Page 1

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

TO REDUCE THE RISK OF INJUR Y, USER MUST READ AND UNDERSTAND OPERATOR'S

MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISA TEUR DOIT LIRE ET BIEN

COMPRENDRE LE MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL

MANUAL DEL OPERADOR.

Cat. No.

No de Cat.

2101-20

M4™ CORDLESS SCREWDRIVER

TOURNEVIS DE M4™

ATORNILLADORES DE M4™

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 2

2

3

PERSONAL SAFETY

GENERAL POWER TOOL SAFETY WARNINGS

WORK AREA SAFETY

ELECTRICAL SAFETY

• Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of f ammable liquids, gases or dust. Power tools create

sparks which may ignite the dust or fumes.

• Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

• Power tool plugs must match the outlet. Never

modify the plug in any way . Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodifi ed plugs and matching outlets will

reduce risk of electric shock.

• Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use

of a cord suitable for outdoor use reduces the risk

of electric shock.

• If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

attached to a rotating part of the power tool may

result in personal injury.

• Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

• If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

WARNING READ ALL SAFETY WARNINGS AND ALL INSTRUCTIONS.

Failure to follow the warnings and instructions may result in electric shock, f re and/or

serious injury. Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

• Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must

be repaired.

• Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

• Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits

etc., in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the inf uence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

• Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

• Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools with

your fi nger on the switch or energising power tools

that have the switch on invites accidents.

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

• Recharge only with the charger speci f ed by

the manufacturer. A charger that is suitable for

one type of battery pack may create a risk of fi re

when used with another battery pack.

• Use power tools only with speci f cally designated battery packs. Use of any other battery

packs may create a risk of injury and fi re.

BATTERY TOOL USE AND CARE

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 3

4

5

Direct Current

Volts

No Load Revolutions per Minute

(RPM)

Underwriters Laboratories, Inc.

United States and Canada

• Hold power tool by insulated gripping surfaces, when performing an operation where the

fastener may contact hidden wiring. Fasteners

contacting a “live” wire may make exposed metal

parts of the power tool “live” and could give the

operator an electric shock.

• Keep hands away from all cutting edges and

moving parts.

• Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE service facility for a free

replacement.

• WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to fi lter out microscopic particles.

3

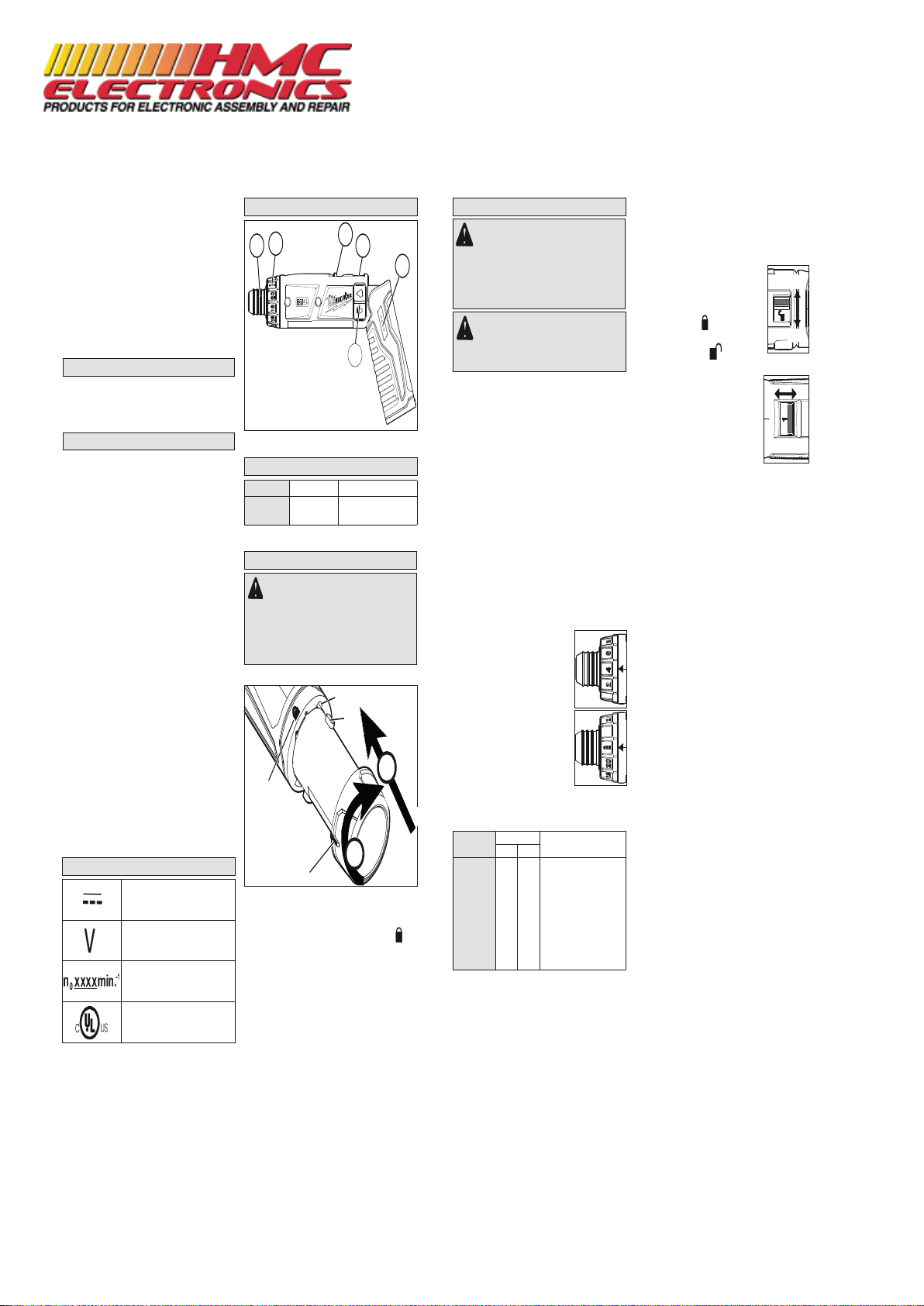

1

2

4

6

1. Bit holder collar

2. Clutch adjusting ring

3. Speed selector

4. Lock switch

5. Fuel Gauge

6. Forward/reverse switch

5

FUNCTIONAL DESCRIPTION

SYMBOLOGY

SPECIFICATIONS

Cat. No. Volts DC No Load RPM

2101-20 4 Low 200

High 600

SPECIFIC SAFETY RULES

• When battery pack is not in use, keep it away

from other metal objects like paper clips,

coins, keys, nails, screws, or other small metal

objects that can make a connection from one

terminal to another. Shorting the battery termi-

nals together may cause burns or a fi re.

• Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact

accidentally occurs, f ush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation

or burns.

SERVICE

• Have your power tool serviced by a quali f ed

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

WARNING Recharge only with

the charger specified for the battery . For

specific charging instructions, read the

operator’s manual supplied with your charger

and battery.

Inserting the Battery into the Tool

1

Slot

Tab

Line

Lock

Line up the tabs on the battery with the slots in the

tool opening. Slide the battery all the way into the

tool. Turn the battery clockwise to lock it in place.

The line on the battery will line up with the

on

the tool. The tool will not run if the battery is not

properly locked into the tool.

Removing the Battery from the Tool

Turn the battery cap counterclockwise to unlock.

Pull the battery out of the tool.

Checking the Fuel Gauge

To determine the amount of charge left in the battery, press the forward/reverse switch. The Fuel

Gauge will light up for 2-3 seconds.

ASSEMBLY

2

WARNING To reduce the risk of injury,

wear safety goggles or glasses with sideshields.

WARNING Always remove battery

pack before changing or removing accessories. Only use accessories specif cally

recommended for this tool. Others may be

hazardous.

Installing Bits

Always remove the battery before inserting or

removing bits. Select the proper style and size bit

for the type of screw you are using.

1. To install the bit, pull out the collar. Press the bit

into the socket until the collar snaps back and

the bit is locked into place.

2. To remove the bit, pull out the collar, then pull

out the bit.

NOTE: It is not necessary to hold the collar out

when installing and removing bits.

Adjusting the Handle

The handle is designed for convenience and control. The durable, center pivot allows the handle to

be used in the conventional shape or folded into a

pistol grip. Access to the forward/reverse switch and

lock switch is comfortable in either handle position.

