Page 1

Technical Data Sheet

Rocky Hill, CT 06067-3910

Telephone: (860) 571-5100

1001 Trout Brook Crossing

FAX: (860) 571-5465

NOT FOR PRODUCT SPECIFICATIONS.

THE TECHNICAL DATA CONTAINED HEREIN ARE INTENDED AS REFERENCE ONLY.

PLEASE CONTACT LOCTITE CORPORATION QUALITY DEPARTMENT FOR ASSISTANCE AND RECOMMENDATIONS ON SPECIFICATIONS FOR THIS PRODUCT.

ROCKY HILL, CT FAX: +1 (860)-571-5473 DUBLIN, IRELAND FAX: +353-(1)-451 - 9959

Hysol® Product E-60NC

formerly Durabond E-60NC

Industrial Version, August 2001

PRODUCT DESCRIPTION

LOCTITE® Hysol® Product E-60NC is a flowable, industrial

grade epoxy potting compound with extended work life. Once

mixed, the two-part epoxy cures at room temperature to form a

rigid, black encapsulant that is non-corrosive to metallic

components on PC Boards and electronic assemblies. The

fully cured epoxy provides excellent environmental and

chemical resistance, and acts as an electrical insulator.

TYPICAL APPLICATIONS

Designed for bonding, potting and encapsulating electrical

components which are sensitive to corrosion. Used in

electronic applications, for component attachment to boards,

housing assembly and potting.

PROPERTIES OF UNCURED MATERIAL

Resin

Typical

Value Range

Chemical Type Epoxy

Appearance Black liquid

Specific Gravity @ 25°C 1.10 1.0 to 1.2

Viscosity @ 25°C, mPa.s (cP)

6,200 5,200 to 7,200

Flash Point (TCC), °C (°F)

>93 (>200)

Hardener

Typical

Value Range

Chemical Type Amine

Appearance Pale yellow liquid

Specific Gravity @ 25°C 1.00 0.9 to 1.1

Viscosity @ 25°C, mPa.s (cP)

13,000 12,000 to 14,000

Flash Point (TCC), °C (°F)

>93 (>200)

