HKC Co HM04, HM11, HM20, HM, HM08 Installation And Maintenance Manual

...

Installation and Maintenance Manual

HKC

HM-SERIES / ACTUATORS

Version- V1

Document No. HQOI-08-EV1

DATE : 2011.12.22

H K C

WWW.HKCON.CO.KR

HKC CO.,LTD.

HM – Series. ELECTRIC ACTUATORS

INTELLIGENT MULTI-TURN ELECTRIC ACTUATORS

VALVE AUTOMATON

HHMM--SSeerriieess EElleeccttrriicc AAccttuuaattoorr

IInnssttaallllaattiioonn aanndd OOppeerraattiioonn MMaannuuaall

HHKKC

C

2

1. Introduction

1.1 Purpose 3

1.2 Manual Guidelines contents 3

1.3 External Parts for Standard Models 4

1.4 Safety Notices 4

2. Product Identification

2.1 Product Identification 6

2.1.1 Marking 6

2.2 Initial inspection 7

2.3 Storage 7

3. General Information and Features

3.1 General 7

3.2 Performance Data 8

3.2.1 AC 3 Phase Model & Torque (Nm) 8

3.2.2 AC 1 Phase Model & Torque (Nm) 8

3.2.3 Solid state design Model & Torque (Nm) 9

3.2.4 Mechanical Data 9

3.3 HM Standard Technical Data (Standard) 10

3.4 HM Option Technical Data (Optional) 11

3.5 Duty Cycle 11

3.6 Hand wheel and Declutching 11

3.7 Lubrication 12

3.8 Internal Parts for Standard Models 13

4. Installation and operation instruction

4.1 Pre-installation for use in general service 14

/ potentially explosive atmosphere

4.2 Actuator Mounting 14

4.3 Actuator Mounting Details (ISO5211 & 5210) 15

4.3.1 Mounting base 15

4.3.2 Disassembly and Assembly of Mounting Base 16

4.3.3 Disassembly and Assembly the Drive Bush in Thrust Base 17

4.3.4 Disassembly and Assembly the Drive Bush in Non-Thrust Base 18

4.4 Electrical Connections and Preliminary Test 18

5. Maintenance

5.1 Maintenance 20

5.2 Tools 20

6. Trouble shooting 21

7. Installation and maintenance tips 22

8 . Wiring Diagram

8-1~3. HM-Standard 3ph, CPT,PCU 23~25

9. Dimension 26

10. Grounding 27

APPENDIX I : HM-series Coding System 28

1

Introduction

1.1 Purpose

This Installation and operating manual

Multi -Turn

electric actuators.

There is no need for removal of the outer casing (exclude wiring), when operating t

HM Multi -

Turn electric actuator, due to its

The terminals for wiring and the internal electronics are sealed tight hence allowing

for unhindered removal procedures

When setting up the a

restrictions and

etc as they are individually displayed on screen

reduce the risk of danger as setup can be remotely carried out at a safer distance

The help menus for the control system of the valve and

screen hence user friendly

Configuration, alarm and status tests are given in English (default)

Movement of valve torque position values for the

1.2 Manual Outline

•

Electrical

•

Actuator

•

Basic configuration setup and actuation walkthroughs

•

Specific on

•

Maintenance and troubleshooting

•

Sales and A/S information

This manual contains important safety information

It is emphasized that the user understands the following material given in this document

before installation and setup of any product before operation and maintenance.

HHMM--SSeerriie

ess

IInnssttaallllaattiioonn aanndd

O

O

explains how to install, operate and maintain

Smart Intelligent

electronic

actuat

.

ctuator

utilize the remote control to set the torque,

.

This feature may

Actuator

are ava

.

.

actuator

is displayed on screen

IP 68 Design

and manual (local or remote) operation procedures

or Valve installation guidelines

-site and custom control requirement tasks

.

EElleeccttrriicc AAccttuuaattoorr

ppeerraattiioonn MMaannuuaall

HHKKC

C

3

the HM

he

ion capability

.

limit switches,

.

ilable on

.

