HMC HV Quick user manual

SHORT OPERATION INSTRUCTIONS

recooling

FOR STEAM STERILIZER HV SERIES

1. SAFETY DIRECTION

This short operating instructions do not replace the manual. Read in every case before start-up and/or before using

steamsterilizer the manual and obey the indicated safety directions!

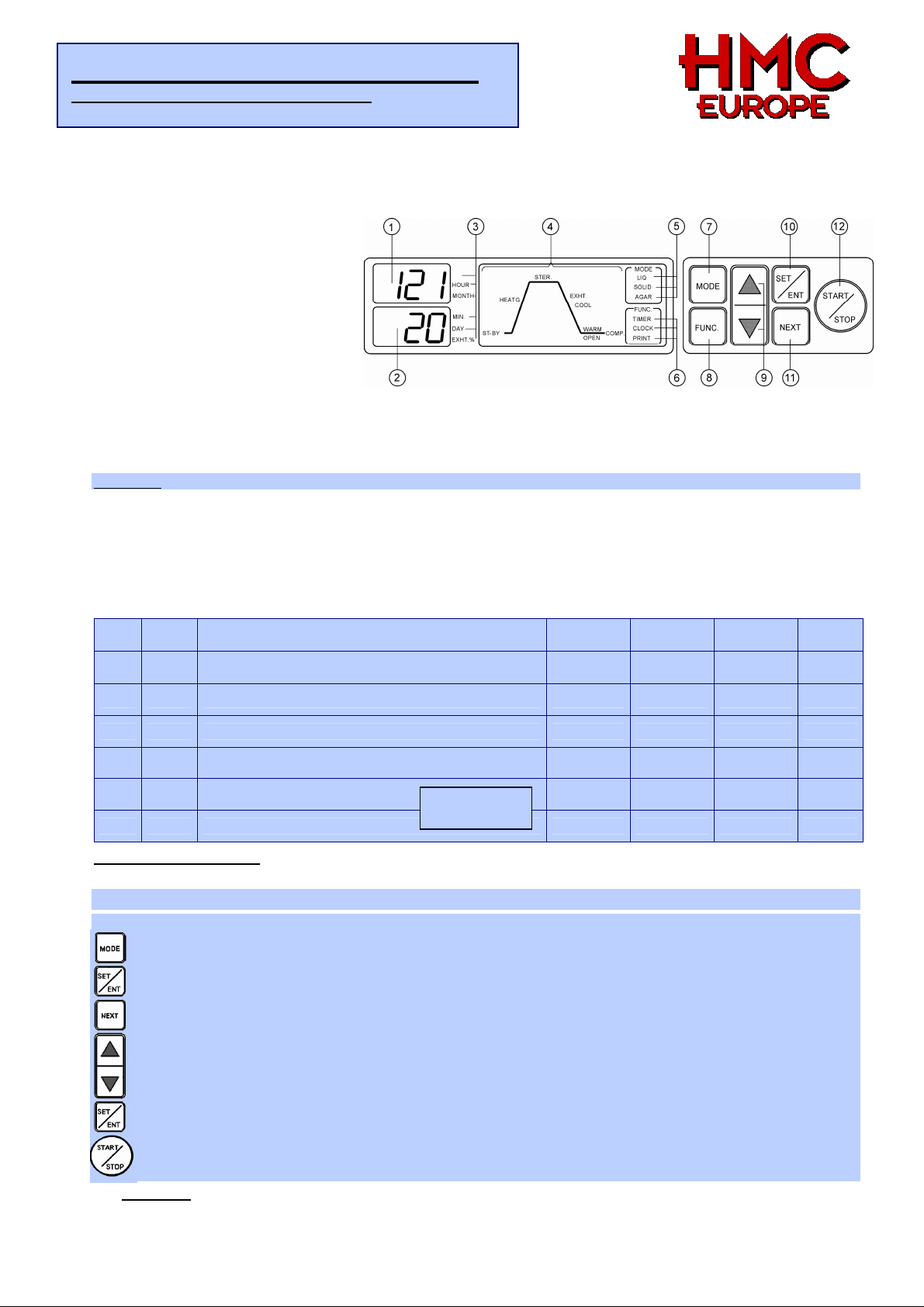

2. DISPLAY AND OPERATION SWITCHES

(1) Indication of temperature, date, errors

(2) Sterilizing time, time, air evacuation %

(3) Unit display

(4) Cycle Display

(5) Mode Display

(6) Func. Display (timer, clock, print)

(7) Mode Switch for selection Mode and

checking set temperature or exhaust%

(8) Func. Switch for activating or

modification of functions

(9) Switch for modification of single parameters

(10) Switch for modification sterilizing parameters

3. OPERATION

Unit must be connected to supply (energy, demineralised-water, pressured air, sewerage)

WARNING: THE OPEN/CLOSE LEVER ONLY WORKS, WHEN POWER SWITCH IS TURNED TO „ON“!!.

