Page 1

HK USP Operators Manual

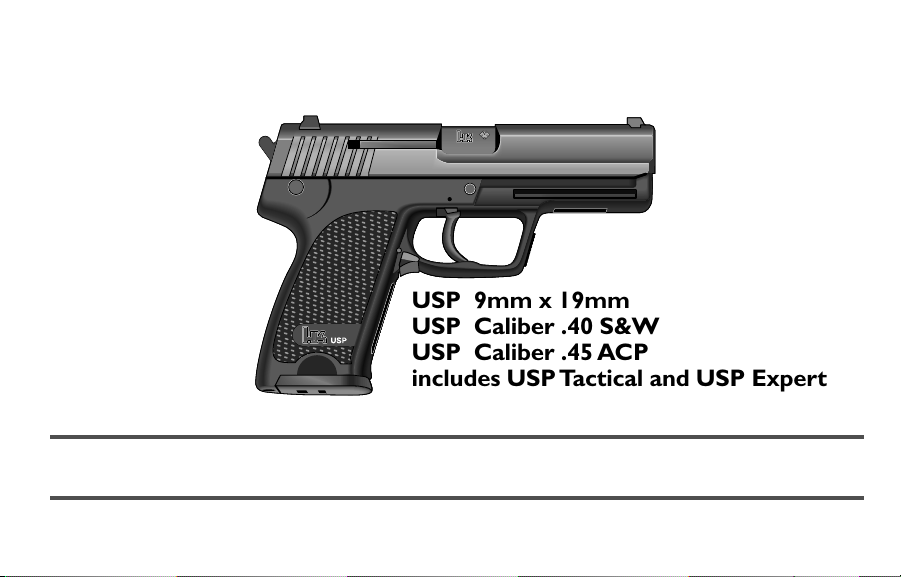

USP 9mm x 19mm • USP Caliber .40 S&W

USP Caliber .45 ACP

In a world of compromise, some don’t.

®

Including USP Tactical and USP Expert

Page 2

SAFETY RULES

Please read this operators manual before handling your firearm

The following safety rules are placed in this manual by Heckler & Koch as an important reminder that firearms safety is your

responsibility. Firearms can be dangerous and can potentially cause serious injury, damage to property or death, if handled improperly.

1. Never point a firearm at anyone, or in any direction other than a SAFE direction, i.e. downrange.

2. Treat all firearms as if they are always loaded.

3. Keep your finger off the trigger and outside of the trigger guard until your sights are aligned on the target.

4. Keep your finger off the trigger and outside of the trigger guard while loading or unloading the firearm.

5. Keep your finger off the trigger and outside of the trigger guard while pulling the firearm out of the holster or while returning it to

the holster.

6. Be sure of your target and the back stop beyond.

7. Never give a firearm to or take a firearm from anyone unless the action is open and the magazine and/or chamber are free of any

ammunition or brass.

8. Be sure that the ammunition you are using is factory loaded, is of the correct caliber for the firearm in which it is to be used, and

that it is not damaged in any way.

9. Before firing, remove the magazine from the firearm, lock the slide open, make sure the chamber is clear of any ammunition or

brass, and check the barrel of the unloaded firearm for any possible obstructions.

10. Before firing any firearm that is unfamiliar to you,make sure that you understand exactly how it functions. A lack of familiarity

with the firearm can result in serious accidents. Attend a certified training course on any firearm which you intend to use or with

which you are not sufficiently familiar.

11. Always wear hearing and eye protection when using your firearm.

12. Keep all body parts, especially the hands and fingers, away from the muzzle to avoid injury or burns.

13. Be sure that no part of either hand touches or interferes with the slide. The slide is moved backwards by the recoil force of the

pistol during firing and may cause serious injury.

14. Firearms should be stored separately from ammunition and beyond the reach of children, and/or any untrained individuals.

15. Avoid the use of any alcoholic beverages or drugs before and during the use of any firearm.

16. Discharging firearms in poorly ventilated areas,cleaning firearms, or handling ammunition may result in exposure to lead, a

substance known to be associated with birth defects, reproductive harm, and other serious injury. Have adequate ventilation at all

times.Wash hands thoroughly after exposure.

Page 3

STOP! KNOW HOW TO CLEAR THIS PISTOL BEFORE ATTEMPTING TO OPERATE.

CLEARING THE PISTOL

The HK USP is not considered “clear” or safe unless:

1.The control lever (if applicable) is on “SAFE” and;

2.The magazine is removed from the pistol and;

3.The slide is locked to the rear and;

4.The chamber is free of brass or ammunition

To Clear the HK USP:

1. Make sure fingers are outside of the trigger guard and the pistol is pointed in a safe direction at all times!

2. Engage control lever (if applicable) - press the safety lever upwards until the “S” aligns with the reference line located

on the frame.

3. Remove magazine - depress the magazine release lever and remove the magazine from the pistol.

4. Open and lock slide - while keeping the pistol pointed in a safe direction, lock the slide open by pulling the slide

rearward as you press the slide release upward.Watch for a cartridge or empty case to be ejected from the pistol.

5. Inspect chamber - inspect chamber for the presence of a cartridge or empty case by:

• Visually viewing chamber through open ejection port and;

• Physically inserting finger into chamber through ejection port to check for the presence of a cartridge or empty

case.

• Remove any cartridges or empty cases from the chamber or from within the pistol.

The HK Universal Self-loading Pistol is now considered “Clear”.

Page 4

© Heckler & Koch,Inc.,1993, 6/95,3/97, 11/97, 5/98,5/99, 11/99, 4/00

(May 2001 Edition)

All rights reserved

HK, Inc., 21480 Pacific Blvd.

Sterling,Virginia 20166-8903

United States of America

Telephone (703) 450-1900 • Fax (703) 450-8160 • www.hecklerkoch-usa.com

Specifications and models subject to change without notice.

®

Page 5

All USP Pistols comply with NIJ Standard – 0112.00

WARNING:A firearm has the capability of taking your life or the life of someone else! Be extremely careful

with your firearm. An accident can occur at anytime and is almost always the result of not following basic safety

rules.

HK USP Operators Manual

USP 9mm x 19mm

USP Caliber .40 S&W

USP Caliber .45 ACP

includes USP Tactical and USP Expert

Page 6

6

TABLE OF CONTENTS

Section 1 Introduction ....................................................................................................................................................................................7

Section 2 Description ....................................................................................................................................................................................12

Nomenclature ..............................................................................................................................................................................12

Specifications ................................................................................................................................................................................13

Section 3 Function and Operation ..............................................................................................................................................................14

Clearing..........................................................................................................................................................................................14

Operating Controls and Components ......................................................................................................................................16

Sights and Sight Adjustment ......................................................................................................................................................19

Section 4 Ammunition ..................................................................................................................................................................................20

Section 5 Instructions for Use ......................................................................................................................................................................22

Clearing..........................................................................................................................................................................................22

Filling and Emptying the Magazine ............................................................................................................................................23

Loading ..........................................................................................................................................................................................23

Firing ..............................................................................................................................................................................................24

Unloading ......................................................................................................................................................................................25

Selection and Use of a Holster....................................................................................................................................................26

Storage and Transport ................................................................................................................................................................27

Section 6 Disassembly and Assembly ........................................................................................................................................................28

Section 7 Cleaning and Maintenance ........................................................................................................................................................38

Cleaning ........................................................................................................................................................................................38

Inspection ....................................................................................................................................................................................39

Lubrication ..................................................................................................................................................................................40

Troubleshooting Problems and Repair ......................................................................................................................................41

USP Accessories ..........................................................................................................................................................................42

Section 8 Exploded View and Parts List (.40 S&W & 9mm)....................................................................................................................44

Exploded View and Parts List (.45 ACP) ..................................................................................................................................46

Section 9 USP Tactical ..................................................................................................................................................................................48

USP Expert ..................................................................................................................................................................................52

HK LOCK-OUT Device ..............................................................................................................................................................56

Firearms Service Record ..........................................................................................................................................................58

Page 7

7

SECTION 1 INTRODUCTION

Congratulations on your purchase of an HK USP pistol.The

Heckler & Koch USP (Universal Self-loading Pistol) is the

first HK pistol designed especially for the demanding needs

of the American shooter.

Features favored by US civilian, law enforcement, and military

users provided the design criteria for the USP. Its controls

are uniquely American, influenced by such famous and

successful designs as the Government Model 1911 pistol—

and like the Model 1911, the USP can be safely carried

“cocked and locked”.

The control lever, a combination safety and decocking lever,

is frame mounted and quickly accessible; unlike the slide

mounted safeties common on many pistols.The USP control

lever has a positive stop and returns to the “fire” position

after decocking.

