HMC HG User manual

HG-50/HG-80

OPERATING MANUAL

(Form: CE-014a-01)

WARNING

● Be sure to read this operation manual carefully and handle it properly.

Introduction

(1) No part of this document may be reproduced without permission.

(2) The contents of this document are subject to change without notice.

(3) This document has been carefully compiled. If you have any questions or require

information not covered in the manual, please contact :

HMC-Europe GmbH

Hafing 21

84549 Engelsberg

Tel.: +49 (0) 8634 625-994

Fax.:+49 (0) 8634 625 996

info@HMC-Europe.com

-1-

Read Carefully Before Using

● Determine the handling person responsible of this product.

● In this manual the following headings are applied to items to which great attention should be

given:

WARNING

CAUTION

IMPORTANT

△△△△

● Never use the autoclave to sterilize any of the following hazardous materials or substances with

NOTE

WARNING

alkali content. Sterilization of such objects can cause explosion, corrosion of the working

chamber or chamber piping, and deterioration of gaskets.

List of Hazardous Materials

① Explosive substances

・ Nitroglycol, nitroglycerin, nitrocellulose, and other explosive nitric esters.

: Items that will aid in proper operation of the equipment.

: Precaution indicating an imminent dangerous situation which if not

avoided may lead to death or serious injury.

: Precaution indicating a dangerous situation which if not avoided may

lead to moderate or slight injury.

: Indicates items you are strongly advised to obey.

・ Trinitrobenzene, trinitrotoluene, picric acid, and other explosive nitro compounds.

・ Peracetic acid, methyl ethyl ketone peroxide, benzoyl peroxide, and other organic peroxides.

② Ignitable substances

・ Metallic lithium, potassium, sodium, yellow phosphorous, phosphorus sulfide, and red

phosphorus.

・ Celluloids, calcium carbide (carbide), lime phosphide, and magnesium powder

・ Aluminum powder, magnesium powder, and metallic powders other than aluminum powder

・ Sodium dithionite (or sodium hydrosulfite)

③ Oxidizing agents

・ Potassium chlorate, sodium chlorate, ammonium chlorate, and other chlorates

・ ・ Potassium perchlorate, sodium perchlorate, ammonium perchlorate, and other

perchlorates.

・ Potassium peroxide, sodium peroxide, barium peroxide, and other inorganic peroxides

・ Potassium nitrate, sodium nitrate, ammonium nitrate, and other nitrates

・ Sodium chlorite and other chlorites

・ Calcium hypochlorite and other hypochlorites

④ Flammable substances

・ Ethyl ether, gasoline, acetaldehyde, propylene oxide, carbon disulfide, and other substances

whose flash points range from -30 to 0°C.

・ Methanol, ethanol, xylene, benzyl acetate (or amyl acetate), and other substances whose

flash points range from 0 to 30°C.

・ Kerosene, gas oil, turpenine oil, isopentyl alcohol (or isoamyl alcohol), acetic acid, and other

substances whose flash points range from 30 to 65°C.

⑤ Flammable gas (hydrogen, acetylene, ethylene, methane, ethane, propane, butane, and other

substances that are gases at a temperature of 15°C under 1 atmospheric pressure.)

-2-

●

When liquid with salt water and much salinity of salt agar etc.

spills in the chamber, blowing, discharge water in the

chamber and wipe up drop of water around the lid gasket

beautifully.

