Thermo Shakers and BlockThermostats

with Smart Control

MKR 13 – MKR 23 – MHR 13 – MHR 23–

MHL 23 – TK 23

Operating Manual

Bedienungsanleitung

2

Content

1. Basic Data ................................................................................................ 4

Safety .............................................................................................................4

Warranty ........................................................................................................5

Disclaimer of warranty ...................................................................................5

Important information ...................................................................................5

Environmental conditions……………………………………………………….………………….6

Temperature accuracy ...................................................................................6

2. First Steps ................................................................................................ 7

Setup ..............................................................................................................7

3. Operation ................................................................................................ 7

Parameter setting ..........................................................................................7

Programming function .................................................................................13

4. Assembly of Accessories ...................................................................... 19

Anti-Condensation Plate BA 24 / 96 .............................................................19

Data transfer ................................................................................................20

5. Troubleshooting ................................................................................... 23

6. Maintenance ......................................................................................... 24

Cleaning ........................................................................................................24

Service ..........................................................................................................25

7. Technical data ....................................................................................... 26

8. Article description blocks & accessories ............................................ 30

9. Explanations……………………………………….…………………………………………………32

3

Inhaltsverzeichnis

1. Basisdaten ................................................................................. 33

Sicherheit ............................................................................................ 33

Gewährleistung und Garantie ............................................................... 34

Haftungsausschluss .............................................................................. 34

Wichtige Hinweise ............................................................................... 34

Umgebungsbedingungen ...................................................................... 35

Temperaturgenauigkeit ........................................................................ 35

2.

Erste Schritte ............................................................................. 36

Inbetriebnahme ................................................................................... 36

3.

Bedienung ................................................................................. 37

Einstellung Parameter .......................................................................... 37

Programmierungsfunktion .................................................................... 43

4.

Montage von Zubehörteilen ....................................................... 50

Antikondensplatte BA 24 / 96 ............................................................... 50

Datentransfer ...................................................................................... 51

5.

Problembehebung ..................................................................... 54

6.

Instandhaltung .......................................................................... 55

Reinigung ............................................................................................ 55

Service ................................................................................................ 56

7.

Technische Daten....................................................................... 57

8.

Artikelbezeichnung Blöcke & Zubehör ........................................ 61

9.

Erläuterungen ............................................................................ 63

Basic Data

The HLC by DITABIS Thermo Shakers and Block Thermostats are used for tempering and mixing of solutions in closed reaction tubes and plates. Please pay

attention that the target temperature of the samples should not exceed the

boiling point of the solution, which should be heated. Please consider this

when setting the target temperature via the software of the Thermo Shaker

or Block Thermostat. If there are any uncertainties regarding the liquids,

which should be heated or cooled, please contact DITABIS. The HLC by DITABIS devices are meant for indoor usage only. Please use only HLC by DITABIS

accessories or accessories recommended by HLC by DITABIS.

Safety

The systems comply with the standards and directives mentioned in the applicable CE declaration.

Please take note of the following safety measures:

Do only connect the system to an earthed mains power

socket of 230 V, 50 Hz.

Do not place hot blocks on inflammable or not heat-resistant

surfaces.

Make sure to only use containers in the block which are

suitable for the desired temperature range.

If liquid gets into the system, immediately pull out the plug

and contact our service department to ensure complete

safety.

Please do not touch or transport hot systems.

Contact with highly flammable fluids must be avoided.

The ventilation of the device must not be blocked. To ensure

the proper ventilation at all times please consider a minimum distance of 10 centimetres on each side of the device.

Damaged mains cable should only be replaced with equal

ones.

4

5

Warranty

All functions of the systems have been tested thoroughly. After that, the

system and the accessories were packed carefully in perfect condition. If,

however, any damages or defects are detected during installation or

setup, please contact your local dealer or the DITABIS service department.

The DITABIS contact information can be found at www.ditabis.de (see also

our Terms and Conditions at www.ditabis.com). If used under normal laboratory conditions according to the Operating Manual, DITABIS grants a warranty

of one year, starting with the day of shipment.

Disclaimer of warranty

In case of unspecified use of the device, the manufacturer assumes no responsibility.

Important information

This manual complies with the standards and directives mentioned in the EN

DIN 61010-1 Norm. IQ, OQ and PQ documents are available on request.

The systems are provided with a high-precision self-optimising

temperature controller. Due to the self-optimisation it might occur that the set temperature is exceeded in individual cases.

Please note, that by heating your samples dangerous gases may

be emitted. In this case, the device must be used with an extractor hood.

If the ThermoMixers are operated with a high shaking frequency,

the vibrations of the system might transmit to the underground.

Please do consider this when placing the system.

i

6

Contact with highly flammable liquids must be avoided. The exchangeable block may be hot.

The ventilation of the device must not be blocked. To ensure the

proper ventilation at all times please consider a minimum

distance of 10 centimetres on each side of the device.

Environmental conditions

The ideal area of operation of the devices is achieved at 80% relative air

humidity at most and lays between +3°C - +50°C ambient air temperature.

This range should not be underrun or exceeded.

Temperature accuracy

Every HLC by DITABIS system is calibrated with a gauged high-precision temperature measuring device to temperature accuracy and reproducibility. This

calibration is performed at a room temperature of +20,0°C at 10 different

temperature calibration points and oil as a reference liquid. HLC by DITABIS

reaches a very high accuracy by measuring the block temperature directly

inside the block. It can, however, not be avoided that the room temperature

affects the sample temperature in case of a large temperature difference

between room and block temperature. The anti-condensation plate reduces

this effect. We recommend using the anti-condensate plate BA 24 / BA 96 or

the tempering tub BT 01 / BT 02. When setting a process time, please note

that the sample temperature is always reached a little later than the displayed block temperature.

7

First Steps

Setup

Plug the mains cable in the IEC socket on the back of the system and connect

it with the mains power 230 V, 50 Hz via a Schuko socket. Please make sure

that you are using earthed mains power sockets.

Changeable blocks

At delivery, the changeable blocks are packed separately. Place the blocks on

the tempering plates and take care of the proper alignment of the central

threaded bolt and the two small corner bolts ensuring that the block lays

accurately on the tempering plate. Then attach the block with the enclosed

socket screw tightly at the bottom of the tempering plate to get the block

fixed for shaking and to obtain even better temperature accuracy. Check the

tight attachment of the block by pulling it up

Never start the process without the block being tightly attached. Do always

use two blocks for two-block systems, even if only one of them is used. This

ensures safety as well as a smooth shaking operation.

Switch on the system with the mains switch on the back of the system. The

start menu will be displayed. The green LED turns on, on the right sight of the

touch panel, as soon as a process is running.

