Page 1

Manual 3.1

English

Page 2

Important Safety Instructions

Before connecting, read instructions

Important Advice on Safety!

Please read before use and keep for later use!

Wichtige Sicherheitshinweise!

Bitte vor Gebrauch lesen und für späteren Gebrauch

aufbewahren!

• Read all of these instructions!

• Save these instructions for later use!

• Follow all warnings and instructions marked on the product!

• Do not use this product near water, i.e. bathtub, sink, swimming

pool, wet basement, etc.

• Do not place this product on an unstable cart, stand or table.

The product may fall, causing serious damage to the product

or to persons!

• Slots and openings in the cabinet and the back or bottom are

provided for ventilation; to ensure reliable operation of the product

and to protect it from overheating, these openings must not be

blocked or covered. This product should not be placed in a built-in

installation unless proper ventilation is provided.

• This product should not be placed near a source of heat such as a

stove, radiator, or another heat producing amplifier.

• Use only the supplied power supply or power cord. If you are not

sure of the type of power available, consult your dealer or local

power company.

• Do not allow anything to rest on the power cord. Do not locate this

product where persons will walk on the cord.

• Never break off the ground pin on the power supply cord.

• Power supply cords should always be handled carefully. Periodically

check cords for cuts or sign of stress, especially at the plug and the

point where the cord exits the unit.

• The power supply cord should be unplugged when the unit is to be

unused for long periods of time.

• If this product is to be mounted in an equipment rack, rear support

should be provided.

• This product should be used only with a cart or stand that is

recommended by HK AUDIO®.

• Never push objects of any kind into this product through cabinet

slots as they may touch dangerous voltage points or short out parts

that could result in risk of fire or electric shock. Never spill liquid of

any kind on the product.

• Do not attempt to service this product yourself, as opening or

removing covers may expose you to dangerous voltage points or

other risks. Refer all servicing to qualified service personnel.

• Unplug this product from the wall outlet and refer servicing to

qualified service personnel under the following conditions:

• When the power cord or plug is damaged or frayed.

• If liquid has been spilled into the product.

• If the product has been exposed to rain or water.

• If the product does not operate normally when the operating

instructions are followed.

• If the product has been dropped or the cabinet has been damaged.

• If the product exhibits a distinct change in performance, indicating a

need of service!

• Adjust only these controls that are covered by the operating

instructions since improper adjustment of other controls may

result in damage and will often require extensive work by a qualified

technician to restore the product to normal operation.

• Exposure to extremely high noise levels may cause a permanent

hearing loss.

• Individuals vary considerably in susceptibility to noise induced

hearig loss, but nearly everyone will lose some hearing if exposed to

sufficiently intense noise for a sufficient time. The U.S. Government´s

Occupational Safety and Health Administration (OSHA) has

specified the following permissible noise level exposures:

Duration Per Day In Hours Sound LeveldBA, Slow Response

8 90

6 92

4 95

3 97

2 100

11/2 102

1 105

1/2 110

1/4 or less 115

• According to OSHA, any exposure in excess of the above permissible

limits could result in some hearing loss.

• Ear plug protectors in the ear canals or over the ears must be worn

when operating this amplification system in order to prevent a

permanent hearing loss if exposure is in excess of the limits as set

forth above. To ensure against potentially dangerous exposure to

high sound pressure levels, it is recommended that all persons

exposed to equipment capable of producing high sound pressure

levels such as this amplification system be protected by hearing

protectors while this unit is in operation.

• Fuses: Replace with IEC 127 (5x 20 mms) type and rated fuse for best

performance only.

TO PREVENT THE RISK OF FIRE AND SHOCK HAZARD, DO NOT

EXPOSE THIS APPLIANCE TO MOISTURE OR RAIN. DO NOT

OPEN CASE;

NO USER SERVICE-ABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

• The unit has been built by HK AUDIO® in accordance with

IEC 60065 and left the factory in safe working order. To maintain this

condition and ensure non-risk operation, the user must follow the

advice and warning comments found in the operating instructions.

The unit conforms to Protection Class 1 (protectively earthed).

• HK AUDIO® ONLY GUARANTEE THE SAFETY, RELIABILITY AND

EFFICIENCY OF THE UNIT IF:

• Assembly, extension, re-adjustment, modifications or repairs are

carried out by HK AUDIO® or by persons authorized to do so.

• The electrical installation of the relevant area complies with the

requirements of IEC (ANSI) specifications.

• The unit is used in accordance with the operating instructions.

• The unit is regularly checked and tested for electrical safety by

a competent technician.

WARNING:

• If covers are opened or sections of casing are removed, except where

this can be done manually, live parts can become exposed.

• If it is necessary to open the unit this must be isolated from all

power sources. Please take this into account before carrying out

adjustments, maintenance, repairs and before replacing parts.

• Adjustment, maintenance and repairs carried out when the unit has

been opened and is still live may only be performed by specialist

personnel who are authorized by the manufacturer (in accordance

with VBG 4) and who are aware of the associated hazards.

• Loudspeaker outputs which have the IEC 417/5036 symbol (Diagram

1, below) can carry voltages which are hazardous if they are made

contact with. Before the unit is switched on, the loudspeaker should

therefore only be connected using the lead recommended by the

manufacturer.

• Where possible, all plugs on connection cables must be screwed

or locked onto the casing.

• Replace with IEC 127 (5x 20 mms) type and rated fuse for best

performance only.

• It is not permitted to use repaired fuses or to short-circuit the fuse

holder.

• Never interrupt the protective conductor connection.

• Surfaces which are equipped with the "HOT" mark (Diagram 2,

below), rear panels or covers with cooling slits, cooling bodies and

their covers, as well as tubes and their covers are purposely designed

to dissipate high temperatures and should therefore

not be touched.

• High loudspeaker levels can cause permanent hearing damage.

You should therefore avoid the direct vicinity of loudspeakers

operating at high levels. Wear hearing protection if continuously

exposed to high levels.

MAINS CONNECTION:

• The unit is designed for continuous operation.

• The set operating voltage must match the local mains supply voltage.

• The unit is connected to the mains via the supplied power unit or

power cable.

• Power unit: Never use a damaged connection lead. Any damage

must be rectified by a competent technician.

• Avoid connection to the mains supply in distributor boxes together

with several other power consumers.

• The plug socket for the power supply must be positioned near the

unit and must be easily accessible.

PLACE OF INSTALLATION:

• The unit should stand only on a clean, horizontal working surface.

• The unit must not be exposed to vibrations during operation.

• Keep away from moisture and dust where possible.

• Do not place the unit near water, baths, wash basins, kitchen sinks,

wet areas, swimming pools or damp rooms. Do not place objects

containing liquid on the unit - vases, glasses, bottles etc.

• Ensure that the unit is well ventilated.

• Any ventilation openings must never be blocked or covered. The unit

must be positioned at least 20 cm away from walls. The unit may

only be fitted in a rack if adequate ventilation is ensured and if the

manufacturer's installation instructions are followed.

• Keep away from direct sunlight and the immediate vicinity of heating

elements and radiant heaters or similar devices.

• If the unit is suddenly moved from a cold to a warm location,

condensation can form inside it. This must be taken into account

particularly in the case of tube units. Before switching on, wait until

the unit has reached room temperature.

• Accessories: Do not place the unit on an unsteady trolley, stand,

tripod, base or table. If the unit falls down, it can cause personal

injury and itself become damaged. Use the unit only with the trolley,

rack stand, tripod or base recommended by the manufacturer or

purchased together with the unit. When setting the unit up, all

the manufacturer's instructions must be followed and the setup

accessories recommended by the manufacturer must be used.

Any combination of unit and stand must be moved carefully. A

sudden stop, excessive use of force and uneven floors can cause the

combination of unit and stand to tip over.

• Additional equipment: Never use additional equipment which

has not been recommended by the manufacturer as this can cause

accidents.

• To protect the unit during bad weather or when left unattended for

prolonged periods, the mains plug should be disconnected. This

prevents the unit being damaged by lightning and power surges in

the AC mains supply.

Diagram 1 Diagram 2

• Das G erät wurde von HK AUDIO® gemäß IEC 60065 gebaut und hat

das Werk in sicherhei tstechnisch einwandfreiem Zustan d verlassen. Um

diesen Zustand zu erhalten und einen gefahrlosen Betrieb sicherzustellen,

muss der Anwender die Hinweise und die Warnvermerke beachten, die

in der Bedien ungsanleitung enthalten sind. Das Gerät entspricht der

Schutzklasse I (schutzgeerdet).

• DIE S ICHERHEIT, ZUVERLÄSSIGKEIT UND LEISTUNG DES GERÄTES

WIRD VON HK AUDIO® NUR DANN GEWÄHRLEISTET, WENN:

• Montage, Erweiterung, Neueinstellung, Änderungen oder Reparaturen von

HK AUDIO® oder von dazu ermächtigten Personen ausgeführt werden.

• die e lektrische Installation des betreffenden Raumes den Anfo rderungen

von IEC (ANSI )-Festlegungen entspri cht.

• das G erät in Übereinstimmung mit der Gebrauchsanweisung verwe ndet

wird.

WARNUNG:

• Wenn Abdeckungen geöffnet oder Gehäuseteile entfernt werden, außer

wenn dies von Hand möglich ist, können Teile freigelegt werden, die

Spannung führen.

• Wenn ein Öffn en des Gerätes erforderlich ist, muss das Gerät von allen

Spannungsquellen getrennt sein. Berücksichtigen Sie dies vor dem

Abgleich, vor einer Wartung, vor einer Instandsetzung und vor einem

Austausch von Teilen.

• Ein A bgleich, eine Wartung oder eine Re paratur am geöffneten Gerät

unter Spannung darf nur durch eine vo m Hersteller autorisierte Fachkraft

(nach VBG 4) geschehen, die mit den verbundenen Gefahren vertraut ist.

• Lautsprec her-Ausgänge, die mit dem IEC 417/5036-Zeichen (Abb.1,

s.unten) versehen sind, können berührungsgefä hrliche Spannungen

führen. Deshalb vor dem Einschalten des Gerätes Verbindung nur mit

dem vom Herst eller empfohlenen Anschlusskabel zum Lautsprecher

herstellen.

• Alle Stecker an Verbindungskabeln müssen mit dem Gehäuse verschraubt

oder verriegelt sein, sofern möglich.

• Es dü rfen nur Sicherungen vom angegebenen Typ und der angegebenen

Nennstromstärke a ls Ersatz verwendet werden.

• Eine Verwendung von geflick ten Sicherungen oder Kurzsch ließen des

Halters ist u nzulässig.

• Niemals die Schutzleiterverbindung un terbrechen.

• Oberfläch en, die mit dem "HOT"-Ze ichen (Abb.2, s.unten) verse hen sind,

Rückwände oder Abdeckungen mit Kühlschlitzen, Kühlkörper und deren

Abdeckungen, sowi e Röhren und deren Abdec kungen können im Betrieb

erhöhte Temperaturen annehmen und sollten deshalb nicht berührt

werden.

• Hohe Lautstärkepegel können dauernde Gehörschäden verursachen.

Vermeiden Sie deshalb die direkte Nähe von La utsprechern, die mit

hohen Pegeln betrieben werden. Verwenden Sie eine n Gehörschutz bei

dauernder Einwirk ung hoher Pegel.

NETZANSCHLUSS:

• Das G erät ist für Dauerbetrieb ausgelegt.

• Die e ingestellte Betriebsspannung mus s mit der örtlichen Netz spannung

übereinstimmen.

• Der A nschluss an das Stromnetz erfolgt mit dem mitgeliefe rten Netzteil

oder Netzkabel.

• Netzteil: Eine beschädigte Anschlussl eitung kann nicht ersetzt werden.

Das Netzteil darf nicht mehr betrieben werden.

• Vermeiden Sie einen Anschluss an das Stromnetz in Verteilerdosen

zusammen mit vielen anderen Stromverbrauchern .

• Die S teckdose für die Stromversor gung muss nahe am Gerät angebracht

und leicht zu gänglich sein.

AUFSTELLUNGSORT:

• Das Gerät sollte nur auf einer sauberen, waagerechten Arbeitsfläche stehen.

• Das G erät darf während des Be triebs keinen Erschütterungen ausgesetzt

sein.

• Feuchtigkeit und Staub sind nach Mögl ichkeit fernzuhalten.

• Das G erät darf nicht in der Nähe von Wasser, Badewanne, Waschbecken,

Küchenspüle, Nassraum, Swimmingpool oder feuchten Räumen betrieben

werden. Keine mit Flüssigkeit gefüllten G egenstände -Vase, Gläser,

Flaschen etc. auf das Gerät stellen.

• Sorgen Sie für ausreichende Belüf tung der Geräte.

• Eventuelle Ventilationsöffnungen dü rfen niemals blockiert oder

abgedeckt werden. Das Gerät muss mindeste ns 20 cm von Wänden

entfernt aufgeste llt werden. Das Gerät da rf nur dann in ein R ack

eingebaut werden, wenn für ausreichende Ventilation gesorgt ist und die

Einbauanweisungen des Herstell ers eingehalten werden.

• Vermeiden Sie direkte Sonneneinstrahlung sowi e die unmittelbare Nähe

von Heizkörpern und Heizstrahlern oder äh nlicher Geräte.

• Wenn das Gerät plötzlich von einem kalten an einen warmen Ort gebracht

wird, kann si ch im Geräteinnern Kondensfe uchtigkeit bilden. Dies ist

insbesondere bei Röhrengeräten zu beachten. Vor dem Einschalten

solange warten bis das Gerät Raumtemperat ur angenommen hat.

• Zubehör: Das Gerät nicht auf einen instabilen Wagen, Ständer, Dreifuß,

Untersatz oder Tisch stellen. Wenn das Gerät herunterfällt, kann es

Personenschäden v erursachen und selbst beschä digt werden.

Verwenden Sie das Gerät nur mit einem v om Hersteller empfohlenen od er

zusammen mit dem Gerät verkauften Wagen, Rack, Ständer, Dreifuß oder

Untersatz. Bei der Aufstellung des Geräte s müssen die Anweisungen des

Herstellers befol gt und muss das vom Hersteller empfohlene Aufstellzubehör verwendet werden. Eine Kombination aus Gerät und Gestell

muss vorsichtigt bewegt werden. Plötzliches Anhalten, übermäßige

Kraftanwendung un d ungleichmäßige Böden könne n das Umkippen

der Kombination aus Gerät und Gestell bewirken.

• Zusatzvor richtungen: Verwenden Sie niemals Zu satzvorrichtungen, die

nicht vom Her steller empfohlen wurden, we il dadurch Unfälle verursach t

werden können

• Zum S chutz des Gerätes bei Ge witter oder wenn es läng ere Zeit nicht

beaufsichtigt ode r benutzt wird, sollte d er Netzstecker gezogen werde n.

Dies verhindert Schäden am Gerät aufgrund von Blitzschlag und

Spannungsstößen i m Wechselstromnetz.

Abb.1 Abb.2

Page 3

Conseils de Securite Importants!

Priere de lire avant l'emploi et a conserver pour

utilisation ulterieure!

Importanti avvertimenti di sicurezza!