It causes the corrosion of the chamber and the piping when

leaving just as it is

●

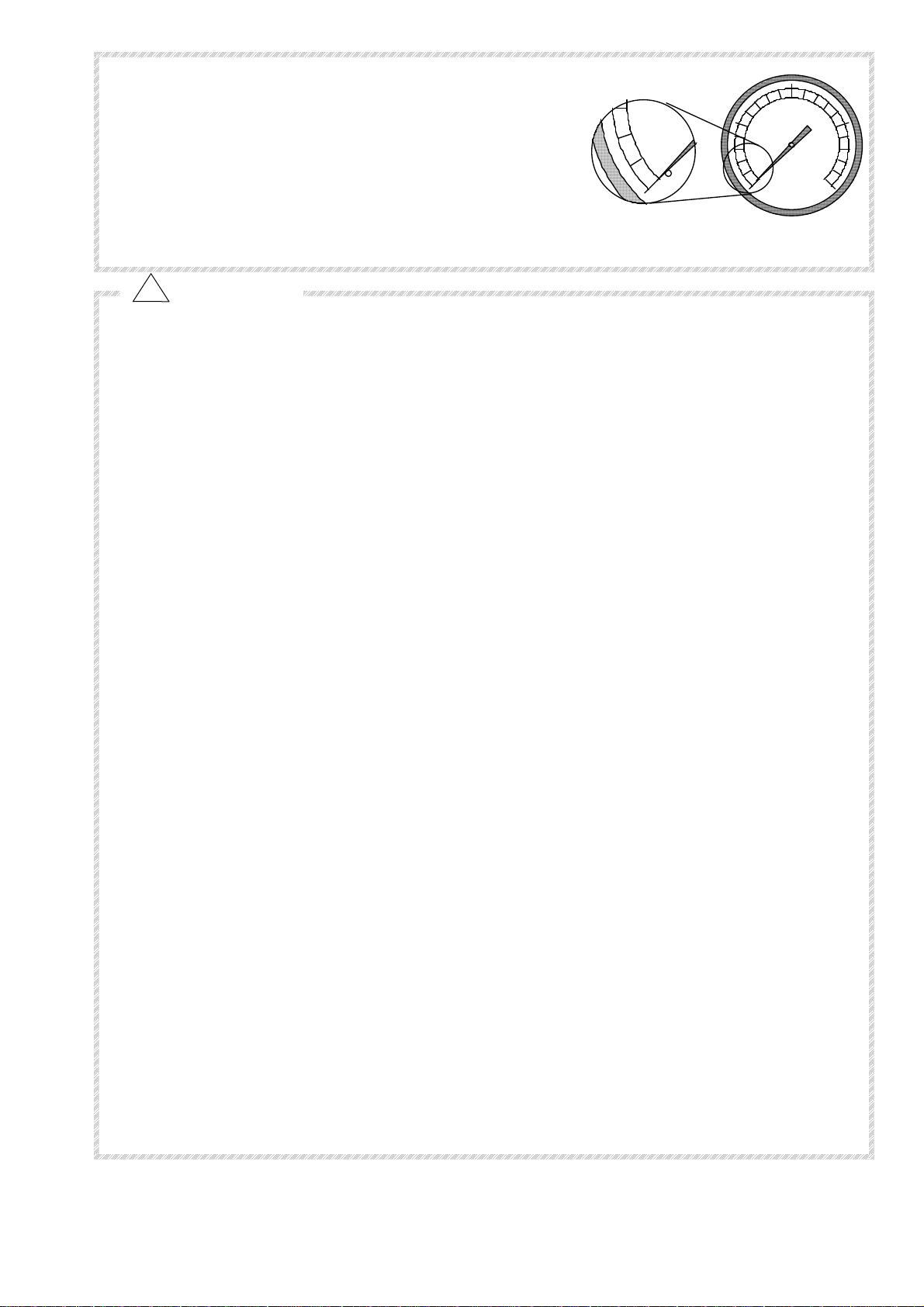

Check that the pressure is below "0MPa" before opening the

0

0.1

0

Pressure

gauge

0.2

0.3

0.4

lid.

●

Absolutely do not attempt to remodel or alter this product.

CAUTION

● Foreign matter (metals, liquid) may enter through the vent hole. Operating the equipment with

such foreign matter inside may cause trouble with the equipment, fire or electric shock.

● Do not forcibly bend, twist, tie or extend the power cord. Do not place heavy objects on the cord.

A damaged cord or exposed wire can cause fire or electric shock.

● Never connect the power cord to a power supply other than one of the rated voltage. Connection

to such a power supply can cause fire or electric shock.

● If grounded socket is unavailable, ground the equipment using a separate ground wire before

connecting the power cord to the power source.

● Connect the grounding cable correctly to the Type D or higher-grade grounding terminal. Never

connect the grounding wire to gas pipes or water pipes.

● Close the lid after confirming that no foreign matter is adhering to the section contacting the lid

gasket. Foreign matter in this section can cause vapor leaks.

● When using a waste processing bag or other kind of bag and disinfecting, place the bag in the

metal mesh holder and then insert it into the chamber. Using the bag “as is” can cause excessive

temperatures, pressures, lack-of-water, etc.

● Be careful not to pinch your hands when closing the lid.

● Do not touch the lid or lid cover when opening or closing the lid.

● Do not put your face or hands close to the chamber when lifting the lid after operations are

complete; steam will gush out of the chamber.

● The lid, chamber, gasket and panel are extremely hot immediately after the completion of

operation. Do not touch the equipment or you may get burned.

● Put on heat insulating gloves before removing a substance from the chamber. Do not put hands

into the chamber until the steam has been vented.

● Some time is required for liquids to cool. Be sure to check that the temperature has dropped

sufficiently before unloading a liquid from the chamber or burns can result.

● Do not unload the exhaust bottle or drain the chamber when the chamber is under pressure.

Boiling water or steam may gush out causing burns.

● Do not remove the exhaust bottle before water in the bottle has sufficiently cooled.

● If any abnormality occurs (e.g. abnormal sounds, smells, smoke), immediately shut the power off.

After checking to see that the abnormal condition does not continue, call our authorized

distributor in your region.

● If the display reading changes between the steps, turn the POWER switch off then on again. If

the problem continues, turn the power switch off and call our authorized distributor in your region.

-3-

How to Read this Manual

● This operation manual consists of the following sections covering the information required for

proper operation of the Autoclave HG-50.

Chapter 1. What is the Autoclave HG-50? :

This section describes the uses and features of the product and the names and functions of its

parts.

Chapter 2. Installation :

This section explains where the equipment should be installed and how to install it. The product

incorporates precision parts, so be sure to follow the instructions covered in this chapter.

Chapter 3. Operation Method :

This section illustrates how to change various set values, and describes operations before

starting the equipment and after automatic operation. This section also covers the display and

performance of the equipment during automatic operation.

Chapter 4. Maintenance and Service :

This section explains the methods for draining water from the exhaust bottle or chamber,

cleaning the body of the equipment, and parts replacement.

Chapter 5. Specifications

This section includes dimensions, power consumption and working range of the product.

Refer to this section as is required.

Chapter 6. Troubleshooting

This section covers troubleshooting procedures for the product. If you encounter a problem, read

this section first.

Appendix

This section contains information on the warranty and a glossary of terms that appear in the

manual. Please refer to this section when necessary.