Operation

Parameter setting

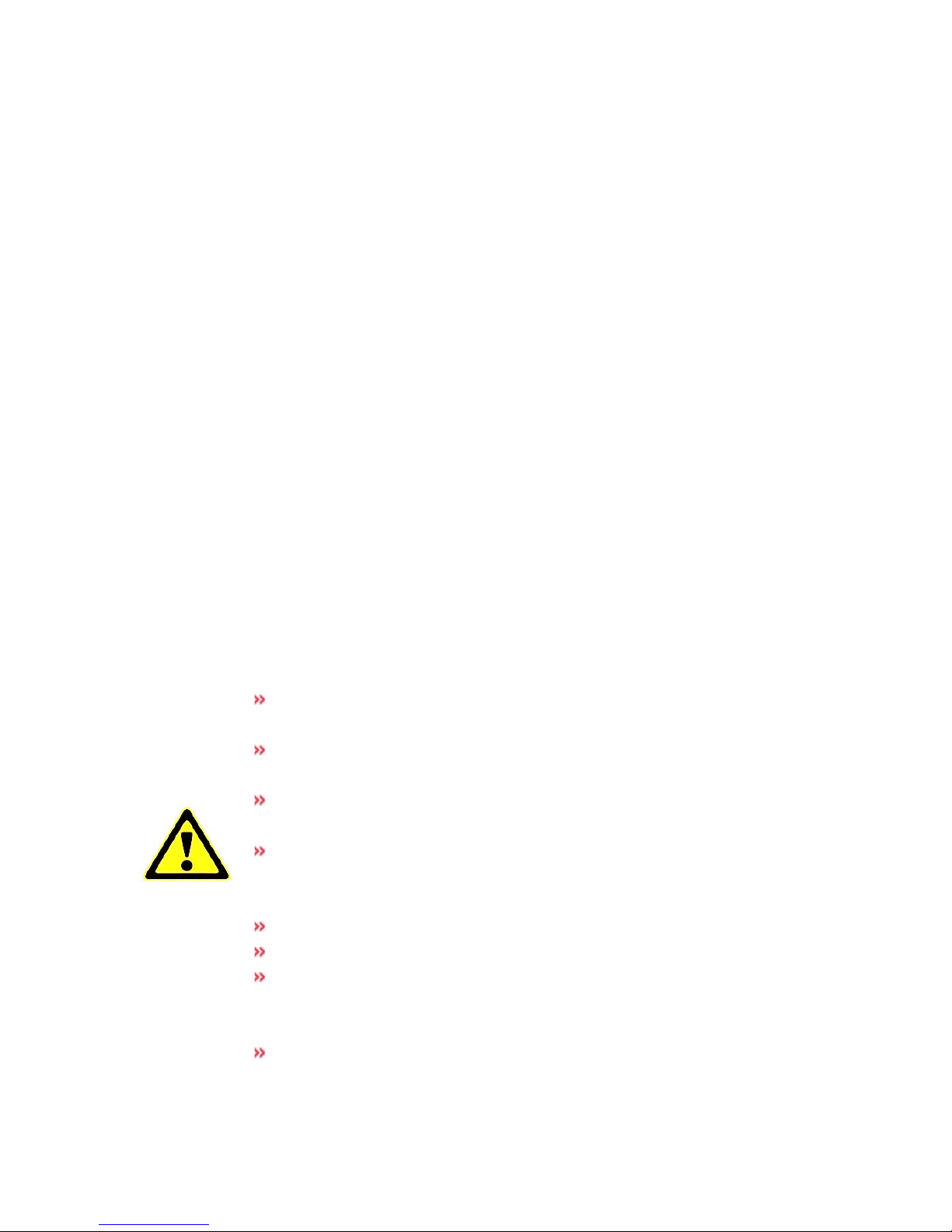

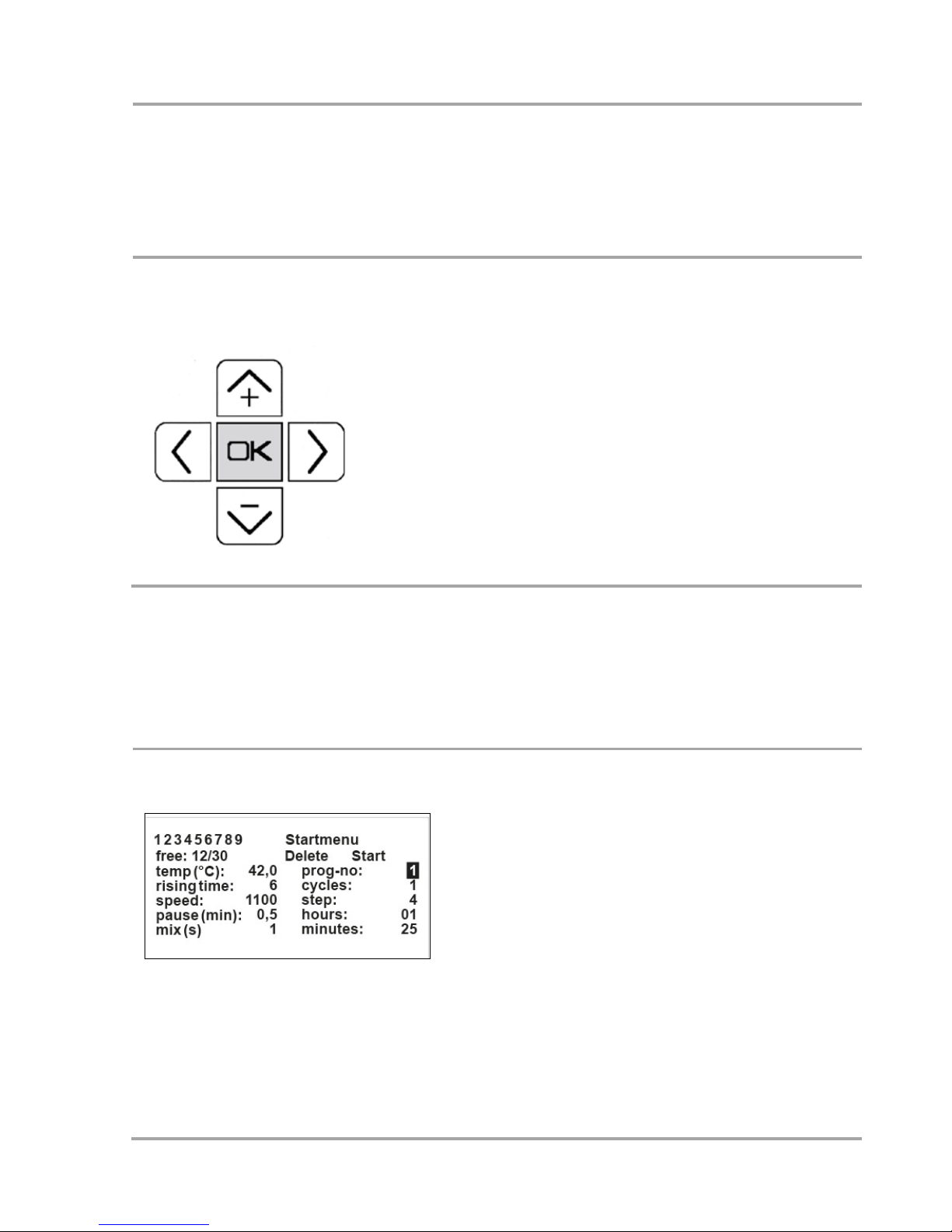

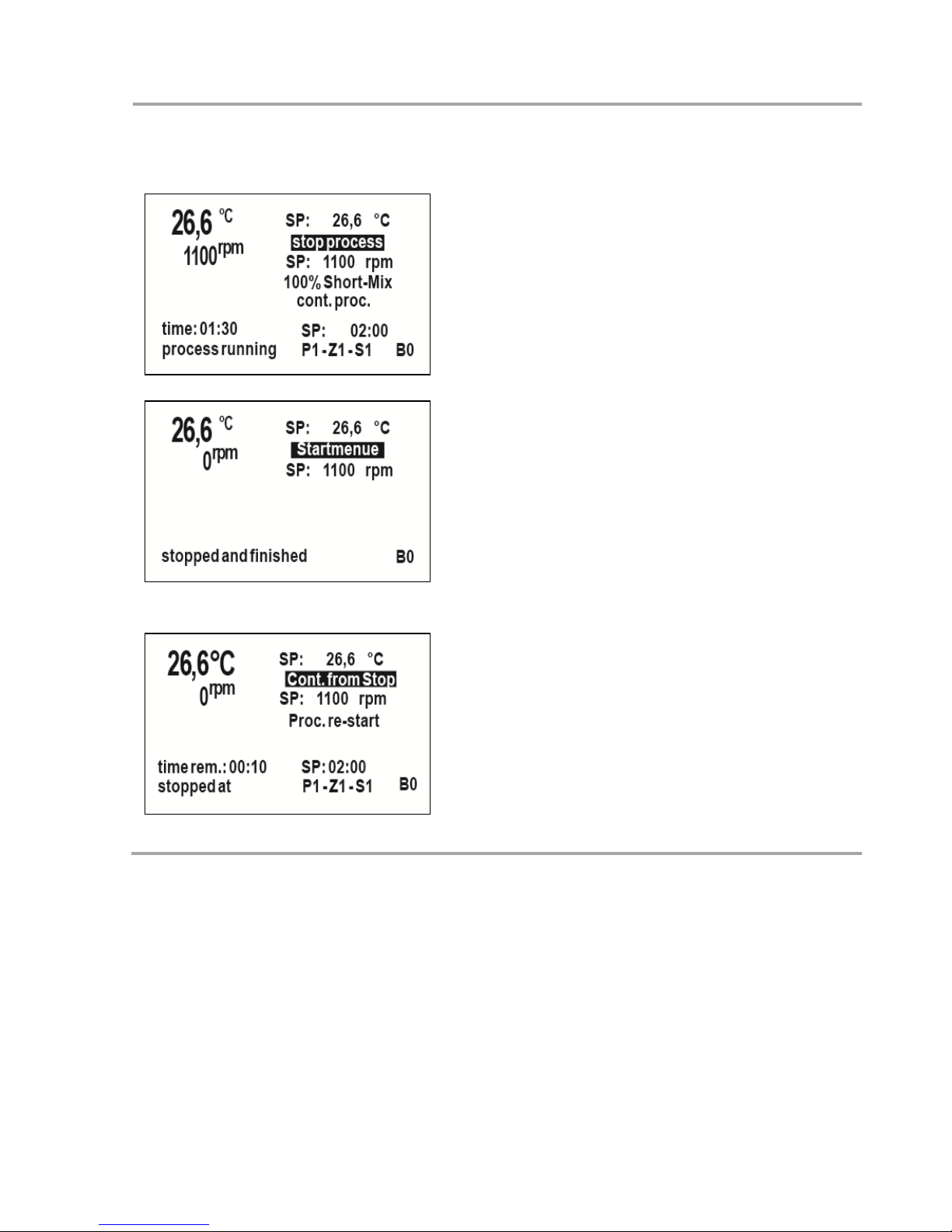

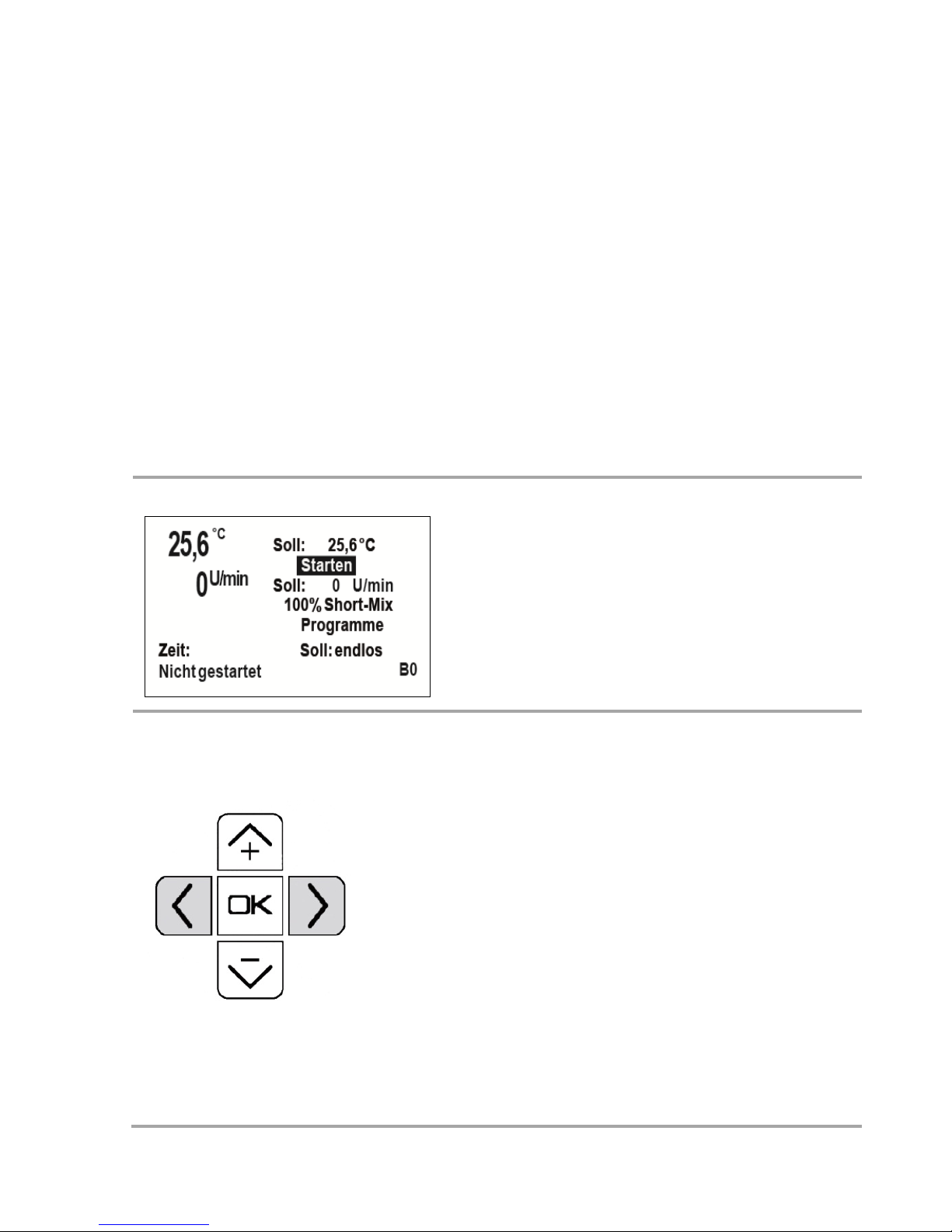

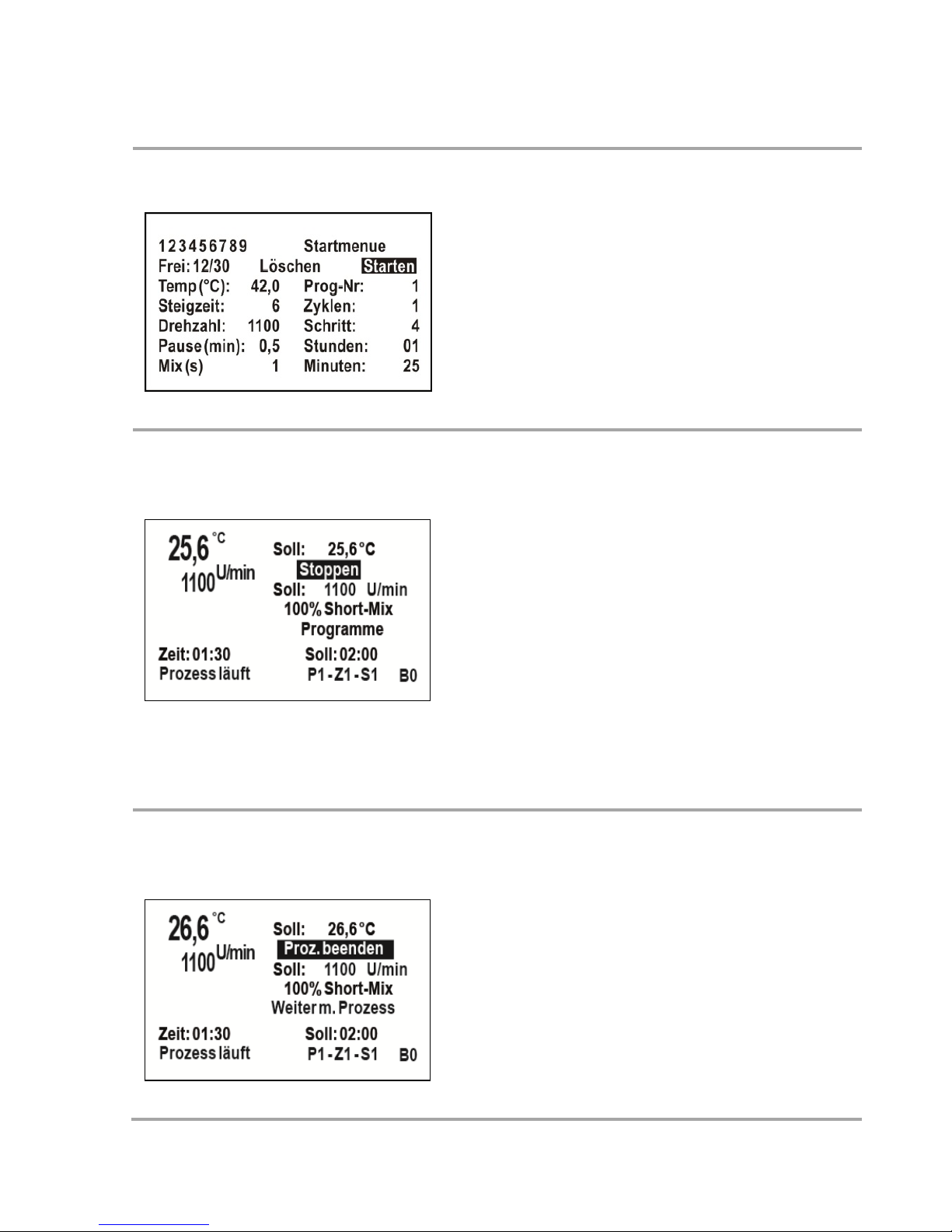

Start menu

This menu is displayed after the power is

switched on, after abortion or after the normal completion of a process. The last set

values are retained even after the switch-off

of the system.