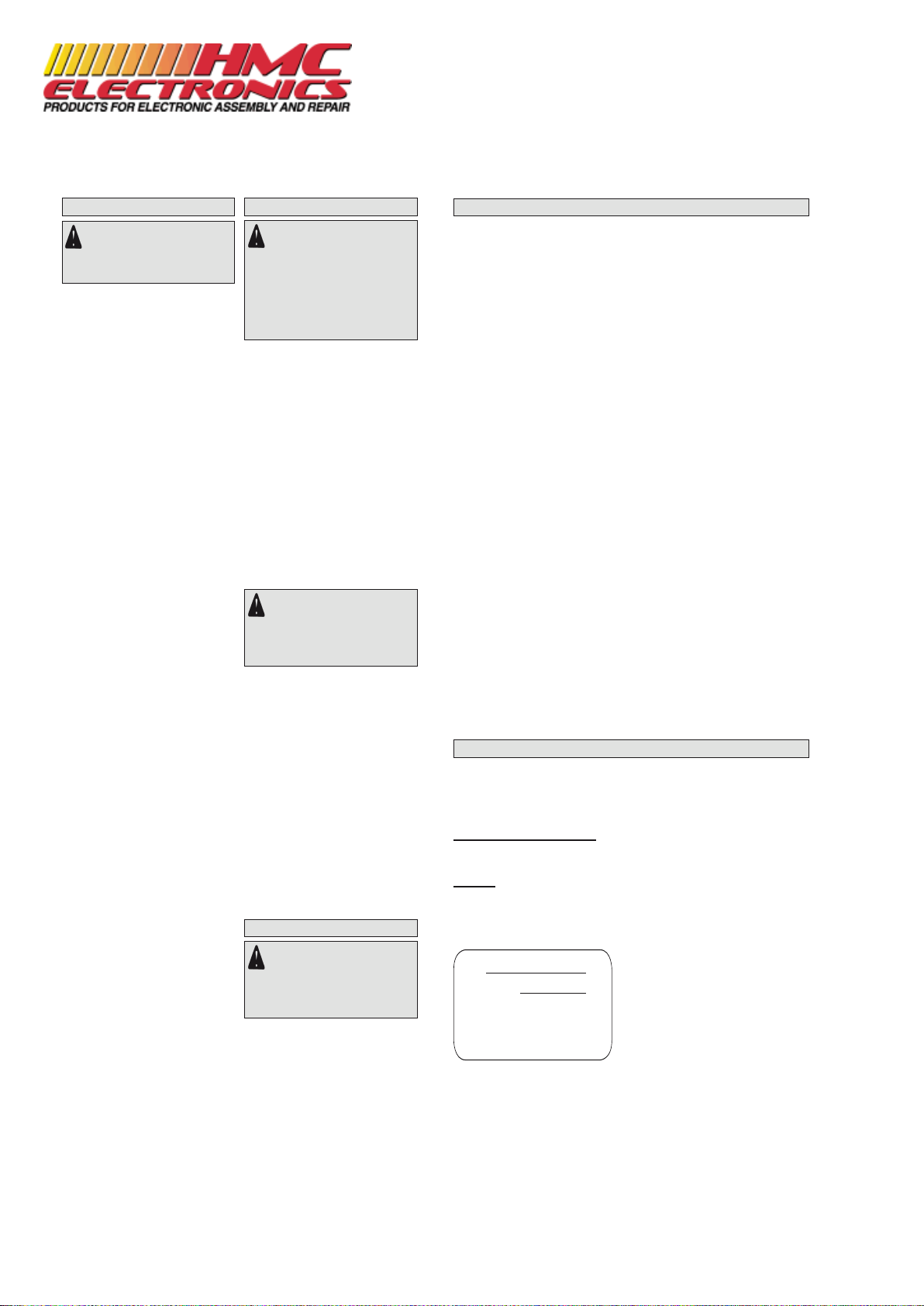

Using the Adjustable Clutch

This tool has an adjustable clutch

for driving different types of screws

into different materials. When properly adjusted, the clutch will slip at

a preset torque to prevent driving

the screw too deep and to prevent

damage to the screw or tool.

To adjust the clutch, turn the clutch

adjusting ring so that the desired

setting (1-21) lines up with the arrow

on the motor housing, as shown.

The torque specifications shown here are approximate values obtained with a fully charged

battery pack.

Using the Lock Switch

When the battery is installed, the tool is in operating condition. The lock switch prevents accidental

starting by locking the forward/reverse switch. Always set the lock switch to “lock” before performing

maintenance, changing accessories,

storing the tool and any time the tool

is not in use.

1. To lock , push the lock switch to

display the lock

symbol.

2. To unlock, push the lock switch to

display the unlock symbol.

Selecting High or Low Speed

1. For low speed and more torque,

push the speed selector back ("1"

is displayed).

2. For high speed and less torque,

push the speed selector forward

("2" is displayed).

Selecting Forward or Reverse

Press and hold the top of the switch ◄ for forward

rotation, and the bottom of the switch ► for reverse

rotation. The switch will automatically return to the

center OFF position when it is released.

Automatic Shut-Off

To prevent extra driving force after the selected

torque has been reached, the tool will automatically

shut off if the clutch slips. At higher clutch settings,

this feature may not immediately engage. Release

the switch to reset the automatic shut-off.

Cold Weather Operation

MILWAUKEE Lithium-Ion battery packs are designed to operate in temperatures below freezing.

When the battery pack is too cold, it may need to

warm up before normal use. Put the battery on a

tool and use the tool in a light application. It may

“buzz” for a short time until it warms up. When the

buzzing stops, use the tool normally.

Unlock

Lock

OPERATION

Clutch

Setting

(in lbs)

Applications

Lo Hi

1

4

7

10

13

16

19

3.7

6.5

9.3

12.8

16.4

20.0

23.4

3.7

6.5

9.3

11.2

N/A

N/A

N/A

Small screws in softwood.

Medium screws in soft-

wood or small screws in

hardwood.

Large screws in softwoods. Medium screws in

hardwood or large screws

in hardwood with pilot

hole.

Drilling

Driving

HI LO

* When set to high speed, set the clutch at 10 or below.

The Automatic Shut-Off may not work at higher clutch

settings (see "Automatic Shut-Off").

NOTE: Because the settings shown in the table are

only a guide, use a piece of scrap material to test

the different clutch settings before driving screws

into the workpiece.

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 4

6

7

APPLICATIONS

WARNING To reduce the risk of elec-

tric shock, check work area for hidden pipes

and wires before drilling or driving screws.

This tool provides a quick, convenient means of

drilling small holes and installing and removing

screws. Because of the many screw sizes, types,

thread engagements and materials available, it is

diffi cult to limit the application of this tool by screw

size. However, for applications in wood, a #6 wood

screw with a full pilot hole is recommended as a

practical limit.

Drilling in Wood, Composition Materials and

Plastic

Always use sharp bits. When using twist drill bits,

pull the bit out of the hole frequently to clear chips

from the bit fl utes. To reduce the chance of splinter-

ing, back work with a piece of scrap wood. Select

low speeds for plastics with a low melting point.

Driving Screws

Drill a pilot hole when driving screws into thick or

hard materials. Set the clutch adjusting ring to the

proper position and set the speed to low. Use the

proper style and size screwdriver bit for the type

of screw you are using.

With the screwdriver bit in the screw, place the tip

of the screw on the workpiece and apply fi rm pres-

sure before pressing the foward/reverse switch up.

Screws can be removed by pressing the foward/

reverse switch down.

Locking the Screwdriver Bit

When the forward/reverse switch is off, the screwdriver bit automatically locks in place allowing you

to use the screwdriver manually. Do this to tighten

screws that require more torque than the driver is

capable of delivering, when confi rming the tight-

ness of a screw or when loosening an extremely

tight screw.

ACCESSORIES

For a complete listing of accessories refer to your

MILWAUKEE Electric Tool catalog or go online

to www.milwaukeetool.com. To obtain a catalog,

contact your local distributor or service center.

WARNING Always remove battery pack

before changing or removing accessories.

Only use accessories specif cally recommended for this tool. Others may be hazardous.

Maintaining Tool

Keep your tool, battery pack and charger in good

repair by adopting a regular maintenance program.

After six months to one year, depending on use,

return the tool, battery pack and charger to A

MILWAUKEE service facility for:

• Lubrication

• Mechanical inspection and cleaning (gears, spindles, bearings, housing, etc.)

• Electrical inspection (battery pack, charger,

motor)

• Testing to assure proper mechanical and electrical

operation

If the tool does not start or operate at full power

with a fully charged battery pack, clean the contacts

on the battery pack. If the tool still does not work

properly, return the tool, charger and battery pack,

to a MILWAUKEE service facility for repairs.

MAINTENANCE

Cleaning

Clean dust and debris from charger and tool vents.

Keep tool handles clean, dry and free of oil or

grease. Use only mild soap and a damp cloth to

clean the tool, battery pack and charger since certain

cleaning agents and solvents are harmful to plastics

and other insulated parts. Some of these include

gasoline, turpentine, lacquer thinner, paint thinner,

chlorinated cleaning solvents, ammonia and household detergents containing ammonia. Never use

fl ammable or combustible solvents around tools.

Repairs

For repairs, return the tool, battery pack and

charger to the nearest service center.

WARNING To reduce the risk of per-

sonal injury and damage, never immerse your

tool, battery pack or charger in liquid or allow

a liquid to f ow inside them.

WARNING To reduce the risk of injury,

always unplug the charger and remove the

battery pack from the charger or tool before

performing any maintenance. Never disassemble the tool, battery pack or charger .

Contact a MILWAUKEE service facility for

ALL repairs.

TECHTRONIC INDUSTRIES' warranty is for 5 year since the original purchase date.

This warranty card covers any defect in material and workmanship on this Power Tool.

To make this warranty valid, present this warranty card, sealed/stamped by the distributor or store where you purchased the product, to the Authorized Service Center (ASC). Or, if this card has not been sealed/stamped, present the

original proof of purchase to the ASC.

Call toll-free 1 800 832 1949 to fi nd the nearest ASC, for service, parts, accessories or components.

Procedure to make this warranty valid

Take the product to the ASC, along with the warranty card sealed/stamped by the distributor or store where you purchased the product, and there any faulty piece or component will be replaced without cost for you. We will cover all

freight costs relative with this warranty process.