-4-

CONTENTS

Introduction·················································································································· Ⅰ

Read Carefully Before User Inspection ···································································· Ⅱ

How to Read this Manual ··························································································Ⅳ

CONTENTS··················································································································Ⅴ

Chapter 1. What is the Autoclave HG-50?·············································1

1. Product Uses···········································································································1

2. Product Features·····································································································1

3. Names and Functions of Each Part·········································································1

Chapter 2. Installation·············································································3

1. Installation Instructions····························································································3

2. Installation Procedure······························································································4

Chapter 3. Operation Method·································································6

Basic Operation Method ··························································································6

1. Power······················································································································ 7

2. Pouring Water··········································································································7

3. Loading Substance··································································································8

4. Selection of Course and Program············································································ 9

5. Changing Set Values (Registering of Values by Customer)··································· 11

6. Changing Function Setting ····················································································14

7. Reservation Operation··························································································· 16

8. Starting Operation·································································································· 18

9. Unloading ··············································································································19

10. After Completion of Operation ·············································································19

11. To Interrupt Operation··························································································20

12. If Power Supply is Cut Off during Operation························································20

13. Operation of Cycles····························································································· 20

Chapter 4. Maintenance and Service···················································24

1. Draining Exhaust Bottle························································································· 24

2. Draining Chamber ·································································································25

3. Cleaning Chamber································································································· 25

4. Cleaning Body······································································································· 26

5. Water Supply to Cooling Tank················································································ 26

Chapter 5. Specifications ·····································································27

Chapter 6. Troubleshooting ·································································28

1. Error Detection (Alarms) ······················································································28

2. Early Troubleshooting···························································································· 29

Appendix································································································30

1. Fast wearing parts································································································· 30

2. Glossary ················································································································30

3. Limited Warranty ···································································································31

-5-

Chapter 1. What is the Autoclave HG-50?

1. Product Uses

・ The product is used to sterilize substances which can withstand high temperature and high

pressure steam such as tools of glass, ceramic, metal or rubber, water, media, reagents and

liquid medicines (Mode 1 – 3) .

・ The product is also used to liquefy media (Mode 4).

2. Product Features

・ In order to secure safety, the product is provided with a lid cover around the section that

becomes hot during operation,.

・ The lid of the product is opened and closed automatically. It is not necessary to bring your

hands near the chamber port to open or close the lid. The safety has been improved this way.

・ The agar cycle, which prevents solidification of sterilized media when they are not taken out

immediately, and the dissolution cycle, which dissolves solidified media, are provided.

・ When the exhaust valve (the opening of the exhaust valve) is set, fine exhaust is conducted

automatically after sterilization.

・ Steam that comes out of the exhaust valve during air release and exhaust is cooled in the

cooling tank to minimize the quantity of steam that is emitted into the room.

・ The temperature, at which the loaded substance cannot be taken out, can be set for safety within

the range of 60-97℃ for each cycle and program number.

・ A reservation timer is provided to permit operation startup at any desired time within the range of

1 hour to 99 hours later.