8

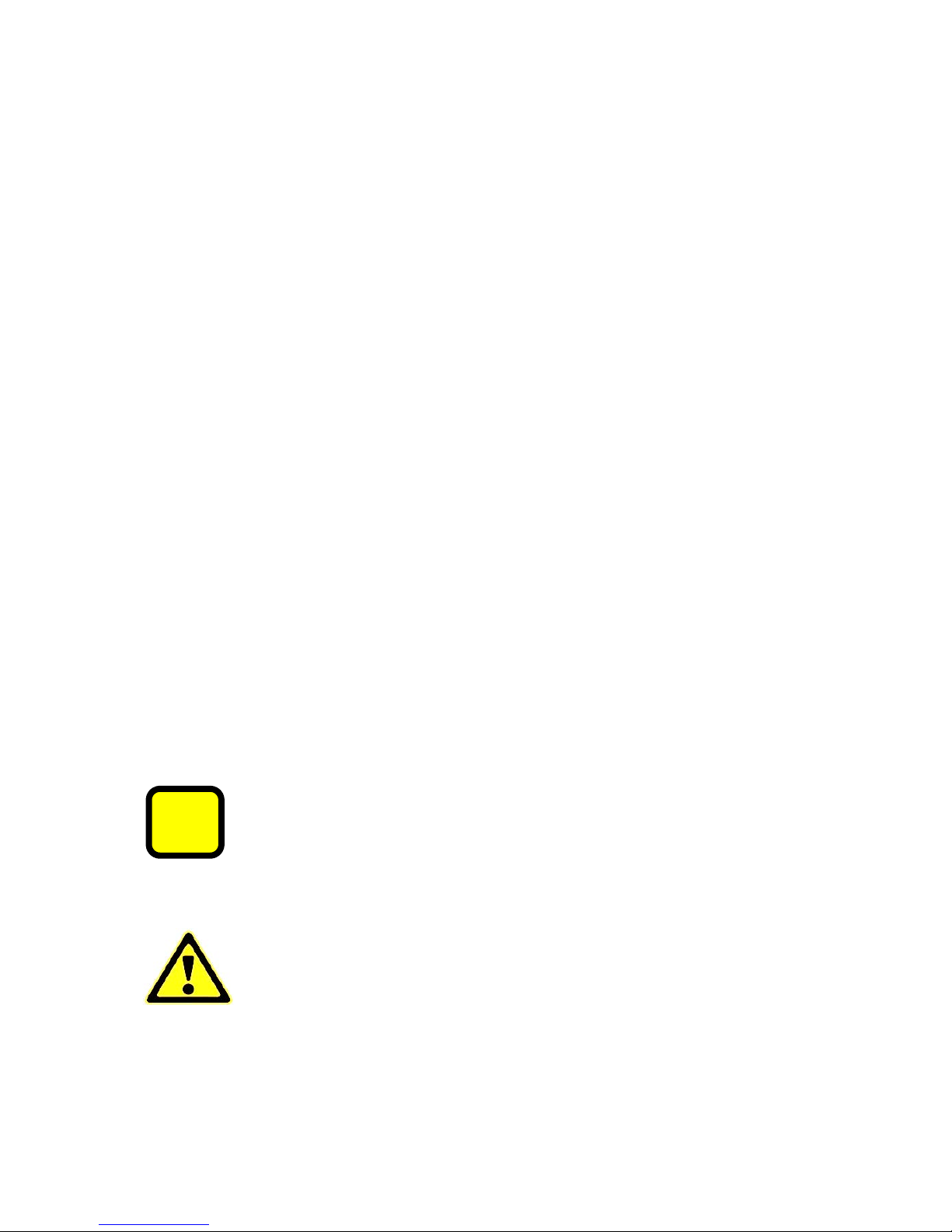

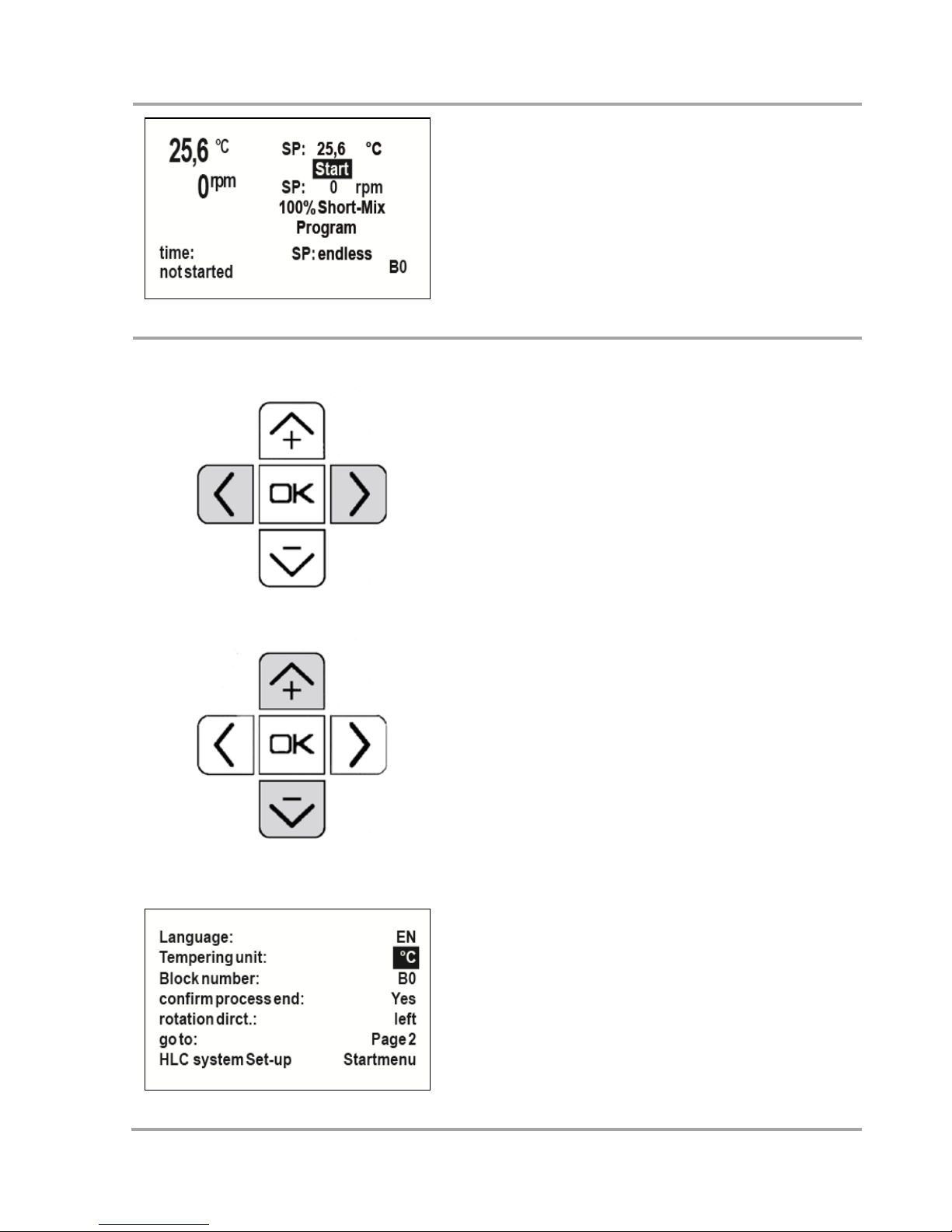

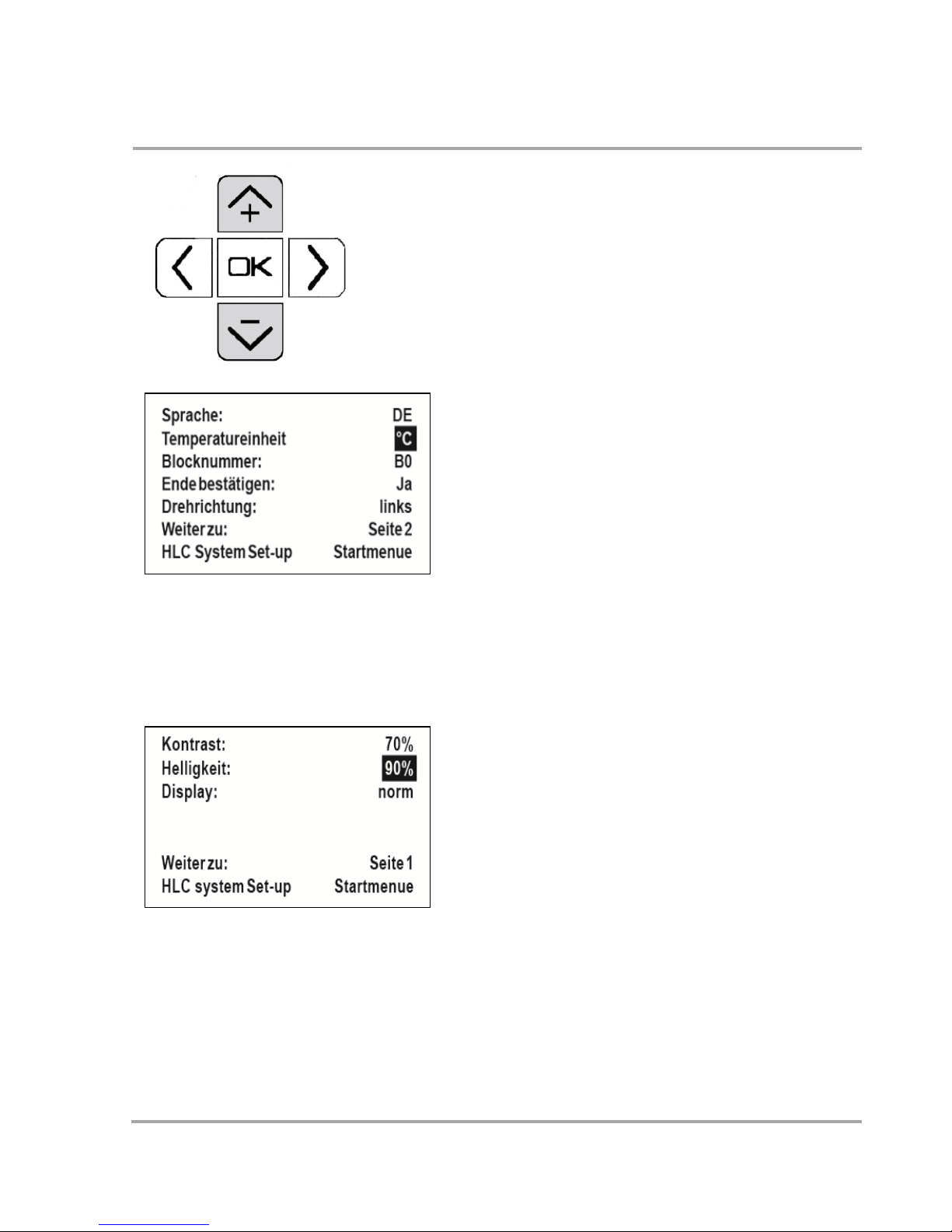

Setup menu

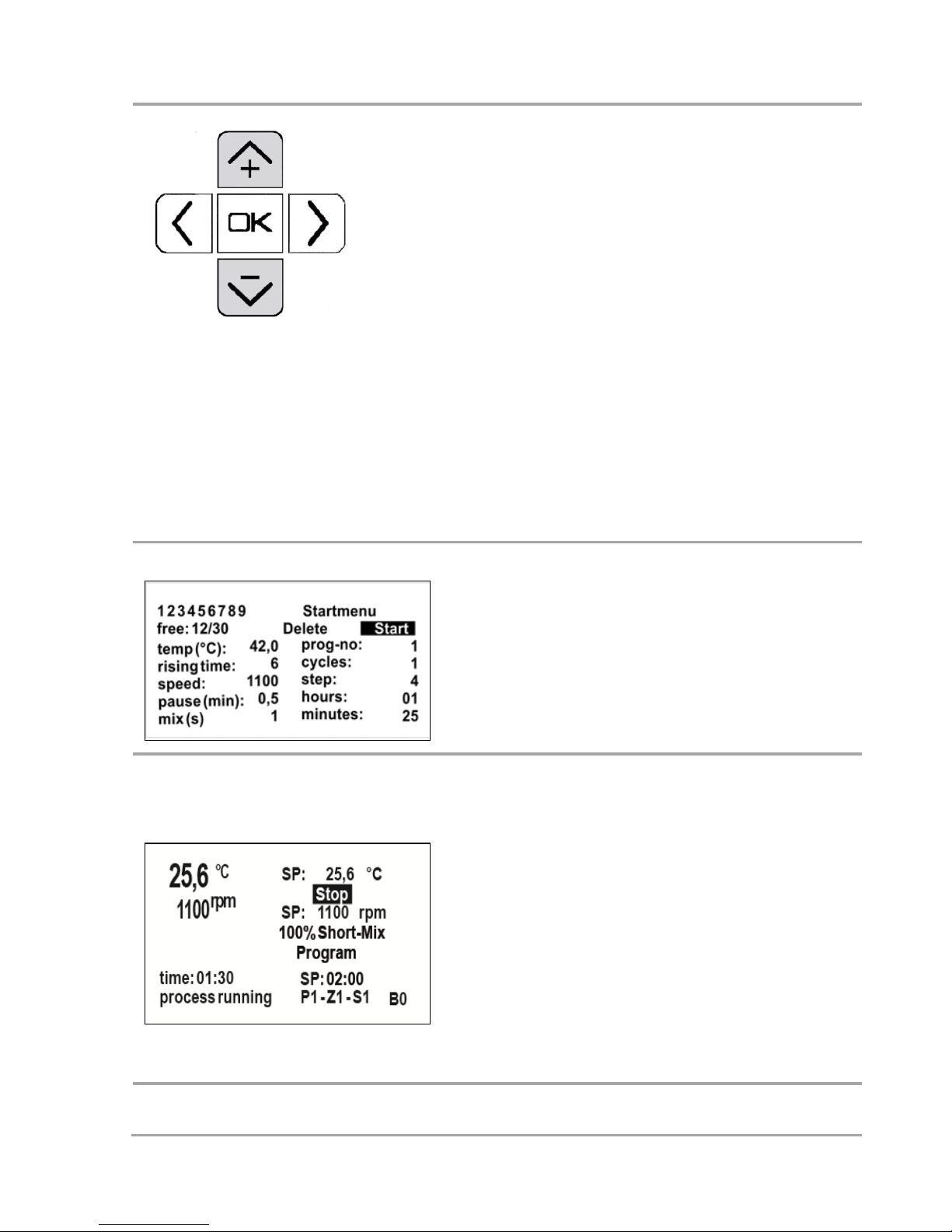

Push the left and right arrow keys at the

same time, then the setup menu is displayed.

With + and – the values can be selected for

setting.

The selected box flashes, with ok it will be

permanently set for changing.

With the keys + and –, the input or the values

can be changed. If an input is confirmed with

ok, the box will highlighted flashing again.

With confirming the button Start menu, the

start menu is displayed again.

The following values can be adapted:

Page 1:

Language: English, German, French, Spanish

Tempering unit: °C or °F

Block number (10-point calibration)

Confirm end:

Yes: at the process end, a signal is audible

until the ok key is pushed. Until then, the

process runs with the previous data.

No: the process ends without confirmation.

9

Rotation direction: right, left

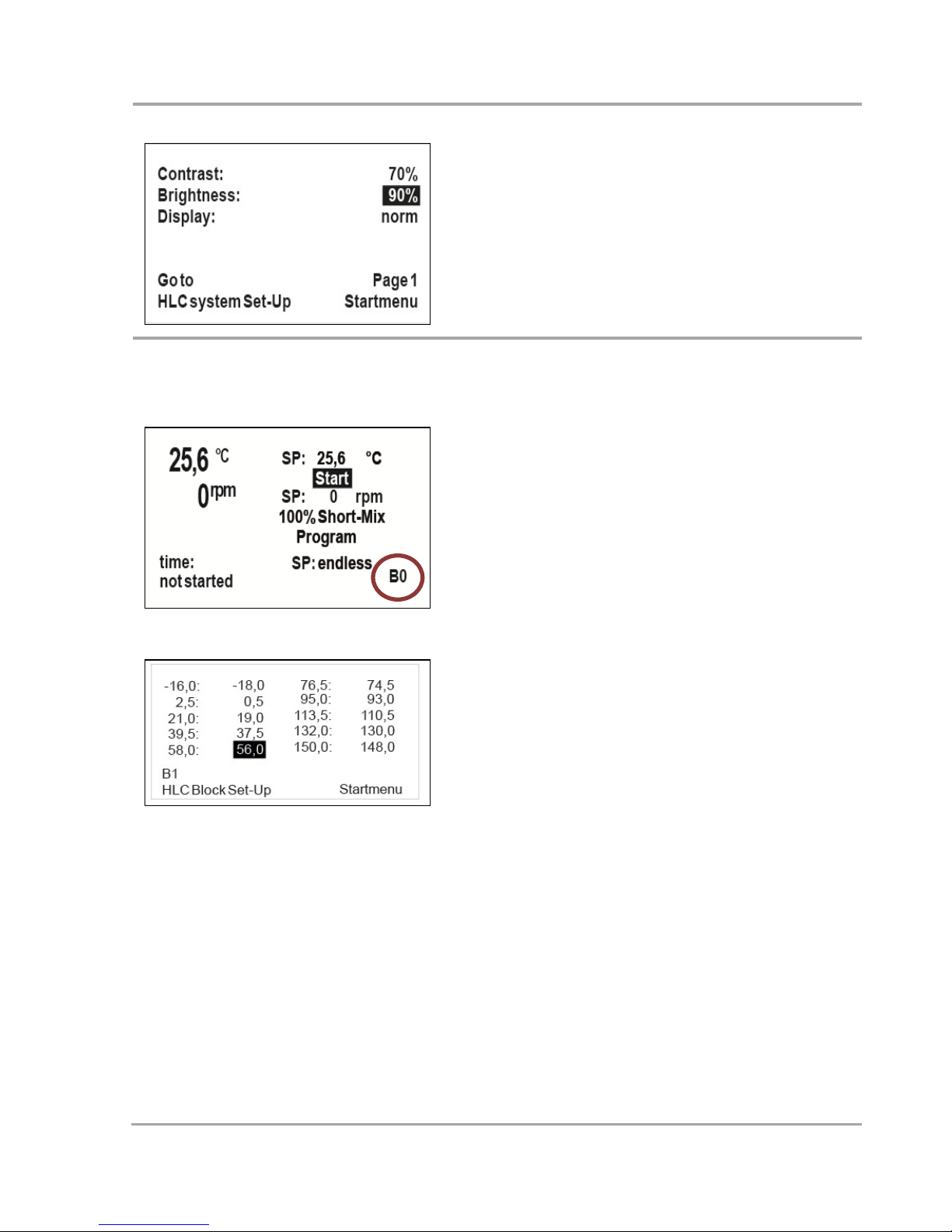

Page 2:

Contrast: Mentioned in %

Brightness: Mentioned in %

Display colour: Normal - inverse

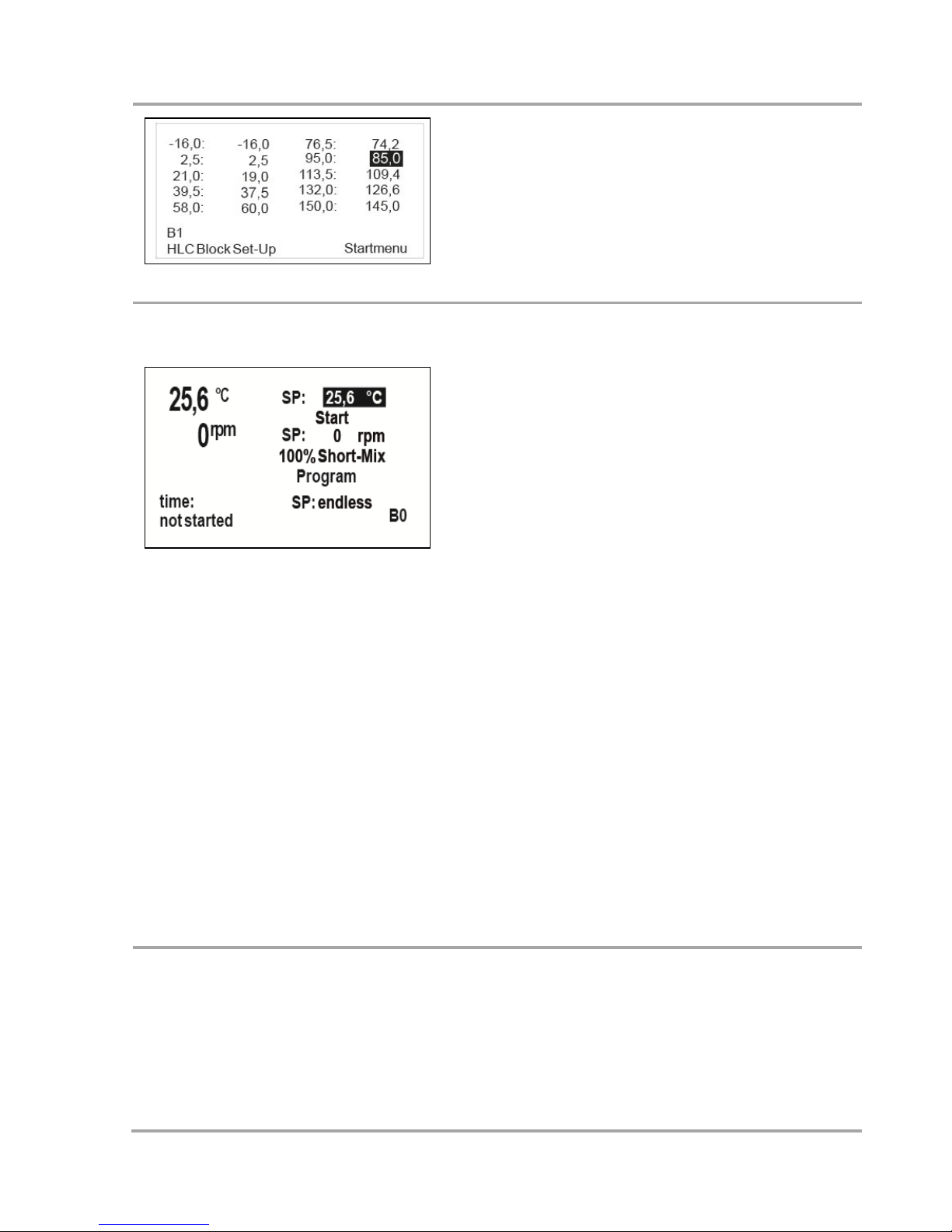

10-point-calibration

By default the standard

calibration begins

with the block number “B0”. 10 temperature

bases are underlying

this calibration. The

calibration is optimized for all DITABIS standard blocks. If you are using customized blocks

you will be able to do individual calibrations

in addition.

For the calibration you need a

gauged high-precision temperature measuring device.

Select block number in the set up menu and

confirm with ok. You are now able to calibrate and save different individual calibrations, from standard block B1 up to 4. Therefore please select B1 to B4. Confirm again

with ok. Now you will get to the calibration

menu. In the first and third column you can

see the temperature base. In the second and

fourth column you can see the variable set

values.

By pushing the + and – keys the entries and

values can be changed. The selected field is

blinking; by pushing ok the field is selected

for changing.

Example:

You have adjusted the device for 95,0°C in the

start menu and are measuring only 85,0°C

10

with a calibrated thermometer inside your

sample. Now you have to change the temperature set value in column four about 10°C.

By doing so you can calibrate every single

base individually.

