HM Digital PS-202 User Manual

USER’S GUIDE

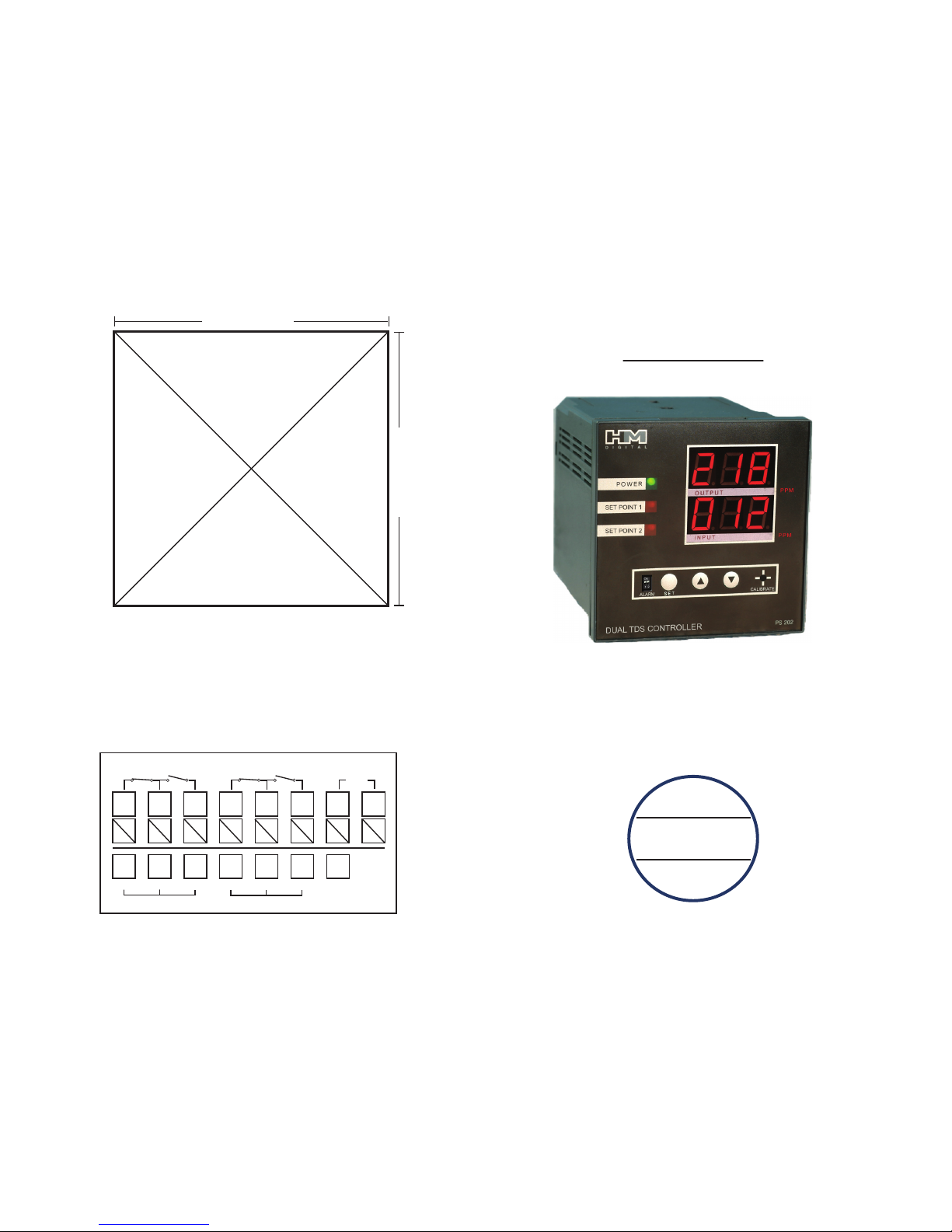

PANEL CUT-OUT DIAGRAM

M

H

D I G I T A L

®

PS-202

PANEL MOUNT DUAL DISPLAY

TDS CONTROLLER

1. Using a knife, cut the diagram out (cut on the outer part of the line).

2. Align the cut-out to your panel and draw cut marks.

3. Cut the hole in the panel to the precise dimensions of the cut-out:

3-9/16 in. x -3-9/16 in. (90 mm x 90 mm)

--> See the installation section for complete instructions.

