Page 1

Call 1-800-835-0606

TT-180

Exposure Units

OWNER’S MANUAL

Fluorescent Table Top

Visit www.hixcorp.com

ext. 209, ext. 211, ext. 220, ext.221 or

For Customer Service, Call 1-800-835-0606

Installation / Setup ..................................................................................... 2

CONTENTS

BEFORE warranty repair you MUST get Prior Authorization:

Loading Screen / Starting Vacuum ............................................................ 3

Expose Screen........................................................................................... 4

Determining Exposure Time ...................................................................4-5

Glass Cleaning .......................................................................................... 6

Bulb Replacement ..................................................................................... 6

Lid Realignment .........................................................................................7

Blanket Replacement .............................................................................. 8-9

Troubleshooting ....................................................................................... 10

Optimum Exposing Time Chart................................................................ 11

Warranty .................................................................................................. 12

(Effective January 1, 2007)

HIX will automatically register the equipment on the date it was shipped to you or your distributor.

WARRANTY

If the equipment was not purchased directly from HIX, but through a distributor (either domestic or

in a safe place to provide verification of your warranty should a problem occur. Thank you.

Please fill in the following information and attach a copy of your receipt for your records.

foreign), please keep a copy of their sales invoice showing the serial number and date it was sold/

shipped to you with this warranty. In this case, we will use the distributor’s invoice date as the

beginning warranty date. STAPLE A COPY OF YOUR RECEIPT TO THIS WARRANTY and keep

Date Purchased: ______________________ From:__________________________________

This warranty applies to equipment manufactured by the HIX Corporation (HIX), Pittsburg, Kan-

Model #: ____________________________ Serial #: ________________________________

sas, U.S.A. HIX warrants to the original purchaser, its Conveyor Dryers, Heat T ransfer Presses, Mug

Presses, Mug Glazer, Retensionable Screen Frames, Textile Printers, Spot Heaters, and Exposure

Units against defects in workmanship and material, except for wear and tear for a period of “One

In the event of a defect, HIX, at its option, will repair, replace or substitute the defective item at no

Y ear” from the date of purchase. HIX warrants its Accessories, Reten S plines/Hardware/Tool Kit, and

Shuttle for a period of 90 days from the date of purchase. DoughXpress and Thermatrol products are

In the case of heat transfer presses (except the Mug Press, Hobby Lite, and FH-3000 Flat & Cube

covered under separate warranty.

cost during this period subject to the limitations of insurance and shipping costs stated below.

Press), HIX warrants the heat casting for the “Life” of the machine for the original purchaser. If a part

becomes obsolete at the time for repair , and/or cannot be reasonably substituted for, HIX will credit,

at half the then current list price or last recorded price, only that part toward a new machine or any

product HIX offers. This credit offer shall be the sole responsibility of the HIX Corporation in the event

of an obsolete part.

E-Mail: sales@hixcorp.com • Fax: (866) 563-4600

1201 E. 27th Terrace • Pittsburg, KS 66762 • U.S.A.

Web site: www.hixcorp.com • Phone: (800) 835-0606

E-Mail: customerservice@hixcorp.com • Fax: (866) 561-0894

This warranty does not cover belts, pads, mug wraps, mug press liners, canvas, rubber blankets,

bulbs, glass, PTFE or finish, rod ends, turn buckles on printers, or mug press or damages due to

accident, misuse/abuse, alterations or damage due to neglect, shipping or lack of proper lubrication

or maintenance. HIX shall not be responsible for repairs or alterations made by any person without

In the case of a problem with the equipment identified herein, HIX Corporation should be con-

the prior written authorization by HIX. This warranty is the sole and exclusive warranty of HIX and no

person, agent, distributor, or dealer of HIX is authorized to change, amend or modify the terms set

forth herein, in whole or in part.

tacted during regular business hours to discuss the problem and verify an existing warranty. HIX

personnel will assist the customer to correct any problems which can be corrected through operation

or maintenance instructions, simple mechanical adjustments, or replacement of parts. In the event

the problem cannot be corrected by phone, and upon the issuance of a return authorization by HIX,

the equipment shall be returned to HIX or an authorized service representative. All insurance and

shipment/freight costs are solely the responsibility of the customer, and not that of HIX, and HIX shall

This expressed warranty is given in lieu of any and all other warranties, whether expressed or

In no event shall HIX’s liability for breach of warranty extend beyond the obligation to repair or

not be responsible for improper handling or damage in transit. HIX offers a reconditioning service

and a core exchange/credit policy on some models. HIX customer service personnel may be con-

tacted for complete return authorization and reconditioning information.

implied, including but not limited to those of merchantability and fitness for a particular purpose, and

constitutes the only warranty made by HIX Corporation.