Mixture

Typical Value

Appearance Black Opaque

Specific Gravity @ 25°C 1.05

Mix Ratio (R:H) by Weight 100 to 91

by Volume 1 to 1

TYPICAL CURING PERFORMANCE

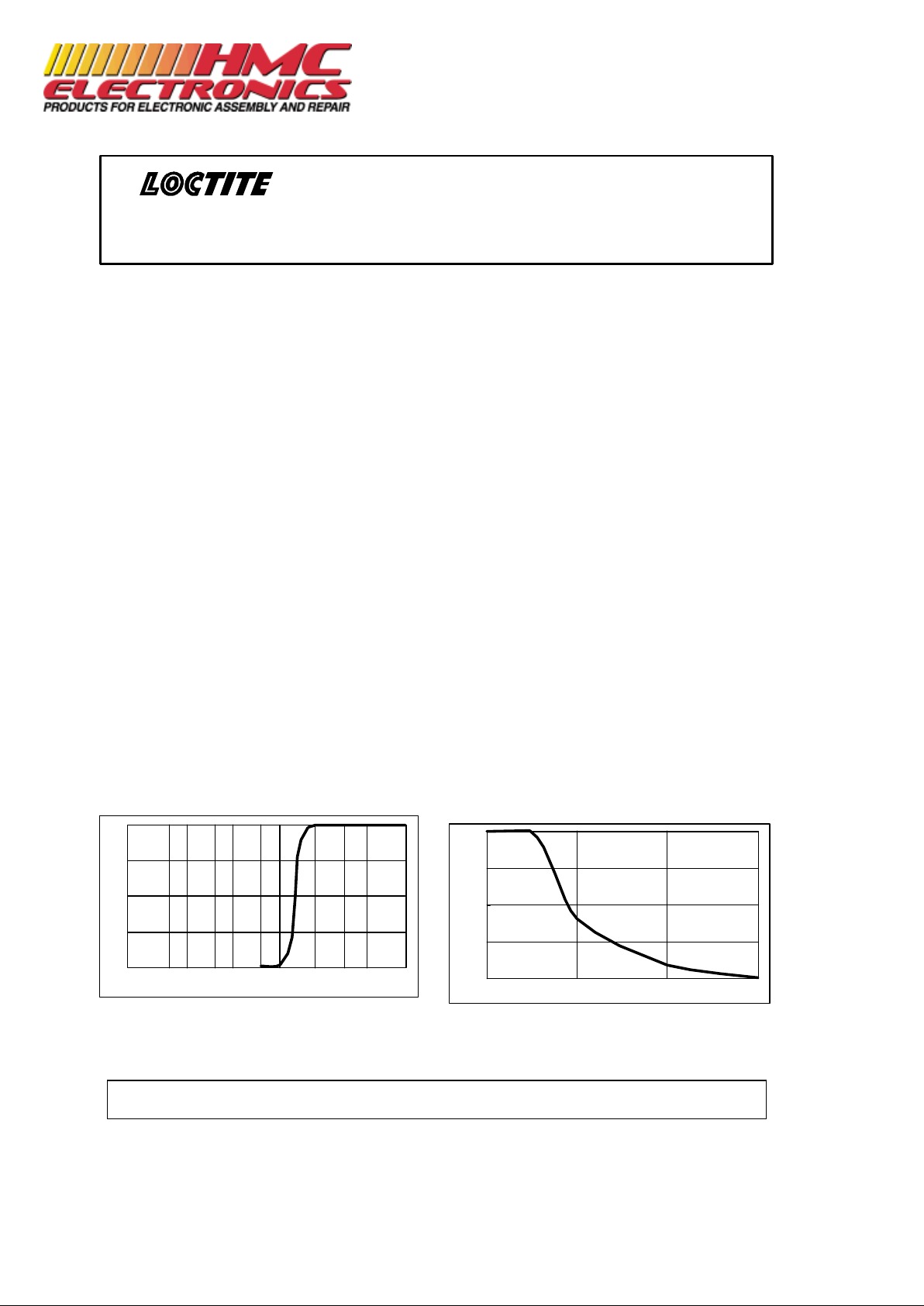

Cure speed

The graph below shows the shear strength developed over

time on abraded, acid etched aluminum lap shears with an

average bondline gap of 3 to 9 mils and tested according to

ASTM D-1002.

Cure Time, Hours @25°C

5min 10min 30min 1hr 3hr 6hr 24hr 72hr0

25

50

75

100

% of Full Strength on Aluminum

1week 1month

Curing Properties

(@ 25°C unless noted)

Typical Value

Working Life, minutes 60

Tack Free time, minutes 180

TYPICAL PROPERTIES OF CURED MATERIAL

(@ 25°C unless noted)

Physical Properties

Typical Value

Dielectric Strength, Volts/Mil 550

Tensile Strength ASTM D638, psi 6,800

Tensile Elongation ASTM D-638, % 8

Hardness ASTM D-1706, Shore D 85

Glass Transition Temperature, Tg, °C

55

PERFORMANCE OF CURED MATERIAL

Shear Strength vs Substrate

(Substrates cured for 5 days @ 22°C)

Substrate Typical Value

Lapshear N/mm2(psi)

Grit-Blasted Steel 18.1 2630

Aluminum (Abraded/Acid Etched, 3 to 9 mil gap) 21.4 3110

Aluminum (Anodized) 7.9 1150

Stainless Steel 7.8 1130

Polycarbonate 5.9 850

Nylon 1.3 190

Wood (Fir) 11.1 1610

Block Shear N/mm2(psi)

PVC 4.6 670

ABS 6.5 940

Epoxy 14.8 2140

Acrylic 1.2 180

Glass 13.9 2020

TYPICAL ENVIRONMENTAL RESISTANCE

Hot Strength

Test procedure : ASTM D-1002

Substrate: Abraded, acid etched aluminum

Bondline gap, mils: 3 to 9

Cure procedure:

12 hours at 65°C & 4 hours at 22°C

Tested at temperature.

