiveMsg(msgBuer)

ABCC_SendRespMsg(msgBuer) WriteMessage()

ABCC_TriggerReceiveMessage()

#dene ABCC_CFG_INT_ENABLED ( TRUE )

#dene ABCC_CFG_INT_ENABLE_MASK_PAR ( ABP_INTMASK_RDMSGIEN )

#dene ABCC_CFG_HANDLE_INT_IN_ISR_MASK ( 0 )

35 (54)

Handling Events in Interrupt Context

Only 40–series.

Anybus®CompactCom™Host Application Implementation Guide

Handling Events Using ABCC_CbfEvent() Callback Function

Only 40–series.

HMSI-27-334 1.7 en-US

Page 38

Step Two

UINT 8 bSourceId

UINT 8 bDestObj

UINT 16 iInstance

UINT 8 bCmd

UINT 8 bDataSize

UINT 8 bCmdExt 0

UINT 8 bCmdExt 1

UINT 16 iDataSize

UINT 16 iReserved

UINT 8 bSourceId

UINT 8 bDestOb j

UINT 16 iInstance

UINT 8 bCmd

UINT 8 bReserved

UINT 8 bCmdExt 0

UINT 8 bCmdExt 1

255 byte message header

1524 byte message

header

36 (54)

Message Handling

The message handling interface functions are found and described in abcc.h.

To send a command message, the user must use the function ABCC_GetCmdMsgBuffer() to

retrieve a message memory buffer. When receiving a response, the user must handle or copy

needed data from the response buffer within the context of the response handler function.

The function ABCC_GetCmdMsgBuffer() can return a NULL pointer, if no more memory

buffers are available. It is the responsibility of the user to resend the message later or treat it as

a fatal error.

Note: the buffer resources are configured in the file abcc_adapt/abcc_drv_cfg.h.

Note: The CompactCom 40-series devices handle up to 1524 bytes of messaging data, whereas