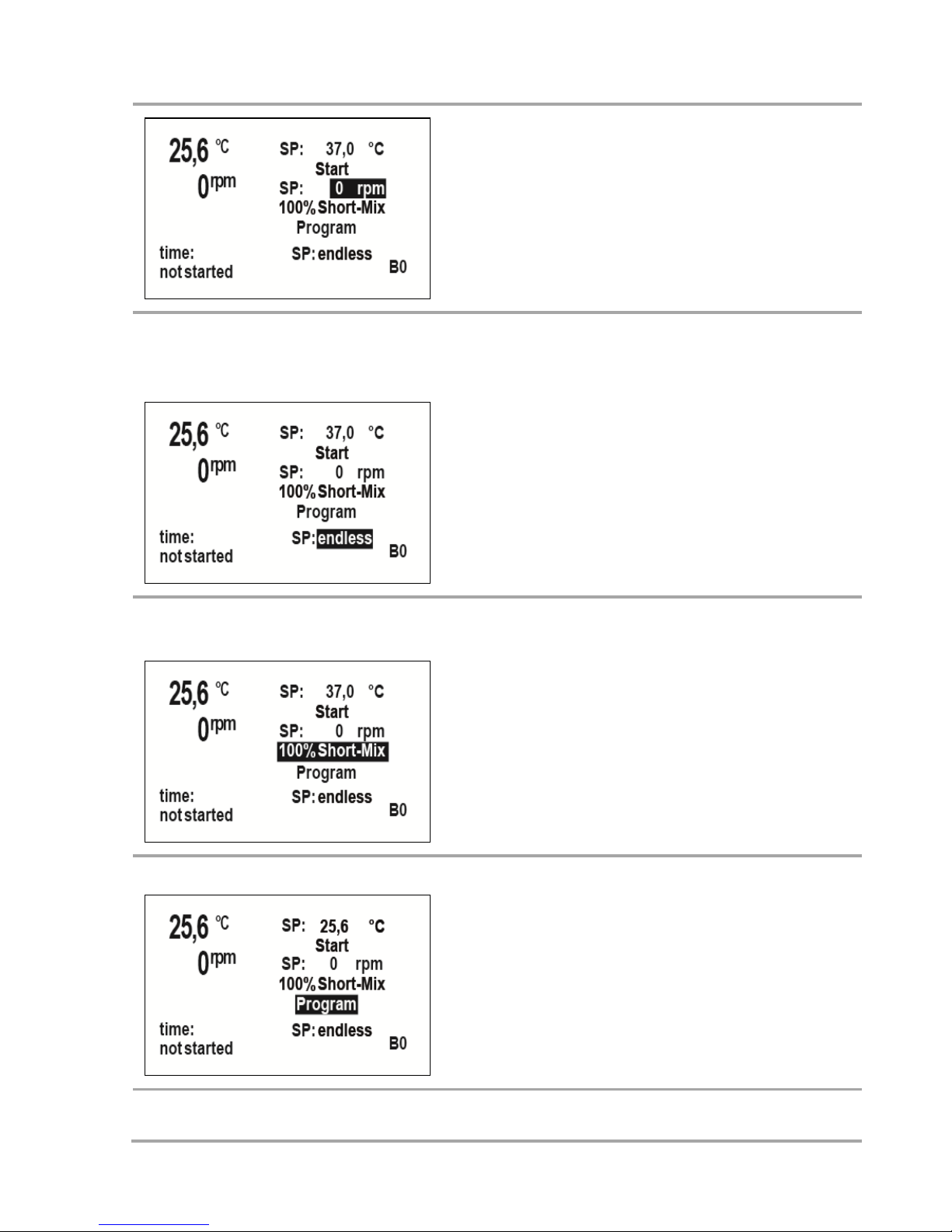

Temperature set value

Navigate with + and – to the temperature

input box and confirm with ok. The individual

numbers can be selected with arrow left and

right, their value can be changed with +

and -. The input is confirmed with ok and the

cursor automatically jumps to the Start button.

A set value change can also be made in the

same way during a running process. After

confirming the input with ok, the new set

value is effective immediately. For the hundreds, the following values can be selected:

0 for temperatures up to +99,9°C

1 for temperatures from +100,0°C

- for temperatures below 0,0°C

Important information

For cooling systems, the minimum temperature may not be smaller than the difference

from room temperature mentioned below.

MKR 13 / TK 23: 16°C below r.t.

MKR 23: 11°C below r.t.

Mix set value

Navigate with + and – to the shaking frequency input box and confirm with ok. The

individual numbers can be selected with

arrow left and right, its value can be changed

with + and –.

The input is confirmed with ok and the cursor

11

automatically jumps to the button

Start

.

The 1. Digit number cannot be selected and

changed. A set value change can also be

made in the same way during a running process. After confirming the input with ok, the

new set value is effective immediately.

Duration of the process (time

setting)

Navigate with + and – to the time input box

and confirm with ok. The individual numbers

can be selected with arrow left and right, its

value can be changed with + and –.

The input is confirmed with ok and the cursor

automatically jumps to the button Start.

For an endless process, select 00:00.

100% Short-Mix (vortexing)

Navigate with + and – to the button 100%

Short-Mix and confirm with ok. The system

shakes with maximum mixing speed regardless of a process is started or not.

During the whole shaking process ok must be

pushed continuously..

Select program mode

Navigate with + and – to the button

Program and confirm with ok. For detailed

information on programming see page 10.

12

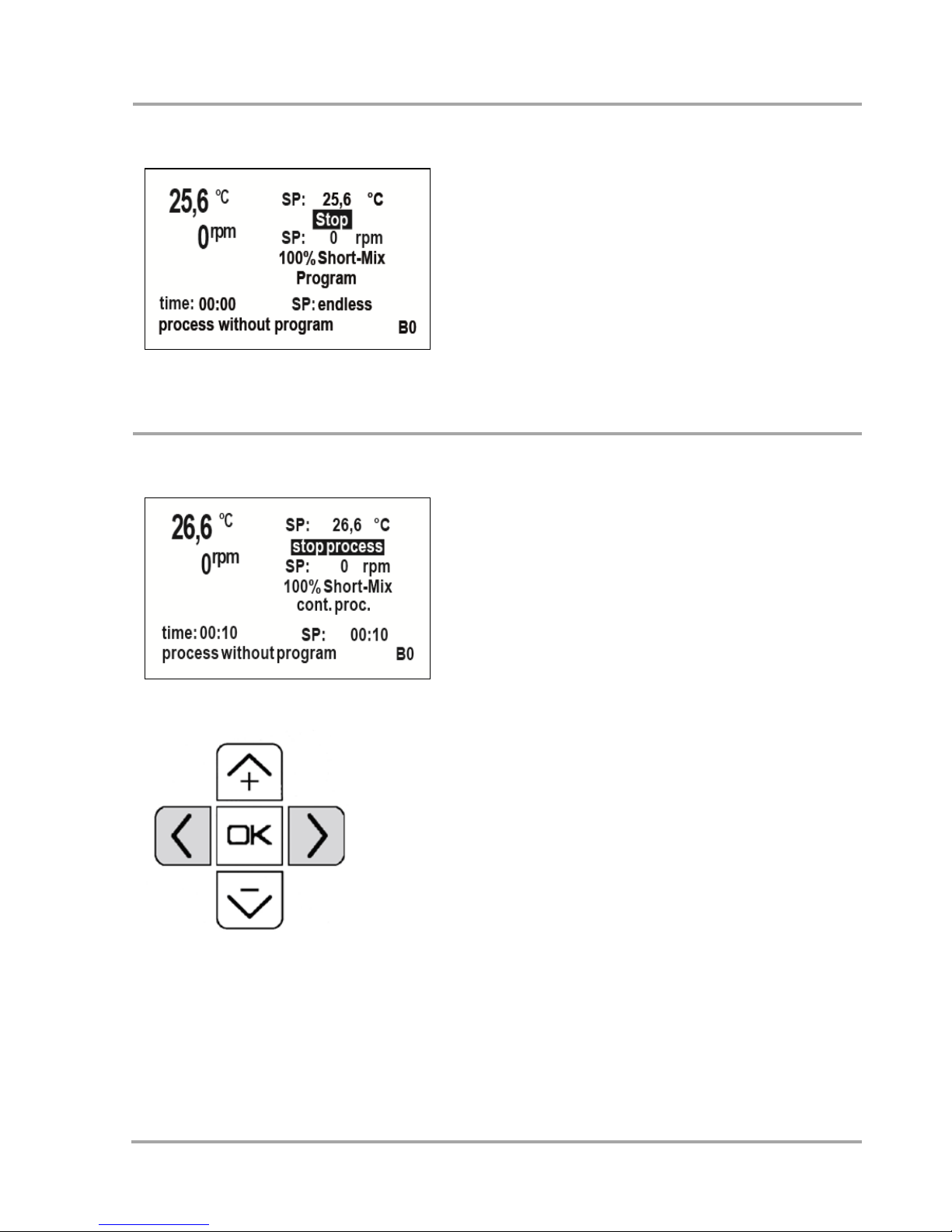

Process without time setting

Only set a set temperature and a set shaking

frequency but set the time on continuous

00:00. Now, the process time is displayed

continuously. It only starts to run if the temperature set value is reached. A set value

change can also be made as described above

during a running process. Changes are retained also after the completion of the process and are displayed in the start menu as

current set values. For terminating the pro-

cess, push Stop.

Process with time setting

If a process time is set, the remaining time is

displayed in the menu. The time only starts to

run if the temperature set value is reached.

This does also apply for subsequent temperature changes. A set value change can also be

made as described above during a running

process.

The process ends without a signal or continuous with a signal until it is terminated

manually. The relevant modus can be set in

the setup menu.

For changes during the process

If set value changes have been made, you can

select to save these changes and to have

them displayed in the start menu as new set

values.

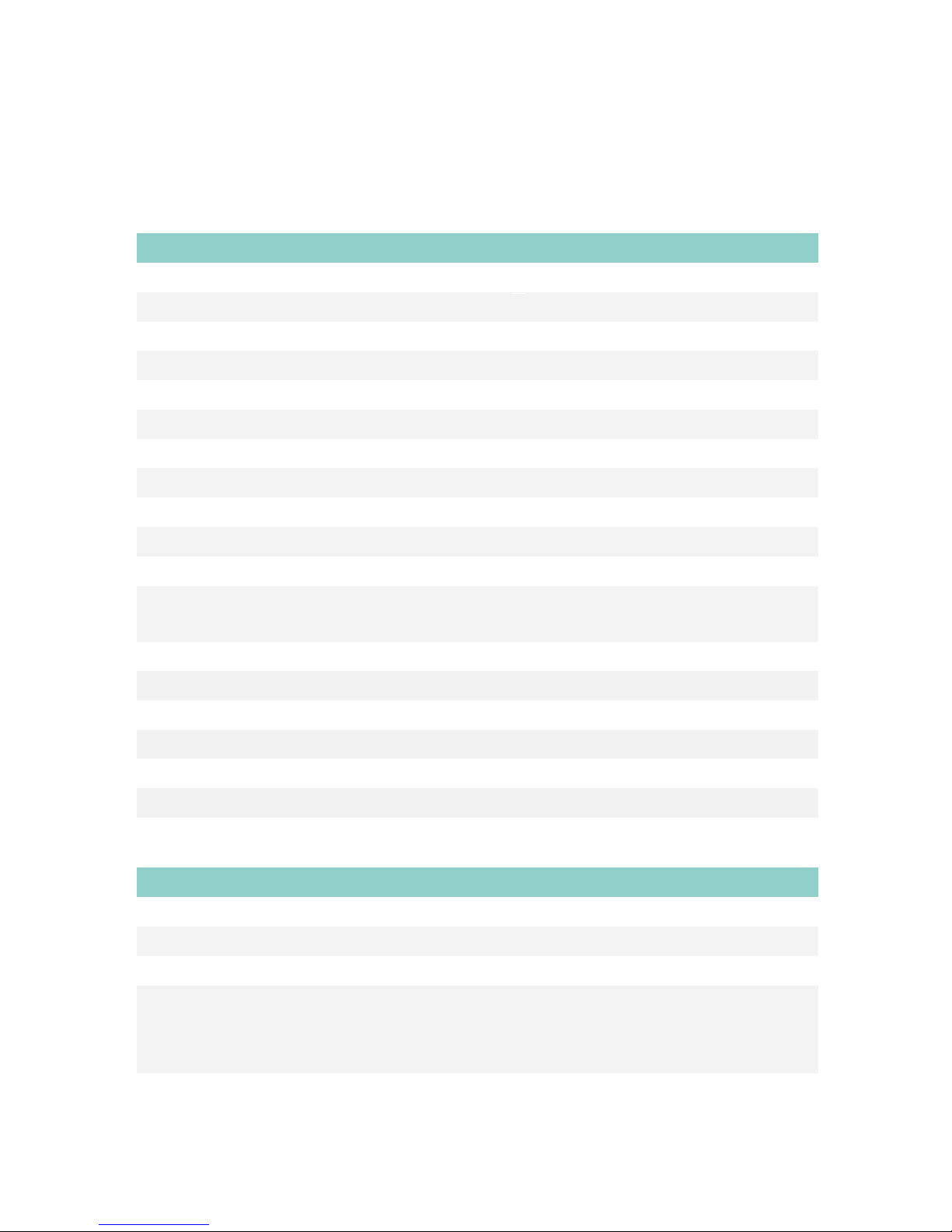

Stopping the process before the expiration

of the time

If the process is stopped or changed before

the expiration of the time, you can select

whether the process really should be termi-

13

nated or if it should continue. Depending on

the selection, the start menu or the selection

to continue the process from the stop (time

runs from stop) or to make a restart (time

runs from zero) is displayed.

Process end

Setting in setup:

Confirm end: Yes

If a process time is preset, the expiration of

the time is indicated by a flashing LED and a

signal, the process continues. You can terminate the process with ok.

Confirm end: No

If a process time is preset, only the information that the process is completed will be

displayed after the expiration of the time. The

device turns off automatically.

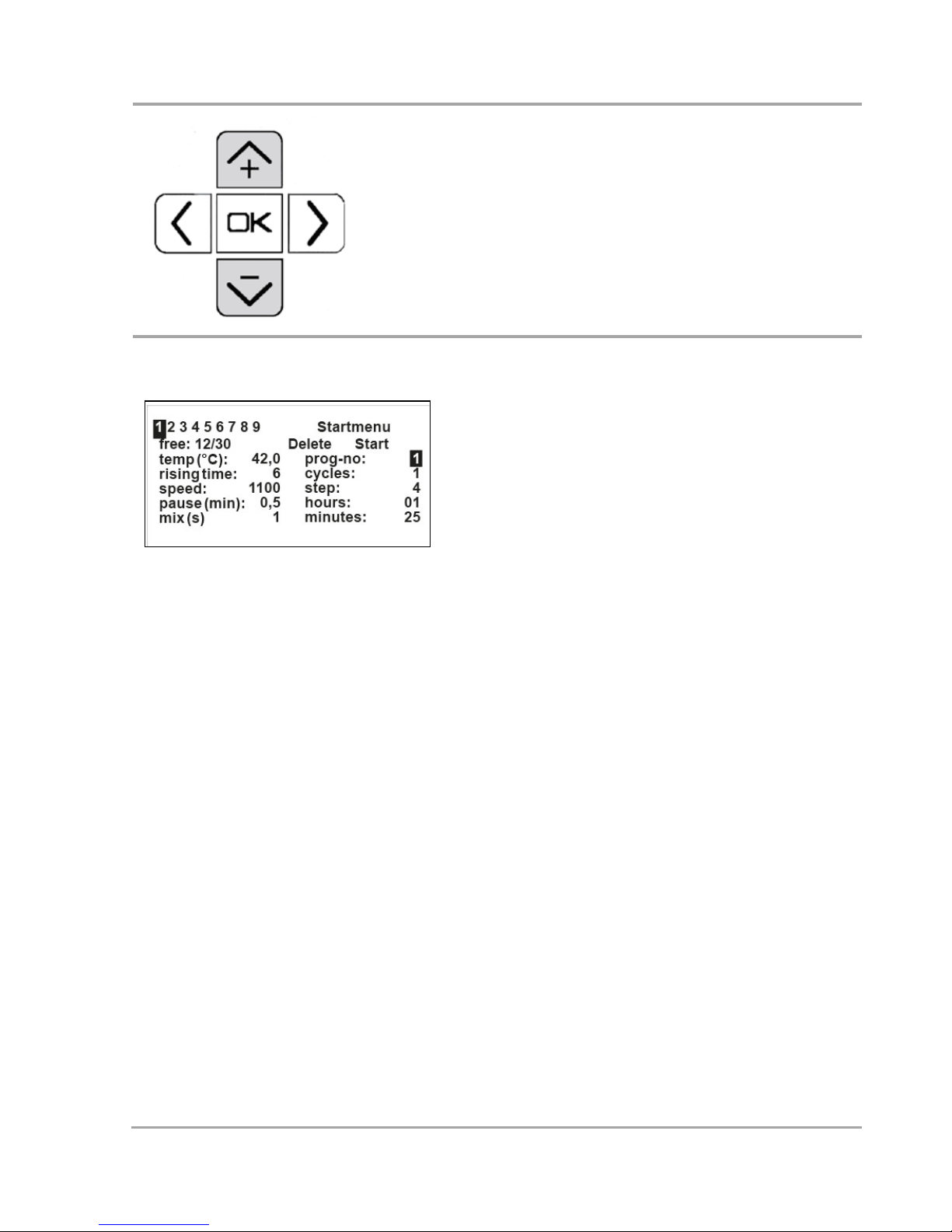

Programming function

Program menu

Navigate with + and – to the button Pro-

grams and confirm with ok. A total of 30

different program steps can be preset,

distributed on max. 9 different programs.

