Page 1

Technical Data Sheet

LOCTITE®416™

January-2010

PRODUCT DESCRIPTION

LOCTITE®416™ provides the following product

characteristics:

Technology Cyanoacrylate

Chemical Type Ethyl cyanoacrylate

Appearance (uncured) Transparent clear liquid

LMS

Components One part - requires no mixing

Viscosity High

Cure Humidity

Application Bonding

Key Substrates Plastics, Rubbers and Metals

LOCTITE®416™ is a general purpose cyanoacrylate instant

adhesive.

Mil-A-46050C

LOCTITE®416™ is tested to the lot requirements of Military

Specification Mil-A-46050C. Note: This is a regional approval.

Please contact your local Technical Service Center for more

information and clarification.

Commercial Item Description A-A-3097:

LOCTITE®416™ has been qualified to Commercial Item

Description A-A-3097. Note: This is a regional approval.

Please contact your local Technical Service Center for more

information and clarification.

TYPICAL PROPERTIES OF UNCURED MATERIAL

Specific Gravity @ 25 °C 1.05

Viscosity, Cone & Plate, mPa·s (cP):

Temperature: 25 °C, Shear Rate: 100 s

-1

900 to 1,500

LMS

Viscosity, Brookfield - LVF, 25 °C, mPa·s (cP):

Spindle 2, speed 12 rpm 1,150 to 1,500

Vapour Pressure, hPa <1

Flash Point - See MSDS

TYPICAL CURING PERFORMANCE

Under normal conditions, the atmospheric moisture initiates the

curing process. Although full functional strength is developed

in a relatively short time, curing continues for at least 24 hours

before full chemical/solvent resistance is developed.

Cure Speed vs. Substrate

The rate of cure will depend on the substrate used. The table

below shows the fixture time achieved on different materials

at 22 °C / 50 % relative humidity. This is defined as the time to

develop a shear strength of 0.1 N/mm².

Fixture Time, seconds:

Mild Steel (degreased) 20 to 50

Aluminum 10 to 30

Zinc dichromate 40 to 100

Neoprene <5

Rubber, nitrile <5

ABS 15 to 40

PVC 20 to 50

Polycarbonate 30 to 70

Phenolic 10 to 40

Cure Speed vs. Bond Gap

The rate of cure will depend on the bondline gap. Thin bond

lines result in high cure speeds, increasing the bond gap will

decrease the rate of cure.