Leggere attentamente prima dell'uso e conservare

per un utilizzo successivo:

¡Indicaciones de seguridad importantes!

¡Léanse antes de utilizar el aparato y guardense para

so uso posterior!

• L'appareil a été conçu par HK AUDIO

a quitté l'entreprise dans un état irréprochable. Afin de conserver cet

état et d'assurer un fonctionnement sans danger de l'appareil nous

conseillons à l'utilisateur la lecture des indications de sécurité contenues

dans le mode d'emploi. L'appareil est conforme à la classification I

(mise à terre de protection).

• SURETE, FIABILITE ET EFFICACITE DE L'APPAREIL NE SONT

GARANTIS PAR HK AUDIO® QUE SI:

• Montage, extension, nouve au réglage, modification ou réparation

sont effectués par HK AUDIO® ou par toute personne autorisée

par HK AUDIO®.

• L'installation électrique de la pièce concernée c orrespond aux normes

IEC (ANSI).

• L'utilisation de l'appare il suit le mode d'emploi .

AVERTISSEMENT:

• A moins que cela ne soit manuellement possibl e, tout enlèvement

ou ouverture du boîtier peut entrainer la mise au jour de pieces

sous tension.

• Si l'ouverture de l'a ppareil est nécessaire, celu i-ci doit être coupé de

chaque source de courant. Ceci est à prendre en considération avant

tout ajustement, entretien, réparation ou changement de pieces.

• Ajustement, entretien ou réparation sur l'appareil ouvert et sous

tension ne peuvent être éffectués que par un spécial iste autorisé par le

fabricant (selon VBG4). Le spécialiste étant conscient des dangers liés

à ce genre de réparation.

• Les sorties de baffle s qui portent le signe IEC 417/5036 (fig. 1, voir

en bas) peuvent être sous tension dangereuse. Avant de brancher

l'appareil utiliser uniquement le câble de raccordement conseillé par

le fabricant pour raccorder les baffles.

• Toutes les prises des câbles de raccordement doivent être, si possible,

vissées ou verrouillées sur le boîtier.

• Utilisez subsidiairement uniquement des fusibles de type et de

puissance de courant nominale donnés.

• L'utilisation de fusibles rafistolés ou court-circuit es est inadmissible.

• Ne jamais interrompre la connexion du circuit protecteur.

• Il est conseillé de ne pas toucher aux su rfaces pourvues du signe

"HOT" (fig. 2, voir en bas), aux parois arrières ou caches munis de

fentes d'aération, éléments d'aération et leurs caches a nsi qu'aux

tubes et leurs caches. Ces éléments pouvant atteindre des

températures élévées pendant l'utilisation de l'appareil.

• Les Niveaux de puissance élévés peuvent entrainer des lésions auditives

durables. Evitez donc la proximité de haut-parleurs utilisés à haute

puissance. Lors de haute puissance continue utilisez une protection

auditive.

BRANCHEMENT SUR LE SECTEUR:

• L'appareil est conçu pour une utilisation continu e.

• La tension de fonctio nnement doit concorder avec la tension secteur

locale.

• Le raccordement au ré seau éléctrique s'effectue a vec l'adaptateur ou le

cordon d´alimentation livré avec l'appareil.

• Adaptateur: Un câble de raccordement abimé ne peut être remplacé.

L'adaptateur est inutilisable.

• Evitez un raccordement au réseau par des boîtes de distribution

surchargées.

• La prise de courant doit être placée à proximité de l'appareil et facile

à atteindre.

LIEU D'INSTALLATION:

• L'appareil doit être placé sur une surface de travail propre et horizontale.

• L'appareil en marche ne doit en aucun cas subir des vibrations.

• Evitez dans la mesure du possible poussière et humidité.

• L'appareil ne doit pa s être placé à proximité d'eau, de baignoire,

lavabo, évier, pièce d'eau, piscine ou dans une pièce humide.

Ne placez aucun vase, verre, bouteille ou tout objet rempli de liquide

sur l'appareil.

• L'appareil doit être suffisamment aéré.

• Ne jamais recouvrir les ouvertures d'aération. L'appareil doit être

placé à 20 cm du mur au minimum. L'appareil peut être monté dans

un Rack si une ventilation suffisante est possible et si les conseils de

montage du fabricant sont suivis.

• Evitez les rayons de soleil et la proximité de radiateurs, chauffages etc.

• Une condensation d'eau peut se former dans l' appareil si celui-ci est

transporté brusquement d'un endroit froid à un endroit chaud.

Ceci est particulièrement important pour des appareils à tubes.

Avant de brancher l'appareil attendre qu'il ait la température ambiante.

• Accessoires: L'appareil n e doit être placé sur un chariot, support,

trépied, bâti ou table instable. Une chute de l'appareil peut entrainer

aussi bien des dommages corporels que techniques. Utilis ez l'appareil

uniquement avec un chariot, Rack, support, trépied ou bâti conseillé

par le fabricant ou vendu en combinaison avec l'appa reil.

Les indications du fabricant pour l'installation de l'appareil sont à

suivre, et les accessoires d'installation conseillés par le fabricant sont

à utiliser. Un ensemble support et appareil doit être déplacé avec

précaution. Des mouvements brusques et des revêtements de sol

irreguliers peuvent entrainer la chute de l´ensemble.

• Equipements supplémentaires: Ne jamais utiliser un équipement

supplémentaire n'ayant pas été conseillé par le fabrican t, ceci pouvant

entrainer des accidents.

• Afin de protéger l'ap pareil pendant un orage ou s'il ne doit pas être

utilisé pendant un certain temps, il est conseillé d'enlever la prise

au secteur. Ceci évite des dommages dûs à la foudre ou à des coups de

tension dans le réseau à courant alternatif.

®

selon la norme IEC 60065 et

Fig. 1 Fig. 2

• L'apparec chio è stato costruito d alla HK AUDIO® secondo la normativa

europea IEC 6 0065 ed ha lasciato il nostro stabilimento in st ato

ineccepibile. Per garantire il mantenimento di tale stato e un utilizzo

assolutamente pri vo di rischi l'utente è tenuto ad osservare le indicazioni

e gli avverti menti di sicurezza contenuti nelle istruzioni per l' uso.

L'apparecchio rispecchia il livello di sicurezza I (collegato a terra).

• Sicurezza , affidabilità e prestazioni dell'apparecchio vengono ga rantiti

dalla HK AUDI O® solo ed esclusivamente se:

• Montaggio , ampliamento, rimessa a punto, modifiche e riparazi oni

vengono eseguite dalla HK AUDIO® stessa o da personale da essa

autorizzato.

• Gli i mpianti elettrici nei locali prescelti per l'uso del l'apparecchio

rispondono alle normative stabilite dall'ANSI .

• L'apparecchio viene utilizzato come indicato nel libretto delle istruzioni

per l'uso.

Avvertimenti:

• In ca so di apertura di parti di rivestimento o rimozi one di parti

dell'involucro, a meno che non si tra tti di pezzi rimovibili semplicemente

a mano, posso no venire alla luce part i dell'apparecchio conduttrici di

tensione.

• Se l'apertura dell'apparecchio dovesse risultare necessaria è indispensabile

staccare preceden temente quest'ultimo da tutt e le fonti di tensione.

Rispettare tale misura di prevenzione anc he prima di un allineame nto, di

operazioni di manutenzione, della messa i n esercizio o della sost ituzione

di componenti all'interno dell'apparecchio.

• Allineame nto, operazioni di manutenzi one o eventuali riparazioni

dell'apparecchio in presenza di tensione vanno eseguite esclusivamente

da personale specializzato ed autorizzato, in grado di eseguire tali

operazioni evitandone i rischi connessi.

• Le us cite degli altoparlanti cont rassegnate dai caratteri IEC 417/5036

(vedi illustrazio ne 1 a fondo pag.) p ossono essere conduttrici di

tensione pericolo sa con cui evitare il contatto. Per questo motiv o, prima

di accendere l'apparecchio, collegare quest'u ltimo agli altoparlanti

servendosi esclus ivamente del cavetto d'allac ciamento indicato

dal produttore.

• Tutte le spine e i cavi di collegamento devono essere avvitati o fissati

all'involucro del l'apparecchio per quanto pos sibile.

• Tutti i fusibili di sicurezza vanno sostituit i esclusivamente con fusibil i del

tipo prescritto e valore della corrente nominale indicato.

• L'utilizz o di fusibili di sicurez za non integri e la messa in corto circuito

del sostegno di metallo sono proibite.

• Non i nterrompere mai il collegame nto con il circuito di protezione.

• Superfici contrassegnate dalla parola "HOT" (vedi illustrazione 2 a fondo

pag.), cosi c ome griglie di aerazione, dispositivi di raffreddamento e i

loro rivestimenti di protezione, oppure v alvole e i relativi rive stimenti

protettivi posson o surriscaldarsi notevolmente durante l'uso e per qu esto

motivo non va nno toccate.

• L'ascolto di suoni ad alto vo lume può provocare danni permanenti

all'udito. Evitate perciò la diretta vicinanz a con altoparlanti ad al ta

emissione di suono e utilizzate cuffie protettive in caso ciò non sia

possibile.

Alimentazione:

• L'apparec chio è concepito per il funzionamento continuo.

• La tensione di esercizio deve corrispondere alla tensione di rete a cui ci

si allaccia.

• L'allacci amento alla rete elettrica avviene tramite alimentatore o cavetto

d'alimentazione c onsegnato insieme all'apparecchi o.

• Alimentat ore: un cavo di connessi one danneggiato non può essere

sostituito. L'ali mentatore non può più es sere utilizzato.

• Evitate u n allacciamento alla rete di corrente utilizzando ca ssette di

distribuzione sov raccariche.

• La sp ina di corrente deve ess ere situata nelle vicinanze dell'apparecchio

e facilmente raggiungibile in qualsiasi m omento.

Locali di collocamento:

• Opportuno collocare l'apparecchio su una superficie pulita e orizzontale.

• Non s ottoporre l'apparecchio in f unzione a scosse e vibra zioni.

• Protegger e l'apparecchio per quanto possibile da umidità e polvere.

• Non c ollocare l'apparecchio vicino ad acqua, vasche da ba gno, lavandini,

lavelli da cu cina, locali umidi o pis cine. Non appoggiare recipie nti

contenenti liquid i - vasi, bicchieri, bot tiglie, ecc. - sull'apparecc hio.

• Provveder e ad una buone aerazione dell'apparecchio.

• Eventuali aperture previste per la ventilazione dell'apparecchio non

vanno ne bloc cate, ne mai coperte. L' apparecchio va collocato ad almeno

20 cm di distanza dalle pareti circos tanti e può essere inser ito tra altre

componenti di un impianto solo in cas o di sufficiente ventilazion e e

qualora le di rettive di montaggio del produttore vengano rispettate.

• Evitare d i esporre l'apparecchio ai raggi del sole e di collocarlo

direttamente nell e vicinanze di fonti di calore come caloriferi, stufette,

ecc.

• Se l' apparecchio viene trasportato rapidamente da un locale freddo ad

uno riscaldato può succedere che al s uo interno si crei della condensa.

Ciò va tenuto in considerazione soprattutto in caso di apparecchi a valvole.

Attendere che l'apparecchio abbia assunto la temperatura ambiente pri ma

di accenderlo.

• Accessori : non collocare l'apparecchi o su carrelli, supporti, treppiedi,

superfici o t avoli instabili. Se l'appare cchio dovesse cadere a t erra

potrebbe causare danni a terzi o dann eggiarsi irreparabilmente. Utili zzate

per il colloc amento dell'apparecchio supporti , treppiedi e superfici che

siano consigliate dal produttore o dirett amente comprese nell'offerta di

vendita. Per il collocamento dell'apparecchio attenetevi strettamente all e

istruzioni del produttore, utilizzando esclus ivamente accessori da esso

consigliati. L'ap parecchio in combinazione ad un supporto va spostato

con molta att enzione. Movimenti bruschi o il collocamento su pavi menti

non piani pos sono provocare la caduta dell'apparecchio e del suo

supporto.

• Accessori supplementari: non utilizza te mai accessori supplementa ri che

non siano consigliati dal produttore, potendo essere ciò causa di incidenti.

• Per p roteggere l'apparecchio in c aso di temporali o nel caso questo non

venisse utilizzat o per diverso tempo si consiglia di staccarne la spina di

corrente. In questo modo si evitano d anni all'apparecchio dovuti a colpi

di fulmine o ad improvvisi aumenti di tensione nel circuito d i corrente

alternata.

Illustrazione 1 Illust razione 2

• El ap arato ha sido producido por HK AUDIO® según el IEC 60065 y salió

de la fábrica en un estado técnicamen te perfecto. Para conservar este

estado y aseg urar un funcionamiento sin peligros el usuario debe tener

en cuenta las indicaciones y advertencias contenidas en las instr ucciones

de manejo. l aparato corresponde a la clase de protección l (toma de

tierra protegida) .

• LA SE GURIDAD, LA FIABILIDAD Y EL RENDIMIENTO DEL APARATO

SOLO ESTAN GARANTIZADOS POR HK AUDIO® CUANDO:

• el mo ntaje, la ampliación, el reajuste, los cambios o las reparaciones

se realicen p or HK AUDIO® o por pe rsonas autorizadas para ello ;

• la in stalación eléctrica del reci nto en cuestión corresponda a los

requisitos de la determinación del IEC (ANSI);

• el ap arato se use de acuerdo con las indicaciones de uso.

ADVERTENCIA:

• Si se destapan protecciones o se retiran piezas de la carcasa, exceptuando

si se puede hacer manualmente, se pue den dejar piezas al desc ubierto

que sean cond uctoras de tensión.

• Si es necesario abrir el apar ato, éste tiene que esta r aislado de todas las

fuentes de al imentación. Esto se debe tener en cuenta antes d el ajuste, de

un entretenimient o, de una reparación y de una sustitución de

las piezas.

• Un aj uste, un entretenimiento o una reparación en el aparato abierto y

bajo tensión sólo puede ser llevado a cabo por un especialist a autorizado

por el produc tor (según VBG 4) que conozca a fondo los pe ligros que ello

conlleva.

• Las s alidas de altavoces que estén provistas de la ca racterística

IEC 417/5036 (figura 1, véase abajo) pueden conducir tensiones

peligrosas al contacto. Por ello es i ndispensable que antes de poner en

marcha el apa rato; la conexión se hay a realizado únicamente con el cable

de empalmes r ecomendado por el productor.

• Las c lavijas de contacto al f inal de los cables conec tores tienen que estar

atornilladas o enclavadas a la carcasa, en tanto que sea posi ble.

• Los f usibles de repuesto que se utilicen sólo pueden ser del tipo indicado

y tener la intensidad nominal indicada.

• El us o de fusibles reparados o la puesta en cortocirc uito del soporte es

inadmisible.

• El em palme del conductor de p rotección no se puede in terrumpir en

ningún caso.

• Las s uperficies provistas de la característica "HOT" (figura 2, véase

abajo), los p aneles de fondo trasero o las protecciones con r anuras de

ventilación, los cuerpos de ventilación y sus protecciones, así c omo las

válvulas electrón icas y sus protecciones pueden alcanzar temperaturas

muy altas dur ante el funcionamiento y por ello no se deberían tocar.