Exceptions

This warranty is not valid in the following situations:

a) When the product is used in a different manners from the end-user guide or instruction manual.

b) When the conditions of use are not normal.

c) When the product was modifi ed or repaired by people not authorized by TECHTRONIC INDUSTRIES.

Note: If cord set is damaged, it should be replaced by an Authorized Service Center to avoid electric risks.

SERVICE AND ATTENTION CENTER

Av Presidente Mazarik 29 Piso 7, 11570 Chapultepec Morales

Miguel Hidalgo, Distrito Federal, Mexico

Ph. 52 55 4160-3547

IMPORTED AND COMMERCIALIZED BY:

TECHTRONIC INDUSTRIES MEXICO, .S.A. DE C.V.

Av Presidente Mazarik 29 Piso 7, 11570 Chapultepec Morales

Miguel Hidalgo, Distrito Federal, Mexico

LIMITED WARRANTY - USA AND CANADA

LIMITED WARRANTY - MEXICO, CENTRAL AMERICA AND CARIBBEAN

Model:

Date of Purchase:

Distributor or Store Stamp:

Every MILWAUKEE power tool (including cordless product – tool, battery pack(s) - see separate & distinct

CORDLESS BATTERY PACK LIMITED WARRANTY statements & battery charger and Work Lights*) is warranted to the original purchaser only to be free from defects in material and workmanship. Subject to certain

exceptions, MILWAUKEE will repair or replace any part on an electric power tool which, after examination, is

determined by MILWAUKEE to be defective in material or workmanship for a period of fi ve (5) years* after the

date of purchase unless otherwise noted. Return of the power tool to a MILWAUKEE factory Service Center

location or MILWAUKEE Authorized Service Station, freight prepaid and insured, is required. A copy of the

proof of purchase should be included with the return product. This warranty does not apply to damage that

MILWAUKEE determines to be from repairs made or attempted by anyone other than MILWAUKEE authorized

personnel, misuse, alterations, abuse, normal wear and tear, lack of maintenance, or accidents.

*The warranty period for, Job Site Radios, M12™ Power Port, M18™ Power Source, and Trade Titan™ Industrial Work Carts is one (1) year from the date of purchase. The warranty period for a LED Work Light and LED

Upgrade Bulb is a limited LIFETIME warranty to the original purchaser only, if during normal use the LED bulb

fails the Work Light or Upgrade Bulb will be replaced free of charge.

*This warranty does not cover Air Nailers & Stapler, Airless Paint Sprayer, Cordless Battery Packs, Gasoline

Driven Portable Power Generators, Hand Tools, Hoist – Electric, Lever & Hand Chain, M12™ Heated Jackets,

Reconditioned product and Test & Measurement products. There are separate and distinct warranties available for these products.

Warranty Registration is not necessary to obtain the applicable warranty on a MILWAUKEE power tool product.

The manufacturing date of the product will be used to determine the warranty period if no proof of purchase is

provided at the time warranty service is requested.

ACCEPTANCE OF THE EXCLUSIVE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN IS A

CONDITION OF THE CONTRACT FOR THE PURCHASE OF EVERY MILWAUKEE PRODUCT. IF YOU DO NOT

AGREE TO THIS CONDITION, YOU SHOULD NOT PURCHASE THE PRODUCT. IN NO EVENT SHALL MIL-

WAUKEE BE LIABLE FOR ANY INCIDENTAL, SPECIAL, CONSEQUENTIAL OR PUNITIVE DAMAGES, OR FOR

ANY COSTS, ATTORNEY FEES, EXPENSES, LOSSES OR DELAYS ALLEGED TO BE AS A CONSEQUENCE

OF ANY DAMAGE TO, FAILURE OF, OR DEFECT IN ANY PRODUCT INCLUDING, BUT NOT LIMITED TO, ANY

CLAIMS FOR LOSS OF PROFITS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES, WRITTEN

OR ORAL. TO THE EXTENT PERMITTED BY LAW, MILWAUKEE DISCLAIMS ANY IMPLIED WARRANTIES,

INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR USE OR PURPOSE; TO THE EXTENT SUCH DISCLAIMER IS NOT PERMITTED BY LAW, SUCH

IMPLIED WARRANTIES ARE LIMITED TO THE DURATION OF THE APPLICABLE EXPRESS WARRANTY AS

DESCRIBED ABOVE. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU, THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

This warranty applies to product sold in the U.S.A. and Canada only.

Please consult the ‘Service Center Search’ in the Parts & Service section of MILWAUKEE’s website www.mil-

waukeetool.com or call 1.800.SAWDUST (1.800.729.3878) to locate your nearest service facility for warranty

and non-warranty service on a Milwaukee electric power tool.

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 5

8

9

RÈGLES DE SÉCURITÉ GÉNÉRALES RELATIVES AUX

OUTILS ÉLECTRIQUES

AVERTISSEMENT LIRE TOUTES LES RÈGLES ET INSTRUCTIONS DE SÉCURITÉ.

Ne pas suivre l’ensemble des règles et instructions peut entraîner une électrocution, un

incendie ou des blessures graves. Conserver les règles et les instructions à des f ns

de référence ultérieure. Le terme «outil électrique» f gurant dans les avertissements ci-

dessous renvoie à l’outil électrique à alimentation par le réseau (à cordon) ou par batterie (sans f l).

• Maintenir la zone de travail propre et bien

éclairée. Les zones encombrées ou mal éclairées

sont favorables aux accidents.

• Ne pas utiliser d’outil électrique dans une atmosphère explosive, telle qu’en en présence

de liquides, de gaz ou de poussières in f ammables. Les outils électriques génèrent des

étincelles qui peuvent enfl ammer les poussières

ou les fumées.

• Tenir les enfants et les personnes non autorisées à l’écart pendant le fonctionnement

d’un outil électrique. Un manque d’attention de

l’opérateur risque de lui faire perdre le contrôle de

l’outil.

• La f che de l’outil électrique doit correspondre

à la prise d’alimentation. Ne jamais modif er la

f che d’une manière quelconque. Ne pas utiliser d’adaptateur avec les outils électriques mis

à la terre (à la masse). Des fi ches non modifi ées

et des prises d’alimentation assorties réduisent le

risque de choc électrique.

• Éviter tout contact corporel avec des surfaces

reliées à la masse ou à la terre telles que

tuyaux, radiateurs, cuisinières et réfrigérateurs. Un risque de choc électrique plus élevé

existe si le corps est relié à la masse ou à la terre.

• Ne pas exposer les outils électriques à la pluie ou

à l’humidité. Le risque de choc électrique augmente

si de l’eau s’infi ltre dans un outil électrique.

• Prendre soin du cordon. Ne jamais utiliser le

cordon pour transporter, tirer ou débrancher

l’outil électrique. Tenir le cordon à l’écart de la

chaleur, des huiles, des arêtes coupantes ou

des pièces en mouvement. Un cordon endom-

magé ou emmêlé présente un risque accru de

choc électrique.

• Se procurer un cordon d’alimentation approprié en cas d’utilisation d’un outil électrique à

l’extérieur. L’utilisation d’un cordon d’alimentation

pour usage extérieur réduit le risque de choc

électrique.

• S’il est nécessaire d’utiliser l’outil électrique

dans un endroit humide, installer un appareil

à courant résiduel (RCD). L’utilisation d’un RCD

réduit le risque de décharge électrique.

• Porter l’équipement de protection requis.

Toujours porter une protection oculaire. Selon

les conditions, porter aussi un masque antipoussières, des bottes de sécurité antidérapantes,

un casque protecteur ou une protection auditive

afi n de réduire les blessures.

• Empêcher les démarrages accidentels.

S’assurer que la gâchette est en position

d’arrêt avant de brancher l’outil à une source

de courant, d’insérer la batterie, de le ramasser

ou de le transporter . Le fait de transporter

l’outil en gardant le doigt sur la gâchette ou de le

brancher lorsque la gâchette est en position de

marche favorise les accidents.

• Retirer toute clé de réglage avant de mettre

l’outil sous tension. Une clé laissée attachée sur

une pièce mobile de l’outil électrique peut entraîner

des blessures.

• Ne pas travailler à bout de bras. Bien garder

un bon équilibre à tout instant. Ceci permet de

mieux préserver la maîtrise de l’outil électrique

dans des situations imprévues.

• Porter des vêtements adéquats. Ne pas porter

de vêtements amples ni de bijoux. Ne pas approcher les cheveux, vêtements et gants des

pièces en mouvement. Les vêtements amples,

les bijoux ou les cheveux longs risquent d’être

happés par les pièces en mouvement.

• Si des dispositifs sont prévus pour l’extraction

et la récupération des poussières, vérifier

qu’ils sont connectés et utilisés correctement.

L’utilisation de ces dispositifs peut réduire les

risques liés aux poussières.

SÉCURITÉ INDIVIDUELLE

SÉCURITÉ ÉLECTRIQUE

SÉCURITÉ DU LIEU DE TRAVAIL

UTILISATION ET ENTRETIEN

DE L’OUTIL ÉLECTRIQUE

• Ne pas forcer l’outil électrique. Utiliser l’outil

électrique approprié à l’application considérée.

L’outil électrique adapté au projet considéré produira de meilleurs résultats, dans des conditions

de sécurité meilleures, à la vitesse pour laquelle

il a été conçu.