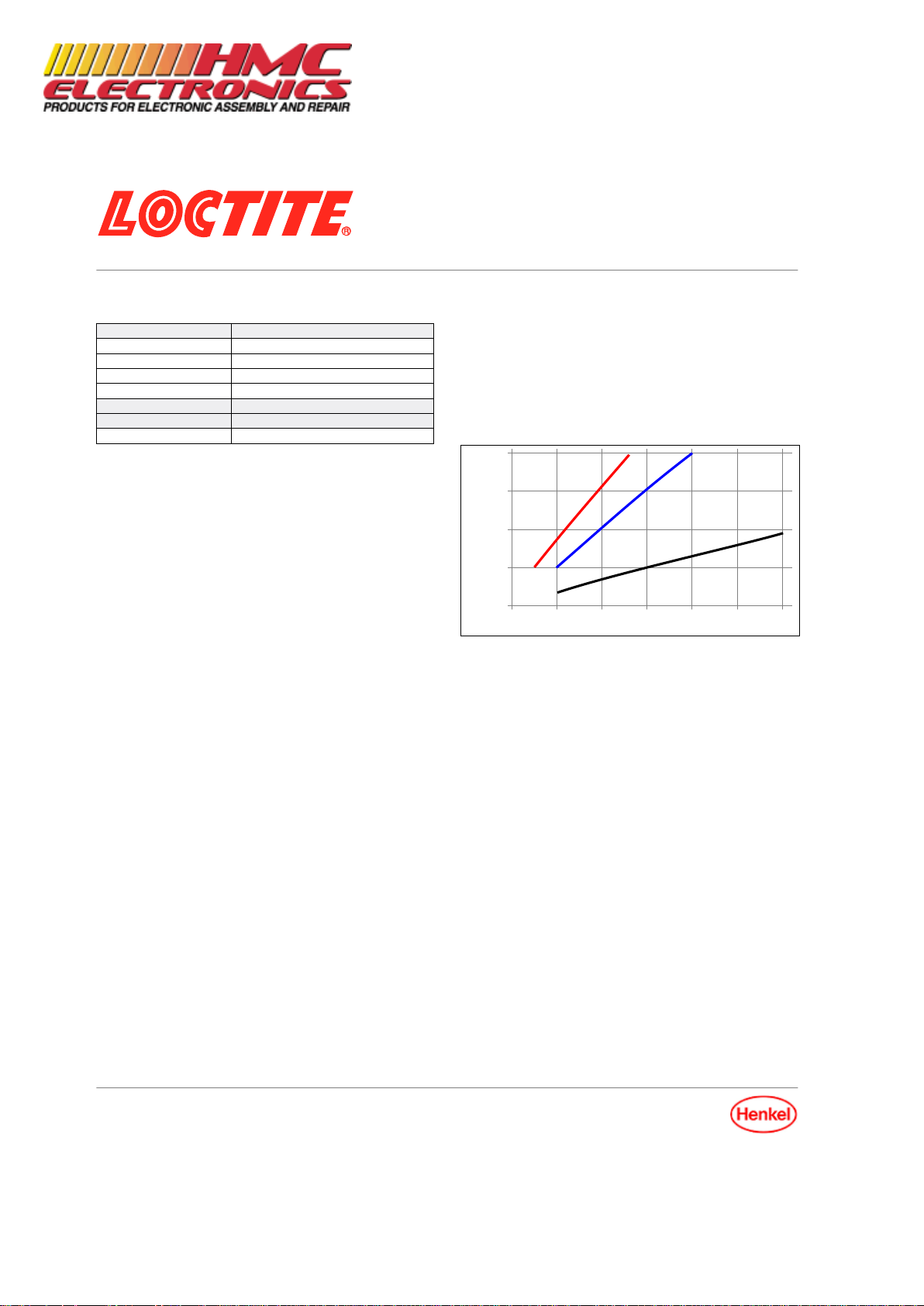

Cure Speed vs. Humidity

The rate of cure will depend on the ambient relative humidity.

The following graph shows the tensile strength developed with

time on Buna N rubber at different levels of humidity.

% Full Cured Strength @ 22 °C

Cure Time, seconds

100

75

50

25

0

0 10 20 30 40 50 60

60% RH

40% RH

20% RH

Cure Speed vs. Activator

Where cure speed is unacceptably long due to large gaps,

applying activator to the surface will improve cure speed.

However, this can reduce ultimate strength of the bond and

therefore testing is recommended to confirm effect.

TYPICAL PROPERTIES OF CURED MATERIAL

After 24 hours @ 22 °C

Physical Properties:

Coefficient of Thermal Expansion,

ISO 11359-2, K

-1

100×10

-6

Coefficient of Thermal Conductivity, ISO 8302,

W/(m·K)

0.1

Softening Point, DIN EN 1427, °C 165

Electrical Properties:

Dielectric Constant / Dissipation Factor, IEC 60250:

0.1-kHz 2 to 3.3 / <0.02

1-kHz 2 to 3.5 / <0.02

10-kHz 2 to 3.5 / <0.02

Volume Resistivity, IEC 60093, Ω·cm 2×10

15

to 10×10

15

Surface Resistivity, IEC 60093, Ω 10×10

15

to 80×10

15

Dielectric Breakdown Strength,

IEC 60243-1, kV/mm

25

TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties

After 24 hours @ 22 °C

Lap Shear Strength, ISO 4587:

Steel (grit blasted) N/mm² 18 to 26

(psi) (2,610 to 3,770)

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 2

TDS LOCTITE®416™, January-2010

Aluminum (etched) N/mm² 12 to 19

(psi) (1,740 to 2,755)

Zinc dichromate N/mm² 6 to 13

(psi) (870 to 1,885)

ABS N/mm² 6 to 20

(psi) (870 to 2,900)

PVC N/mm² 6 to 20

(psi) (870 to 2,900)

Polycarbonate N/mm² 5 to 20

(psi) (725 to 2,900)

Phenolic N/mm² 5 to 15

(psi) (725 to 2,175)

Neoprene N/mm² 5 to 15

(psi) (725 to 2,175)

Nitrile N/mm² 5 to 15

(psi) (725 to 2,175)

Tensile Strength, ISO 6922:

Steel N/mm² 12 to 25

(psi) (1,740 to 3,625)

Buna-N N/mm² 5 to 15

(psi) (725 to 2,175)

"T" Peel Strength, ISO 11339:

Steel (degreased) N/mm <0.5

(lb/in) (<2.8)

After 10 seconds @ 22 °C

Tensile Strength, ISO 6922:

Buna-N N/mm² ≥6.0

LMS

(psi) (≥870)

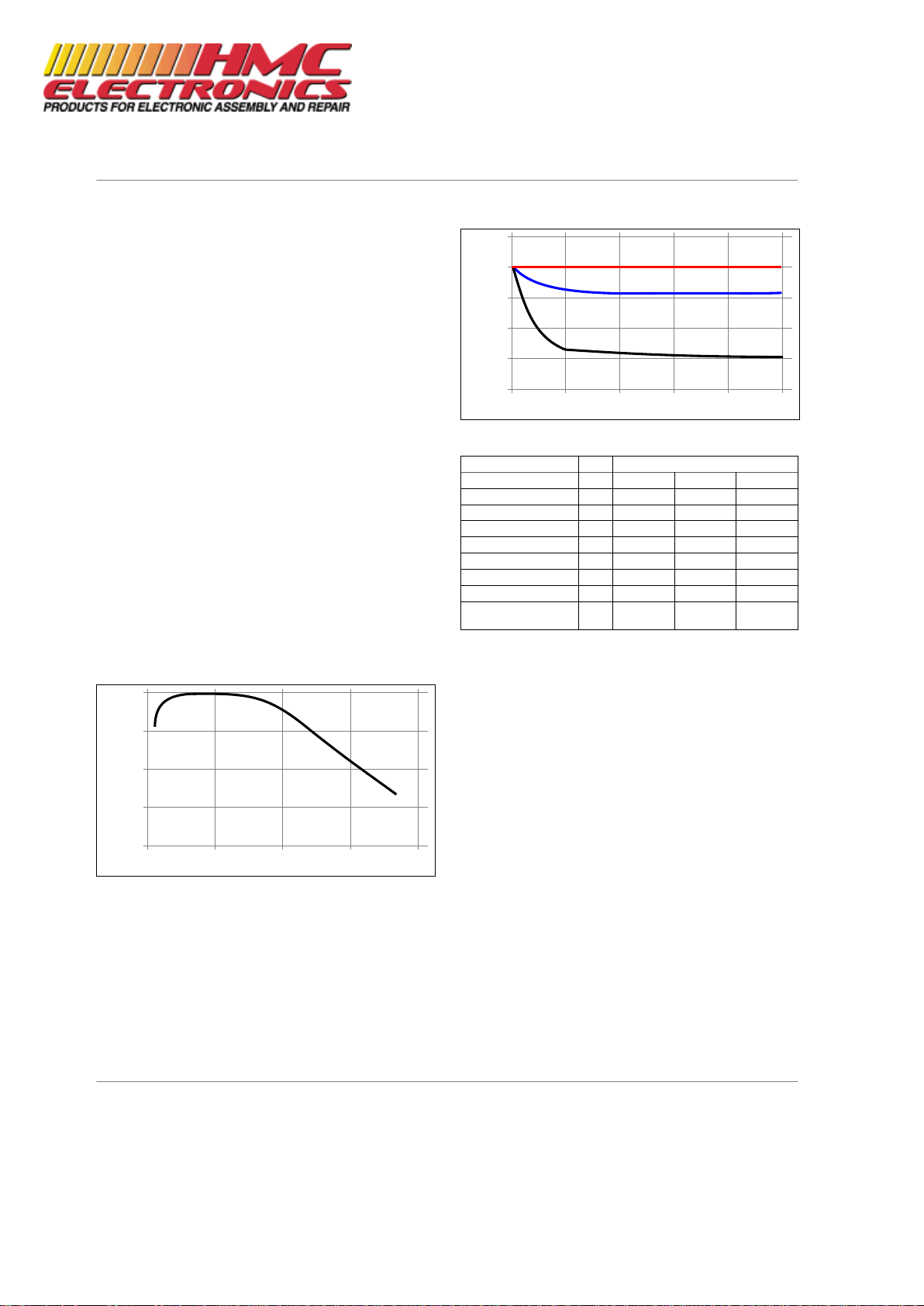

TYPICAL ENVIRONMENTAL RESISTANCE

Cured for 1 week @ 22 °C

Lap Shear Strength, ISO 4587:

Mild Steel (grit blasted)

Hot Strength

Tested at temperature

% Strength @ 22 °C

Temperature, °C

100

75

50

25

0

-50 0 50 100 150

Heat Aging

Aged at temperature indicated and tested @ 22 °C

% Initial Strength @ 22 °C

Exposure Time, hours

125

100

75

50

25

0

0 1000 2000 3000 4000 5000

80 °C

100 °C

60°C

Chemical/Solvent Resistance

Aged under conditions indicated and tested @ 22 °C.

% of initial strength

Environment °C 100 h 500 h 1000 h

Motor oil (MIL-L-46152) 40 100 100 95

Gasoline 22 100 100 100

Isopropanol 22 100 100 100

Ethanol 22 100 100 100

Freon TA 22 100 100 100

1,1,1 Trichloroethane 22 100 100 100

Heat/humidity 95% RH 40 80 75 65

Heat/humidity 95% RH

on polycarbonate

40 100 100 100

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as

a sealant for chlorine or other strong oxidizing materials

For safe handling information on this product, consult the

Material Safety Data Sheet (MSDS).

Directions for use:

1. For best performance bond surfaces should be clean and

free from grease.

2. This product performs best in thin bond gaps (0.05 mm).

3. Excess adhesive can be dissolved with Loctite cleanup

solvents, nitromethane or acetone.

Loctite Material Specification

LMS

LMS dated October-10, 2005. Test reports for each batch are

available for the indicated properties. LMS test reports include

selected QC test parameters considered appropriate to

specifications for customer use. Additionally, comprehensive

controls are in place to assure product quality and

consistency. Special customer specification requirements may

be coordinated through Henkel Quality.

Henkel Americas

+860.571.5100

Henkel Europe

+49.89.320800.1800

Henkel Asia Pacific

+86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 3

TDS LOCTITE®416™, January-2010

Storage

Store product in the unopened container in a dry location.

Storage information may be indicated on the product container

labeling.

Optimal Storage: 2 °C to 8 °C. Storage below 2 °C or

greater than 8 °C can adversely affect product properties.

Material removed from containers may be contaminated during

use. Do not return product to the original container. Henkel

Corporation cannot assume responsibility for product which

has been contaminated or stored under conditions other than

those previously indicated. If additional information is required,

please contact your local Technical Service Center or

Customer Service Representative.

Conversions

(°C x 1.8) + 32 = °F

kV/mm x 25.4 = V/mil

mm / 25.4 = inches

µm / 25.4 = mil

N x 0.225 = lb

N/mm x 5.71 = lb/in

N/mm² x 145 = psi

MPa x 145 = psi

N·m x 8.851 = lb·in

N·m x 0.738 = lb·ft

N·mm x 0.142 = oz·in

mPa·s = cP

Note

The data contained herein are furnished for information only

and are believed to be reliable. We cannot assume

responsibility for the results obtained by others over whose

methods we have no control. It is the user's responsibility to

determine suitability for the user's purpose of any production

methods mentioned herein and to adopt such precautions as

may be advisable for the protection of property and of persons

against any hazards that may be involved in the handling and

use thereof. In light of the foregoing, Henkel Corporation

specifically disclaims all warranties expressed or implied,

including warranties of merchantability or fitness for a

particular purpose, arising from sale or use of Henkel

Corporation’s products. Henkel Corporation specifically

disclaims any liability for consequential or incidental

damages of any kind, including lost profits. The discussion

herein of various processes or compositions is not to be

interpreted as representation that they are free from

domination of patents owned by others or as a license under

any Henkel Corporation patents that may cover such

processes or compositions. We recommend that each

prospective user test his proposed application before repetitive

use, using this data as a guide. This product may be covered

by one or more United States or foreign patents or patent

applications.

Trademark usage

Except as otherwise noted, all trademarks in this document

are trademarks of Henkel Corporation in the U.S. and

elsewhere. ® denotes a trademark registered in the U.S.

Patent and Trademark Office.

Reference 1.2

Henkel Americas

+860.571.5100

Henkel Europe

+49.89.320800.1800

Henkel Asia Pacific

+86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Loading...

Loading...