Page 1

Technical Data Sheet

LOCTITE®290™

January-2010

PRODUCT DESCRIPTION

LOCTITE®290™ provides the following product

characteristics:

Technology Acrylic

Chemical Type Dimethacrylate ester

Appearance (uncured) Green liquid

LMS

Fluorescence Positive under UV light

LMS

Components One component - requires no mixing

Viscosity Low

Cure Anaerobic

Secondary Cure Activator

Application Threadlocking

Strength Medium to High

LOCTITE®290™ is designed for the locking and sealing of

threaded fasteners. Because of its low viscosity and capillary

action, the product wicks between engaged threads and

eliminates the need to disassemble prior to application. The

product cures when confined in the absence of air between

close fitting metal surfaces and prevents loosening and

leakage from shock and vibration. The product can also fill

porosity in welds, castings and powdered metal parts.

Mil-S-46163A

LOCTITE®290™ is tested to the lot requirements of Military

Specification Mil-S-46163A. Note: This is a regional approval.

Please contact your local Technical Service Center for more

information and clarification.

ASTM D5363

Each lot of adhesive produced in North America is tested to

the general requirements defined in paragraphs 5.1.1 and

5.1.2 and to the Detail Requirements defined in section 5.2.

NSF International

Registered to NSF Category P1 for use as a sealant where

there is no possibilty of food contact in and around food

processing areas. Note: This is a regional approval. Please

contact your local Technical Service Center for more

information and clarification.

NSF International

Certified to ANSI/NSF Standard 61 for use in commercial and

residential potable water systems not exceeding 82° C. Note:

This is a regional approval. Please contact your local Technical

Service Center for more information and clarification.

TYPICAL PROPERTIES OF UNCURED MATERIAL

Specific Gravity @ 25 °C 1.08

Flash Point - See MSDS

Viscosity, Brookfield - RVT, 25 °C, mPa·s (cP):