This warranty gives you specific legal rights and you may also have other rights which vary from

replace the nonconforming goods. HIX shall not be liable for any other damages, either incidental or

consequential, or the action as brought in contract, negligence or otherwise.

state to state.

Manufacturers of the Finest Quality Textile and Graphics Screen Printing and Heat Transfer Equipment

©2006 HIX Corp. 12 TT062907

Page 2

11

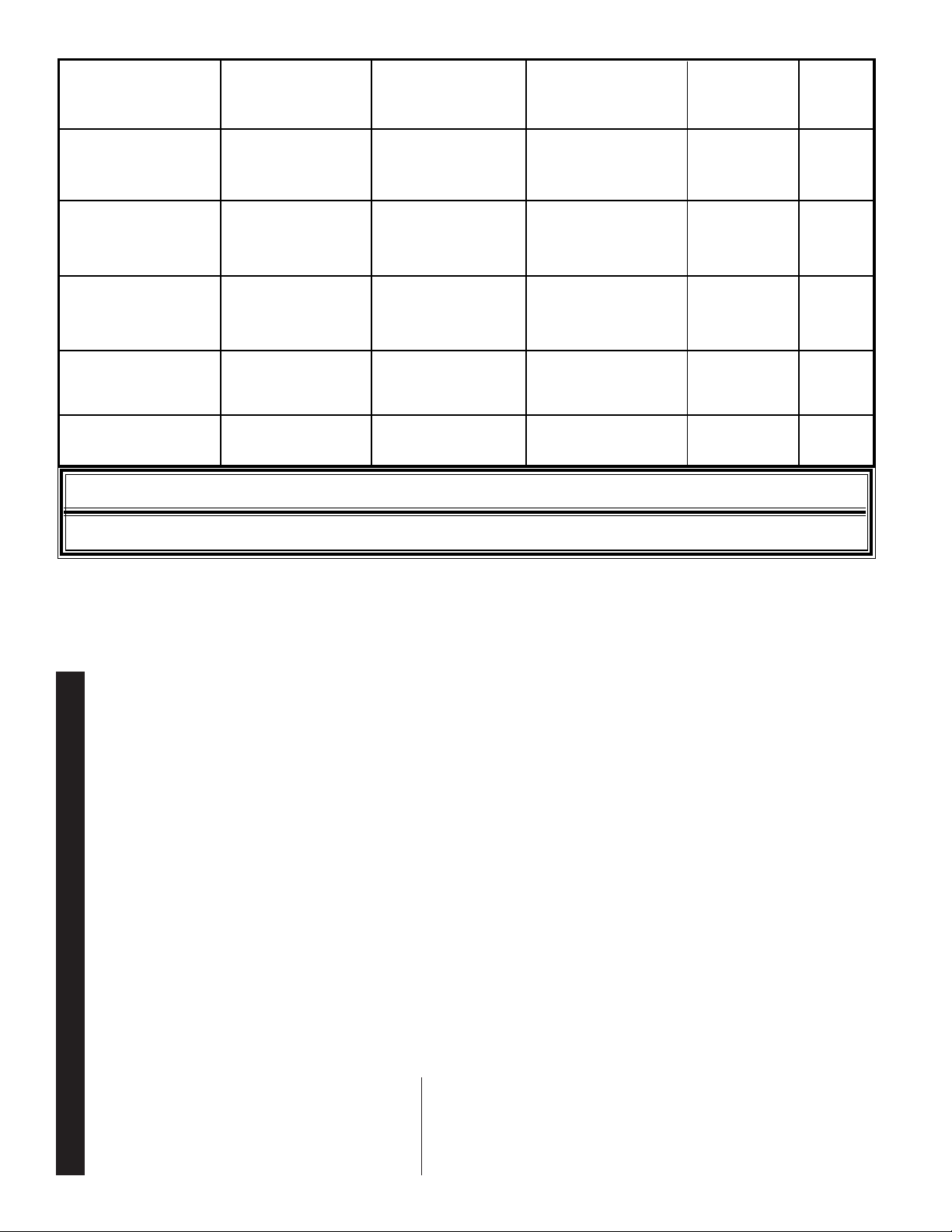

COUNT COLOR BRAND METHOD TIME

DATE MESH EMULSION EMULSION COATING EXPOSURE

OPTIMUM EXPOSING TIME CHART

Use and copy this chart for recording your shop’s popular emulsions and exposure times.