HHMM--SSeerriieess EElleeccttrriicc AAccttuuaattoorr

IInnssttaallllaattiioonn aanndd OOppeerraattiioonn MMaannuuaall

HHKKC

C

4

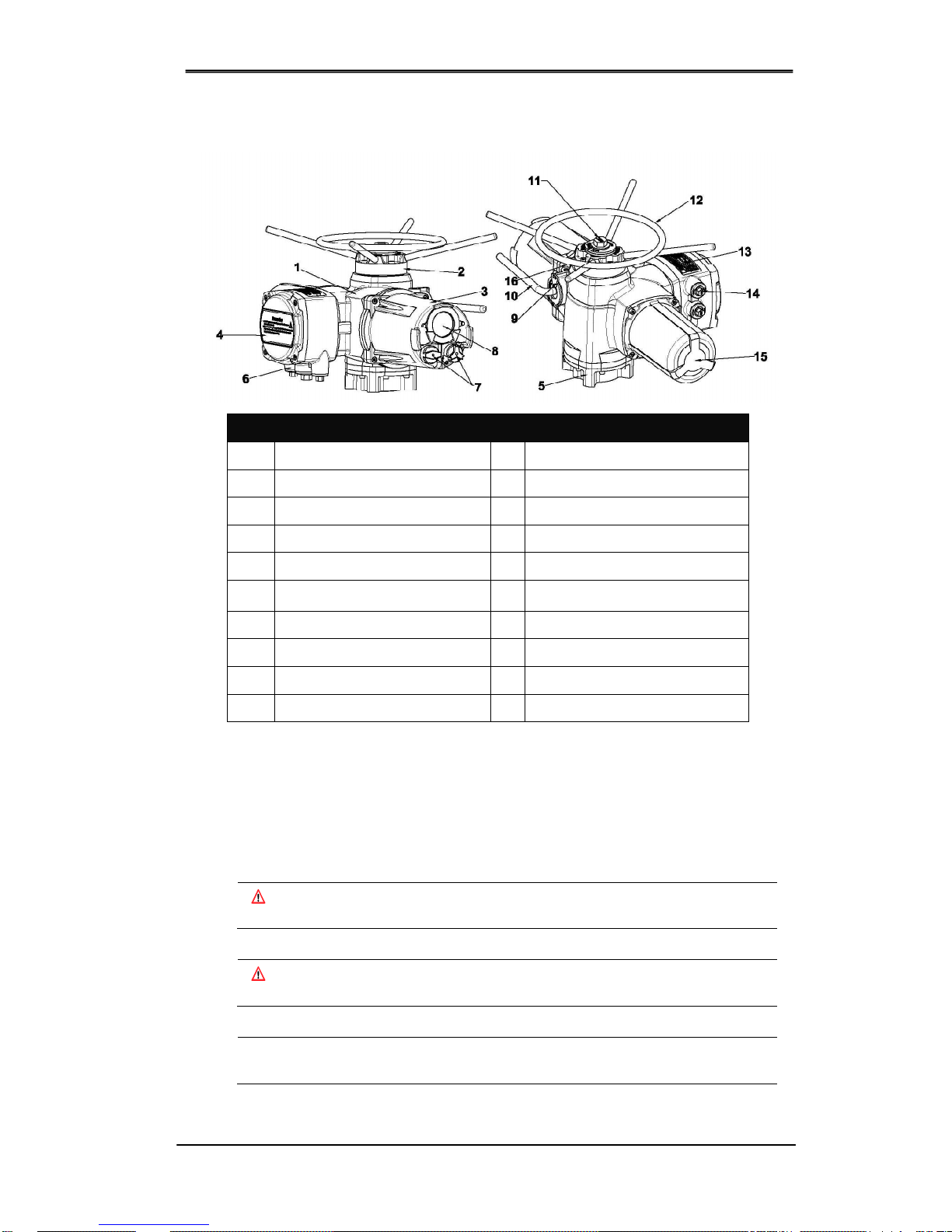

1.3 External Parts for Standard Models

1.4 Safety Notices

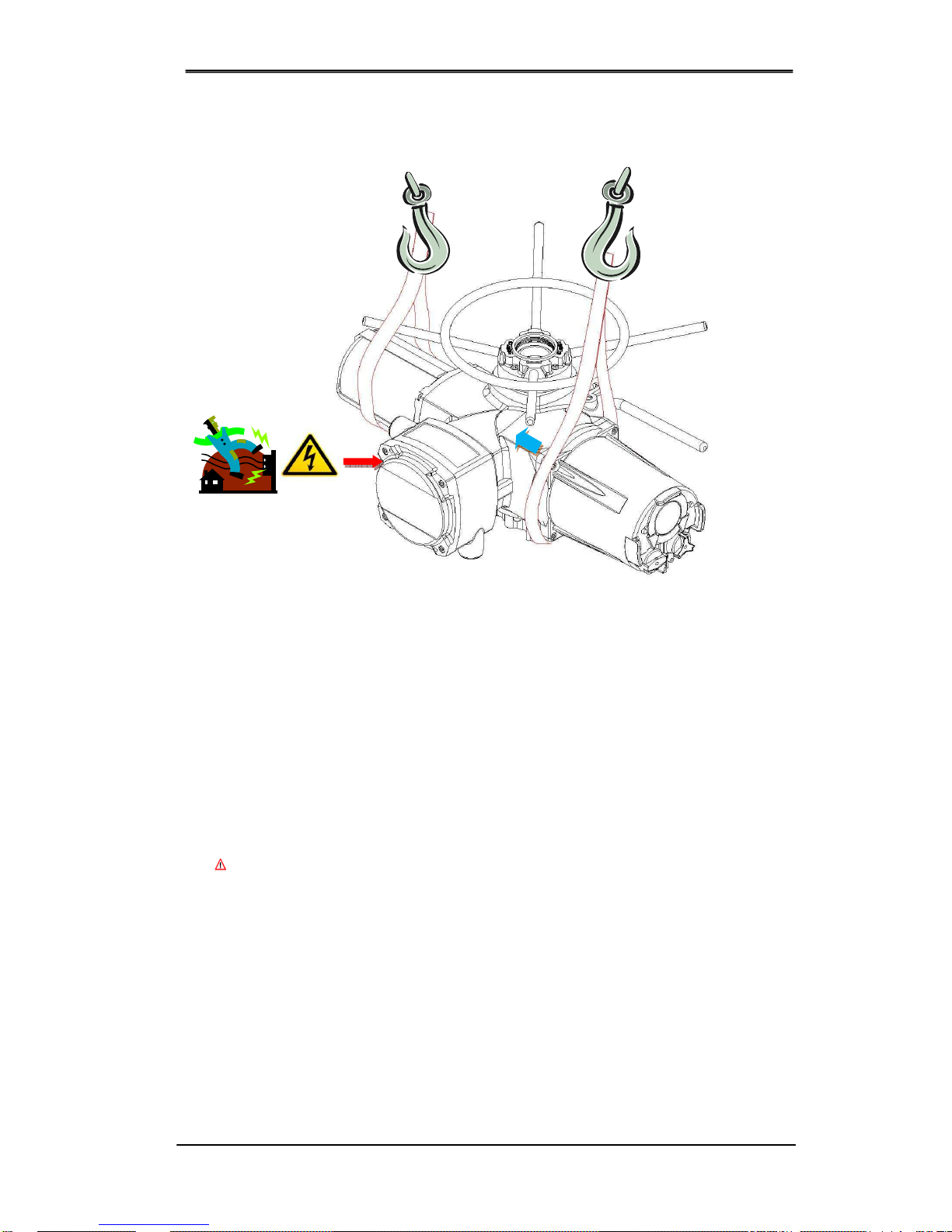

Safety notices throughout this manual detail precautions the user must take to reduce the risk

of personal injury and damage to the equipment. The user must read these instructions before

installation, operation or maintenance.

DANGER : Refers to personal safety. Alerts the user to danger or harm.

The hazard or unsafe practice will result in severe injury or death.

WARNING : Refers to personal safety. Alerts the user to potential danger.

Failure to follow warning notices could result in personal injury or death.

CAUTION : Directs the user’s attention to general precautions that, if not followed,

could result in personal injury and/or equipment damage.