Using a modified Browning-type action with a patented HK

recoil reduction system, the USP is built to take the punishment of the most powerful +P loads.

The polymer frame of the USP was designed using technical

experience gained by HK engineers in the development of

the world’s first composite material pistols, the VP70Z and

P9S.This same high-strength and corrosion free material is

used in the Mark 23 .45 ACP pistol designed by Heckler &

Koch for the US Special Operations Command (USSOCOM).

Major metal components on the USP are also corrosion

resistant. Outside metal surfaces are protected by an

extremely hard, nitro-gas carburized black oxide finish.

Stainless steel models are also available. Internal metal parts

are coated with a special Dow Corning anti-corrosion

process that reduces friction and wear.The HK USP is

presently available in calibers .40 S&W, 9mm Parabellum,

and .45 ACP.

The design characteristics of the HK USP provide a wide

range of flexibility for users. By using a modular approach to

the internal components, the control lever function of the

HK USP can be switched from the left to the right side of

the pistol to accommodate left handed shooters.

The USP can also be converted from one type of trigger

firing mode to another.This includes combination doubleaction and single-action (DA/SA) modes and double action

only (DA-Only) modes.

Page 8

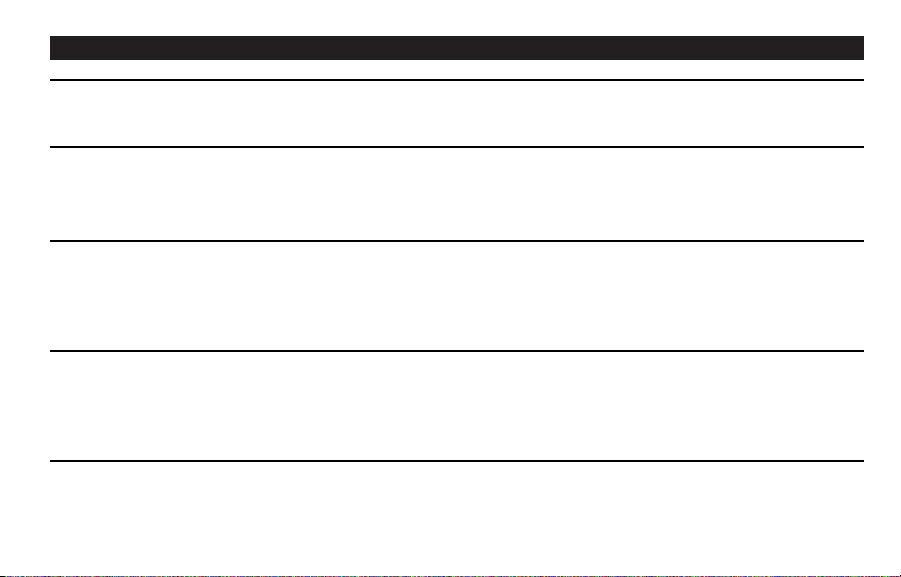

The USP is available in the following trigger/firing mode

configurations (see Figure 9).

NOTE:Trigger/firing mode conversion can only be

made by a HK certified armorer.

➊ DA/SA with “safe” position and control lever (manual

safety/decocking lever) on left side of frame

➋ DA/SA with “safe” position and control lever (manual

safety/decocking lever) on right side of frame

Variants ➊ and ➋ allow the user to carry the pistol in a

single-action mode (cocked and locked) with the manual

safety engaged.This same pistol, without modification, can

be carried in double-action mode, with or without the

manual safety engaged.

➌ DA/SA without “safe” position with control lever

(decocking lever) on the left side of frame

➍ DA/SA without “safe” position with control lever

(decocking lever) on the right side of frame

Variants ➌ and ➍ provides the user with a frame-mounted

decocking lever that does not have the “safe” position.This

combination only allows the hammer to be lowered from SA

position to DA position.It does not provide the “safe” position

8

to prevent the pistol from firing when the trigger is pulled.

➎ DA-Only with “safe” position and control lever (manual

safety) on the left side of frame

➏ DA-Only with “safe” position and control lever (manual

safety) on the right side of frame

➐ DA-Only without control lever (no safety/decocking

lever)

For the DA-Only user, variants ➎, ➏, and ➐ of the USP

operate as double action only pistols with a bobbed hammer

always returning to the DA position (forward) after each

shot is fired.To fire each shot, the trigger must be pulled

through the smooth DA trigger pull.Variants ➎ and ➏ have a

manual safety lever.

No control lever is provided on variant ➐.

➒ DA/SA with “safe” position and control lever (manual

safety) on the left side of frame

➓ DA/SA with “safe” position and control lever (manual

safety) on the right side of frame

Variants ➒ and ➓ allow the user to carry the pistol in a

single-action mode (cocked and locked) with the manual

safety engaged. Unlike variants ➊ and ➋, the control lever

Page 9

9

Figure 9

Fire Modes and Control Functions by Variant

Variant 1

Variant 2

Variant 3

Variant 4

Variant 5

Variant 6

Variant 7

Variant 9

Variant 10

Double Action

Single Action

Double Action Only

Control Lever (Left Side)

Control Lever (Right Side)

Control Lever (Manual Safety)

Control Lever (Decocking)

Control Lever (No Decocking)

Caliber Availability

USP

FIRE MODES

& CONTROL

FUNCTIONS

(conversion by

HK certified

armorer

only)

.45 / .40 / 9mm

.45 / .40 / 9mm

.45 / .40 / 9mm

.45 / .40 / 9mm

.45 / .40 / 9mm

.45 / .40 / 9mm

.45 / .40 / 9mm

.45 / .40 / 9mm

.45 / .40 / 9mm

can not be used to decock the hammer.These variants are

the ideal choice for users who prefer shooting the pistol in

single-action (SA) mode with the thumb placed on top of

the manual safety.This same pistol, without modification, can

be carried in the double-action mode and provides second

primer strike ability to single-action shooters.

Due to this innovative design approach,it is possible to

modify an HK USP into any one of the listed variants.

Changing the trigger/firing mode of the pistol is accomplished by installing a different set of component parts. Not

only can the control lever function (safety/decocking) be

switched from one side of the pistol to the other, it is

possible to have a single-action/double-action (SA/DA)

version converted to a double action only (DAO) version,or

to any other configuration listed. Optional ambidextrous

controls are available and are standard on USP Expert

models.

This unique design allows the HK Universal Self-loading

Pistol to be configured for a variety of purposes depending

on the requirements of the user, without having to purchase

a new pistol.

Page 10

In addition to a wide selection of trigger/firing modes, the

HK USP has an ambidextrous magazine release lever which

is shielded from inadvertent actuation by the design of the

trigger guard. It is possible to depress the magazine release

lever with the thumb or index finger of the firing hand, in

most cases without adjusting the firing grip.

The metal reinforced polymer magazine is stronger and

lighter than conventional metal magazines and will still drop

free of the frame when the magazine release is actuated. By

using metal magazines in the USP .45, grip size is kept to a

minimum. Magazines have a series of viewing holes on the

back side for counting the cartridges remaining inside.

Magazine floor plates can be easily removed without tools

during disassembly.

The extended slide release is positioned to allow easy

actuation without adjustment of the grip of the shooting

hand.Another useful feature is the absence of a magazine

lock-out device.

CAUTION: The USP will fire if the magazine is

removed, a cartridge is in the chamber, and the

trigger is pressed.

One of the most important unique design features of the

10

HK USP is the mechanical recoil reduction system. This

system is incorporated into the recoil/buffer spring assembly

located below the barrel. Not only does this system reduce

the felt recoil to the shooter but it also reduces the recoil

forces to the components of the pistol, thus greatly extending the life expectancy of the USP.

This recoil reduction system buffers the impact of the slide

on the frame as the barrel unlocks and when the slide

travels rearward. This same system was incorporated into

the HK .45 ACP Handgun designed for the US Special Operations Command. Its buffering effect plays a major role in

extending the service life of the HK USP, especially when

considering the punishment inflicted on any pistol when

firing powerful +P cartridges.

The recoil reduction system employed in the HK USP is

insensitive to ammunition types and requires no special

adjustment or maintenance. It functions effectively in all

models of the USP.

Two metal inserts are molded into the polymer frame on

which the slide recoils.These inserts are not subjected to

the full recoil forces of the cartridge due to the buffering

action of the recoil reduction system.

The HK USP is an extremely safe firearm, with no less

Page 11

11

than four safety features, some passive and some active in

nature. Simple to field strip and maintain, the USP is a

reliable and trouble-free pistol.