0

25

50

75

100

% RT Strength

Temperature, °C

15010050

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 2

TDS Hysol E-60NC, August 2001

Loctite and Hysol are Trademarks of Loctite Corporation U.S.A.

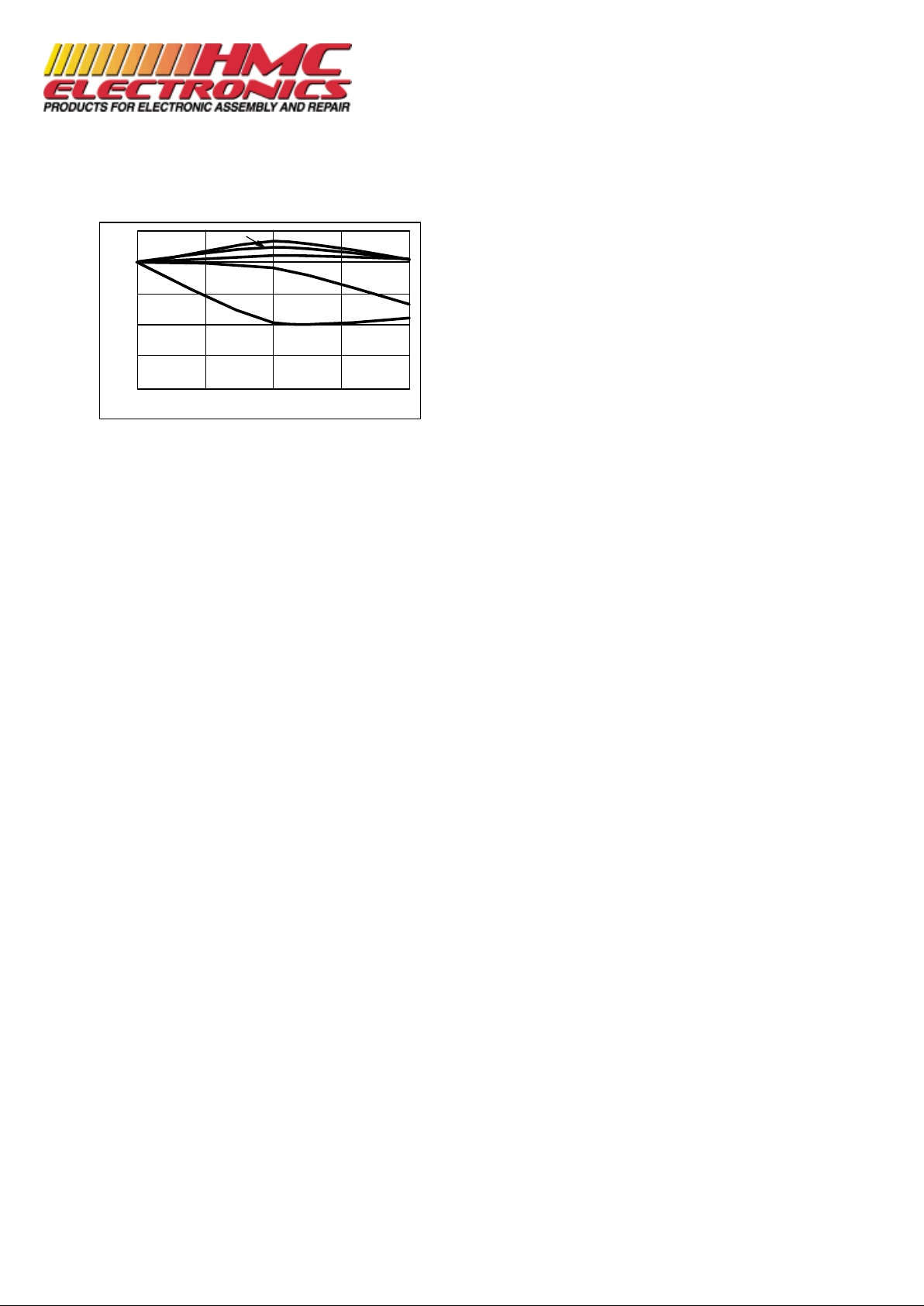

Heat Aging

Cured for 5 days at 22°C on steel with no induced gap, aged at

temperature indicated and tested at 22°C.