• Ne pas utiliser l’outil électrique si le commutateur ne le met pas sous ou hors tension. Tout

outil électrique dont le commutateur de marchearrêt est inopérant est dangereux et doit être

réparé.

• Débrancher la f che de la prise d’alimentation

et/ou la batterie de l’outil électrique avant

d’effectuer des réglages, de changer

d’accessoires ou de ranger l’outil. De telles

mesures de sécurité préventive réduisent le risque

de mettre l’outil en marche accidentellement.

• Ranger les outils électriques inutilisés hors

de la portée des enfants et ne pas laisser des

personnes qui connaissent mal les outils électriques ou ces instructions utiliser ces outils. Les

• Être sur ses gardes, être attentif et faire preuve

de bon sens en utilisant un outil électrique. Ne

pas utiliser un outil électrique en cas de fatigue

ou sous l’in f uence de drogues, d’alcool ou

de médicaments. Un instant d’inattention lors

de l’utilisation d’un outil électrique peut entraîner

des blessures graves.

• Entretenez les étiquettes et marques du fabricant. Les indications qu'elles contiennent sont

précieuses. Si elles deviennent illisibles ou se

détachent, faites-les remplacer gratuitement à un

centre de service MILWAUKEE accrédité.

• AVERTISSEMENT La poussière dégagée par

perçage, sciage et autres travaux de construction

contient des substances chimiques reconnues

comme pouvant causer le cancer, des malformations congénitales ou d’autres troubles de

reproduction. Voici quelques exemples de telles

substances :

• Le plomb contenu dans la peinture au plomb.

• Le silice cristallin contenu dans la brique, le béton

et divers produits de maçonnerie.

• L’arsenic et le chrome servant au traitement

chimique du bois.

Les risques associés à l’exposition à ces substanc-

es varient, dépendant de la fréquence des travaux.

Afi n de minimiser l’exposition à ces substances

chimiques, assurez-vous de travailler dans un

endroit bien aéré et d’utiliser de l’equipement

de sécurité tel un masque antipoussière spécifi quement conçu pour la fi ltration de particules

microscopiques.

• Lorsque l’outil électrique est utilisé pour

un travail risquant de mettre le dispositif de

f xation en contact avec des f ls électriques

cachés, tenez l’outil par les surfaces de

prise isolées. Le contact d’un dispositif de

fi xation avec un fi l sous tension « électrifi e » les

pièces métalliques exposées de l’outil et peut

électrocuter l’utilisateur.

• Tenez les mains à l’écart des arêtes tranchantes et des pièces en mouvement.

PICTOGRAPHIE

1. Mandrin porte-forets

2. Anneau de rélage de

l'accouplement

3. Sélecteur de régime

4. Verrou de rotation

5. Indicateur de niveau d’énergie

6. Inverseur de rotation

DESCRIPTION FONCTIONNELLE

SPÉCIFICATIONS

RÈGLES DE SÉCURITÉ

SPÉCIFIQUES

outils électriques sont dangereux dans les mains

d’utilisateurs non formés à leur usage.

• Entretien des outils électriques. S’assurer de

l’absence de tout désalignement ou de grippage des pièces mobiles, de toute rupture de

pièce ou de toute autre condition qui pourrait affecter le bon fonctionnement de l’outil

électrique. En cas de dommages, faire réparer

l’outil avant de l’utiliser de nouveau. Les outils

électriques mal entretenus sont à la source de

nombreux accidents.

• Garder les outils de coupe affûtés et propres.

Les outils de coupe correctement entretenus et

bien affûtés risquent moins de se gripper et sont

plus faciles à manier.

• Utiliser l’outil électrique, les accessoires, les

grains etc. conformément à ces instructions

en tenant compte des conditions de travail

et de la tâche à effectuer . L’utilisation de cet

outil électrique pour effectuer une opération pour

laquelle il n’est pas conçu peut occasionner une

situation dangereuse.

• Ne recharger la batterie qu’avec le chargeur

spécif é par le fabricant. Un chargeur qui convient

à un type de batterie peut créer un risque d’incendie

s’il est utilisé avec un autre type de batterie.

• N’utiliser les outils électriques qu’avec les

batteries spécialement conçues pour eux.

L’utilisation de batteries d’autres marques peut

créer un risque de blessure et d’incendie.

• Lorsque la batterie est hors service, la ranger

à l’écart d’autres objets métalliques tels que

trombones, pièces de monnaie, clés, clous, vis

et autres petits objets métalliques qui peuvent

établir une connexion d’une borne à l’autre.

Un court-circuit aux bornes de la batterie peut

provoquer des brûlures ou un incendie.

• Du liquide peut être éjecté de la batterie en cas

de manutention abusive ; éviter tout contact.

En cas de contact accidentel avec les projections, rincer à l’eau. En cas de contact avec

les yeux, consulter un médecin. Le liquide

s’échappant de la batterie peut provoquer des

irritations ou des brûlures.

ENTRETIEN

• Faire effectuer l’entretien de l’outil électrique

par un technicien quali f é qui n’utilisera que

des pièces de rechange identiques. La sécurité

d’utilisation de l’outil en sera préservée.

UTILISATION ET ENTRETIEN

DE LA BATTERIE

Tension CD seul

Volts

No Load Revolutions per Minute

(RPM)

Underwriters Laboratories, Inc.

United States and Canada

No. de Cat. Volts CD Tr/min. à vide

2101-20 4 Bas 200

Haut 600

3

1

2

4

6

5

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 6

10

11

AVERTISSEMENT Ne recharger la

batterie qu’avec le chargeur spéci f é. Pour

les instructions de charge spécif ques, lire le

manuel d’utilisation fourni avec le char-geur

et les batteries.

AVERTISSEMENT Il faut tou-

joursretirer la batterie et verrouiller la détente

de l’outil avant de changer ou d’enlever les accessoires. L’emploi d’accessoires autres que

ceux qui sont expressément recommandés

pour cet outil peut comporter des risques.

AVERTISSEMENT Pour minimiser

les risques de blessures, portez des lunettes

à coques latérales.

Insertion de la batterie dans l’outil

Fente

Verrouillage

Alignez les onglets de la batterie avec les fentes

de l’ouverture de l’outil. Glisser la batterie jusqu’au

fond de l’outil. Tourner la batterie dans le sens des

aiguilles d’une montre pour la verrouiller en place.

La ligne sur la batterie s’alignera avec le

de

l’outil. L’outil ne fonctionnera pas si la batterie n’est

pas correctement verrouillée dans l’outil.

Retrait de la batterie de l’outil

Tourner l’extrémité de la batterie dans le sens

inverse des aiguilles d’une montre pour la déverrouiller. Retirer la batterie de l’outil.

Vérif cation de l’indicateur de niveau

d’énergie

Pour déterminer le niveau d’énergie charge restant

de la batterie, appuyer sur l’inverseur du sens de

rotation. L’indicateur de niveau d’énergie s’allumera

de 2 à 3 secondes.

l’accouplement se déclenchera à

un couple préréglé pour empêcher

l’enfoncement trop profond de

la vis dans le matériau et éviter

d’endommager la vis ou l’outil.

Pour régler l’accouplement,

tournez l’anneau de réglage

d’accouplement pour aligner la

position de réglage choisie (1-21)

sur la marque imprimée sur le boîtier du moteur, tel qu’indiqué.

Les spécifi cations de couple sus-

mentionnées sont approximatives

et basées sur une batterie à pleine charge.

MONTAGE DE L’OUTIL

MANIEMENT

1

Alignement

2

Languette

Enfonçage

Perçage

Installation des pièces

Retirez toujours la batterie de l’outil avant d’insérer

ou de retirer les pièces ou les forets. Choisissez le

calibre de pièce tournevis qui convient au calibre

de vis que vous employez

1. Pour installer la mèche, retirer le mandrin. En-

foncer la mèche ou le foret dans la douille jusqu’à

ce que le collier et la mèche soient verrouillés en

place.

2. Pour retirer la mèche ou le foret, retirer le collier,

puis la mèche ou le foret.

NOTE : Il n’est pas nécessaire de maintenir le

collier hors de l’outil pour installer ou retirer des

mèches/forets.

Réglage de la poignée

Le design de la poignée en assure la commodité

et la maîtrise. Son axe durable permet d’employer

l’outil dans sa forme originale ou en pliant la poignée en forme de pistolet. L’accès à l’inverseur et

au verrou de rotation est facile aux deux positions.

Utilisation de l’accouplement réglable

Cet outil est pourvu d’un accouplement ré

glable

pour enfoncer différents calibres de vis dans différents matériaux. Lorsqu’il est correctement réglé,

* Quand l’ensemble à la grande vitesse, a placé

l’embrayage à 10 ou ci-dessous. L’interruption

automatique peut ne pas fonctionner à des arrangements plus élevés d’embrayage (voir “Mise

à l’arrêt automatique”).

N.B. Les réglages indiqués au tableau étant approximatifs, il est conseillé de tester différents

réglages sur un morceau de matériau de rebut

avant de commencer à enfoncer les vis dans le

matériau à ouvrer.

Réglage de

l’accoupement

(N•m)

Applications

Basse Haute

1

4

7

10

13

16

19

0.4

0.7

1.0

1.4

1.9

2.3

2.6

0.4

0.7

1.0

1.3

- -*

- -*

- -*

Petites vis dans le

bois mou.