• Niveles elevados de la intensidad de sonido pueden causar continuos

daños auditivos; por ello debe evitar acercarse demasiado a altav oces que

funcionen a a ltos niveles. En tales c asos utilice protecciones au ditivas.

ACOMETIDA A LA RED:

• El ap arato está proyectado para un funcionamiento continuo.

• La te nsión de funcionamiento ajus tada tiene que coincidir con la tensión

de la red del lugar.

• La co nexión a la red eléctric a se efectuará con la fuente de alimentación

o con el cable de red que se entreguen con el aparato.

• Fuente de a limentación: una linea de conexión dañada no se puede

sustituir. La fuente de alimentación no puede vol ver a ponerse en

funcionamiento.

• Evite una conexión de la red eléctrica a distribuidores c on muchas tomas

de corriente.

• El en chufe para el suministro de corriente tiene que estar cerca del

aparato y ser de fácil acceso.

SITUACION:

• El aparato debería estar situado en una superficie limpia y totalmente

horizontal.

• El ap arato no puede estar exp uesto a ningún tipo de sacudidas durante

su funcionamiento .

• Se de ben evitar la humedad y el polvo.

• El aparato no puede ponerse en funcionamiento cerca del agua, la bañera,

el lavamanos, la pila de la cocina, un recinto con tuberías de agua,

la piscina o en habitaciones húmedas. Tampoco se pueden poner objetos

llenos de líq uido - jarrones, vasos, botellas, etc. - encima de él.

• Procure que el aparato tenga suficiente ventilación.

• Las a berturas de ventilación exis tentes no se deben bloqu ear ni

tapar nunca. El aparato debe estar si tuado como mínimo a 20 cm de la

pared. El apa rato sólo se puede monta r en un rack, si se ha procurado la

suficiente ventil ación y se han cumplido las indicaciones de mont aje

del productor.

• Evite los rayos del sol directos así como la proximidad a radiadores,

electro-radiadores o aparatos similares.

• Si el aparato pasa repentinamente de un lugar frío a otro caliente, se

puede condensar humedad en su interior. Esto se debe tener en cuenta

sobretodo en los aparatos con válvulas electrónicas. Antes de pon er

en marcha el aparato se debe esperar hasta que éste haya adquirido la

temperatura ambie ntal.

• Accesorios: el aparato no se puede colocar encima de carros, estantes,

trípodes, soportes o mesas inestables. Si el aparato se cae puede causar

daños personales y se puede estropear. Coloque el aparato sólo en un

carro, rack, estante, trípode o soporte recomendado por el produc tor o

que se le haya vendido junto con el aparato. En la instal ación se deben

seguir las in dicaciones del productor así como utilizar los acces orios

recomendados por el mismo para colocarlo encima. El conjunto del

aparato con e l pedestal se debe mover con mucho cuidado. Un paro

brusco, la ap licación de una fuerza d esmesurada o un suelo ir regular

puede ocasionar la caida de todo el conjunto.

• Piezas adicionales: no utilice nu nca piezas adicionales que no estén

recomendadas por el productor, ya que se podrían provocar accidentes.

• Para protejer el aparato de u na tormenta o si no se supervisa ni utiliza

durante algún tiempo, se debería desconec tar la clavija de la red. Así se

evitan daños en el aparato a causa de un rayo y golpes de tensión en la

red de corrie nte alterna.

Figura 1 Figura 2

Page 4

Manual

COHEDRA® & COHEDRA® Compact

Preface

This manual is addressed to all technicians who are responsible for setting up, operating and maintaining

the HK Audio® Cohedra™ Compact system. In addition, we would like to explain in detail the principles and

functions of HK Audio® Cohedra™ technology to all interested planning and installation engineers.

Content

A Die COHEDRA® Technology .....................................5

B COHEDRA® Enclosures ...........................................10

B 1 COHEDRA® Compact Enclosures .........................14

C COHEDRA® Transport Solution ...........................17

C 1 COHEDRA® Compact Transport Solution ..........20

D Rigging and Curving COHEDRA® Systems .........22

D 1 Rigging and Curving COHEDRA® Compact ........36

E COHEDRA® Setups with CAPS .................................48

F COHEDRA® Controlling Concept ........................61

G Controller and Controller Software ...............63

H COHEDRA® Power-Racks ..........................................81

I Power Amp VX 2400 ...................................................85

J Patchbay PB5 ..............................................................90

K Service COHEDRA® ....................................................95

K 1 Service COHEDRA® Compact ...................................98

L Appendix/Reference library .................................100

Page 5

5

Chapter A

The COHEDRA® Technology

1 Line Array Approaches in Recent Years ............ 6

2 Development Objectives ................................ 7

2.1 High Frequency Range .................................... 7

2.2 Middle Frequency Range .................................. 7

2.3 Low Frequency Range ....................................... 7

3 Emphasized Radiation Technology™ ............... 7

3.1 The High Frequency Wave Front ....................... 8

3.2 Midrange ..........................................................8

3.3 The Subwoofer-Truest Dynamic Response ..........9

Index of Figures:

Fig. 1: Comparison of a 4 m array's near-to-far

field transition in theory and practice ........6

Fig. 2: Gap due to curving ....................................6

Fig. 3: Emphasized radiation in a line array ..........7

Fig. 3.1: Extended line Array near-field .................... 7

Fig. 4: Effect without gap (red), with evenly

distributed gap (blue), and with

unevenly distributed gap (pink) ................. 7

Fig. 5: Typical J shape ........................................... 7

Fig. 6: The COHEDRA® acoustic lens'

mode of operation ..................................... 8

Fig. 7: The COHEDRA® acoustic lens ................... 8

Fig. 8: Effect of the synthetic fiber fleece ..............9

Fig. 9: Front view of the COHEDRA®

CDR 208 mid/high enclosure ....................9

Fig. 10: 8" speaker cover serving as a

CD horn and part of the

compression chamber ...............................9

Fig. 11: Comparison of moving masses ..................9

Fig. 12: Impulse response: ideal (blue),

10" (red), 18" (purple) ...............................9

A

Page 6

Manual

COHEDRA® & COHEDRA® Compact

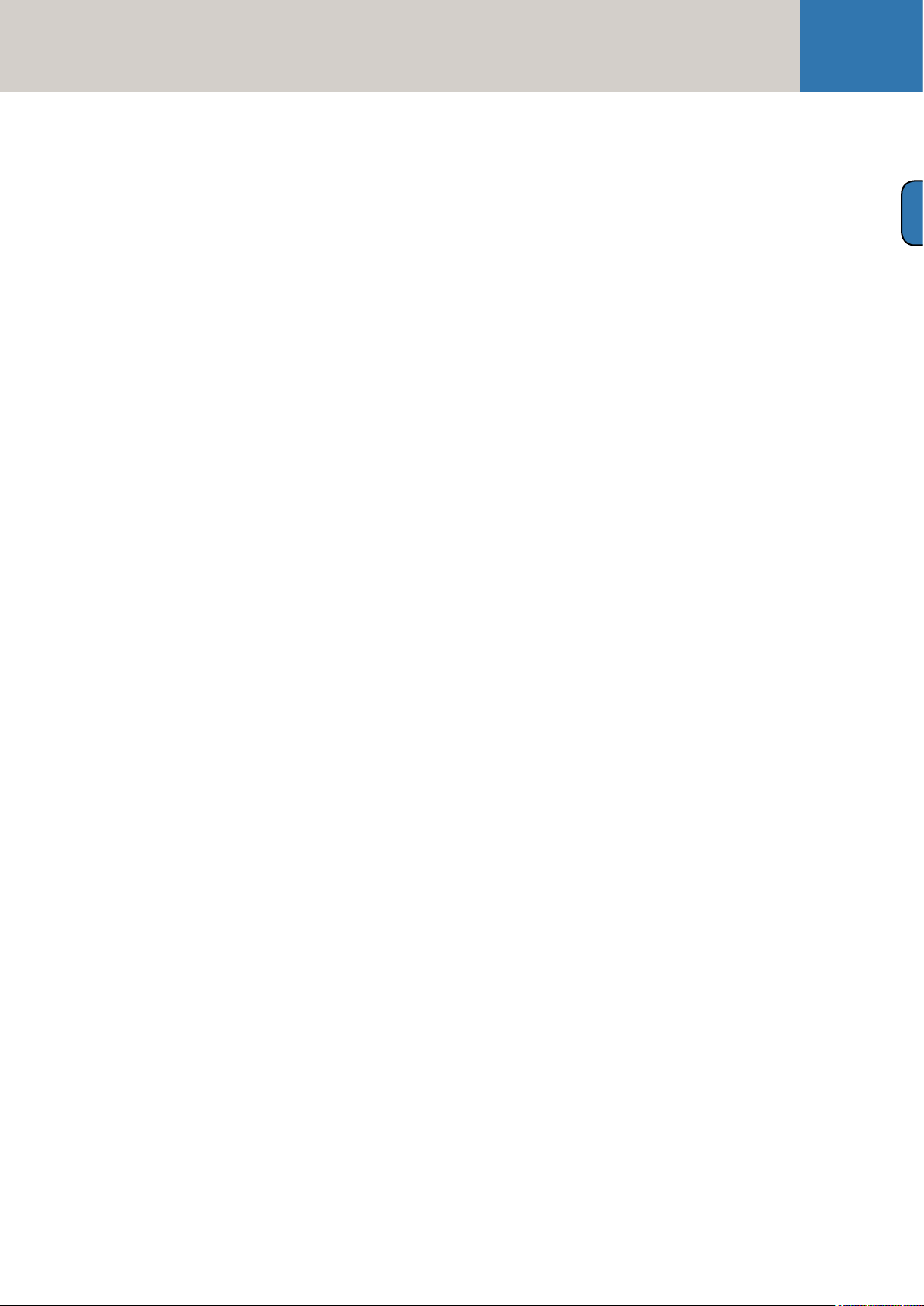

Figure 1: Comparison of a 4 m array’s near-to-far field

transition in theory and practice

1 Line Array Approaches

in Recent Years

Line arrays are a fixture on the contemporary sound

reinforcement scene. The design principle has its

origins in the stacks of cone loudspeakers that were

popular in the '70s.

Some 20 years later, the coherent wave front's ingress

into the high frequency range through waveguides

and acoustical mirrors ushered in a second generation of line arrays.

Here a line source makes use of the near field's diffusion. At a certain distance, the radiated cylindrical

wave front's near field transitions into a spherical

wave front. This transition from a cylindrical to a

spherical wave is contingent upon the length of the

radiator and the radiated frequency. The following

formula by Christian Heil serves to calculate the

distance at which this transition occurs:

H in meters, f in kHz

The answer is quite simple in view of the molecular

structure of air. Air molecules offer frictional resistance, impeding the sound wave's diffusion.

Some sound molecules drift outwards when the

wave's impact excites inert molecules at its fringes.

The cylindrical wave front's keen edges are smoothed

by degrees, gradually transforming the cylindrical

wave into a spherical wave front.

In mathematical terms, this can be described as

a sound vector pointing slightly outward at its

fringes. Because the velocity of propagation remains

constant, the cylindrical wave slowly tran-sition into

a spherical wave.

Technical literature describes the molecular frictional

resistance of air as atmospheric absorption of sound,

which increases exponentially as the frequency rises.

Accordingly, frictional resistance is greater at higher

frequencies, meaning that at higher frequencies,

the transition described occurs at a closer distance

(or smaller ratio).

Similar effects have been observed in analog technology where a square signal is smoothed by a

low-pass filter. It can be said that at some point

the signal regains a sine-like form.

Fig. 2 a: Continuous line source

Fig. 2 b: Gap due to curving

Mark Ureda, in turn, proposed a somewhat different formula for calculating the ratio between the

near and far fields:

l in meters, f in Hz

However, when these formulae are charted in a

graphical comparison, it is evident that their results

are quite similar.

Though in general it would appear that all aspects

of modern line arrays have been described ex-haustively, practical applications reveal some deficiencies.

According to the aforementioned formulae, at a frequency of 16 kHz the near field of a line array with

the length of 4 m extends out to 380 m!

Anyone who has heard a line array of comparable

size perform is sure to confirm that this great a

range cannot be attained in a real-world scenario.

The fact is that these values must be scaled down

substantially (see Fig. 1). Consequently, the aforementioned formulae for a continuous line source

are more theoretical in nature.

Values that are possible in theory are again reduced

in practice because the line source is not in fact

continuous in the high frequency range; instead,

it is composed of individual segments. Even with

the most painstaking effort, it is impossible to prevent

interference with or drop-outs of the continuous line

source in practical applications because housings

and edge diffraction inevitably cause some interference.

Furthermore, in theory this continuous line source

would always be linear! However, gaps are created

in the air when an array is curved, tearing the line

source apart and further reducing the range.

In order to preclude the phenomenon of gaps created

by curving, a line array would have to consist of very

many individual elements (N=>00), which unfortunately is practically infeasible (see Fig. 2 a, 2 b).

An effort to take these deficiencies into account led

to a next generation line array, with the following

section examines.

Consequently, all the aforementioned formulae

concerning a continuous line source are purely

theoretical nature and must be qualified considerably in practical applications.

Why these differences between theory and practice,

and why does a cylindrical wave transition into a

spherical wave front rather than diffuse infinitely?

Page 7

COHEDRA® Technology

7

2 Development Objectives

2.1 High Frequency Range

The tweeter should radiate coherent waves throughout its frequency range. In addition, the phase position should be fine-tuned and tweaked to harmonize

with the midrange woofer to afford the highest

possible fidelity and natural response. In order to

ensure uniform dispersion of sound, the driver should

channel into a constant directivity horn that is

free of undesirable diffractive effects and does not

adulterate the sonic image.

2.2 Middle Frequency Range

Midrange frequencies should be projected in short,

dry bursts. Homogenous dynamic response appropriate to the tweeter is also desirable. Like the

tweeter's time-aligned frequencies, the midrange

woofer should be time-aligned for all frequencies

that it transmits. To fulfill a line array system's

handling potential, its mid/high unit should satisfy

the requirements of full-range voice applications.

2.3 Low Frequency Range

Low frequency energy should be dispersed into the

air faster and with the greatest possible dynamic

precision. A bass array with a large near field is

desirable. Subwoofers should be designed for versatility, affording greatest flexibility in setup options.