Spindle 1, speed 50 rpm 20 to 55

LMS

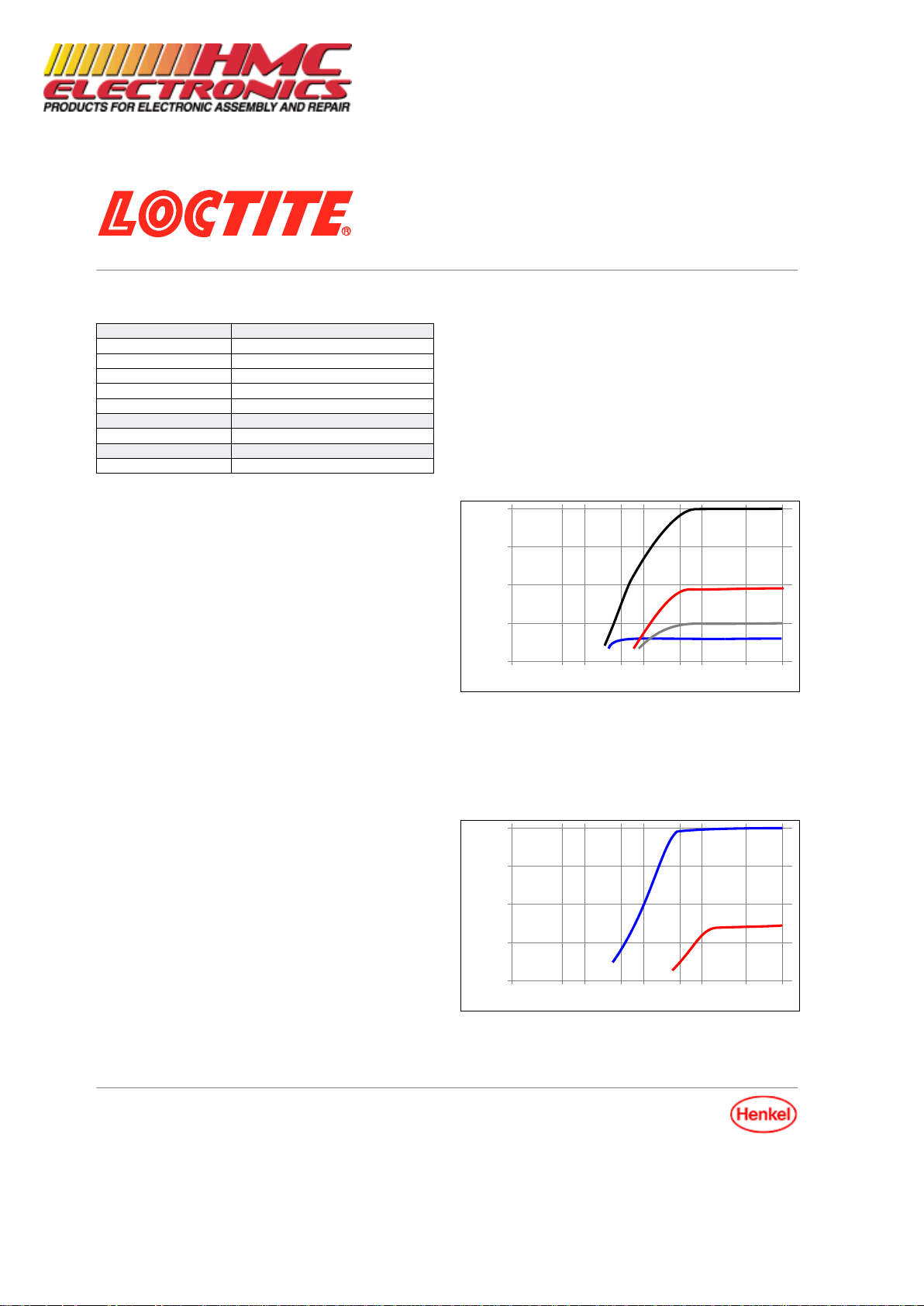

TYPICAL CURING PERFORMANCE

Cure Speed vs. Substrate

The rate of cure will depend on the substrate used. The graph

below shows the breakaway strength developed with time on

M10 steel nuts and bolts compared to different materials and

tested according to ISO 10964.

% of Full Strength on Steel

Cure Time

100

75

50

25

0

1min 5min10min 30min 1h 3h 6h 24h 72h

Steel

Brass

Zinc dichromate

Stainless steel

Cure Speed vs. Bond Gap

The rate of cure will depend on the bondline gap. Gaps in

threaded fasteners depends on thread type, quality and size.

The following graph shows shear strength developed with time

on steel pins and collars at different controlled gaps and tested

according to ISO 10123.

