HKC Co HQ-005 Installation, Operation And Maintenance Manual

Installation, Operation and Maintenance Manual

HQ – 005. ELECTRIC ACTUATORS

QUARTER-TURN ELECTRIC ACTUATORS

HQ-005 Electric Actuators

Version – Ver. 1

Revision – Rev. 3

Document No. HKQI-611

Actuated Solutions Ltd

Unit 9, Evans Place, Durban Road, Bognor Regis, West Sussex, PO22 9RY

Tel: 01243 827469 Fax: 01243 829418 Email: sales@actuated-solutions.co.uk

Website: www.actuated-solutions.co.uk

Small & Compact Design

High corrosion resistance

Beacon indicator with LED lamps

IP67 Weatherproof Aluminium housing

Multi-voltage Power Supply

Long life cycle

Table of Contents

1 INTRODUCTION ................................................................................................................ 1

1.1 Purpose .................................................................................................................................. 1

1.2 Safety Notices ........................................................................................................................ 1

2 PRODUCT IDENTIFICATION ............................................................................................. 2

2.1 Product Identification ............................................................................................................ 2

2.1.1 Marking ............................................................................................................................................... 2

2.2 Initial Inspection .................................................................................................................... 2

2.3 Storage ................................................................................................................................... 2

3 GENERAL INFORMATION AND FEATURES .................................................................... 3

3.1 General Information .............................................................................................................. 3

3.1.1 Performance ....................................................................................................................................... 3

3.1.2 Standard Technical Data ..................................................................................................................... 3

3.1.3 HQ-005 Optional Technical Data (Optional) ....................................................................................... 3

3.1.4 Duty Cycle 1) ........................................................................................................................................ 3

3.1.5 Torque Control ................................................................................................................................... 4

3.1.6 Manual Override................................................................................................................................. 4

3.1.7 Lubrication .......................................................................................................................................... 4

3.2 External Parts for Standard Models ...................................................................................... 5

3.3 Internal Parts for Standard Models ....................................................................................... 5

4 INSTALLATION .................................................................................................................. 6

4.1 Pre-installation for using in General Service ......................................................................... 6

4.2 Actuator Mounting ................................................................................................................ 6

4.2.1 Actuator Mounting Base Details ........................................................................................................ 7

4.3 Limit Switch Setting ............................................................................................................... 8

5 MAINTENANCE ................................................................................................................. 9

5.1 Maintenance .......................................................................................................................... 9

5.2 Tools ....................................................................................................................................... 9

6 TROUBLE SHOOTING .................................................................................................... 10

7 DIMENSIONS ................................................................................................................... 12

Installation, Operation and Maintenance Manual

HQ-005 Electric Actuator

Document No. HKQI-611

1 | P a g e

1 INTRODUCTION

1.1 Purpose

The purpose of this manual is to introduce and explain the installation, operation and maintenance of HQ-005

electric actuators.

A copy of all wiring diagrams can be found online at our website

www.actuated-solutions.co.uk

1.2 Safety Notices

Safety notices in this manual outline precautions the user must take to reduce the risk of personal injury and

damage to the equipment. The user(s) must read these instructions before the installation, operation or

maintenance of HQ-005 electric actuators.

DANGER: Refers to personal safety and alerts the user to danger or harm.

The hazard or unsafe practice will result in severe injury or death.

WARNING: Refers to personal safety. Alerts the user to potential danger.

Failure to follow warning notices could result in personal injury or death.

CAUTION: Directs the user’s attention to general precautions that, if not

followed, could result in personal injury and/or equipment damage.

Installation, Operation and Maintenance Manual

HQ-005 Electric Actuator

Document No. HKQI-611

2 | P a g e

2 PRODUCT IDENTIFICATION

2.1 Product Identification

The actuator name plate is located on the opposite side of the conduit entry. The name plate contains the

following:

2.1.1 Marking

A) General

HQ logo (trade mark)

Model

Torque

Electrical power supply

Type

Rated current

Operating time (seconds)

Serial No.

Option

2.2 Initial Inspection

Upon on the receipt of the actuator, the user should inspect the condition of the product and ensure that

product specification stated in the name plate matches with the order sheet.

Remove the packing wrap or wooden box carefully. Inspect the product for any physical damage

that may have occurred during shipment.

Check the product specification with product ordered. If a wrong product has been shipped,

immediately report to our coordinator.

2.3 Storage

Actuators must be stored in a clean, cool and dry area. The unit should be stored with the cover installed and

the conduit openings sealed. Storage must be off the floor, covered with a sealed dust protector. When

actuators are to be stored outdoor, they must be stored off the ground, high enough to prevent from being

immersed in water or buried in snow.

ELECTRIC ACTUATOR

Q U A R T E R T U R N E L E C T R I C A C T U A T O R

MODEL : HQ-005

POWER:AC95-265V,24VAC/DC

OPERATION TIME: SEC.

SERIAL NO:

TORQUE: 5Kgf.m

TYPE: ON-OFF

RATED CURRENT : A

OPTION:

Installation, Operation and Maintenance Manual

HQ-005 Electric Actuator

Document No. HKQI-611

3 | P a g e

3 GENERAL INFORMATION AND FEATURES

3.1 General Information

HQ-005 electric actuators are designed for the operation of small size quarter turn valves; e.g. ball, butterfly and

damper valves etc. with high reliability and efficiency.