Vis moyennes dans

le bois mou ou petites

vis dans le bois dur.

Grosses vis dans le

bois mou. Vis moyennes dans le bois

durou grosses vis

dans le bois dur avec

trou-guide.

Usage du verrou de rotation

Lorsque la batterie est dans l’outil, celui-ci est prêt

à fonctionner. Le verrou de rotation prévient les

démarrages accidentels en bloquant l’inverseur de

rotation. Placez toujours le verrou de rotation à la

position marquée «LOCK» avant de faire l’entretien

de l’outil, d’en changer les accessoires ou de le

ranger lorsqu’il ne sert pas.

1. Pour verrouiller, appuyez sur

l’interrupteur de verrouillage pour

affi cher le symbole de verrouillage

.

2. Pour déverrouiller, appuyez sur

l’interrupteur de verrouillage pour

affi cher le symbole de déverrouil-

lage .

Choix du régime de vitesse

1. Pour choisir un régime bas et un

couple élevé, pousser le sélecteur

de vitesse vers l’arrière pour affi cher « 1 ».

2. Pour choisir un régime bas et un

couple bas, pousser le sélecteur de vitesse vers

l’arrière pour affi cher « 2 ».

Inversion de la rotation

Appuyez et maintenir enfoncé le haut de

l’interrupteur ◄ pour une rotation normale, et le

bas de l’interrupteur ► pour une rotation inverse.

L’interrupteur retournera automatiquement à la

position centrale éteinte lorsque relâché.

Mise à l’arrêt automatique

Une fois que l’outil a été selectionné, pour éviter

l’entraînement d’une force supplémentaire, l’outil

s’arrêtera automatiquement en cas de glissement de l’accouplement. Cette fonction ne

s’enclenche pas immédiatement sur des réglages

d’accouplement plus élevés. Relâcher la commande pour rétablir la mise à l’arrêt automatique.

Fonctionnement par temps froid

Le bloc de batteries au lithium-ion de MILWAUKEE

sont conçus pour fonctionner à des températures

infé-rieures au point de congélation. Lorsque le

bloc des batteries est très froid, mettre le bloc

des batteries sur l’outil et utiliser celui-ci pour une

utilisation légère. Une alarme sonore peut se faire

entendre pendant un court instant jusqu’à ce qu’il

se réchauffe. Lorsque l’alarme s’arrête, utiliser

l’outil normalement.

AVERTISSEMENT Pour minimiser

les risques d’explosion, choc électrique

et dommages à la propriété, inspectez toujours l’aire de travail pour y déceler les f ls

électriques ou les tuyaux avant d’entreprendre

le forage.

APPLICATIONS

Cet outil fournit un moyen rapide et pratique pour

le perçage de petits trous ainsi que pour le vissage

et le dévissage des vis. Étant donné la grande

variété de calibres, de fi le tages et de formes des

vis et de la nature des matériauz disponibles, il est

diffi cile de déterminer les limites d'application de

cet outil selon le seul calibre des vis. Cependant,

pour les applications dans le bois, une vis à bois

numéro 6 amorcée dans un trou-guide parait une

limite raisonnable.

Perçage du bois, des matériaux synthétiques

et du plastique

Utilisez toujours des forets ou des mèches bien affûtés. Lorsque vous utilisez des forets hélicoïdaux,

retirez-les fréquemment du trou pour enlever les

copeaux des goujures. Afi n de réduire les risques

d’éclatement, appuyez la pièce sur un morceau

de bois de rebut. Sélectionnez des vitesses lentes

pour le perçage de matières plastiques qui ont un

point de fusion assez bas.

Enfonçage de vis

Percez un trou pilote lorsque vous enfoncez des

vis dans des matériaux épais ou durs. Réglez le

anneau de rélage de l'accouplement à la position

correcte et à une vitesse lente. Utilisez le bon type

et la bonne taille d’embout de tournevis pour le

type de vis utilisé.

Avec la mèche de tournevis dans la vis, placer

l’extrémité de la vis sur la pièce de travail et appuyer fermement avant de presser l’inverseur du

sens de rotation vers le haut. Les vis peuvent être

retirées en appuyant l’inverseur du sens de rotation vers le bas.

Verrouillage de la rotation

Lorsque l'inverseur de rotation est à la position

marqée « OFF » la rotation est à du moteur est

effective ment bloquée et le tournevis peut être

utilisé manuellement. Cette caractéristique est

commode pour serrer les vis dont le serrage exige

un couple supérier à celui que l'outil peut fournir,

pour raffermir le serrage des vis et pour dévisser

les vis extrêmement serrées.

Déverrouiller

Verrouiller

Basse Haute

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 7

12

13

Entretien de l’outil

Gardez l’outil, la batterie et le chargeur en bon

état en adoptant un programme d’entretien

ponctuel. Après une période de six mois à un an,

selon l’utilisation, renvoyez l’outil, la batterie et le

chargeur à un centre de service MILWAUKEE ac-

crédité pour les services suivants:

• Lubrifi cation

• Inspection et nettoyage de la mécanique (engrenages, pivots, coussinets, boîtier etc.)

• Inspection électrique (batterie, chargeur, moteur)

• Vérifi cation du fonctionnement électromécanique

Si l’outil ne démarre pas ou ne fonctionne pas à

pleine puissance alors qu’il est branché sur une

batterie complètement chargée, nettoyez les points

de contact entre la batterie et l’outil. Si l’outil ne

fonctionne toujours pas correctement, renvoyez

l’outil, le chargeur et la batterie à un centre de service MILWAUKEE accrédité, afi nqu’on en effectue

la réparation (voir “Réparations”).

Nettoyage

Débarrassez les évents du chargeur et de l’outil

des débris et de la poussière. Gardez les poignées

de l’outil propres, à sec et exemptes d’huile ou de

graisse. Le nettoyage de l’outil, du chargeur et de

la batterie doit se faire avec un linge humide et un

savon doux. Certains nettoyants tels l’essence, la

térébenthine, lesdiluants à laque ou à peinture, les

solvants chlorés, l’ammoniaque et les détergents

d’usage domestique qui en contiennent pourraient

détériorer le plastique et l’isolation des pièces. Ne

laissez jamais de solvants infl ammables ou com-

bustibles auprès de l’outil.

Réparations

Pour les réparations, retournez outil, batterie et

chargeur en entier au centre-service le plus près.

ENTRETIEN

AVERTISSEMENT Pour minimiser

les risques de blessures corporelles, débranchez le chargeur et retirez la batterie

du chargeur ou de l’outil avant d’y effectuer

des travaux d’entretien. Ne démontez jamais

l’outil, la batterie ou le chargeur . Pour toute

réparation, consultez un centre de service

MILWAUKEE accrédité.

AVERTISSEMENT Pour minimiser

les risques de blessures ou de dommages à

l'outil, n'immergez jamais l'outil, la batterie

ou le chargeur et ne laissez pas de liquide

s'y inf ltrer.

ACCESOIRES

AVERTISSEMENT Retirez toujours

la batterie avant de changer ou d’enlever les

accessoires. L’utilisation d’autres accessoires que ceux qui sont spécifiquement

recommandés pour cet outil peut comporter

des risques.

Pour une liste complète des accessoires, prière de

se reporter au catalogue MILWAUKEE Electric Tool

ou visiter le site internet www.milwaukeetool.com.

Pour obtenir un catalogue, il suffi t de contacter votre

distributeur local ou l'un des centres-service.

GARANTIE LIMITÉE - AUX ÉTATS-UNIS ET AU CANADA

TECHTRONIC INDUSTRIES' garantit le produit pendant cinq ans à partir de la date d’achat d’origine. Le présent bon

de garantie couvre tous les vices de matériau et de fabrication que peut affi cher cet outil électrique. Pour assurer la

validité de la présente garantie, veuillez présenter le bon de commande, estampillé du sceau du distributeur ou du

magasin où le produit a été acheté, au centre de réparations agréé. Si le bon de commande n’a pas été estampillé,

veuillez fournir la preuve d’achat d’origine au centre de réparations agréé. Pour un entretien, des pièces, des accessoires ou d’autres composants, composer sans frais le 1-800-832-1949 afi n d’obtenir les coordonnées du centre de

réparations agréé le plus près.

Procédure pour assurer la validité de la garantie

Présenter le produit au centre de réparations agréé, accompagné du bon de commande estampillé du sceau du

distributeur ou du magasin où le produit a été acheté. Toute pièce défectueuse ou tout composant défectueux sera

remplacé sans frais. Milwaukee assume tous les frais de transport liés à ce processus de garantie.

Exceptions

La garantie ne s’applique pas dans les situations suivantes :

a) Si le produit a été utilisé pour une fi n autre que celle indiquée dans le guide de l’utilisateur fi nal ou le manuel d’instructions.

b) Si les conditions d’utilisations ne sont pas habituelles.

c) Si le produit a été modifi é ou réparé par une personne non autorisée par TECHTRONIC INDUSTRIES.

Note : Si le cordon électrique est endommagé, il doit être remplacé par un centre de réparations agréé pour éviter les

risques d’électrocution.

CENTRE DE RÉPARATIONS ET DE SERVICE

Av Presidente Mazarik 29 Piso 7, 11570 Chapultepec Morales

Miguel Hidalgo, Distrito Federal, Mexico

Ph. 52 55 4160-3547

IMPORTÉ ET COMMERCIALISÉ PAR :

TECHTRONIC INDUSTRIES MEXICO, .S.A. DE C.V.