The special “HE” (Hostile Environment) finish employed on

major metal parts of the HK USP resists even the worst

types of corrosion and wear, including prolonged exposure

to salt water. Stainless steel models are also available for

users who prefer the appearance and corrosion resistant

properties of that material.

NOTE: Holster wear of the finish is normal and not

covered under warranty.Any finish may wear over

time.

The barrel of the USP is cold hammer forged for strength

and durability.USPs are fitted with barrels that have HK’s

unique polygonal bore profile. Polygonal bores increase

muzzle velocity and reduce barrel wear.

Finally, a pair of universal mounting grooves are incorporated

into the front of the polymer frame.These grooves allow

various types of accessories and targeting devices, such as

the HK Universal Tactical Light, laser aimers, and optical

sights to be mounted on the HK USP without modification

to the pistol.

NOTE: Improperly designed or installed accessories

may result in damage to the USP mounting grooves

and/or the USP pistol. Such damage is not covered

under the limited lifetime warranty. Be certain to use

only HK Authorized Accessories and follow

installation and precautions carefully.

At Heckler & Koch,form follows function.All HK pistols are

designed and manufactured to meet the operational

requirements of demanding users. The Heckler & Koch USP

is no exception. In a world of compromise, some don’t.

Page 12

12

SECTION 2 DESCRIPTION

USP NOMENCLATURE

Slide Release

Hammer

Slide

Serial Number

Ambidextrous

Magazine

Release

Magazine Floor Plate

Barrel

Locking

Block

Rear Sight

Extractor

Figure 12A (below)

Control Lever

Front Sight

Trigger

Reference Line

Universal Mounting Grooves

Trigger Guard

Slide Release Axle

Finger Recesses

Figure 12B (above)

Frame

Lanyard

Loop

Page 13

13

SPECIFICATIONS

*

USP (.40) USP (9mm) USP (.45 ACP)

Caliber .40 S&W 9mm x 19mm Parabellum .45 ACP

Operating Principle Short recoil Short recoil Short recoil

Action Type Modified Browning type, linkless Modified Browning type, linkless Modified Browning type, linkless

Sights Fixed patridge style, adjustable for windage and elevation. Standard 3-dot or optional tritium.

Total Length 194 mm (7.64 in.) 194 mm (7.64 in.) 200 mm (7.87 in.)

Barrel Length 108 mm (4.25 in.) 108 mm (4.25 in.) 112 mm (4.41 in.)

Sight Radius 158 mm (6.22 in.) 158 mm (6.22 in.) 158 mm (6.22 in.)

Twist Length 380 mm (14.96 in.) 250 mm (9.84 in.) 406 mm (15.98 in.)

Height (Total) 136 mm (5.35 in.) 136 mm (5.35 in.) 141 mm (5.55 in.)

Width of Slide 29 mm (1.14 in.) 29 mm (1.14 in.) 29 mm (1.14 in.)

Width of Frame 32 mm (1.26 in.) 32 mm (1.26 in.) 32 mm (1.26 in.)

Weight (with empty magazine) 840 grams (29.63 oz.) 752 grams (28.47 oz.) 840 grams (29.63 oz.)

Weight of Empty Magazine 50 grams (1.76 oz.) 55 grams (1.94 oz.) 50 grams (1.76 oz.)

Slide Force (to retract slide) 9 kg (19.85 pounds) 9 kg (19.85 pounds) 9 kg (19.85 pounds)

Trigger Travel (rest to hammer release)

Single-action 6.3 mm ( .25 in.) 6.3 mm ( .25 in.) 6.3 mm ( .25 in.)

Double-action 11.3 mm ( .45 in.) 11.3 mm ( .45 in.) 11.3 mm (.45 in.)

Trigger Reach (center of trigger to back of frame)

Single-action 70 mm (2.76 in.) 70 mm (2.76 in.) 70 mm (2.76 in.)

Double-action 75 mm (2.95 in.) 75 mm (2.95 in.) 75 mm (2.95 in.)

Magazine Capacity 13 cartridges

**

15 cartridges

**

12 cartridges

**

(does not include cartridge in chamber)

Safety Features 1. Manual safety lever (Variants 1, 2,5, 6, 9,10), 2.Double-action mode with hammer intercept notch, 3. Firing pin block, 4.Disconnector

* Specifications for the USP Tactical and USP Expert can be found on pages 51 and 55 respectively.

** Law Enforcement & Military only. Due to provisions of the 1994 Crime Bill, magazine capacity for U.S. civilian pistols is 10 cartridges.

Page 14

14

SECTION 3 FUNCTION AND OPERATION

WARNING:Always clear the pistol before handling it.

CLEARING THE PISTOL

The HK USP is not considered “clear” or safe

unless:

1.The control lever (if applicable) is on “SAFE” and;

2.The magazine is removed from the pistol and;

3.The slide is locked to the rear and;

4.The chamber is free of brass or ammunition

To Clear the HK USP:

1. Make sure fingers are outside of the trigger guard and

the pistol is pointed in a safe direction at all times!

2. Engage control lever (if applicable) - press the safety

lever upwards until the “S” aligns with the reference

line located on the frame.

3. Remove magazine - depress the magazine release

lever and remove the magazine from the pistol.

4. Open and lock slide - while keeping the pistol

pointed in a safe direction, lock the slide open by

pulling the slide rearward as you press the slide

release upward.Watch for a cartridge or empty case

to be ejected from the pistol.

5. Inspect chamber - inspect chamber for the presence

of a cartridge or empty case by:

• Visually viewing chamber through open ejection port

and;

• Physically inserting finger into chamber through

ejection port to check for the presence of a cartridge

or empty case.

• Remove any cartridges or empty cases from the

chamber or from within the pistol.

The HK Universal Self-loading Pistol is now considered “Clear”.

GENERAL

(Refer to page 12 for the location of the features

described below)

Heckler & Koch Universal Self-loading Pistols are short

recoil operated.They use a modified Browning style system,

without a link, to lock and unlock the barrel.

Upon firing, the pressure developed by the propellant gases

forces the slide and barrel assembly to the rear. After

moving approximately 3mm,the locking block will stop the

Page 15

15

rearward movement of the barrel.The barrel is pulled

downward due to the engagement of the angled locking

surfaces of the locking block with those located on the end

of the recoil spring guide rod.

The locking block disengages from the slide and the slide

continues rearward independently from the barrel.The slide

extracts and ejects the fired cartridge case, cocks the

hammer, and compresses the recoil spring.

Once fully to the rear, the compressed recoil spring pushes

the slide forward feeding the next cartridge from the magazine into the chamber. If the magazine is empty, the magazine

follower lifts the slide release into position where it can stop

the forward progress of the slide and holds the slide open.If

a cartridge is present in the magazine, the slide will push the

cartridge from the magazine and into the chamber.

WARNING: Do not rely on the slide lock to

determine if the magazine is empty. Always check

visually and physically ensure the pistol is not loaded.

During the last 3mm of forward movement, the slide forces

the angled surfaces of the barrel locking block against

opposing angled surfaces on the recoil spring guide rod.

This action pivots the locking block on the barrel up into

engagement with the ejection port on the slide.The breech

is now locked closed and the next shot can be fired.

The buffer spring dampens the impact of the barrel and slide

on the frame during unlocking and when the slide is forced

fully rearward, thus reducing wear and tear on many of the

component parts of the pistol.

CAUTION: A pair of Universal Mounting Grooves

located on the front of the USP frame allow for a

variety of accessories to be used with the pistol.

Improperly designed or installed accessories may result in damage to the USP mounting grooves and/or

the USP. Such damage is not covered under

warranty. Be certain to use only HK Authorized

Accessories and follow installation and precautions

carefully.

Page 16

16

OPERATING CONTROLS & COMPONENTS

WARNING: The HK USP incorporates single-action

and/or double-action modes of operation.Anytime

the trigger is pulled with the control lever in the fire

(horizontal) position and a cartridge in the chamber,

the pistol will fire from either the hammer down or

cocked positions.

Double/Single-Action modes

In the double-action mode, pulling the trigger will cock the

hammer and immediately release it firing the first chambered

cartridge.All subsequent cartridges will be fired in the singleaction mode because the slide automatically recocks the

hammer after each shot is fired.To fire the first chambered

cartridge in the single-action mode, the hammer must be

manually cocked before pulling the trigger. All shots after the

first shot will be fired single-action because the slide

automatically recocks the hammer after each shot is fired.

In the double-action only mode, the hammer always returns

to the uncocked (forward) position after each shot. All

shots are fired in the double-action mode.