% of Full Strength on Steel

Cure Time

100

75

50

25

0

1min 5min10min 30min 1h 3h 6h 24h 72h

0.05 mm

0.15 mm

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 2

TDS LOCTITE®290™, January-2010

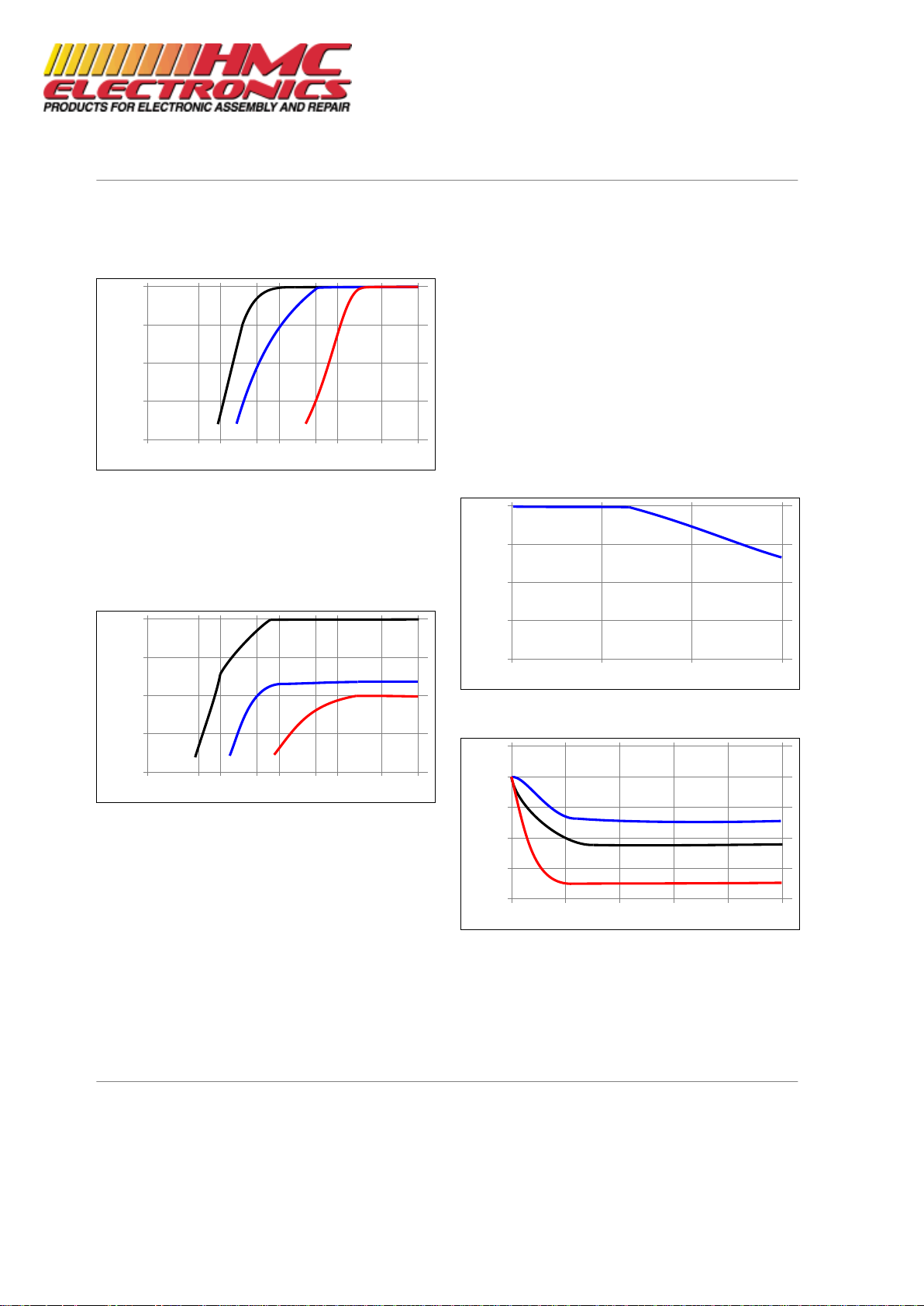

Cure Speed vs. Temperature

The rate of cure will depend on the temperature. The graph

below shows the breakaway strength developed with time at

different temperatures on M10 steel nuts and bolts and tested

according to ISO 10964.

% of Full Strength on Steel

Cure Time

100

75

50

25

0

1min 5min10min 30min 1h 3h 6h 24h 72h

40 °C

22 °C

5 °C

Cure Speed vs. Activator

Where cure speed is unacceptably long, or large gaps are

present, applying activator to the surface will improve cure

speed. The graph below shows the breakaway strength

developed with time on M10 zinc dichromate steel nuts and

bolts using Activator 7471™ and 7649™ and tested according

to ISO 10964.

% of Full Strength on Steel

Cure Time

100

75

50

25

0

1min 5min10min 30min 1h 3h 6h 24h 72h

Activator 7471™

Activator 7649™

No activator

TYPICAL PROPERTIES OF CURED MATERIAL

Physical Properties:

Coefficient of Thermal Expansion,

ISO 11359-2, K

-1

80×10

-6

Coefficient of Thermal Conductivity, ISO 8302,

W/(m·K)

0.1

Specific Heat, kJ/(kg·K) 0.3

TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties

After 24 hours @ 22 °C

Breakaway Torque, ISO 10964:

M10 steel nuts and bolts N·m 10

(lb.in.) (90)

Prevail Torque, ISO 10964:

M10 steel nuts and bolts N·m 29

(lb.in.) (260)

Breakloose Torque, ISO 10964, Pre-torqued to 5 N·m:

M10 steel nuts and bolts N·m 30

(lb.in.) (270)

Max. Prevail Torque, ISO 10964, Pre-torqued to 5 N·m:

M10 steel nuts and bolts N·m 40

(lb.in.) (350)

Compressive Shear Strength, ISO 10123:

Steel pins and collars N/mm² ≥5.4

LMS

(psi) (≥780)

TYPICAL ENVIRONMENTAL RESISTANCE

Cured for 1 week @ 22 °C

Breakloose Torque, ISO 10964, Pre-torqued to 5 N·m:

M10 zinc phosphate steel nuts and bolts:

Hot Strength

Tested at temperature

% Strength @ 22 °C

Temperature, °C

100

75

50

25

0

0 50 100 150

Heat Aging

Aged at temperature indicated and tested @ 22 °C

% Initial Strength @ 22 °C

Exposure Time, hours

125

100

75

50

25

0

0 1000 2000 3000 4000 5000

100 °C

120 °C

150 °C

Henkel Americas

+860.571.5100

Henkel Europe

+49.89.320800.1800

Henkel Asia Pacific

+86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 3

TDS LOCTITE®290™, January-2010

Chemical/Solvent Resistance

Aged under conditions indicated and tested @ 22 °C.