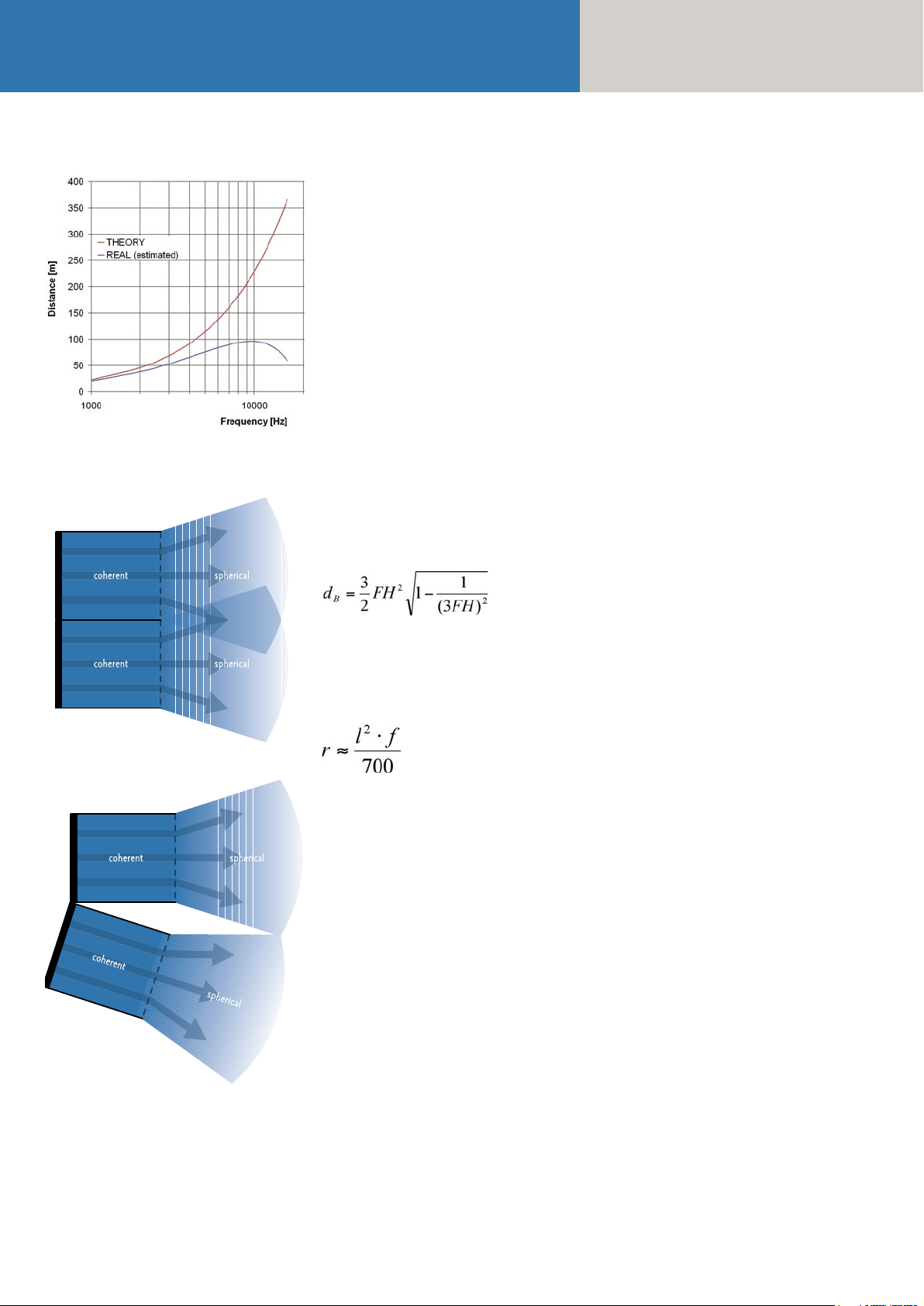

3 Emphasized Radiation

Technology™

So how does one go about developing a next

generation line array? Emphasis is a familiar concept

in analog technology. What this means is that those

signal components that will later be dampened are

emphasized first. To apply this concept to wave

fronts, the fringes that are later smoothed must

be emphasized first. In this case, emphasis means

simply that the edge areas are projected earlier in

time, forming a slightly inward curving wave front

whose sound vectors face slightly inwards

(see Figure 3 a).

ends of every element's wave fronts are reshaped in

the same way. A line source forms again at a certain

distance (Fig. 3.1). Emphasized Radiation technology is thus able to sustain the even wave for a longer

period, thereby significantly extending the line

array's near field in the high frequency range!

To clarify the influence of the gap, the following examines the directivity of an ideal line array without

gaps and of a line array with evenly and unevenly

distributed gaps. Basically, it can be said that every

line source is always accompanied by undesirable

side lobes. Like interference, these side lobes are

clearly audible artifacts and therefore extremely undesirable. Unfortunately, they cannot be avoided altogether, so it is important to minimize their level.

Figure 5 shows that an unevenly distributed gap

(pink) causes more irregular and more pronounced

side lobes. Without a gap (red) present, the array's

first side lobe occurs at a level of -13.58 dB. When

distributed across four elements of the same size

(blue) with the gap accounting for 18 percent of

the surface area, the level increases to -12.83 dB.

If these gaps are distributed unevenly, the level of

the first side lobe rises to -11.93 dB. This is nearly 1

dB higher than the level attained with the unevenly

distributed gap alone!

It is very important that the gap is distributed as

uniformly as possible across the full breadth of the

radiator. COHEDRA® achieves this by using two

different housing shapes for the mid/high array,

affording the greatest possible uniformity in gap

size for all typical configurations. This also ensures

minimum variation in gap size for the J array, a

configuration that today is used almost exclusively.

A

Figure 3 a-c: Emphasized radiation in a line array

Figure 3.1: Extended line Array near-field

Figure 4: Effect without gap (red), with evenly distributed

gap (blue), and with unevenly distributed gap (pink)

When applied to a continuous line source, this

creates a waveform as shown Fig. 3 b. Because

large line arrays typically consist of several identical

segments, a dedicated speaker would be required

for each segment. Apart from the fact that such a

continuous line source would be hard to implement,

practical applications also mandate great flexibility,

rendering such a concept in-feasible.

For these reasons, every element is curved slightly.

(Fig. 3 c). Due to the gaps between the elements,

which as stated above are inevitable anyway, both

Figure 5: Typical J shape

Page 8

Manual

COHEDRA® & COHEDRA® Compact

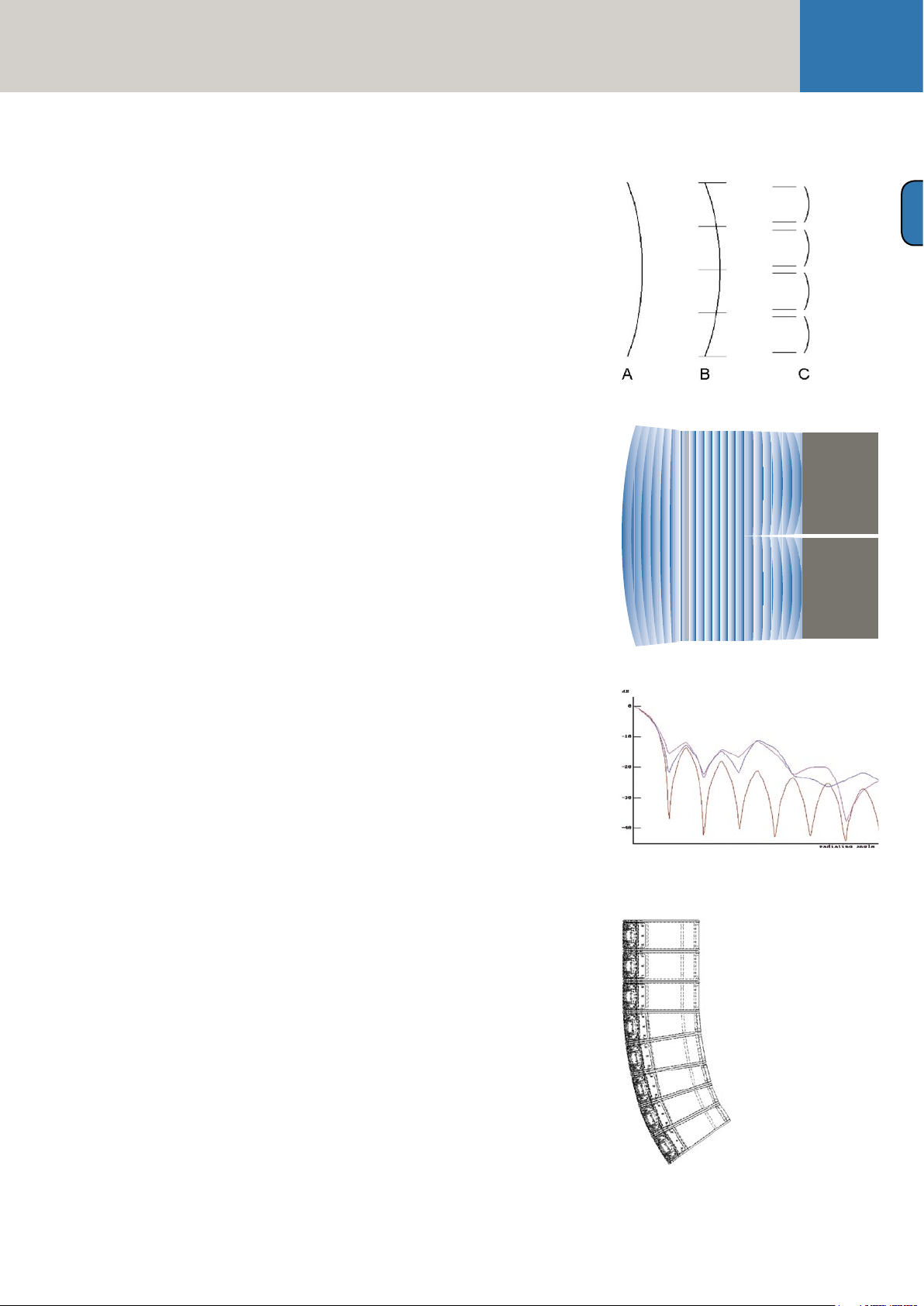

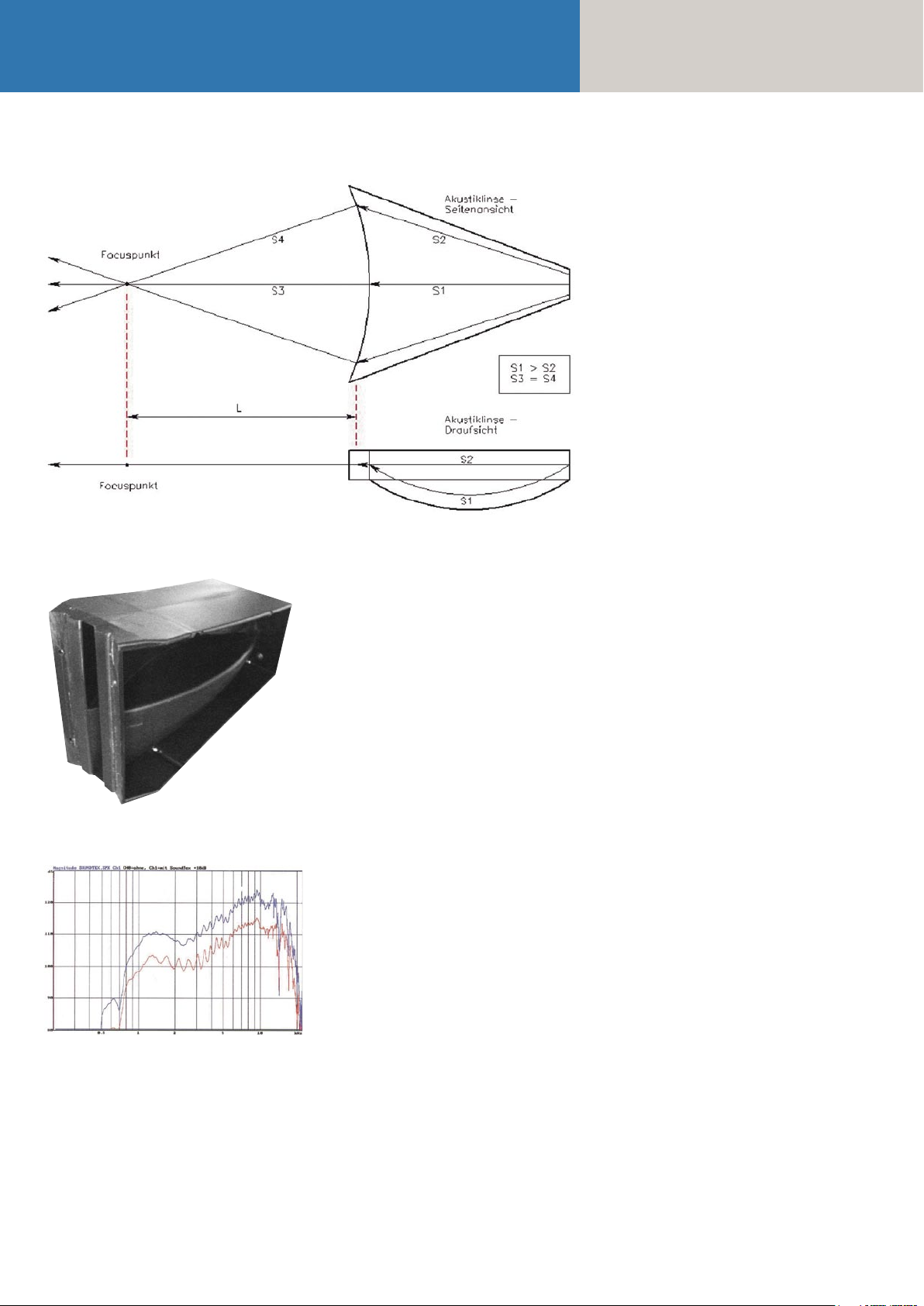

Figure 6: The COHEDRA® acoustic lens’ mode of operation

3.1 The High Frequency

Wave Front

A specially developed and patented acoustic lens

serves to curve the wave front. It transforms the

spherical wave emitted by the high frequency driver

into an inward curving wave front.

To shape a curved wave front, the sound wave's

inner components are re-channeled into a bisected,

centrically symmetrical array. In contrast to an axial

symmetrical array, a centrically symmetrical array

has the advantages of lower manufacturing tolerances. What's more the subdivided cavity enables

fewer standing waves, thereby reducing interference.

Typically, these constructions are relatively long

to minimize the differences between S1 and S2.

However, acoustically speaking this creates something approaching an organ pipe. The only remedy

is to connect a very large horn, an option that for

technical reasons is often infeasible. A covering

with a porous absorber is another possibility. Designed to reduce the velocity jump in sound particle

acceleration, this covering must be acoustically very

transparent.

Figure 7: The COHEDRA® acoustic lens

Figure 8: Effect of the synthetic fiber fleece

To this end, COHEDRA® employs a special synthetic

fiber fleece with defined aerodynamic resistance.

This absorber reduces the velocity jump in sound

particle acceleration, thereby helping considerably

to homogenize frequency response. Figure 8 illustrates the fleece's effect. The red curve shows

amplitude without fleece, the blue curve with

fleece. The two curves are depicted in staggered

formation only for the purpose of illustration.