250 5000

25

50

75

100

% Initial Strength at RT

Hours

750 1,000

125

66°C

93°C

120°C

177°C

150° C

Chemical / Solvent Resistance

Cured for 5 days at 22°C on steel with no induced gap, aged

under conditions indicated and tested at 22°C.

Solvent Temp. % Initial Strength retained at

500 hr 1000 hr

Air

87°C

108 110

Motor Oil (10W-30)

87°C

104 82

Unleaded Gasoline

87°C

96 101

Water/Glycol (50%/50%)

87°C

95 101

Salt/Fog ASTM B-117

22°C

59 85

95% Relative Humidity

38°C

102 100

Condensing Humidity

49°C

78 81

Water

22°C

89 94

Acetone

22°C

78 64

Isopropyl Alcohol

22°C

98 90

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as

a sealant for chlorine or other strong oxidizing materials.

For safe handling information on this product, consult the

Material Safety Data Sheet, (MSDS).

Directions for use

1. For high strength structural bonds, removal of surface

contaminates such as paint, oxide films, oils, dust, mold

release agents and all other surface contaminates.

2. Use gloves to minimize skin contact. DO NOT use solvents

for cleaning hands.

3. Dual Cartridges: To use simply insert the cartridge into the

application gun and start the plunger into the cylinders

using light pressure on the trigger. Next, remove the

cartridge cap and expel a small amount of adhesive to be

sure both sides are flowing evenly and freely. If automatic

mixing of resin and hardener is desired, attach the mixing

nozzle to the end of the cartridge and begin dispensing the

adhesive. For hand mixing, expel the desired amount of

the adhesive and mix thoroughly. Mix approximately 15

seconds after uniform color is obtained. Bulk Containers:

Mix thoroughly by weight or volume in the proportions

specified in Properties of Uncured Material section. Mix

vigorously approximately 15 seconds after uniform color is

obtained.

4. For maximum bond strength apply adhesive evenly to both

surfaces to be joined.

5. Application to the substrates should be made within 60

minutes. Larger quantities and/or higher temperatures will

reduce this working time.

6. Join the adhesive coated surfaces and allow to cure at 25°C

(77°F) for 24 hours for high strength. Heat up to 93°C

(200°F), will speed curing.

7. Keep parts from moving during cure. Contact pressure is

necessary. Maximum shear strength is obtained with a 3-9

mil bond line.

8. Excess uncured adhesive can be cleaned up with ketone

type solvents.

Storage

Product shall be ideally stored in a cool, dry location in

unopened containers at a temperature between 8°C to 28°C

(46°F to 82°F) unless otherwise labeled. Optimal storage is at

the lower half of this temperature range. To prevent

contamination of unused product, do not return any material to

its original container. For further specific shelf life information,

contact your local Technical Service Center.

Data Ranges

The data contained herein may be reported as a typical value

and/or range. Values are based on actual test data and are

verified on a periodic basis.

Note

The data contained herein are furnished for information only

and are believed to be reliable. We cannot assume

responsibility for the results obtained by others over whose

methods we have no control. It is the user's responsibility to

determine suitability for the user's purpose of any production

methods mentioned herein and to adopt such precautions as

may be advisable for the protection of property and of persons

against any hazards that may be involved in the handling and

use thereof. In light of the foregoing, Loctite Corporation

specifically disclaims all warranties expressed or implied,

including warranties of merchantability or fitness for a

particular purpose, arising from sale or use of Loctite

Corporation’s products. Loctite Corporation specifically

disclaims any liability for consequential or incidental

damages of any kind, including lost profits. The discussion

herein of various processes or compositions is not to be

interpreted as representation that they are free from

domination of patents owned by others or as a license under

any Loctite Corporation patents that may cover such processes

or compositions. We recommend that each prospective user

test his proposed application before repetitive use, using this

data as a guide. This product may be covered by one or more

United States or foreign patents or patent applications.

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Loading...

Loading...