% of initial strength

Environment °C 100 h 500 h 1000 h 5000 h

Motor oil (MIL-L-46152) 125 85 85 50 50

Leaded Petrol 22 90 90 90 90

Brake fluid 22 90 90 85 85

Water/glycol 50/50 87 90 90 90 90

Acetone 22 85 85 85 85

Ethanol 22 80 80 80 80

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

and/or oxygen rich systems and should not be selected as

a sealant for chlorine or other strong oxidizing materials

For safe handling information on this product, consult the

Material Safety Data Sheet (MSDS).

Where aqueous washing systems are used to clean the

surfaces before bonding, it is important to check for

compatibility of the washing solution with the adhesive. In

some cases these aqueous washes can affect the cure and

performance of the adhesive.

This product is not normally recommended for use on plastics

(particularly thermoplastic materials where stress cracking of

the plastic could result). Users are recommended to confirm

compatibility of the product with such substrates.

Directions for use:

For Pre-assembled Threaded Parts with Thru Holes

1.

Prior to assembly, clean all threads (bolt and hole) with a

LOCTITE® cleaning solvent and allow to dry.

2. For Thru Holes, apply several drops of product at screw

and body juncture.

3. Avoid touching the bottle tip to the metal surface.

For Assembly

1. For Blind Holes, apply several drops of the product

down the internal threads to the bottom of the hole

For Porosity Sealing

1. Clean area and apply localized heat to the area to

approximately 121°C.

2. Allow to cool to approximately 85°C and apply the

product.

For Disassembly

1. Remove with standard hand tools.

2. In rare instances where hand tools do not work because

of excessive engagement length, apply localized heat to

nut or bolt to approximately 250 °C. Disassemble while

hot.

For Cleanup

1.

Cured product can be removed with a combination of

soaking in a LOCTITE® solvent and mechanical

abrasion such as a wire brush.

Loctite Material Specification

LMS

LMS dated September-01, 1995. Test reports for each batch

are available for the indicated properties. LMS test reports

include selected QC test parameters considered appropriate to

specifications for customer use. Additionally, comprehensive

controls are in place to assure product quality and

consistency. Special customer specification requirements may

be coordinated through Henkel Quality.

Storage

Store product in the unopened container in a dry location.

Storage information may be indicated on the product container

labeling.

Optimal Storage: 8 °C to 21 °C. Storage below 8 °C or

greater than 28 °C can adversely affect product properties.

Material removed from containers may be contaminated during

use. Do not return product to the original container. Henkel

Corporation cannot assume responsibility for product which

has been contaminated or stored under conditions other than

those previously indicated. If additional information is required,

please contact your local Technical Service Center or

Customer Service Representative.

Conversions

(°C x 1.8) + 32 = °F

kV/mm x 25.4 = V/mil

mm / 25.4 = inches

µm / 25.4 = mil

N x 0.225 = lb

N/mm x 5.71 = lb/in

N/mm² x 145 = psi

MPa x 145 = psi

N·m x 8.851 = lb·in

N·m x 0.738 = lb·ft

N·mm x 0.142 = oz·in

mPa·s = cP

Note

The data contained herein are furnished for information only

and are believed to be reliable. We cannot assume

responsibility for the results obtained by others over whose

methods we have no control. It is the user's responsibility to

determine suitability for the user's purpose of any production

methods mentioned herein and to adopt such precautions as

may be advisable for the protection of property and of persons

against any hazards that may be involved in the handling and

use thereof. In light of the foregoing, Henkel Corporation

specifically disclaims all warranties expressed or implied,

including warranties of merchantability or fitness for a

particular purpose, arising from sale or use of Henkel

Corporation’s products. Henkel Corporation specifically

disclaims any liability for consequential or incidental

damages of any kind, including lost profits. The discussion

herein of various processes or compositions is not to be

interpreted as representation that they are free from

domination of patents owned by others or as a license under

any Henkel Corporation patents that may cover such

processes or compositions. We recommend that each

prospective user test his proposed application before repetitive

use, using this data as a guide. This product may be covered

by one or more United States or foreign patents or patent

applications.

Henkel Americas

+860.571.5100

Henkel Europe

+49.89.320800.1800

Henkel Asia Pacific

+86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 4

TDS LOCTITE®290™, January-2010

Trademark usage

Except as otherwise noted, all trademarks in this document

are trademarks of Henkel Corporation in the U.S. and

elsewhere. ® denotes a trademark registered in the U.S.

Patent and Trademark Office.

Reference 0.7

Henkel Americas

+860.571.5100

Henkel Europe

+49.89.320800.1800

Henkel Asia Pacific

+86.21.2891.8863

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Loading...

Loading...