Page 9

COHEDRA® Technology

9

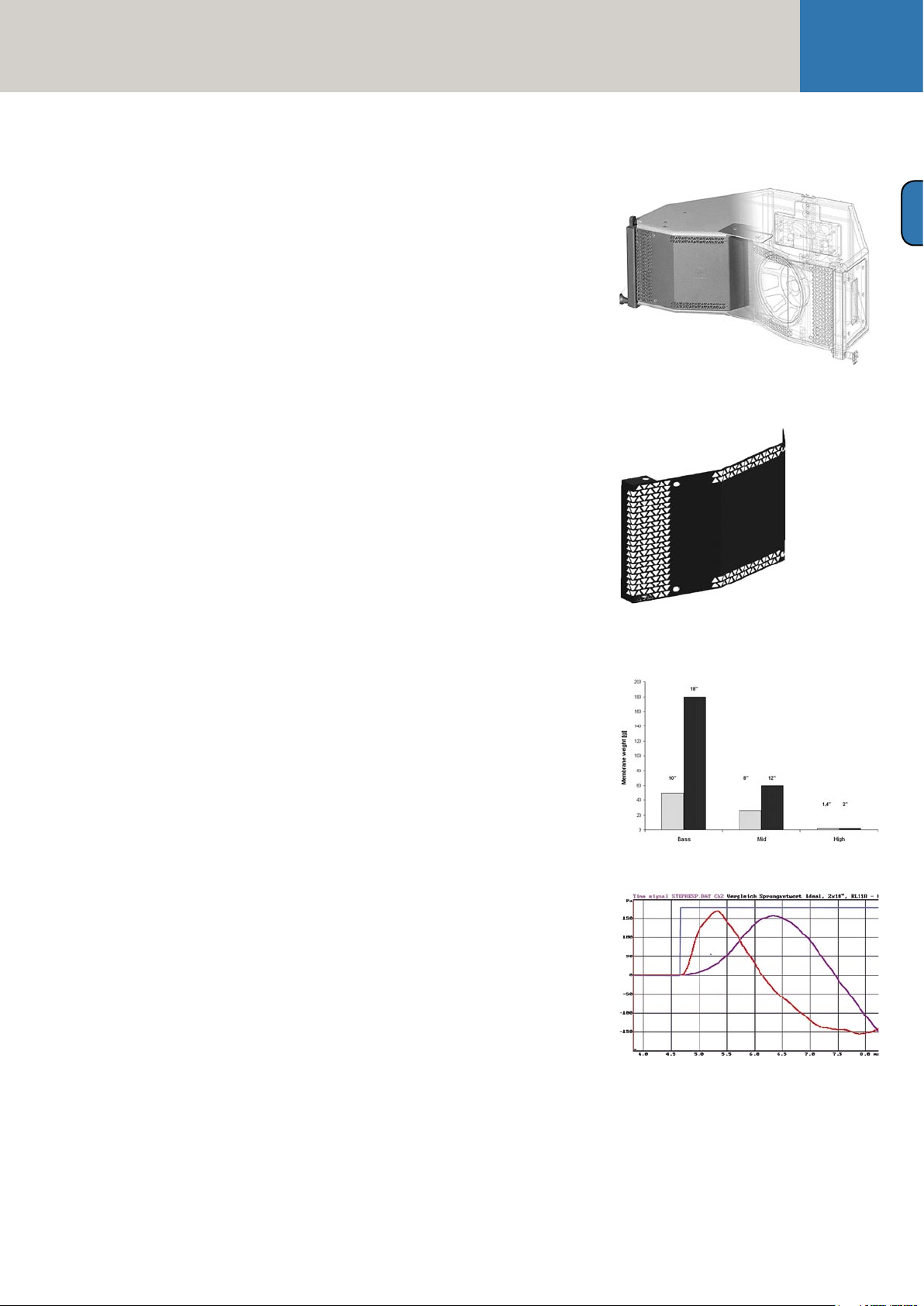

3.2 Midrange

A frequently occurring and often cited drawback

of line arrays is their sensitivity to wind. A look at

the construction of conventional line arrays reveals

that many do without a CD horn. Therefore, the

HF pattern of throw is increasingly constricted. It

is not uncommon for a radiation angle of an HF

unit nominally rated for 120° to come to just 50° at 16

kHz. A light wind from the side audibly carries away

the HF signal. In the case of conventional speaker

clusters this is not so significant because several

HF units are arrayed horizontally and these pick

up the slack to provide HF sound reinforcement.

In a line array, however, it is always just one HF unit

that is arrayed horizontally to target a predetermined

audience area!

A special speaker cover is located in front of the two

8" midrange speakers. Designed to shape the horn

contour with CD characteristic in front of the acoustic

lens, it is free of undesirable diffractive effects and

does not adulterate the sonic image. It does not

constrict the HF range and ensures greater stability

in the face of gusts of wind.

The sound of the 8" speakers emanates through

slots on the top and bottom of this cover. This

enhances the dynamic balance in the range of 130

to 900 Hz.

In addition, the cover creates a compression chamber

that behaves like an acoustical filter, suppressing

frequencies that lie above the rendered frequency

range. Rather than being dissipated, the energy is

displaced to a lower frequency range, thereby substantially increasing efficiency in the rendered frequency range! Because the speaker now acts against

a limited volume of air, distortion decreases so that

very high levels can be achieved with little distortion,

much like in a horn.

3.3 The Subwoofer-

Truest Dynamic Response

A great drawback of conventional woofers is the

considerable moving mass of the speaker (generally, 18"). As a result, low frequency reproduction is

marred by dynamic distortion.

There is only way to satisfy the desire for the driest,

cleanest possible low end response; that is to achieve

the best possible impulse behavior. By definition,

this requires a smaller speaker membrane with less

moving mass. The answer is a special 10" woofer.

Compared below is a typical 18"+12"+2" combination and the COHEDRA® solution. Notably, the

speaker membrane's moving mass in the low and

middle frequency ranges is clearly reduced.

Superior impulse behavior is also evident in the 10"

speaker's transient response. In comparison with

an 18" woofer, the membrane of the 10" woofer is

able to move much faster because its transients are

shorter.

The blue curve shows the in theory ideal response

and the red curve indicates the 10" speaker's transient

response. The purple curve shows the transient response of the 18" woofer. Measurements were taken

using a second order, 130Hz low-pass filter.

New filtering approaches were necessary to make

the most of the 10" woofer's capabilities, which is

why the housing also sports some special design

features. In combination with the bass reflex channel, the baffle boards form a horn, resulting in a

higher level in the low frequency range. The long,

lean chassis supports the formation of bass arrays

as well as ground coupling. In addition, extremely

compact clusters can be configured by setting enclosures on end. Because the loudspeaker chassis is

tropic-proof, the enclosure can do without a leveldampening front covering.

A

Figure 9: Front view of the COHEDRA®

CDR 208 mid/high enclosure

Figure 10: 8" speaker cover serving as a CD horn and

part of the compression chambe

Figure 11: Comparison of moving masses

Figure 12: Impulse response: ideal (blue), 10" (red), 18" (purple)

Page 10

Manual

COHEDRA® & COHEDRA® Compact

Chapter B

The COHEDRA® Loudspeakers

1 COHEDRA® Loudspeakers ..................... 11

1.1 CDR 208 S and CDR 208 T Mid/High

Enclosures ................................................ 11

1.2 CDR 210 Sub Subwoofer ......................... 12

1.3 CDR 210 F Sub Subwoofer .......................13

Index of Figures:

Fig. 1: Cohedra CDR 208 T ..................................11

Fig. 2: Cohedra CDR 208 S ..................................11

Fig. 3: Cohedra CDR 210 Sub ............................. 12

Fig. 4: Cohedra CDR 210 F Sub ...........................13

Page 11

The COHEDRA® Loudspeakers

11

1 COHEDRA®

Loudspeakers

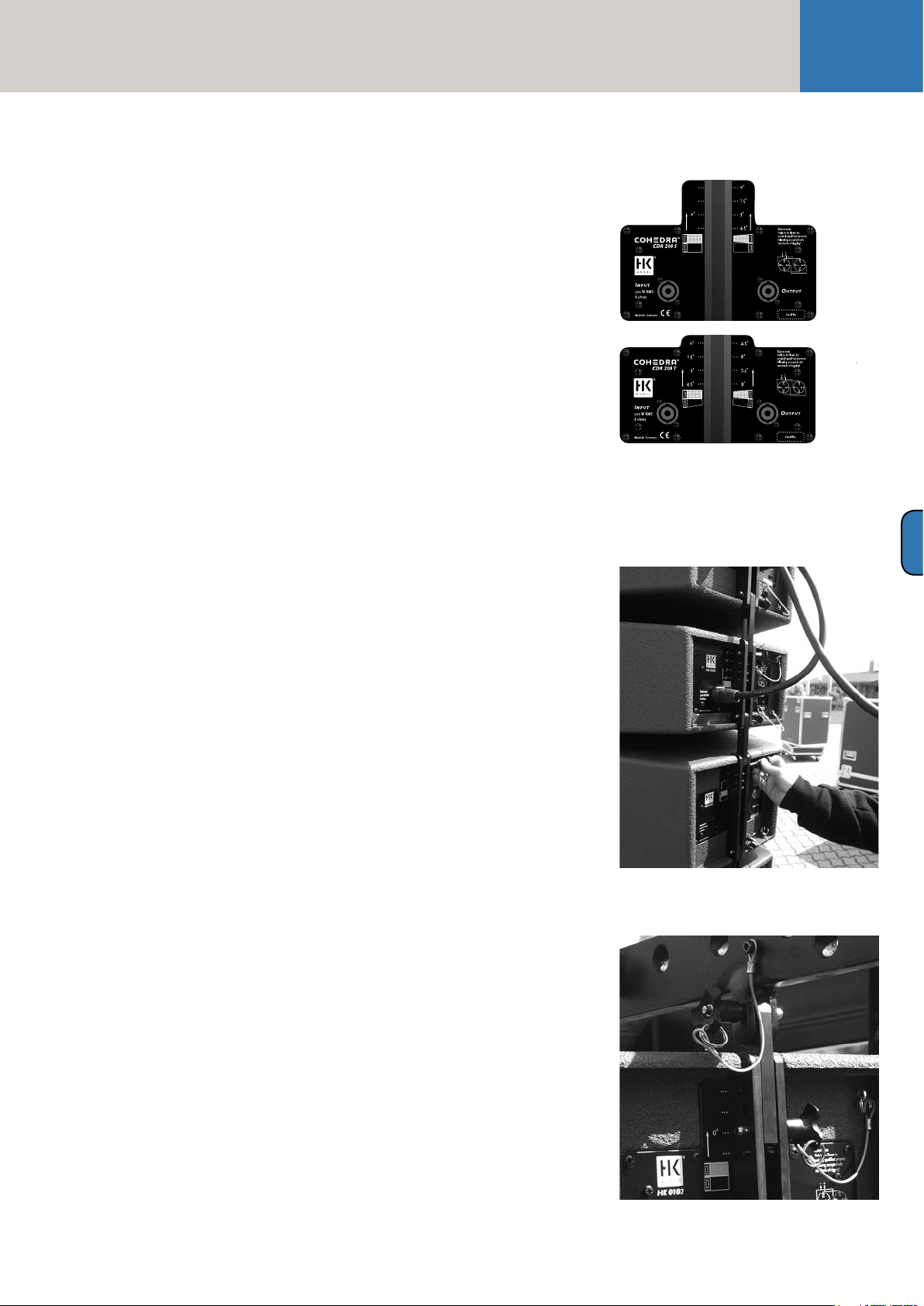

1.1 CDR 208 S and CDR 208 T

Mid/High Enclosures

Design and Construction of the Mid/High Enclosures

Two types of housings are available, the purpose of

the different design being to optimize the typical "J"

form of mid/high arrays. The CDR 208 S is housed

in a straight rather than slanted cabinet. The CDR

208 T (T is short of trapezoidal) enclosure's top

and bottom are slanted at 4.5° angles, a design that

enables the configuration of sharply curving down-fills.

CDR 208 S and CDR 208 T enclosures are made of

19 mm, 13-ply birch plywood and coated with waterrepellent, black acrylic enamel. The baffle board

cover consists of a metal grille that also serves as

a compression chamber and a horn channel for

the 1.4" driver.

The CDR 208 S and CDR 208 T weigh 30 kg.

They are 65 cm wide, 25.5 and 24 cm high, respectively,

and 60 cm deep (including rigging attachments).

Two slot grips have been routed into the side panels

for easy transport and set-up.

Connections

The connector panel on the rear of CDR 208 S (T)

enclosures is recessed to protect the ports from

harm. On these enclosures, you'll find two Speakon

NL 4 connectors. Both ports' four pins are wired in

parallel. Pin assignments are:

pin 1+ = mid/high +, 1- = mid/high -,

2+ = sub +, 2- = sub 2-.

CDR 208 S and CDR 208 T Enclosures'

Technical Data

Power handling (RMS): 500 watts

Power handling (program): 1,000 watts

Impedance: 8 ohms

Chassis: 2x 8" / 1.4" B&C

Frequency range (±3 dB): 88 Hz to 16 kHz

Frequency range (-10 dB): 75 Hz to 19 kHz

SPL (1W / 1m, half-space): 108 dB

SPL (maximum, half-space) *): 139 dB @ 10 % THD

SPL (peak, half-space) *): 146 dB

Crossover frequency: 800 Hz

Horizontal dispersion: 80°, constant directivity

Vertical dispersion: Depends on the no. of stacked

enclosures and curving configuration

B

Figure 1: Cohedra CDR 208 T

Figure 2: Cohedra CDR 208 S

Serving to fly the enclosures are fully integrated

rigging attachments comprising four quick-release

pins and three rigging connectors, two mounted on

the sides and one in the rear.

Electrical and Acoustical Data

CDR 208 S (T) enclosures feature two horn-loaded

8" cone chassis speakers and a 1.4" B&C high frequency driver with a front-mounted acoustic lens in

a CD horn configuration. Aligned in a tri-axial array,

the drivers are addressed via an internal passive

crossover with a separating frequency of 800 hertz.

CDR 208 S (T) enclosures' nominal electrical

power-handling capacity is 500 watts RMS at 8 ohms

impedance. They produce a sound pressure level of

108 dB (1W@1m), measured under half-space conditions. Maximum SPL measured under the same

conditions at a distance of one meter is 139 dB

at 10% THD.

The CDR 208 S (T) enclosures' horizontal dispersion

pattern is 80°. Frequency response ranges from

88 Hz to 16 kHz (±3 dB). The CDR 208 S (T) enclosures are thus able to provide sound reinforcement

public address applications calling speech only

without requiring a subwoofer.

Connections

Ports: 2 Speakon NL 4 ports, wired in parallel

Pin assignments: 1+ = mid/high +, 1- = mid/high,

2+ = sub +, 2- = sub 2-

Housing

Material: 19-mm, 13-ply birch plywood

Coating: Black acrylic enamel

Handles: Two slot grips on the sides

Rigging hardware: Integrated side and rear rigging

attachments with quick-release pins.

Weight:

CDR 208 T 30 kg 66 lbs.

CDR 208 S 30 kg 66 lbs.

Dimensions (W x H x D):

CDR 208 T: 65 x 25.5 x 60 [cm]

25 10/16" x 10 1/16" x 23 10/16" [inch]

CDR 208 S: 65 x 24 x 60 [cm]

25 10/16" x 9 8/16" x 23 10/16" [inch]

*) Specifications refer to a cluster of four Cohedra

components.

Page 12

Manual

COHEDRA® & COHEDRA® Compact

Figure 3: Cohedra CDR 210 Sub

1.2 CDR 210 Sub Subwoofer

Design and Construction of the Subwoofer

The CDR 210 Sub enclosure is made of 19 mm,

13-ply birch plywood and coated with water-repellent, black acrylic enamel. The baffle board cover

consists of a metal grille.