Confirm the highlighted flashing program

number if you want to change it. Confirm

the progr. no. with ok. With + and – , the

program numbers 1-9 can be selected.

If you want to edit the displayed program,

select the different adjustable parameters

with + and –. For editing, confirm with ok

and change the value. For final confirma-

tion confirm with ok again.

14

Setting of the individual paramater

By selecting "Programs" in the start menu, you will have a total number of 30

different (recurrent) program steps available. These can be selected in up to 9 different programs. You have the choice of f. ex. either 9 programs with 3 program

runnings each or f. ex. 1 program with 30 program runnings. For normal operation

the choice will be somewhere in between.

"prog-no." is blinking and shows 1 as standard. By pressing ok any program num-

ber. between 1 and 9 can be selected using buttons + and –. Confirm your entry by

pressing ok and the next field "cycles" will be blinking.

Cycles = Number of repetitions of the program, selection 1-9 possible without

having to confirm "Start" again.

If no changes are to be made, select the next field by using the - (down) button.

By pressing ok you can change the number of cycles from 1 to 9 using the + and –

buttons. Confirm your entry by pressing ok and the next field "step"

will be blinking.

Step = Section within a program. Selection 1-9 possible.

If no changes are to be made, select the next field by using the – (down) button.

15

For changing the program step displayed, press ok. A value between 1 and 30 can

be selected using buttons + and –. Confirm your entry by pressing ok and the next

field "hours" will be blinking. If in the field "minutes" no entries are to be made,

select the next field by using the – (down) button.

Hours = Duration of the section in hours.

If no changes at "hours" are to be made, select the next field by using the – (down)

button. For any changes press ok; the ones column is highlighted and can be

changed with buttons + and –. For changing the tens column use button for mark-

ing and + and – for changing. Confirm your entry by pressing ok and the next field

"minutes" will be blinking.

Minutes = Duration of the section in minutes.

For entries press ok; the tens column is highlighted and can be changed by using

buttons + and –. For changing the ones column use button for marking and + and –

for changing. Confirm your entry by pressing ok and the next field "temp °C" will be

blinking.

Time "endless"

If a program step (normally the last one) shall be running without a time setting

until the program will be completed manually, i.e. endless, the hours and minutes

must be set to 00.

Temperature = Set temperature of the section.

The temperature set value is 37°C as standard. If no changes are to be made, select

the next field by using the – (down) button. To change this value press ok. Every

single digit can be changed. The cursor is placed at the tens column of the set value.

This value can be changed with buttons + and –. To change another digit in this

data field, it must be marked by buttons < and >. The highlighted value will be

changed with button + or –. After setting the value it must be confirmed with ok;

the field "rising time" will be blinking.

Rising time = Time setting for tempering the sample to set temperature. This setting is only required if the sample is to be tempered slower than in presttings of the

device. If the sample is to be tempered as fast as possible, set the value to 0.

With "rising time" the heating or cooling speed compared with the normal speed

16

can be reduced. You have the possibility to determine a certain period (= rising

time; with a max. of 99 minutes to choose) in which a set temperature shall be

reached in the actual program step, if a slower than normal tempering is desired.

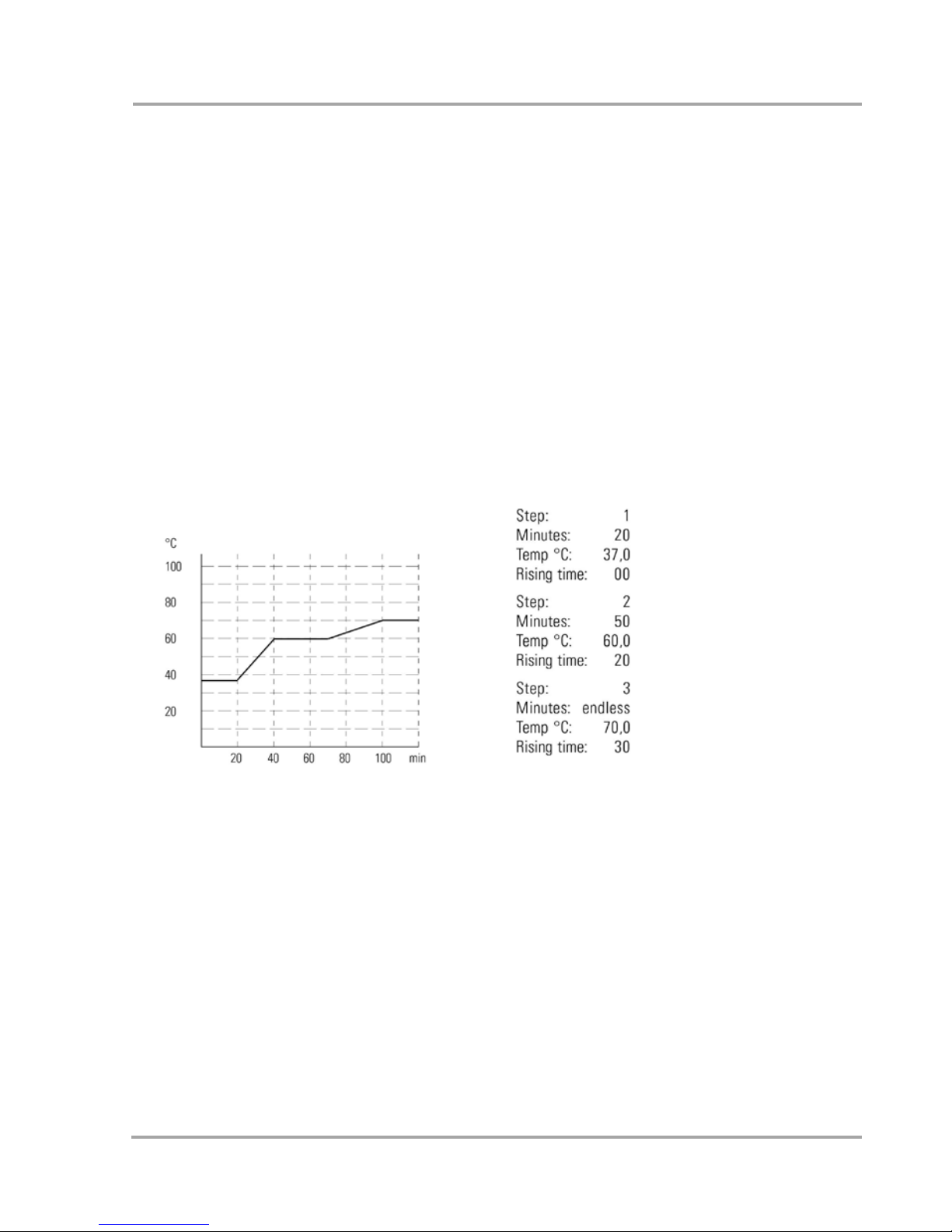

As shown in the illustration beside, a temperature of 60,0°C in step 2 shall be

reached within 20 minutes, starting from a temperature of 37,0°C in step 1. If no

changes are to be made in "rising time" (fastest possible heating or cooling time),

select the next field by using the – (down) button. For changing the standard value

0 press ok; the ones column is highlighted and can be changed with buttons

+ and –. For changing the tens comlumn use button for marking and + and – for

changing. Confirm your entry by pressing ok and the next field "speed" will be blinking.

Example of a temperature program:

Rotational speed = Shaking frequency with which the blocks are shaken.

The last number (1. digit) can not be selected and changed.

For "speed" 0 is set as standard. If no changes are to be made (tempering without

shaking), select the next field by using the – (down) button. To change this value

press ok; every single digit can be changed. The cursor is placed at the hundreds

column of the set value. This value can be changed with buttons + and –. To change

another digit in this data field, it must be marked by buttons < and >. The highlighted value will be changed with button + or –. The last digit (ones column) cannot be

chosen and changed. After setting the value it must be confirmed with ok; the

field "pause" is blinking.

17

Interval shaking = Interval shaking is an alternative when the probe shall not

be subject to permanent shaking. A resting time of up to 9.9 minutes can be set in

"pause". The following short shaking time of up to 9 seconds is set in "mix sec".

This is a reasonable choice for the last program running of a complete program with

time setting "endless" during off working hours.

Pause [min] = Resting time of up to 9.9 minutes. If no intervals are to be set, enter

the value 0.0 here.

Duration of pause is 0.0 as standard. If no changes are to be made, select the next

field "step" by using the – (down) button. To change this value press ok; the ones

column is highlighted and can be changed by using buttons + and –. For changing

the 1/10 digit press button >; the digit is highlighted and can be changed with buttons + and –. Confirm your entry by pressing ok and the next field "mix sec" will be

blinking.

Mix [s] = Short shaking time up to 9 seconds after resting time.

For "mix sec" 1 is set as standard. If no changes are to be made, select the next field

"step" by using the – (down) button. For changing the shaking time press ok and

change time by using buttons + and –. Confirm your entry by pressing ok and the

next field "step" will be blinking.

Entry of further program steps

If another program step shall be added to

a chosen program, press ok at the blinking field "step" and increase the number

of the last program step by 1. Further

entries as already described.

To change the program data entry

To change the chosen program, enter the

program step number to be changed.

Select the field to be changed by using

buttons + and – . Press ok for changing.

Changes are made as already described

18

and must be confirmed with ok. Select a

corresponding field by using buttons +

and – or < / >.

Termination of program data entry

To complete a chosen program, mark

either "Start" (to start the program immediately) - screen 6 will appear, or

"Startmenu" (to save the program only) screen 1 will appear. You can also select

"prog-no." (for entry of another program). When "Delete" is selected, the

complete program with all program steps

as displayed is deleted

Starting a program

Select the relevant prog. no. and confirm

the Start button in the program menu.

Changing parameters during the

program process

Change of temperature and rotational

speed as well as performing a Short-Mix

are possible during a running program.

The set time is the time of the running

step, the remaining time is the time of

the complete process. In the lower right

part of the display, program no., cycle and

step are indicated.

19

Assembly of accessories

Anti-Condensation Plate BA 24 / 96

The anti-condensation plate BA 96 (800013000) is placed on the attached

block, no assembly steps are required. For using the anti-condensation plate

BA 24 (800012900), remove the socket screw in the block with the enclosed

Termination/ interruption of the

program:

If you push Stop, the options stop

process and continue process are dis-

played.

If you select stop process, the Start menu

or Save changes is displayed if parame-

ters have been changed during the process.

If you select Continue with process the

selection Continue from stop or

Process Restart is displayed (program

starts from cycle 1, step 1).

20

screwdriver. Screw the enclosed threaded pin with isolation knob into the

anti-condensation plate. Place the anti-condensation plate on the block and

screw the threaded pin in deeper so that it takes hold of the bolt of the system and with that tightly attaches block and anti-condensation to the system.

Data transfer

A USB 1.1. interface for the communication with a PC is provided as a standard. Connect the system via the USB-port on the left side with a USB-cable to

your PC. If this is not available at your computer, install the suitable USBdriver. You will find it under www.ftdichip.com/Drivers/VCP.htm. These USBdrivers generate a new virtual COM-interface in your PC. The chip in the Smart

Control is called FT232B.

Access process data via USB

Start a terminal program (e.g. Hyper terminal) on your PC. This program you

will find under Windows in "Programs" / "Accessories" / "Communication".

The window "Hyper Terminal" is opened. Proceed systematically, please note

that for the connection setting for "Bits per second" 115200 is selected. Select

at "Transfer": "Record Text", enter the location and define the file name as

.txt Start the Hyper Terminal and the process. Every minute, the following

data are recorded in text format and separated by comma in the form shown

on the right.

Since the data are separated by commas, you can easily create an Excel file

and generate one or more curves from that. If you open the text file you selected for saving, you can see the complete process.

21

START

Setpoints

xx:xx,+37.0,0200,01,01,01,00

:01,00,9,0.2

time

hh:mm,tmp,rpm,prg,cycle,st

ep,steptime hh:mm,rem.

risetime_m,mix_s,pause_m

00:00,+26.9,0000,01,01,01,0

0:00,00,9,0.2

00:01,+33.7,0220,01,01,01,0

0:00,00,9,0.2

00:02,+36.7,0000,01,01,01,0

0:00,00,9,0.2

00:03,+36.9,0000,01,01,01,0

0:00,00,9,0.2

START

Setpoints

xx:xx,+70.0,0300,01,01,02,00

:12,10,9,0.1

time

hh:mm,tmp,rpm,prg,cycle,st

ep,steptime hh:mm,rem.

risetime_m,mix_s,pause_m

00:04,+36.9,0000,01,01,02,0

0:00,10,9,0.1

00:05,+39.1,0000,01,01,02,0

0:01,09,9,0.1

00:06,+42.1,0000,01,01,02,0

0:02,08,9,0.1

00:07,+45.2,0300,01,01,02,0

0:03,07,9,0.100:08,+48.4,030

0,01,01,02,00:04,06,9,0.1

00:09,+51.7,0000,01,01,02,0

0:05,05,9,0.1

00:10,+54.9,0000,01,01,02,0

0:06,04,9,0.1

00:11,+58.2,0300,01,01,02,0

0:07,03,9,0.1

00:12,+61.5,0300,01,01,02,00:08,02,9,0.1

00:13,+64.7,0000,01,01,02,00:09,01,9,0.1

STOP

22

Enter process data via USB

For the process control of a HLC system with Smart Control via a USBinterface, four commands are possible and required:

Start

Starts a process without program with the parameters indicated on the display. Time settings, if applicable, are deleted and overwritten by continuous

since time settings must be programmed on the computer.

Stop

Stops all processes and returns to the start menu, running programs / processes are aborted.

t=0370

Changes the set temperature to a new value.

The temperature must always be entered with four digits.

t=0370 sets 37.0°C, t=0050 sets 5.0°C, t=-060 sets -6.0°C.

t= is the identification for a temperature value. The associated numerical

value reflects the value in tenth of a degree.

The first digit after the = can be a 0, a 1 or a hyphen. Invalid temperature

values are - like for the input at the system - replaced by the next valid value.

r=020

Changes the set rotational speed to a new value.

The rotational speed must always be entered with three digits.

r=120 sets 1,200 1/min, r=045 sets 450 1/min.

r= is the identification for a rotational speed value. The associated numerical

value reflects the value in 10 1/min.

Invalid rotational speed values are - like for the input at the system - replaced

by the next valid value.

23

r=000

Stops the rotational speed, e.g. if shaking should be stopped but tempering be

continued.

Other inputs like e.g. r=0 are interpreted as rotational speed and cause the

motor to rotate with the minimum rotational speed.

Every command must be confirmed with "CR"

In case of unknown commands and/or in case of spelling errors, nothing is

done. The inputs in the setup menu like colour, contrast and brightness of the

display, language, rotation direction etc. can only be done at the operating

panel of the system itself.

Troubleshooting

The display remains blank

Please check if the mains switch on the back side is switched on.

If it is switched on but voltage is present at the socket, check the micro-fuse

and replace if required. (IEC 127-2/III, 250 V, 2 A time-lag).

This fuse - and a spare fuse - are located in the IEC-bushing (in which the connection cable is plugged). The fuse box can be pulled out with a screwdriver.