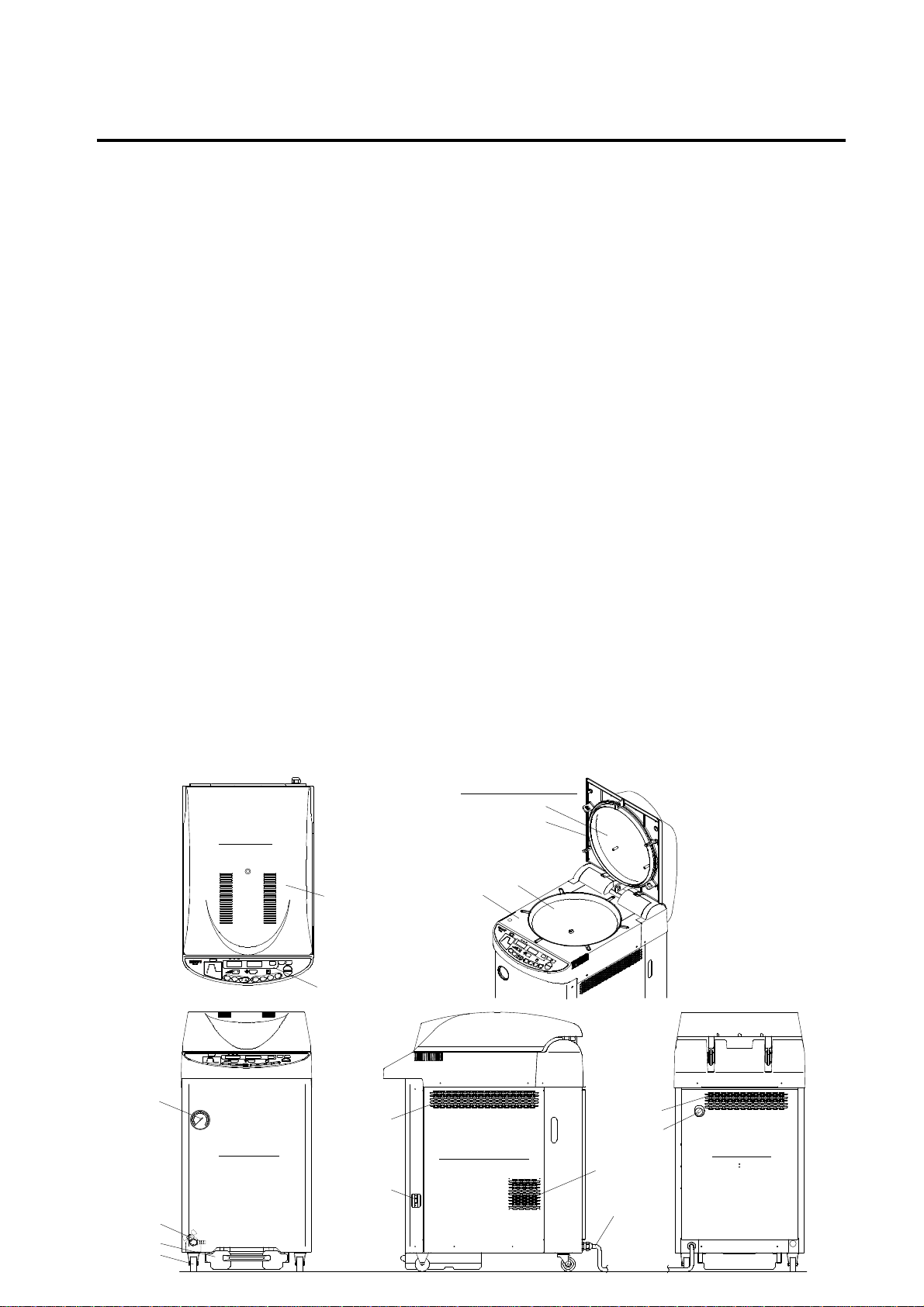

3. Names and Functions of Each Part

●

● Outer View of Body

●●

Top View

Lidcover

Operation panel

Whenthe lid is open

Gasket

Top panel

Chamber

Lid

Pressure gauge

Drain valve

Drain bottle

Caster

0.2

0.3

0.1

0.40

Front View

Vent hole

Main power switch

Right Side View

-6-

Vent hole

Coolingtank

Water filler port

Coolingfan

Powercord

Rear View

F. L

●

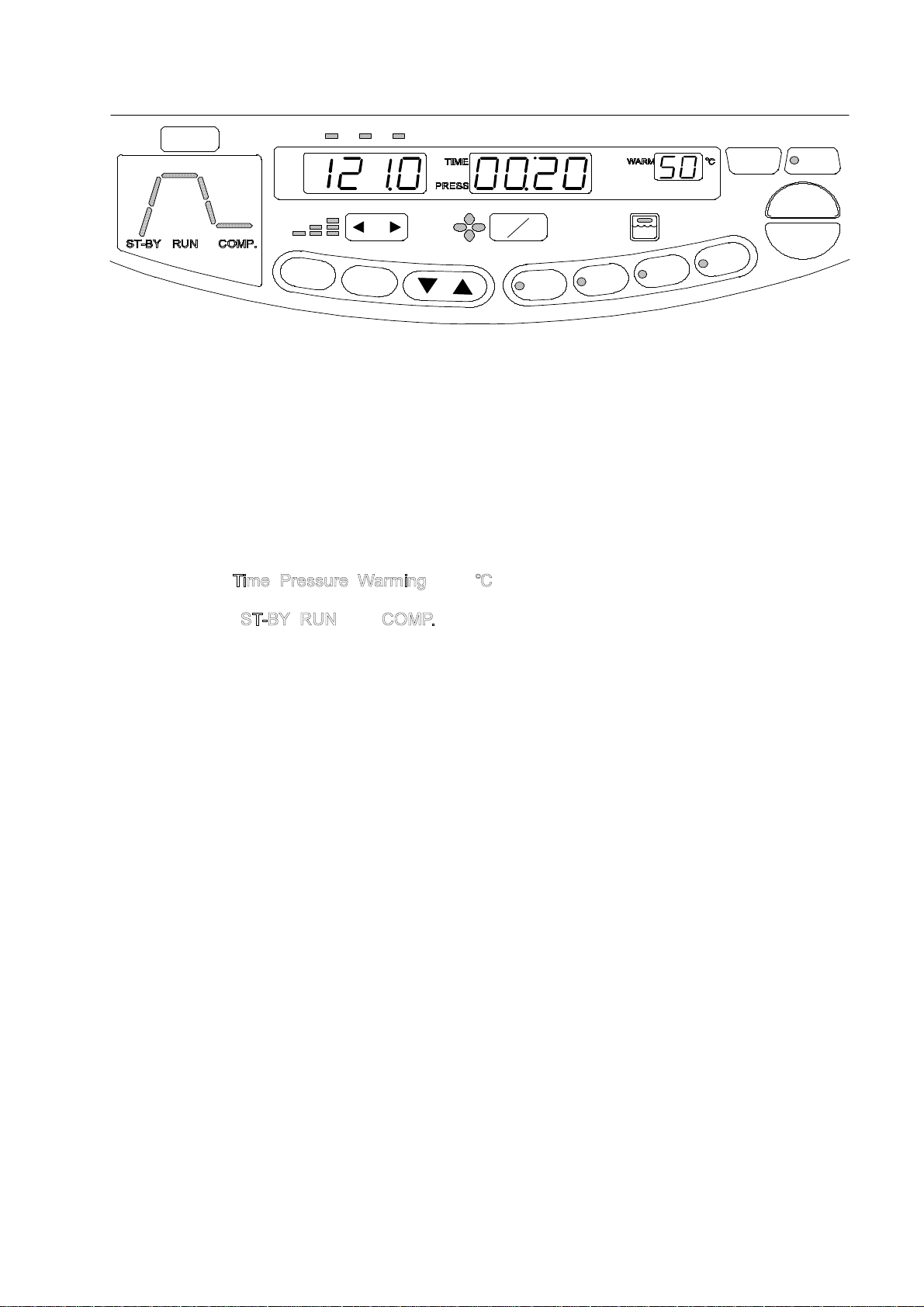

● Operation panel

●●

HEAT

⑧

POWER

STERI/DISSOL

EXHT.

⑥

⑤

WARM

PROGM1

TEMP

①

EXHT.

F

U

N

⑫

⑲

2 3

℃

④

⑮

C

.