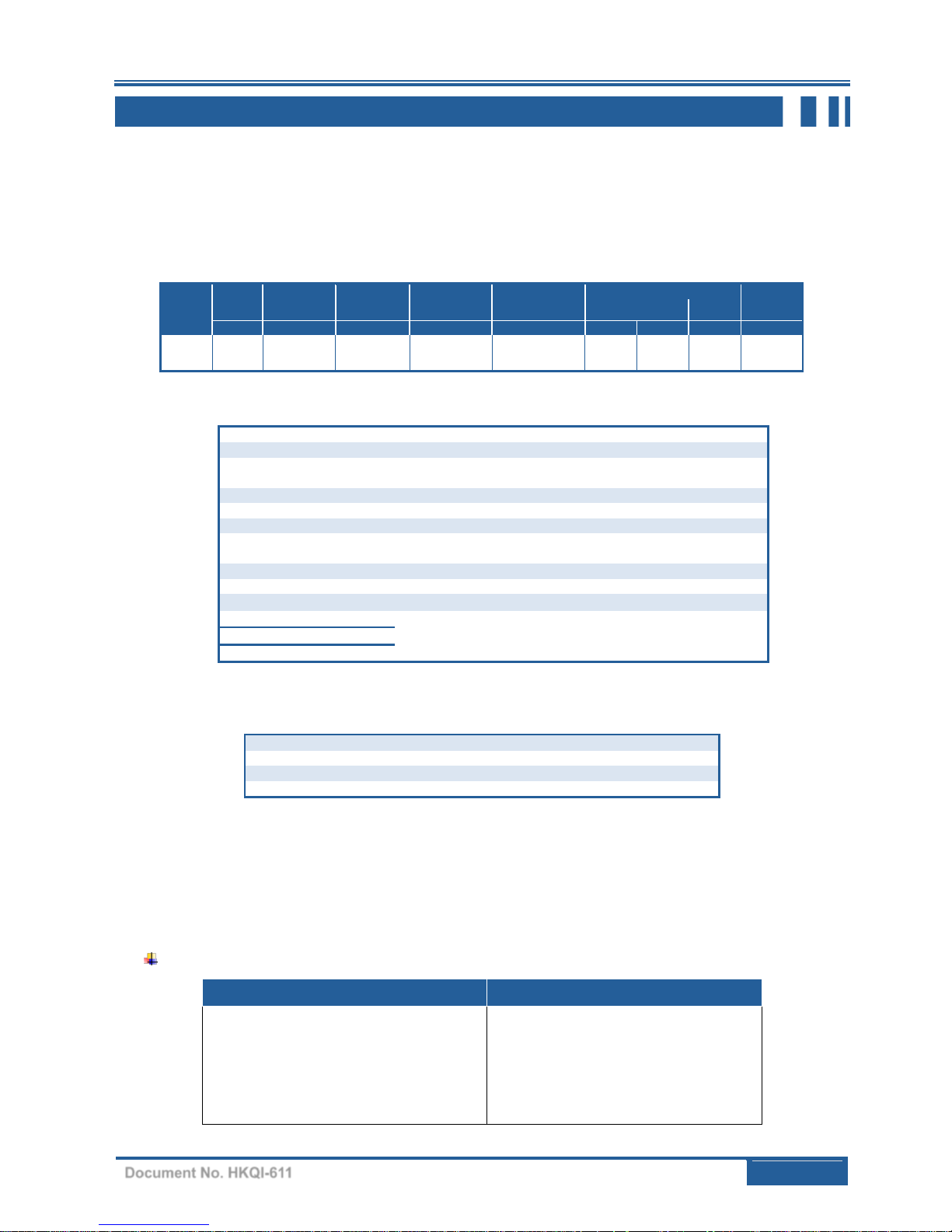

3.1.1 Performance

Type

Max.

output

Torque

Operating

time(sec.)

Duty Cycle

IEC34-1

Mounting

Size

Power

1 Phase

Rated Current (A) 60/50 Hz

Weight

AC

DC/AC

Kg.m

90°

S4 (%)

ISO 5210

AC or DC

110V

220V

24V

kg

HQ-005 5 13

70

F03, F04, F05

F07

95V ~ 265V AC

or

24V DC/AC

1A

0.5A

0.8A

1.2

3.1.2 Standard Technical Data

3.1.3 Optional Technical Data (Optional)

3.1.4 Duty Cycle 1)

Duty cycle rated IEC60034 – S4 70%

Exceeding the actuator’s rated duty cycle may cause thermal overload.

Note:

1)

Type of duty according to VDE 0530 / IEC 60034-1

Enclosure Rated

Weatherproof IP67

Enclosure

High grade aluminum alloy, corrosion resistant coated

Power Supply

110 / 220V AC 1 Ph 60/50Hz

24 V DC/AC

Duty Type

S4 70% / S2 30min (IEC 60034)

Motor

BLDC motor

Limit Switches

2 x open/close SPDT, 250V AC 5A rating

Auxiliary Limit Switches

2 x open/close SPDT, 250V AC 5A rating

Indicator

Continuous position indicator & full position LED lamp

Manual Override

Manual Handwheel

Lubrication

Grease moly EP

Ambient Temperature

-20 ℃~ + 80 ℃

External Coating

Dry powder polyester

TS

Torque overload indicator via flashing LED indication

PIU

Potentiometer Unit (0~1KΩ)

PCU

Proportional Control Unit (input, output 0~10V DC, 4~20mA DC)

CPT

Current Position Transmitter (output 4~20mA DC) , 0~10V

Short – time duty S2

Intermittent duty S4

The operation time at a constant load is short,

so that thermal equilibrium is not reached.

The pause is long enough for the machine to

cool down to ambient temperature. The

duration of the short –time operation is limited

to 15min (10min, 30min)

The duty is a sequence of identical cycles

which consist of starting time, operation time

with constant load and rest period. The rest

period allows the machine to cool down so

that thermal equilibrium is not reached. The

relative on-time at S4-25% or S4-50% is

limited to 25% and 70% respectively.

Loading...

Loading...