The CDR 210 Sub weighs 33 kg.

It is 110 cm wide, 32 high and 40 cm deep.

Two slot grips have been routed into the side panels

for easy transport and set-up.

Electrical and Acoustical Data

The CDR 210 Sub enclosure features two 10" woofers.

The loudspeakers are treated with a special coating

protecting them against dirt and moisture.

The CDR 210 Sub enclosure's nominal electrical

power-handling capacity is 600 watts RMS at 8 ohms

impedance. It produces a sound pressure level of

104 dB (1W@1m), measured under half-space conditions. Maximum SPL measured under the same

conditions at a distance of one meter is 139 dB

at 10% THD. The frequency response of the

CDR 210 Sub ranges from 47Hz to fx (± dB).

Connections

The connector panel on the rear of the CDR 210

Sub enclosure is recessed to protect the ports from

harm. On this enclosure, you'll find two Speakon

NL 4 connectors. Both ports' four pins are wired

in parallel. Pin assignments are:

pin 1+ = mid/high +, 1- = mid/high -,

2+ = sub +, 2- = sub 2-.

The Cohedra CDR 210 Sub Subwoofer's

Technical Data

Power handling (RMS): 600 watts

Power handling (program): 1200 watts

Impedance: 8 ohms

Chassis: 2x 10"

Frequency range (±3 dB): 47 Hz to fx

Frequency range (-10 dB): 39 Hz to f

SPL (1W / 1m, half-space): 104 dB

SPL (maximum, half-space) *): 139 dB @ 10% THD

SPL (peak, half-space) *): 142 dB

Connections

Ports: 2 Speakon NL 4 ports, wired in parallel

Pin assignments: 1+ = mid/high +, 1- = mid/high -,

2+ = sub +, 2- = sub 2-

Housing

Material: 19-mm, 13-ply birch plywood

Coating: Black acrylic enamel

Handles: Two slot grips on the sides

Weight:

33 kg / 72.6 lbs

Dimensions (W x H x D):

110 cm x 32 cm x 40 cm

43 2/16" x 12 4/16" x 15 5/16"

*) Specifications refer to a cluster of four

COHEDRA® components.

x

Page 13

The COHEDRA® Loudspeakers

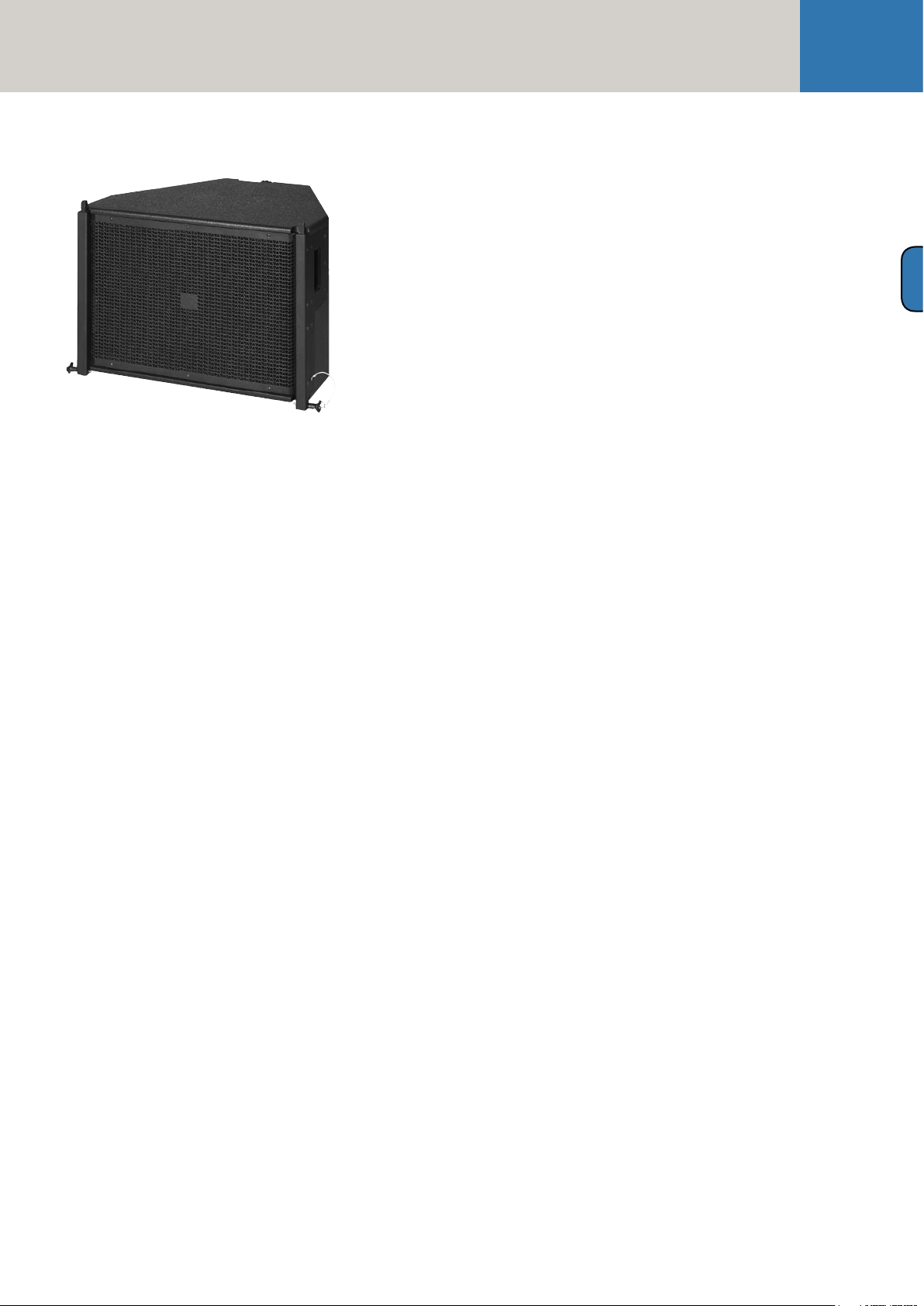

Figure 4: Cohedra CDR 210 F Sub

13

B

1.3 The CDR 210 F Sub Subwoofer

Design and Construction of the Subwoofer

The CDR 210 F Sub's enclosure is made of 19 mm,

13-ply birch plywood and coated with water-repellent, black acrylic enamel. The baffle board cover

consists of a metal grille.

The CDR 210 F Sub weighs 40 kg. It is 65.5 cm

wide, 48 cm high and 60 cm deep. Two slot grips

have been routed into the side panels for easy

transport and set-up.

Electrical and Acoustical Data

The CDR 210 F Sub enclosure features two

10" woofers. The enclosures are provided with

a special coating that protects them against dirt

and water.

The CDR 210 F Sub enclosure's nominal electrical

power-handling capacity is 600 watts RMS at 8 ohms

impedance. It produces a sound pressure level

of 104 dB (1W@1m), measured under half-space

conditions. Maximum SPL measured under the same

conditions at a distance of one meter is 139 dB at

10% THD. Frequency response ranges from 47 Hz

to fx (± dB).

The CDR 210 F Sub Enclosure's Technical Data

Power handling (RMS): 600 watts

Power handling (program): 1200 watts

Frequency range (±3 dB): 47 Hz to fx

Frequency range (-10 dB): 39 Hz to fx

SPL (1W / 1m, half-space): 104 dB

SPL (maximum, half-space) *): 139 dB @ 10% THD

SPL (peak, half-space) *): 142 dB

Impedance: 8 ohms

Chassis: 2 x 10"

Connections

Ports: 2 Speakon NL 4 ports, wired in parallel

Pin assignments: + = mid/high +, 1- = mid/high -,

2+ = sub +, 2- = sub 2- 2-

Housing

Material: 19-mm, 13-ply birch plywood

Coating: Black acrylic enamel

Handles: Two slot grips on the sides

Weight: 40 kg/ 88 lbs.

Dimensions (W x H x D): 65.5 cm x 48.2 cm x 60 cm

25 3/4" x 20" x 23 5/8"

*) Measured using four 4 CDR 210 F Sub enclosures.

Connections

The connector panel on the rear of the CDR 210 F Sub

is recessed to protect the ports from harm. On these

enclosures, you'll find two Speakon NL 4 connectors.

Both ports' four pins are wired in parallel.

Pin assignments are pin 1+ = mid/high +,

1- = mid/high -, 2+ = sub +, 2- = sub 2-.

Page 14

Manual

COHEDRA® & COHEDRA® Compact

Chapter B 1

The COHEDRA® Compact Loudspeakers

1 COHEDRA® Compact Enclosures . . . . . . . . 15

1.1 The CDR 108 C Mid/High Unit 15

1.2 The Subwoofer CDR 210 C 16

Index of Figures:

Figure 1: Cohedra® Compact CDR 108 C 15

Figure 2: Cohedra® Compact CDR 210 C 16

Page 15

The COHEDRA® Compact Loudspeakers

15

1 COHEDRA® Compact

Enclosures

1.1 The CDR 108 C Mid/High Unit

Design and Construction

The CDR 108 C Mid/High unit’s top and bottom

panels are sloped at an angle of 4.5°. Made of 19 mm,

13-ply birch plywood, the enclosure is coated with

water-repellent, black acrylic enamel. For the purpose

of curving the array, your choices of angles (or splay)

are 0°, 1.5°, 3°, 4.5°, 6°, 7.5° and 9°. The baffle board

cover consists of a metal grille; located behind it is

a compression chamber for the 8" speaker and a

CD horn equipped with an acoustical lens for the

two 1" drivers.

The CDR 108 C weighs 17.9 kg. It is 50 cm wide, 26 cm

high and 32.5 cm deep (including rigging attachments).

Two grips on the side panels facilitate transport and

set-up.

Serving to fly the mid/high units are fully integrated

rigging attachments comprising four quick-release

pins and three rigging connectors, two mounted on

the sides and one in the rear.

Electrical and Acoustical Data

The CDR 108 C enclosure is loaded with an 8" cone

chassis speaker and two 1" B&C high frequency drivers

with a front-mounted acoustical lens in a CD horn

configuration. The drivers are addressed via an

internal passive crossover with a separating frequency

of 800 hertz.

The CDR 108 C enclosure’s nominal electrical power-handling capacity is 250 watts RMS at 16 ohms

impedance. It produces a sound pressure level

of 107 dB (1W@1m), measured under half-space

conditions. Maximum SPL measured under the

same conditions at a distance of one meter is

136 dB at 10% THD.

The CDR 108 C Enclosures’ Technical Data

Nominal power handling :

250 watts RMS, 500 watts program

Frequency range: ± 3 dB: 88 Hz – 19 kHz

SPL, 1W @ 1m*: 107 dB

SPL, max. SPL @ 1m*: 136 dB @ 10% THD**

Impedance: 16 ohms

Woofer/midrange speaker: 1x 8" with compression

chamber

High-frequency driver: 2x 1" with COHEDRA®

Acoustic Lens

Horn: 100° CD horn

Crossover frequency: 800 Hz, 12 dB/ octave

Ports: Speakon® NL 4 connectors

Pin assignments: 1+ = mid/ high +, 1- = mid/ high -,

2+ = sub +, 2- = sub 2-

Housing

Material: 15-mm (5/8"), 13-ply birch plywood

Coating: Black acrylic enamel

Front grille: Metal

Rigging hardware: Integrated rigging attachments

Variable splay for curving arrays: 0°, 1.5°, 3°, 4.5°,

6°, 7.5°, 9°

Weight: 17.9 kg / 39.4 lbs

Dimensions (W x H x D):

50 x 26 x 32.5 cm

19-5/8" x 10-1/4" x 12-3/4"

*) SPL measured under half-space conditions

**) measured with 4 CDR 108 Cs

B 1

Figure 1: Cohedra Compact CDR 108 C

The CDR 108 radiates at a horizontal angle of 100°.

Frequency response ranges from 88 Hz to 19 kHz

(±3 dB). The enclosure is thus able to provide

speech reinforcement for public address applications without requiring a subwoofer.

Connections

The connector panel on the rear of the CDR 108 C

is recessed to protect the ports from harm. On this

enclosure, you’ll find two Speakon® NL 4 connectors. Both ports’ four pins are wired in parallel.

Pin assignments are: pin 1+ = mid/high +,

1- = mid/high -, 2+ = sub +, 2- = sub 2-.

Page 16

Manual

COHEDRA® & COHEDRA® Compact

Figure 2: Cohedra Compact CDR 210 C

1.2 The Subwoofer CDR 210 C

Design and Construction of the Subwoofer

Made of 19 mm, 13-ply birch plywood, the CDR 210

C enclosure is coated with water-repellent, black

acrylic enamel. The baffle board cover consists of a

metal grille.

The CDR 210 C weighs 48 kg. It is 55 cm wide, 60

high and 63 cm deep. Two slot grips have been

routed into the top, bottom and back panels for easy

transport and set-up.

Electrical and Acoustical Data

The CDR 210 Sub enclosure is loaded with two 10"

woofers. The loudspeakers are treated with a special

coating protecting them against dirt and moisture.

The CDR 210 C enclosure’s nominal electrical

power-handling capacity is 600 watts RMS at 8

ohms impedance. It produces a sound pressure level

of 104 dB (1W@1m), measured under half-space

conditions. Maximum SPL measured under the same

conditions at a distance of one meter is 139 dB at

10% THD**. The frequency response of the CDR 210

C ranges from 47Hz to fx (± dB).

Connections

The connector panel on the rear of the CDR 210

C enclosure is recessed to protect the ports from

harm. On this enclosure, you’ll find two Speakon®

NL 4 connectors. Both ports’ four pins are wired in

parallel. Pin assignments are pin 1+ = mid/high +,

1- = mid/high -, 2+ = sub +, 2- = sub -.