S

E

T

⑬

FAN

⑯

⑭

② ③

Hr/min.

MPa

OFF

L

DRAINBOTTLE

Q

.

I

A

G

A

ON

④ ④

⑦

L

O

S

R

⑪

⑨ ⑩

LID

℃

CLOSE

L

O

S

S

I

D

D

I

LID

OPEN

⑰

START

STOP

⑱

① Digital Display (Temperature)

The digital display indicates the sterilization set time in the standby state, and it indicates the

chamber temperature during operation.

② Digital Display (Time and Pressure)

The digital display indicates the set time, reservation time, etc. in the standby state, and it indicates

the pressure inside the chamber, time remaining until completion of sterilization, and time

remaining until completion of warming during operation.

③ Digital Display (Warming)

The digital display indicates the warming set temperature, function number, etc. in the standby

state, and it indicates the error when it is detected.

④ Unit Display (

, , , and )

The unit corresponding to the current digital display illuminates.

⑤ State Display ( , , and )

The state display indicates the present state.

⑥ Cycle Display

The action cycle of the preset cycle illuminates, and the current cycle blinks.

⑦ Drain Bottle Display

The red light blinks when the drain bottle is full, and the green light illuminates when it is not full.

⑧ POWER Switch

Used to turn on or off the power to the autoclave.

⑨ LID CLOSE Switch

Used to close the lid.

⑩ LID OPEN switch

Used to open the lid. When the lid can be opened, a green light comes on, and when the lid

cannot be opened because the chamber is hot and highly pressurized, a red light comes on.

⑪ Cycle Switch

Used to select the cycle and program number.

⑫ FUNC. Switch

Used to change and confirm the setting of respective functions.

⑬ SET switch

Used to change and confirm the set value.

⑭ Set Value Increase/Decrease Switch (▲ ▼)

Used to increase or decrease the set value.

⑮ Exhaust Level Switch (ì í)

Used to change the exhaust level.

⑯ FAN Cooling ON/OFF Switch

Used to change fan cooling ON/OFF setting.

⑰ START Switch

Used to start operation.

⑱ STOP Switch

Used to stop operation.

⑲ PROGM Display

The display indicates the present program.

-7-

Chapter 2. Installation

IMPORTANT

● If the equipment is installed in a place which is 800m or higher than sea level (i.e. under low

pressure in mountainous areas), the settings must be changed. In this case, be sure to contact

our authorized distributor in your region. Do not use the equipment before changing.

● When relocating the product, close the lid so that it will not move, and then remove the drain

bottle and power cord.