External Parts

1 Body 11 Top Handle Cover Name Plate

2 Top Handle Cover 12 Hand wheel

3 Control Cover 13 Name Plate

4 Terminal Cover 14 Cable Plug

5 Mounting Base 15 Motor

6

Conduit Entries

(NPT 1”x4EA, 11/2”x1EA)

16 Grease Plug

7 Control Knob

8 Window & Indicator

9 Lever Supporter

10 Hand/Auto Lever

HHMM--SSeerriieess EElleeccttrriicc AAccttuuaattoorr

IInnssttaallllaattiioonn aanndd OOppeerraattiioonn MMaannuuaall

HHKKC

C

5

Note : Read carefully the following information as it is critical to the user’s understanding of the

actuator installation and operation procedures. This manual contains important safety

information. Please ensure it is thoroughly read and understood before installing, operating

or performing maintenance procedures for equipment.

CAUTION

1. Do not open cover during operation

in case of electrical shock

This manual contains critical information related to the operation of the

HM

series

Actuators

. It

is crucial that only trained personnel who understands thoroughly the setup, operations,

controls and inspection procedures due to safety concerns. Follow the manual guidelines

before setup. When misused, the Actuator can cause harm, severe injury or even death due

to high voltages and forces involved. It is highly recommended to request for training prior to

use.

Take extreme care when operating environments exceeds the range of -20°C~80°C. The

Actuator is intended to operate between the given ranges on the nameplate of each actuator.

In the case where products are exposed to temperature ranges that exceed the allowed

range, do not check for damage as it could result in severe injury. Consult with the

manufacturer as soon as possible. Do not attempt to alter the Actuator physically as this

could lead to leakage and malfunction of the product. Before performing maintenance in

potentially hazardous areas, make sure all electrical supplies are shutdown and actuator

relocated to an environmentally safe location.

WARNING

Housing Material:

Up to the HM010~035 of the

HM-Series

, Aluminium is processed

to manufacture the housing. Bolts etc are manufactured of stainless steel and base

from Cast Iron. The Models from HM40 ~ IQ90 are a mixture of Aluminium and

Ductile Iron. Before operating an

Actuator

the user must verify environmental

compatibility to avoid chemical corrosion. Study to determine safety must be

conducted before use.

Self-heating motor temperature:

In normal operation mode the temperature of the

Actuator cover may exceed 60⁰C and advise great caution when handling.

Motor thermal protection (By Pass):

Whenever the configurations are set to

bypass the Actuator cover temperature, any Hazardous area handling certificates

becomes invalid. Keep in mind hen using this mode that the risk of electrical danger

increases. The user must

measures.

Actuator manual operation

follow as directed.

In remote mode, the Actuator can be controlled to be switched on and off.

2

Product

Identification

2.1

Product Identification

The

actuator name plate is located on the

plate contains the following

2.1.1

Marking

a) General

HQ logo

(trade mark)

Model

Speed

Base Size

Torque Max

Motor supply

Motor Rating

Option

Serial No.

Nominal Motor current

Indication contacts

Enclosure

Name of manufacturer and country shall not be printed based on OEM

HHMM--SSeerriie

ess

IInnssttaallllaattiioonn aanndd

O

O

utilize

protective equipment and take additional safety

:

Read the manual operation

section carefully and

side of the opposite of

the conduit entry. The name

information.

EElleeccttrriicc AAccttuuaattoorr

ppeerraattiioonn MMaannuuaall

HHKKC

C

6

.

HHMM--SSeerriieess EElleeccttrriicc AAccttuuaattoorr

IInnssttaallllaattiioonn aanndd OOppeerraattiioonn MMaannuuaall

HHKKC

C

7

2.2 Initial inspection

When the inspecting the actuator, check the product for damage and ensure the name plate

concurs with the order sheet.

Remove packaging wrap or wooden box carefully. Inspect the product for any

physical damage that may have occurred during shipment.

Check the product specification with product ordered. If an incorrect product has

been shipped, immediately report the issue to our coordinators.