The Cohedra CDR 210 C Subwoofer’s Technical Data

Power handling (RMS): 600 watts RMS,

1200 watts program

Frequency range (±3 dB): 47 Hz to fx

Frequency range (-10 dB): 39 Hz to fx

SPL, 1W @ 1m*: 104 dB

SPL, max. SPL @ 1m*): 139 dB @ 10% THD**

Impedance: 8 ohms

Woofers: 2x 10"

Connections: 2 NL 4 Speakon® ports, wired in parallel Pin assignments: 1+ = mid/ high +, 1- = mid/ high

-, 2+ = sub +, 2- = sub 2-

Housing

Material: 19-mm (3/4"), 13-ply birch plywood

Coating: Black acrylic enamel

Front grille: Metal

Handles: Four slot grips

Rigging hardware: Integrated pick points

Weight: 48 kg (105.6 lbs)

Dimensions (W x H x D): 50 cm x 60 cm x 63 cm

19 3/4" x 23 3/4" x 24 3/42

*) SPL measured under half-space conditions

**) measured with 4 CDR 210 Cs *)

Page 17

Chapter C

COHEDRA® Transport Solution

The COHEDRA® Transport Solution .................... 18

1.1 Mid/High Enclosures ..................................... 18

1.2 Subwoofers .................................................... 18

1.3 Dimensions and Weights of the Cases

and Bass Bin Dollies ...................................... 19

1.4 COHEDRA® Truck Space ................................ 19

Index of Figures:

Fig. 1: COHEDRA® Mid/ High-Case ................... 18

Fig. 2: COHEDRA® Subwoofer-Dolly .................. 18

Fig. 3: 16 Mid/ High-Cabinets

and 16 Subwoofers ................................... 19

Fig. 4: 24 Mid/ High-Cabinets

and 24 Subwoofers ................................... 19

Fig. 5: 32 Mid/ High-Cabinets

and 32 Subwoofers ................................... 19

Fig. 6: 48 Mid/ High-Cabinets

and 48 Subwoofers ................................... 19

17

C

Page 18

Manual

COHEDRA® & COHEDRA® Compact

The COHEDRA®

Transport Solution

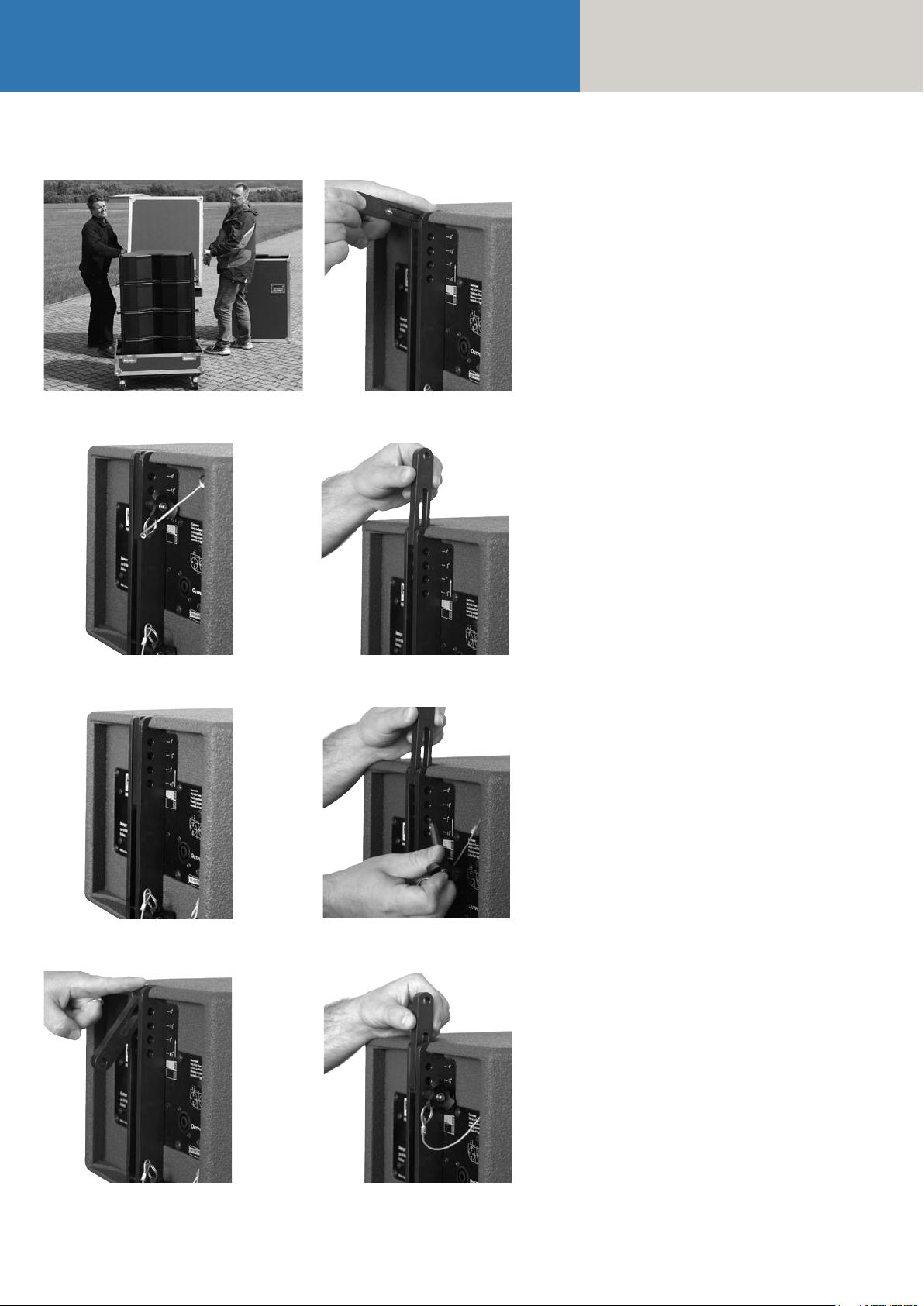

1.1 Mid/High Enclosures

A specially designed case serves to transport the

COHEDRA® CDR 208 S, CDR 208 T mid/high and

the CDR 210 F Sub enclosures.

The floor of the mid/high enclosure case is adjustable

to 0° and 4.5°. This enables you to configure the S

and T model housing as desired without having to

disassemble clusters consisting of up to four mid/

high enclosures for transport.

1.2 Subwoofers

Figure 1: COHEDRA® Mid/ High Case

Figure 2: COHEDRA® Subwoofer Dolly

Serving to transport subwoofers is a dolly designed

to carry four stacked subwoofers. Subwoofers are

secured to the dolly using a cargo strap.

1.3 Dimensions and Weights of

the Cases and Bass Bin Dollies:

Case for four CDR 208s or two CDR 210 F Sub:

Width: 80 cm (31 1/2")

Depth: 74 cm (29 1/8")

Height: 131 cm (51 5/8")

Weight: approx. 150 kg (330 lbs.)

Four CDR 210 Subs with dolly and strap:

Height: 148 cm (58 1/4"), casters included

Width: 40 cm (15 3/4")

Depth: 110 cm (43 1/4")

Weight: 138 kg (304 lbs.)

PR 16 (lying):

Width: 60 cm (23 5/8")

Height: 65.5 cm (25 3/4") (depth, when standing

on casters)

Depth: 95 cm (37 3/8") (height, when standing

on casters)

Weight: approx. 125 kg (275 lbs.)

PR 8 (lying):

Width: 60 cm (23 5/8")

Height: 38.5 cm (15 3/16") (depth, when standing

on casters)

Depth: 95 cm (37 3/8") (height, when standing

on casters)

Weight: approx. 65 kg (143 lbs.)

Flying Hardware Case (on casters):

Width: 120 cm (47 1/4")

Depth: 80 cm (31 1/2")

Height: 58 cm (22 3/4")

Weight: approx. 90 kg (198 lbs.)

Page 19

COHEDRA® Transport Solution

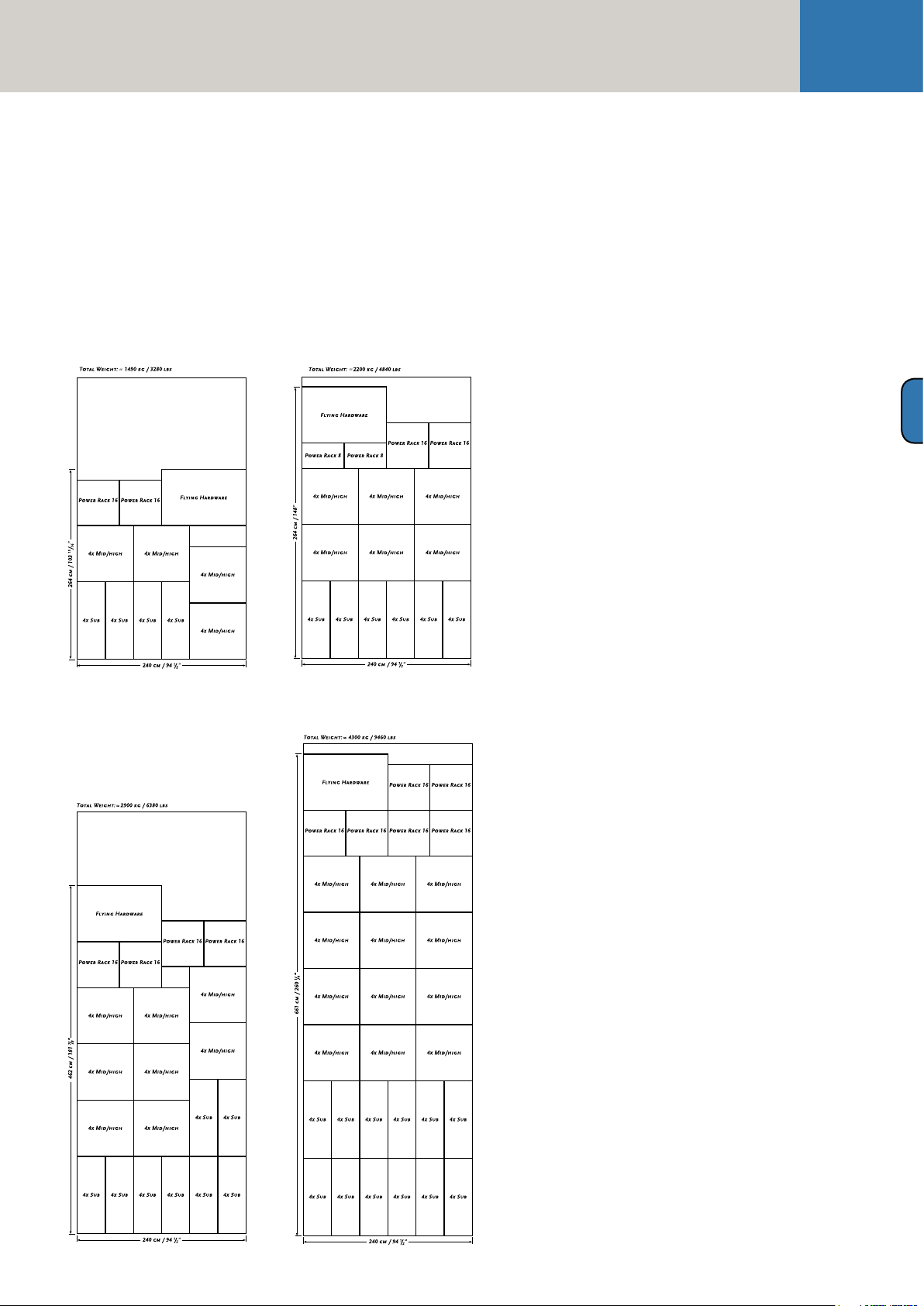

1.4 COHEDRA® Truck Space

The dimensions of COHEDRA® cases, racks and

dollies were selected specifically to make the most

of available truck space. The diagrams below offer

suggestions on how to load different COHEDRA®

systems into a truck with a width of 240 cm.

19

C

Page 20

Manual

COHEDRA® & COHEDRA® Compact

Chapter C 1

COHEDRA® Compact Transport Solution

1 COHEDRA® Compact Transport Solution . . . .21

1.1 CDR 108 C Mid/High Case . . . . . . . . . . . . . . . 21

1.2 Dimensions and Weights . . . . . . . . . . . . . . . . . 21

Index of Figures:

Fig. 1: COHEDRA® Compact Mid/High Case. . . 21

Fig. 2: 16 Mid/High enclosures and

8 Subwoofers. . . . . . . . . . . . . . . . . . . . . . . 21

Page 21

208 cm / 81

7

/

8

COHEDRA® Compact Transport Solution

21

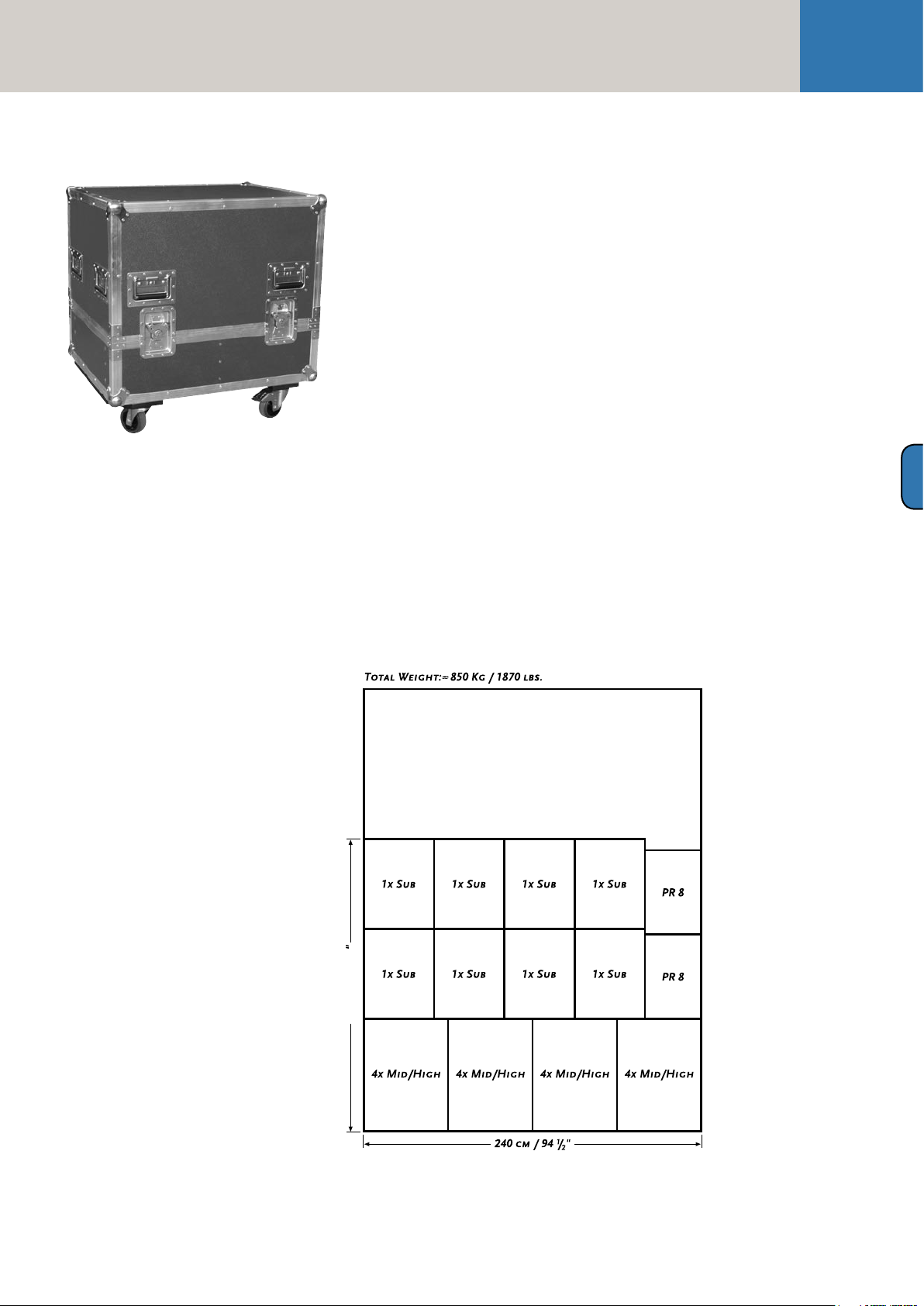

Figure 1: COHEDRA® Compact Mid/High Case

1 COHEDRA® Compact

Transport Solution

1.1 CDR 108 C Mid/ High Case

A specially designed case serves to transport

COHEDRA® Compact CDR 108 C mid/high enclosures. One case accommodates four CDR 108 Cs

and a standard rigging frame each.