CONTACT DIAGRAM

3 9/16 in. (90 mm)

3

9

/16 in. (90 mm)

AC

WHITEREDBLACK

LINE 1 SENSOR (IN)

110-220V

LINE 2 RELAY (SWITCH)

N.C. N.O.

WHITEREDBLACK

LINE 2 SENSOR (OUT)

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

16

17

18

19

20

21

22

23

LINE 1 RELAY (SWITCH)

N.C. N.O.

HM PS-202

2 7

Thank you for purchasing HM Digital’s PS-202 The PS-202 is a dual display panel mount total dissolved

solids (TDS) controller that monitors and controls levels of TDS in water. The controller has two

independent maximum set point to help maintain a limit of TDS allowed in two water lines, such as the

product water and the feed water. If the TDS level rises to either set point, the controller will activate a

warning light, sound an alarm (optional) and switch the dry contact position from the normal position

(to operate a valve, pump, etc.). Once the TDS level drops below the set point, this will deactivate the

light and alarm and switch the contacts back to the normal position (normally open or closed).

CONTACT INFO

BOX CONTENTS

SPECIFICATIONS

If you have any problems or questions regarding your controller, please contact HM Digital, Inc.

HM Digital, Inc. info@hmdigital.com

5819 Uplander Way www.tdsmeter.com

Culver City, CA 90230 1-800-383-2777

U.S.A

1. Controller 3. Two sensor cables (grey) 5. Mounting brackets

2. Two sensors (SP-1) 4. Power cord (black) 6. U.S. plug adapter

TDS Range: 0 - 999 ppm (mg/L)

Resolution: 1 ppm

Accuracy: ±2% (of the reading)

Temperature Compensation: Automatic (ATC) (1-60

o

C)

Calibration: Manual by trimmer pot calibration screw

Set-Point: Single point, controlled by on-screen up/down buttons (to any point within the range)

Set-Point Relay: dual, isolated, 2A, Max. 220V, resistive load 100,000 strokes

Relay Control: The unit will open or close a circuit via dry contacts when the ppm level of either

sensor reaches or exceeds the control setting (simple switch). It can be used to control a pump,

solenoid valve or other device. Each relay control is independent.

Relay Voltage: 5V (the connected device needs its own power source)

Alarm: Optional steady beep (set by user), one for each set point.

Probe: ½” NPTF bushing

Cable Length: 3 meter (9.8 ft) shielded cable

Display: Bright tri-color L.E.D.

Power Supply: 110V/230V, ±10% Vac; 50/60Hz

Enclosure: Front and back with ABS

Environment: -10 to 50

o

C (4 to 122oF); RH max 95% non-condensing

Dimensions: 7.2 x 7.2 x 10.2 cm (2.8 x 2.8 x 4 in.)

Monitor Weight: 476 grams (1 lb 0.8 oz)