Magazine

USP .45 magazines are all metal while .40 caliber and 9mm

magazines are made from a high-strength polymer with a

metal insert located in the upper third of the housing.The

metal insert increases the strength and durability of the magazine. Cartridges are positioned within the magazine in a

staggered arrangement but are fed into the pistol from a

single row under the feed lips.The cartridges are visible

through the numbered viewing holes located in the back of

the magazine. For maintenance and cleaning, all magazine

floor plates can be easily removed.

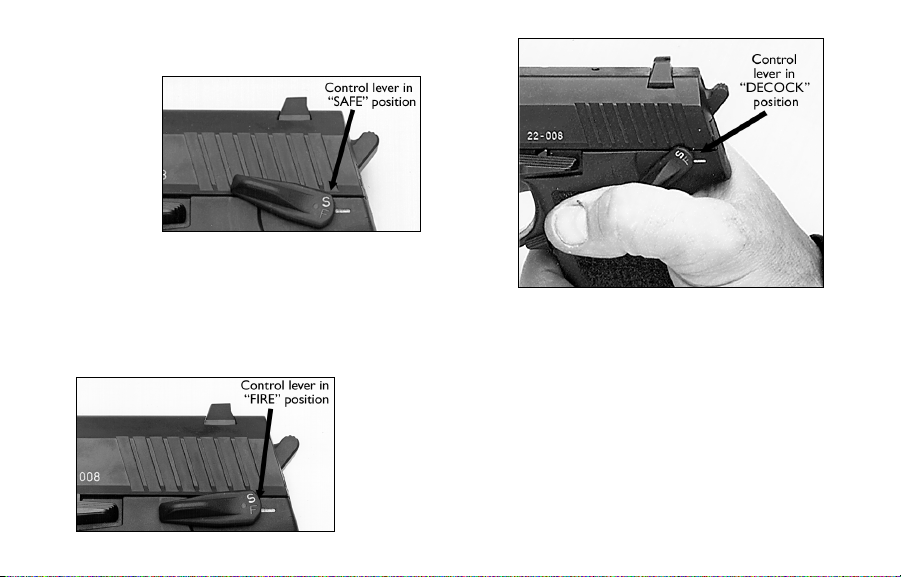

Control Lever

This manually operated lever is located on the side of the

frame below the rear sight. This lever is operated with the

firing thumb and can perform both functions of a safety lever

and a decocking lever, depending on the parts installed.Note

Some variants do not have a control lever.

Control lever as a safety lever - On HK USPs with the

“SAFE” position (Variants 1,2, 5, 6, 9, & 10),the front of this

lever is fully raised above horizontal so that the “S” on the

lever itself aligns with the reference line on the frame. (See

Figure 17A ) With this control lever engaged, the release of

the hammer is blocked in the single-action mode of fire. In

Page 17

17

Figure 17C

Control lever as a decocking lever - On HK USPs without

the “SAFE” position (Variants 3 & 4),the front of the control

lever cannot be raised above horizontal and the pistol will

fire anytime the trigger is pulled with a cartridge in the

chamber. The lever only functions as a decocking lever to

lower the cocked hammer into the double-action mode.

The cocked hammer is lowered when the decocking lever is

fully depressed by the operator (See Figure 17C).This lever

is spring actuated and springs back up into the horizontal

(fire) position when released.

the double-action mode, the hammer will partially cock but

will not release to fire the pistol.

Figure 17A

To fire the pistol, the front of the control lever is moved

down into a horizontal position into the “FIRE” position. In

this position, the “F” on the lever aligns with the reference

line located on the frame. (See Figure 17B) With the

control lever set on “F”, the pistol will fire if the trigger is

pulled and a cartridge is present in the chamber.

Figure 17B

Page 18

18

Control lever as a safety/decocking lever

On USP Variants 1 and 2, the control lever can be placed in

the safe, fire, and decocking positions described earlier.

A USP fitted with this control lever can be carried as a single

action or double action pistol, with or without the safe

position.The control lever also allows the cocked hammer

to be decocked when the control lever is fully depressed.

(See Figure 17C). Optional ambidextrous controls levers

are also available for the USP and are standard on the USP

Expert.

CAUTION: The USP should not be carried in the

single action mode without the control lever in the

safe position.

Extractor

The extractor of the HK USP pistol does not act as a

loaded chamber indicator, except on the USP Expert and

Tactical models.

Slide Release

This lever is located on the left side of the frame directly

above the trigger. This lever is used to lock the slide open,

to release the slide, and to disassemble the pistol.

As a slide stop, it is lifted upward by the magazine follower

or the operator’s finger as the slide travels rearward during

recoil or manual manipulation.The slide release engages in

the recess located on the left side of the slide at it’s

midpoint.The slide release is spring actuated and is held

down out of engagement with the slide until required.The

slide release will automatically hold the slide open when the

last shot is fired.As a disassembly lever, the slide release is

removed from the left side of the frame when the slide is

held partially rearward.

Magazine Release Lever

This ambidextrous, spring actuated lever holds the magazine

in place within the grip by engaging in the notch found on

the front of the magazine housing. Depressing this lever

downward with the firing index finger or thumb will allow

the magazine, regardless of the number of cartridges inside,

to drop free of the frame.The magazine release lever is

shielded from accidental actuation by the design of the

polymer frame and trigger guard surrounding it.

Frame

All sides of the reinforced polymer frame are textured to

ensure a firm grip, even with wet hands or under conditions

of rapid fire. The trigger guard is extended and grooved to

provide a firm grip when using two hands or gloves to fire

the pistol. The frame is a one-piece molded component with

Page 19

19

metal inserts (locking insert and guiding part) cast into the

frame during production.The slide rides on these metal

inserts during operation. The frame contains mounting

grooves for accessory attachment and finger recesses

located to the left and right of the magazine well for manual

extraction of the magazine, if necessary.The serial number of

the pistol is engraved in the metal insert incorporated into

the front of the frame in front of the trigger guard and on

the left side of the slide.

Sights and Sight Adjustment

The sighting system on the HK USP is the

proven 3-dot arrangement first made

popular on earlier model HK pistols. By

aligning all three dots horizontally on the

target, with the front sight dot centered between the rear sight dots, the operator can

quickly and easily engage the target with a

high degree of accuracy (See Figure 19).

With the optional tritium sights installed,

precise and rapid target engagements are

possible under low light conditions as well.

The rear sight can be adjusted for windage

by drifting the sight to the left or to the

right, depending on the desired shot place-

ment. Bullet impact on target will move in the same direction that the rear sight is moved. Be careful not to damage

the slide finish when adjusting the rear sight.

Adjustments for elevation are accomplished by exchanging

the front sight with a higher or lower sight, available from

HK.The height of the front sight is indicated on the underside.The front sight must be removed by using a drift punch

or an HK USP sight pusher.The accessory HK sight pusher

can be used to install, remove, and adjust the front and rear

sights on all USP and USP Compact pistols.

To raise the bullet impact on target, a shorter front sight is

installed.To lower the bullet impact on target, a taller front

sight is installed. Installing the next higher or lower front

sight will change the point-of-impact 2 inches at 25 meters,

depending on the ammunition used. All HK USPs are

function fired and zeroed at the factory at 25 meters, pointof-aim, point-of-impact.Your actual zero may vary depending

on the ammunition used and/or your style of shooting. USP

Expert and USP Tactical models are fitted with click

adjustable sights without the 3-dot arrangement.These

optional adjustable sights are available with and without selfluminous tritium dots for all full size USP pistols.

Figure 19

Page 20

2. Prior to loading the magazine and chamber, carefully in-

spect all cartridges for the following abnormalities:

• Cracked, split, dirty or corroded cases

• Improperly seated projectiles and/or primers

• Damaged projectiles

3. Do not attempt to fire a cartridge in which the projectile

has been forced back into the case. Upon firing, this

condition may result in increased chamber pressure

above safe limits.

4. Do not fire ammunition through the pistol that:

• Is reloaded, remanufactured, or hand loaded

• Is foreign and/or outdated military surplus

• Is assembled with corrosive primer and/or propellant

• Is loaded specifically for use in submachine guns.

• Is exposed to oil, grease, water, or direct sunlight.

Remove contaminants if possible before use and cool

down ammunition exposed to direct sunlight or heat.

(Exposure to sources of heat could raise the chamber

pressure of the cartridge above safe limits.)

20

SECTION 4 AMMUNITION

WARNING:Heckler & Koch specifically disclaims any

responsibilities for any damage or injury that should

occur because of, or as a result of, the use of faulty,

remanufactured, or reloaded (hand loaded)

ammunition, or of cartridges other than those for

which the pistol was originally chambered for.

