HKC Co APL-8 Installation, Operation & Maintenance Manual

APL-8 Series Limit Switch Box

Installation Operation & Maintenance Manual

Doc No. : HUMG-APL8-16 Rev0 Page 1 / 12 Valve Automation Leader, HKC

APL-8 Series Valve Position Monitor

Installation, Operation & Maintenance Manual

Address : Seonggok-dong, 155, Byeolmang-ro, Danwon-gu, Ansan-si, Gyeonggi-do, South Korea

Tel : +82 -31-488-8266, Fax : +82 -31-488-8269, Home page : www.hkcon.co.kr , email : hkcon@hkcon.co.kr

APL-8 Series Limit Switch Box

Installation Operation & Maintenance Manual

Doc No. : HUMG-APL8-16 Rev0 Page 2 / 12 Valve Automation Leader, HKC

Table of Contents

1. General ...................................................................................................................... 3

2. Ordering Information ................................................................................................. 3

3. Standard specification ............................................................................................... 3

4. Preparing for Installation ............................................................................................ 4

4.1. Marking ..................................................................................................................... 4

4.2. Pre-Installation for use in potentially explosive atmosphere....................................... 4

5. Standard Features ..................................................................................................... 5

6. Installation ................................................................................................................. 5

6.1. Mounting bracket .............................................................................................. 5

6.2. Mounting limit switch box.................................................................................. 6

6.3. Setting cam ....................................................................................................... 6

6.4. Wiring ............................................................................................................... 7

6.5. Setting Position Transmitter Unit (APL- 8 . 6) .................................................. 10

7. Maintenance ............................................................................................................ 10

8. Inspection ................................................................................................................ 11

9. Storage .................................................................................................................... 11

10. Trouble Shooting ..................................................................................................... 11

11. Tools ........................................................................................................................ 11

12. Installation and Maintenance Tips ............................................................................ 11

APL-8 Series Limit Switch Box

Installation Operation & Maintenance Manual

Doc No. : HUMG-APL8-16 Rev0 Page 3 / 12 Valve Automation Leader, HKC

1. General

1.1. HKC APL series limit switch box is designed to provide accurate and reliable valve position signaling and

indicating of most valves or actuators manufactured.

1.2. APL limit switch box consists of a visual position indicator, quick-set cam ass’y, terminal strip, switch ass’y

and easy mounting bracket. Quick-set cam allows for a quick and simple hand operation in the setting of

switches.

2. Ordering Information

APL - 8 1 0 N

① ② ③

① Enclosure type of flame proof is based on IECEx EPS 13.0043X:

Ex d IIC T 6 Gb

Enclosure type of flame proof is based on ATEX EPS 14 ATEX 1 695 X:

II 2 G Ex d IIC T 6 Gb

Enclosure type of flame proof is based on

KCs

15-AV2BO-0650X

: Ex d IIC T6 Gb

② Switch type

10 : 2-SPDT (Wonwoo : SZM-V16-5FA-61)

11 : 3-SPDT (Wonwoo : SZM-V16-5FA-61)

12 : 4-SPDT (Wonwoo : SZM-V16-5FA-61)

13 : 2-SPST (Wonwoo : SZM-V16-5FA-61)

14 : 2-DPDT (Omron : DZ-10GW-1B)

15 : 2-SPDT + Potentiometer (Wonwoo : SZM-V16-5FA-61)

16 : 2-SPDT + Signal Unit(4~20mA) (Wonwoo : SZM-V16-5FA-61)

20 : Proximity Sensor (P&F : NJ2-V3-N)

21 : Proximity Sensor (Autonics : PS17-5DNU)

23 : Proximity Sensor (P&F : NBB2-V3)

25 : Proximity Sensor (P&F : NJ2-V3-N) + Potentiometer

26 : Proximity Sensor (P&F : NJ2-V3-N) + Signal Unit (4~20mA)

30 : Reed type Proximity Sensor (MS-B 301)