Av Presidente Mazarik 29 Piso 7, 11570 Chapultepec Morales

Miguel Hidalgo, Distrito Federal, Mexico

GARANTIE LIMITÉE – MEXIQUE, AMÉRIQUE CENTRALE ET CARAÏBES

Modèle :

Date d’achat :

Sceau du distributeur ou du magasin :

Chaque outil électrique MILWAUKEE (y compris les produits sans fi l [outils, piles, chargeur de piles, lampe de travail];

consulter les énoncés de la GARANTIE LIMITÉE DES BLOCS-PILES SANS FIL) est garanti à l’acheteur d’origine

être exempt de vice de matériau et de fabrication. Sous réserve de certaines exceptions, MILWAUKEE réparera ou

remplacera toute pièce d’un outil électrique qui, après examen par MILWAUKEE, s’est avérée être affectée d’un vice de

matériau ou de fabrication pendant une période de cinq (5) ans* après la date d’achat, sauf indication contraire. Retourner

l’outil électrique, à un centre de réparations en usine MILWAUKEE ou à un poste d’entretien agréé MILWAUKEE, en

port prépayé et assuré. Une copie de la preuve d’achat doit être présentée au moment de retourner le produit. Cette

garantie ne couvre pas les dommages que MILWAUKEE détermine être causés par des réparations ou des tentatives

de réparation par quiconque autre que le personnel agréé par MILWAUKEE, des utilisations incorrectes, des altérations, des utilisations abusives, une usure normale, une carence d’entretien ou des accidents.

*La période de garantie applicable pour les radios de chantier, le port d’alimentation M12™, Source d'énergie M18™,

et les chariots de travail industriels Trade Titan™ est d’une durée d’un (1) an à partir de la date d’achat. La période de

la garantie couvrant la lampe de travail à DÉL et l’ampoule améliorée à DÉL est une garantie À VIE limitée à l’acheteur

d’origine seulement; si, lors d’une utilisation normale, l’ampoule à DÉL présente une défectuosité, la lampe de travail

et l’ampoule seront remplacées sans frais.

*Cette garantie ne s’applique pas aux cloueuses-agrafeuses pneumatiques, aux pulvérisateurs à peinture sans air,

aux blocs piles pour outils sans fi l, aux génératrices d’alimentation portatives à essence, aux outils à main, aux monte-

charge – électrique, à levier et à chaîne (manuel), aux vestes chauffantes M12™, aux produits réusinés, ni aux produits

d’essai et de mesure. Il existe des garanties distinctes pour ces produits.

L’enregistrement de la garantie n’est pas nécessaire pour bénéfi cier de la garantie en vigueur sur un outil électrique

MILWAUKEE. La date de fabrication du produit servira à établir la période de garantie si aucune preuve d’achat n’est

fournie lorsqu’une demande de service sous garantie est présentée.

L’ACCEPTATION DES RECOURS EXCLUSIFS DE RÉPARATION ET DE REMPLACEMENT DÉCRITS AUX

PRÉSENTES EST UNE CONDITION DU CONTRAT D’ACHAT DE TOUT PRODUIT MILWAUKEE. SI VOUS

N’ACCEPTEZ PAS CETTE CONDITION, VOUS NE DEVEZ PAS ACHETER LE PRODUIT. EN AUCUN CAS

MILWAUKEE NE SAURAIT ÊTRE RESPONSABLE DE TOUT DOMMAGE ACCESSOIRE, SPÉCIAL OU INDIRECT,

DE DOMMAGES-INTÉRÊTS PUNITIFS OU DE TOUTE DÉPENSE, D’HONORAIRES D’AVOCATS, DE FRAIS, DE

PERTE OU DE DÉLAIS ACCESSOIRES À TOUT DOMMAGE, DÉFAILLANCE OU DÉFAUT DE TOUT PRODUIT,

Y COMPRIS NOTAMMENT LES PERTES DE PROFIT. CERTAINS ÉTATS ET PROVINCES NE PERMETTANT

PAS L’EXCLUSION OU LA LIMITATION DES DOMMAGES DIRECTS OU INDIRECTS, LES RESTRICTIONS CIDESSUS PEUVENT NE PAS ÊTRE APPLICABLES. CETTE GARANTIE EST EXCLUSIVE ET REMPLACE TOUTE

AUTRE GARANTIE EXPRESSE, QU’ELLE SOIT ORALE OU ÉCRITE. DANS LA MESURE PERMISE PAR LA LOI.

MILWAUKEE RENONCE À TOUTE GARANTIE IMPLICITE, Y COMPRIS, SANS S’Y LIMITER, TOUTE GARANTIE

IMPLICITE DE QUALITÉ MARCHANDE OU D’ADAPTATION À UNE UTILISATION OU À UNE FIN PARTICULIÈRE.

DANS LA MESURE OÙ UNE TELLE STIPULATION D’EXONÉRATION N’EST PAS PERMISE PAR LA LOI, LA DURÉE

DE CES GARANTIES IMPLICITES EST LIMITÉE À LA PÉRIODE APPLICABLE DE LA GARANTIE EXPRESSE, TEL

QUE DÉCRIT PRÉCÉDEMMENT. CERTAINS ÉTATS ET PROVINCES NE PERMETTANT PAS DE LIMITATION DE

DURÉE DES GARANTIES IMPLICITES, LES RESTRICTIONS CI DESSUS PEUVENT NE PAS ÊTRE APPLICABLES.

LA PRÉSENTE CONFÈRE À L’UTILISATEUR DES DROITS LÉGAUX PARTICULIERS; IL BÉNÉFICIE ÉGALEMENT

D’AUTRES DROITS QUI VARIENT D’UN ÉTAT À L’AUTRE.

Cette garantie s’applique aux produits vendus aux États-Unis et au Canada uniquement.

Veuillez consulter la rubrique Centre SAV MILWAUKEE, dans la section Pièces & Service du site Web de MILWAUKEE,

à l’adresse www.milwaukeetool.com, ou composer le 1-800-SAWDUST (1-800-729-3878) afi n de trouver le centre de

réparations en usine MILWAUKEE le plus près.

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 8

14

15

SEGURIDAD EN EL ÁREA

DE TRABAJO

SEGURIDAD ELÉCTRICA

ADVERTENCIAS DE SEGURIDAD GENERALES PARA LA

HERRAMIENTA ELÉCTRICA

• Mantenga limpia y bien iluminada el área de

trabajo. Las áreas desordenadas u oscuras con-

tribuyen a que se produzcan accidentes.

• No utilice herramientas eléctricas en atmósferas explosivas, como en la presencia de

líquidos, gases o polvo in f amables. Las her-

ramientas eléctricas crean chispas que pueden

incendiar el polvo o las emanaciones.

• Mantenga a los niños y otras personas alejadas

mientras utiliza una herramienta eléctrica. Las

distracciones pueden hacerle perder el control.

• Los enchufes de las herramientas eléctricas

deben ser del mismo tipo que el tomacorrientes. Nunca realice ningún tipo de

modif cación en el enchufe. No use enchufes

adaptadores con herramientas eléctricas

con conexión a tierra. Se reducirá el riesgo de

descarga eléctrica si no se modifi can los enchufes

y los tomacorrientes son del mismo tipo.

• Evite el contacto corporal con superf cies con

conexión a tierra, como tuberías, radiadores,

estufas y refrigeradores. El riesgo de descarga

eléctrica aumenta si su cuerpo está conectado a

tierra.

• No exponga la herramientas eléctricas a la

lluvia o a condiciones de humedad. El agua

que entra en una herramienta eléctrica aumenta

el riesgo de descarga eléctrica.

• No abuse del cable. Nunca use el cable para

transportar la herramienta eléctrica, tirar de

ella o desenchufarla. Mantenga el cable alejado

del calor, los bordes a f lados o las piezas en

movimiento. Los cables dañados o enmarañados

aumentan el riesgo de descarga eléctrica.

• Cuando se utiliza una herramienta eléctrica

en el exterior , use una extensión que sea

apropiada para uso en el exterior. El uso de un

cable apropiado para el exterior reduce el riesgo

de descarga eléctrica.

• Si debe operar una herramienta eléctrica en

un lugar húmedo, utilice un suministro protegido por un dispositivo de corriente residual

(RCD). Usar un RCD reduce el riesgo de que se

produzcan descargas eléctricas.

nas. Despistarse un minuto cuando se utiliza una

herramienta eléctrica puede tener como resultado

lesiones personales graves.

• Use un equipo de protección personal. Lleve

siempre protección ocular . Llevar un equipo

de protección apropiado para la situación, como

una máscara antipolvo, zapatos de seguridad

antideslizantes, un casco o protección auditiva,

reducirá las lesiones personales.

• Evite el encendido accidental. Asegúrese

de que el interruptor esté en la posición de

apagado antes de conectarlo a la toma de

alimentación o a la batería, al levantar o mover

la herramienta. Mover herramientas con el dedo

en el interruptor o enchufarlas con el interruptor

en la posición de encendido contribuye a que se

produzcan accidentes.

• Quite todas las llaves de ajuste antes de

encender la herramienta. Una llave que esté

acoplada a una pieza giratoria de la herramienta

puede provocar lesiones personales.