The system does not cool, heat or shake as set

Check whether the display indicates the correct system type name at poweron. If not, please contact your local dealer or the HLC by DITABIS service department.

There are excessive temperature fluctuations

Check the seat of the changeable block by pulling it up. If it is too loose or if

the block exhibits roughness, e.g. contamination, the heat / coolness is not

transferred correctly.

24

Information on the capacitive touch display

The touch display reacts on finger pressure, even when wearing thin latex

gloves, but not on stylos.

Due to its glass surface, the front panel is insensitive to dirt, chemicals and

mechanical damage. Please avoid scratches in the coating since they can

cause malfunctions. Please take note of the following cleaning instructions.

Maintenance

Cleaning

Regularly clean the housing and the changeable blocks of the

Thermo Shakers and BlockThermostates.

Precautions for avoiding electric shocks

Electronic devices can cause electric shocks in case of an operat-

ing error. Never try to repair electric parts. Never open the housing.

• Switch off the system and disconnect it from the power

supply before starting with cleaning or disinfection

works.

• Never let get liquids inside the housing (ventilations

slit).

• Do not perform spray disinfection.

• Do only connect the system with the power supply if it is

completely dry.

The repair service may only be performed by staff authorized

and trained by the manufacturer. A modification of the system is

not permitted.

25

Caution when handling aggressive chemicals

Do not use aggressive chemicals like e.g. strong and weak bases,

strong acids, formaldehyde, acetone, halogenated hydrocarbons

or phenol for cleaning the system and its accessories.

• In case of contamination with aggressive chemicals,

clean the system with a neutral detergent immediately.

• Use neither corrosive detergents nor aggressive solvents

or abrasive polishing agents.

Cleaning

1. Please disconnect the system from the power supply before you start

cleaning.

2. Please clean all outer parts of the system with a mild detergent and a

lint-free cloth.

3. Please wipe off the detergent with Aqua dest..

4. Please dry all cleaned parts.

Disinfection

1. Please disconnect the system from the power supply before you start

disinfecting.

2. Let the system cool down.

3. Please clean the system as described above.

4. Please select a disinfection method compliant to the applicable local

legal regulations and directives.

5. Please wipe off all outer parts of the system with the disinfectant and

a lint-free cloth.

Service

If a technical problem arises, please contact your local dealer or the DITABIS

service department. The DITABIS contact information can be found at

www.ditabis.com. If required, the system will be returned for repair – please

take note of our service guidelines, which can be found at www.ditabis.com as

well.

26

Decontamination before shipment

If you send the system to the authorised technical service for repair or to your

distributor for disposal, decontaminate all parts you want to send. Document

the decontamination in a Decontamination Certificate (incl. serial number)

and include it with the shipment.

Technical data

Technical Data

MKR 13

Temperature-working range

Amb. -16°C to +100°C

Temperature-adjustable range

-10°C to +105°C

Accuracy / resolution

+/- 0.1°C / 0.1°C

Max. heating time

6.0°C / min

Max. cooling time

12.0°C / min

Shaking frequency

200 – 1,500 rpm

Orbit

3 mm round

Dimensions (without block) W x D x H

220 x 330 x 144 mm

Block - capacity

1 changeable block

Weight (without block)

9.0 kg

Power input

130 W

Electr. supply

230 V / 50 Hz

(115 V / 60 Hz available)

Fuse

2AT

Protection class

IP21

Environmental conditions

Ambient air temperature

3° – 50°C

in service (non-condensing)

Relative humidity

max. 80%

27

Technical Data

MKR 23

Temperature-working range

Amb. -11°C to +70°C

Temperature-adjustable range

0°C to +80°C

Accuracy / resolution

+/- 0.3°C / 0.1°C

Max. heating time

3.5°C / min

Max. cooling time

6.5°C / min

Shaking frequency

200 – 1,200 rpm

Orbit

3 mm round

Dimensions (without block) W x D x H

220 x 330 x 144 mm

Block - capacity

2 changeable blocks

Weight (without block)

9.5 kg

Power input

200 W

Electr. supply

230 V / 50 Hz

(115 V / 60 hz available)

Fuse

2AT

Protection class

IP21

Environmental conditions

Ambient air temperature

3° – 50°C

in service (non-condensing)

Relative humidity

max. 80%

Technical Data

MHR 13

Temperature-working range

Amb. +3°C to +130°C

Temperature-adjustable range

0°C to +137°C

Accuracy / resoultion

+/- 0.1°C / 0.1°C

Max. heating time

11.5°C / min

Shaking frequency

200 – 1,500 rpm

Orbit

3 mm round

Dimensions (without block) W x D x H

220 x 330 x 109 mm

Block - capacity

1 changeable block

Weight (without block)

6.5 kg

Power input

200 W

28

Electr. supply

230 V / 50 Hz

(115 V / 60 Hz available)

Fuse

2AT

Protection class

IP21

Environmental conditions

Ambient air temperature

3° – 50°C

in service (non-condensing)

Relative humidity

max. 80%

Technical Data

MHR 23

Temperature-working range

Amb. +3°C to +130°C

Temperature-adjustable range

0°C to +137°C

Accuracy / resolution

+/- 0.1°C / 0.1°C

Max. heating time

9.5°C / min

Shaking frequency

200 – 1,500 rpm

Orbit

3 mm round

Dimensions (without block) W x D x H

220 x 330 x 109 mm

Block - capacity

2 changeable blocks

Weight (without block)

7.0 kg

Power input

350 W

Electr. supply

230 V / 50 Hz

(115 V / 60 Hz available)

Fuse

2AT

Protection class

IP21

Environmental conditions

Ambient air temperature

3° – 50°C

in service (non-condensing)

Relative humidity

max. 80%

29

Technical Data

MHL 23

Temperature-working range

Amb. +3°C to +130°C

Temperature-adjustable range

0°C to +137°C

Accuracy / resolution

+/- 0.1°C / 0.1°C

Max. heating time

9.5°C / min

Shaking frequency

200 – 1,300 rpm

Orbit

3 mm linear

Dimensions (without block) W x D x H

220 x 330 x 109 mm

Block - capacity

2 changeable blocks

Weight (without block)

7.0 kg

Power input

350 W

Electr. supply

230 V / 50 Hz

(115 V / 60 Hz available)

Fuse

2AT

Protection class

IP21

Environmental conditions

Ambient air temperature

3° – 50°C

in service (non-condensing)

Relative humidity

max. 80%

Technical Data

TK 23

Temperature-working range

Amb . -16°C to +90°C

Temperature-adjustable range

-10°C to +105°C

Accuracy / resolution

+/- 0.3°C / 0.1°C

Max. heating time up

4.0°C / min

Max. cooling time

7.0°C / min

Dimensions (without block) W x D x H

220 x 330 x 144 mm

Block - capacity

2 changeable blocks

Weight (without block)

7.5 kg

Power input

130 W

Electr. supply

230 V / 50 Hz

(115 V / 60 Hz available)

30

Article description blocks & accessories

Blocks

Art. No.

Dimensions of the Containers

For

800010800

BM 02 for 96 x 0.2 ml conical & 8-container stripes

micro

800010900

BM 05 for 38 x 0.5 ml conical

test tubes

800011000

BM 15 for 24 x 1.5 ml conical

800011100

BM 20 for 24 x 2.0 ml cylindrical

For sample

800011500

BP 10 for 24 x D=10.3 mm, 46 mm deep, round bottom, lid

tubes

800011600

BP 12 for 24 x D=12 mm, 20 mm deep, flat bottom

800011700

BP 15 for 24 x D=15 mm, 30 mm deep, flat bottom

800011800

BP 16 for 24 x D=16.5 mm, 46 mm deep, round bottom, lid

800014200

BP 17.0 for 24 x D=17 mm, 30 mm deep, flat bottom

800016100

BP 19.2 for 24 x D=18.7 mm, 25 mm deep, flat bottom

800015200

BP 23.0 for 12 x D=22.5 mm, 56 mm deep, flat bottom

800016000

BP 25.5 for 12 x D=23.0 mm, 56 mm deep, flat bottom

800011900

BP 28 for 8 x D=28 mm, 40 mm deep, flat bottom

For centri-

800012200

BZ 15 "Falcon" tubes 14 x 15 ml, with isolation lid

fuge tubes

800012300

BZ 50 for "Falcon" tubes 6 x 50 ml, with isolation lid

For PCR

800010400

BC 96 for 96-well "V"-bottom

plates

800010300

BC 84 for 384-well

For micro

800012000

BV 96 for 96 x round or "V"-bottom

plates

800010600

BF 96 for flat bottom

For deep- well

plates

800010500

BD 96 for 96-deep-well-plates

For other

800011200

BN 10 for 36 rectangular cuvettes, outer diameter 12.5 mm

applications

800012100

BW 01 as tub for deep-well, stacked microtiter plates and other con-

Fuse

2AT

Protection class

IP21

Environmental conditions

Ambient air temperature

3° – 50°C

in service (non-condensing)

Relative humidity

max. 80%

31

tainers, incl. isolation lid and unloading device

800014100

SO 10.4 for 24 x D=10,4 mm, 180 mm deep

800012600

SO 12.0 for 24 x 12ml test tubes

800012700

SO 20.5 for 12 x 20ml test tubes

For customized

800010700

BM 00 without drilling, height 25 mm

containers

800011300

BO 37 without drillings, height 37 mm

800011400

BO 50 without drillings, height 50 mm

For Slides

800012400

BY 12 for 12 slides for hybridisation

Accessories

Art. No.

Description

800012800

BI 01 Isolation lid

800013800

BT 01 Tempering tub for 1 block, transparent

800013900

BT 02 Tempering tub for 2 blocks, transparent

800012900

BA 24 Anti-condensation plate for 1 block (micro test tubes)

800013000

BA 96 Anti-condensation-plate for 1 block (PCR / test plates)

800013100

BR 05 Rack with holder f. tubes 0.5 ml

800014300

BR 15 Rack with holder f. tubes 1.5 / 2,0ml

32

Explanations

Caution! Risk of electric shock!

Caution!

Caution! Hot surface!

Important information

Earth conductor

Fuse

i

33

Basisdaten

Die HLC by DITABIS Thermomixer und Blockthermostate dienen dem Temperieren und Mischen von Lösungen in geschlossenen Reaktionsgefäßen und

Platten. Bei der Einstellung der Zieltemperatur der Proben in der Software des

Thermomixers ist darauf zu achten, dass sich diese unterhalb der Siedetemperatur der zu erwärmenden Lösungen befindet. Im Falle von Unklarheiten im

Bezug auf die zu erhitzenden oder zu kühlenden Flüssigkeiten kontaktieren Sie

bitte DITABIS. Die HLC by DITABIS Geräte sind für die Verwendung in Innenräumen bestimmt. Verwenden Sie bitte ausschließlich HLC by DITABIS Zubehör oder das von DITABIS empfohlene Zubehör.

Sicherheit

Die Geräte sind konform zu den entsprechenden CE-Erklärungen.

Bitte beachten Sie folgende Sicherheitsmaßnahmen

Schließen Sie das Gerät nur an eine Schuko-Steckdose 230 V,

50 Hz an.

Stellen Sie keine heißen Blöcke auf eine brenn- oder

schmelzbare Unterlage.

Stellen Sie sicher, dass die verwendeten Gefäße im Block für

den gewünschten Temperaturbereich geeignet sind.

Sollte einmal Flüssigkeit in das Gerät gelangen, ziehen Sie

den Netzstecker und kontaktieren Sie unsere Serviceabteilung, damit vollständige Sicherheit gewährleistet ist.

Bitte berühren oder transportieren Sie kein heißes Gerät.

Vermeiden Sie jeden Kontakt des Gerätes mit leicht entzünd-

lichen Flüssigkeiten.

Die Lüftungsschlitze des Gerätes müssen jederzeit frei zu-

gänglich sein.

Defekte Netzkabel dürfen ausschließlich durch gleichwertige

Netzkabel ersetzt werden.

34

Gewährleistung und Garantie

Alle Funktionen der Systeme wurden ausführlich getestet. Das Gerät und das

Zubehör wurden anschließend sorgfältig verpackt. Wenn dennoch beim Aufstellen oder der Inbetriebnahme Schäden oder Mängel festgestellt werden

sollten, kontaktieren Sie bitte Ihren Händler vor Ort oder die DITABIS Serviceabteilung. Hier wird eine erste Einschätzung des Defekts durchgeführt. Die

DITABIS Kontaktdaten finden Sie unter www.ditabis.com. Bei Nutzung des

Gerätes unter Laborbedingungen und unter Beachtung der Bedienungsanleitung beträgt die Gewährleistung ein Jahr, gerechnet vom Tage des Versandes.

Als Premium-Kunde erweitert sich die Garantie auf insgesamt drei Jahre und

Sie erhalten eine kostenlose Reparatur im Garantiefall - auch bei Verschleißteilen. Des Weiteren erhalten Sie ein kostenloses Ersatzgerät innerhalb von

48h im Reparaturfall. Unser kostenloser Rückrufservice und E-Mailsupport mit

einer Reaktionszeit von 24h steht Ihnen ebenso zur Verfügung wie unser kostenloser Abhol- und Rücksendungsservice.

Die Premium-Kunden-Garantie wird mit den oben beschriebenen Konditionen

in Deutschland angeboten. Für andere Länder gelten abweichende Angebote,

die wir Ihnen gerne zukommen lassen.

Haftungsausschluss

Bei nicht sachgemäßem Gebrauch der Geräte übernimmt der Hersteller keine

Haftung.

Wichtige Hinweise

Diese Bedienungsanleitung wurde auf Grundlage der EN DIN 61010-1 Norm

erstellt. IQ, OQ und PQ Dokumente erhalten Sie gesondert auf Anfrage.

Die Geräte sind mit einem hochgenauen, selbstoptimierenden

Temperaturregler ausgestattet. Es ist durchaus normal, dass im

Rahmen der Selbstoptimierung im Einzelfall die eingestellte Temperatur leicht überschritten wird.

i

35

Es ist darauf zu achten, dass sich bei der Erhitzung von Proben gefährliche Gase bilden können. Sollte dies der Fall sein, müssen die

Geräte in Abzügen verwendet werden.

Bei hoher Schüttelfrequenz der Thermomixer ist es möglich, dass

sich die Vibrationen des Gerätes auf die Stellfläche übertragen.

Bitte berücksichtigen Sie dies bei der Platzierung des Gerätes.

Vermeiden Sie jeden Kontakt des Gerätes mit leicht entzündlichen

Flüssigkeiten, da der Block / die Blöcke sehr heiß werden können.

Die Lüftungsschlitze des Gerätes müssen jederzeit frei zugänglich

sein. Ein Mindestabstand von 10 cm an den Seiten des Gerätes

muss eingehalten werden, damit eine korrekte Belüftung gewährleistet ist.

Umgebungsbedingungen

Der optimale Funktionsbereich der Geräte liegt bei einer relativen Luftfeuchtigkeit von max. 80% und einer Umgebungstemperatur zwischen +3°C - +50°C.

Diese Werte sollten nicht über- oder unterschritten werden.

Temperaturgenauigkeit

Jedes HLC by DITABIS-Gerät wird mit einem geeichten, hochgenauen Temperaturmessgerät auf Temperaturgenauigkeit und Reproduzierbarkeit kalibriert.

Diese Kalibrierung findet bei einer Raumtemperatur von +20,0°C unter Berücksichtigung von 10 unterschiedlichen Temperatur-Kalibrationspunkten und

Öl als Testflüssigkeit statt. Die Absolutkalibrierung der Heizeinheit kann auch

kundenspezifisch für einen bestimmten Temperaturbereich durchgeführt

werden. HLC by DITABIS erreicht eine sehr hohe Genauigkeit u.a. dadurch,

dass die Blocktemperatur im Block gemessen wird. Es kann jedoch vorkommen, dass bei großen Temperaturdifferenzen zwischen Raum- und Blocktemperatur ein entsprechender Einfluss der Raumtemperatur auf die Probentemperatur festzustellen ist. Um diesen Einfluss zu reduzieren, empfehlen wir, die

36

Antikondensplatte BA 24 / BA 96 oder die Temperierhaube BT 01 / BT 02 zu

verwenden. Bitte beachten Sie bei der Vorgabe einer Prozesszeit, dass die

Probentemperatur immer etwas später erreicht wird als die angezeigte Blocktemperatur.