③ Enclosure material (Body & Cover)

N : Aluminum alloy

S : Stainless steel

3. Standard specification

Model APL-8..N/S,

Enclosure Rate Weatherproof IP67(Std), IP68(Option), Flame proof Ex d IIC T6(Option)

Enclosure Aluminum alloy ADC12

Ambient Temperature -20 ℃ ~ + 60 ℃

Cable Entries 4 x 3/4 NPT (Standard, flame proof)

M20, M25 (Optional flame proof), PF3/4”, PT3/4” (Optional)

Travel Angle 90 degree +/- 10%

Position Indicator Open : Yellow, Close : Red

Language : English (option : French, German)

Mechanical switch SZM-V16-5FA-61 Wonwoo Starion,

16A 1/2HP 125/250Vac, 0.6A 125Vdc, 0.3A 250Vdc, 5A 125Vac

Proximity sensor NJ2-V3-N(P&F) 5~25 Vdc, 15mA max

PS17-5DNU(Autonics) 12~24 Vdc, 0.2mA max

MS-B 301 Reed type proximity sensor, 250 Vdc 3.0 A max

Potentiometer 1kΩ (option : 0~5kΩ , 0~10kΩ)

Current Output Signal Unit 4~20mA, 20~4mA

Terminal Strip 8 point (option : 9~14P)