• No se estire demasiado. Mantenga los pies

bien asentados y el equilibrio en todo momento. Esto permite tener mejor control de la

herramienta eléctrica en situaciones inesperadas.

• Vístase de manera apropiada. No lleve ropa

suelta ni joyas. Mantenga el cabello, la ropa y

los guantes lejos de la piezas en movimiento.

La ropa fl oja, las joyas o el cabello largo pueden

quedar atrapados en las piezas en movimiento.

• Si se proporcionan dispositivos para la conexión de sistemas de recolección y extracción de

polvo, asegúrese de que estén conectados y

se usen apropiadamente. El uso de estos dis-

positivos puede reducir los peligros relacionados

con el polvo.

SEGURIDAD PERSONAL

ADVERTENCIA LEA TODAS LAS ADVERTENCIAS E INSTRUCCIONES DE

SEGURIDAD. Si no sigue todas las advertencias e instrucciones, se pueden provocar

una descarga eléctrica, un incendio o lesiones graves.

Guarde todas las advertencias e instrucciones para consultarlas en el futuro.

El término “herramienta eléctrica” en todas las advertencias incluidas más abajo se re f ere a su

herramienta operada por conexión (cable) a la red eléctrica o por medio de una batería (inalámbrica).

USO Y CUIDADO DE LAS

HERRAMIENTAS ELÉCTRICAS

• No fuerce la herramienta eléctrica. Use la herramienta eléctrica correcta para la aplicación.

La herramienta eléctrica correcta funcionará mejor

y de manera más segura a la velocidad para la

que se diseñó.

• No use la herramienta eléctrica si el interruptor

no la enciende ni la apaga. Cualquier herrami-

enta eléctrica que no se pueda controlar con el

interruptor es peligrosa y se debe reparar.

• Desconecte el enchufe de la toma de alimentación y/o la batería de la herramienta eléctrica

antes de realizar cualquier ajuste, cambiar

accesorios o almacenar las herramientas eléctricas. Dichas medidas preventivas de seguridad

reducen el riesgo de que la herramienta se prenda

accidentalmente.

• Manténgase alerta, ponga cuidado a lo que

está haciendo y use el sentido común cuando

utilice una herramienta eléctrica. No use una

herramienta eléctrica cuando está cansado o

bajo la inf uencia de drogas, alcohol o medici-

• Sostenga la herramienta eléctrica de las su-

perf cies de sujeción aisladas al llevar a cabo

una operación en la que el tornillo pueda hacer

contacto con cableado oculto. El contacto de los

tornillos con un cable que conduzca electricidad

puede hacer que las partes metálicas de la herramienta se electrifi quen y podría ocasionar una

descarga eléctrica al operador.

• Mantenga las manos alejadas de todos los

bordes cortadores y partes en movimiento.

• Guarde las etiquetas y placas de especi f caciones. Estas tienen información importante.

Si son ilegibles o si no se pueden encontrar,

póngase en contacto con un centro de servicio

de MILWAUKEE para una refacción gratis.

• ADVERTENCIA Algunas partículas de polvo

resultantes del lijado mecánico, aserrado, esmerilado, taladrado y otras actividades relacionadas

a la construcción, contienen sustancias químicas

que se saben ocasionan cáncer, defectos congénitos u otros daños al aparato reproductivo. A

continuación se citan algunos ejemplos de tales

sustancias químicas:

• plomo proveniente de pinturas con base de plomo

• sílice cristalino proveniente de ladrillos, cemento

y otros productos de albañilería y

• arsénico y cromo provenientes de madera

químicamente tratada.

El riesgo que usted sufre debido a la exposición

varía dependiendo de la frecuencia con la que

usted realiza estas tareas. Para reducir la exposición a estas sustancias químicas: trabaje

en un área bien ventilada, y utilice equipo de

seguridad aprobado como, por ejemplo, máscaras

contra el polvo que hayan sido específi camente

diseñadas para fi ltrar partículas microscópicas.

1. Collar de soporte

para punta

2. Anillo ajustador del embrague

3. Selector de velocidad

4. Interruptor de seguridad

5. Indicador de carga

6. Interruptor de acción y reversa

DESCRIPCION FUNCIONAL

USO Y CUIDADO DE LAS

HERRAMIENTAS CON BATERÍA

MANTENIMIENTO

REGLAS ESPECIFICAS

DE SEGURIDAD

• Almacene las herramientas eléctricas fuera

del alcance de los niños y no permita que

personas no familiarizadas con ellas o estas

instrucciones las utilicen. Las herramientas

eléctricas son peligrosas en las manos de usuarios

no capacitados.

• Mantenimiento de las herramientas eléctricas. Revise que no haya piezas móviles

que estén desalineadas o que se atasquen,

piezas rotas ni ninguna otra condición

que pueda afectar el funcionamiento de

la herramienta eléctrica. Si se encuentran

daños, haga que le reparen la herramienta

antes de usarla. Las herramientas mal man-

tenidas son la causa de muchos accidentes.

• Mantenga las herramientas de corte limpias

y af ladas. Es menos probable que se atasquen

las herramientas de corte con fi los afi lados que

se mantienen de manera apropiada y también son

más fáciles de controlar.

• Use la herramienta eléctrica, los accesorios,

las brocas, etc. siguiendo estas instrucciones,

teniendo en cuenta las condiciones de trabajo

y la tarea que se va a realizar. El uso de la her-

ramienta eléctrica para operaciones diferentes de

aquellas para las que se diseñó podría originar

una situación peligrosa.

• Recárguela solamente con el cargador especif cado por el fabricante. Un cargador que

sea apropiado para un tipo de batería puede crear

riesgo de incendio cuando se use con otra batería.

• Use las herramientas eléctricas solamente con

baterías específ camente diseñadas. El uso de

cualquier otro tipo de batería puede crear riesgo

de lesiones o incendio.

• Cuando no se use la batería manténgala

alejada de otros objetos de metal como clips

para papel, monedas, llaves, clavos, tornillos

u otros objetos de metal pequeños que puedan

realizar una conexión entre los bornes. Realizar

un cortacircuito en los terminales de la batería

puede provocar quemaduras o un incendio.

• Bajo condiciones abusivas, puede salir líquido

expulsado de la batería; evitar el contacto. Si

se produce un contacto accidental, lavar con

agua. Si el líquido entra en contacto con los

ojos buscar ayuda médica adicional. El líquido

que sale despedido de la batería puede causar

irritaciones o quemaduras.

• Haga que un técnico calificado realice el

mantenimiento de la herramienta eléctrica utilizando solamente piezas de repuesto idénticas.

Esto asegurará que se mantiene la seguridad de

la herramienta eléctrica.

ESPECIFICACIONES

Cat. No. Volts cd rpm

2101-20 4 Baja 200

Alta 600

3

1

2

4

6

5

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 9

16

17

ADVERTENCIA Recargue la batería

sólo con el cargador especificado para

ella. Para instrucciones especí f cas sobre

cómo cargar, lea el manual del operador

suministrado con su cargador y la batería.

ADVERTENCIA Para reducir el riesgo

de lesiones, trabe siempre el gatillo o

quite la batería antes de cambiar o quitar accesorios. Use solamente acceso rios específ camente recomenda dos para esta herra mienta.

El uso de otros puede resultar peligroso.

ADVERTENCIA Para reducir el riesgo

de lesiones, use siempre lentes de seguridad o anteojos con protectores laterales.

Instalación de las puntas

Quite siempre la batería antes de insertar o retirar

las puntas. Seleccione el tipo y tamaño adecuado

de punta para atornillador, de acuerdo al tipo de

tornillo que usted va a usar.

1. Para instalar la punta, saque el collar. Oprima

la punta en la boquilla hasta que el collar se

contraiga y la punta quede bloqueada en su

lugar.

2. Para quitar la punta, saque el collar y a continu-

ación la punta.

NOTA: No es necesario mantener el collar fuera

al instalar o quitar las puntas.

Ajustando la empuñadura

La empuñadura está diseñada para operar a

convenience y con control. El ddurable pivote

central permite que la empuñadura sea usada en

su forma convencional o doblada para formar una

empuñadura tipo pistola. El acceso al interruptor

de seguridad es muy fácil y cómodo en cualquiera

de las posiciones de la empuñadura.

Uso del embrague ajustable

Esta herramienta tiene un embrague ajustable para

poder atornillar diferentes tipos de tornillos dentro

de diferentes materiales. Cuando

está adecuadamente ajustado, el

embrague se colocará en un torque

predeterminado con el objeto

de prevenir que se atronille muy

profundamente el tornillo asi como

para evitar dañar tanto al tornillo o

a la herramienta.

Para seleccionar la adecuada

posición del embrague (1-21) para

el tipo de material y tornillo que

usted va a usar, refi érase a la tabla

mostrada a la derecha.

Como se inserta la batería en la herramienta

Ranura

Lengüeta

Bloqueo

Alinee las lengüetas de la batería con las ranuras

en la abertura de la herramienta. Deslice la batería

por toda la longitud de la herramienta. Gire la batería en el sentido de las manecillas del reloj para

trabarla en su lugar. La línea de la batería coincidirá

con las

de la herramienta. La herramienta no

funcionará hasta que la batería no esté correctamente trabada en la herramienta.

Como se quita la batería de la herramienta

Gire la tapa de la batería en el sentido contrario a

las manecillas del reloj para destrabar. Extraiga la

batería de la herramienta.