1. Installation instructions

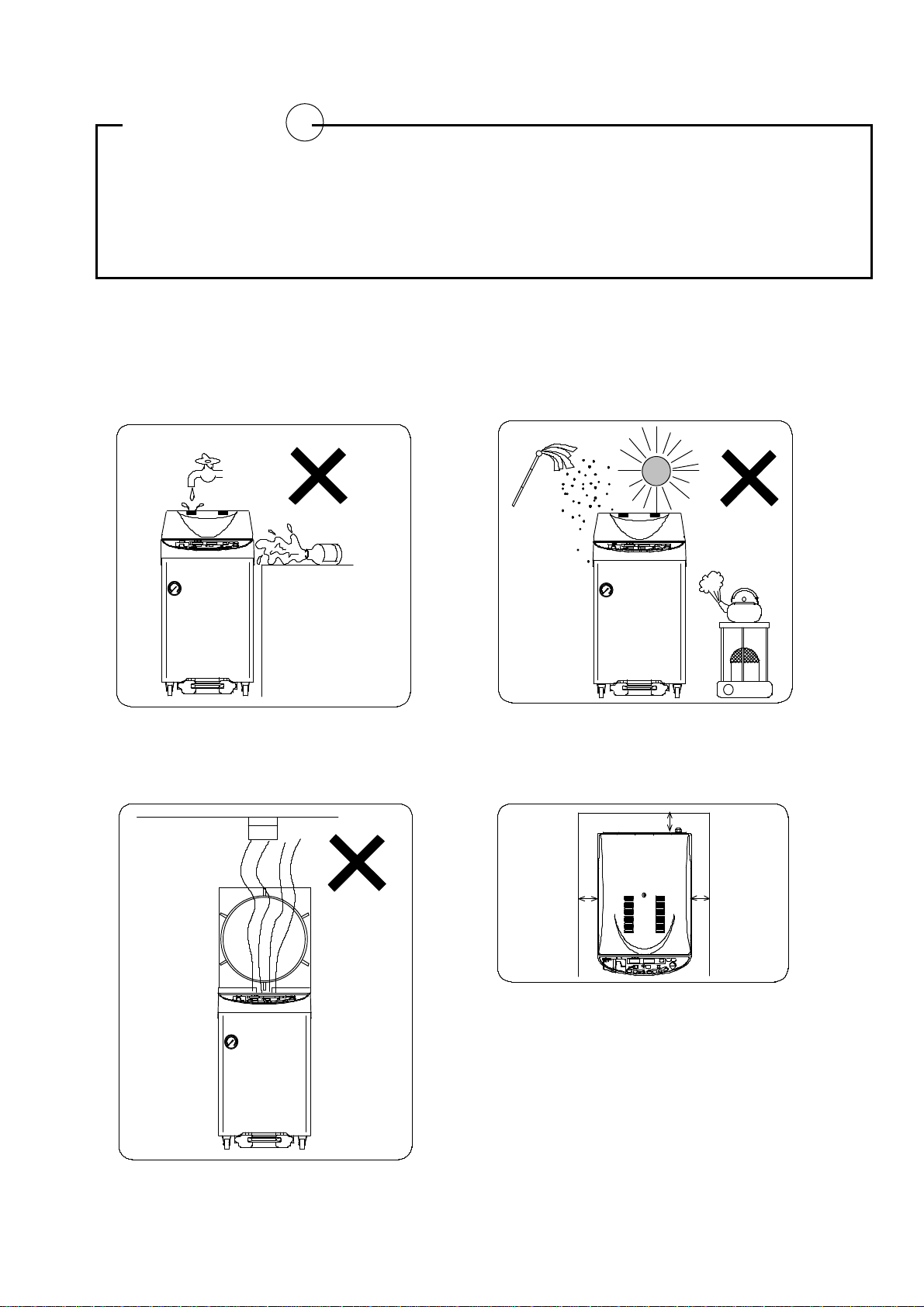

①

Avoid installing the equipment in a place where its

body may be exposed to water or chemicals, or

where corrosive and explosive gases may be

produced neareby.

②

Avoid installing the equiopment in a place which is

exposed to hight humidity, direct sunlight or much

dust.

0.2

0.3

0.1

0.40

③

Avoid placing the equipment directly under a fire

detector. If you open the lid immediately after

completion of operation, steam comes out of the

working chamber, and may activate the detector.

0.2

0.3

0.1

0.4

0

0.2

0.3

0.1

0.40

④

Arrange the equipment with a clearance of 10 cm

or wider on the right side and 12 cm or wider on

the rear side to prevent the vent hole from

being blocked.

12cmor more

10cmor more

⑤

Avoid an installation place which is subject to impact

10cmor more

or vibration.

⑥

Place the unit in a level, firm place.

⑦

Avoid installing in a place which is subjected to a room

temperature of 5℃or below or 35℃or above.

-8-

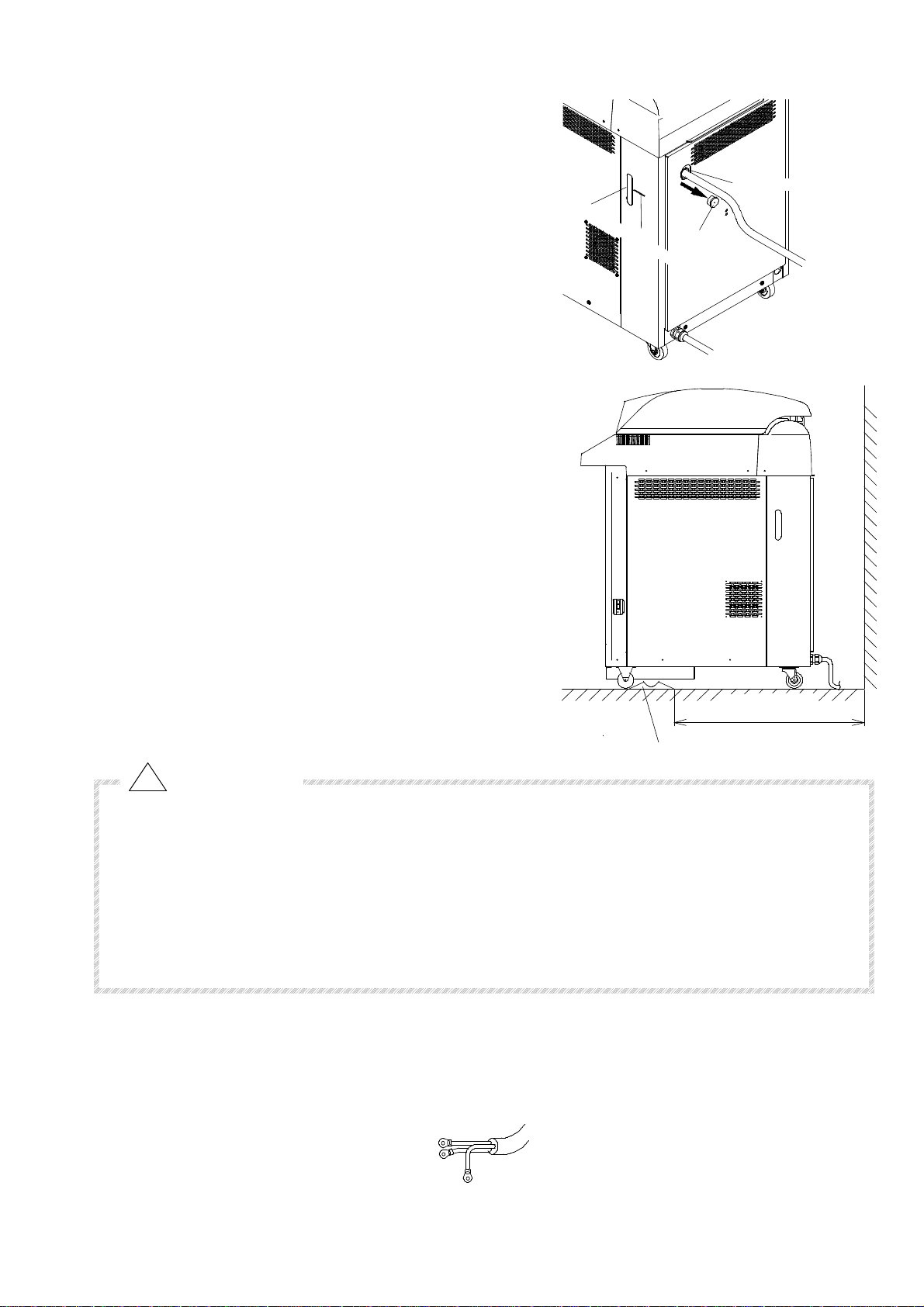

2. Installation Procedure

① Pour water into the cooling tank.