External Coating Thermally hardened polyester powder coating

APL-8 Series Limit Switch Box

Installation Operation & Maintenance Manual

Doc No. : HUMG-APL8-16 Rev0 Page 4 / 12 Valve Automation Leader, HKC

4. Preparing for Installation

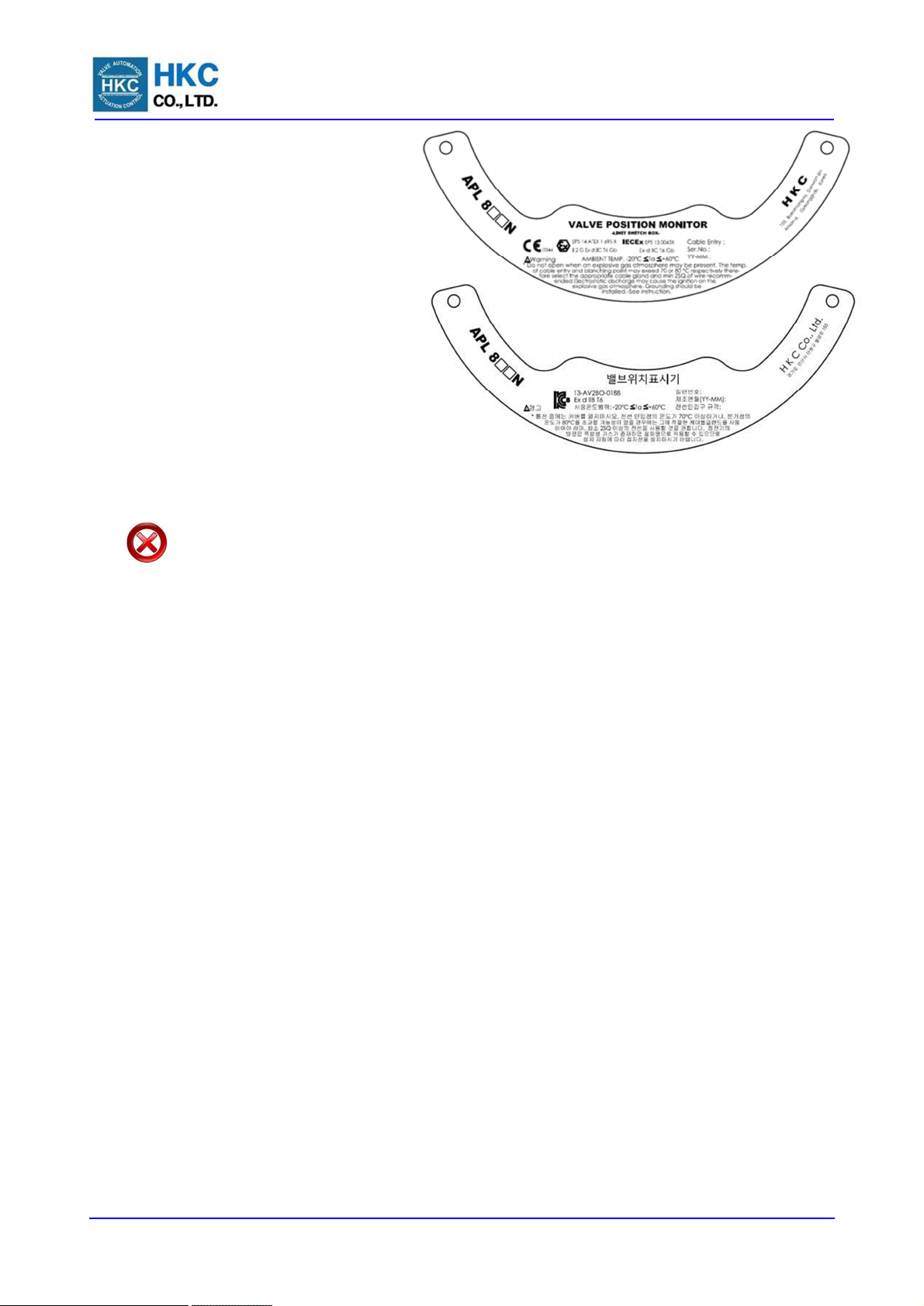

4.1. Marking

HKC Logo / Trade mark

Model

Switches type

Enclosure type & Cert No. for flame proof:

Ambient temperature

Serial No.

Manufacturred year & month (YY-MM)

Cable entry size

Warning letter

Maker address

4.2. Pre-Installation for use in

potentially explosive atmosphere

Installation, commissioning, maintenance, repairs and modification work must only be performed by

qualified personnel with extensive knowledge on how to work explosion-proof electrical equipment.

Warning : Read this installation and maintenance manual carefully and completely Before attempting

to install, operate, or troubleshoot the HKC product.

4.2.1. Cable Connection

① Sealing devices must be used and shall be fitted directly at enclosure wall when using conduit.

② Cable glands shall be suitable for the environment and shall be certified as flameproof it used in

Zone 1 application.

③ Cable glands and shall be installed minimum 6 full threads and the length of thread is minimum

8mm.

④ The temperature at cable entry and blanching point may exceed 70℃ and 80℃ respectively

therefore select the appropriate cable gland and min 2SQ of wire is recommended when you install”

⑤ For cable entries or conduit entries that are not used, user or installer shall close by certified

blanking elements(stopping plugs) so that the flameproof properties of the enclosure are

maintained.

4.2.2. Groundings

① Always ground the enclosure in accordance with local electric codes. The most effective enclosure

grounding method is a direct. Connection to earth ground with minimal impedance. Methods for

grounding the enclosure include:

Internal ground connection : The internal ground is located inside the body.

External ground connection : The ground bracket is located on the side of body.

(Min 2SQ wire required)

4.2.3. Special Condition for safe use

① Electrostatic discharge from window(over 1GΩ) may cause the ignition on the explosive gas

atmosphere. By adapting the conducting window bolts make reduce the risk from electrostatic

discharge.

② Before installation or maintenance products, shut off incoming power and grounding should be

connected.

4.3. Initial inspection

When the user receipts the product, inspect the condition of the product and ensure the name plate

comparing with order sheet.

4.3.1. Remove packing wrap or wooden box carefully. Inspect the product for any physical damage that

may have occurred during shipment.

4.3.2. Check the product specification with product ordered. If a wrong product has been shipped,

immediately inform to our coordinator.

For IECEx and ATEX

Loading...

Loading...