Pour water into exhaust bottle till marking

Pour water through chamber until hole at the centre of heater cover.

Place the substance to be sterilised into the chamber.

Flexible temperature sensor

Be sure that temperature sensor is activated (press Switch Func. till „FL ON“ comes

4. SELECTING MODE

Prog.

MODE Description Lid

-No

1 LIQ

2 LIQ liquids 80/90/95°C

Sterilization of agar medium (warmed for the

prevention of coagulation after sterilization)

(11) Switch for selection parameters

(12) Switch starts and stops the program

Sterilising

opening.

80/90/95°C

temp.

121°C 20 10

121°C 20 10

Sterilising

time

Exhaust

%

3 SOLID Solids, instruments, glass 98°C 121°C 20 10

4 AGAR Dissolution of AGAR with warming cycle 50°C 80/90/95°C

5 LIQ

Liquids with warming cycle 50°C

only for fast

80/90/95°C

6 LIQ Liquids with cooling 80/90/95°C

100°C 20 10

121°C 20 cooling

121°C 20 cooling

Lid-opening-temperature

For precaution al Liquid programs have standardized take-from-temperature of 80°C

Modification lid-opening-temperature

Modification of lid-opening-temperature is only possible when flexible temperature sensor is installed and activated.

Select program,

first you reach the program number, then the standard opening temperature [80 oPN]

Press switch for coming to programme mode, the temperature display blinks

Pressing switch to 80 oPn

Press switch up or down till needed lid-opening-temperature is reached for example 95 oPN

Press switch, the modified temperature is programmed.

Press switch, the lid opening temperature will be announced short time and the program starts

Direction: 80°C lid-opening-temperature for Liquids in closed glass bottles

90°C lid-opening-temperature for Liquids in closed plastic bottles

95° lid-opening-temperature for Liquids in open bo ttles

V:\HMC-Europe\Beschreibungstexte\HV\Bedienungsanleitungen\Kurzbedienungsanleitungen\Kurzbedienungsanleitung engl..doc Stand Juli 2003

Modification of other programparameters (temperature, time, exhaust)

Select program

Press switch temperatur blinks

Press switch, successsive blinks min (time), warming temperature oPN (80,90,95) and take-offtemperature

Press switch for modifiing (blinking) parameters

Press switch for saving modivication

Press switch to start program

5. START PROGRAM

Test the feeding water level (demineralised-water)

Choose the suitable program.

Liquid sterilisation: Look for correct take-of-temperature.

Place the flex. temperature sensor in suitable vessel, therefore turn the lock/unlock lever

to (left) „LOCK“ position

Press the switch

First you see the take-off-temperature and the steamsterilizer starts. „HEATG“ blinks.

6. STOP PROGRAM

Press the switch

The program can be stopped at every time .After reaching the selected lid-opening temperature and the ambient air