・ Remove the cap from the water filler port at the

back of the unit, and pour water through the

water filler port by using a hose, etc. up to the

center of the level confirmation window at the

side of the unit.

After water supply, return the cap back to the

original position.

(Hoses, etc. are not provided. Please prepare

them by yourself.)

② Put casters on the caster stoppers so that the

unit will not move.

・ Place two casters at a position more than 64 cm

away from the wall, and push the unit so that the

front casters will be on the stoppers.

・ Be sure to set the caster stoppers, otherwise the

full water function of the drain bottle may not be

activated.

③ Connect the power cord to the rated power supply.

W

a

t

e

r

l

e

v

C

e

l

e

c

n

h

t

e

e

r

c

k

Cap

w

i

n

d

o

w

Water filler port

・ Be sure to connect the grounding wire.

64 cm or more

CAUTION

Caster stopper

● Do not forcibly bend, twist, tie, or extend the power cord. Do not place heavy objects on the cord.

A damaged cord or exposed wire may cause fire or electric shock.

● Never connect the power cord to a power supply with a voltage other than the rated voltage.

Connection to such a power supply may cause fire or electric shock.

● If not plugging the sterilizer into a grounded socket, ground the equipment separately before

connecting it to the power source.

● Never ground to a gas pipe or vinyl chloride water service pipe.

・ Connect the unit to a power unit of as below and to ground the Green/Yellow grounding wires.

・ AC100V: 20Amp or more, AC110V: 19Amp or more, AC120V: 17Amp or more,

・ AC220V: 10Amp or more, AC230 and AC240V : 9Amp or more.

CONNECT TO RATEDVOLTAGE

White

Black

Connect

to ground

Green/Yellow

-9-

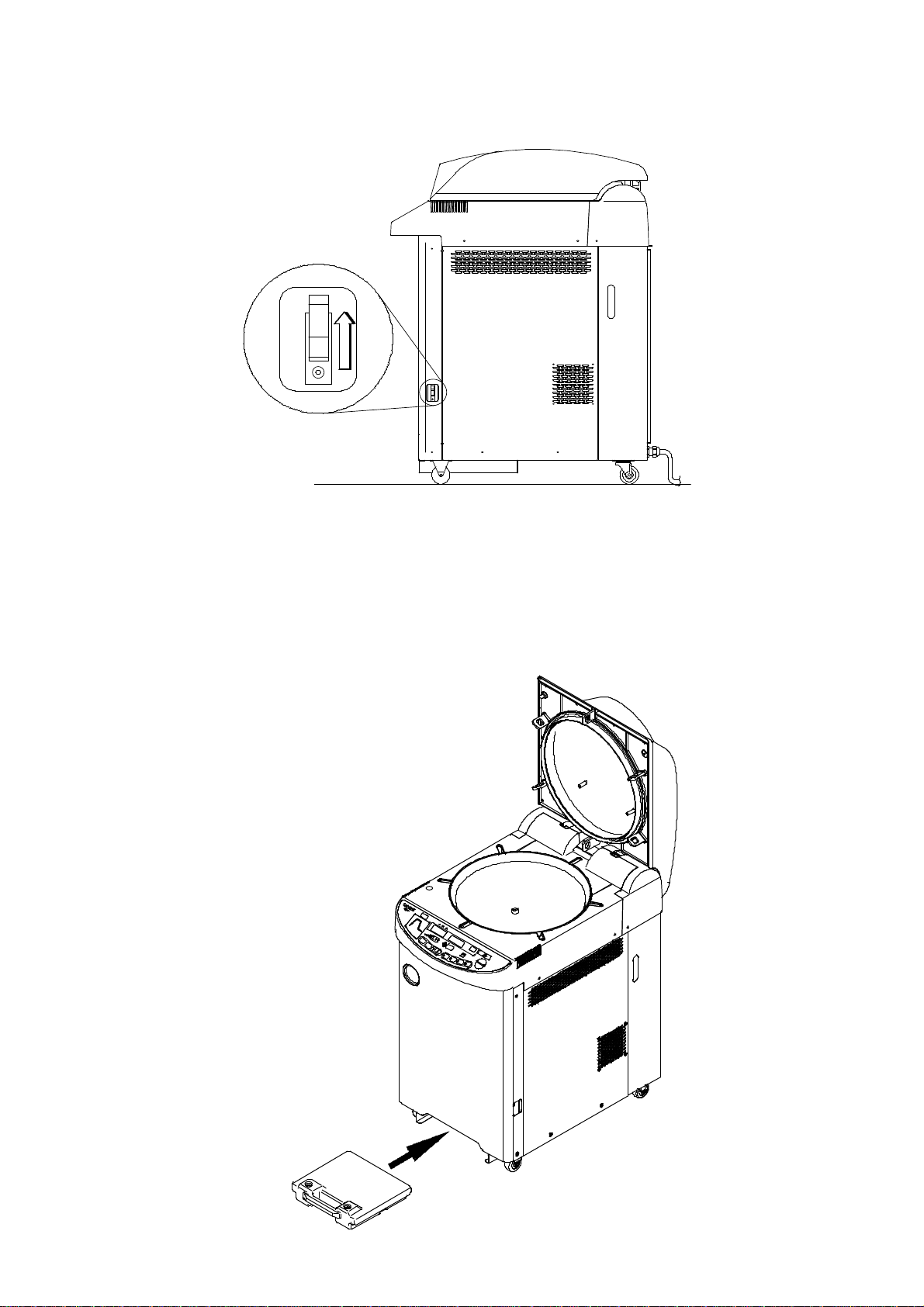

④ Turn ON the main power switch.