The HK USP is designed to fire quality, factory loaded ammunition loaded to SAAMI specifications for use specifically

in handguns. For use with ammunition with hard primers (i.e.

some NATO spec. cartridges), a special hammer spring is

available.

The following guidelines should be considered when selecting the correct ammunition for your pistol.

1. Be sure the ammunition you have chosen is compatible

with your pistol – proper caliber, cartridge, bullet weight,

etc. Caliber markings on the USP appear on the left side

of the slide and on the barrel locking block, visible

through the ejection port on the right side of the slide.

Page 21

WARNING:The use of incorrect ammunition in the

pistol could result in damage to the pistol and /or

injury to the operator or bystanders.

NOTE: In compliance with NIJ Standard—0112.00,

currently there are no known ammunition types that

meet the general guidelines set forth in this section

that are not compatible with the USP 9mm, USP .40,

or USP .45 pistols.All USP pistols are approved for

use with +P and +P+ ammunition.The use of +P and

+P+ ammunition does accelerate wear and reduce

the service life on the component parts of any pistol,

including the HK USP.

21

Page 22

• Visually viewing chamber through open ejection port

and;

• Physically inserting finger into chamber through ejection port to check for the presence of a cartridge or

empty case.

• Remove any cartridges or empty cases from the

chamber or from within the pistol.

The HK Universal Self-loading Pistol is now

considered “Clear”.

Filling and Emptying the Magazine

NOTE: Do not attempt to load more than the

prescribed number of cartridges into the magazine.

Do not alter the shape of the magazine housing, follower, or spring.To do so may cause stoppages or the

magazine may not seat properly in the pistol. For

easier loading and to increase magazine service life

use a magazine loader.

22

SECTION 5 INSTRUCTIONS FOR USE

CLEARING THE PISTOL

The HK USP is not considered “clear” or safe unless:

1.The control lever (if applicable) is on “SAFE” and;

2.The magazine is removed from the pistol and;

3.The slide is locked to the rear and;

4.The chamber is free of brass or ammunition

To Clear the HK USP:

1. Make sure fingers are outside of the trigger guard and

the pistol is pointed in a safe direction at all times!

2. Engage control lever (if applicable) - press the safety

lever upwards until the “S” aligns with the reference

line located on the frame.

3. Remove magazine - depress the magazine release

lever and remove the magazine from the pistol.

4. Open and lock slide - while keeping the pistol

pointed in a safe direction, lock the slide open by

pulling the slide rearward as you press the slide

release upward. Watch for a cartridge or empty case

to be ejected from the pistol.

5. Inspect chamber - inspect chamber for the presence

of a cartridge or empty case by:

Page 23

5. Repeat steps 1-4 until the magazine is full. The

viewing holes in the back of the magazine allow the

operator to confirm the number of cartridges present

within the magazine.

Emptying the Magazine

Exert pressure with a finger on the base of the cartridge and

push each cartridge forward out of the magazine one at a

time until the magazine is empty.

Loading the Pistol

WARNING:Forcefully inserting a loaded magazine

into the USP may cause the pistols slide to close,

chambering a cartridge and making the USP ready

to fire. When inserting a magazine, always be

certain that the pistol is pointed in a safe direction

with your fingers off the trigger and outside the trigger guard.Failure to do so could cause you to unintentionally fire the pistol, resulting in serious injury or

death.

Administrative Loading

Used to initially load the pistol before it is to be fired.

23

Filling the Magazine (See Figure 23 below)

Figure 23

1. Hold the magazine in the non-firing hand with the

back side of the magazine resting against the palm.

2. Using the firing hand, hold a cartridge between the

index finger and thumb with the projectile facing the

palm.

3. Press the rim of the cartridge down against the

forward edge of the magazine follower or on the top

cartridge already in the magazine.

4. Slide the cartridge back into the magazine under the

feed lips.

Page 24

24

Slide rearward or forward,chamber empty

1. Make sure fingers are outside of the trigger guard

and the pistol is pointed in a safe direction at all

times!

2. On safe - place the control lever in the safe position (if

applicable)

3. Insert magazine - insert the magazine firmly into the

frame. Tug on the magazine to insure that it is fully seated

and engaged.

4. Chamber a cartridge - chamber a cartridge by depressing the slide release or by pulling the slide fully to

the rear and releasing it. Do not ride the slide forward!

5. Decock/On Safe - depress the control lever to decock

the hammer and/or place the control lever on “safe”.

6. Top off - remove the magazine and top it off by inserting

one additional cartridge.

7. Reinsert magazine- replace the magazine firmly into

the frame. Tug on the magazine to insure that it is fully

seated and engaged.

Firing the Pistol

WARNING:1. Be sure of your target and what’s

behind it! A bullet from a pistol travels as far as a

mile. It can easily penetrate wood or plasterboard

walls or even a car door.

2. Be sure that your hands and all parts of your body

are kept away from the muzzle of your pistol at all

times!

3.Always wear eye and ear protection when firing

the pistol.

Single-action mode (Hammer cocked)

1. Disengage control lever - disengage the control lever

by pressing it downward with the firing thumb so that the

“F” on the lever aligns with the reference line located on

the frame.

2. Aim - aim at the target.

3. Fire - fire the pistol by pressing the trigger straight to the

rear with gradually increasing pressure.

4. Reengage control lever - reengage control lever in

“safe” position to remain in the single-action mode once

firing is completed.

Page 25

CAUTION: Single action mode trigger pull is lighter

& shorter than double action mode. Keep your finger off the trigger & outside the trigger guard except

when firing the USP.

Double-action mode (Hammer uncocked)

1. Disengage control lever (if applicable) - disengage the

control lever by pressing it downward with the firing

thumb so that the “F” on the lever aligns with the reference line located on the frame.

2. Aim - aim at the target.

3. Fire - fire the pistol by pressing the trigger straight the

rear with gradually increasing pressure.

4. Decock or engage control lever - fully depress the

control lever (if applicable) to return to the double-action

mode or place the control lever on safe to remain in

single-action mode.

NOTE:Variant 7, the double-action only model of the

USP does not have a control lever.The hammer of this

variant (and variants 5 & 6) will automatically return

to the uncocked position each time the slide returns

to its forward position.

Unloading the Pistol

To unload the pistol, follow the “Clearing” procedure.

25

CLEARING THE PISTOL

The HK USP is not considered “clear” or safe unless:

1.The control lever (if applicable) is on “SAFE” and;

2.The magazine is removed from the pistol and;

3.The slide is locked to the rear and;

4.The chamber is free of brass or ammunition.

To Clear the HK USP:

1. Make sure fingers are outside of the trigger guard and

the pistol is pointed in a safe direction at all times!

2. Engage control lever (if applicable) - press the safety

lever upwards until the “S” aligns with the reference

line located on the frame.

3. Remove magazine - depress the magazine release

lever and remove the magazine from the pistol.

4. Open and lock slide - while keeping the pistol

pointed in a safe direction, lock the slide open by

pulling the slide rearward as you press the slide

release upward.Watch for a cartridge or empty case

to be ejected from the pistol.

5. Inspect chamber - inspect chamber for the presence

of a cartridge or empty case by:

• Visually viewing chamber through open ejection port

and;

• Physically inserting finger into chamber through

ejection port to check for a cartridge or empty case.

Page 26

WARNING: If a cartridge is assembled without

powder (a fault of the manufacturing process), the

primer alone has enough power to propel the bullet

into the bore.A bullet lodged in the bore may cause

damage to the barrel and/or pistol if another cartridge is fired and could cause personal injury or even

death.This event is commonly called a “squib load” or

“pop and no kick” and is characterized by a reduced

report and little or no movement of the slide.An alert

operator could notice the occurrence of this event in

time to avoid firing the next cartridge.

Selection and Use of a Holster

When selecting a carrying holster for the HK USP, it is

important to consider the following points:

1.The holster must not make contact with or actuate

any of the operating controls.This includes the

hammer, slide release, magazine release lever, and most

importantly the control lever and the trigger. The

design of the holster must also not actuate these

controls when the pistol is carried in, drawn from, or

returned to the holster.

2.The holster should not cause the slide to move

(unlock) when the pistol is returned to the holster.

3.Accommodations must be provided in the holster for

26

• Remove any cartridges or empty cases from the

chamber or from within the pistol.

The HK Universal Self-loading Pistol is now

considered “Clear”.

If the pistol fails to fire, clear and disassemble it and check

for:

1. Obstructions in the chamber, bore or frame. Remove

obstructions.