EYE IRRA TION OR BLINDNESS. TO PREVENT

read these instructions thoroughly. Disconnect all

electric power before performing maintenance on

the unit. Never operate this equipment with the

power supply cover removed. If you find that this

should be necessary, contact a licensed electri-

cian. Make sure the circuit for this unit is well

grounded.

INSTALLATION

CAUTION: Before installing or operating the unit be sure to

DAMAGE TO YOUR EYES AND SKIN, AVOID

WARNING: ULTRA VIOLET LIGHT CAN CAUSE SKIN AND

DIRECT EXPOSURE TO THE LAMP WHILE IT

IS ON.

circuit to be used.

Installation

1. Carefully uncrate exposure unit from its shipping container .

2. Place exposure unit on a level surface close to the wall

2

ductor. Maximum length, 25’ (7.62m).

sure all foreign objects, such as packing material, have been

removed. Clean top side of glass to remove any dust.

WARNING: When using an extension cord, use 14 ga.-3 con-

3. Check unit over for any transportation damage and make

to read and follow all instructions included with the pump.

4. Remove vacuum pump from shipping container. Be sure

180 exposure unit.

5. Plug pump into receptacle located on the back of the TT-

side of the exposure unit lid.

6. Connect vacuum hose on pump to fitting on the back right

Page 3

INSTALLATION/ OPERATION

Screen

Bleeder Cord

top is closed and latched (both sides) to prevent

UV light exposure to eyes or skin.

3

switch.

Setup

1. Plug in your unit to your power source and turn on power

WARNING: During operation make sure the vacuum blanket

Loading Screen / Starting Vacuum

side down. Maximum screen size 23” x 31”.

1. Raise the lid and place frame in center of glass, screen

as possible. (See illustration above) NOTE: This cord fa-

cilitates vacuum and releasing or draining off the vacuum

after exposure.

2. Place bleeder cord inside frame as close to the frame side

3. Close lid and latch with the rubber latch-hooks.

4. Turn on vacuum switch.

5. Check for proper draw down of blanket.

10

TROUBLESHOOTING

Page 4

REPAIRS

tation allowing the material to sag down to your working

surface.

hesive.

were removed. Tighten all screws securely. Caution: over

tightening screws may strip the threads in the lid frame.

knife along the outside of the aluminum frame.

985

8. Lay new blanket material across the lid in the proper orien-

Blanket Replacement

9. Seal the rubber to the blanket frame with the included ad-

10. Replace the aluminum strips on the same side that they

11. Trim any excess blanket material by running a sharp utility

4

OPERATION

Digital Timer

button on the front of the timer face. Timer will display

“Minutes” and “Seconds”.

the face of the timer to lock in this new setting. Failure to

press the “MD” button will not “lock” in the new setting.

start the timer and turn the exposure lamp on.

exposure lamp will extinguish.

before time expires, you may do so by pressing the

“RST” button on the face of the timer.

Digital Timer Operating Instructions TT-180

1. Turn Main Power “On”. Timer will illuminate.

2. To change time setting, press the “UP” or “Down” arrow

3. Once the new time is entered, press the “MD” button on

4. Press the “Start” button on the control panel. This will

5. Timer will count down and when time reaches zero, the

6. If at any time you want to extinguish the exposure lamp

Expose Screen

going to expose. See “Determining Your Optimum Expo-

sure Time” page 6 or your filled in chart in the back of this

1. Set for the optimum exposing time for the screen you are

Underexposed: results in weak stencil with poor emulsion

adhesion and reduced resistance to printing inks and wash

book if you have already determined your exposing time.

2. Push start button to initiate your set exposure time.

vacuum switch and unlatch the rubber latch hooks to

release the lid.