2.3 Storage

Actuators must be stored in a clean, cool and dry area. The unit shall be stored with

the cover installed and the conduit openings sealed. Storage must be off the floor,

covered with a sealed dust protector. When placing an Actuator outdoors, they must

be stored off the ground, high enough to prevent being immersed in water or buried

in snow. If the Actuator cannot be placed immediately, make sure to store it in a dry

area. It is recommended that if the Actuator cables cannot be installed immediately

use the plastic plug with PTFE tape to block/seal where the metal plugs are located.

When sealed correctly, the internal electronics are preserved from external corrosion

for extended periods of time (up to 1 year). Note that there is no need, when working

on the Actuator, to remove any electronics. If the control cover is removed, the

warranty may be void. Each individual Actuator will be tested before delivered hence,

given instructions have been correctly followed, setup and operation should be

smooth.

3

General Information and Features

3.1 General

HM series electric multi-turn actuators

are controlled via the Smart Intelligent actuator

system and suitable for various industrial plants such as ship construction, power

plants, petrochemical semiconductor plants and many other high-end industrial

uses. Additionally, depending on the specific application, 9 different models are

available.

HM-04,08,011,020,040,060,100,150,200,300

HHMM--SSeerriieess EElleeccttrriicc AAccttuuaattoorr

IInnssttaallllaattiioonn aanndd OOppeerraattiioonn MMaannuuaall

HHKKC

C

8

3.2 Performance Data

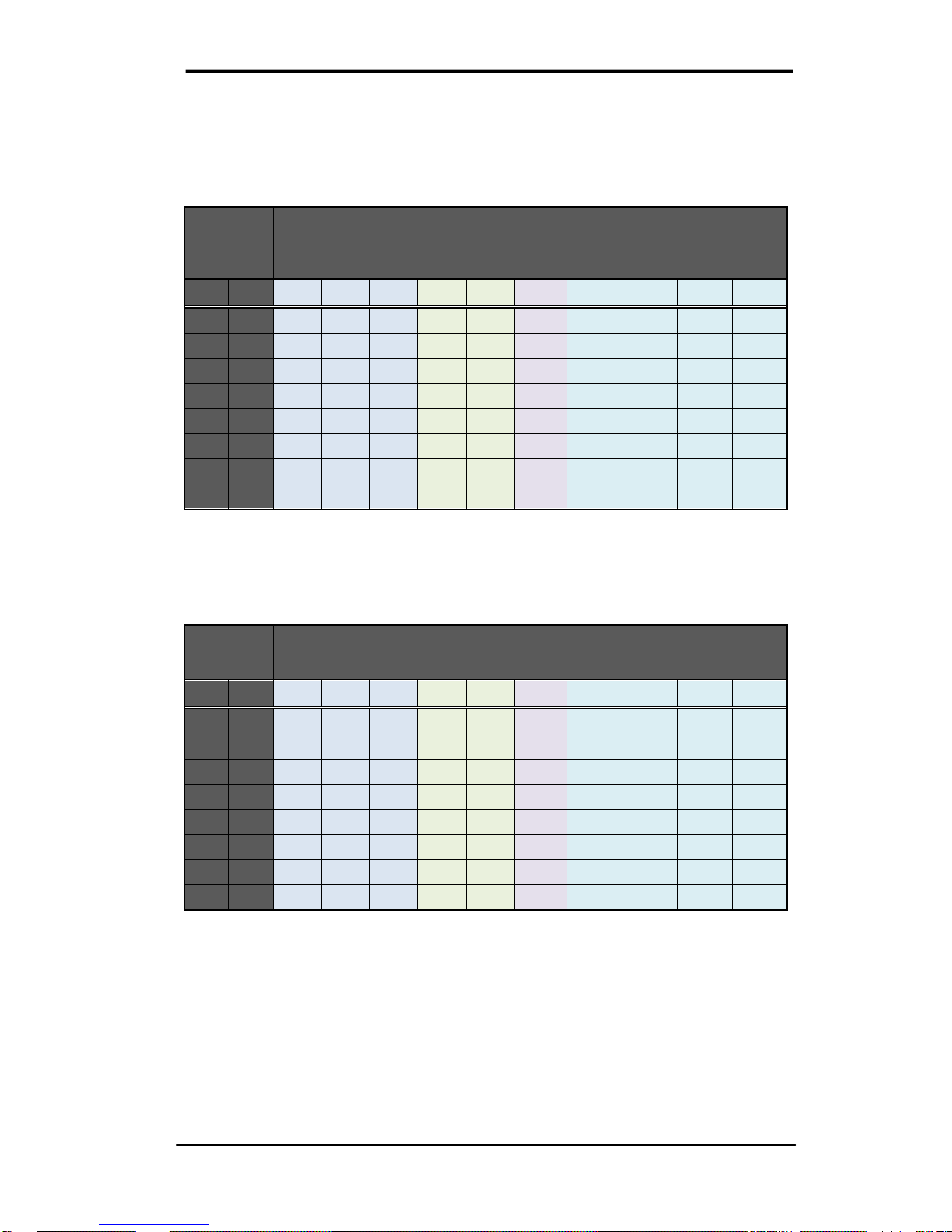

3.2.1 AC 3Phase Model & Torque(Nm)

RPM

MODEL & TORQUE(Nm)

3Phase

50HZ 60HZ HM04 HM08 HM11 HM20 HM40 HM 60 HM100 HM150 HM200 HM300

18 21 35 80 110 200 400 600 1000 1500 2000

24 29 35 80 110 200 400 600 1000 1500 2000 3000

36 43 35 80

200 300 540 850 1300 1700

48 57 35 68

200 250 470 680 1000 1360

72 86 35 48

176 250 470 680 1000 1360

96 115 35 40

142 230 370 540 750 1000

144 173

105 150 260 400 650 860

192 230

540 730

3.2.2 AC 1Phase Model & Torque(Nm)

RPM

MODEL & TORQUE(Nm) 1Phase

AC110~220V (HM040 은 220V 이상)

50HZ 60HZ HM04 HM08 HM11 HM20 HM40 HM 60 HM100 HM150 HM200 HM300

18 21 - 65 - 165 450

- - - - -

24 29 - 60 - 130 400

- - - - -

36 43 - 45 - 130 350

- - - - -

48 57 - 40 - 125 320

- - - - -

72 86 - 30 - 100 230

- - - - -

96 115

- 25 - 80 190

- - - - -

144 173

- - - 60 135

- - - - -

192 230

- - - - - - - - - -

*(RED) At high speeds, do not operate without a GEAR BOX mechanism as this may result in problems!

*Maximum torque for actuator is shown. (BLUE) Operation for AC 220V or over have been outlined.