2. Bad ammunition.Try new ammunition.

3. Unserviceable magazine. Replace magazine.

4. Fouling or lack of lubrication. Clean and lubricate the

pistol in accordance with the instructions contained

within this manual.

5. Evidence of severely worn or broken parts. Contact

your authorized HK dealer or unit armorer.

If your pistol still fails to operate correctly, contact your unit

armorer, authorized HK dealer, or Heckler & Koch’s Repair

Department for guidance.

Page 27

27

4. Clean and lubricate the pistol and it’s components at

least every twelve (12) months during storage.

5. Store the pistol and it’s components in a clean, dry,

dust-free environment with regulated temperature

controls.

6. Store the pistol and ammunition separately under lock

and key.

any accessories that might be present on the pistol.

4. Choose holster designed specifically for the USP.

Returning the Pistol to the Holster

The HK USP must be made “safe” (or cleared) prior to

returning it to the holster.The pistol is considered safe to

return it to the holster when:

1.All fingers are off of the trigger and out of the trigger

guard and;

2.The pistol is “clear” or;

3.The hammer is in the decocked (down) position or;

4.The control lever is engaged in the safe position when

the hammer is cocked.

WARNING:The pistol must never be returned to the

holster unless the above procedures have been followed or injury or death could occur.

Storage and Transport

1. Store or transport the pistol and its components

clean and lubricated.

2. Store and transport the pistol without cartridges in

the chamber, magazine, or in the storage container.

3. Store and transport the pistol with the slide forward

and the hammer down (uncocked).

Page 28

28

SECTION 6 DISASSEMBLY AND ASSEMBLY

CLEARING THE PISTOL

The HK USP is not considered “clear” or safe unless:

1.The control lever (if applicable) is on “SAFE” and;

2.The magazine is removed from the pistol and;

3.The slide is locked to the rear and;

4.The chamber is free of brass or ammunition

To Clear the HK USP:

1. Make sure fingers are outside of the trigger guard and

the pistol is pointed in a safe direction at all times!

2. Engage control lever (if applicable) - press the safety

lever upwards until the “S” aligns with the reference

line located on the frame.

3. Remove magazine - depress the magazine release

lever and remove the magazine from the pistol.

4. Open and lock slide - while keeping the pistol

pointed in a safe direction, lock the slide open by

pulling the slide rearward as you press the slide

release upward. Watch for a cartridge or empty case

to be ejected from the pistol.

5. Inspect chamber - inspect chamber for the presence

of a cartridge or empty case by:

• Visually viewing chamber through open ejection port

and;

• Physically inserting finger into chamber through

ejection port to check for the presence of a cartridge

or empty case.

• Remove any cartridges or empty cases from the

chamber or from within the pistol.

The HK Universal Self-loading Pistol is now

considered “Clear”.

Disassembly (Field stripping) Pistol

1. Depress the slide release and allow the slide to move

forward.

2. Using the firing hand, retract and hold the slide to the

rear so that the axle of the slide release is visible

through the recess in the left side of the slide (See

Figure 29A).

3.With the non-firing hand, completely remove the slide

release from the left side of the frame by pressing on

it from the right side of the frame.

Page 29

Figure 29A

CAUTION: Hold the recoil/buffer assembly in place

while removing the slide from the frame. If not, this

assembly could be released under spring tension and

could possibly cause injury to personnel, or become

damaged or lost.

29

4. Remove the slide with barrel and recoil/buffer spring

assembly by sliding it forward off of the frame. (see

Figure 29B below)

Figure 29B

5. Carefully remove the recoil/buffer spring assembly

from the barrel and slide by lifting up on the rear

of the recoil spring guide rod. The entire assembly

can now be lifted out of the slide (see Figure 30)

6. Remove the recoil spring from around the recoil

spring guide rod. On USP models with “captive” recoil

springs, disassembly is not recommended.

Page 30

30

7. Lift the rear of the barrel by the locking block and

withdraw it from the slide.

Figure 30

NOTE: Disassembly of the pistol is now complete.

Only HK certified armorers should disassemble the

pistol further.

Pistol Assembly

1. Position the barrel in the slide so that:

• The muzzle of the barrel fits in the hole in the front

of the slide.

• The locking block portion of the barrel fits within

the ejection port and the angled locking surfaces of

the locking block are visible along the bottom of the

slide.

2. Place either end of the recoil spring over the front

end of the recoil spring guide rod.

3. Install the recoil/buffer spring assembly into the slide

so that the front of the recoil spring guide rod engages

in the small hole provided in the front of the slide.

4. Compress the recoil spring slightly and align the opposing angled locking surfaces on the rear end of the

recoil spring guide rod with those located on the bottom of the barrel locking block. (See Figure 32A & B)

5. Push the rear of the recoil/buffer spring assembly forward enough so that the recoil spring retainer can be

engaged on the shelf provided on the front of the barrel locking block. (See Figure 32A, B,& C)

Page 31

31

Figure 31A

Figure 31B Civilian magazine (left)

Law Enforcement/Military magazine (right)

Page 32

Figure 32A (relationship of recoil/buffer spring

assembly to barrel locking block inside of slide)

Figure 32B (recoil/buffer spring assembly and barrel

properly positioned in the slide)

6. Hold the slide in the non-firing hand with the thumb

holding the rear end of the recoil/buffer spring assembly in place on the slide.

32

Figure 32C

.

7. Check the position of the sear axle on the frame.

Ensure that it does not protrude from either side of

the frame. (See Figure 31 on page 31)

8. Hold the frame in the firing hand. Position the rear of

the slide above the front edge of the frame.

9. Slowly draw the slide back onto the frame so that the

metal inserts in the frame fit into the grooves on the

inside of the slide. (See Figure 33)

Page 33

33

Figure 33

10. Retract the slide to the point where the recess in

the left side of the slide is positioned over the hole

where the axle of the slide release will go and hold

it there.

11. Insert the slide release from left to right into the

frame until it is flush with the side of the frame.

NOTE:Assembly of the pistol is now complete. Clear

the pistol and check it for correct assembly and operation. Be sure the slide moves freely on the frame

and with the pistol cleared and pointed in a safe direction, ensure all controls operate correctly. As

applicable, check double-action mode, single-action

mode, safety, decock function, slide release, and the

magazine release.

Page 34

34

Figure 34

4. Gradually allow the locking plate and magazine spring

to expand out of the magazine housing.

5. Remove the locking plate, magazine spring and magazine follower from the magazine housing.

Disassembly of magazines produced after October

1994 for U.S. civilian use.

1. Using a blunt pointed instrument depress the locking

insert detente located in the floor plate and hold it

there (see Figure 34).

2. Place a portion of either hand over the base of the

magazine to control the release of the magazine spring

and locking insert.

3.With the locking detente still depressed, squeeze the

floor plate locking tabs located on the right and left

MAGAZINE DISASSEMBLY

CAUTION:Beware of the spring tension exerted by

the magazine spring while removing and installing

the magazine floor plate. Keep the base of the magazine pointed in a safe direction (away from the face

and eyes) at all times during disassembly.

Different types of USP magazines are in use, depending on

model, caliber, and after the Fall of 1994; whether the

magazines were produced for civilian or military/law

enforcement use.

Disassembly of Law Enforcement/Military restricted

use magazines and magazines produced before

October 1994.

1. Using a blunt pointed instrument depress the locking

detente located in the floor plate and hold it there

(see Figure 34).

2. Place a portion of either hand over the base of the

magazine to control the release of the magazine spring

and locking plate.

3. Slowly slide the floor plate forward off of the magazine housing.

Page 35

35

Figure 35B Restricted Use Magazine

Figure 35C 10 round Civilian Magazine

Magazine Follower

Magazine

Spring

Magazine

Housing

Locking Tabs

Locking Insert

Locking Tab

Recesses

Floor Plate

Magazine Follower

Magazine

Housing

Floor Plate

Locking Plate

Magazine

Spring

sides of the magazine.

Figure 35A

4. Gradually allow the locking insert and magazine spring

to expand out of the magazine housing. (see Figure

35A)

5. Remove the locking insert, magazine spring and mag-

azine follower from the magazine housing.

Page 36

36

4. Push the locking plate down into the magazine housing against the pressure of the magazine spring and

hold it there.

5. On 10-round magazines, push the floor plate up

onto the base of the magazine housing until the

locking tabs engage in the sides of the housing. Check

to see if the locking tabs on the floor plate are

securely locked into the housing and the locking detente on the locking plate fits within the hole in the

floor plate.

On restricted use magazines, push the floor plate

over the base of the magazine housing and the locking

plate from front to rear. Make sure the floor plate is

fully seated on the magazine housing and the locking

detente on the locking plate fits within the hole in the

floor plate.