Determining Your Optimum Exposure Time By Trial

1. Follow normal operations explained previously.

3. At the end of the set exposure time you can turn off the

2. Inspect your newly exposed screen for proper exposure.

up solvents. Overexposed: results in loss of fine detail.

Page 5

OPERATION

sion type or new mesh count. This procedure should

also be followed periodically as bulb intensity will lessen

with age. Use chart at the end of this booklet.

sion type, new mesh count or mesh type (i.e. yellow,

orange, white). This procedure should also be followed

periodically since the bulb intensity will lessen with age.

emulsion type fill in the chart provided at end of this manual

as a ready reference. This will save you time in the future.

Determining Your Optimum Exposure Time

By Exposure Calculator (Preferred Method)

3. Once you have determined the proper exposure for your

NOTE:This procedure should be followed for each new emul-

1. Follow normal operations explained on page 4.

instructions.

2. Place exposure calculator on screen following calculator’s

3. Set timer dial to double the estimated exposure time.

instructions.

4. Inspect your newly exposed screen according to calculator’s

cated on the exposure calculator.

5. Multiply the previously set exposure time by number indi-

type. Fill in the chart provided at end of this manual as ready

reference.

6. This new number is the proper exposure for you emulsion

NOTE: This procedure should be followed for each new emul-

shooting Chart for possible causes. If you determine

that your blanket has begun to leak, it needs to be

replaced. New blanket material can be ordered from

REPAIRS

Blanket Replacement

NOTE: If the blanket fails to pull a vacuum, check the Trouble-

HIX Corporation.

located so that they can be replaced in the same

location.

plastic cap from the lid end of one of the gas springs.

While holding the lid, pull the end of the gas spring straight

out and off of the ball connector as you continue to manu-

ally hold the lid up.

Caution: It is important to do this operation with the lid

up, failing to do so could cause injury due to the sudden

release of pressure on the gas spring!

NOTE: Mark from which side the aluminum strips were

1. Begin with the lid in the open position. Remove the

2. Remove the vacuum hose from the lid.

wrenches, remove the 4 nuts and bolts holding the lid to

the hinges.

3. Gently lay lid back down onto glass. Using two 9/16”

upside down on a flat surface.

4. Remove the entire lid assembly from the frame and lay

so that they can be replaced in the same location.

5. Mark from which side of the aluminum strips were located

6. Remove all screws from the aluminum stips.

7. Remove the blanket material and any adhesive still

attached to the lid frame.

Page 6

MAINTENANCE

failing to do so could cause injury due to the

sudden release of pressure on the gas spring!

ber gasket under the lid frame. This rubber gasket may

compress over time. If the vacuum does not occur, the

rubber gasket may be compressed. These problems

can be alleviated by lowering the hinges.

mark on the frame of the unit corresponding with a mark on

the lower leaf of the hinges.

lower leaf of the hinges.

pressure on the glass and frame of the unit and

should be avoided. If the lid is difficult to close or

does not stay closed under it’s own weight, the hinges

should be raised.

work repeat this process and drop the hinges another

Lid Realignment

NOTE: The vacuum is sealed under the lid by means of rub-

CAUTION: It is important to do this operation with the lid up,

1. Fully open the lid.

2. Using a pencil, tape, or other suitable indicator, place a

Vacuum

Bleeder Cord

3. Using a 9/16” wrench, loosen the four bolts fastening the

4. Let each hinge drop approximately 1/16” using the

indicator placed on the hinge in step 2.

5. Tighten all four bolts securely and test unit. If this does not

1/16”

Warning: Lowering the hinges too much can place excess

6 7

OPERATION

In order to maintain short exposure times, keep the unit’s

Glass Cleaning or Bulb Replacement

exposure glass clean. Dusting is usually sufficient. If more

When you notice your exposure times getting longer or if

cleaning is required use a soft cloth moistened with alcohol.

A dusty environment will require more cleaning.

the lamp fails to operate, check the Troubleshooting Chart

on page 10.

To clean back side of glass or replace bulbs:

putty knife. If you lift the glass, do so carefully

so as to not scratch or break the glass. Never

use a screwdriver .

glass resting on its gasket).

1. Carefully lift front of glass from the gasket (leave back of

2. Remove old bulb, Insert new bulb.

3. Carefully replace the glass as it was before.

4. Clean underside and lay back down carefully.

WARNING: To lift glass use flexible (non rigid) item such as

Loading...

Loading...