HHMM--SSeerriieess EElleeccttrriicc AAccttuuaattoorr

IInnssttaallllaattiioonn aanndd OOppeerraattiioonn MMaannuuaall

HHKKC

C

9

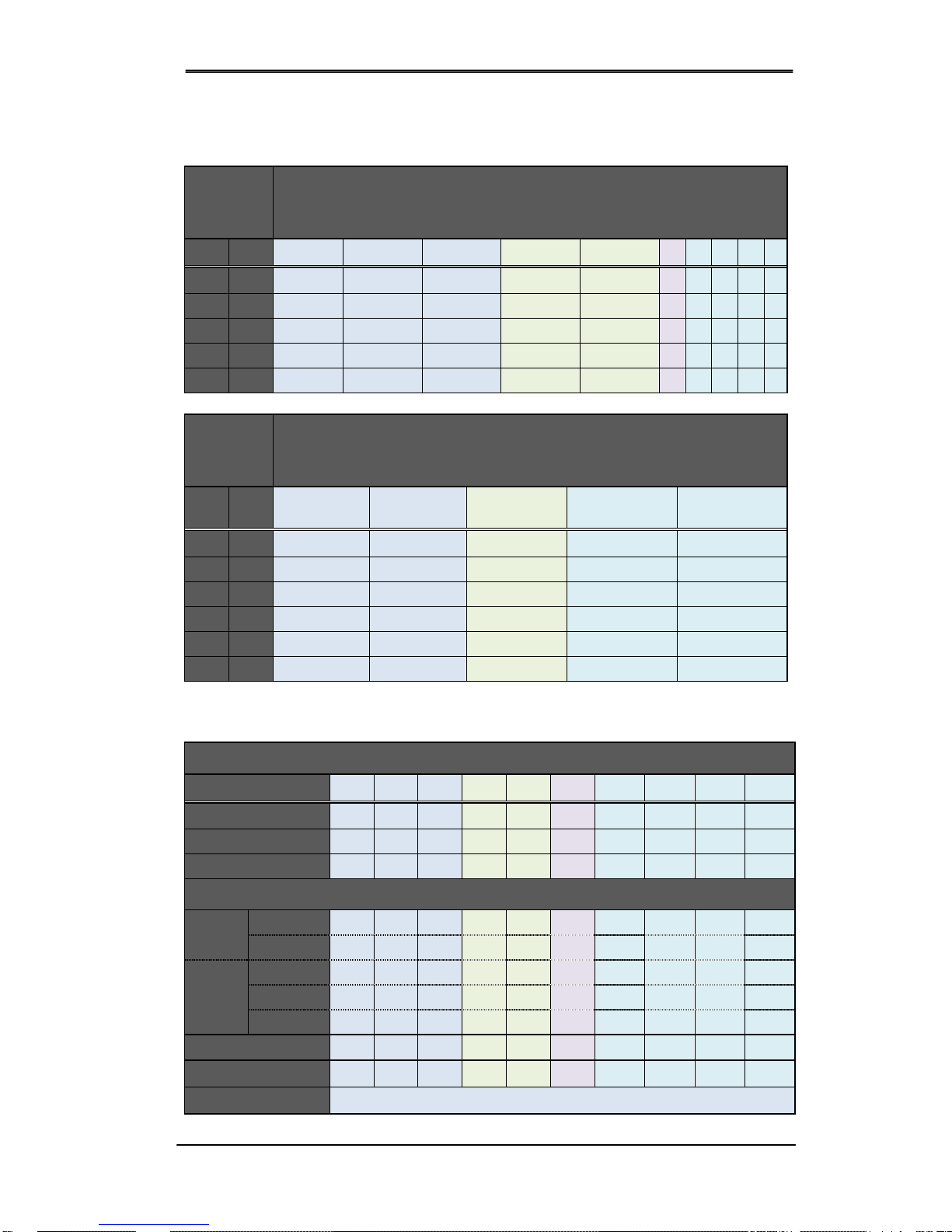

3.2.3 Solid state design Model & Torque(Nm)

RPM

MODEL & TORQUE(Nm)

Solid state type 3Phase (AC380V~)

50HZ 60HZ HM04 S3 HM08 S3 HM11 S3 HM20 S3 HM40 S3

18 21 35 80 110 200 400

24 29 35 80 110 200

36 43 35 80

48 57 35 68

72 86 35 48

RPM

MODEL & TORQUE(Nm)

Solid state type 1Phase

50HZ 60HZ

HM08 S1

(AC110~240V)

HM20 S1

(AC220~240V)

18 21 65 165

24 29 60 130

36 43 45 130

48 57 40 125

72 86 30 100

96 115

25 80

3.2.4 Mechanical Data

Mechanical Data

MODEL

HM04 HM08 HM11 HM20 HM40 HM60 HM100 HM150 HM200 HM300

Flange size(ISO5211)

F10 F10 F10 F14 F14 F16 F25 F30 F25 F30

Weight

30 30 30 65 65 70 190 190 200 200

Thrust rating(Nm)

44 44 44 100 100 150 220 220 334 445

Stem acceptance diameter maximum size

(BASE) unit: mm

Thrust

Rising

32 32 32 38 38 54 64 70 70 83

Non-rising

26 26 26 32 32 45 51 57 57 73

Non

large type

42 42 42 60 60 80 100 100 120 120

Thrust

ISO type

20 20 20 30 30 40 50 50 50 N/A

blank type

20 20 20 30 30 44 50 60 60 N/A

Hand wheel ratio

Direct Direct Direct Direct Direct Direct Direct

18:1 18:1 18:1

Option

15:1 15:1 15:1 15:1 15:1 23:1 54:1 54:1 54:1 54:1

Cable entry

STANDARD PF 1”x 4EA PF 1½”x1 OPTION NPT 1”x 4EA NPT 1½”x1

Loading...

Loading...