On all magazines, check the magazine for proper

assembly by insuring that the follower slides up and

down freely within the magazine housing and with

spring tension. Also check that the magazine follower

rises within the magazine housing to be nearly flush

against the bottom of the magazine lips.

MAGAZINE ASSEMBLY

Figure 36

1. Place the magazine follower onto the magazine spring

with the end of the spring positioned on the left of

the follower. (See Figure 37)

2. Insert the follower and magazine spring into the

magazine housing as depicted in Figure 36.

3. Place the locking plate, or locking insert on US civilian magazines, onto the protruding end of the magazine spring so that the rounded corners face towards

the front of the magazine.

Page 37

37

Figure 37

“Civilian use” 10-round magazine (left), Law

Enforcement/Military “restricted use” magazine

(right)

Page 38

38

Normal Cleaning - Performed after each firing or every

twelve (12) months.

Major Cleaning - Often referred to as “detailed cleaning”.

Performed after the firing of 500 cartridges or when the

pistol is exposed to, or laden throughout with sand, dust,

water (especially salt water), or other visible contaminants

or foreign matter.

Normal Cleaning

Slide

• Gently scrub all internal surfaces of the slide using the

nylon toothbrush moistened with solvent.

• Remove all loose fouling from all surfaces of the slide

using a rag and cotton swabs.

Recoil/buffer spring assembly

• Remove all visible fouling using solvent,a nylon

toothbrush, a rag and cotton swabs.

Barrel (with locking block)

• Moisten a bronze bore brush with solvent and scrub

the bore from chamber to muzzle at least six (6)

passes, back and forth.

• Remove the loose fouling from the bore using cleaning patches.

SECTION 7 CLEANING & MAINTENANCE

NOTE:The service life and performance of your HK

USP is dependent upon the correct handling and

proper care by the operator.

Materials Required - At a minimum, we suggest the

following materials to properly clean the HK USP.

• Cleaning rod with handle and patch holder

• Nylon toothbrush

• Bronze bristle bore brush (in the appropriate caliber)

• Cleaning patches (in the appropriate caliber)

• Lint-free wiping rag

• Cleaning solvent/lubricant

• Cotton swabs

CAUTION: Use safety goggles when using solvents

and exercise care if using compressed air.

Modular Pistol Cleaning Kits (HK article no. 701956 9mm,

7011957 .40 S&W, and 701958 .45ACP) are available from

Heckler & Koch for thorough cleaning of the HK USP and

other firearms.

Cleaning Intervals - There are two types of operator

cleaning for the USP. Normal and Major cleaning.

Page 39

The parts can then be dried using compressed air or

with a rag and cotton swabs.

NOTE:All parts of the HK USP can be immersed in

any cleaning solvent that it is safe to put your hands

into, including ultrasonic cleaning solution. Painted

surfaces of the pistol (i.e. control lever, frame, and

extractor markings) can be removed by using

ultrasonic cleaning machines.

Inspection

During and after cleaning visually inspect the pistol and its

components for any irregularities that may cause problems

or stoppages during its operation. Generally, you should

keep a watchful eye out for the discrepancies listed below.

Always clear the pistol before conducting your inspection!

• Damaged or missing parts

• Improper assembly or function

• Absence of free movement, where applicable

• Absence of spring tension, where applicable

• Unaccustomed looseness

• Parts exhibiting signs of cracks, burrs, dents, or

obvious signs of damage or stress

39

• Gently scrub the exterior of the barrel and locking

block with the nylon toothbrush moistened with

solvent.

• Remove all loose fouling from the exterior of the

barrel using a rag and cotton swabs.

Frame

• Gently scrub all internal surfaces where carbon fouling is present using the nylon toothbrush moistened

with solvent. Concentrate on the area normally

covered by the slide.

• Using a rag and cotton swabs, remove all loose fouling

from all areas of the frame.

Magazine

• Gently scrub the top of the magazine, concentrating

on the follower and feed lips, using the nylon

toothbrush moistened with solvent.

• Using a rag and cotton swabs, remove all loose fouling

from all surfaces of the magazine.

Major Cleaning

Major Cleaning is the same as normal cleaning except that:

• The magazine is disassembled for cleaning.

• All parts should be rinsed with, or immersed in

solvent and thoroughly scrubbed with a nylon brush.

Page 40

40

• Presence of stops or tactile clicks, where applicable

• General overall cleanliness

• Presence of sufficient lubrication

• Presence of corrosion or degradation of surface finish

CAUTION:This pistol has been developed by capable

and experienced engineers. Its present design represents an optimization of a combination of safety,

speed of deployment, accuracy, dependability, and

durability. Do not attempt to make this pistol

“better” by altering any of its components. Altering

any part of the pistol or magazine may cause injury or

death and will also void any Heckler & Koch warranty

on the product.

Lubrication

Metal surfaces of the USP are treated with HK’s special

corrosion & wear resistant Hostile Environment (HE) finish.

However, this surface treatment does not completely reduce

the friction between moving parts and it is recommended

that a lubricant be applied to the pistol to ensure proper

functioning.Any type of high-quality, medium weight lubricant

(oil) specifically designed for use on firearms will work well

on the HK Universal Self-loading Pistol. Do not use

lubricants that boast of their ability to penetrate metal as

these substances may deaden primers.

Where and How Much

No Lube

Surface is dry and not slippery to the touch

• All plastic components

Light Lube

A finger run across the surface yields little or no lube

• Bore, chamber, and exterior of barrel; including

O-ring and muzzle threads if applicable

• All metal parts

• All internal parts in slide and frame

• Magazine spring

• Recoil/buffer spring assembly

• Sights

• USP .45 ACP magazine housing

Medium Lube

A finger run across the surface yields some lube but lube

does not run down surface when it is held in a vertical

position.

Page 41

41

• Barrel locking block

• Slide rails and grooves

• All operating controls

• Detent plate & detent slide (items 26 & 36, see

diagram on pages 46 & 48)

• Locking insert and guiding part in frame

• Extractor

Heavy Lube

Lubrication runs down the surface when it is held in a vertical position

No heavy lube is required on the HK USP.

Reapply lubricant periodically during firing as it burns off

from the heat.Apply lubricant using a clean shaving brush,

cotton swabs, patches, or rag.A spray bottle of lubricant

also works well when using compressed air to circulate the

lubricant into all parts and to remove the excess from the

pistol.

Troubleshooting Problems and Repair

The ten inspection areas listed above should be checked

prior to contacting HK if your pistol fails to function

properly. Other common causes of problems that are often

overlooked include:

• Fouled or improperly lubricated pistol

• Bad ammunition

• Damaged magazines

• Operator error

If your HK USP still fails to function, please contact Heckler

& Koch Customer Service at (703) 450-1900 for the name

and address of your nearest HK Authorized Repair Facility.

Military and law enforcement users, contact your unit

armorer or HK Customer Service.

NOTE: If after reviewing this manual you still have

questions, please contact your HK dealer or

telephone the Heckler & Koch Customer Service

Department. Please address any suggested changes

or improvements to this manual to the HK Creative

Services Department.

Page 42

42

The Mark II HK UTL can be quickly attached or removed

from the pistol and provides an immediate source of

illumination.With easy to use controls, the UTL ensures law

enforcement professionals or home owners can identify potential threats in critical low light situations.

Using a USP fitted with a UTL makes alignment of the light

and pistol easier than using a separate flashlight.A separate

light can be difficult to use and hold while manipulating a

pistol in a life threatening situation.The UTL can also be

detached from the pistol and used in place of a conventional

flashlight.

The Mark II UTL is designed and manufactured by Insight

Technology Inc. (ITI), the same firm that created the special

flashlight and laser aiming module used on the .45 caliber HK

Mark 23 pistol developed for the US Special Operations

Command.

Available exclusively from Heckler & Koch, Inc., the Mark II

UTL fits all variants of the USP pistol, including the USP

Compact, and can be purchased with an optional remote

cable switch, and tactical nylon carrying pouch.