pressure (Check that the pressure is at “0Mpa” ) the lid can be opened. Turn the

position. Open the lid

lock/unlock lever

to (right) „UNLOCK“

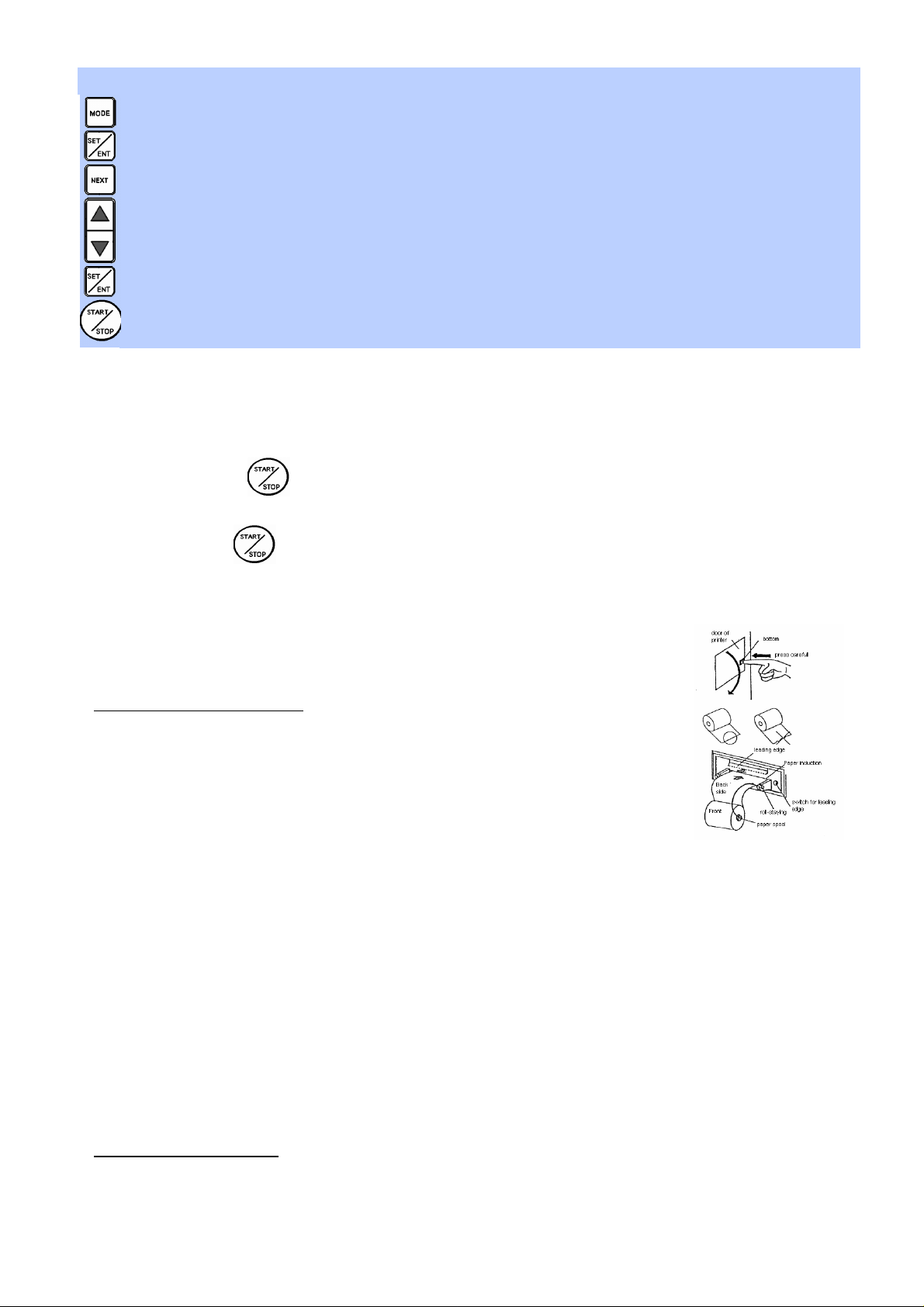

7. PRINTER

The printer will be actevated with

date, sterilising program, time and exhaust speed.

Description of paper leading edge

Func-Switch and documents the program parameter

Activate the printer.

Press careful the bottom of printer door and open it.

Cut the paper roll straight.

Set the roll exactly as shown in the drawing. Then, slowly insert the leading edge, square and

flat, into the leading slot and press the feed switch.

8. EXHAUST AIR FILTER

The exhaust air filter system filters the steam-air mixture when sterilising microbiological contaminated material and waste .

The filter system and the filter cartridge is sterilised with each cycle. („In-line“-sterilisation).

The filter cartridge is integrated in a stainless steel case.

This filter case you find inside of the autoclave, it is outside not visible.

The filter system don’t need any adjustment. The average running time is 1.000 hours. The filter cartridges should be

changed regularly. Therefore replace the right cover of the steamsterilizer. You can order Filter cartridges (Part.No.50019)

on HMC Europe or your distributor.

9. ERROR

If you press switches to fast or wrong, you hear a periodic peep-sound and the programming can’t continue. You cancel this

error when you turn short time the

Error descriptions in details you find in the operation-manual.

European Service Center

HMC Europe GmbH, Hafing 21, D-84549 Engelsberg, Germany

Tel.: 0049 08634/625 994, Fax.: 0049 08634/625 996, email: info@hmc-europe.com

lock/unlock lever

to (right) „UNLOCK“-position.

V:\HMC-Europe\Beschreibungstexte\HV\Bedienungsanleitungen\Kurzbedienungsanleitungen\Kurzbedienungsanleitung engl..doc Stand Juli 2003

Loading...

Loading...