THIS SPACE INTENTIONALLY LEFT BLANK

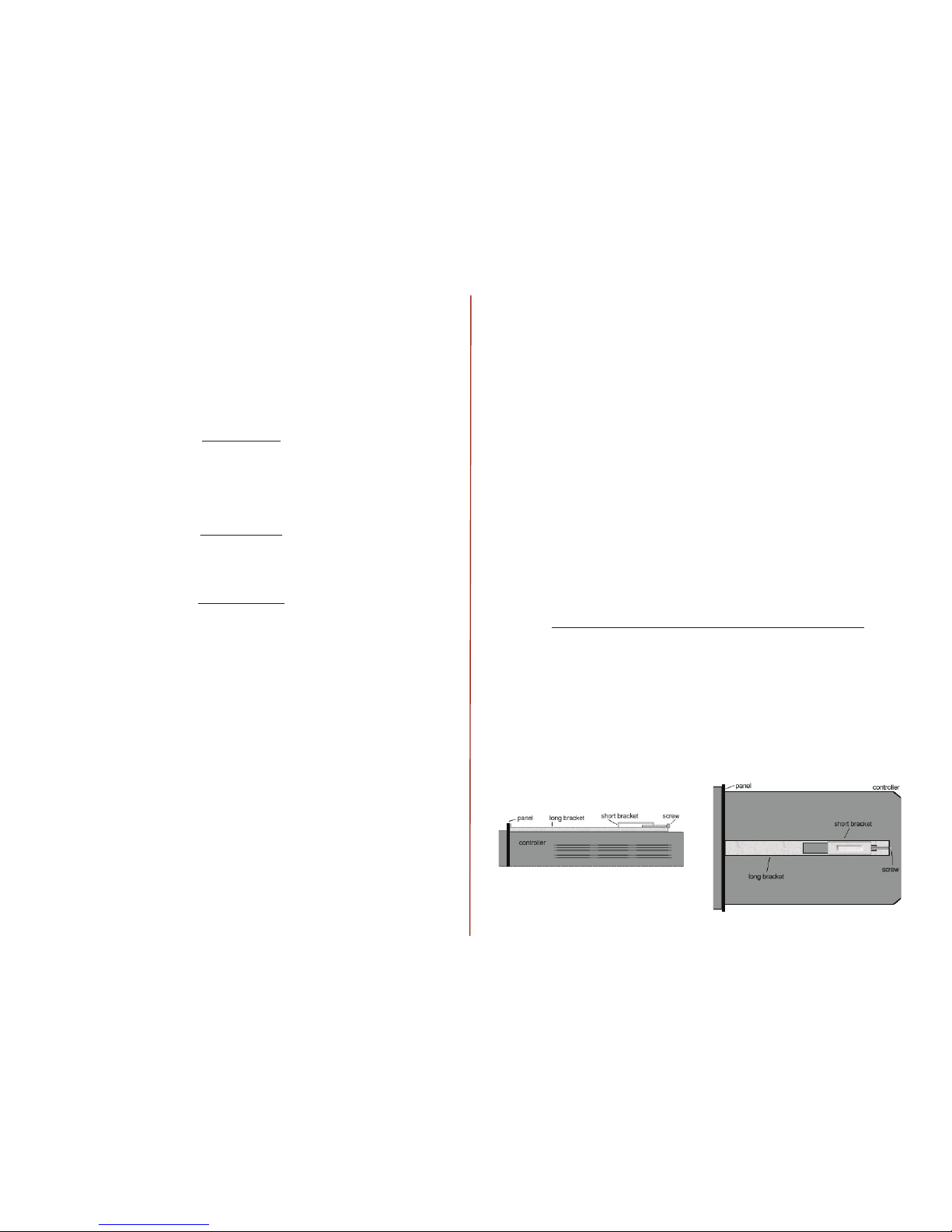

ATTACHING THE MOUNTING BRACKETS

1. Slide the controller through the hole in the panel.

2. From the rear of the controller, place one long bracket with the ridge side facing up, on the top of the

controller.

3. Place a short bracket, with the legs facing down, through the holes in the long bracket, and into the

holes in the controller. The hooked leg should be closer to the controller face.

4. Slide the long bracket towards the controller face, so that the front end is pressed against the panel.

5. Secure a screw from the hole in the long bracket through the hole in the short bracket. Tighten, but

do not overtighten.

6. Do the same for the bracket on the bottom of the controller. Tighten both brackets equally.

TOP VIEW

SIDE VIEW (of the top bracket)

Loading...

Loading...