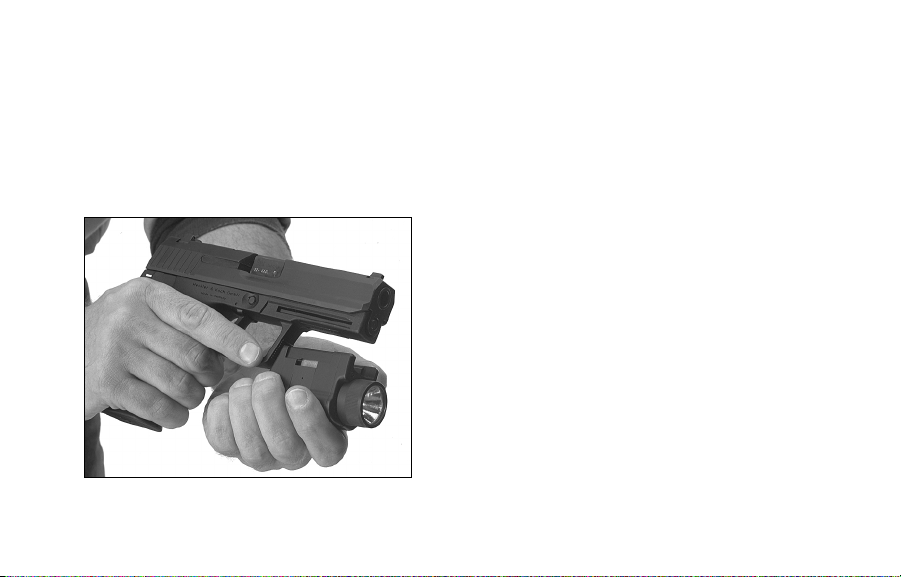

USP ACCESSORIES

Heckler & Koch and Insight Technology Inc. have developed a

powerful accessory light that attaches to the HK USP pistol.

Smaller and more powerful than a conventional flash-light,

the Mark II HK Universal Tactical Light (UTL) adds a dimension of tactical flexibility to the USP absent in other modern

semiautomatic pistols.

Figure 42

The Mark II UTL is a compact and powerful

accessory light for the USP.

Page 43

43

Key features of the HK UTL

• compact and rugged design fits all models of the USP

and USP Compact pistol

• lamp brightness superior to most flashlights

• focusable beam, spot to flood

• clip-on/clip-off design, can be installed or removed in

seconds

• integral on-off switch prevents inadvertent operation

Figure 43

The HK Mark II UTL can be installed and removed

from any USP in seconds with one hand.

• uses easily replaceable standard lithium batteries

• fingertip on-off operation (toggle switch pushed to

right, intermittent on only, toggle switch pushed to

left, intermittent and constant on)

• optional remote switch and accessory pouch available

Other USP Accessories

A variety of USP accessories and enhancements are available

and include tritium sights, click adjustable sights, a sight

installation tool, and ambidextrous control levers. Contact

HK for a complete list and pricing.

Page 44

4444

SECTION 8 EXPLODED DIAGRAM & PARTS LIST

Figure 44

USP (.40 S&W and 9mm Models)

Page 45

4545

Item Description Identification No. Item Description Identification No.

Item Description Identification No.

USP Parts List (.40 S&W and 9mm Models)

1 Extractor spring 214188

2 Extractor 214187

3 Roll pin,

ISO 8748 - 3 X 14 mm (3x)

980838

(extractor,firing pin, mag release)

4 Front sight* (6.4 mm) 214220

Front sight* (6.6 mm) 214221

Front sight* (6.8 mm)

standard

214222

Front sight* (7.0 mm) 214223

Front sight* (7.2 mm) 214224

Front sight* (7.4 mm) 214225

6 Rear sight 214194

7 Barrel (.40 S&W) 214209

Barrel (9 X 19 mm) 214344

8 Slide (.40 S&W) 214186

Slide, complete** (.40 S&W) 214150

Slide (9 X 19 mm) 214304

Slide, complete** (9 mm x 19) 214345

9 Firing pin spring 214190

10 Firing pin 214189

11 Firing pin block spring 214192

12 Firing pin block 214191

13 Recoil spring 214148

13A Front recoil spring retainer 214721

13B Snap ring 929191

14 Buffer spring retainer 214208

15 Buffer spring 214207

16 Recoil spring retainer 214206

17 Recoil spring guide rod 214205

17 Recoil/buffer spring assembly

complete with captive recoil spring**

18 Roll pin,

ISO 8748 - 3.5 X 10mm

982782

(buffer spring retainer)

19 Slide release 214181

20 Trigger bar, complete 214176

21 Trigger bar detent 214165

22 Trigger bar detent spring 214166

23 Disconnector 214840

23A Disconnector** 214160

24 Sear axle 214101

25 Catch 214773

25A Control latch 214817

25B Catch (old style)** 214159

26 Detent plate (variant 1 & 2) 214099

Detent plate** (variant 3 & 4) 214254

Detent plate** (v.5,6,9,& 10) 214255

27 Shaped spring (slide release) 214171

28 Flat spring 214167

29 Hammer (variant 1-4, 9 & 10) 214825

Hammer,complete** 214301

with pin (variant 1-4, 9 & 10)

29A Hammer (variant 1-4, 9 & 10)** 214106

30 Hammer, bobbed (v.5, 6, 7) 214256

Hammer,bobbed, complete** 214308

with pin (variant 5, 6,7)

31 Cyl. pin,

ISO 8750 -1.5 X 8mm

982783

(hammer strut pin)

32 Hammer axle (new style) 214774

Hammer axle** (v.1-6,9, 10) 214303

Hammer axle** (variant 7) 214258

33 Control lever (variant 1, 5,9) 214184

Control lever (variant 2,6, 10) 214309

Control lever (variant 3) 214352

Control lever (variant 4) 214253

34 Sear (variant 1-4, 9, 10) 214180

Sear,complete** 214179

34A Tube (variant 5, 6,7)** 214413

35 Roll pin, ISO 8748 - 2 X 10mm 982785

(sear,variant 1, 2, 3,4, 9, 10)

36 Detent slide

(variant 1-6, 9,10)

214105

37 Compression spring, 214104

(detent slide) variant 1-6, 9,10

38 Frame, incomplete 214172

39 Trigger rebound spring 214164

40 Trigger axle 214154

41 Trigger 214153

42 Magazine release 214169

43 Magazine release spring 214170

44 Hammer strut (new style) 214819

Hammer strut** 214157

45 Hammer spring 214300

46 Lanyard loop insert 214341

47 Lanyard loop insert pin 214314

48 Magazine follower 214211

Mag. follower

(10-rd, .40 & 9mm)

** 214211

49 Magazine spring 214212

Magazine spring

(10-rd)

** 214850

50 Floorplate 214213

Floorplate (10-rd, .40 cal.) ** 214845

Floorplate (10-rd, 9mm) ** 214848

51 Locking plate 214288

52 Magazine housing

(13-rd, .40 cal.)

214214

Magazine housing

(15rd, 9mm)

214350

Magazine housing

(10rd, .40 cal.)

214846

Magazine housing

(10rd, .9mm)

214849

Locking plate

(10rd, .40 cal.)

** 214844

Locking plate

(10rd, .9mm)

** 214847

Magazine complete

(10rd, .40 cal.)

** 214854

Magazine complete

(10rd, 9mm)

** 214855

Magazine complete

(13rd, .40 cal.)

** 214864

Magazine complete

(15rd, 9mm)

** 214866

**Not pictured in diagram

Page 46

4646

Figure 46

USP (.45 ACP Model)

Page 47

4747

Item Description Identification No. Item Description Identification No.

Item Description Identification No.

1 Extractor spring 214188

2 Extractor 214828

3 Roll pin,

ISO 8748 - 3 X 14 mm(3x)

980838

(extractor,firing pin, mag. release)

4 Front sight* (6.4 mm) 214220

Front sight* (6.6 mm) 214221

Front sight* (6.8 mm)

standard

214222

Front sight* (7.0 mm) 214223

Front sight* (7.2 mm) 214224

Front sight* (7.4 mm) 214225

6 Rear sight 214194

7 Barrel 214815

8 Slide,incomplete 214827

Slide, complete 214826

9 Firing pin spring 214190

10 Firing pin 214189

11 Firing pin block spring 214192

12 Firing pin block 214191

13 Recoil spring 214843

13A Front recoil spring retainer 214721

13B Snap ring 929191

14 Buffer spring retainer 214208

15 Buffer spring 214822

16 Rear recoil spring retainer 214206

17 Guide rod, incomplete 214830

17 Recoil/ buffer spring assembly

complete 214829

18 Roll pin,

ISO 8748 - 3.5 X 10mm

929908

(buffer spring retainer)

19 Slide release 214181

20 Trigger bar,complete 214176

21 Trigger bar detent 214165

22 Trigger bar detent spring 214166

23 Disconnector 214840

24 Sear axle 214101

25 Catch 214773

25A Control latch 214817

26 Detent plate (variant 1 & 2) 214099

Detent plate** (variant 3 & 4) 214254

Detent plate** (v.5,6,9,& 10) 214255