Erste Schritte

Inbetriebnahme

Das Netzkabel wird auf der Geräte-Rückseite in die IEC-Buchse gesteckt und

mit dem Netz 230 V, 50 Hz über eine Schuko-Steckdose verbunden. Bitte stellen Sie sicher, dass Sie ausschließlich eine geerdete Steckdose verwenden.

Wechselblöcke

Bei der Auslieferung sind die Wechselblöcke separat verpackt. Setzen Sie die

Blöcke auf die Temperierplatten und achten Sie auf die richtige Platzierung

des mittleren Gewindebolzens und der 2 kleinen Eckbolzen, so dass der Block

passgenau auf der Temperierplatte aufliegt. Bitte achten Sie darauf, dass die

Unterseite der Blöcke sauber ist. Schrauben Sie den Block dann mit der

Schraube mit dem beiliegenden Innensechskant fest an den Boden der Temperierplatte, um eine Fixierung des Blockes beim Schütteln zu erhalten und

eine noch bessere Temperaturgenauigkeit zu erreichen. Testen Sie durch

Hochziehen des Blockes, ob dieser fest sitzt.

Starten Sie den Prozess nie, ohne dass ein Block festgeschraubt

ist. Setzen Sie bei den Zwei-Block-Systemen immer zwei Blöcke

ein, auch wenn nur einer genutzt wird. So wird die Sicherheit sowie ein ruhiger Schüttelbetrieb gewährleistet.

i

37

Schalten Sie das Gerät mit dem Hauptschalter auf der Rückseite des Gerätes

ein, auf dem Display erscheint das Startmenü. Die grüne LED rechts oben auf

dem Touchdisplay leuchtet, sobald ein Prozess läuft.

Bedienung

Einstellung Parameter

Startmenü

Dieses Menü erscheint nach dem Einschalten

des Gerätes, nach dem Abbrechen oder dem

automatischen Ende eines Prozesses.

Die letzten Sollwerte bleiben auch nach dem

Ausschalten des Gerätes erhalten.

Set-Up Menü

Drücken Sie die Pfeiltaste links und rechts

gleichzeitig, dann öffnet sich das Set-Up

Menü. Mit + und – können die Werte zum

Einstellen angewählt werden. Das angewählte Feld blinkt, mit ok wird es zum Abändern

fest hinterlegt. Mit den Tasten + und – können die Eingaben oder die Werte geändert

werden.

Wird eine Eingabe durch ok bestätigt, wird

das Feld wieder blinkend unterlegt. Über

Bestätigen des Buttons Startmenü gelangen

Sie wieder zum Startbildschirm.

Folgende Werte können angepasst werden:

38

10-Punkt-Kalibrierung

Seite 1:

Sprache: Englisch, Deutsch, Französisch,

Spanisch

Temperatureinheit: °C oder °F

Blocknummer (10-Punkt-Kalibrierung)

Ende bestätigen:

Ja: bei Prozessende ertönt ein Signalton bis

ok gedrückt wird. So lange läuft der Prozess

mit den letzten Daten.

Nein: der Prozess endet ohne Bestätigung.

Drehrichtung: rechts, links

Seite 2:

Kontrast: angegeben in %

Helligkeit:angegeben in %

Displayfarbe: normal - inverse

Standardmäßig ist in der Software die BlockKalibrierung „B0“ eingestellt. Dieser Standard

Kalibrierung liegen 10 Stützpunkte zu Grunde.

Sie ist optimiert auf alle DITABIS Standardblö-

cke. Bei individuell angefertigten Blöcken

können Sie zusätzlich auch eine individuelle,

auf Ihre Bedürfnisse abgestimmte Kalibrierung vornehmen. Für diese individuelle Kalibrierung benötigen Sie ein geeichtes Temperaturmessgerät.

Wählen Sie im Set-Up Menü

den Punkt

„Blocknummer“ und bestätigen mit ok

. Sie

können neben dem Standardblock B1 bis zu 4

weitere individuelle Kalibrationen vornehmen

und speichern. Wechselblöcke kalibrieren

39

und abspeichern. Dazu wählen Sie B1 bis B4

aus. Bestätigen Sie erneut mit ok. Jetzt kommen Sie in das Kalibriermenü. In der ersten

und dritten Spalte sehen Sie die Temperaturstützpunkte. In der zweiten und vierten Spalte die variablen Einstellwerte. Mit den Tasten

+ und - können die Eingaben oder die Werte

geändert werden. Das angewählte Feld blinkt,

mit ok wird es zum Abändern fest hinterlegt.

Beispiel:

Sie haben das Gerät im Startmenü auf 95,0°C

eingestellt und messen direkt in der Probe

mit einem kalibrierten Thermometer nur

85,0°C. Jetzt müssen Sie den Temperaturstützpunkt um -10°C, also auf 85,0°C verändern. Auf diese Art können Sie jeden einzelnen Stützpunkt kalibrieren.

Temperatur-Sollwert

Navigieren Sie mit + und – zum Temperatur-

eingabefeld und bestätigen Sie mit ok. Die

einzelnen Ziffern können mit Pfeil links und

rechts angewählt werden, ihr Wert kann mit

+ und – geändert werden. Die Eingabe wird

mit ok bestätigt und der Cursor springt auto-

mtatisch zum Button Starten.

e

e

40

Eine Sollwertänderung kann auch auf gleiche

Weise während eines laufenden Prozesses

vorgenommen werden. Nach Bestätigung der

Eingaben durch ok wird der neue Sollwert

sofort wirksam. Bei der Hunderter-Stelle

können gewählt werden:

0 für Temperaturen bis +99,9°C

1 für Temperaturen ab +100,0°C

- für Temperaturen unter 0,0°C

Wichtiger Hinweis

Bei den Kühlgeräten darf die

minimale Temperatur nicht kleiner der unten

angegebenen Differenz zur Raumtemperatur

sein.

MKR 13 / TK 23: 16°C unter Rt.

MKR 23: 11°C unter Rt.

Mix-Sollwert

Navigieren Sie mit + und – zum Schüttelfre-

quenzeingabefeld und bestätigen Sie mit ok.

Die einzelnen Ziffern können mit Pfeil links

und rechts angewählt werden, ihr Wert kann

mit + und – geändert werden. Die Eingabe

wird mit ok bestätigt und der Cursor springt

automtatisch zum Button Starten. Die EinerZiffer kann nicht ausgewählt und geändert

werden. Eine Sollwertänderung kann auch

auf gleiche Weise während eines laufenden

Prozesses vorgenommen werden. Nach Bestätigung der Eingaben durch ok wird der

neue Sollwert sofort wirksam.

Dauer des Prozesses (Zeitvorgabe)

Navigieren Sie mit + und – zum Zeiteingabe-

41

feld und bestätigen Sie mit ok. Die einzelnen

Ziffern können mit Pfeil links und rechts angewählt werden, ihr Wert kann mit + und -

geändert werden. Die Eingabe wird mit ok

bestätigt und der Cursor springt automtatisch

zum Button Starten.

Soll der Prozess endlos laufen, stellen Sie

00:00 ein.

100% Short-Mix (Vortexen)

Navigieren Sie mit + und – zum Button 100%

Short-Mix und bestätigen Sie mit ok. Das

Gerät schüttelt mit der maximalen Mixgeschwindigkeit, unabhängig davon ob ein Prozess gestartet ist oder nicht.

Programmmodus wählen

Navigieren Sie mit + und – zum Button Pro-

gramm und bestätigen Sie mit ok. Details zur

Programmierung siehe Seite 40.

Ablauf ohne Zeitvorgabe

Stellen Sie lediglich eine Soll-Temperatur und

eine Soll-Schüttelfrequenz ein, setzen sie Zeit

jedoch auf endlos 00:00, so wird die Prozess-

zeit ständig angezeigt. Diese beginnt erst zu

42

laufen, wenn der Temperatur Sollwert

erreicht ist.

Auch während eines laufenden Prozesses

können sämtliche Sollwerte - wie oben beschrieben - geändert werden. Änderungen

bleiben auch nach Beendigung des Prozesses

erhalten und erscheinen im Startmenü als

aktuelle Sollwerte.

Zum Beenden des Prozesses drücken Sie

Stoppen.

Ablauf mit Zeitvorgabe

Wird eine Prozesszeit eingestellt, wird im

Menü die Restzeit angezeigt. Die Zeit beginnt

erst zu laufen, wenn der Temperatur-Sollwert

erreicht ist. Dies gilt auch für nachfolgende

Temperaturwechsel. Auch während eines

laufenden Prozesses können sämtliche Sollwerte - wie oben beschrieben - geändert

werden. Der Prozess endet ohne Signal oder

läuft weiter mit Signal, bis er manuell gestoppt wird. Der entsprechende Modus kann

im Set-Up Menü gewählt werden.

Bei Änderungen während des Prozesses

Sind Sollwertänderungen vorgenommen

worden können Sie wählen, ob diese Änderungen gespeichert werden sollen und im

Startmenü als neue Sollwerte erscheinen.

Stoppen des Prozess vor Ablauf der Zeit

Wird der Prozess vor Ablauf der Zeit gestoppt

oder geändert, können Sie wählen, ob der

Prozess wirklich beendet werden soll oder ob

er weiter laufen soll. Je nach Wahl erscheint

das Startmenü oder die Auswahl, ob der Pro-

43

zess ab Stopp weiterlaufen soll (Zeit läuft ab

Stopp) oder ob es einen Neustart geben soll

(Zeit beginnt ab Null).

Programmierungsfunktion

Programmmenü

Navigieren Sie mit + und – zum Button

Programme und bestätigen Sie mit ok.

Es können insgesamt 30 unterschiedliche

Programmschritte vorgeben werden, die

auf max. 9 verschiedene Programme

verteilt sind.

Die "Programmnummer" ist standardmäßig mit einer 1 versehen, das Feld ist

blinkend unterlegt. Bestätigen Sie die

Programmnummer mit ok.

Mit + und – können die Programmnr. 1-9

ausgewählt werden. Soll die standarmäßige 1 oder die Änderung übernommen

werden, so drückt man ok und das Feld

"Zyklen" wird blinkend unterlegt.

44

Einstellung der einzelnen Paramater

Zyklen = Anzahl der Wiederholungen des Programmes, Auswahl von 1-9 möglich.

Soll keine Änderung vorgenommen werden, so fährt man mit - auf das nächste Feld.

Soll die Anzahl der Zyklen verändert werden, so ist ok zu drücken, das Feld wird fest

unterlegt. Der Wert kann mit den Tasten + und – zwischen 1 und 9 gewählt werden.

Ist die gewünschte Anzahl der Zyklen eingestellt, so ist dies mit ok zu bestätigen,

das Feld "Schritt" wird blinkend unterlegt.

Schritt = Teilabschnitt innerhalb eines Programmes. Auswahl von 1-9 möglich.

Soll der angezeigte Programmschritt geändert werden, so ist ok zu drücken, das

Feld wird fest unterlegt. Der Wert kann mit den Tasten + und – zwischen 1 und 30

gewählt werden. Ist der gewünschte Schritt für die folgenden Eingaben eingestellt,

so ist dies mit ok zu bestätigen, das Feld "Stunden" wird blinkend unterlegt.

Stunden = Dauer des Teilabschnitts in Stunden.

Sollen Eingaben vorgenommen werden, so ist ok zu drücken, die Einer-Stelle wird

fest unterlegt, sie kann mit den Tasten + und – gewählt werden. Soll die ZehnerStelle geändert werden, so ist mit auf die Zehner-Stelle zu fahren. Sie kann mit

+ und – gewählt werden. Ist die gewünschte Stundenzeit eingestellt, so ist diese mit

ok zu bestätigen, das Feld "Minuten" wird blinkend unterlegt.

Minuten = Dauer des Teilabschnitts in Minuten.

Sollen Eingaben vorgenommen werden, so ist ok zu drücken, die Zehner-Stelle wird

fest unterlegt, sie kann mit den Tasten + und – gewählt werden. Soll die Einer-Stelle

geändert werden, so ist mit auf die Einer-Stelle zu fahren. Sie kann mit + und –

45

gewählt werden. Ist die gewünschte Minutenzeit eingestellt, so ist diese mit

ok zu bestätigen, das Feld "Temp °C" wird blinkend unterlegt.

Zeit "endlos":

Soll ein Programmschritt (vornehmlich der letzte innerhalb eines Programmes)

endlos lange lau

fen bis das Programm manuell beendet wird, so ist sowohl bei

Stunden als auch bei Minuten jeweils eine 00 einzugeben.

Temperatur = Solltemperatur des Teilabschnitts

Der Temperatur-Sollwert ist standardmäßig mit 37,0 versehen. Sollen in dem Feld

"Temp °C" keine Eingaben vorgenommen werden, so fährt man mit –

auf das

nächste Feld. Soll der Wert geändert werden, so ist ok zu drücken, es kann jede

einzelne Ziffer geändert werden. Der Cursor steht an der Zehner-Stelle des Sollwertes. Dieser Wert kann mit den Tasten + und – geändert werden. Soll eine weitere

Stelle in diesem Datenfeld geändert werden, so muss sie mit den Tasten < und >

angefahren werden. Der fest unterlegte Wert wird wieder mit den Tasten + und –

geändert. Ist der Sollwert mit sämtlichen Ziffern eingestellt, so ist dieser mit ok zu

bestätigen, das Feld "Steigzeit" wird blinkend unterlegt.

Steigzeit = Zeitangabe, in der die Probe auf die Solltemperatur temperiert werden

soll. Diese Angabe ist nur nötig, wenn die Probe langsamer als die Voreinstellung

temperiert werden soll. Soll die Probe schnellstmöglich temperiert werden, hinterlegen Sie den Wert 0.

Man kann vorgeben, in wieviel Minuten die in dem aktuellen Schritt eingegebene

Temperatur erreicht werden, wenn langsamer temperiert werden soll als dies tech-

nisch möglich ist. Im unten aufgeführten Beispiel soll die Temperatur von 60,0°C

46

des Schrittes 2 innerhalb von 20 Minuten von der Temperatur 37,0°C des Schrittes 1

erreicht werden. (Die max. Eingabe bei der Steigzeit beträgt 99 min). Sollen in dem

Feld "Steigzeit" keine Eingaben vorgenommen werden (schnellstmögliche Heiz-

bzw. Kühlzeit), so fährt man mit – auf das nächste Feld. Soll der standardmäßige

Wert 0 verändert werden, so ist ok zu drücken, die Einer-Stelle wird fest unterlegt,

sie kann mit den Tasten + und – gewählt werden. Soll die Zehner-Stelle geändert

werden, so ist mit auf die Zehner-Stelle zu fahren. Sie kann mit + und - gewählt

werden. Ist die gewünschte Steigzeit eingestellt, so ist diese mit ok zu bestätigen,

das Feld "Drehzahl" wird blinkend unterlegt.

Beispiel eines Temperaturprogrammes

Drehzahl = Schüttelfrequenz, mit der die Blöcke geschüttelt werden sollen.

Die Einer-Ziffer kann nicht ausgewählt und geändert werden.

Soll der Wert geändert werden, so ist ok zu drücken, es kann jede einzelne Ziffer

geändert werden. Der Cursor steht an der Hunderter-Stelle des Sollwertes. Dieser

Wert kann mit den Tasten + und – geändert werden. Soll eine weitere Stelle in

diesem Datenfeld geändert werden, so muss sie mit den Tasten < und > angefahren

werden. Der fest unterlegte Wert wird wieder mit den Tasten + und – geändert. Die

letzte Einer-

Ziffer kann nicht ausgewählt und geändert werden. Ist der Sollwert

eingestellt, so ist dieser mit ok zu bestätigen, das Befehlsfeld "Pause"wird blinkend

unterlegt.

47

Intervall-Schütteln = Will man die Probe nicht ständigem Schütteln aussetzen, so

kann man dies mit dem "Intervall-Mixen" ermöglichen.

Es kann eine Ruhezeit in "Pause" von bis zu 9,9 Minuten vorgegeben werden. Die

darauf folgende kurze Schüttelzeit wird in "Mix sec" bis zu 9 Sekunden eingegeben.

Besonders sinnvoll scheint diese Wahl beim letzten Programmschritt eines Pro-

grammes mit der zeitlichen Eingabe von "endlos", wenn das Labor z.B. unbesetzt

ist, um das Programm komplett abzuschließen. Stellen Sie die Intervalle mit Pause

[min] und Mix [s] ein.