Revisión del indicador de carga

Para determinar la carga restante en la batería,

oprima el interruptor de acción/reversa. El indicador

de carga se encenderá de 2 a 3 segundos.

ENSAMBLAJE

OPERACION

SIMBOLOGÍA

Corriente directa

Voltas

No Load Revolutions per Minute

(RPM)

Underwriters Laboratories, Inc.

United States and Canada

1

Alinear

2

Poder

atornillar

Taladrado

* Cuando el sistema a la velocidad, fi jó el embrague

en 10 o abajo. El cierre automático puede no trabajar en ajustes más altos del embrague (véase

el “Apagado automático”).

NOTA: Dado que los niveles de ajuste mostrados

en el cuadro son solo una referencia, se sugiere

usar un pedazo de material de desperdicio y probar

en él los diferentes ajustes del embrague antes

de proceder a colocar tornillos en el material de

trabajo.

Uso del interruptor de seguridad

Una vez que se ha instalado la batería, la herramienta está en condiciones de operación. El

interruptor de seguridad previene encendidos accidentales ya que bloquea al interruptor de acción

y reversa. Siempre coloque el interruptor de seguridad en posición de “asegurado” (“lock”) antes de

realizar operaciones como: darle mantenimiento,

cambiar accesorios, almacenar la herramienta o en

cualquier otra ocasión en que no se vaya a usar la

herramienta.

1. Para trabar, pulse el interruptor de

la traba para mostrar el símbolo de

trabado

.

2. Para destrabar, pulse el interruptor

de la traba para mostrar el símbolo

de destrabado .

Seleccionando la velocidad alta o baja

1. Para la velocidad baja y mayor

torque, empuje hacia atrás el

selector de velocidad (se muestra

“1”).

2. Para la velocidad alta y menor

torque, empuje hacia adelante el

selector de velocidad (se muestra

“2”).

Selección de acción o reversa

Pulse y sostenga la parte superior del interruptor

◄ para rotación directa, y la parte inferior del

interruptor ► para rotación inversa. Al soltar el

interruptor, este regresará automáticamente a la

posición central de apagado.

Apagado automático

Para evitar una fuerza motora excesiva después

de alcanzar el torque seleccionado, la herramienta

se apagará automáticamente si el embrague

patina. Es posible que esta función no se active

inmediatamente a mayores ajustes del embrague.

Libere el interruptor para restablecer la función de

apagado automático.

Funcionamiento en clima frío

El paquete de batería de iones de litio de

MILWAUKEE están diseñados para funcionar

en temperaturas bajo cero. Cuando el paquete

de batería se encuentre muy fría, colóquela en

una herramienta y utilice ésta en una tarea ligera.

Es posible que “zumbe” por un breve período de

tiempo hasta que se caliente. Una vez que el zumbido cese, utilice la herramienta de manera normal.

Las especifi caciones de torque mostradas en este

cuadro son valores aproximados obtenidos con una

batería con plena carga.

Ajuste del

embrague

(N•m)

Applicaciones

Baja Alta

1

4

7

10

13

16

19

0.4

0.7

1.0

1.4

1.9

2.3

2.6

0.4

0.7

1.0

1.3

- -*

- -*

- -*

Tornillos pequeños en

madera suave.

Tornillos medianos

en madera suave o

tornillos pequeños en

madera dura.

Tornillo largos en

madera suave. Tornillos

medianos en madera

dura o tornillos largos

en madera dura con

perforación piloto.

Sin asegurer

Asegurado

Alta Baja

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

http://www.hmcelectronics.com

(800) 482-4440

Page 10

18

19

APPLICACIONES

ADVERTENCIA Para reducir el riesgo

de electrocución, antes de taladrar o

colocar tornillos verif que que en el área de

trabajo no hayan tuberías o cables ocultos.

Esta herramienta ofrece un medio rápido y conveniente para perforar agujeros pequeños e instalar

y quitar tornillos. Debido a la gran cantidad de

tipos de tornillos, tamaños, cuerdas y materiales

disponibles, es muy difícil limitar las aplicaciones

de esta herramienta al solamente el tamaño del tornillo. Sin embargo, para aplicaciones en madera, el

límite práctico sería un tornillo para madera #6, con

una perforación piloto o guia previamente realizada.

Taladrado en madera, materiales compuestos

y plásticos

Siempre use brocas afi ladas. Cuando use brocas

helicoidales, tire de la broca hacia fuera del orifi cio

para eliminar las rebabas de las estrías de la broca.

Para reducir la producción de astillas, apoye el

trabajo con una pieza de material de desecho. Se

recomienda seleccionar velocidades lentas para

plásticos con un punto de derretimiento bajo.

Cómo colocar tornillos

Perfore un orifi cio piloto cuando coloque tornillos

en materiales gruesos o duros. Coloque el anillo

ajustador del embrague en la posición correcta y

ajuste la velocidad a “baja”. Use el estilo y tamaño

de destornillador de berbiquí correcto para el tipo

de tornillo que está utilizando.

Con la punta del destornillador colocada en el

tornillo, coloque la punta del tornillo sobre la pieza

de trabajo y aplique presión fi rmemente antes de

mover el interruptor de acción/reversa hacia arriba.

Se puede quitar los tornillos al oprimir el interruptor

de acción/reversa hacia abajo.

Trabando la punta

Cuando el interruptor de acción y reversa está en

posición “OFF”, la punta queda automáticamente

trabada en su lugar, permitiendo usar la herramienta como si fuera un atornillador de mano. Esta

característica es muy práctica para poder apretar

tornillos que requieren mas torque del que la herramienta es capaz de entregar, o para verifi car el

apriete de un tornillo, o para sacar un tornillo que

esté muy apretado.

Mantenimiento de la herramienta

Adopte un programa regular de mantenimiento

y mantenga sus baterías y cargador en buenas

condiciones. Despues de 6 meses a un año,

dependiendo del uso dado, envíe su herramienta, batería y cargador, al Centro de Servicio

MILWAUKEE mas cercano para que le hagan:

• Lubricación

• Inspección mecánica y limpieza (engranes,

fl echas, baleros, carcaza, etc.)

• Inspección eléctrica (batería, cargador, motor)

• Probarla para asegurar una adecuada operación

mecánicay eléctrica

Si la herramienta no arranca u opera a toda su

potencia con una batería completamente cargada,

limpie, con una goma o borrador, los contactos de

la batería y de la herramienta. Si aun asi la herramienta no trabaja correctamente, regrésela, con

el cargador y la batería, a un centro de servicio

MILWAUKEE para que sea reparada.

MANTENIMIENTO

ADVERTENCIA Para reducir el

riesgo de una lesión, desconecte siempre la

herramienta antes de darle cualquier mantenimiento. Nunca desarme la herramienta ni

trate de hacer modi f caciones en el sistema

eléctrico de la misma. Acuda siempre a un

Centro de Servicio MILWAUKEE para TODAS

las reparaciones.

ADVERTENCIA Para reducir el

riesgo de una explosión, no queme nunca

una batería, aun si está dañada, “muerta” o

completamente descargada.

Para una lista completa de accessorios, refi érase

a su catálogo MILWAUKEE Electric Tool o visite

nuestro sitio en Internet: www.milwaukeetool.com.

Para obtener un catálogo, contacte su distribuidor

local o uno de los centros de servicio.

ACCESORIOS

ADVERTENCIA Para reducir el riesgo

de lesiones, siempre extraiga la batería antes de cambiar o retirar accesorios. Utilice

únicamente accesorios específicamente

recomendados para esta herramienta. El

uso de accesorios no recomendados podría

resultar peligroso.

Limpieza

Limpie el polvo y suciedad de las ventilas del cargador y la herramienta. Mantenga los mangos y empuñaduras limpios, secos y libres de aceite o grasa.

Use solo jabón neutro y un trapo húmedo para

limpiar la herramienta, batería y el cargador, ya

que algunos substancias y solventes limpiadores

son dañinos a los plásticos y partes aislantes. Algunos de estos incluyen: gasolina, turpentina,thíner,

lacas, thíner para pinturas, solventes para limpieza

con cloro, amoníaco y detergentes caseros que

tengan amonia. Nunca usa solventes infl amables

o combustibles cerca de una herramienta.

Reparaciones

Si su herramienta, batería o cargador están dañados, envíela al centro de servicio más cercano.

GARANTÍA LIMITADA - E.U.A. Y CANADÁ

TECHTRONIC INDUSTRIES., garantiza por 5 años este producto a partir de la fecha original de compra.

Esta garantía cubre cualquier defecto que presenten las piezas, componentes y la mano de obra contenidas en este

producto Para América Central y el Caribe se debe confi rmar en el Centro de Servicio Autorizado el plazo de la garantía.

Para hacer efectiva la Garantía deberá presentar al Centro de Servicio Autorizado la Póliza de Garantía sellada por

el establecimiento en donde adquirió el producto. Si no la tienen, podrá presentar el comprobante de compra original.

Usted puede llamar sin costo al teléfono 01 800 832 1949 o por correo electrónico a la dirección "servicio@ttigroupna.

com", para ubicar el Centro de Servicio Autorizado más cercano a su domicilio, en el cual además podrá adquirir partes,

componentes, consumibles y accesorios, que usted necesite.

Procedimiento para hacer válida la garantía