・ Raise the lever of the main power switch at the right side of the unit.

Main powerswitch

Raise.

⑤ Referring to “Chapter 3, Operation Method”, open the lid and take out the accessories.

⑥ Place the bottom plate in the chamber.

⑦ Attach the drain bottle.

・ Check that there is no foreign substance or irregularity on the floor where the drain bottle is

to be set.

Drain bottle

-10-

Chapter 3. Operation Method

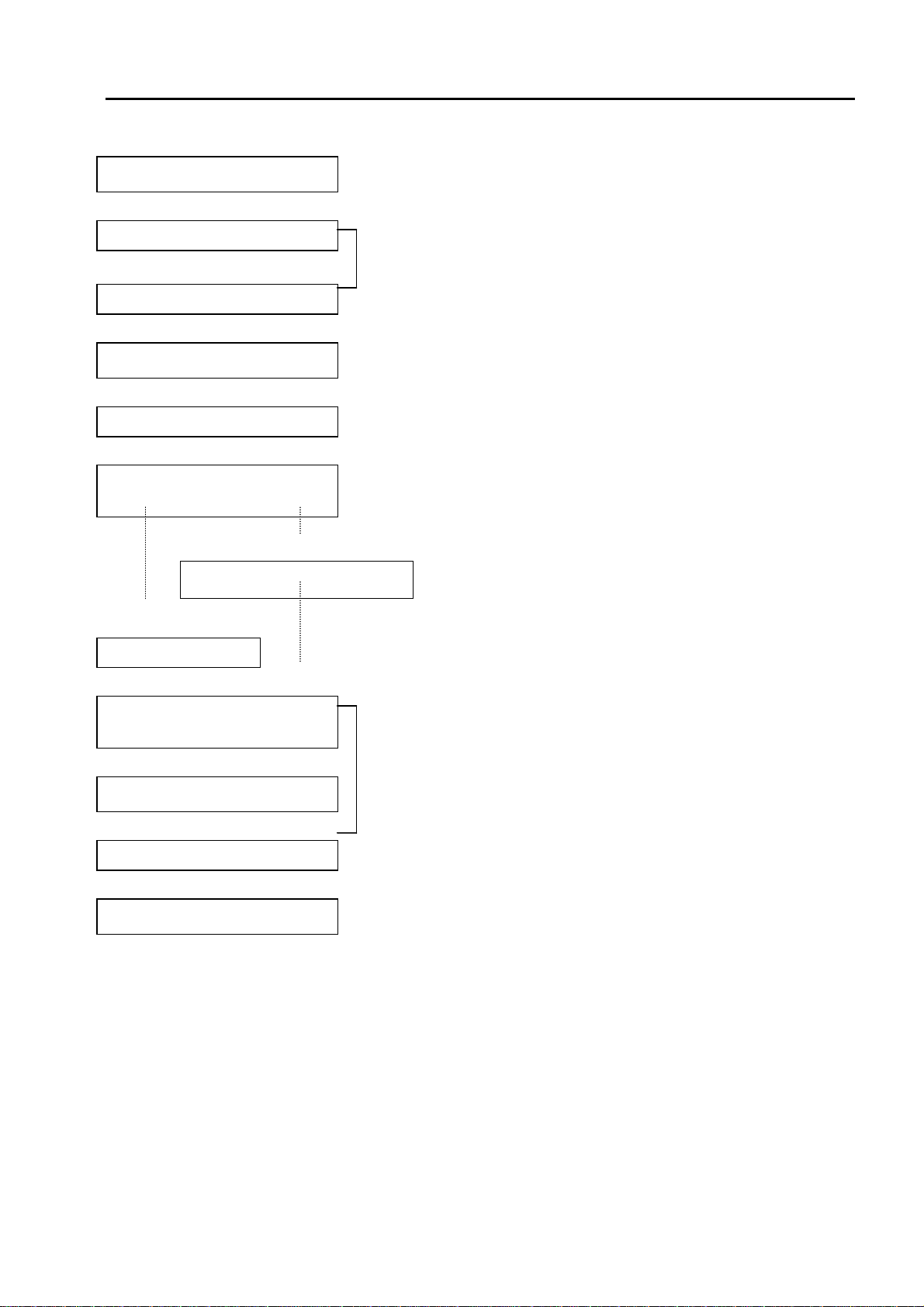

Basic Operation Method

Turn “ON” Power Switch

▼

Open the lid

▼

Pour water

▼

Load substance

▼

Check and select cycle

▼

Check and change set

values

▼

Set Turn-on Timer

▼

――――――

―――――

――――――

(When starting operation by Turn-on Timer)

See "1. Turning ON Power Switch” on page 7.

See "2. Pouring Water" on page 7.

See "3. Loading Substance" on page 8.

See "4. Selection of Cycle and Program" on page 9.

See "5. Changing Set Values" on page 11.

See “7. Checking and Setting of Turn-on Timer”

on page 16

Start operation

▼ ▼

Check if operation is

completed

▼

Open the lid

▼

Unload substance

▼

Turn “OFF” Power Switch

―――――

――――――

See "8. Starting Operation" on page 18.

See "9. Unloading" on page 19.

See "10. After Completion of Operation" on page 19.

-11-

Loading...

Loading...