Pause [min] = Ruhezeit von bis zu 9,9 Minuten. Sollen keine Intervalle ausgeführt

werden, geben Sie hier den Wert 0,0 an. Die Pausenzeit ist standardmäßig mit 0,0

versehen.

Sollen in dem Feld "Pause" keine Eingaben vorgenommen werden, so fährt man mit

– auf das nächste Feld "Schritt". Soll der Wert geändert werden, so ist ok zu drü-

cken, es kann jede einzelne Ziffer geändert werden. Nach dem Druck von ok wird

die Einer-Stelle unterlegt, sie kann mit den Tasten + und – gewählt werden. Soll die

Zehntel -Stelle geändert werden, so dückt man auf die Taste >, die Ziffer wird unterlegt, sie kann mit + und – gewählt werden. Ist eine Pausenzeit eingestellt, so ist

diese mit ok zu bestätigen, das Feld "Mix sec" wird blinkend unterlegt.

Mix [s] = Kurze Schüttelzeit bis zu 9 Sekunden nach Ruhepause.

In dem Feld "Mix sec" steht standardmäßig eine 1 wenn es angefahren wird. Sollen

in dem Feld "Mix sec" keine Eingaben vorgenommen werden, so fährt man mit –

auf das nächste Feld "Schritt". Soll die Schüttelzeit geändert werden, so ist ok zu

drücken, sie kann mit den Tasten + und – gewählt werden. Ist die gewünschte Zeit

eingestellt, so ist diese mit ok zu bestätigen, das Feld "Schritt" wird blinkend unter-

legt.

Eingaben weiterer Programmschritte

Soll innerhalb des gewählten Programmes

ein weiterer Programmschritt eingegeben

werden, so ist bei dem blinkend unterleg-

ten Feld "Schritt" die Taste ok zu drücken,

48

die Zahl des letzten Programmschrittes

muss um eins erhöht werden. Die weitere

Eingabe erfolgt wie bereits beschrieben.

Ändern der Programmeingaben

Soll das gewählte Programm geändert

werden, so ist die Nummer des Programmschrittes einzugeben, in dem Änderungen vorgenommen werden sollen.

Das zu ändernde Feld kann mit den Tas-

ten + und – ausgewählt werden (wird

blinkend unterlegt). Zur Änderung ist ok

zu drücken, die Änderung erfolgt jeweils

wie bei der Eingabe beschrieben, sie muss

mit ok bestätigt werden. Mit den Tasten

+ und – wird ein entsprechendes

Feld angefahren.

Beenden der Programmeingaben

Soll das gewählte Programm beendet

werden, so gelangt man mit der Taste +

zu den Feldern "Starten" (um das

Programm sofort zu starten).

49

Starten eines Programmes

Wählen Sie die entsprechende

Programmnummer und bestätigen Sie

den Starten-Button im Programmenü.

Änderungen der Parameter während

des Programmablaufs

Änderungen der Temperatur und Drehzahl sowie das Durchführen des ShortMixes sind während eines laufenden

Programms möglich.

Als Sollzeit wird die Gesamtzeit des Programmschrittes, als Restzeit die des laufenden Prozesses angegeben. Im Display

unten rechts werden Programmnummer,

Zyklus und Schritt angezeigt.

Beenden / Unterbrechen des

Programms:

Wenn Sie Stoppen bestätigen, erscheinen

die Optionen Proz. Beenden und Weiter

mit Proz.

Bei der Wahl von Proz. Beenden erscheint

Startmenue oder Änderungen speichern,

50

falls während des Prozesses Änderungen

an den Parametern vorgenommen wurden.

Wählt man Weiter mit Proz. erscheint die

Auswahl Weiter ab Stopp oder Proz.

Neustart (Programm startet bei Zyklus 1,

Schritt 1).

Montage von Zubehörteilen

Antikondensplatte BA 24 / 96

Die Antikondensplatte BA 96 (800013000) wird auf den festgeschraubten

Block gesetzt, es sind keine Montageschritte erforderlich. Zur Verwendung

der Antikondensplatte BA 24 (800012900) entfernen Sie die Innensechskantschraube in dem Block mit dem beiliegenden Schraubendreher. Schrauben Sie

den beiliegenden Gewindestift mit Isolierknopf in die Antikondensplatte.

Legen Sie die Antikondensplatte auf den Block und schrauben Sie den Gewindestift weiter, sodass sie in den Bolzen des Gerätes fasst somit den Block und

die Antikondensplatte fest mit dem Gerät verbindet.

51

Datentransfer

Eine USB 1.1. Schnittstelle zur Kommunikation mit einem PC ist serienmäßig

vorhanden. Verbinden Sie das Gerät über den USB-Anschluss an der linken

Seite mit einem USB-Kabel mit Ihrem PC. Falls auf Ihrem Rechner noch nicht

vorhanden, installieren Sie den geeigneten USB-Treiber. Diesen finden Sie

unter www.ftdichip.com/Drivers/VCP.htm. Diese USB-Treiber erzeugen im PC

eine neue virtuelle COM-Schnittstelle. Der Chip in der Smart Control heißt

FT232B.

Prozessdaten über USB entnehmen

Starten Sie auf Ihrem Rechner ein Terminal-Programm (z.B. Hyper-Terminal).

Dieses Programm finden Sie unter Windows in "Programme" / "Zubehör"/

"Kommunikation". Es wird das Fenster "Hyper Terminal" geöffnet. Gehen Sie

systematisch weiter vor, beachten Sie, dass bei der Anschlusseinstellung bei

"Bits pro Sekunde" 115200 gewählt wird. Wählen Sie bei "Übertragung": "Text

aufzeichnen", geben den Speicherort an und bestimmen den Dateinamen als

.txt Starten Sie Hyper Terminal und den Prozess. Jede Minute werden folgende Daten im Textformat aufgezeichnet und durch ein Komma getrennt:

Zeit ab Start (hh:mm) Zeit ab neuem Programmschritt

Temperatur in °C (tmp) (step time)

Drehzahl in 1 / min. (rpm) Steigzeit (rem. risetime_m)

Programm-Nr. (prg.) Intervall Mix (mix_s)

Zyklus (cycle) Intervall Pause (pause_m)

Programmschritt (step)

Wenn Sie die Textdatei öffnen, die Sie zum Speichern gewählt haben, können

Sie sich den gesamten Prozessablauf in nebenstehender Form ansehen. Da die

Daten durch Kommas getrennt sind, können Sie sich auf einfache Art eine

Excel-Datei erstellen und daraus eine oder mehrere Kurven erzeugen.

52

START

Sollwerte / Setpoints

xx:xx,+37.0,0200,01,01,01,00:01,00,9,0.2

time hh:mm,tmp,rpm,prg,cycle,step,steptime hh:mm,rem.

risetime_m,mix_s,pause_m

00:00,+26.9,0000,01,01,01,00:00,00,9,0.2

00:01,+33.7,0220,01,01,01,00:00,00,9,0.2

00:02,+36.7,0000,01,01,01,00:00,00,9,0.2

00:03,+36.9,0000,01,01,01,00:00,00,9,0.2

START

Sollwerte / Setpoints

xx:xx,+70.0,0300,01,01,02,00:12,10,9,0.1

time hh:mm,tmp,rpm,prg,cycle,step,steptime hh:mm,rem.

risetime_m,mix_s,pause_m

00:04,+36.9,0000,01,01,02,00:00,10,9,0.1

00:05,+39.1,0000,01,01,02,00:01,09,9,0.1

00:06,+42.1,0000,01,01,02,00:02,08,9,0.1

00:07,+45.2,0300,01,01,02,00:03,07,9,0.100:08,+48.4,0300,01,01,02,00:04,06

,9,0.1

00:09,+51.7,0000,01,01,02,00:05,05,9,0.1

00:10,+54.9,0000,01,01,02,00:06,04,9,0.1

00:11,+58.2,0300,01,01,02,00:07,03,9,0.1

00:12,+61.5,0300,01,01,02,00:08,02,9,0.1

00:13,+64.7,0000,01,01,02,00:09,01,9,0.1

STOP

Prozessdaten über USB eingeben

Zur Prozesssteuerung eines HLC by DITABIS Gerätes mit Smart Control über

eine USB-Schnittstelle sind 4 Befehle möglich und notwendig:

Start

Startet einen Prozess ohne Programm mit den Parametern, die auf dem Display stehen. Eine eventuelle Zeitvorgabe wird gelöscht und durch endlos

überschrieben da zeitlich Abläufe am Rechner programmiert werden müssen.

53

Stopp

Stoppt jeden Prozess und führt zum Startmenü zurück, laufende Programme

/ Prozesse werden abgebrochen.

t=0370

Verändert die Solltemperatur auf einen neuen Wert.

Die Temperatur muss immer vierstellig eingegeben werden.

t=0370 stellt 37,0°C ein, t=0050 stellt 5,0°C ein, t=-060 stellt -6,0°C ein.

t= ist das Erkennungszeichen für einen Temperaturwert. Der Zahlenwert dahinter gibt den Wert in Zehntelgrad an. An der ersten Stelle nach dem = kann

eine 0, eine 1 oder ein Trennstrich stehen. Ungültige Temperaturwerte werden -wie bei der Eingabe am Gerät- durch den nächsten gültigen Wert ersetzt.

r=020

Verändert die Solldrehzahl auf einen neuen Wert.

Die Drehzahl muss immer dreistellig eingegeben werden.

r=120 stellt 1.200 1/min ein, r=045 stellt 450 1/min ein.

r= ist das Erkennungszeichen für einen Drehzahlwert. Der Zahlenwert dahinter

gibt den Wert in 10 1/min an. Ungültige Drehzahlwerte werden -wie bei der

Eingabe am Gerät- durch den nächsten gültigen Wert ersetzt.

r=000

Stoppt die Drehzahl, wenn z.B. nicht mehr geschüttelt aber weiter temperiert

werden soll.

Andere Eingaben, wie z.B. r=0 werden als Drehzahl interpretiert und lassen

den Motor mit der Mindestdrehzahl drehen.

Jeder Befehl muss mit einem "CR" abgeschlossen werden

Bei unbekannten Befehlen und / oder bei Fehlern in der Schreibweise wird

nichts ausgeführt. Die Eingaben im Set-Up-Menü, wie Farbe, Kontrast und

Helligkeit des Displays, die Sprache, die Drehrichtung usw. können nur durch

das Bedienteil am Gerät selbst vorgenommen werden.

54

Problembehebung

Das Display bleibt dunkel

Bitte überprüfen Sie, ob der Hauptschalter an der Rückseite eingeschaltet ist.

Falls dies nicht der Fall ist, an der Steckdose aber Spannung anliegt, prüfen Sie

die Feinsicherung und tauschen diese ggf. aus. (IEC 127-2/III, 250 V, 2 A träge).

Diese Sicherung - und eine Ersatzsicherung - befinden sich in der IEC-Buchse

(in die das Anschlusskabel gesteckt ist). Mit einem Schraubendreher lässt sich

der Sicherungskasten herausziehen.

Das Gerät kühlt, heizt oder schüttelt nicht wie eingestellt

Überprüfen Sie, ob das Display beim Einschalten des Gerätes die richtige Gerätetypenbezeichnung anzeigt. Falls dies nicht der Fall sein sollte, kontaktieren Sie bitte Ihren Händler vor Ort oder die HLC by DITABIS Servicabteilung.

Es entstehen große Temperaturschwankungen

Prüfen Sie den Sitz des Wechselbockes durch Hochziehen. Wenn dieser zu

locker angeschraubt ist oder der Block Unebenheiten z. B. Verschmutzungen

aufweist, wird die Wärme / Kälte nicht korrekt übertragen.

Hinweise zum kapazitiven Touchdisplay

Das Touchdisplay reagiert auf Fingerdruck, auch in dünnen LatexHandschuhen, jedoch nicht auf Stylos. Aufgrund der Glasoberfläche ist die

Frontscheibe sehr unempfindlich gegen Schmutz, Chemikalien und mechanische Beschädigungen. Vermeiden Sie Kratzer in der Beschichtung, da diese zu

Störungen führen könnten. Bitte beachten Sie die nachfolgenden Reinigungshinweise.

55

Instandhaltung

Reinigung

Reinigen Sie regelmäßig das Gehäuse der und die Wechselblöcke der

Thermomixer und Blockthermostate.

Vorsichtsmaßnahmen zur Vermeidung von Stromschlägen

Elektrische Geräte können bei Fehlbedienung einen Stromschlag

verursachen. Versuchen Sie niemals elektrische Teile zu reparieren. Öffnen Sie niemals das Gerätegehäuse.

• Schalten Sie das Gerät aus und trennen Sie es von der

Stromversorgung, bevor Sie mit der Reinigung bzw. Des-

infektion beginnen.

• Lassen Sie keine Flüssigkeiten in das Gehäuseinnere ge-

langen (Lüftungsschlitze).

• Führen Sie keine Sprühdesinfektion durch.

• Schließen Sie das Gerät erst vollständig trocken wieder

an die Stromversorgung an.

Der Reparaturservice darf nur durch autorisiertes und geschultes

Personal vorgenommen werden. Eine Modifikation des Gerätes

ist nicht zulässig.

Vorsicht bei Verwendung von aggressiven Chemikalien

Verwenden Sie an dem Gerät und Zubehör keine aggressiven

Chemikalien wie z.B. starke und schwache Basen, starke Säuren,

Formaldehyd, Aceton, halogen

ierte Kohlenwasserstoffe oder

Phenol.

• Reinigen Sie das Gerät bei Verunreinigungen durch ag-

gressive Chemikalien umgehend mit einem neutralen

Reinigungsmittel.

• Verwenden Sie weder ätzende Reinigungsmittel, noch

aggressive Lösungs- oder schleifende Poliermittel.

56

Reinigung

1. Trennen Sie das Gerät bitte von der Stromversorgung, bevor Sie mit

der Reinigung beginnen.

2. Reinigen Sie alle äußeren Teile des Geräts bitte mit einer milden Sei-

fenlösung und einem fusselfreien Tuch.

3. Entfernen Sie die Seifenlösung mit Aqua dest.

4. Bitte trocknen Sie alle gereinigten Teile sorgfältig ab.

Desinfektion

1. Trennen Sie das Gerät bitte von der Stromversorgung, bevor Sie mit

der Desinfektion beginnen.

2. Lassen Sie das Gerät abkühlen.

3. Reinigen Sie das Gerät bitte wie oben aufgeführt.

4. Wählen Sie eine Desinfektionsmethode, die den für Ihren Anwen-

dungsbereich geltenden gesetzlichen Bestimmungen und Richtlinien

entspricht.

5. Wischen Sie bitte alle äußeren Teile des Geräts mit dem Desinfekti-

onsmittel und einem fusselfreien Tuch ab.

Service

Falls ein technisches Problem auftritt, kontaktieren Sie bitte Ihren Händler vor

Ort oder die DITABIS Serviceabteilung. Hier wird eine erste Einschätzung des

Defekts durchgeführt. Die DITABIS Kontaktdaten finden Sie unter

www.ditabis.com. Falls notwendig, wird das Gerät zur Reparatur eingeschickt

– beachten Sie hierzu bitte die Servicerichtlinien, welche auf www.ditabis.com

zu finden sind.

Dekontamination vor Versand

Wenn Sie das Gerät im Reparaturfall zum autorisierten technischen Service

oder im Entsorgungsfall zu Ihrem Vertragshändler schicken, dekontaminieren

Sie bitte alle Teile, die Sie versenden möchten. Dokumentieren Sie die Dekontamination in einer Dekontaminationsbescheinigung (inkl. Seriennummer)

und legen Sie bitte diese beim Versand bei.

57

Technische Daten

Technische Daten

MKR 13

Temperatur-Arbeitsbereich

Rt. -16°C bis +100°C

Temperatur-Einstellbereich

-10°C bis +105°C

Genauigkeit / Auflösung

+/- 0,1°C / 0,1°C

Max. Heizgeschwindigkeit

6,0°C / min

Max. Kühlgeschwindigkeit

12,0°C / min

Schüttelfrequenz

200 – 1.500 U / min

Schüttelhub

3 mm rund

Abmessungen (ohne Block) B x T x H

220 x 330 x 144 mm

Block - Kapazität

1 Wechselblock

Gewicht (ohne Block)

9,0 kg

Leistungsaufnahme

130 W