1.2 Dimensions and Weights

Case for four CDR 208 s:

Width: 80 cm/ 31 1/2"

Depth: 60 cm/ 23 5/8"

Height (standing on casters): 70 cm/ 27 1/2"

Weight (without rigging frame) : approx. 98 kg/ 215 lbs.

Weight (with rigging frame) : approx. 108 kg/ 238 lbs.

PR 16 (lying):

Width: 60 cm/ 23 5/8"

Height: 65.5 cm/ 25 3/4"

Depth (standing on casters): 95 cm/ 37 3/8"

Weight: approx. 125 kg/ 275 lbs.

PR 8 (lying):

Width: 60 cm/ 23 5/8"

Height: 38.5 cm/ 15 1/8"

Depth (standing on casters): 95 cm/ 37 3/8"

Weight: approx. 65 kg/ 143.3 lbs.

CDR 210 C:

Width: 50 cm/ 19 3/4"

Height: 60 cm/ 23 1/4"

Depth (standing on casters): 75 cm/ 29 1/2"

Weight: approx. 48 kg/ 105.6 lbs.

C 1

Page 22

Manual

COHEDRA® & COHEDRA® Compact

Chapter D

Rigging & Curving the COHEDRA® System

Rigging and Curving Mid/high Cabinets ............... 23

1 Use 26

1.1 Intended Use .................................................. 23

1.2 Unintended Use .............................................. 23

2 Warranty and Liability .................................... 23

3 Important Notes on Safety ............................. 23

3.1 Responsibilities of the Operator ..................... 23

3.2 Storage, Maintenance, Inspection and

Repair of COHEDRA® Rigging Hardware .......24

3.3 Technical Specifications of

the Rigging Hardware ..................................... 24

3.4 Maximum Permissible Number

of Flown COHEDRA® Mid/High Units ...........24

3.5 Maximum Number of Flown

COHEDRA® CDR 210 F Subwoofers ............... 25

3.6 Ground-stacked Mid/High Enclosures ........... 25

3.7 Pick Points for Flying Mid/high Enclosures .... 25

3.8 Structural Modifications of Rigging Hardware 25

3.9 Original HK AUDIO® Accessories: ................. 25

3.10 Initiation and Operation ................................. 25

4 Components of the Rigging Hardware .......... 26

5 Determining the Curving Angle between

Two COHEDRA® Mid/High Enclosures ......... 27

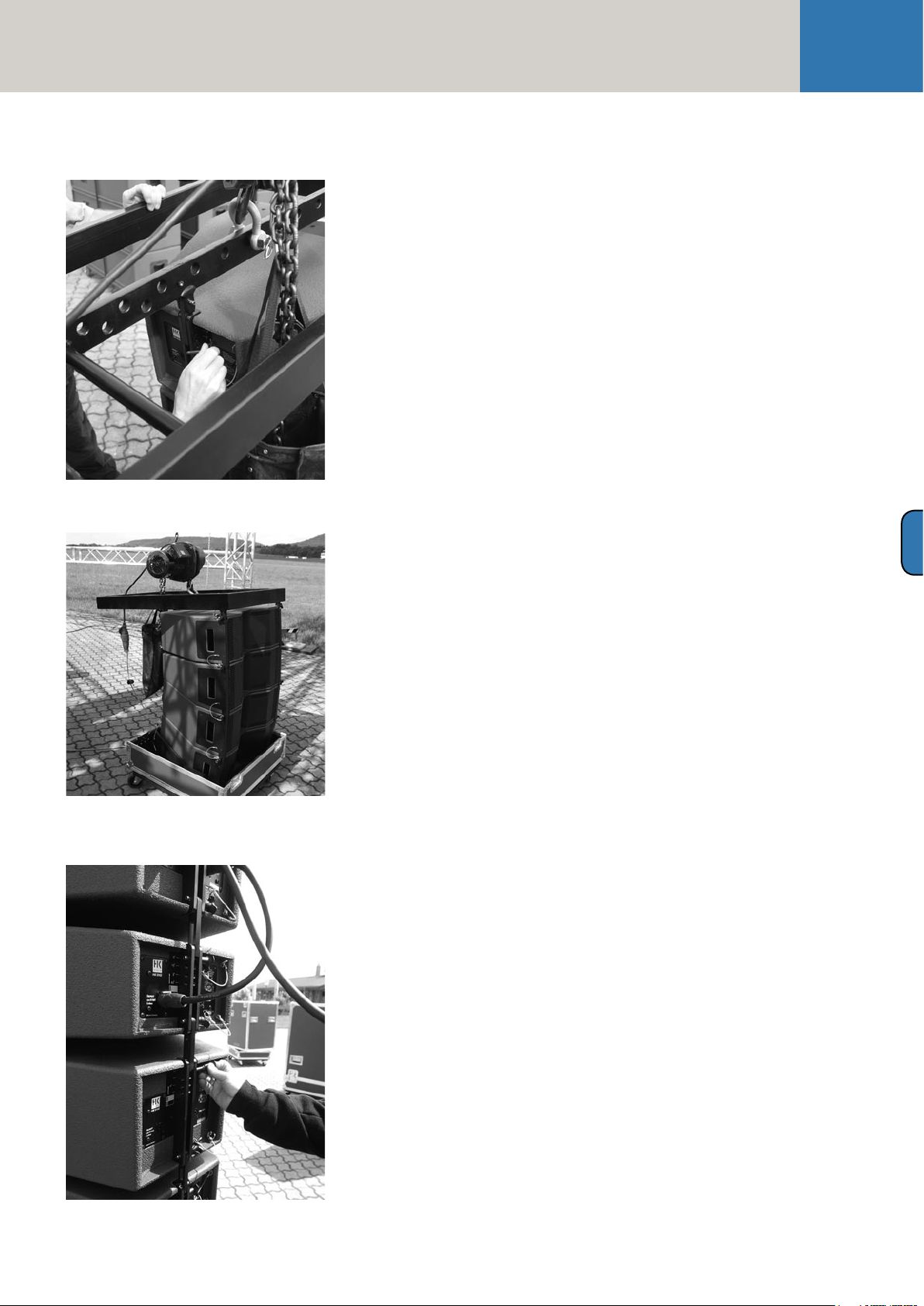

6 Preparations ................................................... 27

7 Mounting the Top Rigging Frame .................. 28

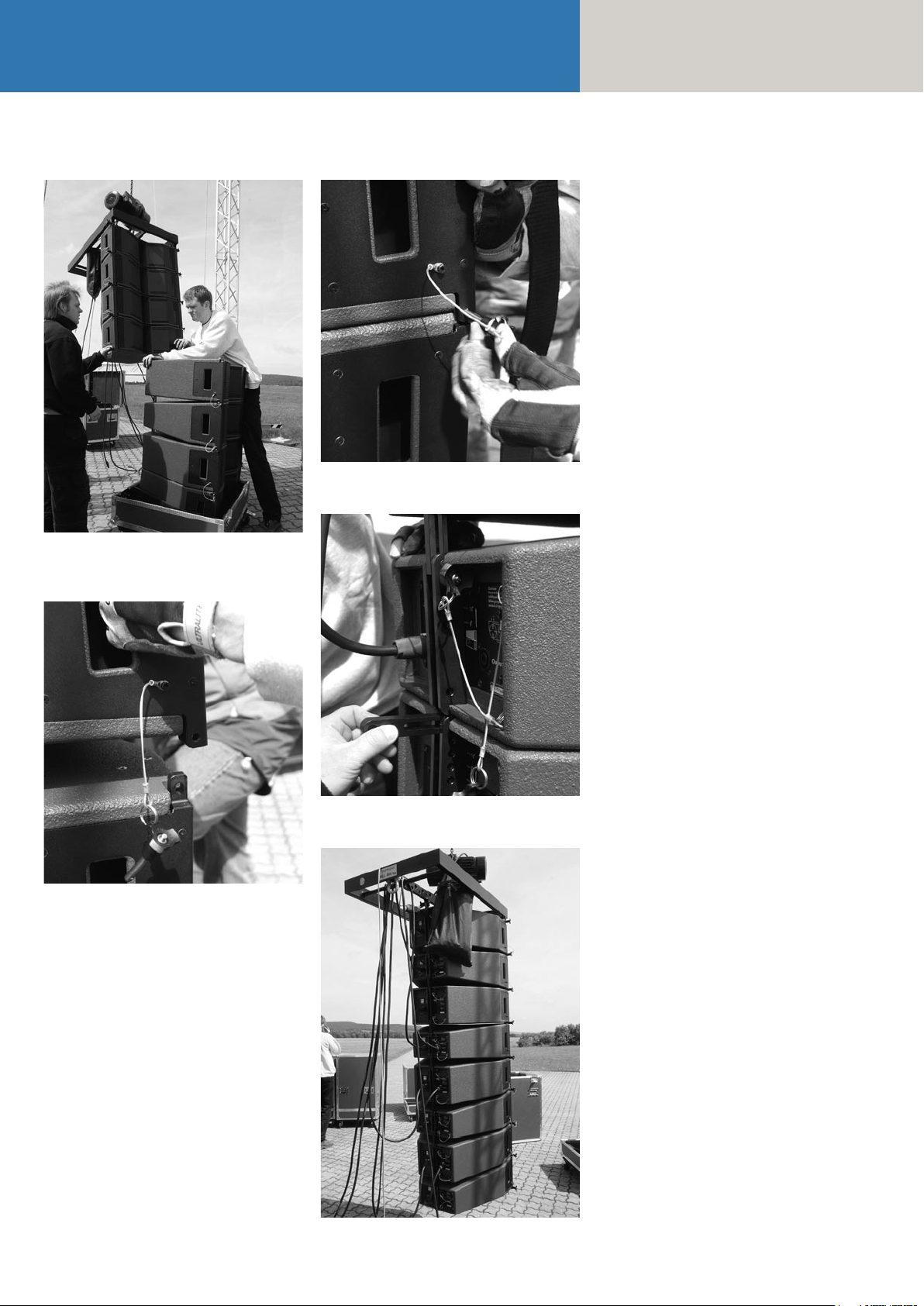

8 Mounting Additional Mid/High Enclosures .. 30

9 Attaching the Bottom Rigging Frame

and Raising the Mid/high Array ..................... 31

10 Ground Stacking ............................................ 32

10.1 Ground Stacking with the Stack Frame ........... 32

10.2 Ground Stackin with the Rigging Frame ......... 32

11 Setting up Subwoofers ................................... 32

11.1 Sub Array ........................................................ 32

11.2 Bass Cluster/ Stacking .....................................33

11.3 Bass Clusters in Blocks ....................................33

12 Flying CDR 210 F Subs ................................... 34

Index of Figures:

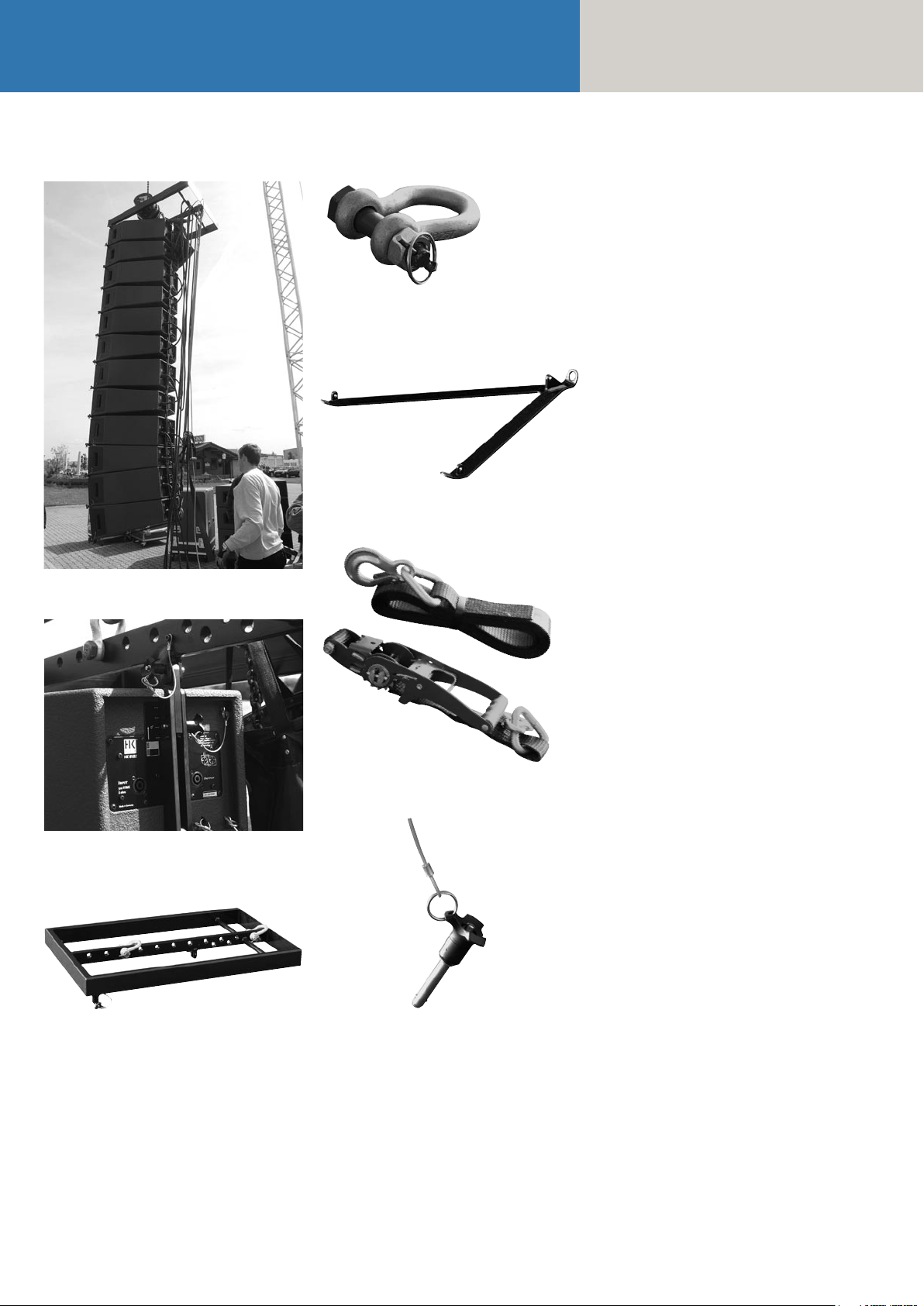

Fig. 1: 12 COHEDRA® mid/high enclosures .......26

Fig. 2: Mid/high enclosure with

integrated flight attachments .................. 26

Fig. 3: Top rigging frame .................................... 26

Fig. 4: Shackles for attaching motors, straps ..... 26

Fig. 5: Bottom rigging frame ..............................26

Fig. 6: Lashing strap for curving the array ..........26

Fig. 7: Quick-release pin .....................................26

Fig. 8: The curvature between two

COHEDRA® mid/high enclosures ........... 27

Fig. 9: Setting the curving angle on a

flown array ............................................... 27

Fig. 10: Connector component attached

on the top rigging frame for